PMM

PROFESSIONAL M OTOR M ECHANIC

ENTER THE CPD ZONE!

YOU COULD EARN ONE CPD CREDIT THIS MONTH

Let’s get technical

GUIDE TO BOSCH’S DIAGNOSTICS SOFTWARE

INFORMATION ON ADAPTIVE RIDECONTROL

TROUBLESHOOTING

A DPF ISSUE

INSTALLATIONTIPS ON MMT CLUTCHES

ALL THINGS

BRAKES COVERED

FREE TOTHE TRADE

THEHIVE Q&AINSIDE LOUISEBAKER IN PROFILE

FIND AJOB IN YOUR AREA

PRODUCT TEST: ROWASHER

OCTOBER 2023

Editor’s Picks

11 LISTEN UP

PMM’s Freya Coleman takes us through her highlights from the recent PMM podcast episode, where she caught up with Louise Baker from Womanic to try and to get to the bottom of why more women aren’t mechanics.

16

TECHNICALLY SPEAKING

As part of this month’s CPD Zone, PMM’s diagnostics expert Ben Johnson look at a BMW X5 40E that was refusing to start. Make sure to read and scan the QR code to claim your CPD point.

58 PUT TO THE TEST

See what John Rayment from Rayments Garage has to say about his experience with Rozone’s Rowasher as he trials it in his workshop.

76 CLASSICS MADE MODERN: PART 2

If you’ve ever considered converting a classic car into an EV then make sure to catch the second part of our articles on Fellten, a company that provides kits and assistance on workshops tackling the conversion.

71 REMANUFACTURING Contents VOLUME 24 ISSUE 9 OCTOBER 2023 Features Total Average Net Distribution 54,319 1st July 2021 – 30th June 2022 PMM OCTOBER 2023 3

Regulars 6-9 NEWS & VIEWS 15-28 CPD ZONE 32-45 BUSINESS & TRAINING 38-45 SPECIAL REPORTS 41 ONLINE SPOTLIGHT 42 PIT STOP 78-82 IN THE WORKSHOP 82 COMPETITION

47-56 BRAKES & CLUTCHES

65-69 OILS, LUBRICANTS & ADDITIVES

59-62 THE MODERN WORKSHOP

Editor KIERAN NEE

News and Products Editor

FREYA COLEMAN

Digital Manager

KELLY NEWSTEAD

Group Manager

ROBERT GILHAM

Account Manager

ALEX DILLEIGH

Magazine Designer

GEMMA WATSON

Group Production Manager

CAROL PADGETT

Production Assistant

CLAIRE SWENDELL

Distribution Manager

KARL CLARK

Subscriptions

PROFESSIONAL MOTOR MECHANIC is a business magazine for firms and individuals involved in all aspects of the motor trade. It is published eleven times a year and is available nationally FREE to the trade through leading motor factors. It is also available through the post at a cost of £30.

EUROPE and OVERSEAS

UK £30 post paid

Air mail £80 post paid Europe £50 post paid

Printed by PCP Telford

Published by HAMERVILLE MEDIA GROUP

Regal House, Regal Way, Watford, Herts, WD24 4YF.

Tel: Watford (01923) 237799

Fax: (01923) 246901

E-mail: pmm@hamerville.co.uk

Sales enquiries: pmmsales@hamerville.co.uk

Website: www.pmmonline.co.uk

Facebook: /ProfessionalMotorMechanic

Twitter: @pmmmagazine Copyright © 2023

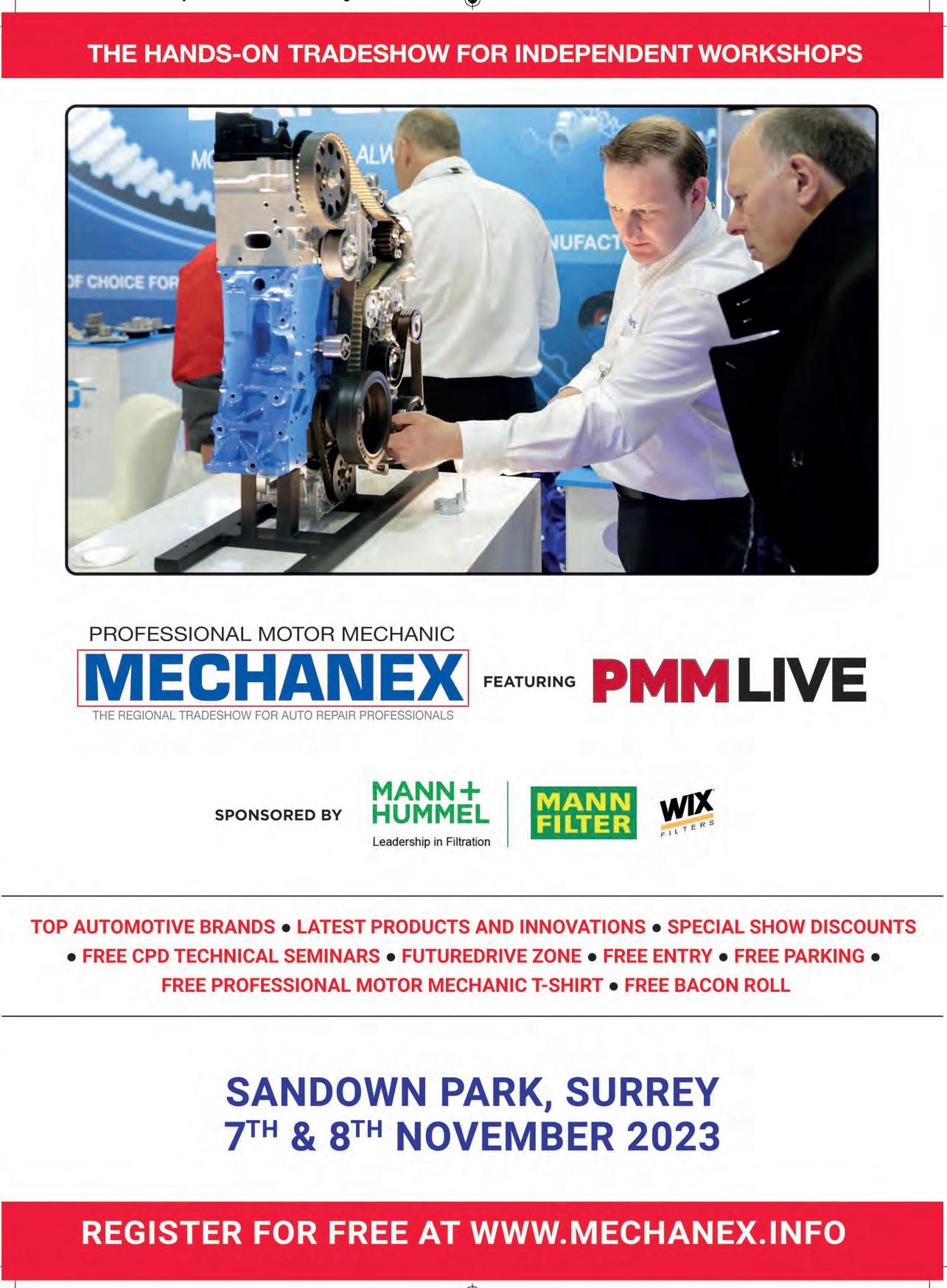

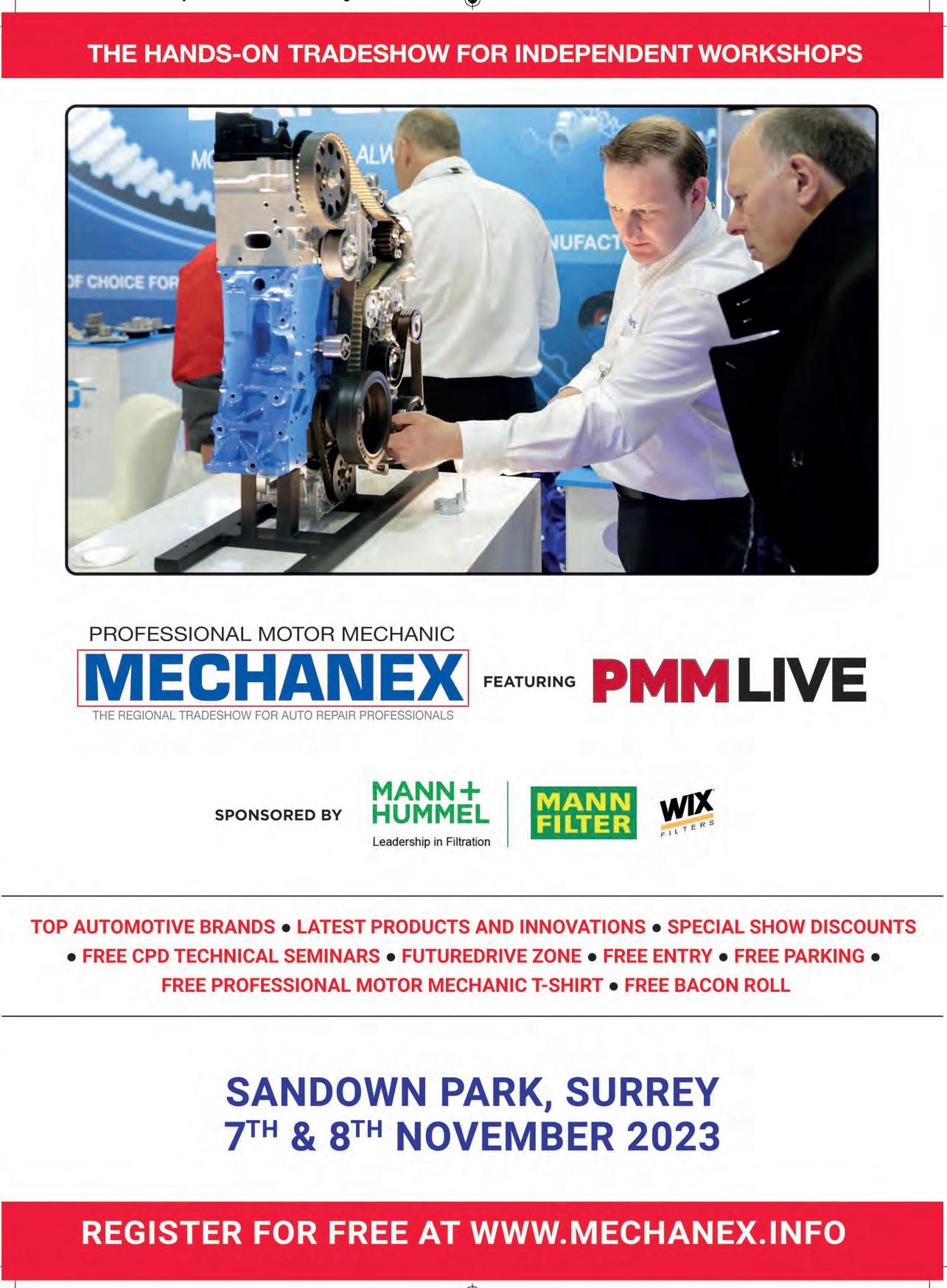

Always at this time of year I start to feel a twinge of excitement and I don’t know why: summer is over, Christmas still a while away… ah, yes, that’s it, Mechanex is just around the corner. This year, I am especially excited because it is the inaugural year of the PMM Live element of the show, so for the first time visitors will see our logo all over the hall and will be reminded who actually runs the show!

We’ll be running a more comprehensive preview in the next issue of the magazine, as well as dedicating a special episode of the podcast to catching up with our headline sponsors Mann+Hummel, so be sure to check those out. But in the meantime, we have a Q&A in this issue with the latest addition to the PMM Live seminar area – Mr Neil Pattemore, who will be updating visitors on the latest goings on at home and in Europe with respect to keeping the aftermarket both independent and competitive. With updates on Motor Vehicle Block Exemption and the introduction of the SERMI scheme, safeguarding access to data for independent workshops, there will be plenty to talk about.

Also for this issue, we reached out to some of the diagnostics tools suppliers to find out what makes Mechanex such a great show for diagnostics. It seems that workshop owners are using the show as the perfect opportunity to upgrade their equipment, and it’s no wonder given the great deals suppliers offer visitors.

Personally, I think Mechanex offers something other trade shows don’t. There is an excitement in the hall that fills the two days that is lacking in other shows. What sets MechanexPMM Live apart is the hands-on element, the demonstrations, the straight-talking discussions of tools and products that will make you money. And, really, isn’t that what this is all about? If you’re going to take a day out from work to come to Sandown Park, it needs to be worth it. Whilst the free parking, free bacon roll and the free t-shirt are certainly nice, it’s the training seminars from our two seminar stands and from our headline sponsor’s exhibit stand, coupled with all the new products and product deals, that really make it worthwhile.

The BIG Show Kieran Nee

Editor

JOIN M E EACH M ONTH ON THE PMM PODCAST

VIEWPOINT

and

do not necessarily agree with the views expressed by contributors,nor do they accept responsibility for any errors of translation in the subject matter in this

Listen on Amazon Podcasts Listen on Spotify Podcasts Listen on Apple Podcasts

Find every episode at www.pmmonline.co.uk/podcasts Also available:

The publishers

editor

publication.

Associate member

PMM NEWS

NEWSIN BRIEF

■ LEGISLATION DRIVING DPF DEMAND With particle number counters being brought into roadworthiness tests in Belgium, The Netherlands, Switzerland and Germany, BM Catalysts have predicted that similar measures could soon be seen in UK, pushing DPF demand.

■ DVSA PUTS BRAKES ON MOT CAMERA PLAN Due to security concerns, the DVSA has paused its trial of the use of connected cameras in garagess. This would have trialled the use of devices with built-in cameras to take a photo of a vehicle’s number plate, removing the need to enter the number manually and aiming to reduce human error.

■ EV VALUES HAVE DROPPED, BUT DEMAND IS UP Figures shared with This is Money show that the ten most-depreciating used cars in July were all EVs – such as the Tesla Model X with prices down 29.7 per cent. However, according to a report by the SMMT, demand for second-hand electric cars is on the rise.

■ THE MOTOR OMBUDSMAN PARTNERS WITH AA APPROVED GARAGES Objectives with the partnership include expanding the number of garages adhering to the ombudsman’s code of practice and increasing the standards delivered by AA garages.

with

Freya Coleman

EV training warning issued

With the Prime Minister himself, Rishi Sunak, casting doubts on the 2030 petrol and diesel ban, the IMI is urging the government to continue investing in EV training.

When quizzed on the 2030 deadline, Sunak responded “we’re going to make progress towards net zero but we’re going to do that in a proportionate and pragmatic way that doesn’t unnecessarily give people more hassle and more costs in their lives – that’s not what I’m interested in and prepared to do.”

Amidst these reports that the date of the 2030 ICE vehicle ban could be pushed back, the IMI is warning that the delay cannot be a ‘free pass’ to delay investment in EV training. This comes as the institution reports a 10 per cent drop in the number of newly qualified EV technicians, compared to the same period in 2022.

Steve Nash, CEO of the IMI, has said: “The government has a difficult job to do to balance the UK’s ability to be ready for the 2030 deadline with the hard to ignore environmental threats. The lack of a strong strategy to date for UK-based control of the supply chain is certainly raising questions about the vulnerabilities this could create for our economy and infrastructure.

“However, if the government acknowledges its miscalculation and moves the deadline it is absolutely crucial that this

Noise complaints

Noise cameras that can automatically detect cars with excessively loud ehausts are supported by 58 per cent of drivers, according to new research from the RAC.

This follows the Department for Transport’s £300,000 trials in Bradford, Great Yarnmouth, Birmingham and South Gloucestershire. Cars eceeding the 74-

is not seen as a ‘free pass’ to delay investment in infrastructure and training. Our latest data already shows that we are already behind the trajectory needed to have an automotive aftermarket workforce EV-ready.

“The IMI predicts that by 2030 the UK will require 107,000 IMI TechSafe qualified technicians to meet the evolving demands of the growing parc of electric vehicles. This figure rises to 139,000 by 2032, with our projections indicating a potential shortfall of 25,000 technicians if the current trends persist.”

decibel legal limit trigger the micrphones mounted on the cameras, with photos used by local police to identify and fine drivers.

The government hopes this will help crack down on dangerous boy racers and those who fit their cars with modified exhausts. So, expect to see less of these in the workshop if the cameras are successful.

6 OCTOBER 2023 PMM

“Any change in government strategy over the 2030 deadline must not mean investment in training can be paused.”

Steve Nash, CEO of the IMI.

FOR UP-TO-DATE NEWS, SIGN UP FOR OUR WEEKLY E-NEWSLETTER. SIMPLY SCAN THE QR CODE

Help shape apprenticeships

The IGA is asking dependent workshops to share their insights on apprenticeship opportunities, the feedback hoping to encourage an increase in government support in the promotion of apprentice recruitment and training within the sector.

Stuart James, chief executive of the IGA, commented, “Investing in apprenticeships is essential for securing the future of our industry. The dedication and expertise of a skilled workforce are vital in meeting the everevolving demands of the automotive sector.”

1380 %

the estimated jump in EVs in Cornwall according to analysis by Schneider Electric, with 471 EVs per charger along the coast. This data comes as we approach the UK’s 2030 petrol and diesel ban, doing nothing to ease range anxiety.

£ 776

is now the average cost of car insurance in the UK, increasing £119 in three months according to data from Confused.com. This puts car insurance as the third highest household bill in the UK.

1 in 5

In pictures:

Mechanex, the hands-on show for hands-on techs is more committed than ever to bringing PMM to life with new opportunities to debate the future of independent workshops. Returning to Sandown Park in Surrey on the 7th and 8th of November.

Northern Ireland MOT delay

As motorists in Northern Ireland are facing a three-month wait for an MOT, there are calls for the reintroduction of a temporary exemption certificate, which was last used during the pandemic.

According to the John Stewart, Ulster Unionist Party infrastructure spokesperson, this backlog comes as “no surprise to anyone”, as issues have been brewing since inspections in January 2020 found lift faults in 48 out of 55 test centres, followed by the closure of test

centres during the Covid-19 pandemic.

In response, roads policing superintendent Gary Busch responded the “Driving and vehicle agency (DVA) will make every effort to secure a MOT test date for any motorist whose MOT is due to expire”.

The Department for Infrastructure has said that the DVA is now exceeding prepandemic MOT test levels, with 1.15 million tests conducted in 2022/23, a 25 per cent increase from 2021-2022.

motorists no longer “brimming” their tank thanks to mortgage and rent hikes says the Startline Used Car Tracker. 12 per cent have stopped using their car entirely because of high housing costs.

£

160 k

the amount customers are still owed after a garage in Warrington closed in spring of 2022, the director filing for personal bankruptcy.

NEWSIN NUMBERS

PMM OCTOBER 2023 7

DATES FORTHE DIARY

■ Mechanex, The UK’s longest-running trade show dedicated solely to the independent aftermarket will once again be held at Sandown Park on Tuesday 7th and Wednesday 8th November. This year’s exhibitors so far include Alldata, JLM Lubricants, Liqui Moly, MAHA, Rotronics and many more!

Registration AND parking is free, so scan the QR code to register!

■ Garage management software Garage

Hive has announced the Blend is back on the 7th of October 2023 at the Eastside Rooms in Birmingham, with tickets now on sale. It is a two-in-one event featuring a conference during the day where you can hear from industry speakers on how to run your business more efficiently, before the evening event with a threecourse meal and the chance to network.

■ Bookings are now open for the IAAF annual conference and awards dinner, taking place at DoubleTree by Hilton, Milton Keynes on Thursday 7th of December. The conference features a line-up of leading industry voices, and in the evening, delegates will be invited to the awards dinner, with Tom Allen, opening a show aiming to recognise outstanding achievements across the automotive aftermarket.

Why aren’t more women in the workshop?

If you’ve ever wondered why there aren’t more women in the motor industry, you wouldn’t be alone – the percentage of women in the automotive indsutry sits at just 19 per cent and the number of women actually in the workshop, working on cars, is even lower.

But why would garages want to hire women? According to Louise Baker, garage owner and mechanic who we spoke to for the PMM podcast, she advises that “You need to open your doors, if you have more women in there that know what they’re talking about, not just the women on the counters, you’ll see that we're a bit more empathetic, we're a bit more meticulous and I do think we have a better relationship when we're talking woman on woman than when we’re talking man and woman. That's just the way it is, you feel more comfortable.”

Ultimately, the more woman that get into the trade, the more people will see that this is something that they can do. As PMM’s Freya Coleman and Louise Baker discussed in the

Agaragemakeover

Euro Performance has invested a sixfigure sum in what it calls a ‘significant workshop refit’ to upgrade its nine lifts and equipment, as well as installing airconditioning, flooring, a reception, meeting rooms and staff break out facilities. As part of the makeover, it has recently invested in a website, also giving its online space an updated look.

Owner, Gareth Davies, said: “Even though we’re right in the middle of the refurb, for the workshop it’s business as usual. To add to everything that’s going on, I also knew we needed a team of garage sector

podcast episode, it’s important for young girls to know that becoming a mechanic is an option for them and this is why Louise often goes into her daughter’s school to preach about how cool her job is. By speaking to Louise about her career and her company ‘Womanic’, PMM hopes to highlight female talent and inspire more women to pick up a spanner.

To listen, scan the QR code

website specialists to partner with us and build a strong online presence. Whilst the virtual world is no less complicated than overseeing the garage re-fit, thankfully I found Jim and his team at Garage Services Online. What a game-changer they’ve been.”

8 OCTOBER 2023 PMM PMM

NEWS with Freya Coleman

A sunny helping hand

More people than ever before have been reaching out to the automotive charity Ben’s helpline for support, with 2023 seeing a 23 per cent increase in enquiries (year on year).

Given the knock-on effect money stress can have on people’s mental health and wellbeing, this comes as no surprise. Ben has apparently supported 128 households that couldn’t afford to put food on the table, 66 households that couldn’t pay their rent or mortgage costs and 52 households that couldn’t afford utility bills.

In addition to supporting basic living costs, the charity was also giving families the opportunity to enjoy spending time together during the summer holidays, and take the pressure of families that face impending back to school costs.

NEWSIN QUOTES

“ The IMI fully supports the UK government's ambition to transition to zero emission vehicles. This new inquiry...is timely and essential. We are particularly pleased to see that the environment and climate change committee, led by Baroness Parminter, recognise the importance of seeking input from the automotive sector itself, as well as motorists.”

Hayley Pells, policy and public affairs lead at the IMI, commenting on the House of Lord’s enquiry into electric vehicles

“ GSF Car Parts will continue to operate with total independence from LKQ Corporation during the transitionary period. Our 180 branches remain open for business as usual and will continue to offer excellent service to trade and retail customers.”

GSF Car Parts president and COO Sukhbir Kapoor’s response to the completion of the acquisition of Uni-Select.

MESSAGE ME YOUR NEWS AT FCOLEMAN@HAMERVILLE.CO.UK

In pictures: Speed of Sight charity hosted a track day at Castle Combe Circuit in Wiltshire, giving people with any disability the chance to drive themselves around the racing circuit.

PMM THE PODCAST

With women making up just 19 per cent of the automotive industry, and even less than this actually working as technicians, I wanted to shine some light on female talent in the trade in the hopes it might inspire young girls and older women alike. For this episode Louise Baker immediately came to mind – her keenness to spread the message that women have a place in the workshop coupled with her experience running her own garage business made her the perfect candidate. It also helped that we’d worked with Louise before in the magazine, in 2017 when she first opened her business.

PMM ’s news and products editor Freya Coleman hopped on a train recently to speak to Louise Baker, the woman behind Womanic. Together, we try and get to the bottom of why more women aren’t picking up a spanner and getting their hands dirty. If you’re not already convinced, here, Freya takes a look at some of her highlights from the episode.

A bit of background

So I’m self-taught in everything I do, so I’m selftaught in cars. I made my own website. I made my own my own business cards, I do my own social media. I do my own PR, I do my own advertising,

A head scratcher

marketing. I pretty much do everything on my own. It’s really full on and it gets a lot and it can get a bit overwhelming, but when I have a quiet day, I take a step back and just reflect over the week. I'm super lucky.”

From speaking to Louise, it was clear to me how much she loves her job, and she was perplexed as to why more people don’t want to be mechanics, so I asked her what her favourite part of the job was:

My favourite part of the job is getting a head scratcher that no one else can solve, and then I solve it. I’ve had a couple of them – I had a Mini Countryman in not so long ago, a good customer of mine actually, she’d just bought it. I think she got it from a decent, reputable dealer, and every time she drove, so she’d drive off in the car and then when she’d come back, it wouldn’t start again.

“She had it recovered, she had it took to her local garage, she had it taken to Mini and Mini couldn’t figure out what it was. And she phoned me, she’s like, ‘Lou, I don’t know what's

going on. It’s doing my head in now.’ So, I was watching Love Island and when I was watching Love Island, I was just doing a bit of research and I found out that the relays fail.

“So, I went round the house the next day and I was like, ‘let’s just try it, you know?’ I can literally just switch the relay, it’s not costing you any money and she’d already spent like £300£400 having people trying to diagnose it. So, I switched the relays out and it didn’t happen. And I thought, oh my goodness, I've sussed it, I can’t believe it. She went out and, to this day, it’s not failed.”

PMM OCTOBER 2023 11

A look inside:

Overcoming Obstacles

It hasn’t always been smooth sailing though...

So, being a single mum and having my own business and working on my own, it's really hard to juggle and spread my time out wisely becaus if I don't work, I don't get paid and if I don't get paid then I can't take my daughter out. So, now it's the school holiday, she's going to expect to go and do stuff. But if I take a day off, I'm not going to get paid for it.”

You'll be spending money not getting money?

“100 per cent. So now I have to plan my time. I try to do at least one thing a week with her that in my head's planned, I know what I need to do and as long as there's no spanners thrown into the works that throw me off course, I'll figure it out.”

A dedicated mechanic

This episode highlight came when I was chatting with Louise after the official ‘recording’ of the podcast, and she mentioned how she struggled with confidence early on in her career – something I’m sure a lot of people can relate to. I dug out my recorder as Louise was underneath a car and captured the following:

So when I first started out, it’s no secret that when let’s say I’ve done a lower arm on a car, I’ve been known to sneak out at like two, three o’clock in the morning back to my customer’s house and get onto the floor, under the car and just double check that I’ve pinched the wheel bolts up — it’s just pure paranoia. When you first start out, you’re just constantly overthinking. And I’d go sleep worrying that I’d not pinched something up or I’d not marked

A final message

something, and I’d just panic.

“So literally I had to go out there with a breaker bar and I’d pinch the wheels up and the customer would be fast asleep in bed, none the wiser. It was perfectly fine and I’d done everything I was supposed to do, but I’d just constantly second guess myself. And I suppose now, I still do it a little bit, but nowhere near as much as I did when I first started – it’s just confidence.”

My final highlight from interviewing Louise was her advice for anyone wanting to pursue a career in a workshop:

My advice is to just do it. Just do it. Don’t think about it. Just do it. Don’t procrastinate. If you want to do it and you love it, and you enjoy it, no matter

what it is, whether it’s cars, whether it’s anything, if you’ve got an interest in it, just do it. Don’t let anyone tell you that you can’t do it.”

LISTEN TO ALL OF THE EPISODES SO FAR ON THE PLATFORM OF YOUR CHOICE, SIMPLY SCAN THE QR CODE

12 OCTOBER 2023 PMM

“I feel like as a woman in the trade, I have a public service to make sure that every other woman in the trade gets into schools.”

YOU ARE NOW ENTERING

PMM has teamed up with the CPD Group to offer you the chance to gain CPD points while you read every issue!

Continuing professional development (CPD) can be broadly defined as any type of learning you undertake which increases your knowledge, understanding and experience of a subject area and your role within it. To help professionals to better document and prove this process, our new CPD Zone features articles that have been checked, verified and accredited by a thirdparty specialist organisation.

The content within the CPD Zone will provide you with 1 CPD Credit, or 1 hour’s worth of continuous professional development.

Once you have read through the articles contained within, you will be able to scan the QR code at the end of the last article. This will provide you with a downloadable certificate, personalised to you. This can then be used as part of your ongoing CPD record, as needed to satisfy various organisations and schemes. Regular readers of PMM, therefore, could earn 11 CPD points just by reading the magazine each month.

DO NOT SCAN THE QR CODE UNLESS YOU HAVE READ ALL OF THE CONTENT WITHIN THIS SECTION!

CPD relies on self-certification, which in turn relies on professionalism and honesty from those who participate. We have great faith in the diligence and professionalism of our readers – we are called Professional Motor Mechanic, after all. It is fairly safe to assume that if you are picking up PMM each month, then you are already interested in reading and understanding technical content. Indeed, we are a lifeline for many in the industry who rely on us to spread the word on the latest changes and developments originating with the OEMs.

THIS PROCESS IS COMPLETELY FREE

Don’t worry – you won’t have to pay a penny to gain your CPD points each month. It’s on us!

All certificates are valid for one year from the issue date. If you have any issues downloading the certificate or using the system please email us at: pmm@hamerville.co.uk

NEW USERS –ACCESS YOUR BESPOKE CPD CERTIFICATE IN FIVE STEPS

Read ALL of the articles within this month’s CPD Zone

Scan the QR code or enter the RDR.Link in your web browser –both are found at the end of the last article in this section

Enter your email address

Fill out your details on the contact form

Download your certificate for use as part of your annual CPD record

PREVIOUS USERS –ACCESS YOUR CPD CERTIFICATE IN FOUR STEPS

Read ALL of the articles within this month’s CPD Zone

Scan the QR code or enter the RDR.Link in your web browser –both are found at the end of the last article in this section

Enter your name and email address

Download your certificate for use as part of your annual CPD record

PMM OCT0BER 2023 15

CPDZONE READ ME TO COLLECT YOUR CPD POINT

TROUBLESHOOTER

Why did the X5 40E start intermittently?

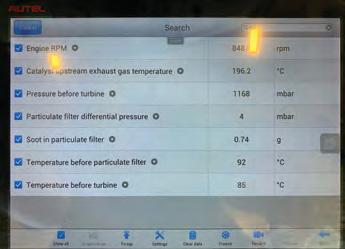

Ben Johnson is driven to his wits’ end by yet another BMW X5 40E in the workshop. This time, the car refused to start, until it did start… meaning it wasn’t simply the fuse at fault.

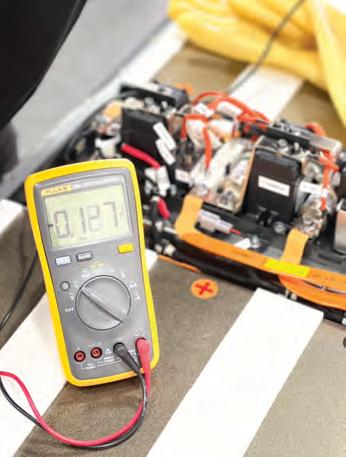

These days, the phrase “here we go again” seems to slip from my lips more often than not. It's a refrain that frequently accompanies the sight of yet another X5 40E being towed in, the nature of its latest breakdown a mystery. This Monday morning was no different, as another one –this time an M-sport variant –sat forlornly in the car park. The recently installed towing hook in the front bumper area caught the glint of the early morning sun, its golden hue suggesting that before any diagnostics could commence, a push inside might be necessary. True to form, the tow truck driver had chosen the most distant spot from the workshop to deposit it.

With a sense of determination, I attempted to start the engine. After two unsuccessful tries, hope was not lost. As the saying goes, perseverance pays off, and on the third attempt, the engine roared to life, albeit with a touch of smoke billowing from the tailpipe. But that

was inconsequential. The primary goal was achieved: it could be driven to my ramp under its own power. After all, no one relishes the thought of exerting the effort to push nearly two tonnes early on a Monday morning.

Once securely positioned on my ramp, I made another attempt at starting, only to be met with resolute refusal. Despite my efforts to crank it, the engine remained stubbornly silent. Alongside the sound of the starter motor's efforts, a check control message appeared, displaying “fuel system” on the Kombi LCD screen.

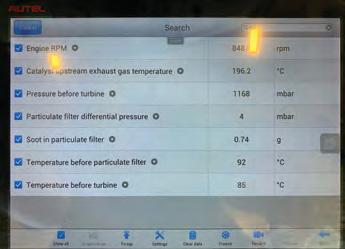

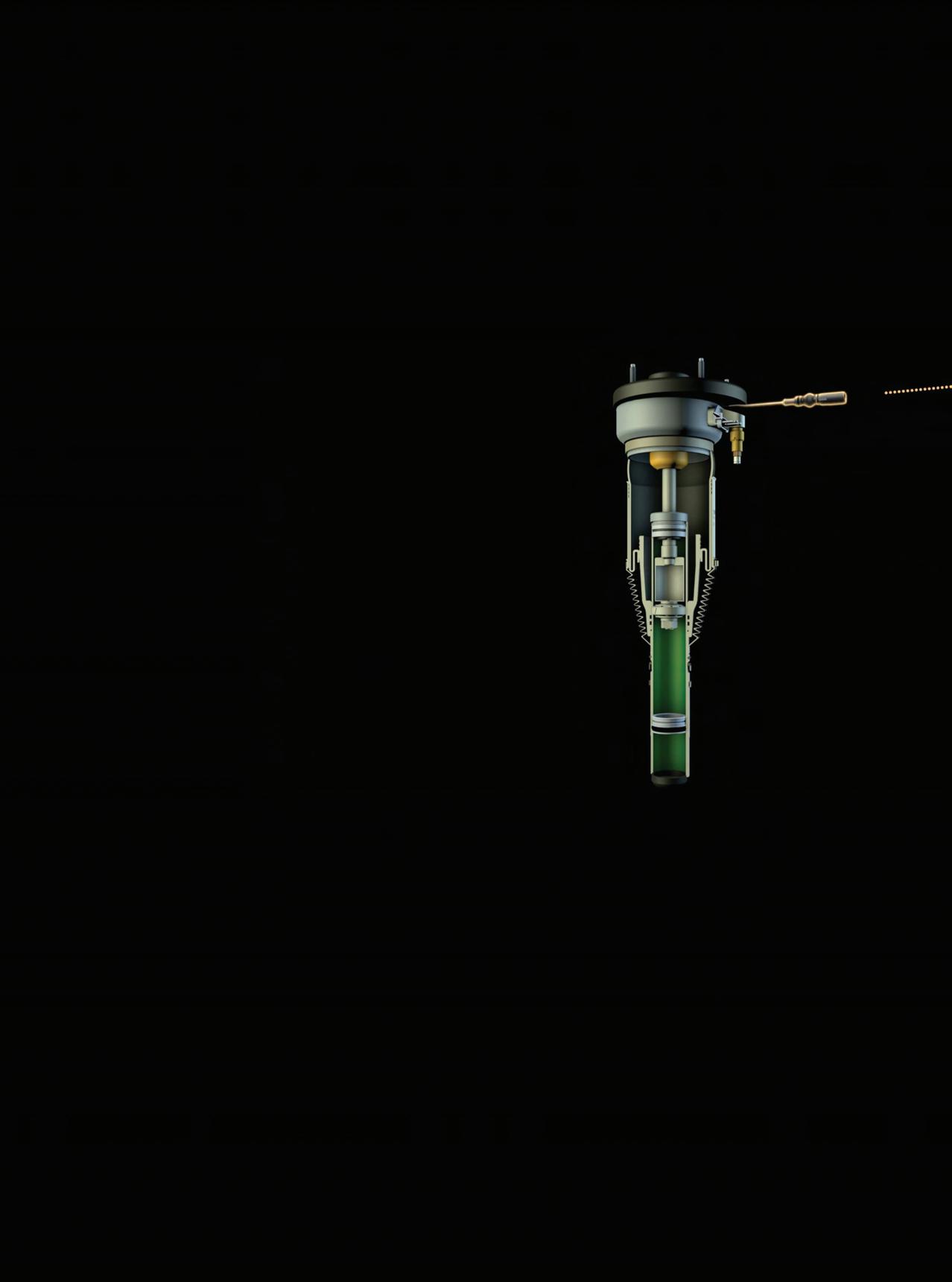

The diagnostic process using ISTA promptly unveiled fault codes pinpointing issues within the fuel system. Specifically, the codes indicated both excessively low high-pressure

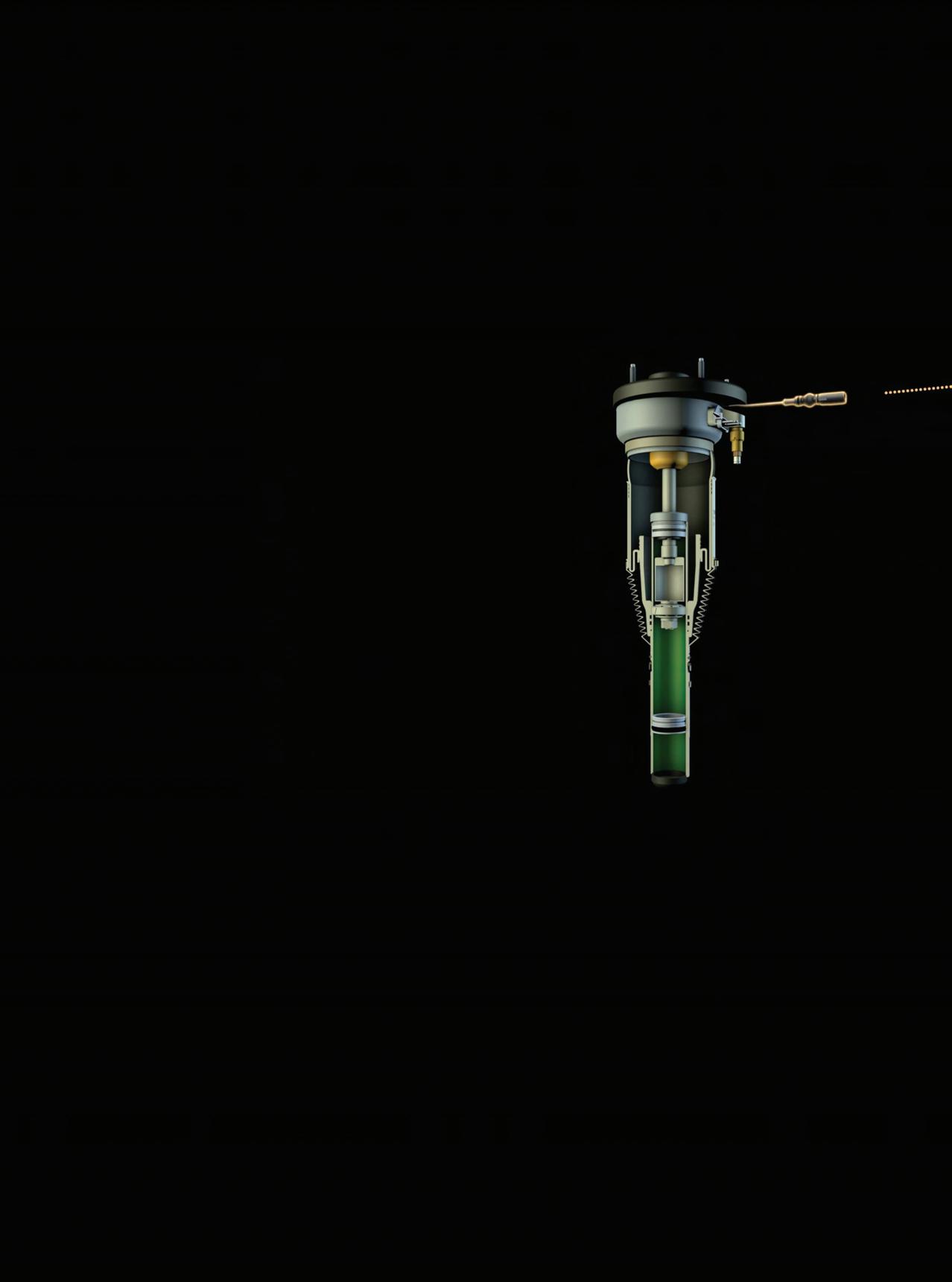

and low-pressure levels. In the realm of the X5 40E, the fuel system is straightforward and is overseen by the EKPS control unit. Operating on the PT-CAN bus, this unit's primary responsibility involves energising the fuel pump –serving as the single-phase variant in this vehicle. Additionally, the EKPS undertakes the task of regulating fuel pressure, ensuring that minimal output from the in-tank low-pressure pump suffices when fuel demand decreases. This modulation is achieved through precision PWM control. The fault codes do not explicitly pinpoint a faulty control unit per se, rather the fault codes are stored due to the feedback from the fuel rail pressure sensor during engine cranking –pressure that is too low triggers the DME to set the fault codes. To provide an in-depth perspective on the fuel system, I've crafted an illustrative diagram (Fig.2).

Getting started

So, where does one begin? Initiating a comprehensive vehicle test exposed a clear lack of communication from the EKPS control unit on the PT-CAN bus. As I consistently emphasise to newcomers embarking on this career path, the starting point is invariably the fuse check. True to form, the 20 amp fuse had met its demise. Positioned within the rear fuse box –located on the right rear section of the boot area –it’s this fuse that provides a permanent live power supply to the EKPS (Fig.3). The root cause behind the EKPS’

READ ME TO COLLECT YOUR CPD POINT CPDZONE

A plethora of warning lights. Cranking but not starting

Basic overview of the low pressure fuel system on the X5 40E

“As I consistently emphasise to newcomers embarking on this career path, the starting point is invariably the fuse check.”

16 OCTOBER 2023 PMM

Ben Johnson, diagnostics expert

Sure enough the EKPS fuse had blown, but why?

communication failure on the PT-CAN became evident, and logically, this issue would prevent the car from starting, given the fuel pump’s reliance on the EKPS. Yet, an intriguing puzzle remained: why did the vehicle fail to start for both the customer and myself, but then obediently roar to life after three attempts? This mystery was soon to be unravelled, revealing an intermittent pump malfunction that at some point had managed to evade excessive current draw. My working hypothesis is that this intermittent behaviour prevented the fuse from blowing earlier and the pump had simply just gone open circuit sporadically.

Pinpointing the issue

The open circuit phase was clearly now over as inserting a fresh fuse unveiled a repetitive pattern –every time the engine wascranked, the fuse would succumb immediately, joining its fallen comrades in the electrical graveyard (aka the bin). After enduring this exasperating cycle four times, I exercised prudence and shifted my focus towards disengaging the EKPS connector, marking the commencement of the testing phase.

Upon inserting another fuse and activating the ignition, a glimmer of progress emerged –the EKPS showcased its willingness to communicate. Consequently, my focus

pivoted to scrutinising the fuel pump itself, especially considering that detaching the fuel pump from the EKPS connector prevented the fuse from blowing. It was a clear indication that the fuse was blowing due to the excessive current draw attributed to a faulty fuel pump.

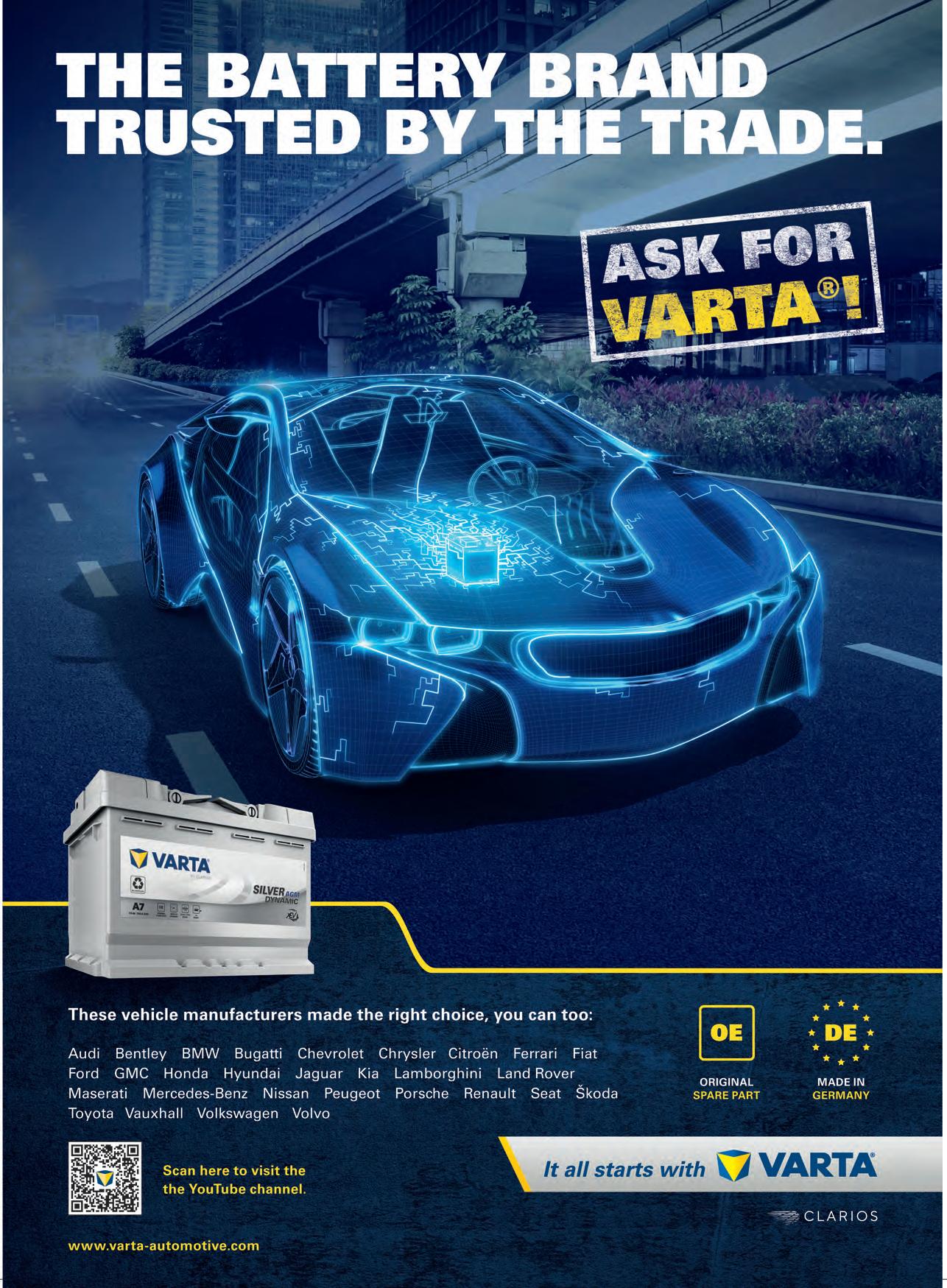

The task at hand demanded the deployment of an amp clamp, although the fuse’s swift demise made it nearly impossible to capture a meaningful reading. Compounded by the unavailability of my usual, smaller, amp clamp, I was compelled to employ a substantially larger clamp calibrated for the hundreds

range. To obtain a tangible reading, I resorted to recording the clamp screen on my iPhone and subsequently reviewing the playback. The revelation was staggering: the current draw surged to an astonishing 98.7 amps. It became abundantly clear why the seemingly feeble 20-amp fuse met its end instantaneously every time the car was cranked over (Fig.6).

Having meticulously inspected the pump and discovering no anomalies, I deemed it necessary to check the pump wiring leading back to the EKPS. My efforts to unveil potential issues yielded no traces of shorting to ground or to 12V. A thorough assessment, conducted with both ends of the harness

disconnected, again yielded nothing out of the ordinary. Armed with this evidence gathering, the course of action became clear: the decision was made to order and fit a fresh pump and EKPS. The outcome was as anticipated –the issue was resolved. Curiously, there were no indicators of scorching, arcing, or loose connections; the root cause appeared to be confined within the pump itself.

Although a simple fault find, this fault discovery brought a profound sense of relief, especially considering the myriad of issues that this generation of X5 has been prone to. It highlighted that the problem at hand wasn’t as severe as the array of potential faults that could have arisen.

The temptation to disassemble the pump in search of a cause was outweighed by the fact that the vehicle was fixed and running well. In a world where time is perpetually in short supply, expediency dictated moving forward to the next waiting customer. With any luck, the forthcoming months might usher in a period of respite, marked by a reduction—ideally, an eradication—of issues afflicting hybrid X5s and a well-earned break from these troublesome vehicles.

PMM OCTOBER 2023 17

The EKPS connector. Note the transparent shielding wire (not shown in the schematic)

No voltage and a blown fuse to the EKPS power supply

WANT TO KNOW MORE? FOR MORE INFORMATION WWW.RDR.LINK/ABB001

Surprisingly low resistance across the pump

Huge peak draw of almost a hundred amps on a 20 Amp circuit spells trouble.

KNOW YOUR PARTS

Adaptive Ride Control Systems

Suspension specialist Arnott explains how adaptive damping systems operate, providing a better understanding of how this suspension technology works.

As the automotive industry continues to enhance drivability and make the ride more comfortable, suspension technology plays an ever more important role. Suspension systems have been equipped with classic coil spring and shock absorber set-ups for a long time. Conventional leaf and coil spring systems evolved into air suspension systems and regular hydraulic shock absorbers evolved to highly advanced adaptive damping systems (that can be matched with both coil and air suspension systems). These innovations optimised the ride and handling for different driving conditions.

A typical modern adaptive ride control system contains the following components: adaptive dampers, an electronic control unit, a sensor set, and a driver preference switch. The sensor set is typically a combination of accelerometers that are located on the body, and position sensors located near the suspension at all four corners of the vehicle. Most vehicles with an adaptive damping system feature a driver preference switch. This is a button on the dashboard that allows the driver to select a preferred driving mode such as comfort or sport.

In this article, the “adaptive damper” can be any electronically controlled adjustable damper (including magnetic ride) since the basic operating principles for the system are the same.

How it works

Adaptive damping systems began by using variable dampers with two or more discrete settings. The more modern adaptive systems use “continuously variable” dampers instead. The working principle between (older) discrete setting and (modern) continuously variable dampers is essentially the same. The difference is that in a discrete setting shock the valve is ON/OFF (fully open or fully closed), whereas a continuously variable valve allows the damper setting to be adjusted to any value between preestablished firm and soft setting limits.

The ride control ECU is the brain of an adaptive damping system. The ECU is connected to sensors located on the body and the suspension at all four corners of the vehicle. Additionally, the ECU is also connected to the vehicle’s main data bus to get inputs including vehicle speed, throttle position, steering angle, transmission, and brake applications and others.

The ECU receives these different data streams and uses them as inputs to an algorithm which continuously calculates the magnitude and direction of the vehicle’s body motions in heave, pitch, roll and yaw as well as the motion of each wheel relative to the vehicle body. The motion calculation results are then used to determine the

damping force required at each individual corner of the vehicle to provide the desired ride and handling characteristics – as defined by the algorithm and the position of the driver preference switch.

Once the ideal damping force has been calculated, the ECU provides the appropriate amount of electrical current to each damper to obtain the desired damping characteristics. This entire process occurs in milliseconds – more than fast enough to react to almost any road input.

Except for the magnetic ride systems, the damping force of adaptive dampers are controlled in more or less the same way. The firm and soft damping force limits of adaptive dampers are controlled by shim stacks installed in separate flow passages within the damper. The damping force adjustment is typically achieved by opening or closing a

READ ME TO COLLECT YOUR CPD POINT CPDZONE

The more modern adaptivesystems use “continuously variable” dampers instead of variable dampers with two or more discrete settings.

18 OCTOBER 2023 PMM

Signal from the car’s computer

fluid flow control valve to regulate the amount of fluid flowing through each flow passage.

For example, if a softer damping characteristic is needed in a continuously variable adaptive damper, the flow control valve will adjust so that more fluid will flow within the damper and will pass through the shim stack which defines the soft setting, and less fluid will flow through the passage containing the firm valve stack.

The next step

The Arnott eRide R&D team focuses on a collaboration with the continuously variable ride control systems currently being used by the different car manufacturers. Getting it right is quite a delicate process because electronic control strategy and the execution of that strategy is a combination of car

manufacturer’s requirements and supplier offerings. The reality is that every ECU design works a little differently and the algorithms can be significantly different –even if the same shock design is being used.

To design and implement such technology for the aftermarket, it was crucial to make the eRide valve design functional and working in compliance with the variety of ECU set ups and valve designs. For example, the switching speed – which is the reaction time to switch between damper settings – can vary

greatly. A change made for the switching speed for a particular application may work as improvement for a specific model but could actually cause performance issues for other vehicle applications. The eRide technology can be used to replace any continuously variable shock with an internal valve. Other valves with alternative designs are currently in development and will be released by the company at a later stage.

The continuous commitment and hard work of all the teams has led to a valve design that Arnott claims allows it to match or exceed OE ride and handling in all applications.

WWW.RDR.LINK/ABB002

Every ECU design works a little differently and the algorithms can be significantly different.

WANT TO KNOW MORE? FOR MORE INFORMATION

PMM THE PODCAST

WHAT DO CHANGING A BATTERY, CHANGING A BABY (JUST THE NAPPY) AND CHANGING YOUR MORNING RADIO STATION ALL HAVE IN COMMON?

THEY OFFER THE PERFECT OPPORTUNITY TO LISTEN TO THE PROFESSIONAL MOTOR MECHANIC PODCAST WITH KIERAN NEE.

HEAR ADVICE ON PRICING JOBS, MANAGING PARTS SUPPLY, ELECTRIFICATION, RECRUITMENT AND MUCH MORE.

Listen on Google Podcasts Listen on Apple Podcasts Listen on Amazon Podcasts Listen on Spotify Podcasts LISTEN NOW ON YOUR PODCAST PLATFORM OF CHOICE

BEST PRACTICE

Brake pads

Blue Print offers some best practice advice on two brake pad ranges, one for PSA group vehicles, the other for Mazdas.

Rear Brake Disc with wheel bearing

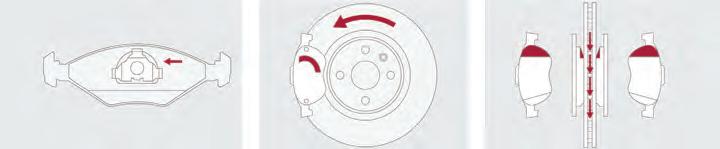

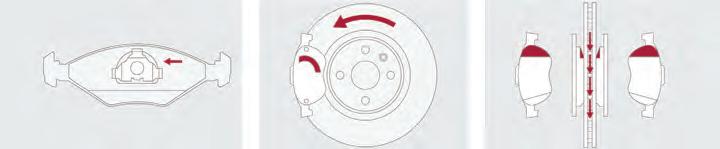

Many Peugeot, Citroën and DS models are equipped with rear brake discs that have an integrated wheel bearing. As a result, this type of assembly allows for significant weight saving, since the brake disc also becomes the wheel hub. This preassembled part also makes replacement quicker and easier for the workshop, whilst eliminating the risk of mounting a bearing with incorrect clearance or seal positioning. However, care must be taken when fitting this type of brake disc to the stub axle as this disc/bearing assembly is also fitted with a multipole reluctor for the wheel speed sensor. With the old brake disc removed from the vehicle, the wheel speed sensor should be inspected for excess corrosion surrounding the mounting area. It is important to note that any excess metal corrosion can alter the position of the sensor – affecting its functionality. This can lead to direct contact with the reluctor, causing damage to the new brake disc assembly (Fig.1).

Part numbers

ADP154305, ADP154351 Models

Various Peugeot, Citroën and DS models

Subsequently, an increased air gap between the sensor and the reluctor can also occur, resulting in an anti-lock brake system fault – logged as a sensor implausibility signal fault code in the brake control unit.

Therefore, during the installation of a new brake disc it should be identified if the speed sensor is in contact with the multipole reluctor, or if the air gap is not correctly aligned. If discovered to be incorrect, the brake disc and speed sensor should be removed. The sensor seating location should be cleaned of corrosion and – if damaged –the sensor refitted or replaced. With the new brake disc re-installed, and the sensor correctly aligned, a clear 1-2mm air gap between the reluctor and the sensor will be visible (Fig.2).

Adjustment unit for handbrake adjustment

Part number

febi 104935

Models

Various BMW models

FUNCTION

The handbrake lever pulls on the two cables which transmits the applied force to an expander (adjustment unit for handbrake adjustment) within the brake drum housing for each rear wheel. The expander is attached to the end of the handbrake cable. As the cable is pulled, it causes the

expander to open. The expander is forced against the brake shoes where it then pushes the top of the shoes apart. In doing so, it presses the friction material against the inner surface of the brake drum. If the parking brake is functioning correctly, the shoes will press sufficiently to securely lock the wheel.

PMM OCTOBER 2023 21

READ ME TO COLLECT YOUR CPD POINT CPDZONE

Fig. 1 Damaged reluctor due to contact with the sensor

Fig. 2 Brake disc and sensor correctly installed

CAUSE OF FAILURE

Seized operation of the expander or wear is quite common. This causes the parking brake shoes to bind or leads them to not be effective. The parking brake on these vehicles is a drum brake system integrated into the rear brake disc. As a result, the

parking brake linings barely wear, and the condition of the hand brake can only be determined when the brake discs are removed. It is recommended that the hand brake shoe expander is replaced when the parking brake shoes are replaced, or, alternatively, every four years.

Rear brake pads, rear brake discs

Part numbers

ADC44288, ADM542112, ADM542114, ADM543124, ADM543127

Models

PROBLEM:

When replacing the rear brake pads and/or the rear brake discs, the vehicle is required to be set into maintenance mode. By doing this, the EPB motor gear unit will operate and allow the brake pistons to be pressed in for brake maintenance purposes.

CAUSE:

When the EPB is applied, the EPB system detects the current brake disc position and automatically adjusts it to the optimum EPB release position (brake pad to disc clearance). Failure to carry out the correct procedure (i.e. initially setting the vehicle into maintenance mode) will potentially cause an operational problem with the EPB system.

SOLUTION:

When performing repairs and maintenance to the rear brakes on the vehicles listed above, it is important to set the vehicle into maintenance mode as explained on the following page.

Caution: If performing this procedure while the vehicle is on the ground, block the front and rear wheels using wheel blocks. Failure to do this may result in the vehicle moving when the electric parking brake is released.

The EPB system will not work if the battery voltage is insufficient. Therefore, it is advised to use a battery support unit while carrying out this operation.

Setting to maintenance mode

Switch the ignition ON (engine off). Release the electric parking brake. Switch the ignition off, and then switch the ignition ON (engine off) within 5 seconds while maintaining the following conditions.

■ Press the electric parking brake switch.

■ Depress the accelerator pedal fully. Verify that the electric parking brake warning light is illuminated in an amber colour and the mode is switched to maintenance mode.

Switch the ignition off. Carry out all necessary repairs or replacement of the rear brakes.

Ending maintenance mode

Switch the ignition ON (engine off). Switch the ignition off, and then switch the ignition ON (engine off) within 5 seconds while maintaining the following conditions.

■ Pull-up the electric parking brake switch.

■ Depress the accelerator pedal fully. Verify that the electric parking brake warning light turns off and the maintenance mode is ended. Switch the ignition off.

After all repairs have been completed, check the EPB operation when the engine is running or with a fully charged battery (engine off).

22 OCTOBER 2023 PMM READ ME TO COLLECT YOUR CPD POINT CPDZONE

Mazda 6, Mazda CX-5 equipped with electronic parking brake (EPB)

KNOW

MORE INFORMATION WWW.RDR.LINK/ABB003

WANT TO

MORE? FOR

If performing this procedure while the vehicle is on the ground, block the front and rear wheels using wheel blocks.

HOW TO

Replace the clutch on a 2014 Citroën DS3

In this month’s Schaeffler LuK Clutch Clinic, REPXPERT Alistair Mason is replacing the clutch in a 2014 Citroën DS3 fitted with a 1.2 VTi engine. The vehicle has covered a little more than 55,000 miles and the owner has reported that the clutch appears to be “slipping”.

Vehicle Information

Manufacturer: Citroën

Model: DS3

Year: 2014

Engine 1.2 VTi

Mileage: 55,000

Schedule time: 5.75 hours

Gearbox removal

With the vehicle positioned on the lift and the bonnet opened, disconnect the battery, and then raise the vehicle lift to gain access to the underside, to remove the engine undertray and then drain the gearbox oil. Whilst the oil is draining remove both front wheels, both driveshaft nuts and the N/S/F wheel arch liner (Fig.1).

Remove both bottom ball joint pinch bolts and lever the bottom arms down to remove the bottom ball joints from the hub assemblies, ease the outer CV joints out of the hubs and then lever both driveshafts out of the gearbox and remove from the vehicle. Refit the gearbox oil drain plug and tighten, then remove floor brace/strengthening bar and the lower bell housing bolts, but leave two easily accessible bolts to support the gearbox until its removal. Remove the lower

gearbox mounting, the exhaust front pipe mounting, starter motor bolts (Fig.2) and then the clutch slave cylinder (Fig.3).

Lower the vehicle lift to gain access to the engine bay (Fig.4), remove the engine ECU that is attached to the battery carrier, remove the complete air filter assembly, the battery and then the battery carrier, which then gives good access to the top of the gearbox (Fig.5).

Disconnect the earth cable, reverse light switch and gearchange cables, release and

READ ME TO COLLECT YOUR CPD

24 OCTOBER 2023 PMM

POINT CPDZONE

ease the wiring loom that is located across the top of the bell housing out of the way to give access to the upper bell housing bolts, and then remove the upper bell housing bolts. Support the engine using either an engine support brace, sub frame mounted support or a second transmission jack, and support the gearbox with a transmission jack, then remove the upper gearbox mounting, lower the engine and gearbox assembly slightly, remove the two easily accessible bell housing bolts and ease the gearbox away from the engine. When the input shaft is clear of the clutch, lower the transmission and remove the gearbox from the vehicle.

Clutch removal and replacement

Remove the clutch assembly from the flywheel (Fig.6) by removing the six retaining bolts and ease the clutch pressure plate off the alignment dowels and remove the clutch pressure plate and clutch plate. At this point the reason for clutch slip in this particular repair was evident, as the clutch plate had worn down to the friction material rivets.

Remove excess clutch dust from the flywheel and back of the engine using some clutch and brake dust cleaner, inspect the back of the engine for any leaks that could contaminate the new clutch, rectifying if required. Remove the glaze from the flywheel surface using some emory cloth and clean again with clutch and brake dust cleaner.

Turning to the clutch release system in the gearbox, remove the release bearing and fork, check all contact points and pivot points for any wear and replace if necessary. In this repair, there was some wear on the release bearing guide tube, so this was also replaced.

Note – This clutch has a slightly different design as it is a pressed steel clutch, as opposed to a cast iron machined pressure plate, which has many advantages, whilst still meeting all the required technical specifications.

Clean the bell housing area with clutch and brake dust cleaner, apply a light smear of high melting point grease to the input shaft splines, now mount the new clutch plate onto the input shaft and move back and forth. This has two purposes: it confirms the clutch plate is correct and also evenly distributes the

grease. Remove the clutch plate and wipe off any excess grease, locate the release arm and new release bearing into position and secure onto the pivot point (Fig.7).

Mount the new clutch onto the flywheel using a suitable clutch alignment tool, but ensure that the clutch plate is facing the correct direction indicated by “gearbox side”. Clean the clutch pressure plate face using clutch and brake dust cleaner, align the clutch pressure plate on the flywheel dowels, insert the clutch bolts, and tighten in an even and sequential sequence, before torquing them to the manufacturer’s specification, then remove the clutch alignment tool (Fig.8).

There are a couple of final checks to do before installing the gearbox: first, make sure the gearbox alignment dowels are located correctly and second, ensure the bell housing area is clear of cables etc. that could get caught when positioning the gearbox (Fig.9).

Gearbox installation

With the aid of a transmission jack, position the gearbox close to the engine, then spend a little time to ensure that the alignment is correct, and ease the gearbox into position and locate it onto the alignment dowels. Fit two easily accessible bell housing bolts and tighten, then fit the upper gearbox mounting and bolt into position. Refit all other components in reverse order of removal and replenish the gearbox oil.

After the battery lead has been reconnected, reset all electrical consumers and carry out a full road test to ensure that the repair has been successfully completed.

PMM OCTOBER 2023 25

WANT TO KNOW MORE? FOR MORE INFORMATION WWW.RDR.LINK/ABB004

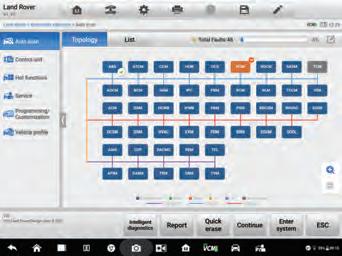

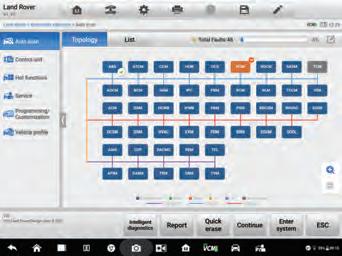

DIAGNOSTIC GUIDE

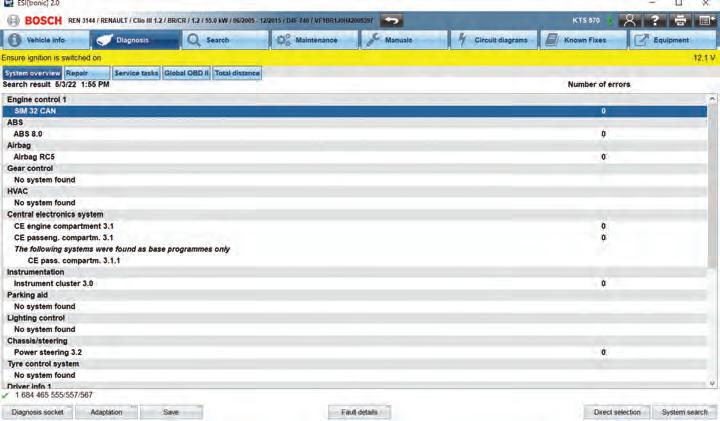

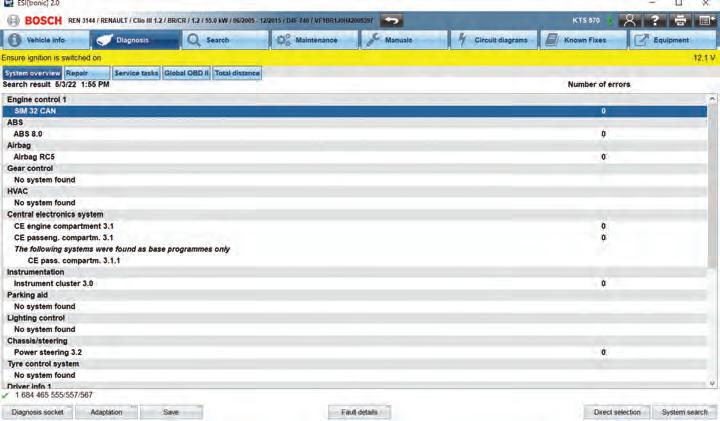

Using Bosch’s ESI[tronic] 2.0 software: a monthly guide

A few years ago, PMM ran a guide from Bosch on its KTS diagnostics software, ESI[tronic] 2.0. We thought it would be a good idea to revisit the guide with Bosch and find out what’s changed. In this second instalment, we are understanding the system overview feature and learning how to produce protocol reports.

The ‘system overview’ feature on the ESI[tronic] 2.0 works as the user’s ‘complete vehicle diagnostic check’, allowing you to carry out the necessary tasks efficiently for every vehicle that comes through your workshop doors for a service or repair. This helps you to quickly and easily identify intermittent issues, pending technical problems and mechanical difficulties, that the driver or customer may not be aware of.

This feature will also run a systematic check on the vehicle, ensuring it has a clean bill of health for when it is handed back to the owner after a repair or service. Allowing you to know that you are delivering the best service possible to your customers (Fig.1).

How to perform a system overview

STEP

Open the diagnosis main tab.

STEP

Click on the ‘system search’ F12 soft key in the system overview sub tab.

STEP

The KTS will then perform a full ‘control unit search’ of all communicating systems.

STEP

Double click any of the system names in the categories for direct access to the ECU

diagnostic functions for further information and testing. If a fault code is erased here, it will refresh when a user returns to it –enabling you to save and show the before and after status to show the vehicle owner.

STEP

Store the complete list in the job report with the F3 save button. You can also access a specific list of diagnostic trouble codes (DTCs) and any available descriptions via the F5 fault details button. Again, this can be saved to the job protocol with a tap of the F3 save soft key.

When the system overview is complete, you will see a list of all ECU systems that are communicating and an indication if any fault codes are present. This is particularly beneficial when users are analysing a vehicle prior to any in-depth diagnostic testing as some faults, for example ESP problems, can log a DTC in more than one ECU.

Once you have retrieved the overview list, if necessary, any of the system names in the categories can be double-clicked. This will take the user straight to the ECU diagnostic functions for additional investigation and testing. From here, if the fault code no longer shows ups, the overview list will refresh itself once you return to it.

Alternatively, you can also select the “delete all faults” button to delete all DTCs across multiple systems or ECUs – in a single click.

It’s worth noting that many newer vehicles

PMM OCTOBER 2023 27

READ ME TO COLLECT YOUR CPD POINT CPDZONE

will now support a fast CAN bus search of all of the ECUs on the vehicle system communication network. In some instances, a vehicle brand can have up to 60 ECUs that can all be checked in under a minute, speeding up the technician’s task of assessing the diagnostic state of the vehicle. Yet, for other vehicle brands, this process may take a little longer, due to the KTS checking each ECU individually for presence and fault status of each group. The new generation of KTS (560/590) is able to communicate simultaneously over two communication channels in parallel to significantly speed up the time required for a complete vehicle scan.

Prepare your report

The system overview function enables you to easily produce a professional and accurate vehicle report. The tool helps you justify any repairs that you need to carry out on the vehicle to the owner (Fig.2).

Document the end-to-end process followed by your technicians during any diagnostic fault-finding work and share the before and after progress with your customers.

Choose to include a variety of different information in your reports – from ECU system names and identification details to the number of trouble codes stores and their descriptions.

Storing information

The amount of information included in your protocol can be stored under ‘user settings’ in the main menu. This allows you to save or erase whichever information you choose to, which can be beneficial when you are justifying a lengthy repair process or operation time (Fig.3).

You can also choose to include your garage details that will appear in the report, alongside the option to include the job number, customer’s details, and any advisory

comments to be communicated to the customer. Importantly, the protocol file can be saved in a PDF format, which is useful for technicians to print and to attach to an invoice, highlighting to customers of what problems were found and repaired.

Each time a technician selects a different vehicle with the software and some information is saved, a new protocol report will be created. A key new feature of the ESI[tronic] 2.0 is that you can continually save data to a previous protocol within the ‘last 30 vehicles’ list if you return to an unfinished job (Fig.4).

Next month we will discover how the Bosch ESI[tronic] software streamlines everyday service tasks in the workshop.

WANT TO KNOW MORE? FOR MORE INFORMATION

WWW.RDR.LINK/ABB005

REDEEM YOUR CPD CREDIT

Congratulations, you have reached the end of the CPD Zone!To access your CPD credit from The CPD Group, scan the QR Code below or

WWW.RDR.LINK/ABB006

28 OCTOBER 2023 PMM READ ME TO COLLECT YOUR CPD POINT CPDZONE

A key new feature of the 2.0 is that you can continually save data to a previous protocol within the ‘last 30 vehicles’ list if you return to an unfinished job.

WILL HYDROGEN REPLACE

Whenever I get involved in a discussion about the future of transport there is often somebody who will categorically state that hydrogen cars are the only way forward. This usually arises from the idea that using a hydrogenpowered vehicle will be much the same as using a petrol- or dieselpowered one, so we don’t need to change our habits. We would be able to fill it up almost anywhere, giving a range of several hundred miles, so when the need arises, we can drive the entire length of the country. After all, you can’t do that in an EV – they often add.

I agree, you can’t do that journey non-stop in an EV (yet) but how many times do you need to do it anyway?

Their next argument is usually something about how the national grid will not be able to charge all the EVs. In response I add that a hydrogencar uses at least three times (some say more) as much electricity as a pure EV (or uses dirty hydrogen from a gas refinery).

Their last resort is usually something related to all the rare earth metals used in an EV and its battery.

EVS ?

At this point I remind them that a fuel cell electric vehicle (FCEV) has all the same technology as an EV (including a battery) but it also has a complex fuel cell with associated high-pressure tanks and pipes. The Toyota Mirai, for example, even has a massive supercharger.

Even at this stage of the discussion the desire not to have to change what they do (in my opinion) means that they are still not convinced that hydrogen is not the fuel of the future for cars. I need to try harder, so here we go!

HYDROGEN

Clean (green or yellow) hydrogen is created by electrolysing water using electricity from renewable

resources. Electrolysis is the decomposition of a chemical by passing an electric current through a liquid.

Currently, most hydrogen is currently obtained by steam reformation from natural gas, meaning the CO2 produced is roughly equivalent to that produced by petrol or diesel engines.

Hydrogen can be used in fuel cells to power electric motors or can be burned directly in internal combustion engines. Fuel cells are the most efficient. Hydrogen is an environmentally friendly fuel at the point of use as it only produces water as a by-product. It also has a very high energy density. However, it has to be compressed to between 350 and 700 bar to achieve a suitable tank volume for a normal vehicle.

ADVANTAGES

● No air pollutants or greenhouse gases at the point of use in a fuel cell.

● It produces only NOx when burned in internal combustion engines.

DISADVANTAGES

● Expensive to produce and is only available at a few locations

● Fuel cells are an expensive addition to an EV.

Next month we will examine how a fuel cell converts this clean hydrogen back into electricity and how the efficiency of an EV and an FCEV compare.

Sponsored by FOR MORE INFORMATION GO TO WWW.RDR.LINK/ ABB007

READ ME TO COLLECT YOUR CPD POINT

FIG.2 Basic electrolysis process

FIG.1 An FCEV is a complex machine

Hydrogen is, indeed, the fuel of the future, according to Tom Denton, just not for cars…

PARTONE

Champion of the independent aftermarket Neil Pattemore joins

2023 has been a big year for the independent aftermarket, with updates to the Motor Vehicle Block Exemption regulations as well as the (planned) introduction of cybersecurity assurances. Luckily, industry expert Neil Pattemore is on hand once again to guide workshop owners through the complicated landscape of regulations and competition law.

2023 sees PMM once again rounding up the most important suppliers in the aftermarket to provide workshop owners and technicians with an engaging, informative day out of the workshop. The UK’s longestrunning trade show dedicated solely to the independent aftermarket will once again be held at Sandown Park on Tuesday 7th and Wednesday 8th November.

Mechanex is well known within the independent aftermarket for offering visitors a hands-on experience, bringing them the latest updates and expertise from across the industry and providing an exciting day away from the workshop. Registration to visit the show is free and so is

parking, so why not come and take a look at what the biggest names in the aftermarket have to show you. In such a competitive industry, Mechanex is an opportunity you can’t afford to miss. If you like PMM, you’ll love Mechanex – it’s simply the magazine in a live format.

Hi Neil, it's been a busy year in your world, can you give us a quick run-down of some of the developments that will directly impact independent garages?

Following a welcome revision of the motor vehicle block exemption in the UK, the competition and markets authority have recognised some of the important changes in the way that vehicles are diagnosed, serviced and repaired. However, there are still important aspects that require changes in other related UK legislation to ensure that independent operators can continue to have the ability to offer competitive services and consumer choice.

Without these changes in legislation, it is likely that it will become more difficult and expensive for independent operators, who will become increasingly under the control of vehicle manufacturers, to the detriment of both the UK aftermarket and consumers.

32 OCTOBER 2023 PMM

● SANDOWN PARK ● 7-8TH NOVEMBER ● FREE ENTRY

TO FIND OUT MORE ABOUT THIS YEAR’S MECHANEX AND PMM LIVE GO TO WWW.MECHANEX.INFO

Q&A with Neil Pattemore

REGISTER HERE:

MECHANEX-PMM LIVE seminar line-up!

Neil Pattemore

Why is access to data and competition law important to uphold?

The very basis of competition is enshrined in both EU and UK legislation, but as vehicle technologies have evolved, the devil is in the detail and it has also become more difficult for legislators to keep abreast of these technological changes. The ‘access to data’ is fundamental to being able to diagnose and repair a vehicle, but the ‘good old days’ of simply plugging into the OBD socket are fast disappearing. The use of electronic certificates to access data via the OBD socket imposes new restrictions on what data, by whom, for what service and at what cost. Allied to the increase in embedded diagnostics in the vehicle, cloudbased applications and remote access to the vehicle all put further distortions into equal abilities and effective competition.

Competition law is critically important and the recent revisions to the block exemption regulations are welcome, but equally, there needs to be corresponding revisions of the

vehicle type approval legislation that also contains many critical elements about ‘access to data’.

When it comes to cyber-security, don't the VMs have a point? Cars are more complex than ever and repairs by the wrong person could prove fatal.

Of course, the security of the vehicle is very important, but this should not mean that competition should not, or cannot, exist. The legislator needs to be involved to set the ‘rights and roles’ of what needs to be possible for true competition to exist, based on the principle that if a (cyber)security process is implemented by the vehicle manufacturer that this process should work for anyone who needs to access a vehicle and its data. The process should not be ‘security by obscurity’, but should be a robust process with access and content set by legislation. However, by definition, who is working on the vehicle and for what purpose will need to be transparent.

You're a regular at our Mechanex show and now our PMM Live seminar stand - why should visitors come and hear what you have to say? What's your background?

The Aftermarket cannot simply continue to think that ‘it worked yesterday, so I can do the same tomorrow’ when the vehicle, it’s systems, interfaces and methods of diagnosis and repair are changing so much. There are many aspects to both understand and consider for each individual business owner and attending these seminars at this time has never been so important.

Do you think it's important to communicate with people in a live environment?

Absolutely! Listening, asking the questions that are most pertinent to your own business, as well as talking to other business owners and to key suppliers all in one place cannot easily be done without being there.

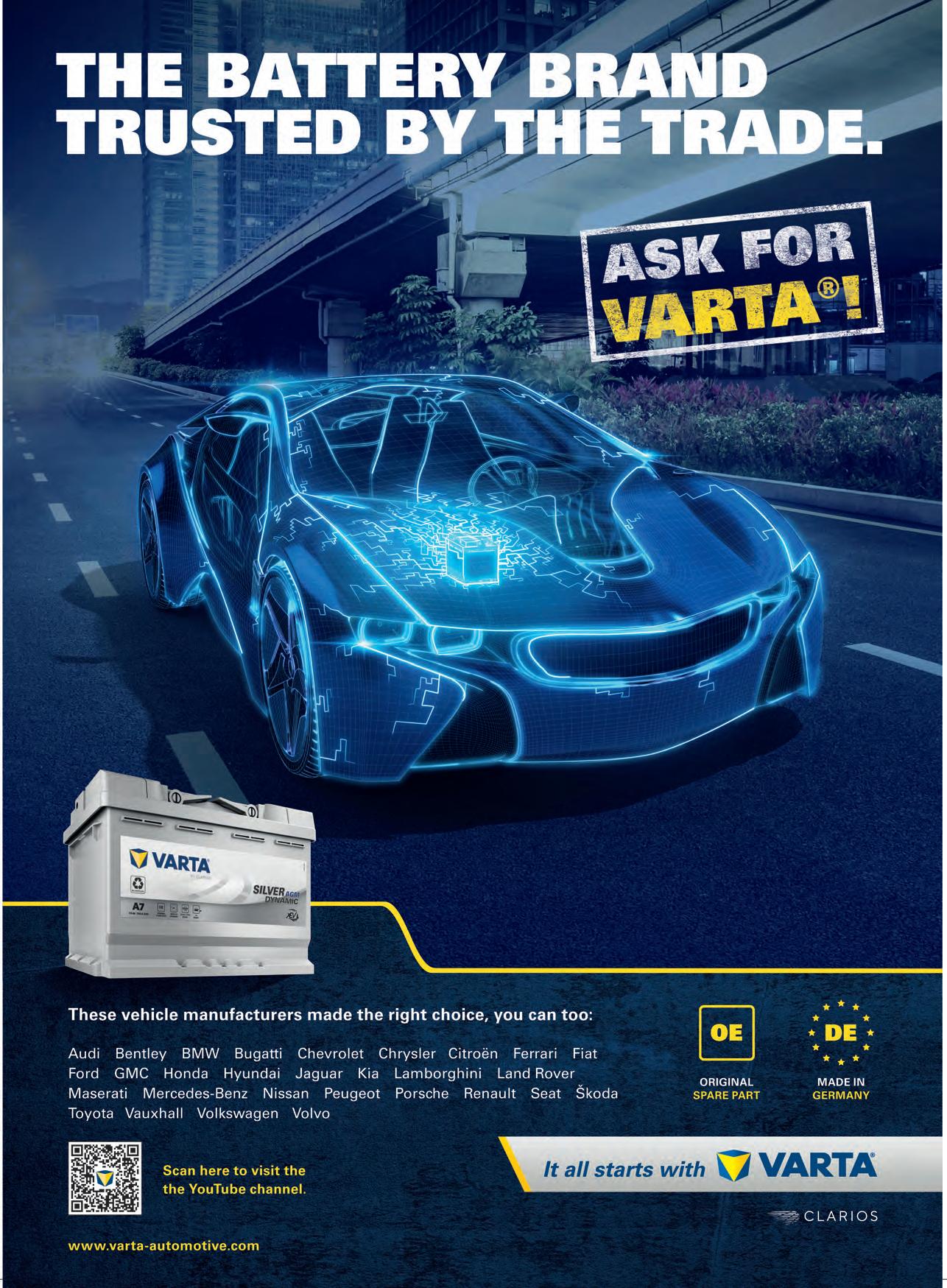

Adding DIAGNOSTICS options to your workshop business

PMM speaks to the Autel team to find out what workshops can do to take the next step, or even the first step, in their diagnostics journey.

For any workshops reading who have yet to invest seriously in diagnostics, where do you recommend they start? Should all garages be looking to acquire some specialist diagnostic equipment?

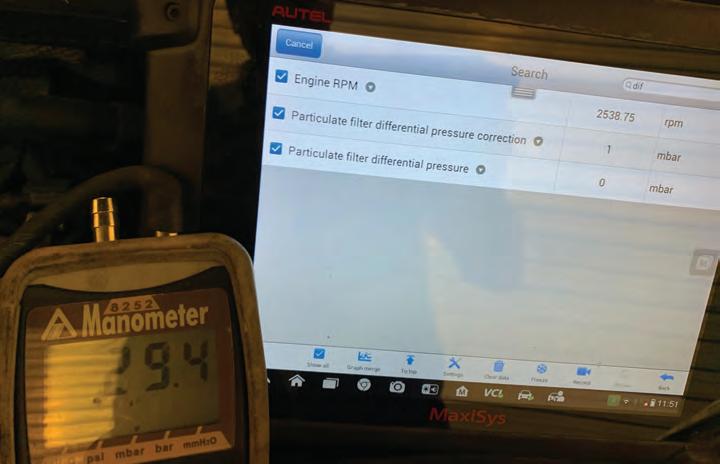

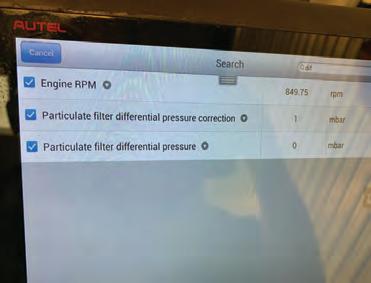

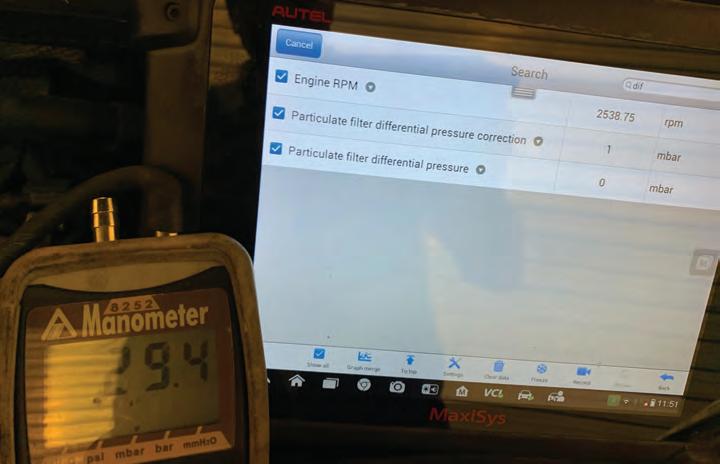

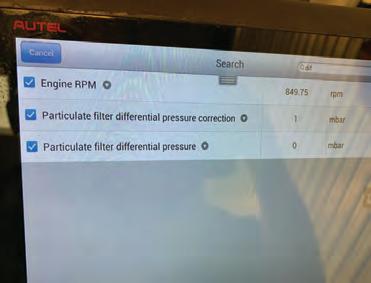

Diagnostics is required to complete the simplest of tasks like brake pads and general service work. The bigger issue is how complex vehicles are becoming and with the shortage of vehicle parts it has never been so important to diagnose correctly the first time around. We are seeing greater demand for higher end tools that offer ECU reprogramming and oscilloscopes for component testing than ever before.

How is diagnostics evolving? What effect is the security gateway and the recent SERMI scheme going to have on the independent aftermarket?

It’s no secret that diagnostics access is becoming harder for the aftermarket. Security gateways are the biggest disruption to aftermarket diagnostics in recent years which is why Autel UK is committed to delivering the best in class tools with full access, this is shown by the recent additional of Nissan to the current gateways supported along with Fiat, Chrysler, Alfa, Jeep, Renault and soon to be VAG and Mercedes also.

ADAS is now a legally required component on passenger vehicles. Does this mean ordinary workshops now need to own ADAS calibration equipment? Is calibration even necessary?

It shouldn’t be a doubt that calibrations are necessary, these systems are safety critical and any work that could affect the function of these systems needs to be corrected. Autel is committed to supporting workshops and as such have added ADAS awareness features to our scan tools highlighting any ADAS system on the initial fault scan helping workshops follow the correct route to repair. All our sales and support staff are fully IMIaccredited in ADAS repair and calibration.

How can effective diagnostics increase a workshop’s revenue?

The biggest way diagnostics can help is efficiency, having a quick, easy-to-use tool

packed with function is everything we aim for. Spending longer trying to reset a service light then carrying out the actual service is a position many workshops find themselves in without the correct diagnostics tool.

BUSINESS & TRAINING WANT TO KNOW MORE? FOR MORE INFORMATION WWW.RDR.LINK/ABB008 PMM OCTOBER 2023 35

LEVELLING UP

OESAA ACADEMY LIVE

The original equipment suppliers aftermarket asssociation has announced that Hugh Baird college in Liverpool will host this month’s OESAA academy live event.

Banner Batteries, DENSO, Laser Tools, MAHLE Aftermarket, Schaeffler, VARTA, Brembo, HELLA, Bosch, Dayco, Fil Filter, ZF Aftermarket, with the support of Garage Online Services, have all confirmed their attendance at least one of the events taking place in Exeter, which has already taken place and Liverpool (4th and 5th October).

OESAA academy live, headlined by GSF, is a platform for independent professionals to bring colleagues and join industry counterparts for an invaluable and enjoyable evening of training, networking, and hospitality.

On the Wednesday evening, OESAA members will be stationed in the ‘workshop arena’. Delegates will have

JOB OPPORTUNITIES

access to experts, where they will be able to witness on-stand presentations, live demonstrations and be presented with opportunities to chat one-to-one.

There will also be training classrooms designated to various OESAA members, which will give attendees a front-row seat to the latest news in technology, diagnosistics, and replacement.

Furthermore, visitors will have the chance to go home with some fantastic prizes – including some of the latest video consoles – while there will be ample food and refreshments on offer throughout the evening.

There is no need to sign-up to OESAA academy live! Visitors are welcome to both Wednesday evenings from 5pm with the event set to conclude at approximately 9pm.

WWW.RDR.LINK/ABB009

NISSENS

On a mission to support the independent sector to be profitable at all levels, Nissens Automotive offers education in various forms, from live onsite sessions, through online selflearning courses, to technical marketing materials in both print and digital formats. This knowledge is served in 15 languages and delivered by 25 dedicated technical trainers and is available worldwide.

The company has further expanded its training concept, an educational solution for automotive professionals in the field of air conditioning, engine cooling, efficiency, and emissions, to leverage their technical skills, with a series of free live webinars conducted by their product specialists. In addition to receiving a huge amount of knowledge, participants may engage in Q&A sessions and share their experience.

To join the free webinars on the Nissens Facebook page or watch the recordings of past events,

WWW.RDR.LINK/ABB010

PMM brings you some job listings you may be interested in if you are looking to change company. These listings have been supplied by MechanicFinder.com.

Topdon UK Diagnostic Technician

Drive Green Vehicle Technician

BOSCH

Reading

Haverhill, Suffolk

Yardley’s Garage Vehicle Technician/MOT Tester Sutton, Ashfield.

Mototechnics Vehicle technician

Coalville

Autochoice Mechanic Bristol

Abbey Motor Group Mechanic/MOT Tester

Automate Technician

THEMOTGUY Class 4 & 7 tester

Redhill Surrey

Watton, Norfolk

North East and North Yorkshire

To get in touch regarding a job listing, email pmm@hamerville.co.uk

For those of you who are keen to learn more about the very latest in modern vehicle technology, Bosch has launched a brand new training course; ‘battery management, smart charge and 48 volt systems’, course code VSE55. Content of this will cover smart energy management, stop/start components and operation and micro hybrid topology for 12V, 24V and 48V, as well as many other features of modern vehicle energy management.

WWW.RDR.LINK/ABB011

PMM OCTOBER 2023 37

BUSINESS & TRAINING

PMM brings together some of the training and recruitment opportunities available to you.

Q&A

PMM talks to Dawn Metcalfe,Garage Hive

PMM sits down with Garage Hive’s Operations Manager and the woman behind its trade event,The Blend, to find out more about what the event holds for workshop owners this month.

Hi Dawn, could you tell our readers about The Blend and what it offers workshops?

The Blend started in 2019 as just an idea to gather Garage Hive users to network and speak to the team in person. Now, it has grown into a conference and networking event for all UK and Irish garage ownersand key staff members which is also complemented by a podcast.

The Blend 2023 offers a wide range and choice of industry expert presentations about garage business essential information varying from “how to unlock hidden profit” to fellow garage owners’ experiences and HR topics. It also has a specially selected expo area where the guests can talk to brands like Castrol and , GSF Car Parts, Pichler Tools, Micheldever, Pagid, Autogem and more. Of course, there is a choice of Garage Hive expert sessions for those interested in the software.

Between the presentations, there are plenty of breaks to network with other garage owners and gain new perspectives on issues they face. This year, we are also hosting an awards dinner for which garageshad the opportunity to submit their business or their staff for an award.

What sets the Blend apart from other trade events in the calendar?

We noticed that plenty of automotive events focus on the technical side of garages, technician training, tools and similar; however, the industry lacks the business side conferences and networking where garage owners can learn more and get inspired to manage their business effectively to reach their business goals. That's why delegates have the opportunity to dive into topics like business growing pains, front-of-house, planning an exit and more. Our priority is to provide high-quality information to the attendees; also, it is a non-profit event, and we will donate any profit that is made.

What can attendees expect this year with respect to last year?

This year we have more presentation choices for attendees to pick and mix which sessions they want to attend, a larger expo area and the exciting additional awards categories for “garage of the year” and “staff recognition”, as we believe in and want to celebrate driven businesses and teams.

Why is it important for garage owners and key members of staff to take time out to attend events?

For garage owners who are interested in working for their business, not in the business, this is the place and time to be. If they are interested in following the latest industry trends and staying ahead of the curve, the speaker sessions will educate them on what is happening, what they can do now and what to prepare for in the future. The event gathers a lot of goal-oriented garage owners, some of whom are working towards growing their business, and others to retire or leave the business in good hands.

What are you most looking forward to at the event?

I am most looking forward to the conversations that will arise between the guests and the ideas that will be born out of this networking both for garage owners and for us, Garage Hive, to grow and adapt the software to the needs of the garages. We cannot forget the opportunity to speak to known brands at the exhibition, where new partnerships can be built.

What information do readers need to know before attending?

The Blend 2023 takes place in Birmingham at the Eastside Rooms on Saturday, the 7th of October. It is a full-day conference starting at 9:30 am and finishing with an awards dinner. It is easy to enquire about tickets through the event’s official website.

BUSINESS & TRAINING 38 OCTOBER 2023 PMM

TO KNOW MORE? FOR MORE INFORMATION WWW.RDR.LINK/ABB012

WANT

SHOCK ABSORBERS B4 AND B6: BILSTEIN EXPLAINS THE POTENTIAL OF THE DAMPTRONIC® VARIANTS

SMART SPARE PARTS FOR INTELLIGENT SUSPENSIONS.

The things that surround us are becoming more and more intelligent – especially in automotive engineering. Keyword: active suspensions. “Depending on the situation or the driver’s wishes, they oscillate between dynamic and comfortable, sometimes with more or less intermediate levels or damping force spread. This provides the perfect driving experience and safety,” explains Dimitris Kouvaras, Global Training Manager of BILSTEIN Academy. The other side of the coin: If shock absorbers for active suspensions are defective or worn out, replacement is significantly more expensive than conventional “materials”. Owners of older cars in particular are therefore looking for affordable alternatives to original parts.

Fair value replacements from the aftermarket are significantly cheaper, but rarely support active control. This turns an active high-tech suspension into a passive one. Garages that want to offer their customers a better solution can, however, fall back on the BILSTEIN B4 and B6 aftermarket shock absorbers with the DampTronic® add-on.

These replicate all the features of the OE shock absorbers and are just as easy to install according to the plug-and-play principle. For vehicles with air suspension, BILSTEIN also offers its B4 air suspension modules. Unlike many remanufactured products (reconditioned old parts), they continue to support active suspension control.

BILSTEIN B4 DAMPTRONIC® AND B6 DAMPTRONIC® IN COMPARISON

The BILSTEIN B4 gas pressure shock absorber is 100% the same as the factory-fitted components in terms of quality and functionality – but at a lower price. This applies to the actively controllable DampTronic® variants just as much as to the basic product used for passive suspension systems. People who have to master particularly tough everyday conditions with their vehicle or simply want to increase its performance can opt for the BILSTEIN B6 DampTronic®. It represents improved OE replacement in combination with active suspension systems. Going beyond the original, it offers a noticeable plus in safety and performance – without lowering or changing springs and without additional TÜV registration. Its higher performance reserves are particularly effective in the following scenarios: on poor or winding roads, in dynamic driving, in dangerous situations, when towing a trailer, when transporting external loads – such as bicycle racks or roof racks –and generally with heavily loaded vehicles.