THE C P D B OOK I VOLUME O NE 2 024

THE C P D B OOK I VOLUME O NE 2 024

For all your decorative wiring solutions

All decorative switch plates are modular as standard.

o un ont quickl all l easil es.

al or r all F dec your etivdecora The MiniGrid equire. ou r y plate o cr ou t y ws This allo ear decorativ ll l dec A ear ® switch any y an virtuall eate tandard. tes ch pla wit furnished pla

t mounted changedex y

This allows you to create virtually any switch plate you require. The MiniGrid® modules are all easily and quickly exchanged or mounted onto unfurnished plates.

The team at NAPIT ‘codebreak’ more of the latest reader submissions

12 Metal consumer units in installations forming part of a TT earthing system: what are the key considerations?

15 Is the use of MCBs dwindling?

16 Addressing some of the common queries around EV charge point installations

19 A look at different installation methods and mechanical protection requirements

22 The importance of providing installations with surge protective devices

25 What do IP ratings mean and why is IP68 important?

What are the operating characteristics of a protective multiple earthing (PME) facility?

‘Dr Zzeus’ Tom Brookes answers more of your fire-related questions

30 The importance of safe isolation and why using the right equipment is an absolute must

32 A look at some of the essentials of client handover documentation

34 How to deal with problems with USB socket-outlets that have been faulty following insulation resistance testing

35 How does the ‘Electrician Plus’ concept work?

36 The team at NAPIT ‘codebreak’ more of the latest reader submissions

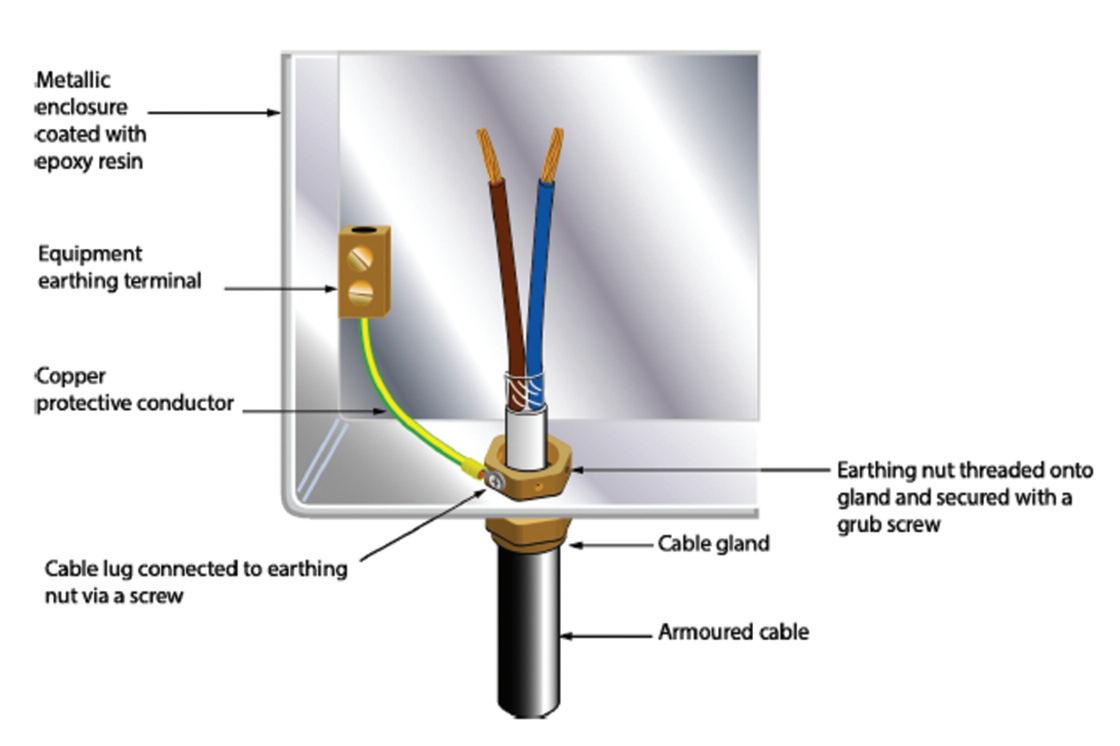

38 Guidance on the use of the metallic armouring of a cable as a circuit protective conductor (cpc), main protective bonding conductor or an earthing conductor

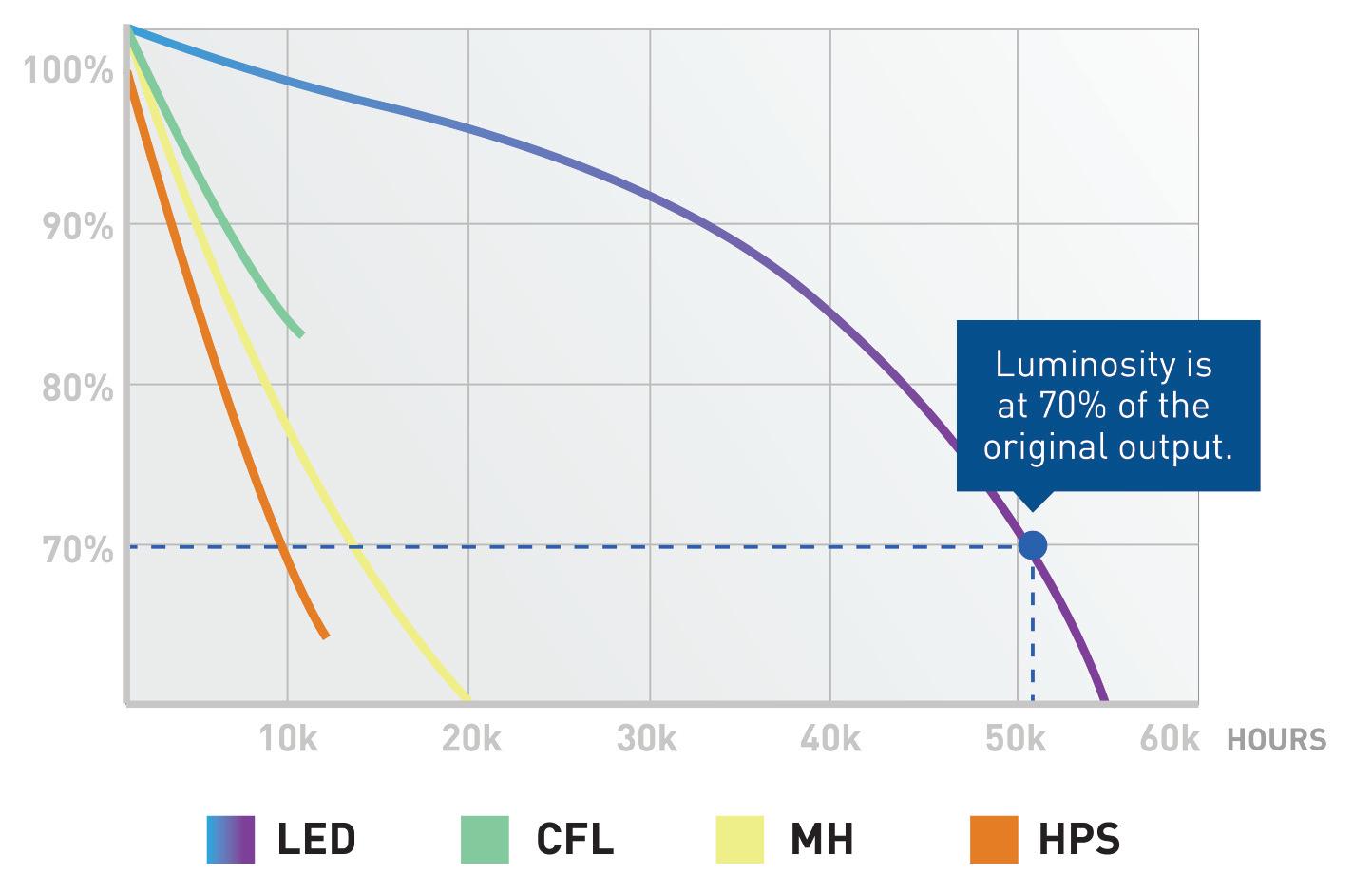

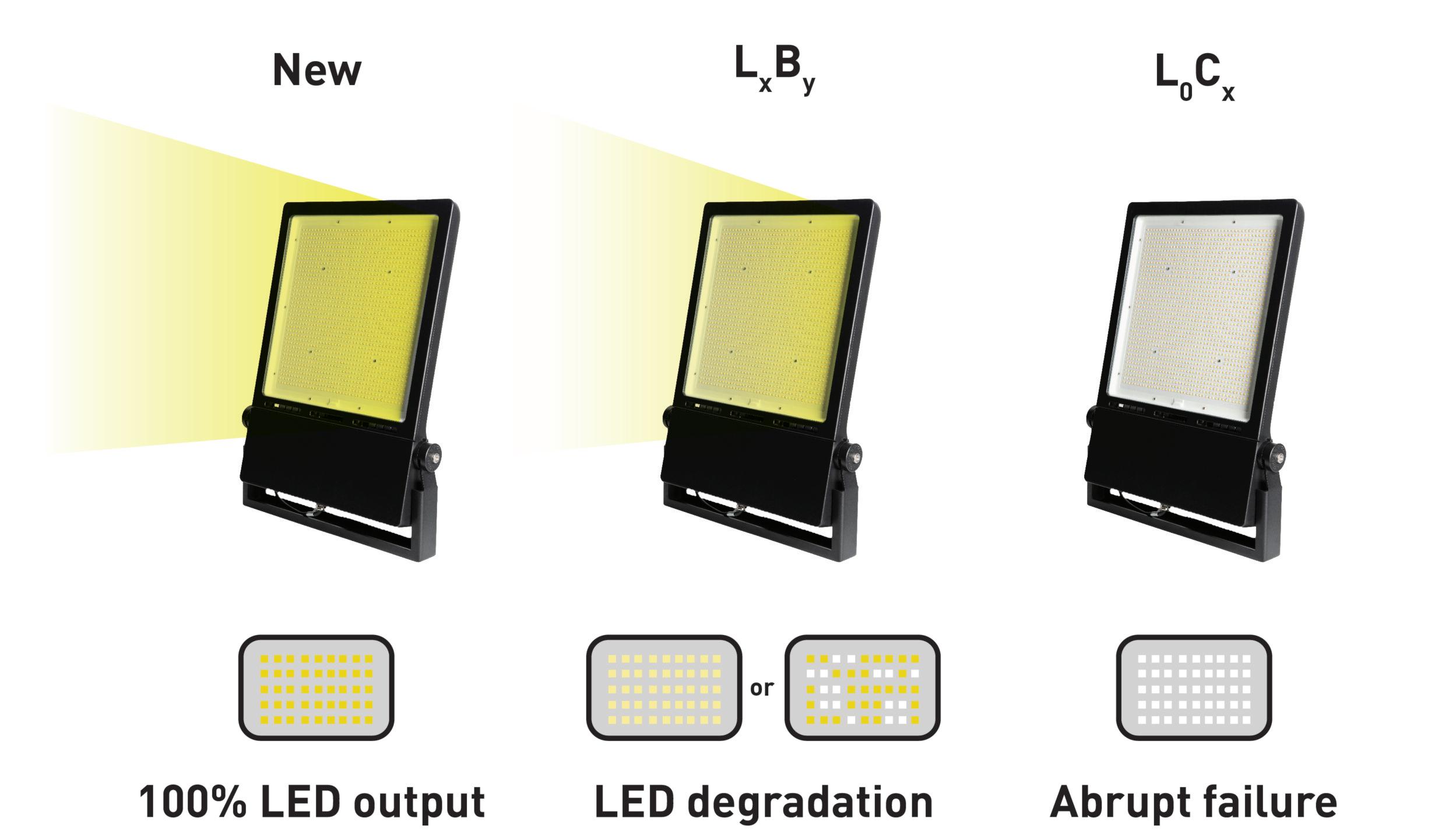

40 How to respond to the age-old conundrum of how long LEDs really last

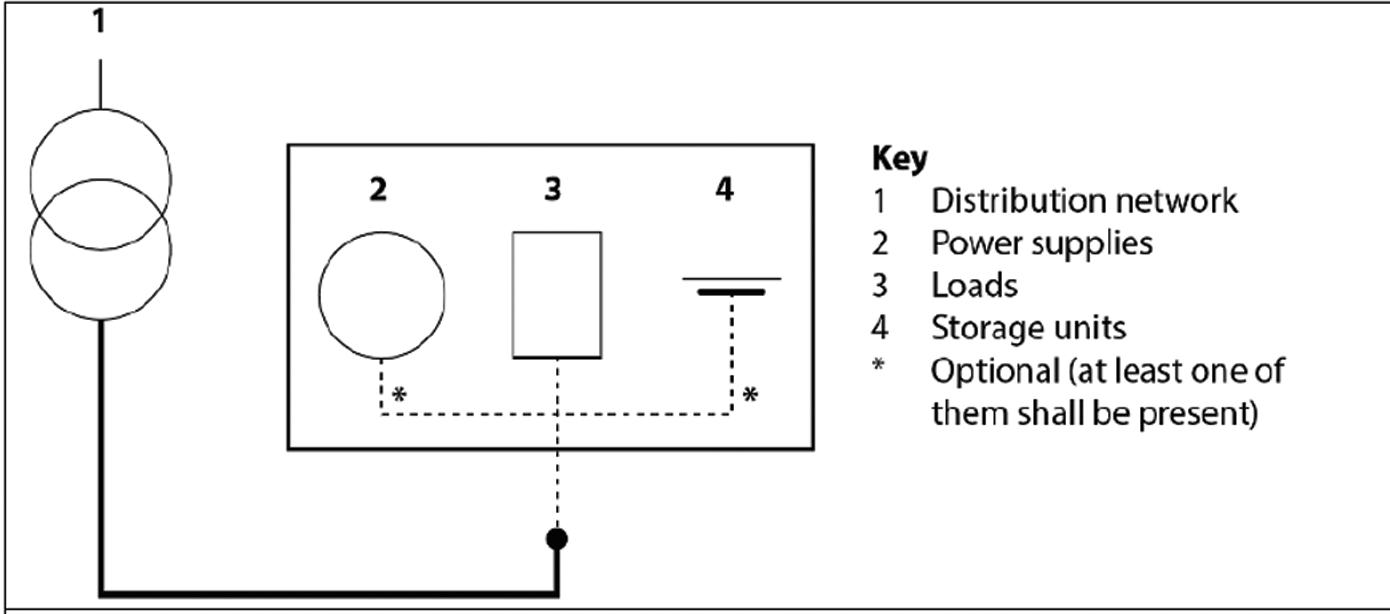

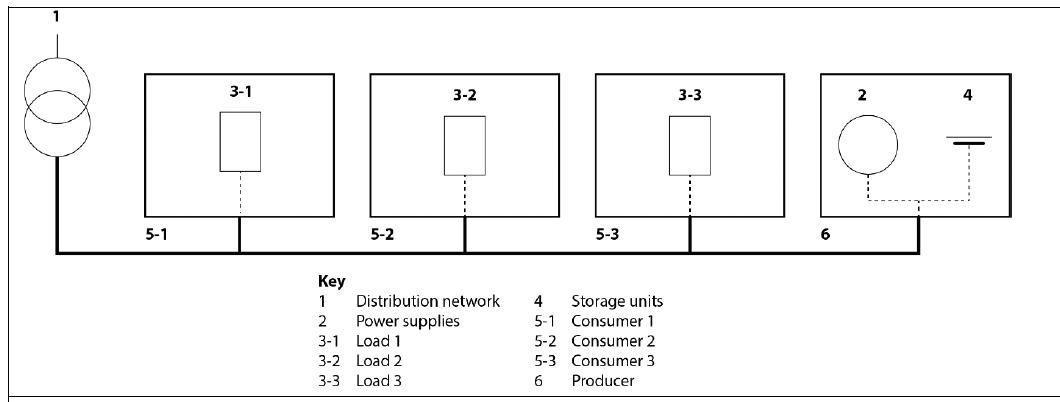

43 A look at Chapter 82 of BS 7671 and embedded renewable sources, either used in conjunction with the existing supply for an installation or as an alternative and independent source of electrical energy forming a prosumer’s low-voltage electrical installation (PEI)

46 The team at NAPIT ‘codebreak’ more of the latest reader submissions

48 Getting a better handle on the Construction Industry Scheme (CIS) and specific rules for how contractors must handle payments made to subcontractors for construction work

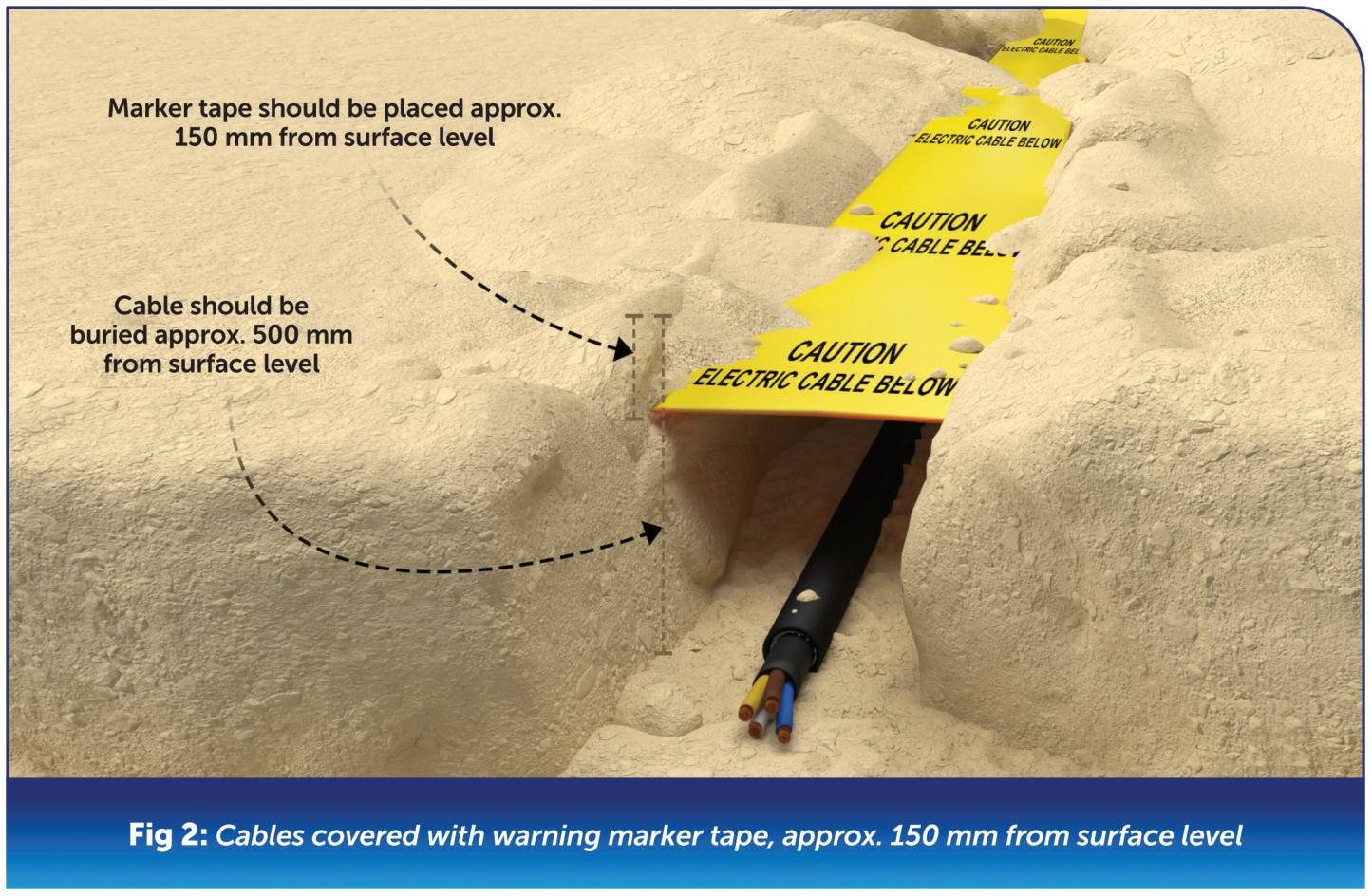

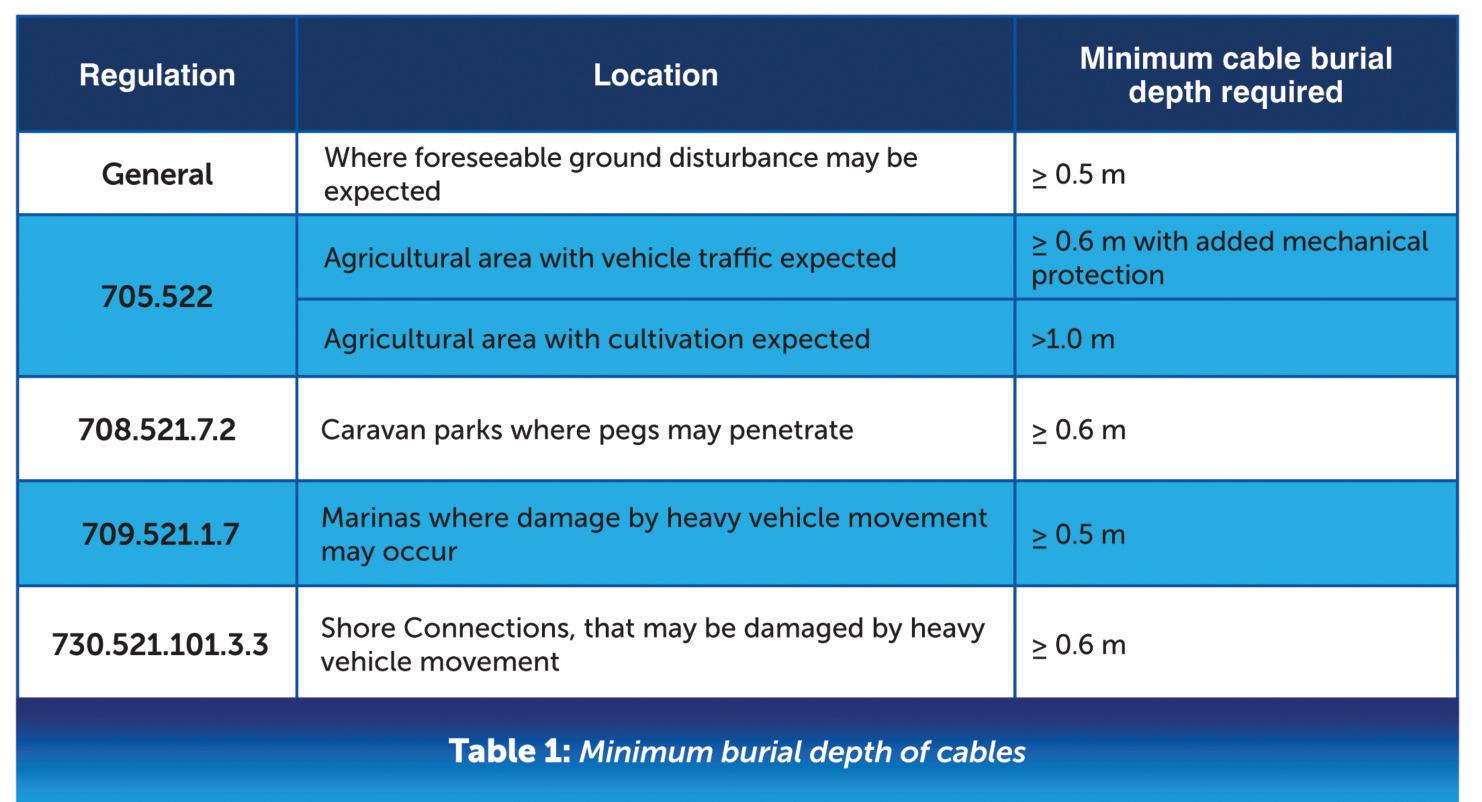

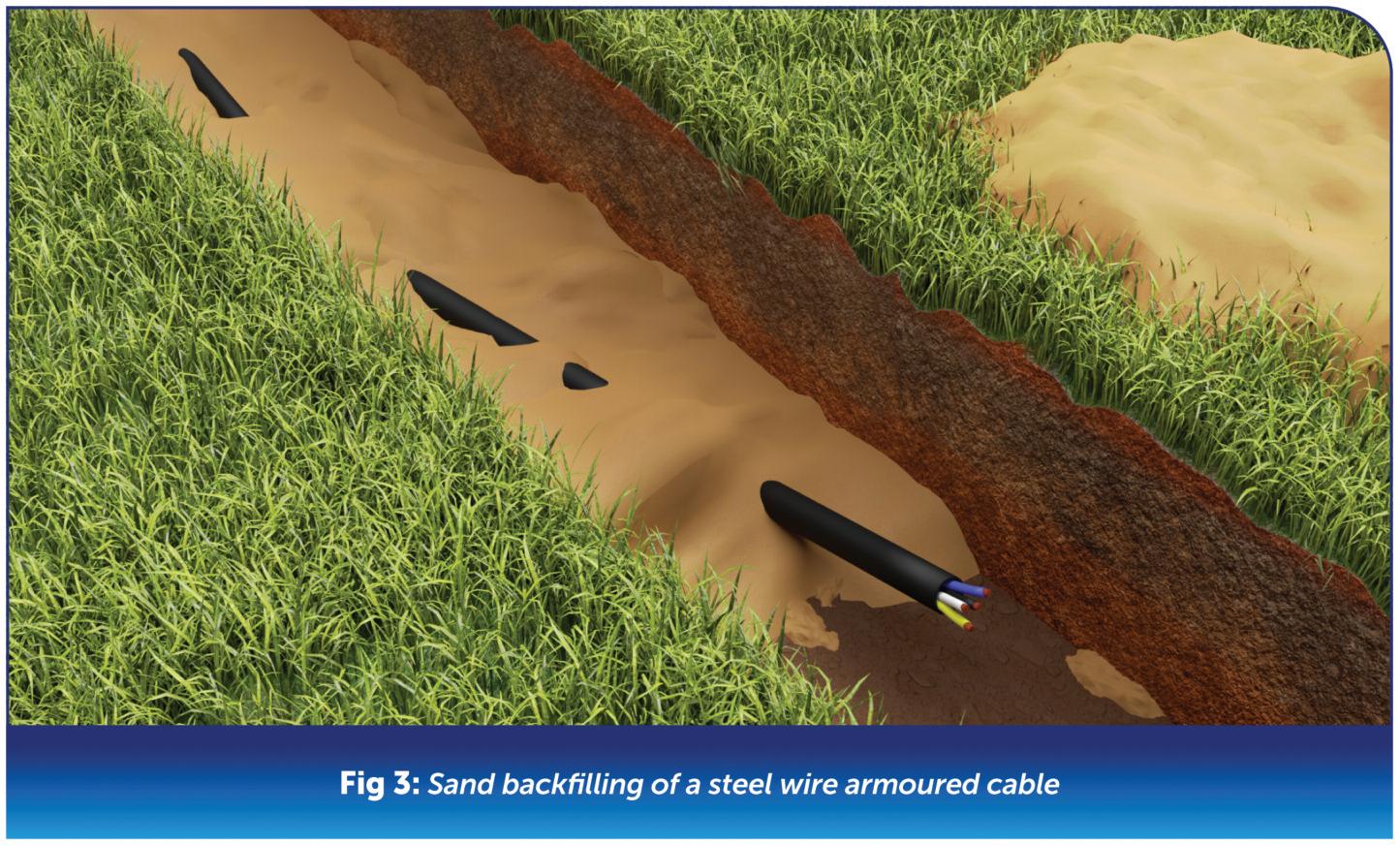

50 Examining the practice of burying cables

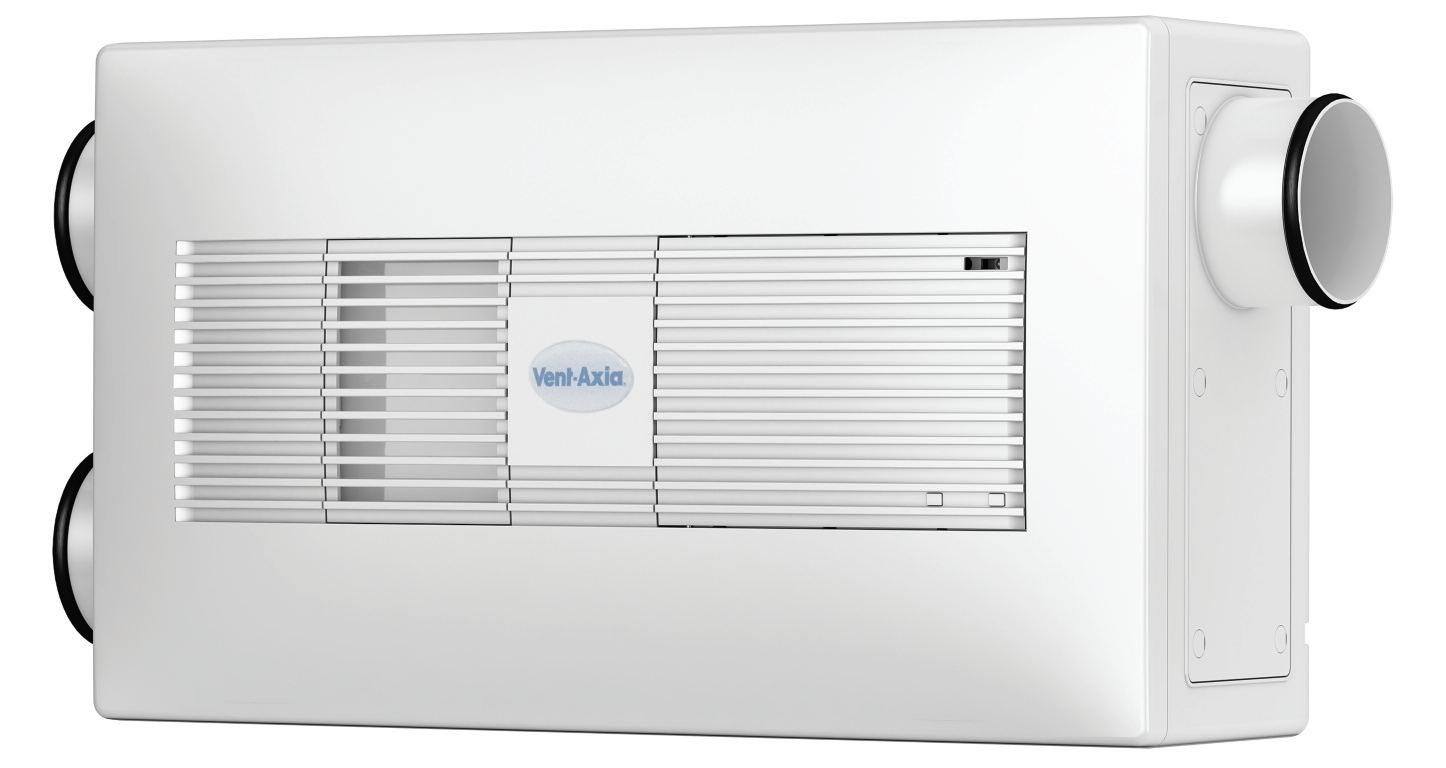

52 What are the requirements of the amended Approved Document Part F and how can electricians meet them?

70 Can flexible cables be used in fixed installations?

73 Taking a look at protective earthing systems and unravelling the difference between PME and PNB

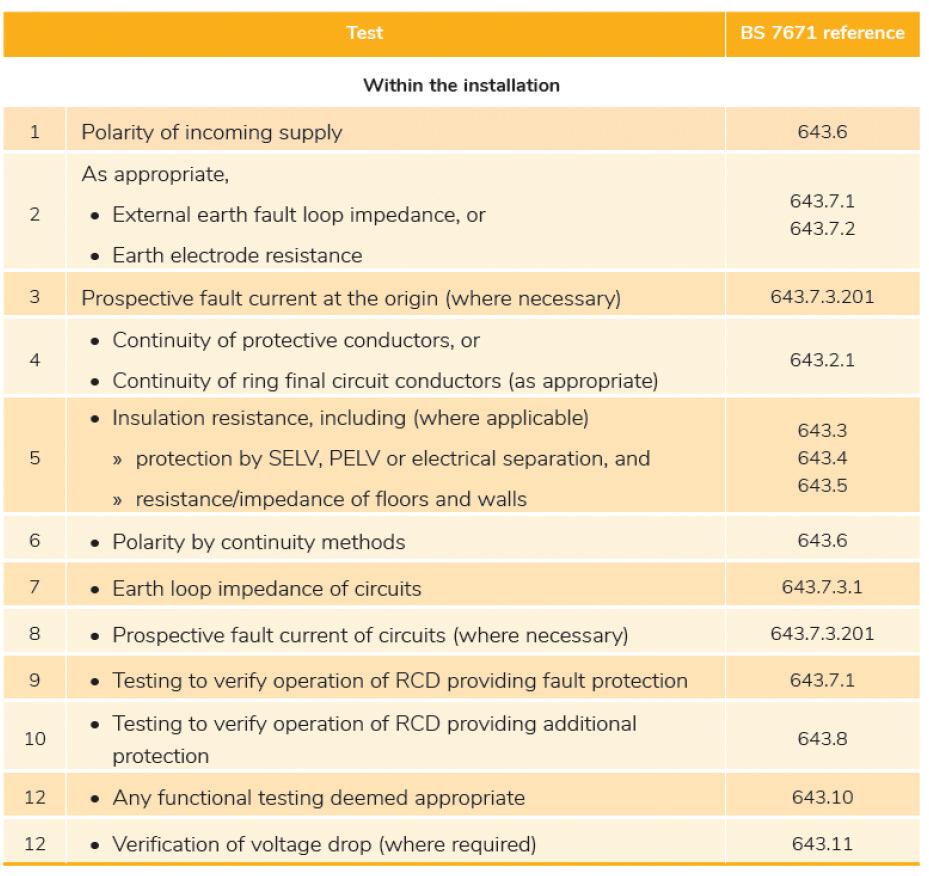

74 Which sequence of testing would be appropriate for use when carrying out a periodic inspection?

76 The team at NAPIT ‘codebreak’ more of the latest reader submissions

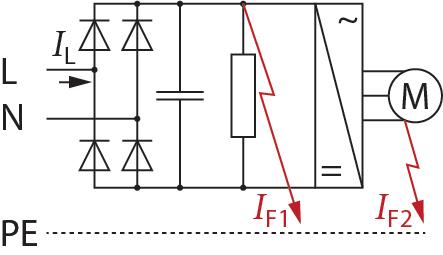

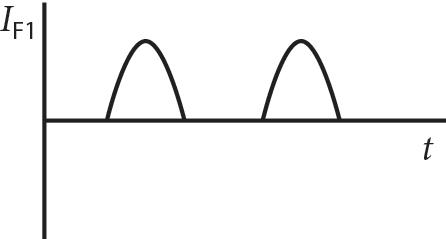

79 RCDs for heat pump installations: what are the 18th Edition recommendations?

82 The considerations when selecting a suitable wiring system for an electrical installation

84 How to establish voltage drop limits within an electrical installation

54 The team at NAPIT ‘codebreak’ more of the latest reader submissions

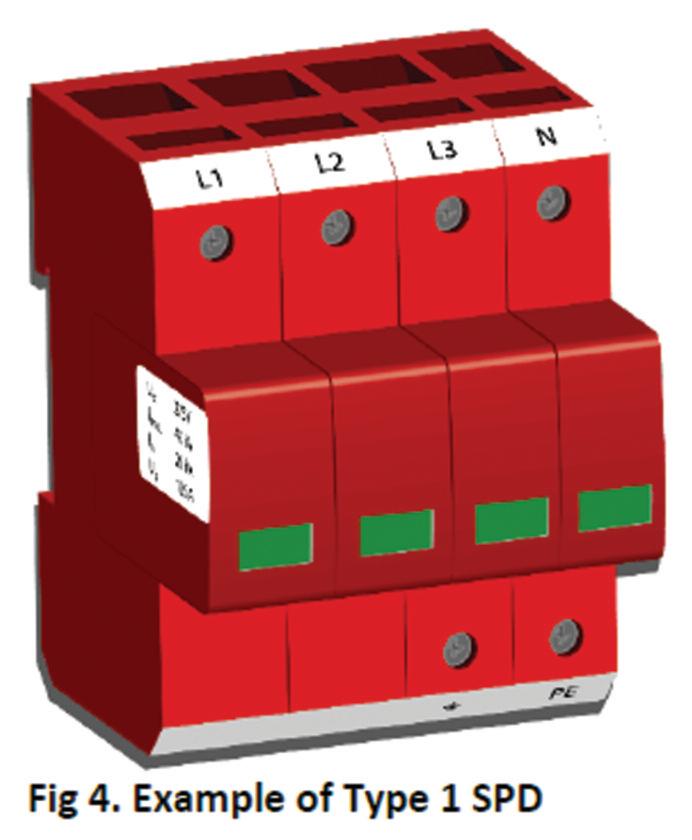

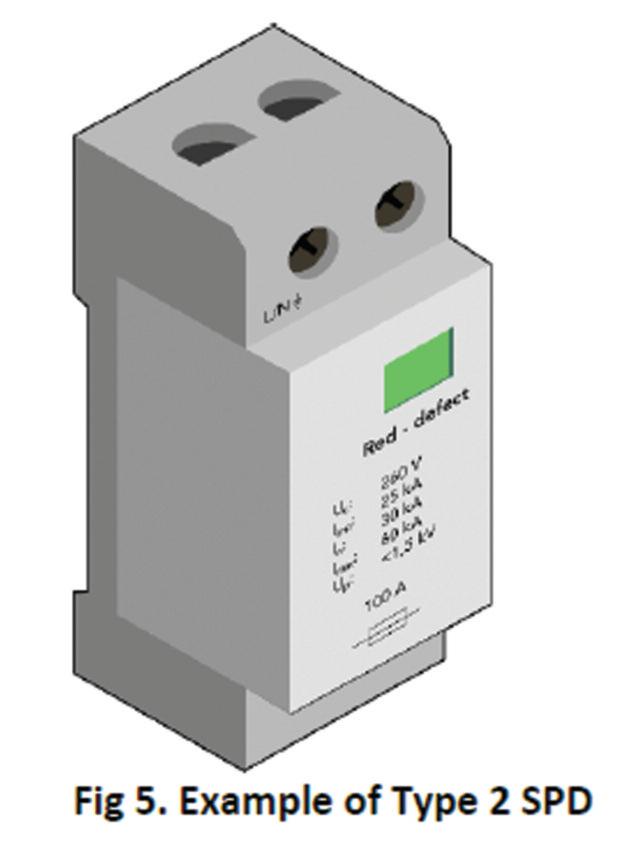

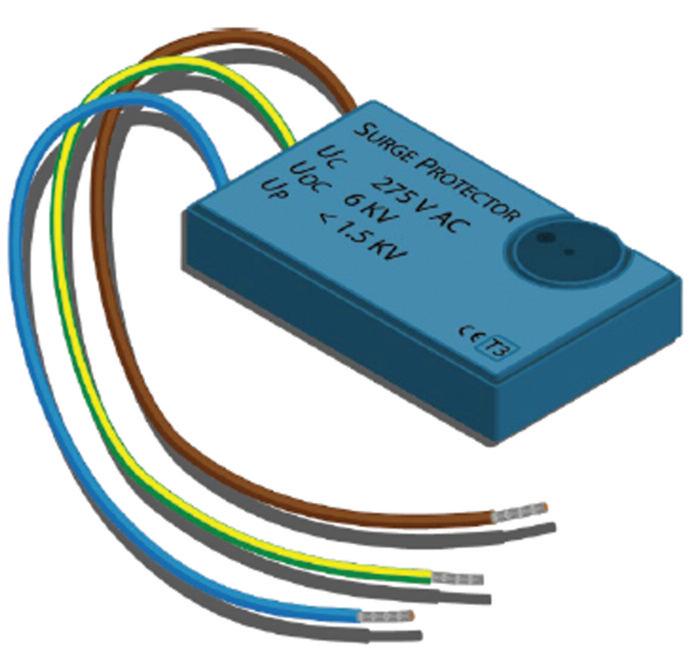

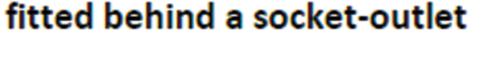

57 A look at the types of SPD recognised by BS 7671 and their location within an installation

61 Smoke alarm installations – what is the hidden requirement in BS 7671?

62 ‘Dr Zzeus’ Tom Brookes answers more of your fire-related questions

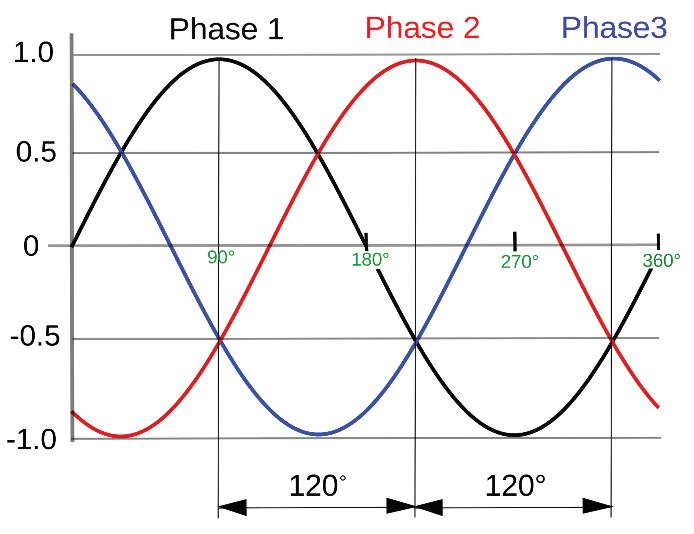

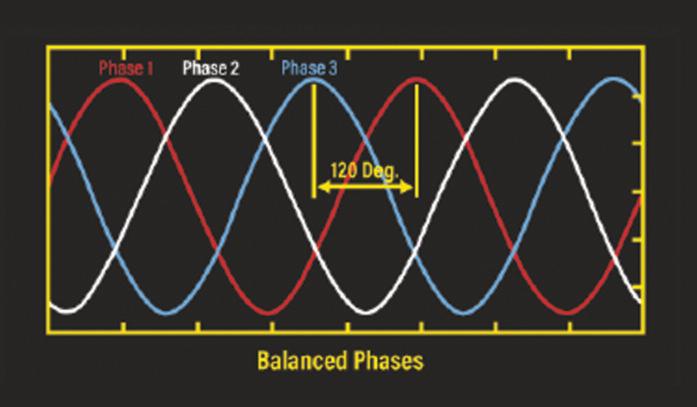

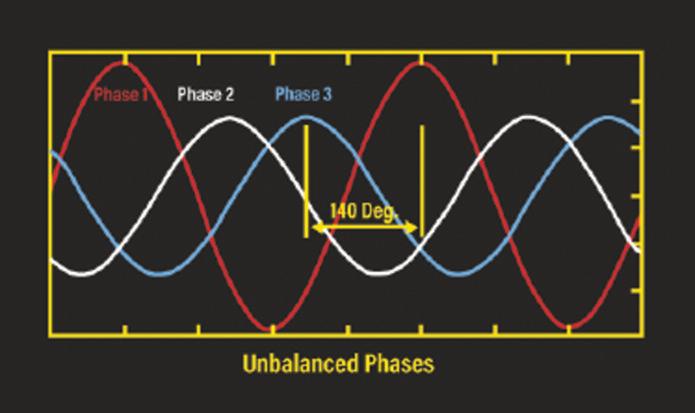

63 What are the key features that set single-phase and three-phase power supplies apart?

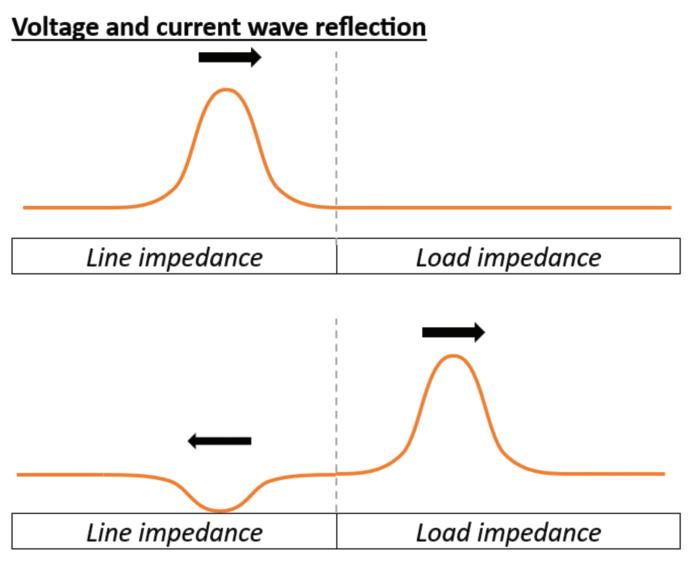

64 A guide to navigating electrical reflections in circuits

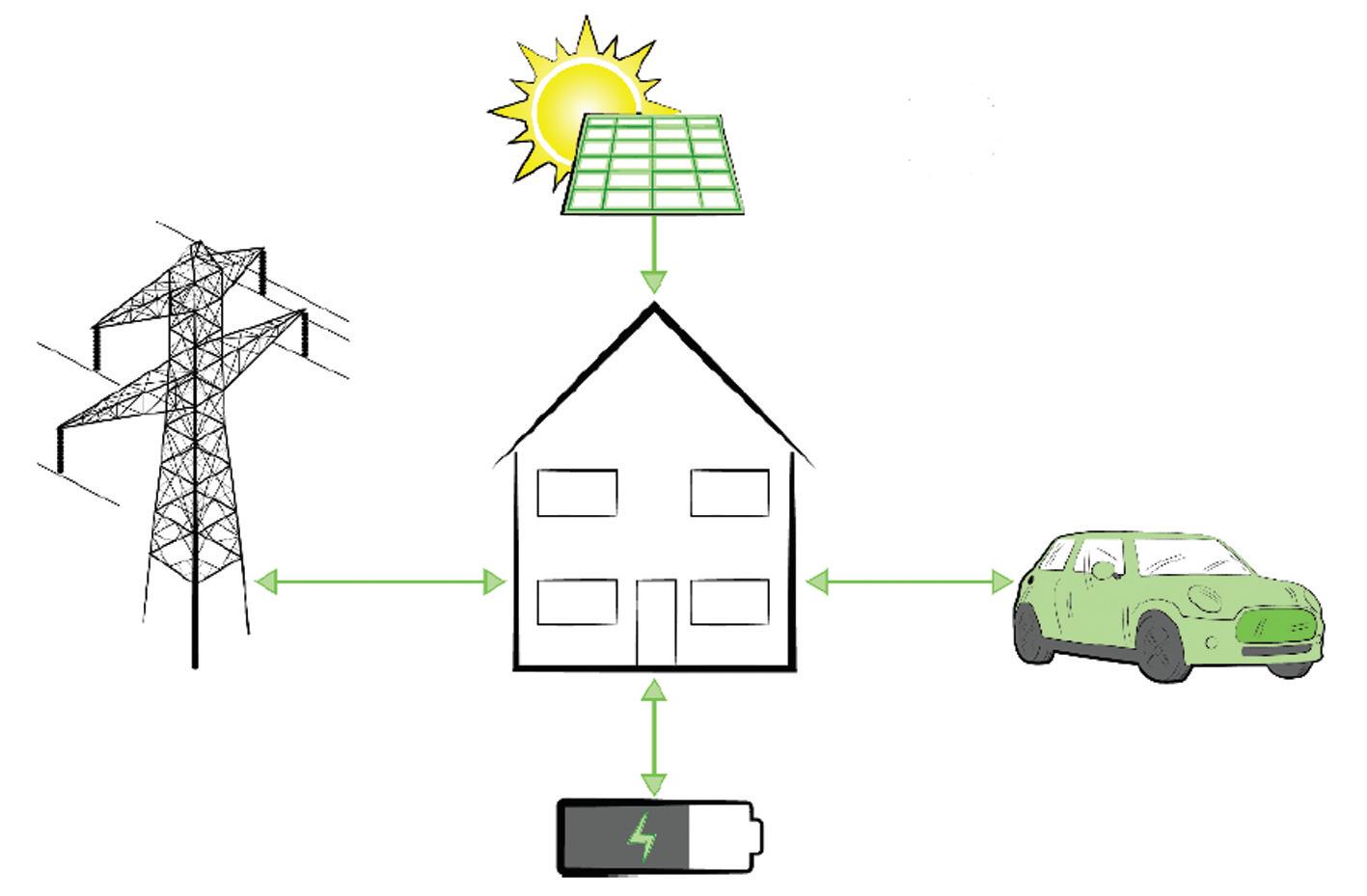

67 Throwing some light on the battle to use self-generated green energy

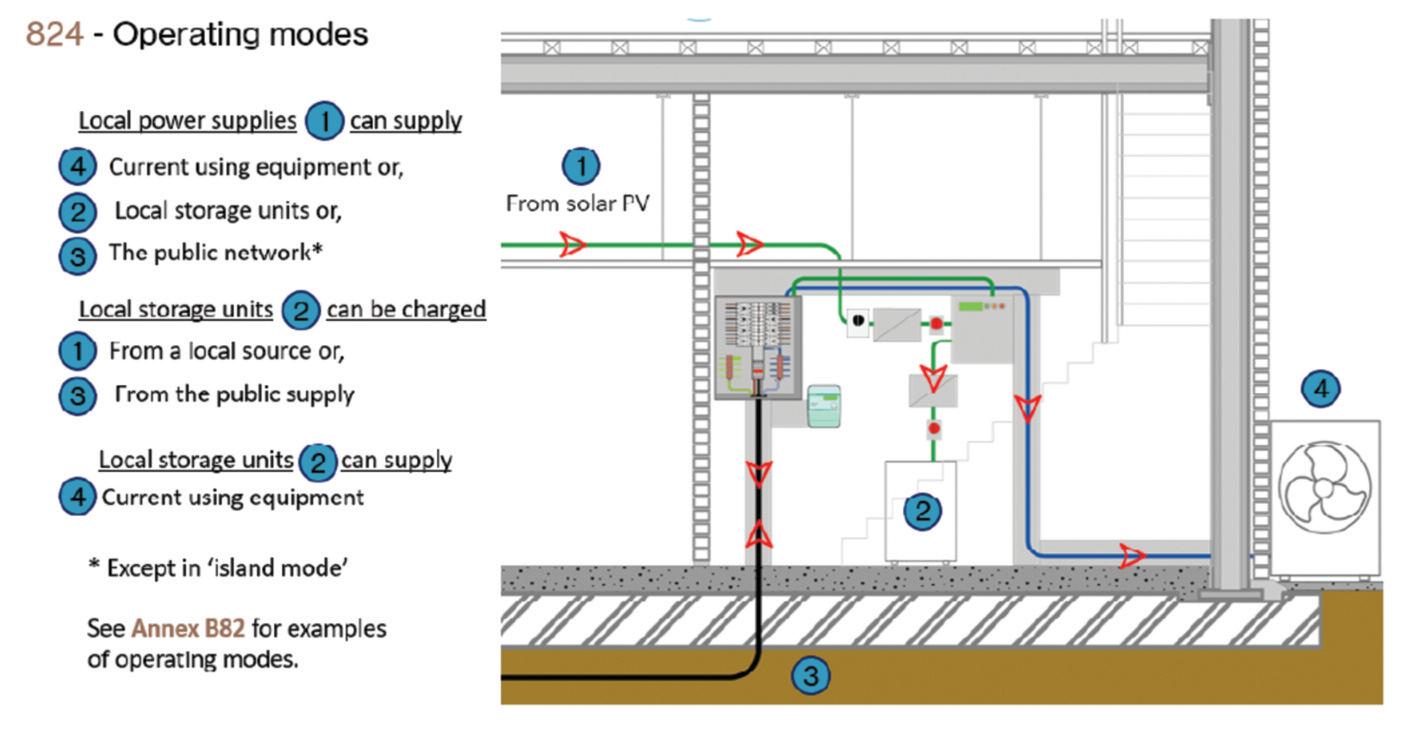

86 The issues that will influence the decision as to whether or not fused leads need to be employed when using electrical test instruments

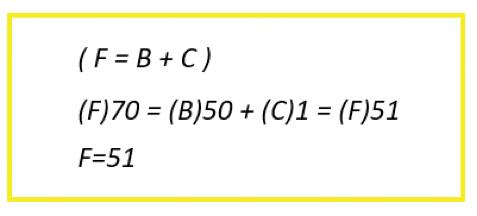

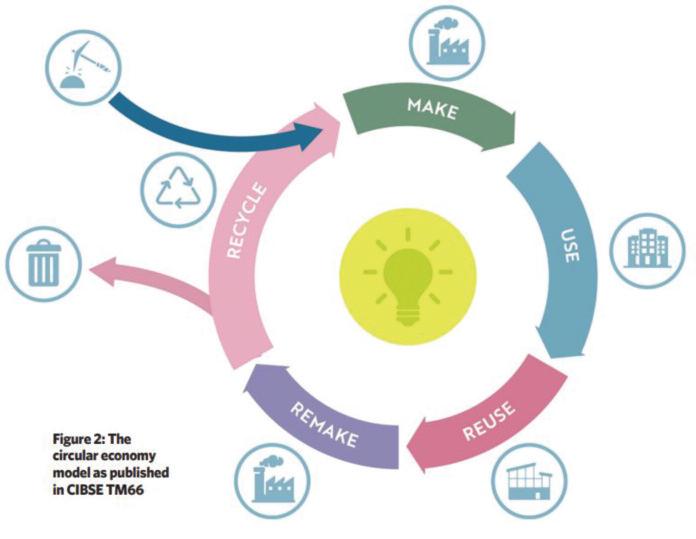

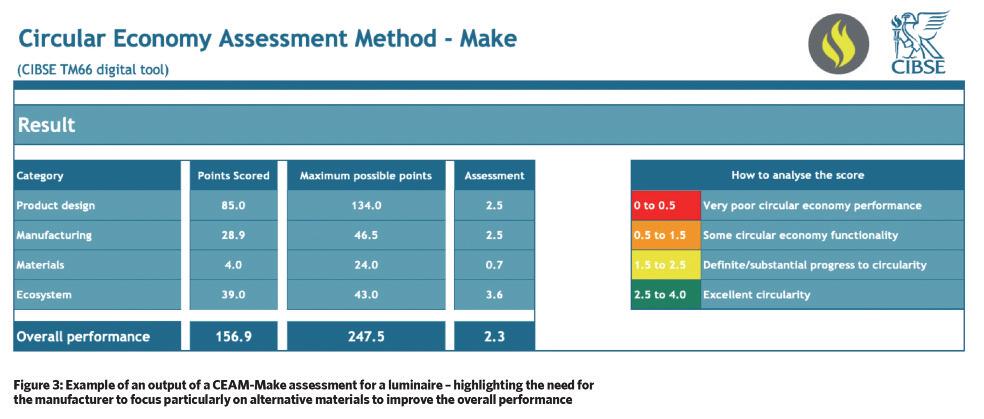

88 How do product circularity ratings work?

90 ‘Dr Zzeus’ Tom Brookes answers more of your fire-related questions

93 Exploring site preparation and resistance to both contaminants and moisture

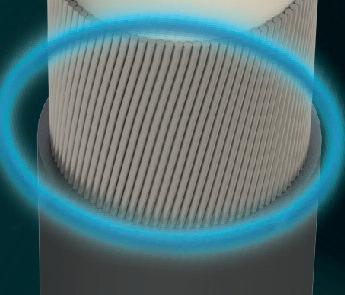

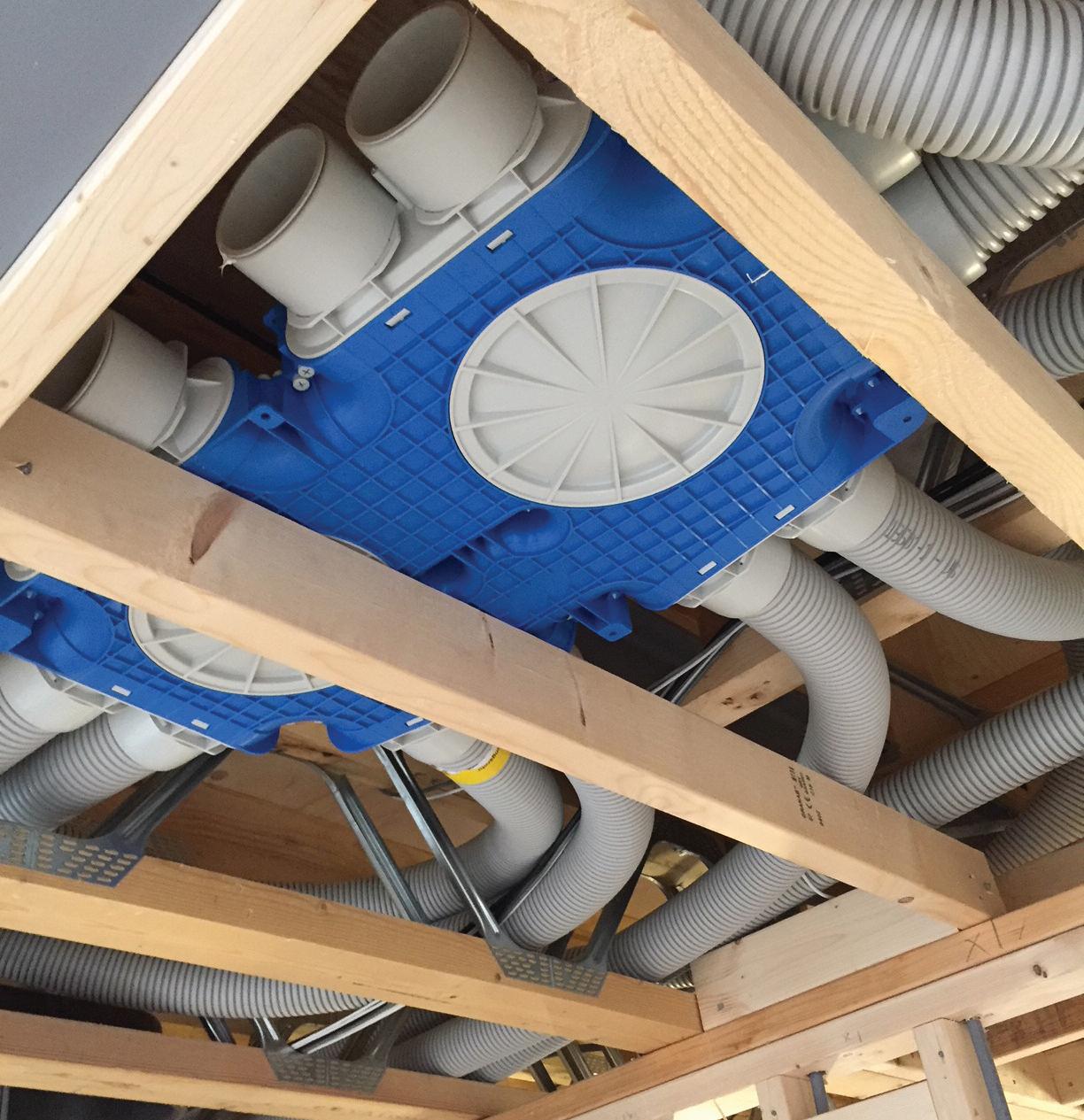

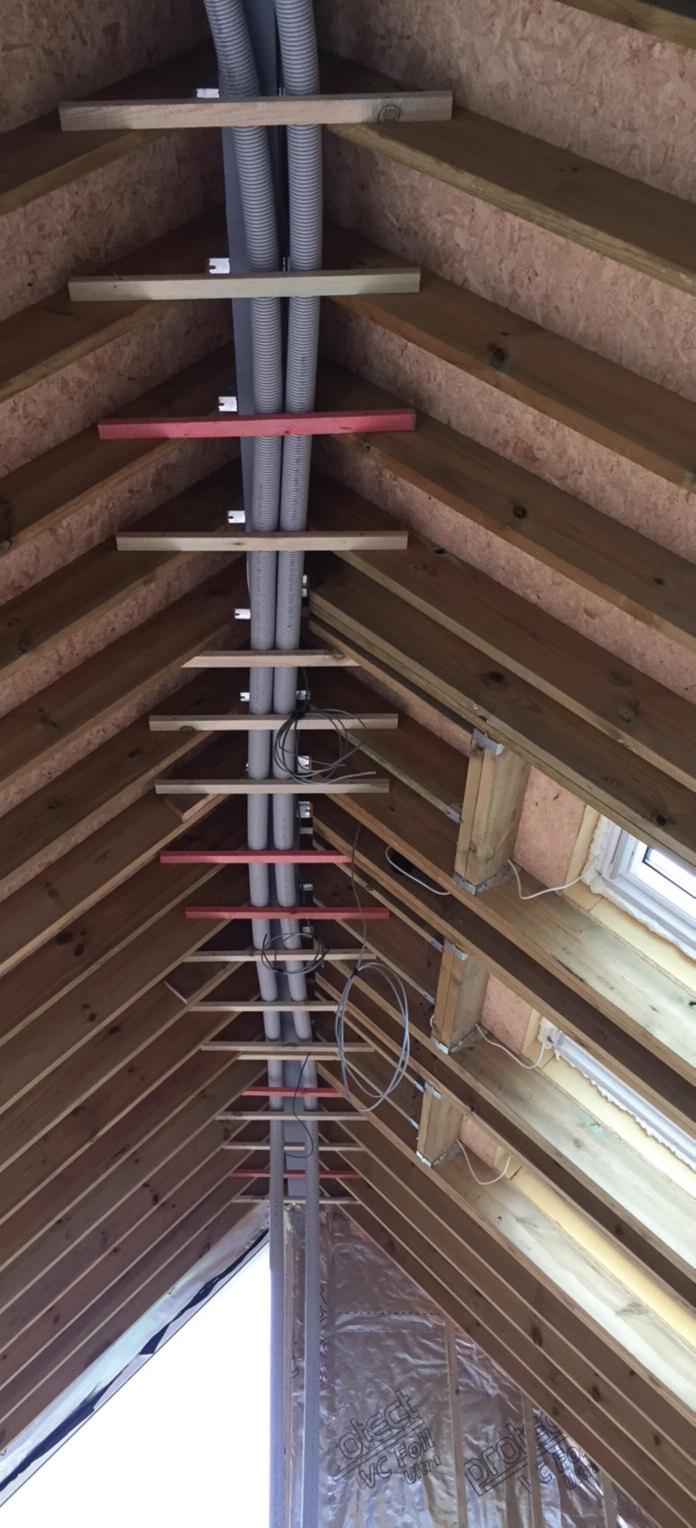

94 How ventilation system design can be made simple for electricians who are keen to install MVHR but aren’t sure how to design and specify

96 The team at NAPIT ‘codebreak’ more of the latest reader submissions

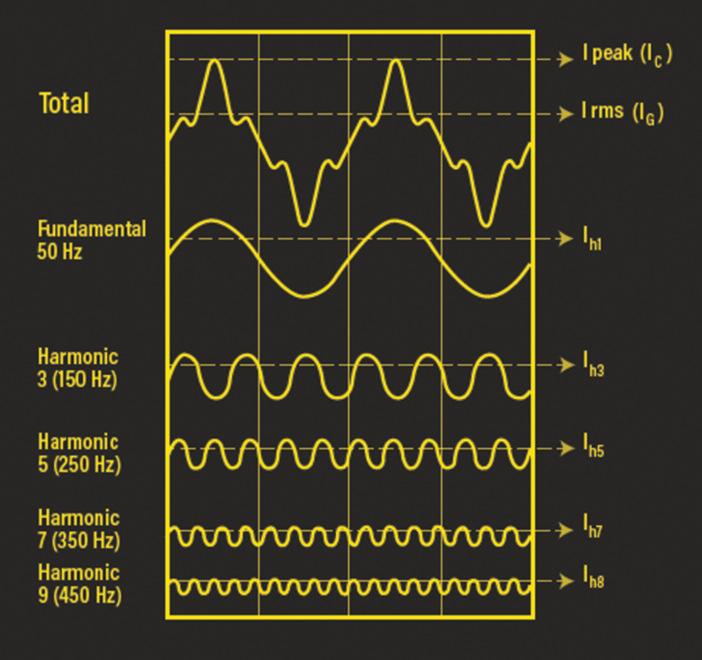

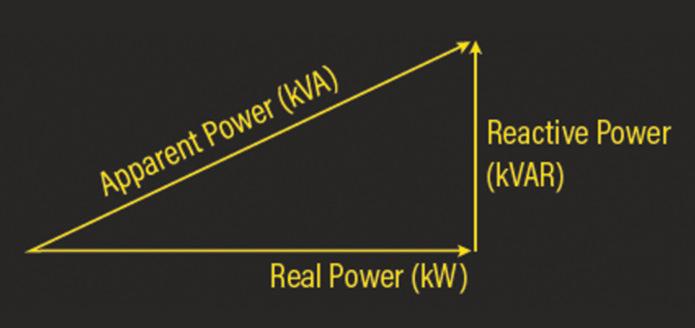

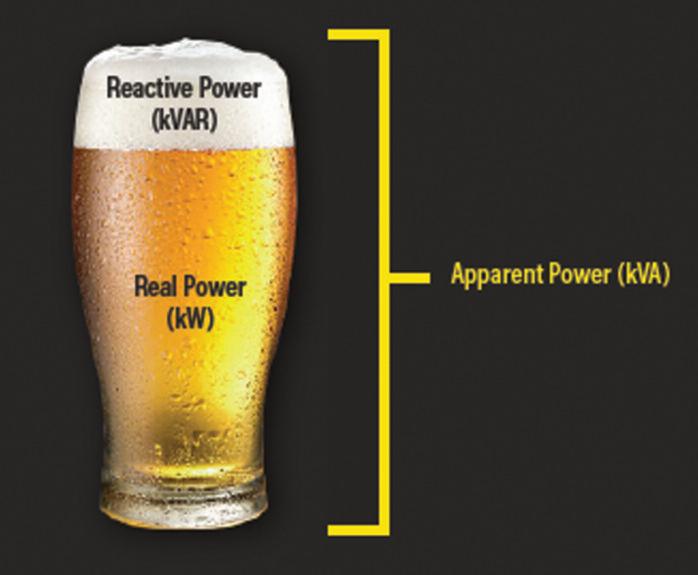

98 Power quality and energy efficiency – what should you be aware of ?

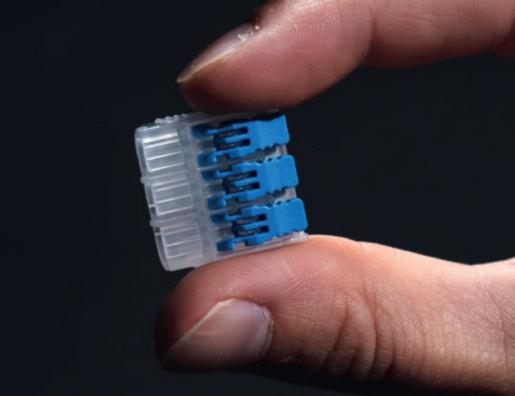

As a result of the ongoing cost of living crisis, many electricians are finding themselves working longer hours and extra shifts. In such testing times, any product that can deliver even marginal time savings is welcome. Mike Cullom, Northern Europe Sales Manager of IDEAL Electrical, discusses the benefits of innovative lever and push-in wire connectors for faster, easier and safer wire terminations.

Are tradespeople working too hard?

It’s fair to say that tradespeople are working hard in the UK. According to research1, the average

tradesperson works between 41 and 50 hours per week, with a fifth working more than 50 hours per week. This is compared to the UK average of 36.4 hours worked by full-time workers per week2.

What’s more, the ongoing cost of living crisis is leaving tradespeople with no choice but to work longer hours and take on extra shifts in an effort to increase their level of income. A recent survey found the number one cause of concern for tradespeople is the cost of living crisis, with almost two in five (39%) saying it’s a major cause of stress, and the same number (39%) admitting to working extra shifts as a result3.

With tradespeople run off their feet, every little helps when it comes to completing jobs in a timely manner without compromising on

quality. This is exactly where lever and pushin wire connectors come in handy, as even small-time savings on a single task like wire terminations can add up to substantial time savings over the length of an installation.

Simply strip, push and connect

Suitable for joining solid, stranded or flexible conductors, lever and push-in connectors deliver faster, easier and safer wire terminations, and offer a more cost-effective alternative to terminal blocks.

Secure cables in place in mere seconds using a simple strip, push, connect action – no screwdriver or crimping required.

Lever wire connectors:

• Re-useable | 2, 3 and 5 port models

• Allow the use of multiple wires of different sizes and types within the same lever connector.

• Solid and rigid stranded: 0.2mm2 -4mm2

• Flexible: 0.14mm2-4.0mm2

Push-in and in-line connectors:

• Available in 2-8-port models

• 0.5mm2 – 6.0mm2 depending on use of solid or stranded wire

Practical design features

• A clear window at the bottom of the connector to allow easy inspection

• Check port for testing

• Stripping length indication

• Simply push in when using on solid and rigid stranded wires

• 32A or 41A depending on connector

The right connector for every termination

• CE, UKCA and fully compliant with the 18th Edition Wiring Regulations.

As the UK’s cost of living crisis continues to impact the construction and trades industry, the workforce will remain stretched, so it’s a no-brainer to select user-friendly products that speed up installations and make electricians’ lives easier.

Designed to make wire terminations faster and simpler, lever and push-in wire connectors prevent errors and ensure consistency, allowing wire terminations to be carried out more quickly and with less risk of snagging –perfect for when time is of the essence.

idealind.com | idealindustries.com

[1] https://screwfixmedia.com/uk-tradesmen-working-harderthan-ever/

[2] https://www.statista.com/statistics/280763/average-workinghours-uk/#:~:text=Average%20weekly%20hours%20of%20 work,in%20the%20UK%201992%2D2023&text=As%20of%20 July%202023%2C%20the,United%20Kingdom%20was%20 36.4%20hours.

[3] https://www.ironmongerydirect.co.uk/research/mentalhealth-in-the-trades

W O R K T H R O U G H E A C H S E C T I O N A N D E A R N 6

C P D C R E D I T s ( o r 6 h o u r s o f l e a r n i n g )

T O WA R D S YO U R P R O F E S S I O N A L R E C O R D !

continuing professional development (CPD) can be broadly defined as any type of learning you undertake which increases your knowledge, understanding and experiences of a subject area or role

To help professionals to better document and prove this process, the CPD Book contains content and articles that have been checked, verified and accredited by a third-party specialist organisation

Collectively, the content within this specially designed publication has been deemed worthy of 6 CPD credits, or 6 hours’ worth of CPD, with each individual section providing 1 credit, or 1 hours’ worth of CPD.

Once this content has been consumed, readers will have the

opportunity to scan a QR code which will provide a bespoke, downloadable certificate that can be used as part of a professional’s ongoing CPD record

DO NOT SCAN THE QR CODE UNLESS YOU HAVE READ ALL OF THE CONTENT WITHIN EACH SECTION!

A large element of CPD involves self-certification and relies on professionals being honest about what they have actually read, consumed and digested A QR code has been placed with the final article in each of the six learning sections within this publication and ONLY once you have read ALL of the articles within each section, should you then scan the code to receive your bespoke certificate

By skipping any of these steps, you’re not just cheating the system, but yourself and your fellow professionals at the same time!

NEW USERS – ACCESS YOUR BESPOKE CPD CERTIFICATE IN FIVE STEPS

1. Read ALL of the content and articles included within the six sections

2. Find the QR code with the last article in each section and scan

3 Enter your email address

4. Fill out your details on the contact form

5. Download your certificate for use as part of your annual CPD record

PREVIOUS USERS – ACCESS YOUR CPD CERTIFICATE IN FOUR STEPS

1. Read ALL of the content and articles included within the six sections

2. Find the QR code with the last article in each section and scan

3. Enter your name and email address.

4. Download your certificate for use as part of your annual CPD record

All certificates are valid for one year from the issue date If you’re having any issues with downloading your certificate or using the system, please email us at: pe@hamerville.co.uk

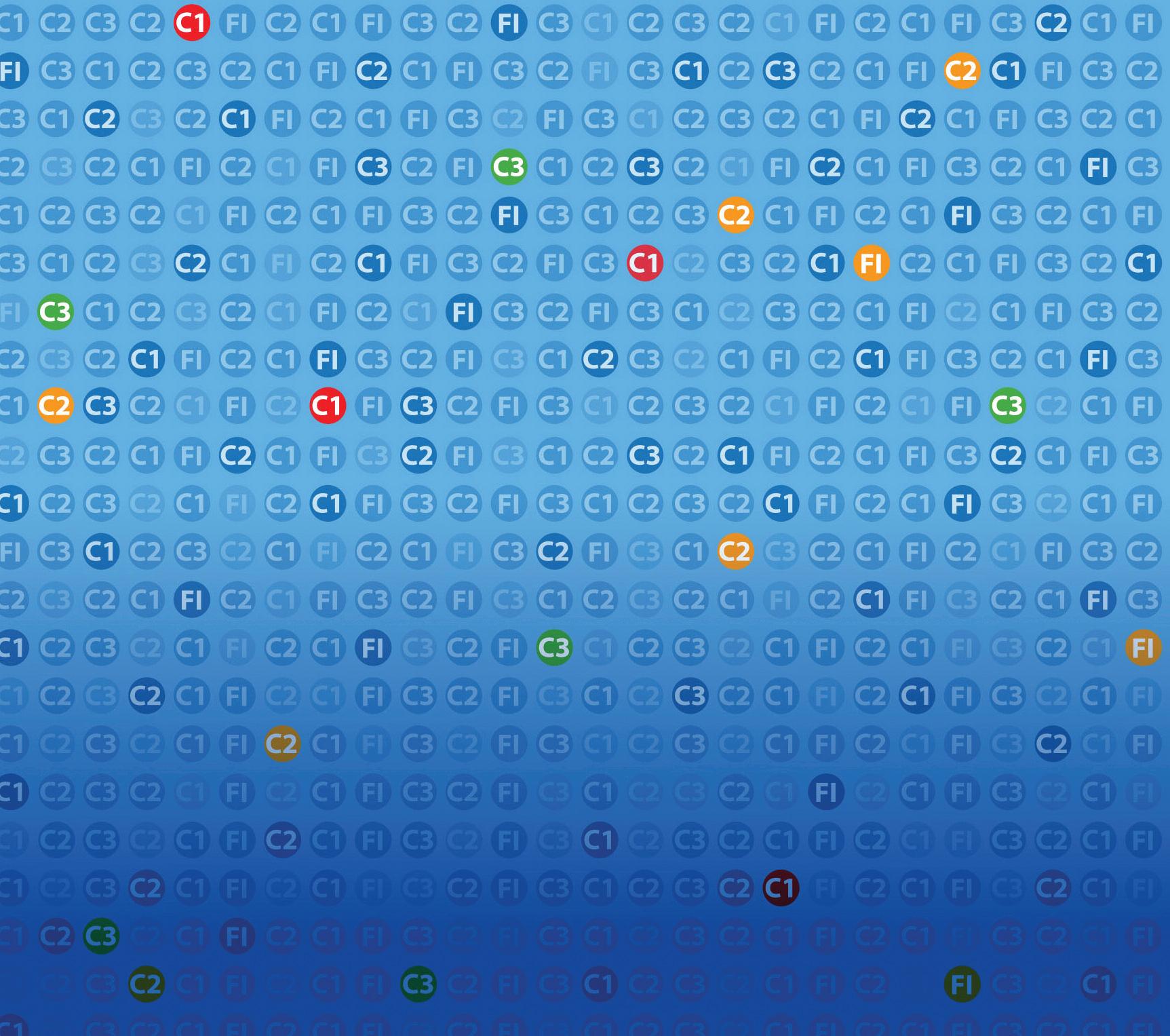

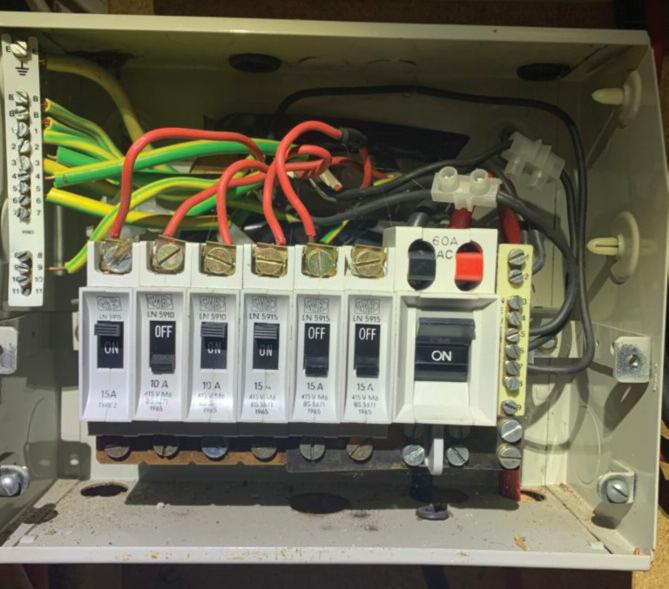

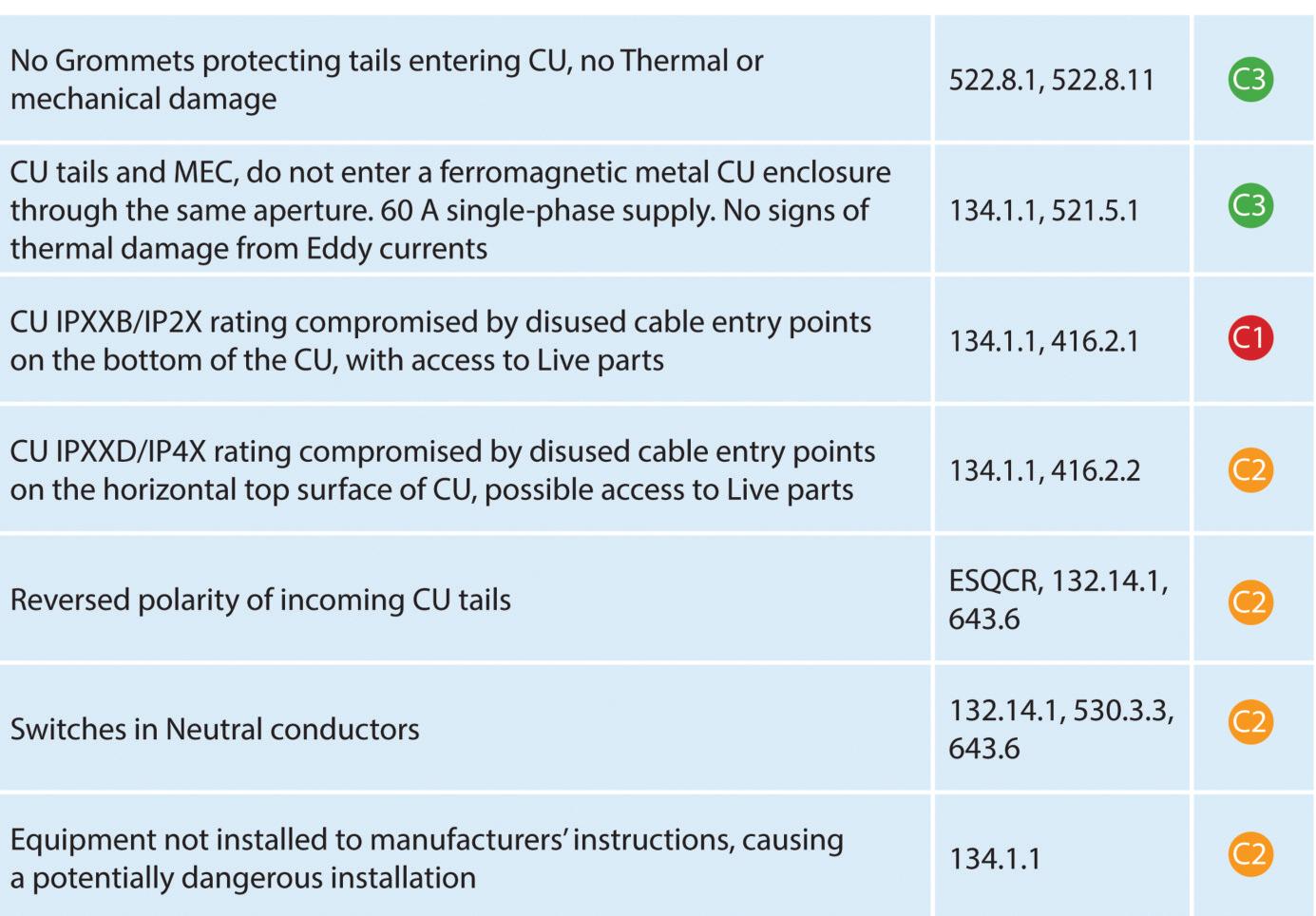

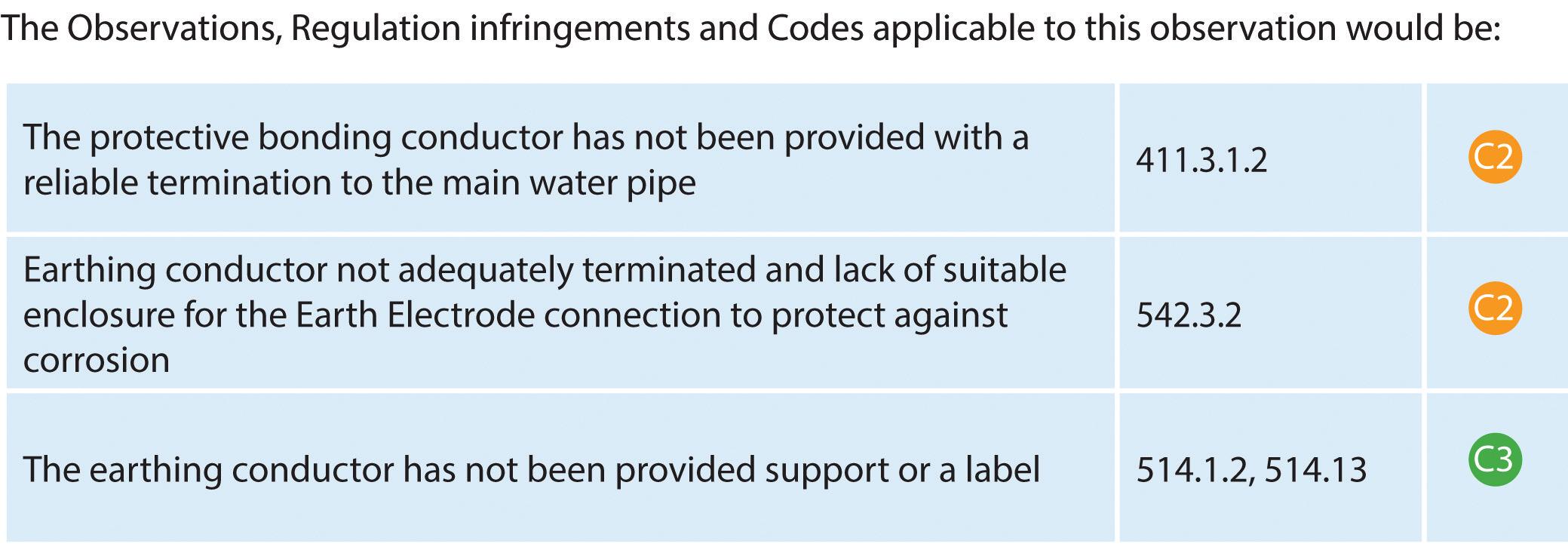

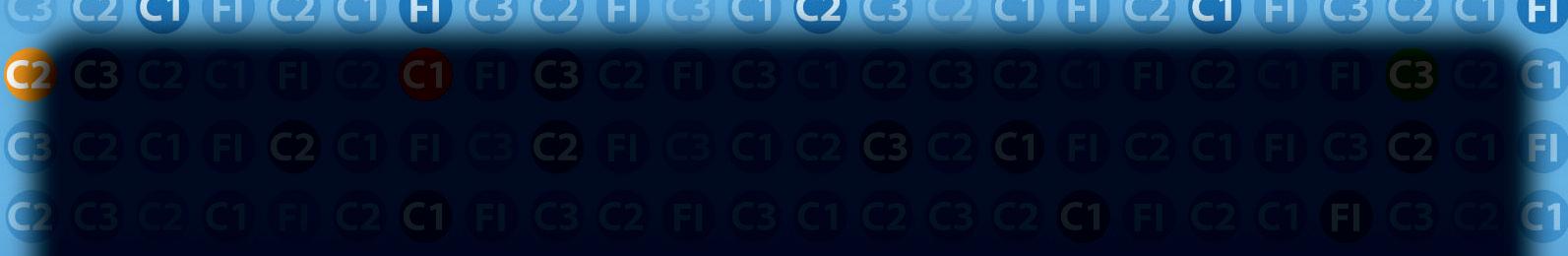

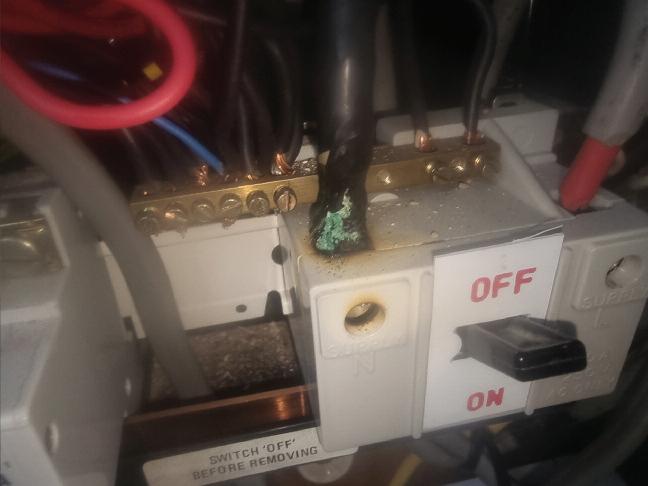

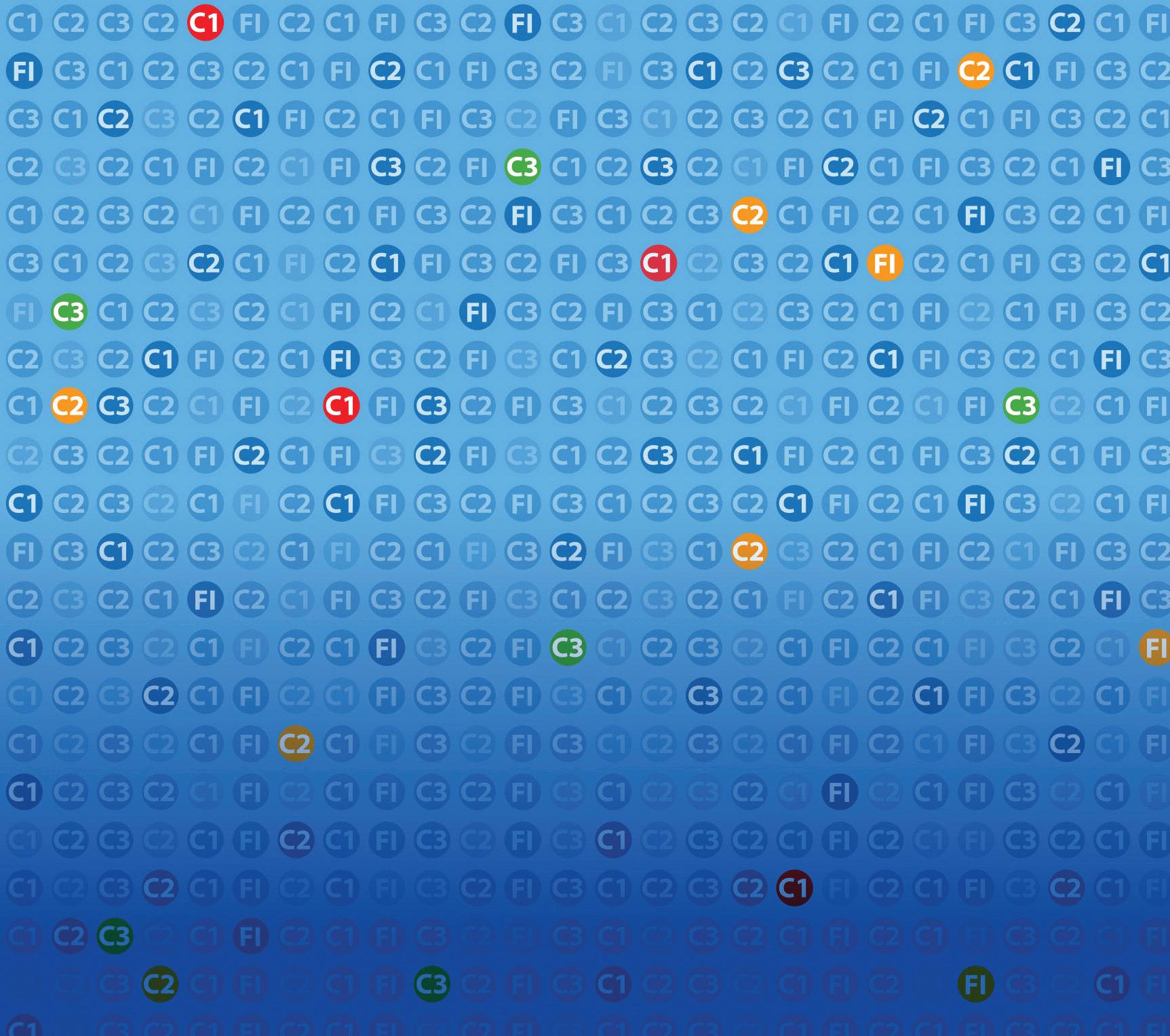

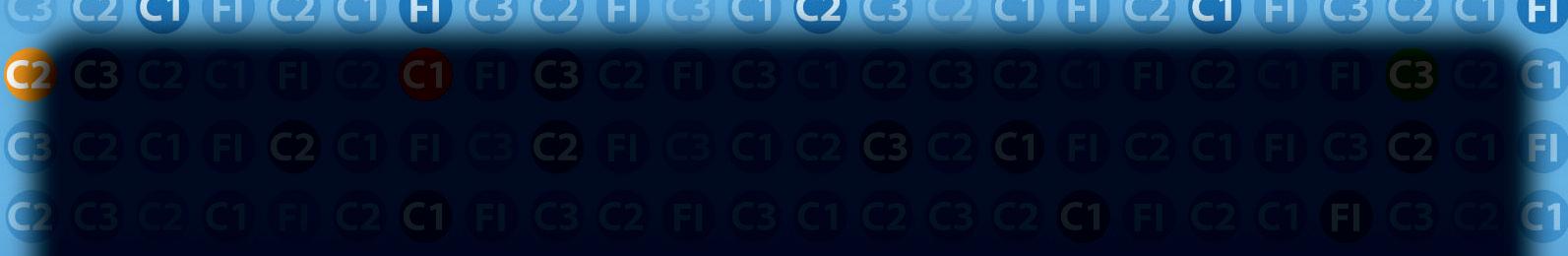

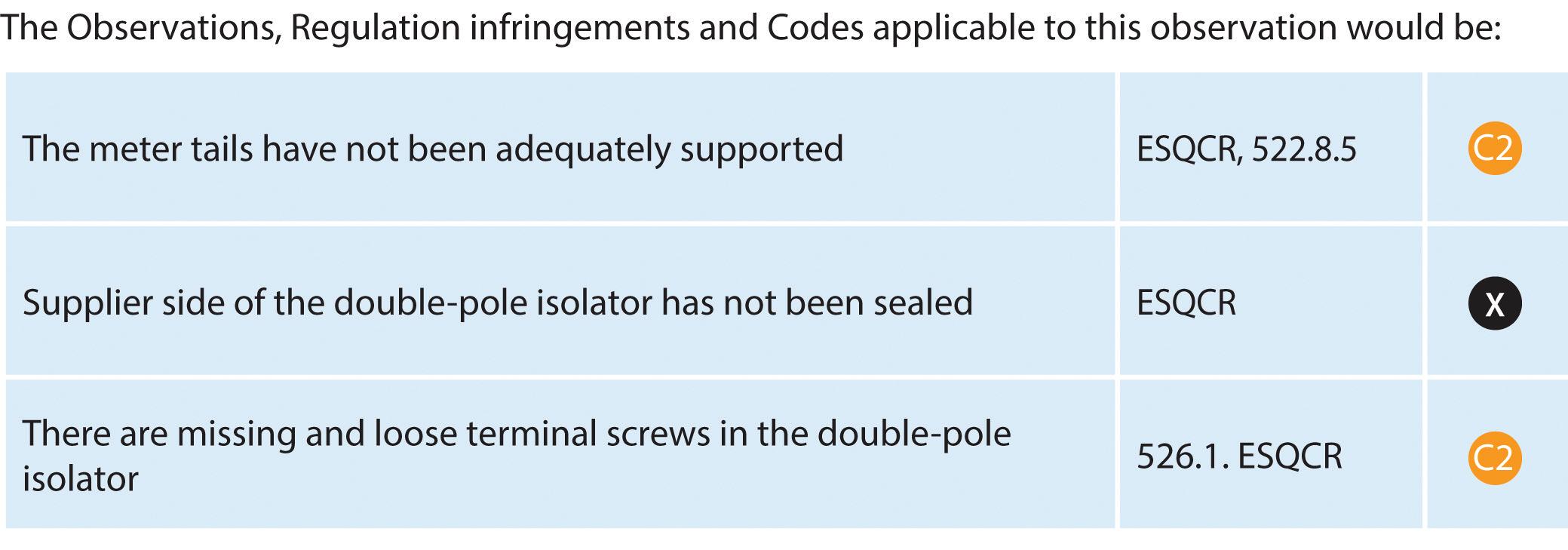

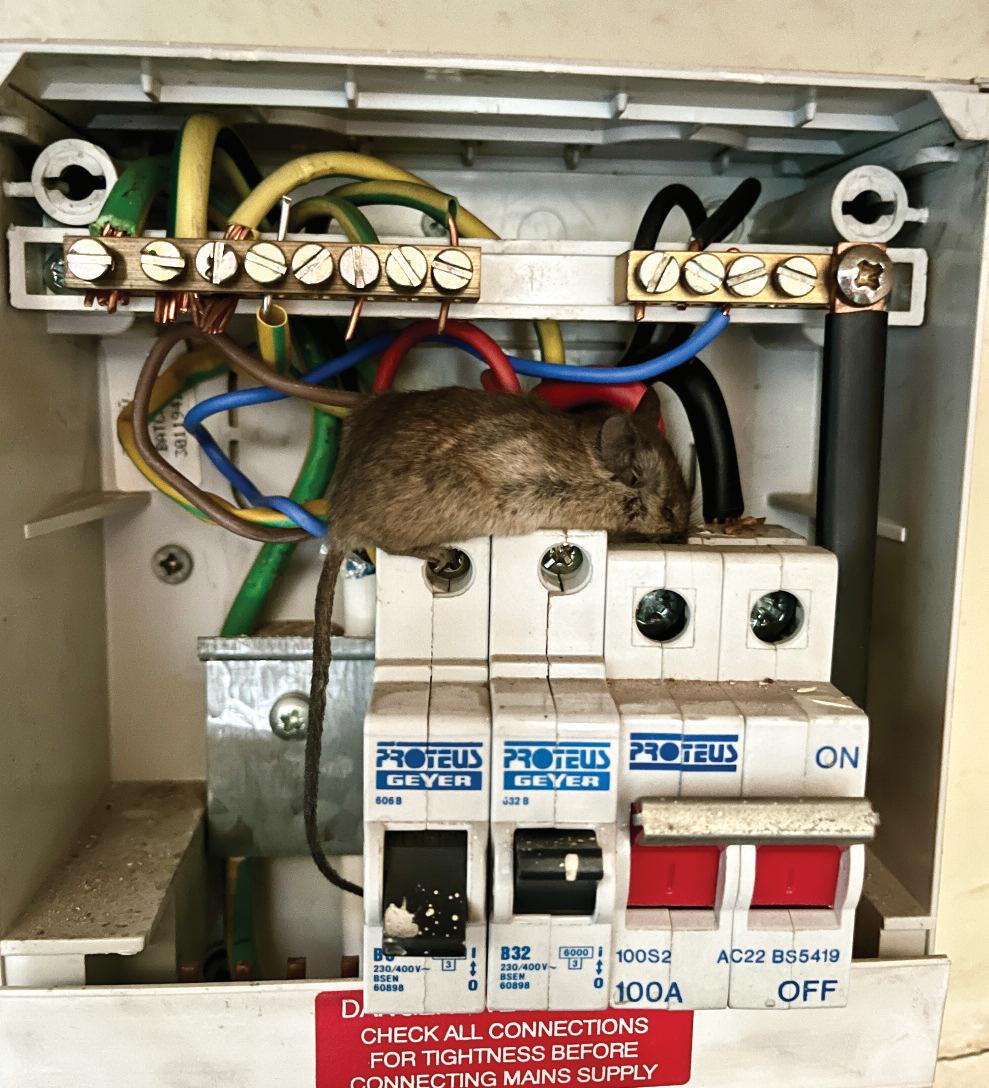

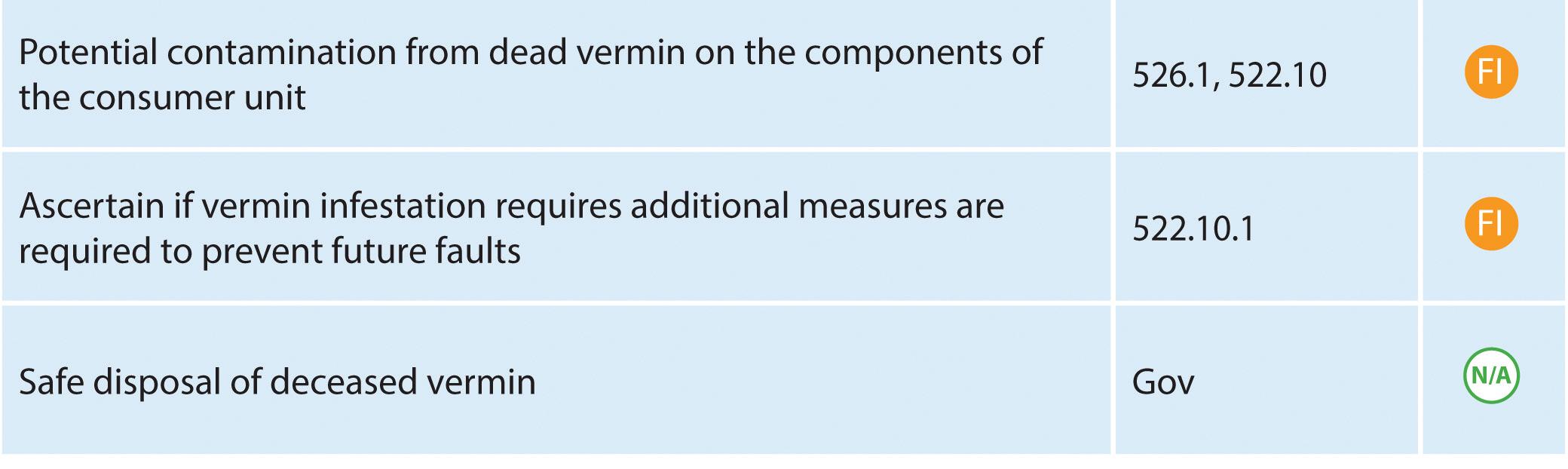

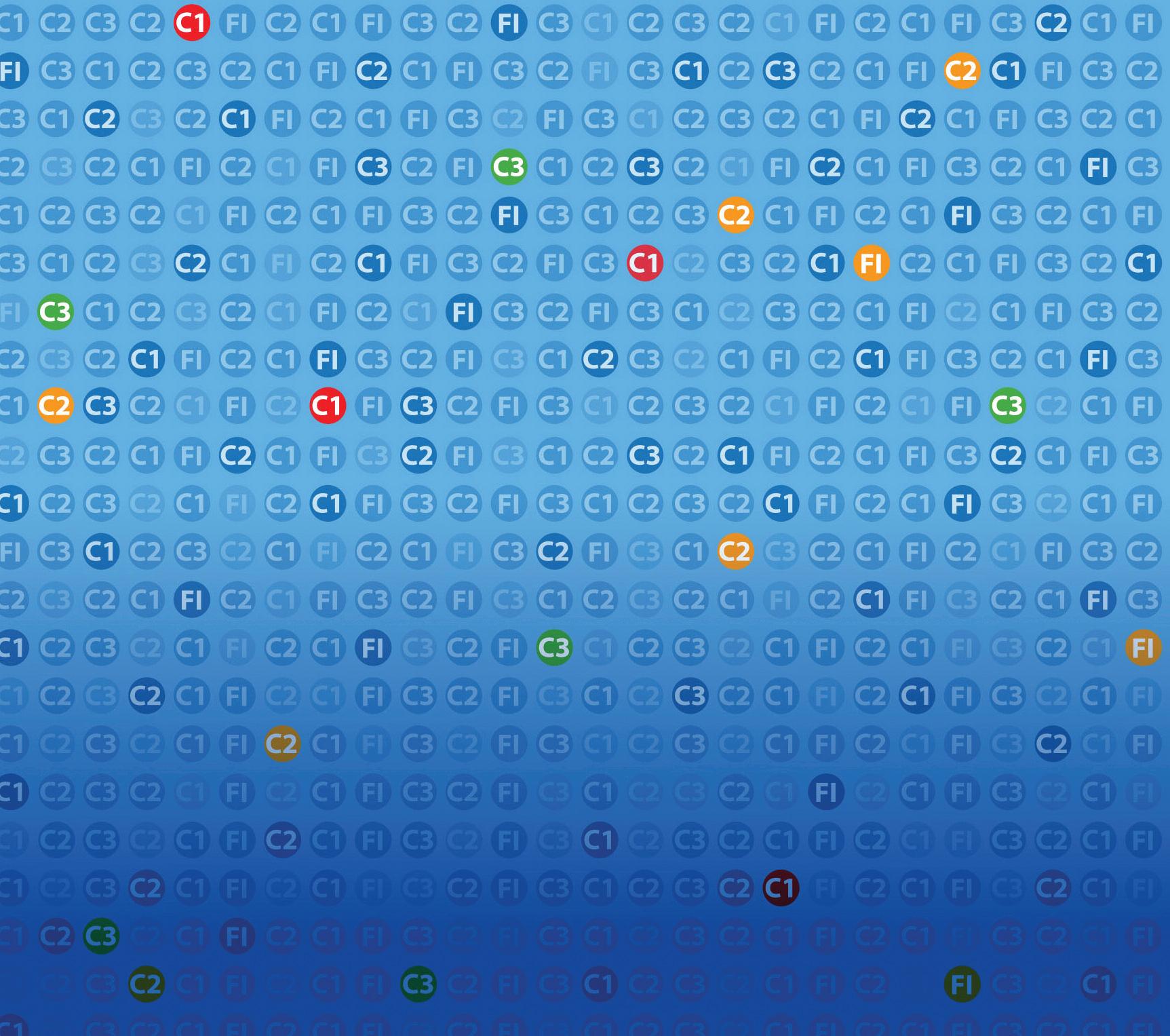

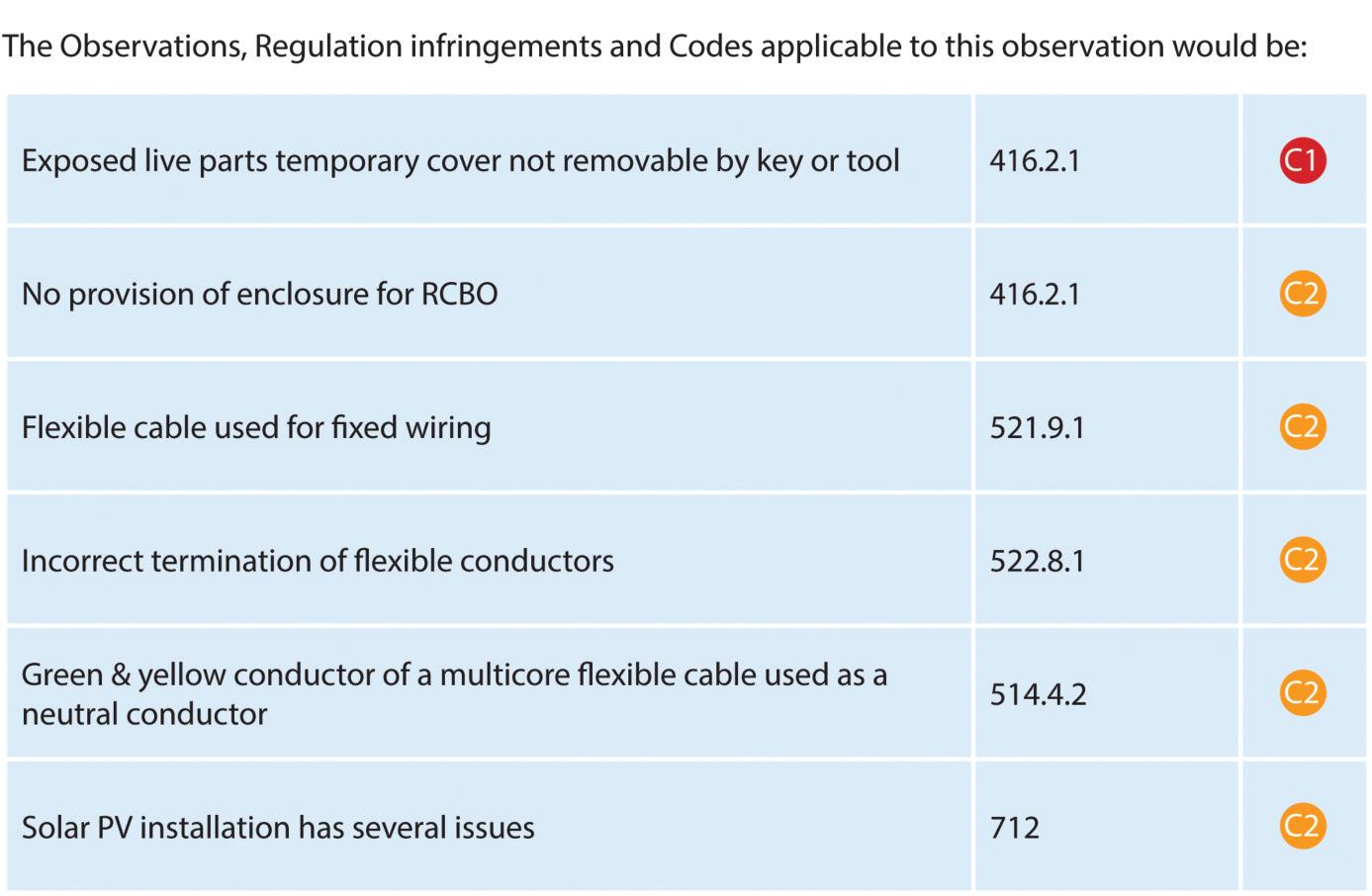

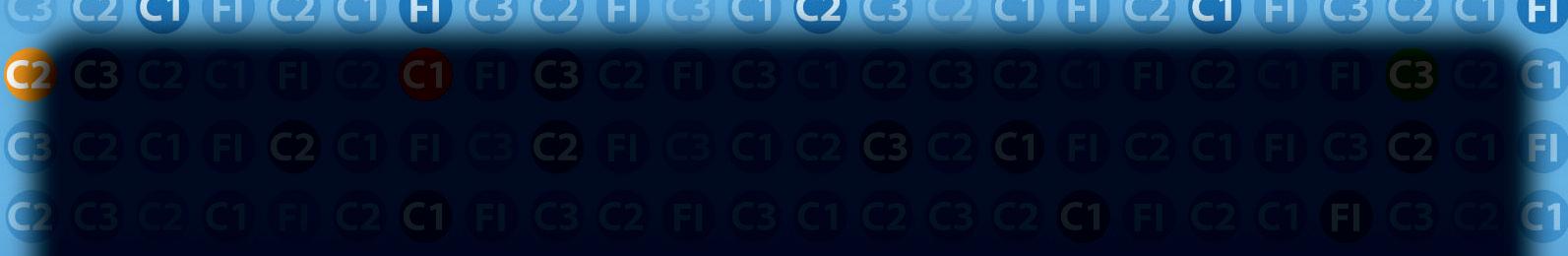

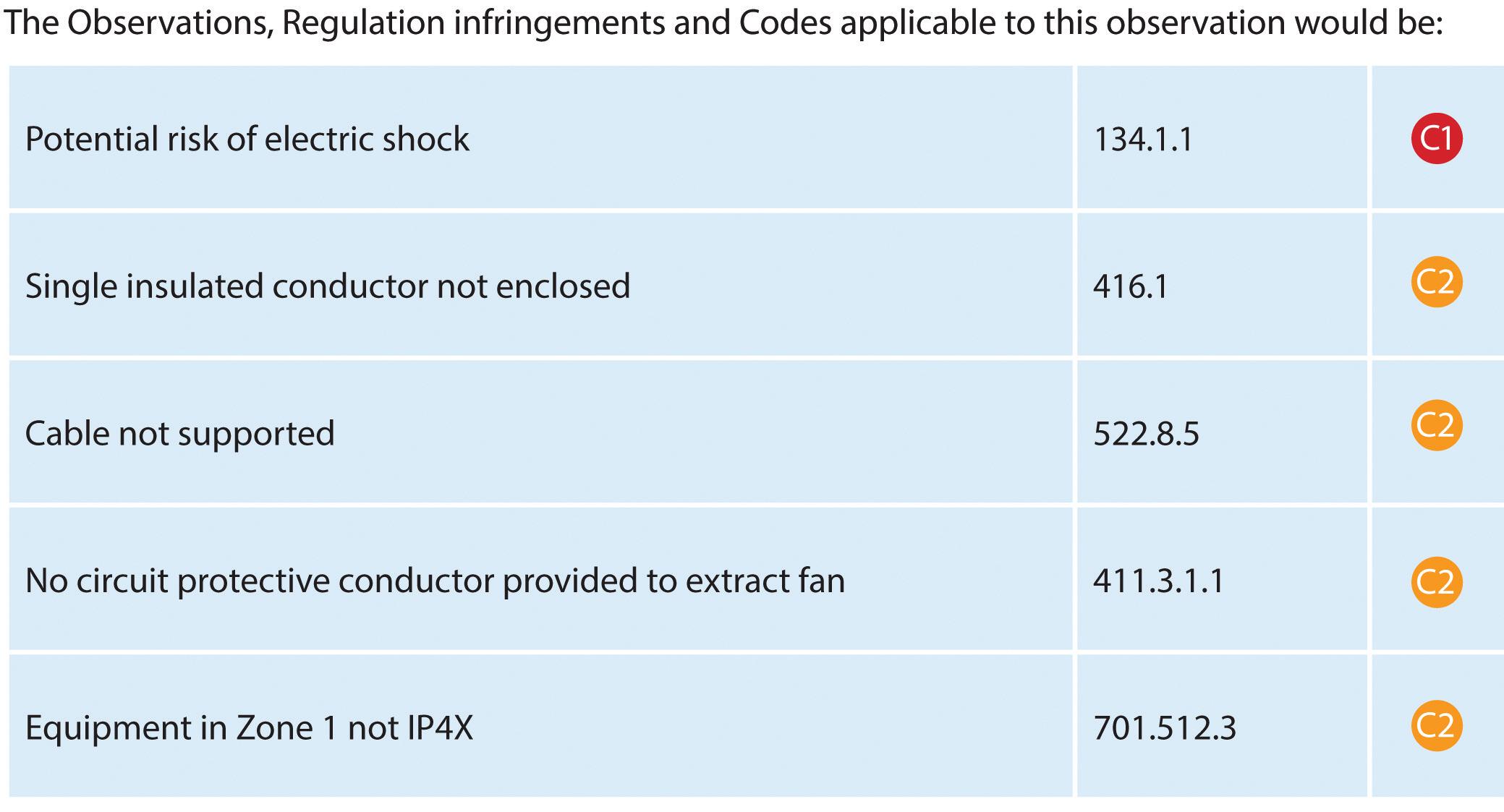

You can never assume that an older installation was installed, commissioned, and tested correctly We often find that older installations can harbour some poor and dangerous practices As we work through the findings, the lack of grommets is no more than perhaps a C3 unless there is mechanical and thermal damage. They ’ve not been there for 40 years, without either, but that ’s not to say ever y installation would be like this Eddy currents only really star t to take effect on equipment subjected to continual high current loads.

In domestic single and polyphase installations, up to 100 A, it ’s ver y unlikely there will be a problem We generally see Eddy current overheating and damage on polyphase commercial and industrial installations, dealing with larger loads In this case, the installation is only 60 A, and storage heaters are only energised for a c yclic period so, unless there are signs of thermal damage, no more than a C3

There also appear to be some cable entr y points not being used, which are likely to represent an IP issue. One certainly

seems to have almost direct access to the bus bar The area of concern here is the reversed polarity, which may well operate normally in a healthy circuit Older storage heaters generally don’t have complex electronic controllers that require correct polarity and, subsequently, don’t have reversed polarity diode protection, which stops the equipment from operating and forces maintenance to be carried out

Also, as the polarity is reversed, we now have switches in neutral conduc tors, which isn’t allowed, and no individual circuit isolation, as the MCBs are only isolating the neutral Not noticing the reversal, a maintenance engineer would think they have isolated a circuit to carr y out some maintenance, only to find that the neutral circuit conduc tors are still live.

The only way to isolate any of the installation storage heaters would be to isolate them at the CU main isolator

GET THE BOOK AND CRACK

Updated for BS 7671:2018+A2:2022, NAPIT ’s EICR Codebreakers publication is purpose -written to aid contractors, inspectors and clients, and now includes updates to align with Amendment 2 of the IE T 18th Edition Wiring Regulations The book is the per fect technical aid for electrical professionals and their customers.

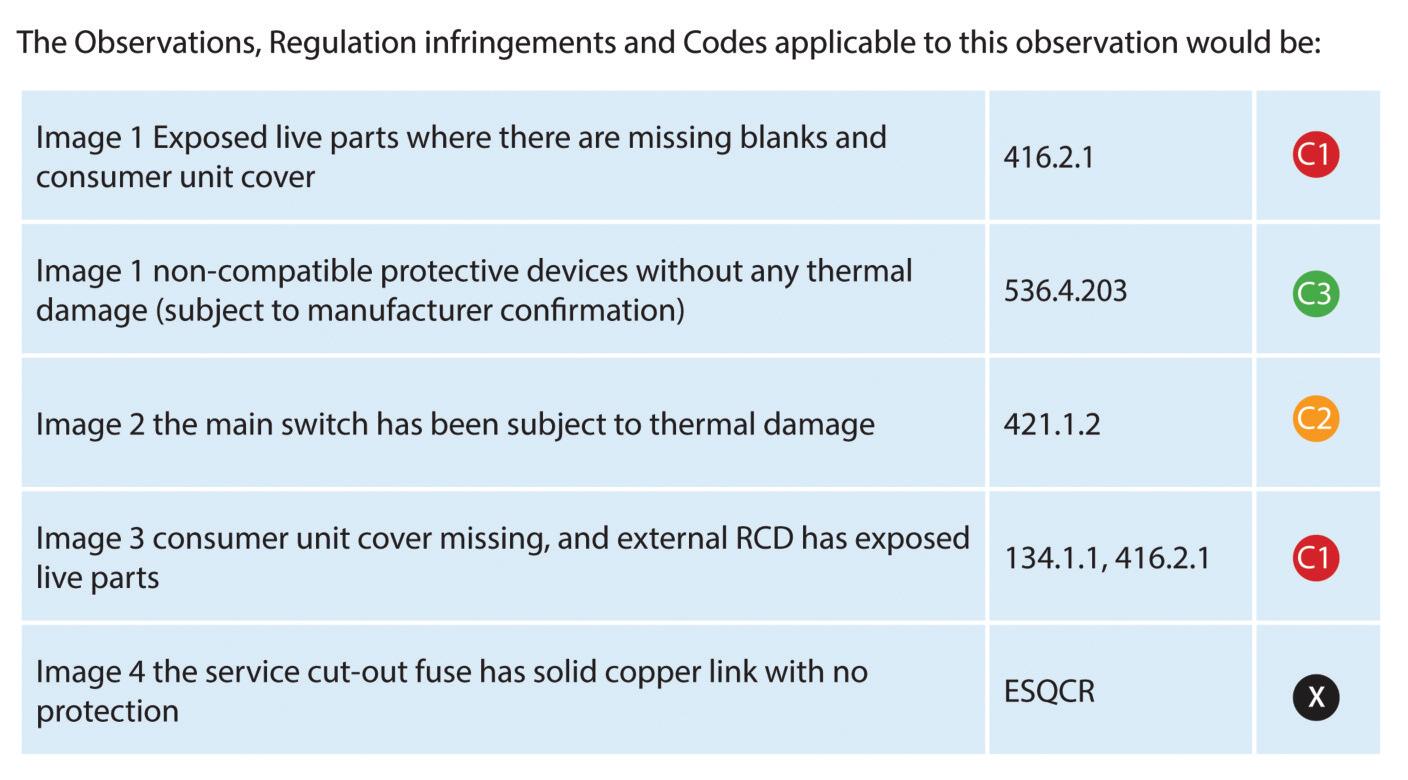

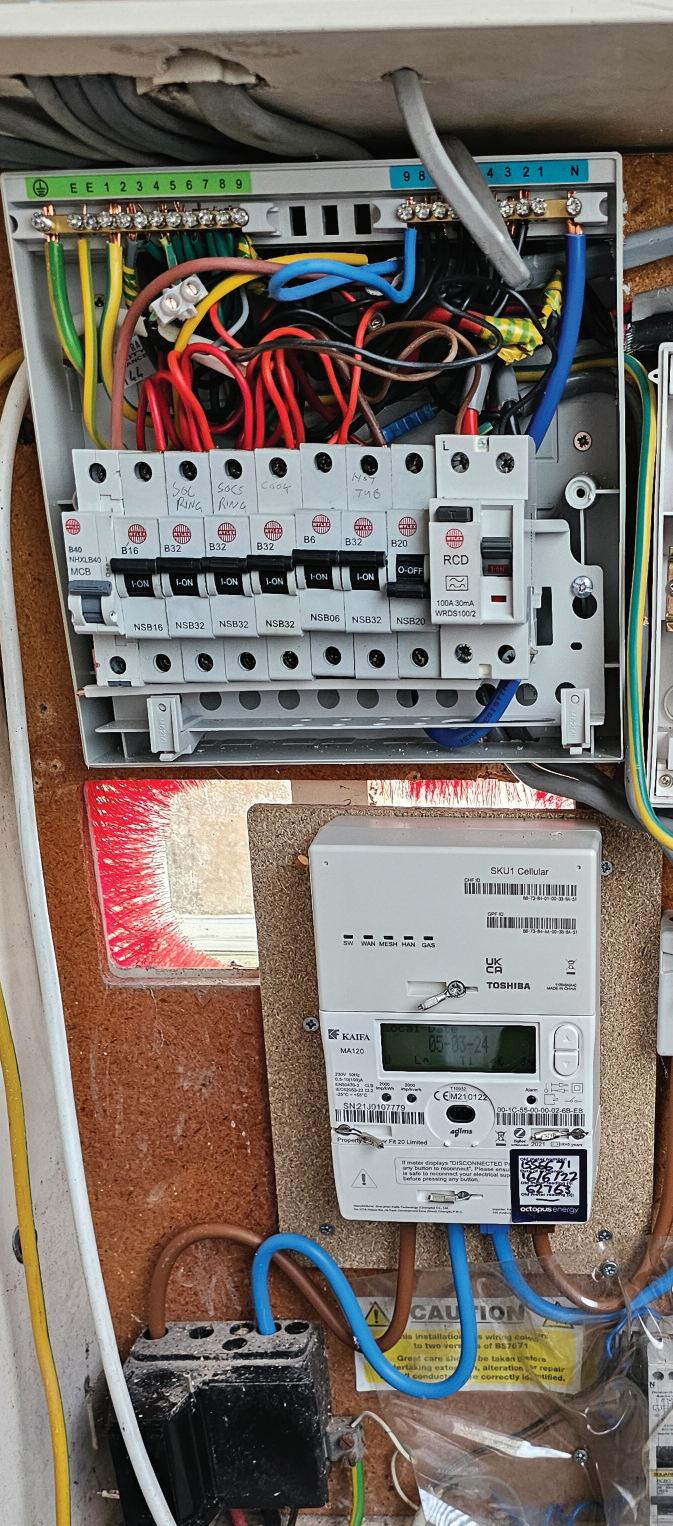

Need help with cracking those all-impor tant EICR codes? Ever y month the technical team at NAPIT will be studying your latest ‘Caught on Camera’ photos and offering advice on the next steps, should you find a similar installation. If you want the team at NAPIT to help crack your codes then send your pic tures through to us at: pe@hamer ville.co.uk

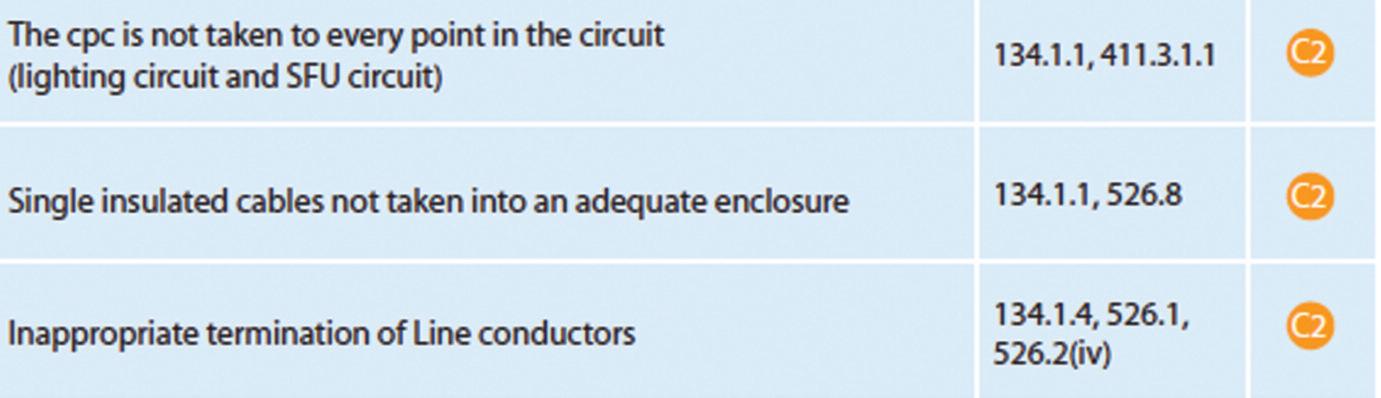

There were so many photos from Kyle’s call- out, so I chose those that I found would give the best impression of the many faults he’d found

Firstly, the left and centre photos show the connections for recessed downlights In both photos, we can clearly see that the cpc has been cropped and not continuous; this means that a cpc has not been taken to ever y point and accessor y in the circuit This alone is an unsatisfactor y finding, but the centre photo shows that the manufacturer had supplied a terminal to connect the cpc, which would have ensured the integrity of the cpc throughout the circuit.

The outer sheath of the twin and ear th cable on both light fittings has been

removed, leaving single insulation exposed and not taken into the enclosure – another unsatisfactor y finding It looks as if the line conductor terminals have been twisted together, leaving only one of the conductors in a termination, relying on the twisting to give mechanical joint stability, so again not satisfactor y

In the third photo, which I’m assuming is a fused connection unit (FCU) (as the photo isn’t too clear), we can again see the cpc is cut and not continuous; therefore, not taken to each accessor y and point in the circuit. With the general lack of elec trical understanding, by removing the cpcs, which are fundamental to safety, it ’s more than possible that the dishwasher has a current present on its housing or casing.

The current present could be innocent leak age current, which is classed as functional and therefore normal, but without a cpc to allow this to have a pathway back to the ME T, anyone in contact with it could become the pathway. I t is most likely that the shocks were perceived shocks. Regardless, perceived shocks can instill a significant amount of fear into those receiving them and highlight that the installation user could receive a fatal electric shock in the event of a fault

A genuinely horrific installation, cobbled together by someone with no understanding, sk ills, or conscience.

The A2:2022 18th Edition Codebreakers publication is priced at £22.00 (members) and £24.00 (non-members). It is available in both hard copy and digital versions * Price is VAT exempt and excludes postage and packaging.

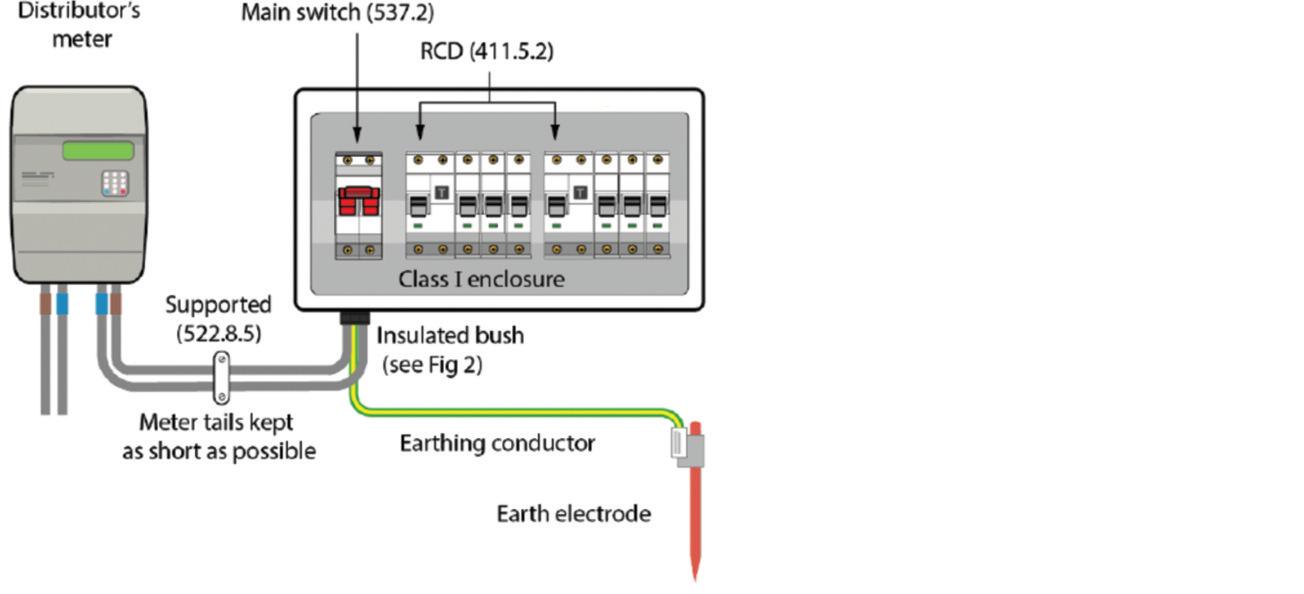

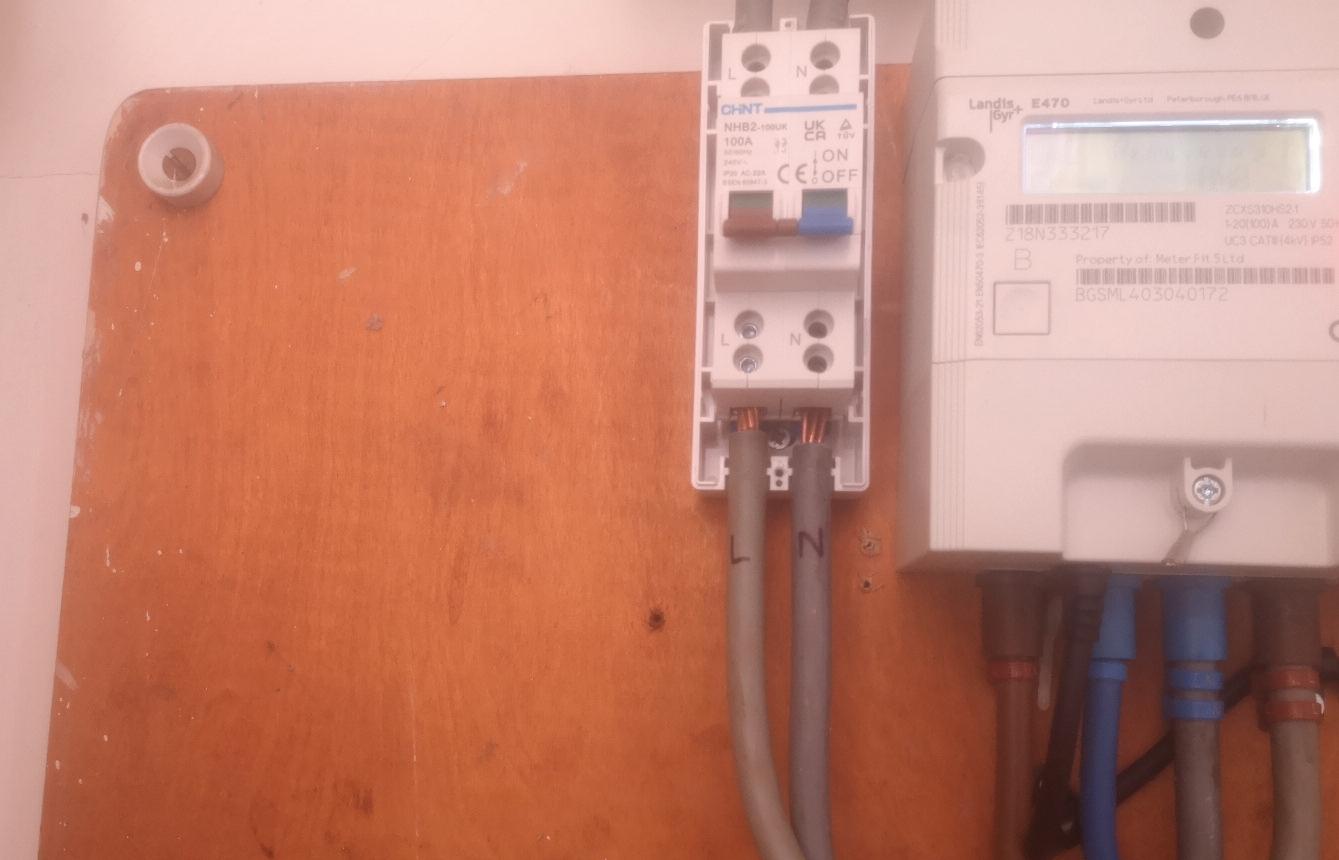

This article from the experts at NICEIC aims to provide guidance for contractors when required to install a consumer unit and/or similar switchgear manufactured from a noncombustible material meeting the requirements of regulation 421.1.201, in a domestic installation forming part of a TT system earthing arrangement.

Where an installation forms part of a TT system earthing arrangement, irrespective of the type of material the consumer unit is manufactured from, regulation 411 5 2 typically requires the installation of one or more RCDs as a protective measure for fault protection

Any RCD providing fault protection shall be erected at the origin of the installation that is to be protected (531.3.5.3.1). In an installation with multiple origins, this requirement shall apply to each origin

Most TT installations are likely to also contain multiple RCDs providing additional protection, or possibly fault protection, either protecting groups of circuits and/or individual circuits. Where this is the case these protective devices shall be selected and erected as to limit the risk from unwanted tripping (531 3 2) Similarly, where multiple devices are installed and there is a need to minimise the inconvenience of unwanted tripping during a fault, the requirements for selectivity will need to be considered (536 4 1 4)

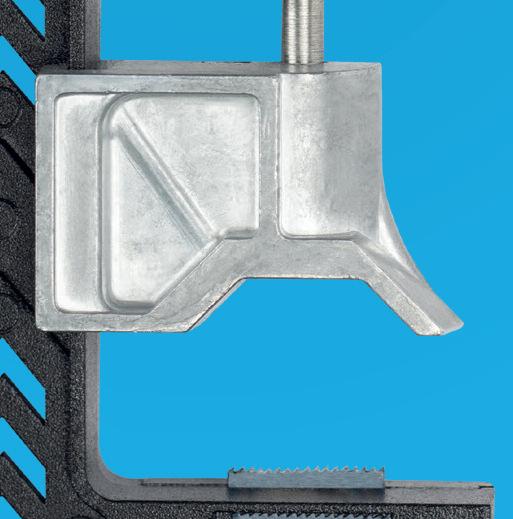

The installation of a metallic consumer unit complying with BS EN 61439-3 is most likely to be the preferred option for

achieving compliance with the non-combustibility requirements of regulation 421 1 201 However, care must be applied to the installation method adopted where a metal (Class I) consumer unit is installed in an installation forming part of a TT system

An earth fault occurring between the line conductor of the meter tails and the metallic enclosure, as shown in Fig 1, will not be detected by the RCD installed in the consumer unit. The metallic casing of the consumer unit and subsequently all other conductive parts connected to the main earthing terminal (MET) of the installation will rise to a potential approaching close to the supply voltage (230 V to Earth), creating a potential shock risk.

Under such circumstances, due to the

high external earth fault loop impedance (Ze) typically associated with a TT system, which can often exceed 100 Ω, the earth fault current is unlikely to reach the level required to operate the service fuse, and even if it does the operating time is unlikely to be within the 1 s disconnection time required by regulation 411 3 2 4

For example, if the maximum earth fault loop impedance is taken as 100 Ω also taking into account the seasonal changes of ground resistance for a single phase supply, and minimum voltage factor (C min) of 0 95, the earth fault current that will flow under such fault conditions can be calculated as follows:

��fc = 230 x 0 95= 2 2 �� 100

Clearly, this level of fault current is insufficient to operate the distributors’ overcurrent protective device and therefore, unless a low value of (Z s) can be assured and maintained while meeting the requirements of regulation 411 5 3 for fault protection, such a fault will remain uninterrupted For this reason it is preferred that fault protection for an installation forming part of a TT system is provided by an appropriately rated RCD (411.5.2).

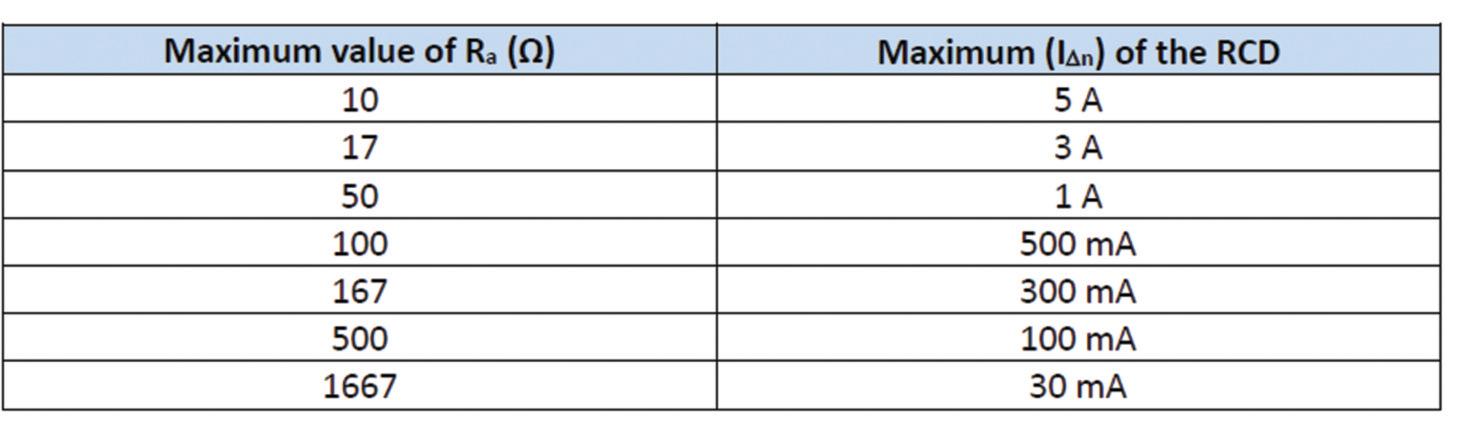

In addition, the selection of an appropriate RCD for a particular installation shall meet the requirements of regulation 531 3 5 3 2 Such that, the rated residual operating current (��Δ ��) of the chosen RCD shall not exceed the (��Δ ��) corresponding to the maximum value of earth resistance (Ra), including that of the earth electrode and protective conductor connecting all exposed-conductive-parts

In the aforementioned example the maximum earth fault loop impedance is 100 Ω and therefore, the maximum rated residual operating current of the chosen RCD shall not be greater than 500 mA, given in Table 53 1 of BS 7671 and partially reproduced in Table 1

It may not be possible to eliminate all risk associated with protecting meter tails from a fault to earth typically, between the origin and the RCD protective device within the consumer unit However, by adopting longstanding industry practices applied by many electrical contractors, such as those listed below, the risk can be mitigated sufficiently:

● use of thermoplastic or thermosetting insulated and sheathed cables for the meter tails (531 3 5 3 2 201), and ● positioning of the consumer unit in close proximity to the energy meter, reducing the length of the meter tails to a minimum to mitigate the risk of damage,

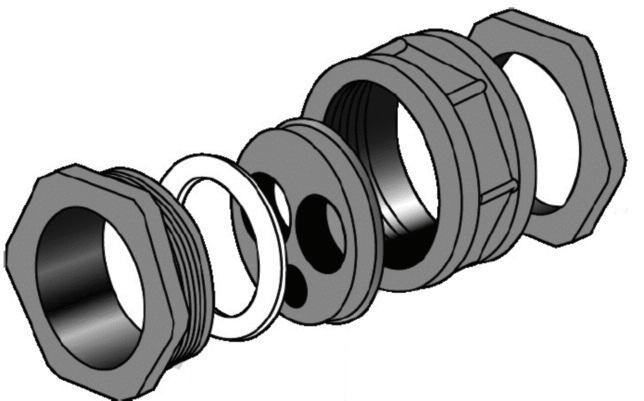

● fitting an insulated cable gland, bush or similar to protect the cables from abrasion as the meter tails enter the metallic consumer unit and/or protective enclosure, as shown in Fig 2.

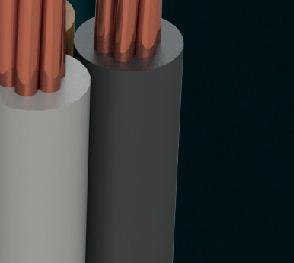

Additionally, in order to avoid the effects from induced eddy currents in the metallic enclosure and any consequent heating effects, all associated meter tails should enter the consumer unit through the same entry point (one cable entry knock-out hole).

The requirement of regulation 421 1 201 is intended to ensure that any source of ignition, such as arcing caused by a loose termination occurring within the consumer unit and/or switchgear assembly, is prevented from igniting the enclosure while reducing the risk of any fire from spreading externally

It is for this reason that the entry points of all cables, including that of the meter tails, into the metallic consumer unit should not, so far as reasonably practicable, reduce the fire integrity provided by such equipment Cable entries, such as those often used for back entry into the consumer unit must be provided with suitable sealing methods and may include intumescent gaskets, grommets and/or fire sealants to maintain the degree of fire integrity

However, it is generally accepted that the requirements of regulation 416 2 1 and 416 2 2 which are intended to prevent contact with live parts also help to maintain the fire integrity of the consumer unit. A degree of protection of at least IPXXB or IP2X should be maintained for the top surface of the consumer unit and a degree of protection of at least IPXXD

or IP4X maintained for all other surfaces of the enclosure

Where the installation of a consumer unit is to take place on or in a combustible prefabricated wall, additional precautions must be applied to prevent the ignition of surrounding materials. Equipment having a greater degree of protection will be required which must be maintained of at least IP3X (422 4 1) Using appropriate types of equipment conforming to the relevant standards for temperature rise will meet this requirement (422 4 201)

Where the installed equipment, such as an all-insulated construction consumer unit, fails to meet the requirement of regulation 422 4 201 further preventative measures shall be applied to prevent the spread of fire. This may include the use of a secondary enclosure manufactured from a non-combustible material of suitable thickness, for the containment of the consumer unit (422 4 202)

There is a greater risk associated with the installation of a metallic consumer unit in an installation forming part of a TT system earthing arrangement It is for this reason that consideration must always be given to the location of the consumer unit and length of meter tails in relation to the energy meter.

Appropriate installation methods and practices that have been applied by electrical contractors for many years continue to minimise the risk of damage to the meter tails and subsequent earth faults It must be recognised the need to maintain the degree of ingress protection and the fire integrity of the consumer unit in relation to the type of installation method

Recessed Light Source for Enhanced Visual Comfort & Reduced Eyestrain

Front-Access

CCT4 Switch

Colour-Coded Lever Terminals

Dual-Wattage Base Switch

Transparent Connector Cover Loop In, Loop Out

The fire rated downlight you asked for, now with anti-glare.

Available in your local wholesalers

e y Availabl Av esal al whol oc our l e ser

Multiple Trims to Adapt On-The-Go: Black, White, Chrome. Matching Reflector Insert for Soft Illumination

Keith Willcock, Product Manager for Siemens Alpha Circuit Protection Products, reviews the implications for designers and installers of electrical installations from the latest requirements for additional protection for socket outlets in BS 7671, including Amendment 2.

Regulation 411 3 3

Within Chapter 41 (protection against electric shock) Regulation 411 3 3 now tells us:

‘ in AC systems additional protection, by use of a 30mA residual current device, must be provided for socket outlets (not rated higher than 32 A) in locations where those socket outlets are likley to be used by persons of capabilty BA1, BA2 & BA3 There are no exceptions to this requirement ’ Previously this regulation did not overtly consider user capability The regulation concerned itself with the equipment type i e socket outlets Now the person using the socket outlets is the principal consideration for designers and installers

What are BA1, BA2 & BA3?

The terms BA1, BA2 & BA3 are explained in BS 7671 Appendix 5 of the Wiring Regulations, which includes a list of external influences, and, in table B, under the sub heading of ‘Utilization’ BA, refers to the capability of persons. BA1 is described as an ordinary person (a person who is neither a skilled person nor an instructed person), BA2 as children, and BA3 as disabled persons

Which locations are included?

Regulation 411.3.3 does not give a list of typical locations, so designers and

installers have to determine for themselves which locations include socket outlets that are liable to be used by ordinary persons, children or disabled persons

Typical obvious locations will include schools, universities, offices, factories, hospitals, nurseries, care homes, hotels, and indoor/outdoor locations Actually, its hard to exclude any locations, the requirement really means all workplaces, all leisure facilities, and all living accommodation. No exceptions permitted.

What is a socket outlet?

People probably imagine a common BS 1363, 13 A, three pin socket outlet when they read Regulation 411 3 3, but the regulation isn’t limited to 13 A sockets – it includes all types of socket outlets up to a maximum rating of 32 A

The regulations state that a socket outlet is a device, provided with contacts, which is intended to be installed with the fixed wiring, and intended to receive a plug Taking account of all the types of premises with the relevant locations covered by this regulation there will be a wide variety of socket outlets that must have additional protection by a 30mA residual current device, including 2, 5, 13, 15, 16, 20 and 32 A round pin, square pin, fused or unfused indoor or outdoor sockets.

The simplest compliant solution is to use an individual Type A 30mA RCBO on each circuit that supplies power to any socket outlet This will meet the requirement for additional protection, avoid unwanted tripping, and maintain power continuity on healthy circuits

Type A RCBOs are suitable for circuits with equipment incorporating electronic components that may produce DC currents; such equipment is commonplace in modern installations. Type A RCBOs are designed to trip on alternating sinusoidal residual current and on residual pulsating direct current MCBs won’t meet the requirements of BS 7671 for additional protection and shouldn’t be utilised for the circuits that supply socket outlets which will be used by ordinary persons, children or disabled persons

Footnote:

Designers should not group several socket circuits on a single 30mA residual current device as this can actually cause unwanted/nuisance power outages to healthy circuits that share an RCD with a faulty circuit, and is very unlikely to comply with the wider requirements of BS 7671: Chapters 13 & 31, Regulations 531 3 2 etc

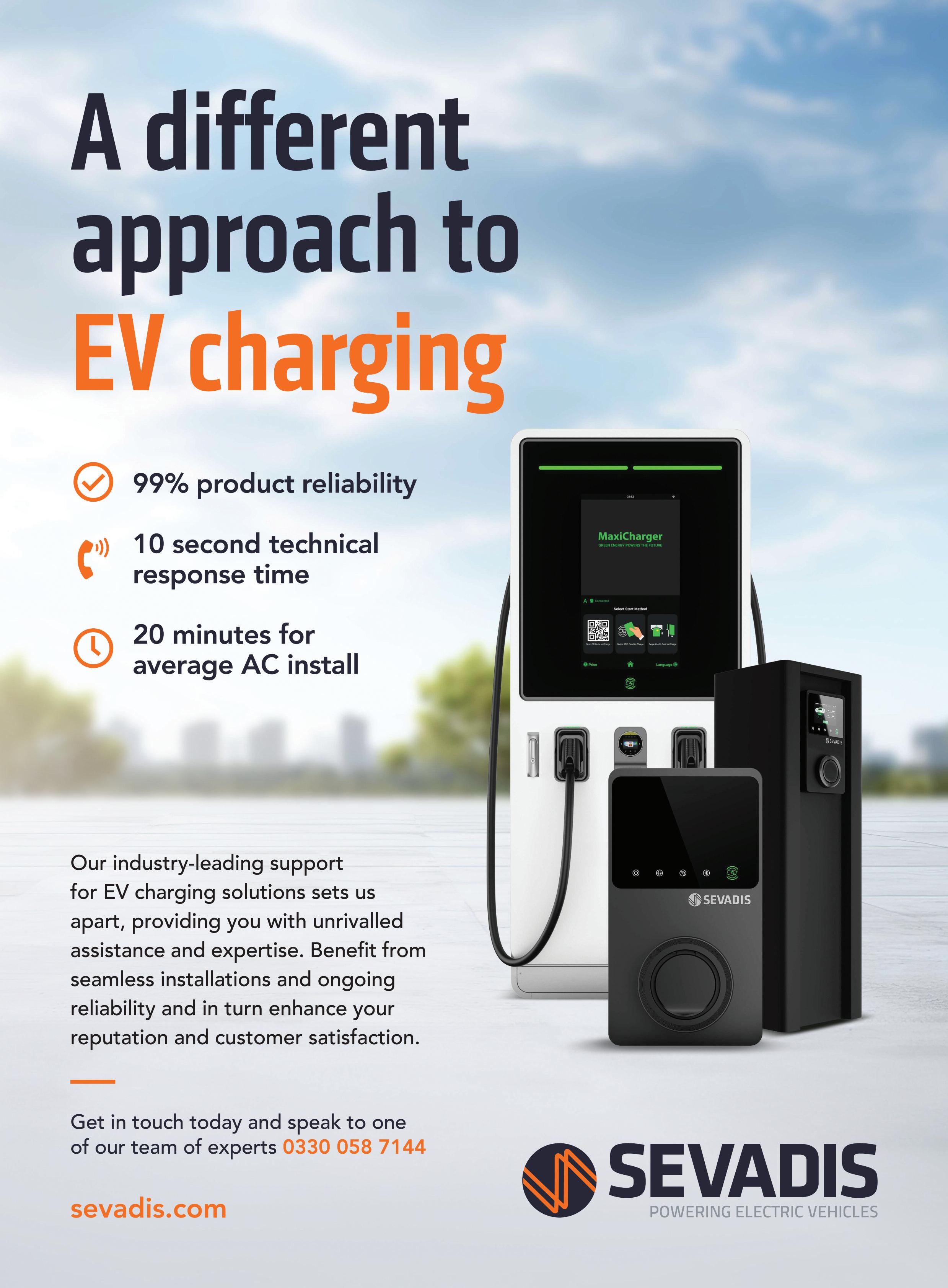

Installers at our UK training sessions will ask a lot of questions when they’re learning how to best install EV charge points But, there are certain topics that will crop up time and again at training events up and down the country

In my experience, installers are keen to find out all about EV charging, how the charging units work and the steps to effective installations They’re an inquisitive lot and ask some very good questions at each session

Last month I covered questions relating to EV charge point RCD protection, IK impact ratings and AC & DC chargers This month I’ll broach two more questions:

QWhich type of load management is needed?

Introduction of any EVSE equipment to a property will inevitably add additional strain onto the supply network and the local installation itself It is important to understand what the maximum demand of the property is prior to installation of charging points It is also important to remember that diversity cannot be applied to EVSE since it will operate at

In this follow up to his first article, Viktors Nikolajevs, CTEK’s Skillbase Manager in the UK, answers more of the key questions that installers are commonly raising around EV charge point installations.

the rated level continuously, unless limited through configuration or instructed otherwise by the vehicle

BS 7671:2018+A2:2022 Section 722 311 201 states that load curtailment, including reduction or disconnection, either automatically or manually, can be taken into consideration when determining the maximum demand of the installation In many situations manual load reduction (through configuration) can impede the user experience when charging vehicles, so automatic approaches through load management equipment or software would be more appropriate.

There are two variations of load management solutions available – static and dynamic Dynamic load management typically includes installation of additional meters and/or current transformers to the incoming supply to measure the overall power consumption of the property The measured values would then be assessed by the EVSE or the load management controller, allowing the EVSE to use the remainder of the supply to charge the EV

Furthermore, DNOs may require dynamic load management to be installed if the Maximum Demand thresholds, explained in Energy Network Association (ENA) Electric Vehicle Charge Point and Heat Pump Connections Process, are reached or if local transformers have limited capacity

Static load management can be used in installations where the actual power consumption of the property is known and is relatively stable The power consumption of the property does not need to be measured continuously, so there is no need for additional meters or CTs, and there is a dedicated amount of power capacity dedicated only for vehicle charging. The load management is then

carried out against this dedicated power capacity. Such solutions can be well suited for small office buildings with a low number of charging points

Installers and designers have to consider whether online or offline load management is more appropriate When using online (cloud-based) solutions, consider how the charging points would behave in case of internet access loss This behaviour varies from manufacturer to manufacturer, and in some cases can either send the chargers to minimum output mode, maximum output mode or disable them completely.

Offline solutions operate locally. Should connection to the internet be lost, the load management will continue to function as pre-programmed by the installer

QWhat is the OCPP and why do I need to know about it?

Open Charge Point Protocol (OCPP) is an open-source communication protocol used to make EV networks open and accessible It can be thought of as a common language, which allows different hardware manufacturers and software developers to produce cross-compatible solutions, even if they have never worked together

OCPP-compliant hardware providers allow the customers to decide how they want to operate their charging points, which software they use or which EV charge point tracking Apps can interact with the stations Additionally, should a manufacturer of OCPP-compliant hardware or the back-end provider go out of business, the owner will have an easy way of switching the back-end, rather than completely losing access to their charging points

In simple terms, when manufacturers implement OCPP support, the EV charge point owner/operator can decide what software platform they want to use to manage their charging network and set up methods of payments The EV charge point operator can then manage charging stations from different manufacturers in the same software

Another aspect of often overlooked benefits of OCPP is hardware longevity If the manufacturer of EV charging stations without OCPP support goes out of business or stops supporting those stations on their platform, then the stations would lose all of their smart functionality or become completely disabled Having OCPP allows switching the back-end software to prolong the

longevity of hardware should such unforeseen circumstances occur.

Currently, there are three versions of OCPP available – 1 5, 1 6 and 2 0 1 The most commonly used version now is 1 6 Both the charging point and the back-end solution should be able to use the same version of OCPP for successful connection.

The appetite for EV installation training is growing all the time as more installers want to expand their knowledge of what is a huge growth market.

A City & Guilds survey of installers found 45% of employers only recruit electricians who are already qualified or competent to install EV chargers So, here at CTEK we’re committed to providing our Skillbase training to many more installers

Installers are invited to free online CTEK training events to learn more about installing EV charging infrastructure The sessions will run at 9am and 1pm

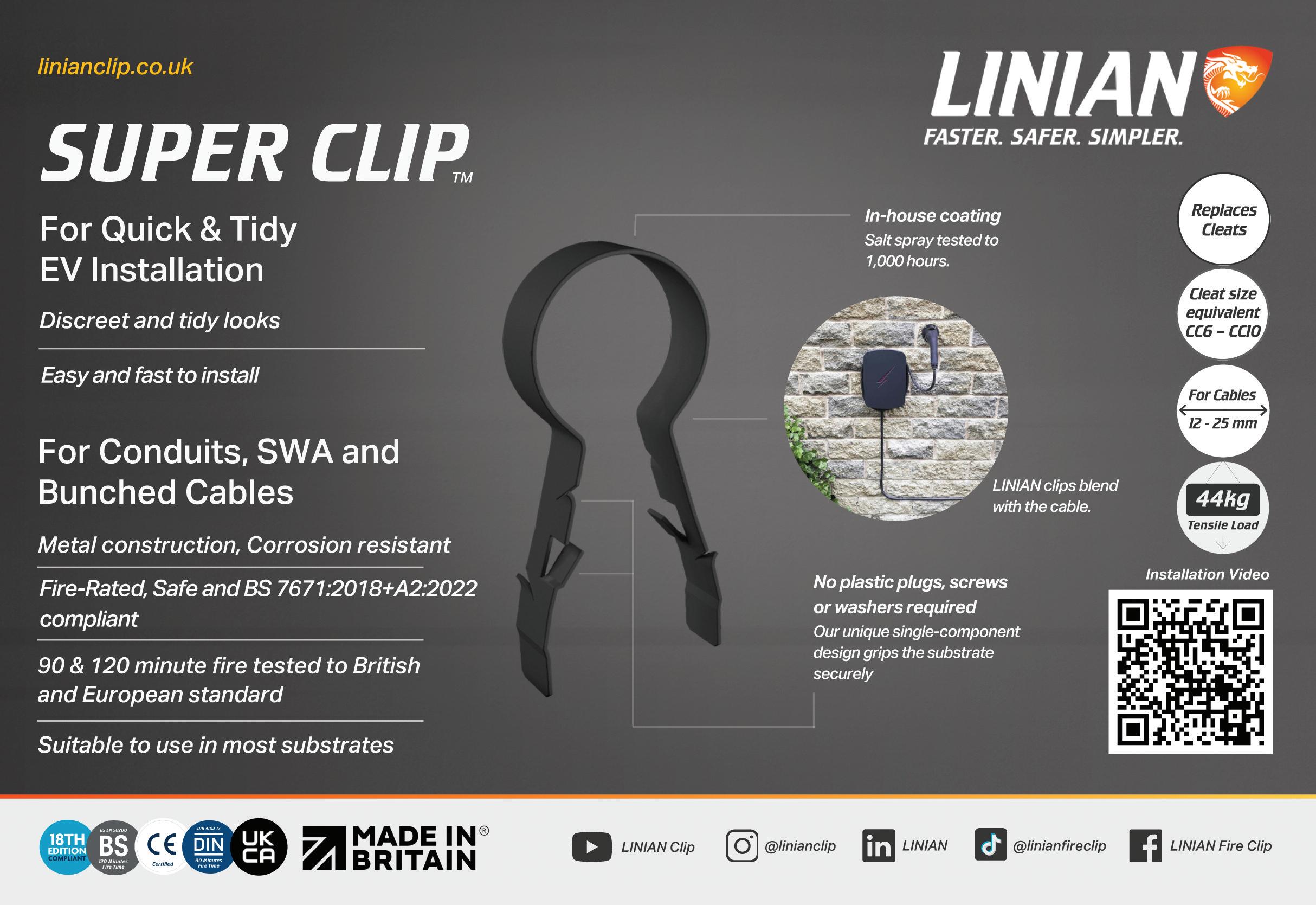

The technical experts at NAPIT look at different installation methods and the mechanical protection requirements for each.

Installation or wiring methods?

Whenever we speak to contractors or they ask our advice on an installation or wiring type, there is often some confusion over the different installation methods and how they can be used.

Let’s be clear, wiring methods are different ways of saying installation methods, so they are generally taken as being the same principle

What’s a wiring system?

These differ slightly from installation methods and refer to a cable or system containing both basic and mechanical protection when installed and commissioned correctly

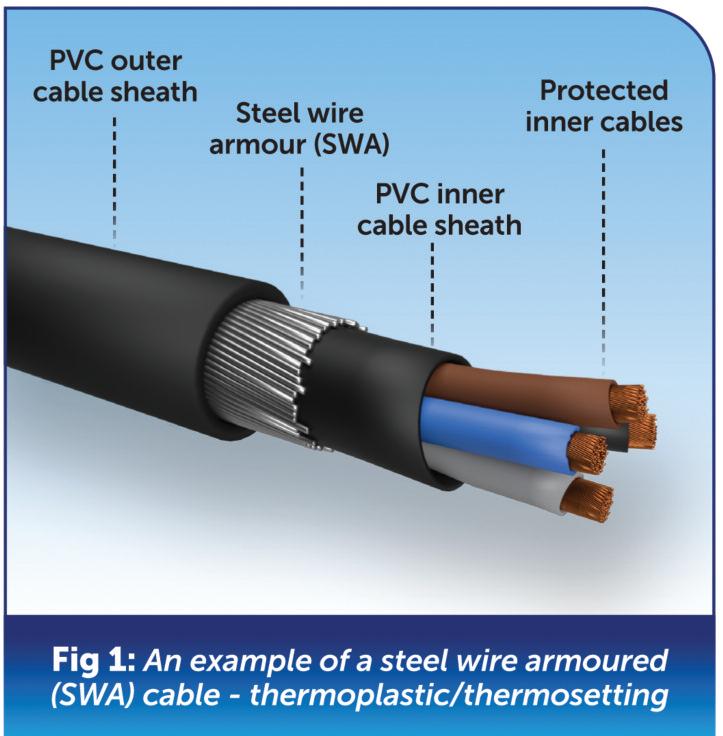

PVC/PVC flat twin and earth cables are classed as a wiring system as they possess all of these properties and also include a cpc, as do SWA, MICC, soft skin

fire cables (FP200 and similar) and many other similar cable types

The systems we use to support these cables are referred to as containment because they contain the cable wiring system A containment system or method

is not a wiring system, and in most cases, it can be used for, or with, many different wiring systems

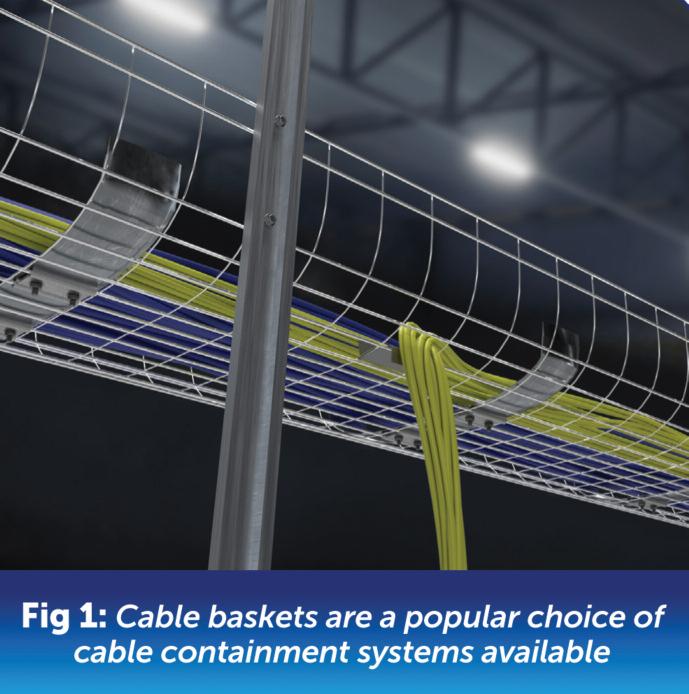

One such example of a containment system is the cable basket, as shown in Fig 1, where the open metal frame design offers less surface area so increases air circulation and prevents both heat and dust build-up

Another cable containment system is the cable tray, as displayed in Fig 2, which are commonly used to support a multitude of light-weight cables. In the same way, we may choose to use cable clips or cleats These can be used for many differing wiring systems; the clips or cleats themselves vary by design, but the principle behind their use is basically the same

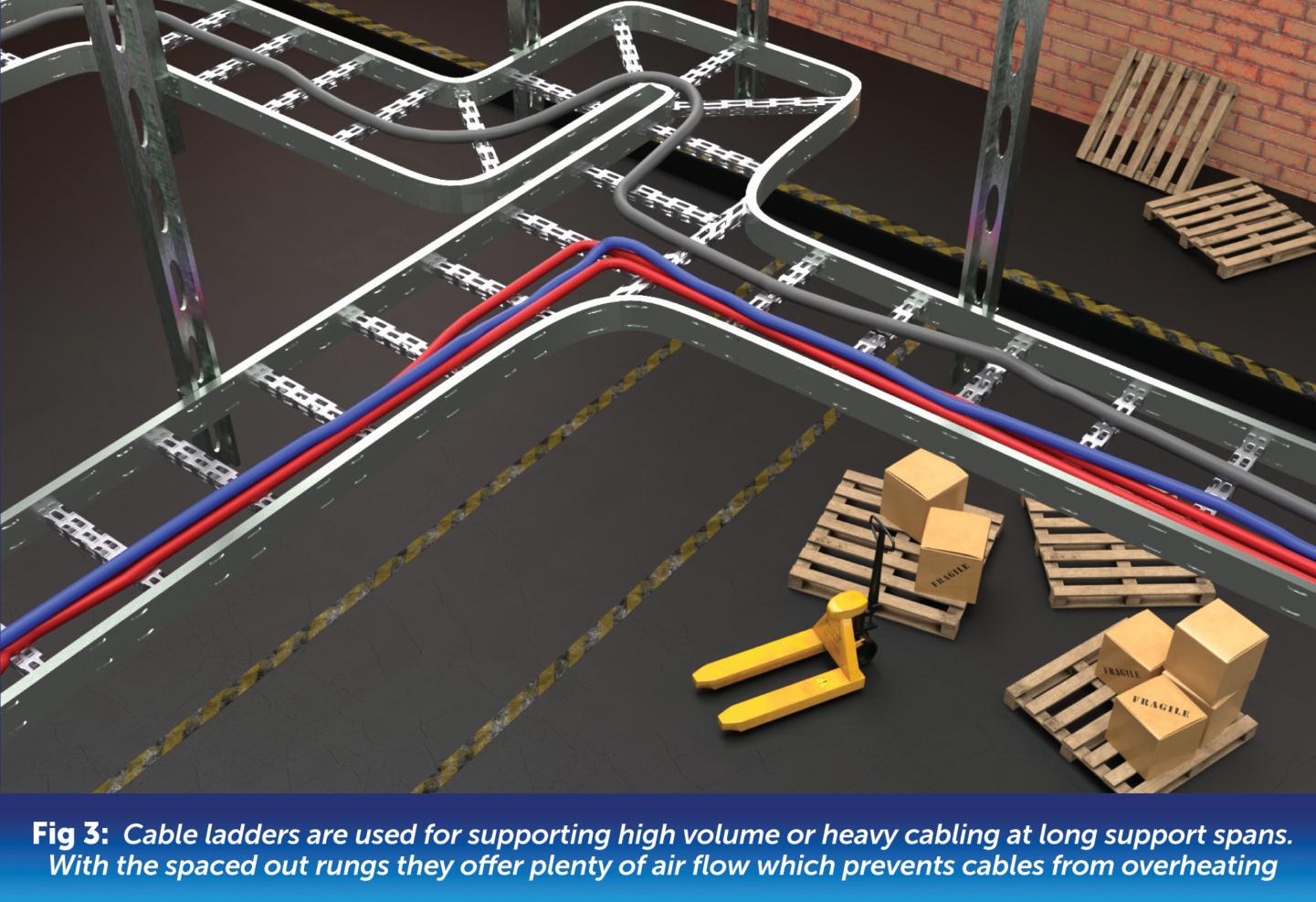

For heavy duty and high volume cables, cable ladders are typically used as a containment system, as shown in Fig 3

When we use singles, 6491X and similar, these are only half of the system

As 6491X cable only possesses basic insulation and no mechanical protection, we have to install them inside suitable mechanical protection. We can’t call 6491X cable a system, unless we also refer to its mechanical protection part at the same time

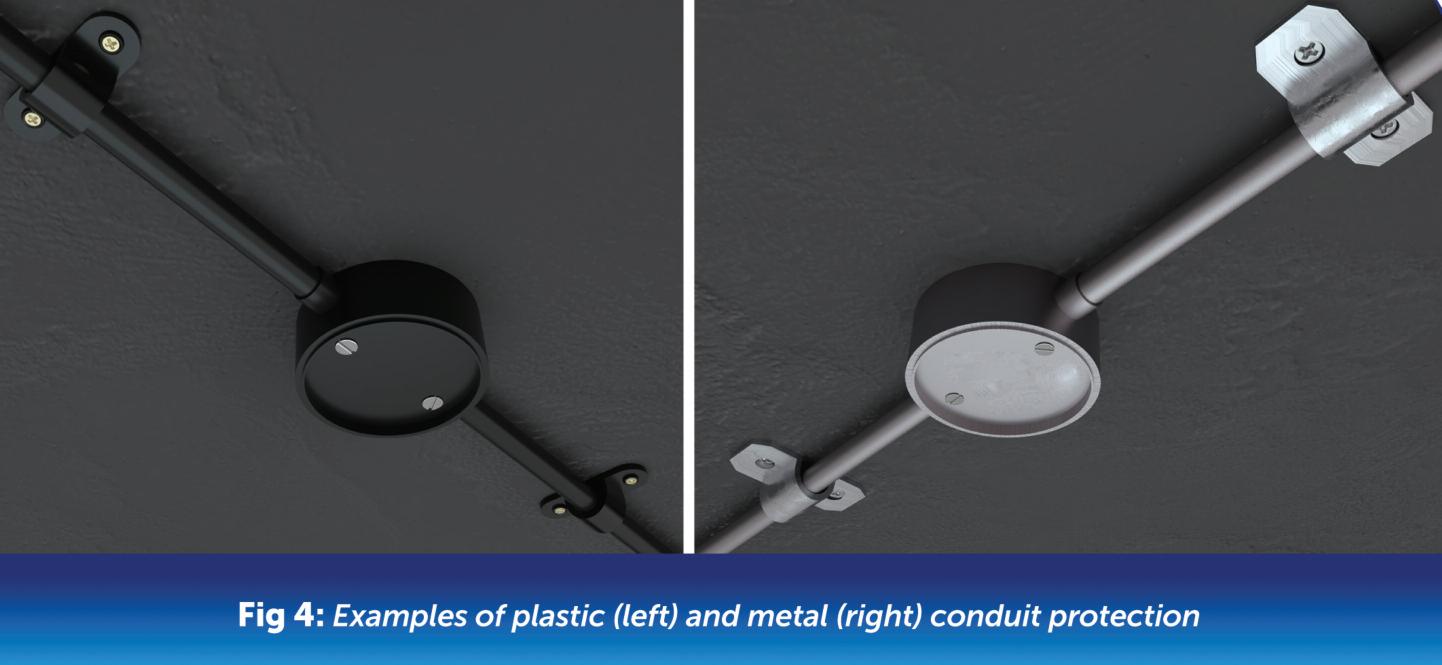

There are two basic principles for mechanical protection of 6491X single cables, which are conduit and trunking These again are split into two types of material construction, leading to four distinct types in total

Fig 4 shows the two material types for conduit protection, metal and plastic

For 6491X to be called a system, it needs to be referenced with one of these four mechanical protection parts. These two mechanical protection parts of a system, conduit or trunking, although they serve the same purpose, have very different properties and skill sets needed to install them

Fig 5 and Fig 6 indicate the two material types of trunking, metal and plastic Indeed, the different materials used to construct each of them also have very different installation techniques and skill set requirements

We generally wouldn’t use a separate containment for 6491X/conduit systems, as the system itself is the containment. A conduit system, whether metallic or plastic, will use saddles to secure them, but these are considered to be integral to the wiring system and not optional We wouldn’t lay conduit or trunking onto a cable tray or basket, for example, as this is not a proper use of either piece of equipment.

Flexible metallic conduit is often utilised for connections to equipment, although there has been an increase in its use for connecting solid metallic conduit between expansion joints within buildings and similar

One thing to remember is that flexible metallic conduits are unsuitable for use as a cpc; therefore, any links between fixed metallic conduits would require earthing links to ensure the earth continuity of the containment system.

What about the cpc?

With metallic conduit and trunking, the structure itself takes on the role of the cpc, so only the line and neutral of the circuit are carried internally, with a connection made at the accessory to either the conduit or the trunking

Plastic conduit and trunking are obviously non-conductive, so the cpc for each circuit must be taken inside with the line and neutral conductors to each accessory served

one do I use?

A designer can use whichever they choose to, but will generally be driven by the following:

● Client needs or requirements

● Usage

● External influences

● Durability

● Accessibility for maintenance, repairs or alterations

Whichever method is used, the installer must possess the correct skills needed Complex wiring systems need high levels of competence and experience to ensure compliance with BS 7671.

Both plastic conduit and trunking arguably require less complex equipment and training to construct; however, they are not easy to install correctly Metal conduits generally require specialist equipment to install, and metallic conduits will likely involve powered cutters or tooling.

When dealing with containment, the same applies, although generally speaking, power tools will need to be used to install most cable tray and ladder products

Can you mix and match?

Mixed systems are often seen and indeed necessary, for example, when going from a trunking system to a conduit system to disseminate final circuits for point of use, etc

We also see cable systems inside trunking to reduce the need for

unnecessary containment, where the circuits wired in a cable system are limited. It’s usual to see the odd SWA, MICC or other such cables in trunking alongside 6491X singles, especially where modifications and alterations to an installation have been made

Things can get trickier with conduits, as the friction from pulling a sheathed cable system through them can damage them and any other 6491X singles in the same conduit

In both cases, the designer needs to take into account any thermal constraints, as a wiring system may have its current capacity impaired by the enclosed effects of being encased in a conduit or trunking Likewise, the thermal constraints of the 6491X conductors may be affected where a sheathed wiring system is introduced to

the same conduit or trunking

We can’t mix and match 6491X or similar singles by placing them on either a cable tray or ladder, as they would not have mechanical protection So, from a mix-and-match perspective, wiring systems can use trunking and conduit as a containment method if thermal constraints allow, but singles must be in either conduit or trunking.

Often seen as a domestic-only wiring system, PVC/PVC flat twin and earth, is actually far from it Twin and earth and similar variations are wiring systems in their own right, and can be used in commercial and industrial installations, where the designer sees fit

The only problem you will find is that

they are less flexible, given their solid conductors, below 4 mm2. Other than that, they can be used anywhere a similarly specified cable wiring system can be used, providing they meet the requirements for low smoke and fumes

We have several options for the type of installation method we use; each has its merits, drawbacks and varying levels of difficulty of installation This is beneficial as it gives the designer options to choose the best possible solution

Hager’s Technical Training Manager, Paul Chaffers, discusses the importance of providing installations with surge protective devices (SPDs) and looks at requirements and considerations of BS 7671:2018+A2:2022.

in our everyday life, we’re surrounded by electrical equipment which may contain sensitive electronic components Such products are vulnerable to transient overvoltages and can have their lifespan significantly reduced through degradation and damage. Understanding overvoltage protection can be very complex, but from an electrician’s point of view, the Wiring Regulations are now much simpler than previous editions that required complex thunderstorm risk assessments

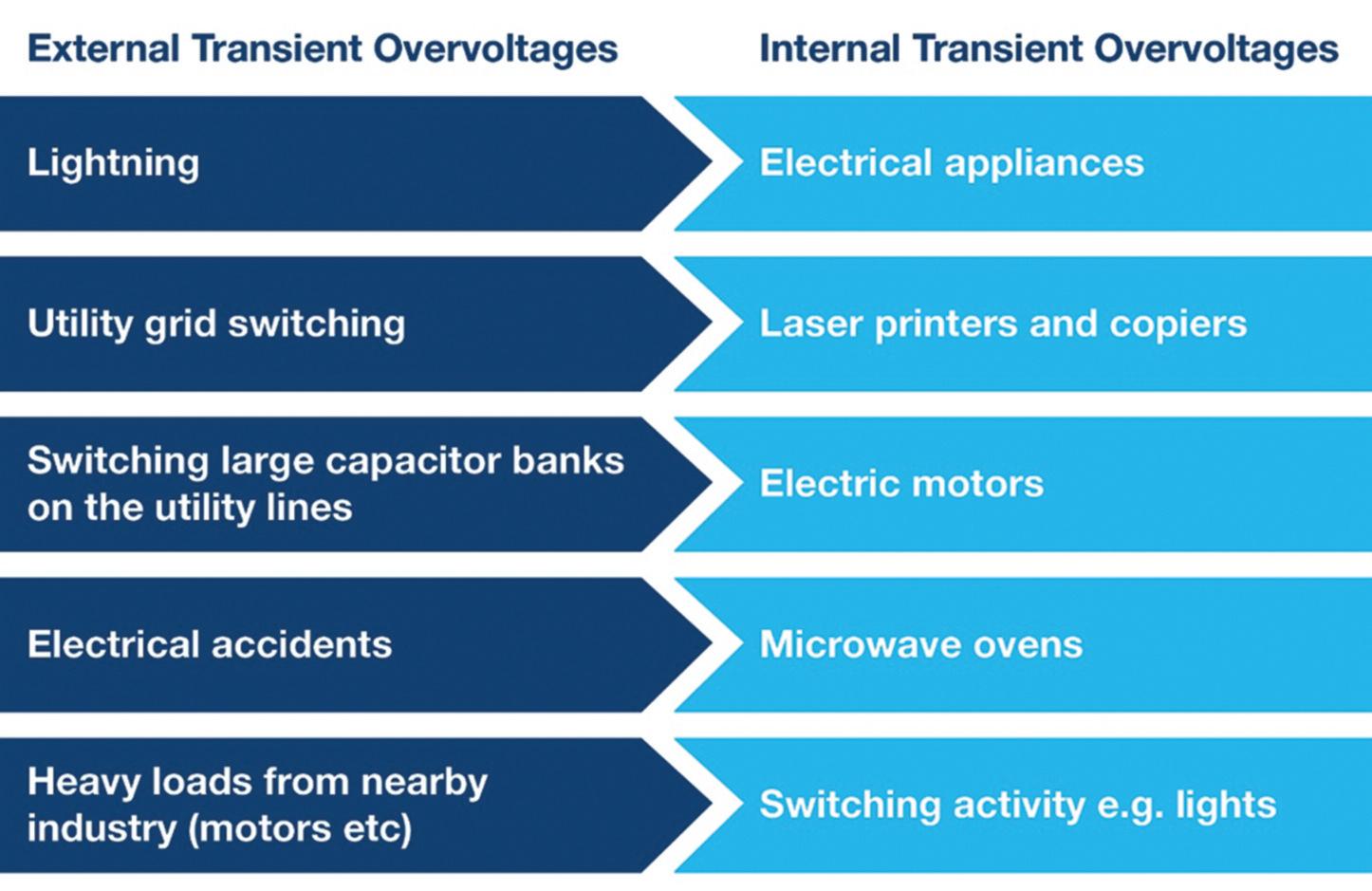

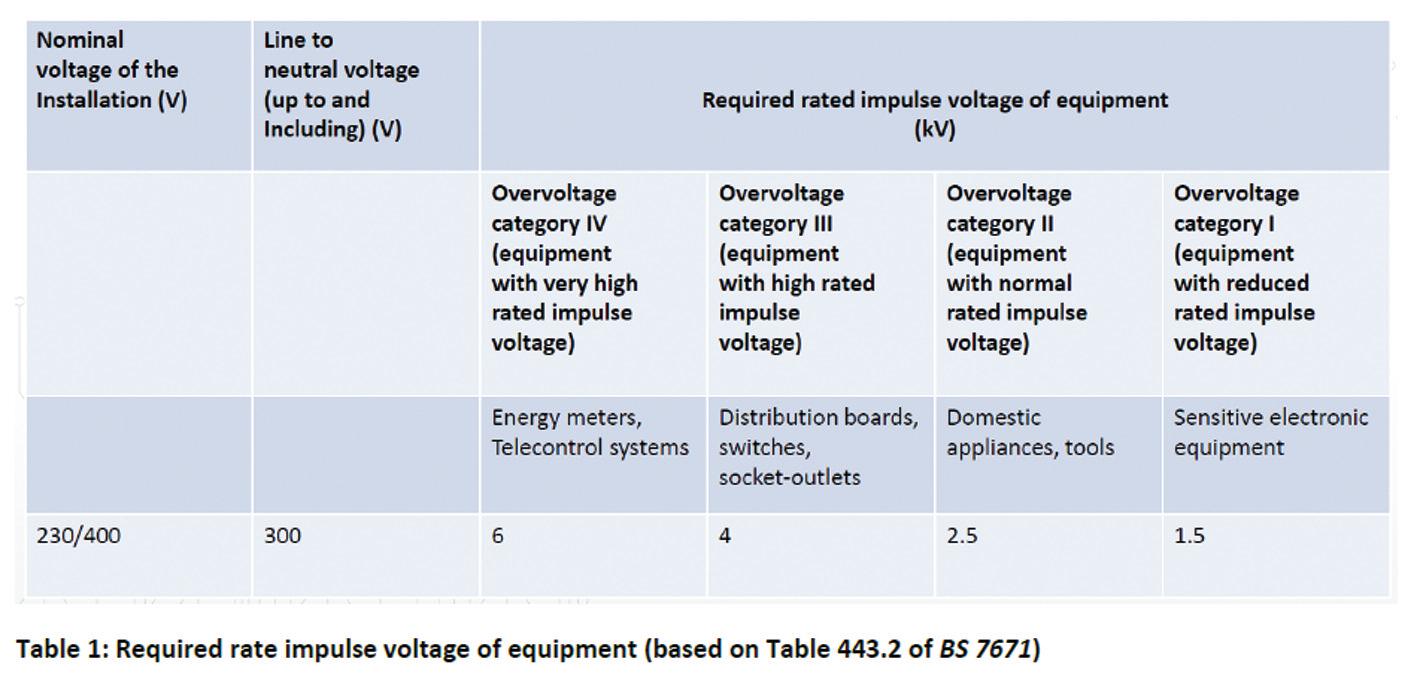

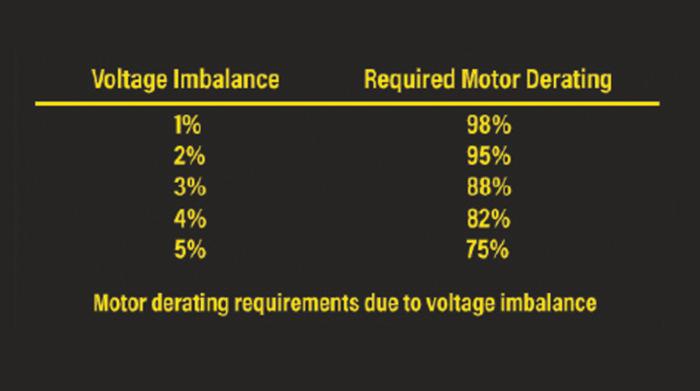

Voltage disturbances in the form of overvoltage can originate from outside of an installation or from within the installation itself In fact, about 35% of all transients come from outside the facility with the remaining 65% generated inside our homes and facilities – see Table 1 (pictured, right) for examples of where such transients may originate from

Understanding how to use BS 7671 correctly is the key to success Unfortunately, too often installers look at an isolated “Section” or “Part” of the Regs, without considering the general requirements that must always be applied An example of this would be only looking at Section 443 (Protection against transient overvoltages of atmospheric origin or due to switching) and not considering the Fundamental Principles.

BS 7671 Chapter 13 deals with Fundamental Principles, with Regulation 131 1 providing a number of conditions in electrical installations that may present a risk of injury Indent (iv) of Regulation 131 1 includes voltage disturbances (undervoltage and overvoltage) meaning

that where there is a threat of this occurring, protection is required

Furthermore, Regulation 131.6.2 requires persons and livestock shall be protected against injury, and property shall be protected against damage as a consequence of overvoltages

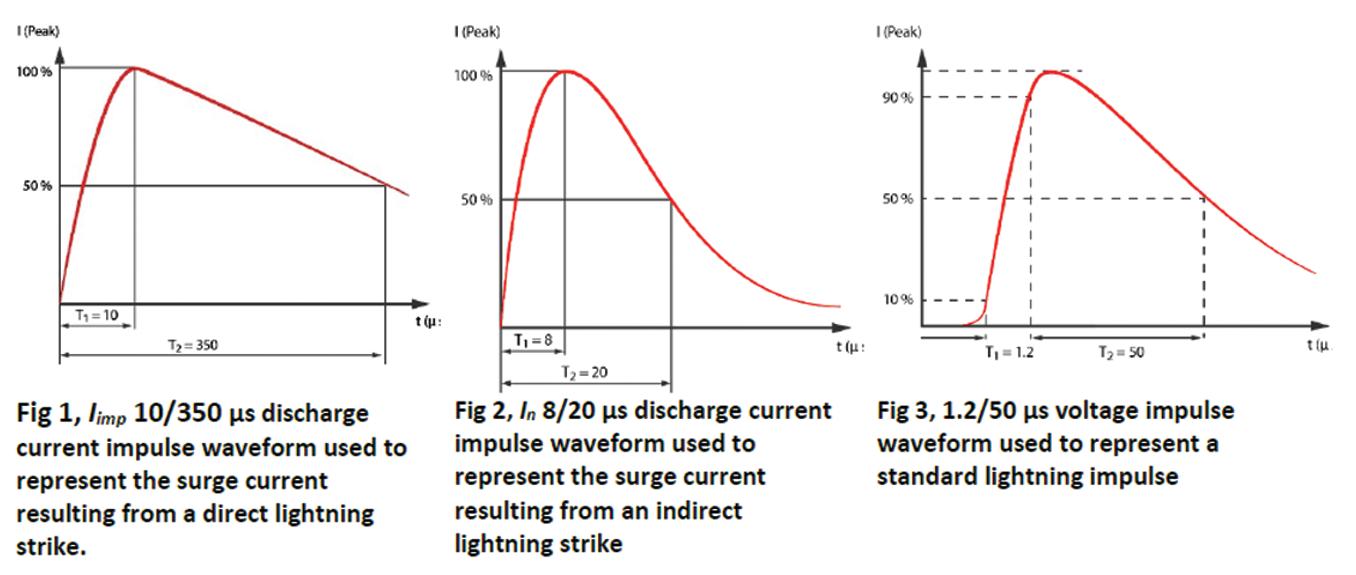

Part 2 of BS 7671 does provide some clarity for understanding the consequences of direct lightning strikes or indirect lightning strokes, as follows:

Direct lightning strike

Lightning strike impacting a component of the network directly.

NOTE 1: Examples of components of the network are: conductor, tower, substation equipment, etc

NOTE 2: Consequences of a direct lightning strike include the thermal, magnetic and

“Voltage disturbances in the form of overvoltage can originate from outside of an installation itself.”

mechanical effects of the discharge current as well as the surges resulting from its voltage drop along the discharge path

Indirect lightning stroke

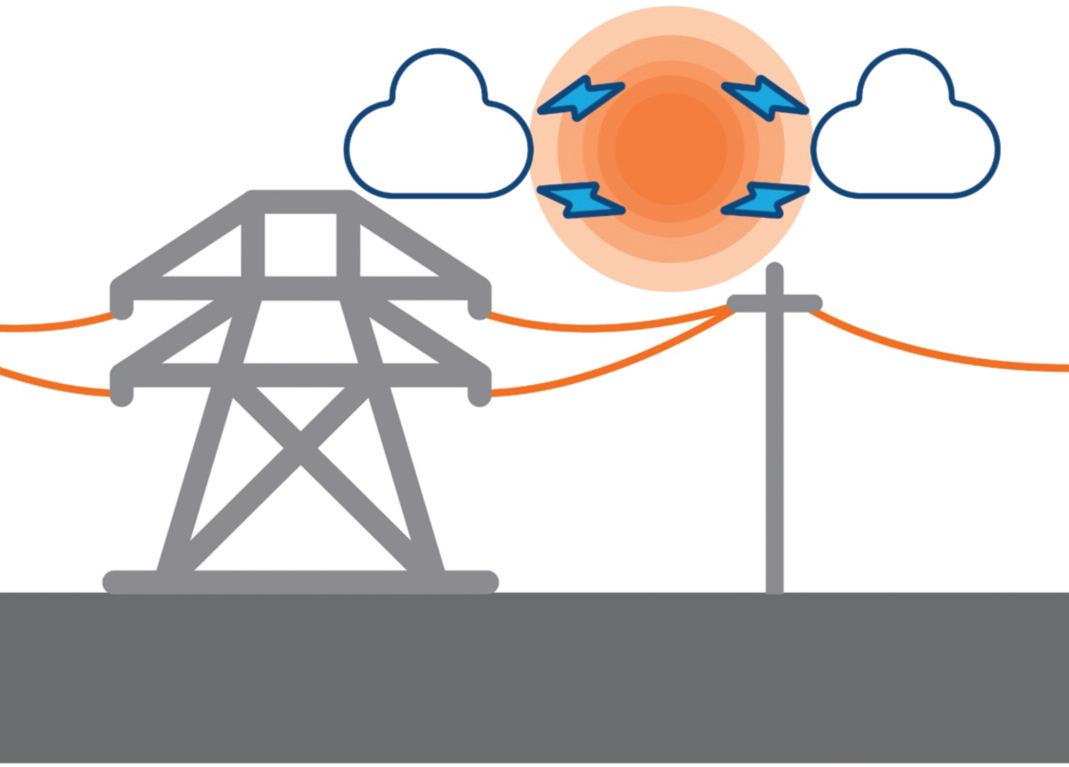

Lightning strike that does not impact directly any part of the network but that induces an overvoltage in that network.

NOTE: Consequences of an indirect lightning stroke for electrical installations are the associated overvoltages and the energy content of the incoming surge wave Should lightning strike near power lines (indirect stroke), then the magnetic effect of this lightning current rushing to earth

will induce a voltage on anything conductive (i e power lines passing through this magnetic field) This is known as inductive coupling – see Fig 1

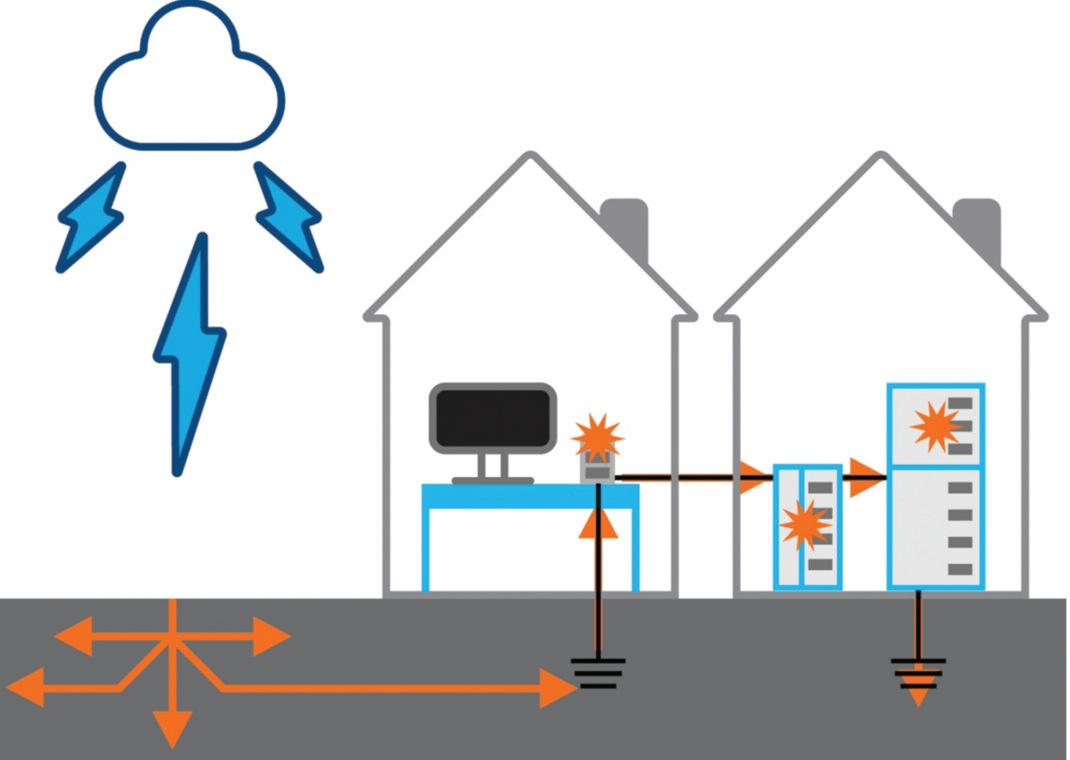

The power cable could even be underground and if the lightning struck somewhere nearby a massive amount of current will be injected into the ground

As the current flows away, a voltage will be induced; this is known as resistive coupling which is the most common cause of indirect atmospheric transient overvoltages

Such transients occur when a lightning strike raises the electrical potential of one or more of a group of electrically interconnected buildings, as illustrated in Fig 2 Examples of vulnerable interconnections include:

● DNO feed from substation to building

● Submains from building to building

● Supplies to external equipment, lampposts, CCTV, EV charge points etc

● Telephone lines

● Data and communication lines

Overvoltage control

Chapter 443 deals with protection against transient overvoltages of atmospheric origin, or overvoltages which are associated with switching activity within an installation, with Regulation 443.4.1 prescribing:

‘Protection against transient overvoltages shall be provided where the consequence caused by overvoltage could:

● Result in serious injury to, or loss of human life, or

● Result in significant financial or data loss

For all other cases, the default position is to provide protection against transient overvoltages unless the owner of the installation states that it is not required due to any loss or damage being tolerable If the client makes this decision, obviously they will be accepting the risk of equipment damage and any consequential loss

The modern home will have an abundance of electronic equipment which could easily be damaged by overvoltage and for this reason SPDs are often included

It should be noted that where the word “shall” is used in BS 7671, the implication of that Regulation is a requirement and normative

Overvoltages associated with lightning are severe, but overvoltages associated with switching are more common and in fact can be longer in duration and contain more energy than transient overvoltages of atmospheric origin

This means that where inductive or capacitive equipment is installed, it is likely that switching overvoltages or disturbances will occur. Regulation 443 4 2 deals with transient overvoltages caused by equipment and advises that protection against overvoltages shall be considered

Examples of inductive or capacitive equipment likely to cause such disturbances within an installation are:

● Motors

● Transformers

● Capacitor banks

● Storage units

● High current loads

The examples provided in Regulation 443 4 2 are associated with commercial installations, however consideration for protection against switching overvoltages is equally as important for residential applications. High inrush currents associated with the switching of LED light fittings is one example of equipment likely to cause voltage disturbance and a good example of the type of sensitive equipment that requires protection

Regulation 443 1 1 explains that switching overvoltages typically have a lower amplitude than transient overvoltages of atmospheric origin This means that where protection is provided for transient overvoltages of atmospheric origin, it will usually protect against switching overvoltages

Where the threat of lightning is low and no protection is provided, protection will still be required for switching activity For this reason, Hager recommends consumer units are fitted with Type 2 SPDs and can supply consumer units with SPD kits factory fitted, saving contractors time otherwise spent installing the individual parts

DOWNLOAD HAGER’S 18TH

EDITION AMENDMENT 2

BITESIZE GUIDE AT:

Chris Hudson, MD of Hudson Lighting, explains more about the importance of IP68 ratings for recessed outdoor lights and gives a general overview of IP ratings and what they mean.

Ingress Protection (IP) ratings are crucial for understanding the environmental resilience of electrical fixtures, especially outdoor lighting An IP rating consists of two digits, indicating the device's resistance to solids and liquids, respectively However, the specific requirements for outdoor recessed lights demand a higher level of protection, with IP68 being the ideal choice Before we delve into why IP68 is vital for recessed lights, let's overview the IP rating system:

● IP00: Offers no protection against contact with any object or ingress of water.

● IP10 – IP40: Offers protection against objects larger than 50 mm (IP10) down to 1 mm (IP40), but no water resistance

● IP50 – IP60: Fully dust-protected, but offers no protection against water ingress

● IPX1 – IPX4: No protection against dust ingress but offers water protection against vertically falling drops (IPX1) up to splashing water from any direction (IPX4)

● IPX5 – IPX6: Still no dust protection, but can withstand water jets (IPX5) or powerful water jets (IPX6)

● IP5X – IP6X: Fully dust-protected (IP5X) to dust-tight (IP6X) but offers no water protection

● IP65 – IP66: Dust-tight and can resist water jets (IP65) or powerful water jets (IP66).

● IP67: Dust-tight and can withstand temporary immersion in water up to 1 metre

● IP68: Dust-tight and can endure continuous immersion in water beyond 1 metre Recessed outdoor lights often face more strenuous conditions, potentially sitting in/under water for extended periods – conditions that would severely challenge IP66 or IP67 rated lights

While IP66 and IP67 lights offer protection against powerful water jets and temporary immersion in water, neither is suitable for prolonged water exposure, typical for recessed lights That's where IP68 comes into play

IP68 rated lights are dust-tight and can withstand continuous immersion in water beyond 1 metre. This makes them an ideal

choice for recessed outdoor lights It ensures your lighting investment withstands the elements and continues to perform optimally, even under challenging conditions While the difference between IP67 and IP68 may seem minor, it's this small distinction that significantly impacts the lifespan and performance of your garden lights.

SECTION 1 ENDS! SCAN THE QR CODE TO CLAIM YOUR CPD CREDIT FOR

The aim of this article from the experts at NICEIC is to explain the operating characteristics of the protective multiple earthing (PME) earthing facility, a type of TN-C-S system, which is commonly provided for both new and existing electrical installations.

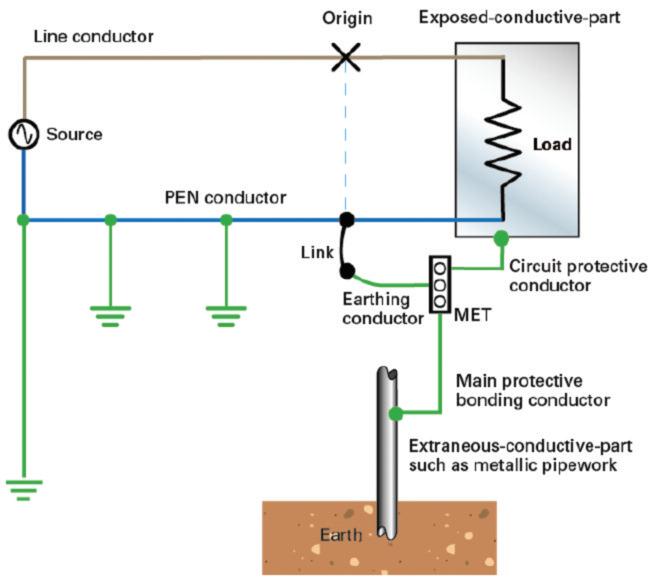

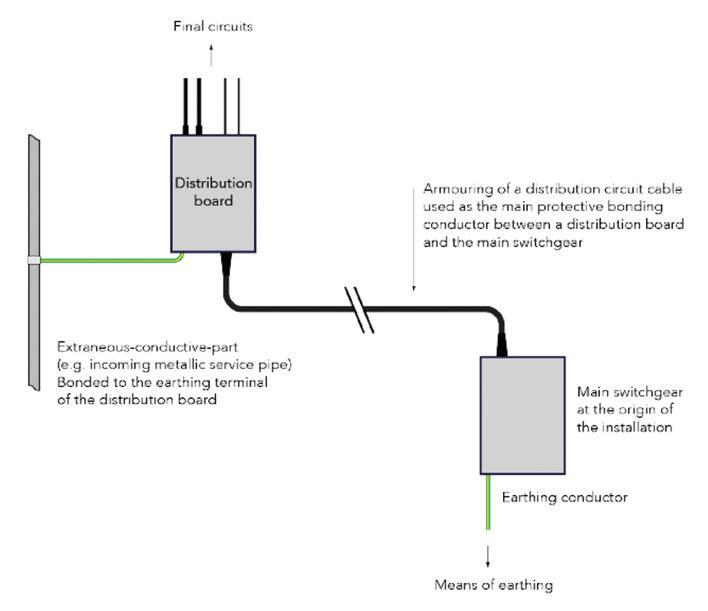

In a PME arrangement the supply neutral conductor functions as both protective and neutral conductors and is connected to multiple earthing points along the route of the supply network, as shown in Fig 1

The supply neutral conductor of a PME earthing facility – often referred to as a PEN (protective earth and neutral) or CNE (combined neutral and earth) conductor –is terminated at the distributor’s switchgear (cut-out) where connection of the earthing conductor to the supply neutral is achieved by means of an internal link provided by the distributor

Regulation 543.4.1 states that within an installation PEN conductors shall not be used, except where one of the conditions described in regulation 543 4 2 is met Therefore, separate neutral and earth conductors must be used within the consumer’s installation

Because the supply neutral is connected to earth in a PME system, the fault return path for both line to earth and line to neutral faults is via the combined

“ ... a PME system is not permitted in hazardous locations such as petrol stations where there is high risk of ignition of explosion.”

Fig 2. Open-circuit in the PEN conductor

conductor Using the combined conductor in this way has the advantage of providing the return path with a low impedance, therefore allowing for rapid disconnection of circuit protective devices under fault conditions

The Distribution Network Operator (DNO) will typically specify a significantly lower maximum external fault loop impedance Ze for a TN-C-S system than for a TN-S system of the same current rating

The returning current in a PME system has two possible paths, through the combined conductor and the general mass of Earth Depending on their relative impedances, some current, often referred to as neutral current diversion (NCD) or circulating neutral current, may return via the general mass of Earth For this reason, a PME system is not permitted in hazardous locations such as petrol stations where there is high risk of ignition or explosion. Other issues relating to a PME system include the following:

A small voltage difference may exist between the PME earthing terminal at the origin of the installation and the general mass of Earth under normal conditions and is dependent on the distribution network configuration and loading conditions

This small voltage above Earth potential could, under certain circumstances result in a ‘perceived shock’ for a person simultaneously in contact with an exposed-conductive-part

or extraneous-conductive-part and ‘Earth potential’. Such effects may occur in locations where a reduction in body resistance is likely due to the presence of water such as a shower area within a sports facility

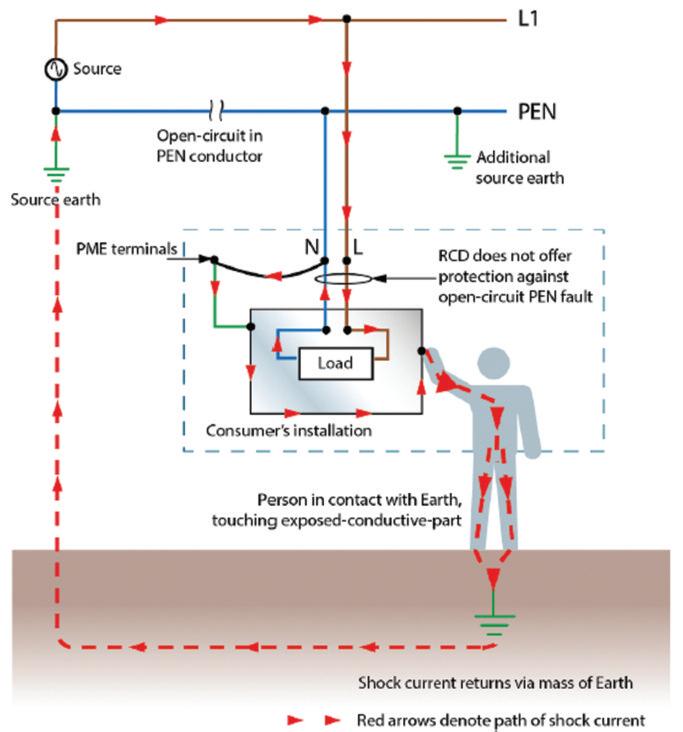

An open-circuit in the PEN conductor within the network, as shown in Fig 2, can cause the combined neutral/earth terminal at the consumer’s cut-out to rise above Earth potential, due to its carrying of load currents from installations downstream of the open-circuit. Consequently, the protective conductors at the main earthing terminal and subsequently all other protective conductors within the installation are also likely to rise in potential

Similarly, any metallic parts, such as gas and water pipework connected within the consumers’ installation are also likely to rise above Earth potential, creating a shock risk to any person in simultaneous contact with such parts and the general mass of Earth

There is also the potential risk of fire and thermal damage to cables, in particular, flat twin and earth cables where the non-insulated protective conductor typically has a smaller cross-sectional area (csa) than the associated live conductors

For this reason, it may be inappropriate to use a PME system arrangement in some premises and prohibited in certain other installations For example, regulation 9(4) of the Electricity Safety Quality and Continuity Regulations 2002 (as amended) prohibits the connection of a combined neutral and protective conductor to any metal work in a caravan or boat.

However, connection to the PME terminal is permitted for fixed buildings of the location such as offices, restaurants or shops, although it must not be used for the caravan or boat mooring supplies

To reduce the risks linked with a PME, the combined conductor is earthed at

“ ... any metallic parts, such as gas and water pipework connected within the consumers’ installation are also likely to rise above Earth potential, creating a shock risk...”

multiple points along the network and bonding is provided within the consumer’s installation, in accordance with BS 7671

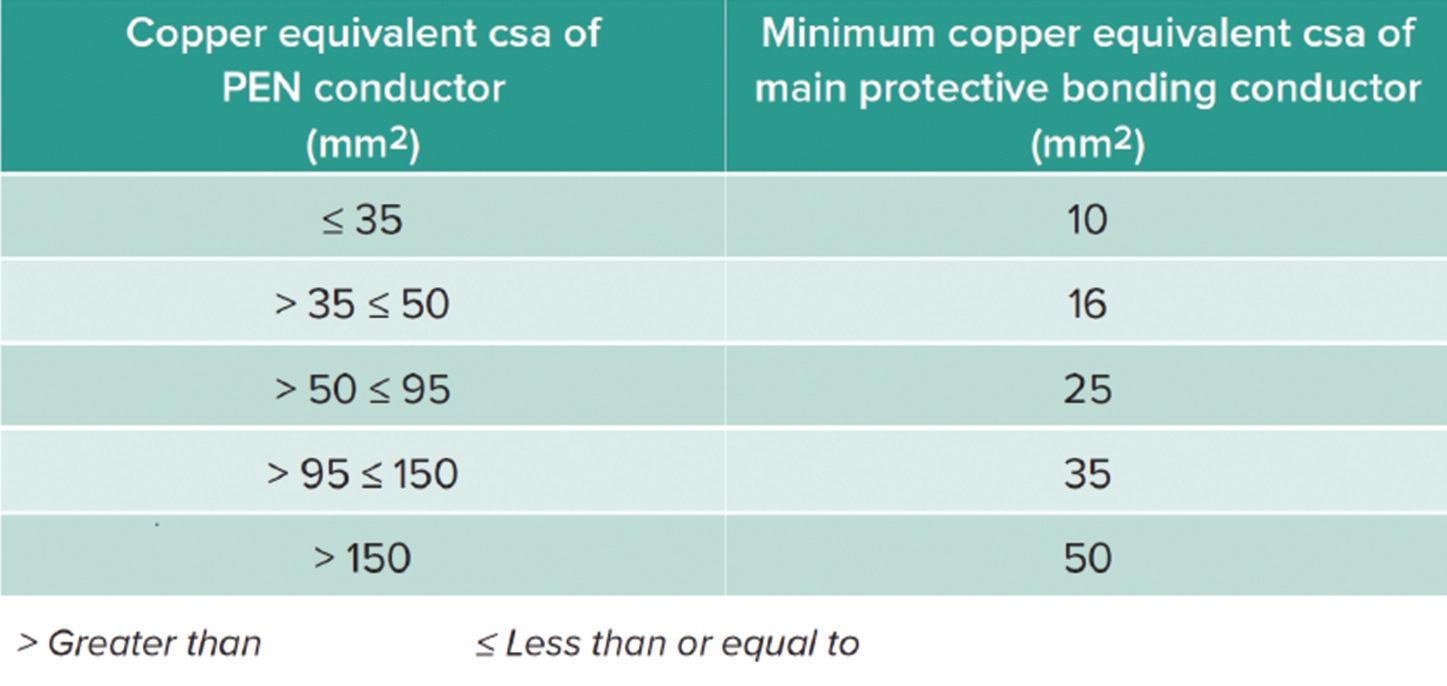

Due to the low earth loop impedance and increased fault currents within a consumer’s installation, typically associated with PME, all main protective bonding conductors must be sized in relation to the PEN conductor of the supply and Table 54 8 of BS 7671, reproduced in Table 1 However, in some cases the local distribution network conditions may require a larger conductor than those listed in Table 1.

Note: Table 54 8 of BS 7671 is also applicable for a PNB system arrangement, a variant to the PME system

Where the PME supply is extended from a dwelling to a detached outbuilding, such as a garage, these bonding requirements will also need to

be applied to any extraneous-conductive parts within that area.

Due to the practicalities for satisfying these bonding requirements at the load end the contractor may decide to convert the earthing arrangement within the garage to a TT system incorporating an earth electrode (542 1 2 3) combined with an appropriate RCD (411.5.2).

Although the TT system earthing arrangement provides less onerous conditions for bonding than that associated with PME, it also presents its own set of issues There is a potential risk of causing damage to other buried services when installing earth electrodes. In addition, the difficulties in providing suitable electrode separation from other buried metalwork connected to the supply PEN conductor

Although the distributor may have initially provided a PME earthing arrangement for an installation, where an addition or alteration is to be made it is the responsibility of the installation designer to assess its suitability and adequacy for the altered circumstances. Where necessary, alternative means of earthing, such as a TT system earthing arrangement, may be used

‘DR. ZZEUS’ TOM BROOKES, md of zzeus training and CHAIRMAN OF THE FSA, ANSWERS YOUR QUESTIONS RELATED TO FIRE SAFETY COMPLIANCE.

In a previous column (December 2023), I answered a question related to the skills of fire alarm and security installers and whether some of the old skills have been lost.

This gave advice on how to measure the resistance of a cable and also how to calculare the resistance of a 1.5 mm standard fire alarm cable.

This time around we’re going to answer a final question that relates to the subject: how do you take an insulation reading on a fire cable?

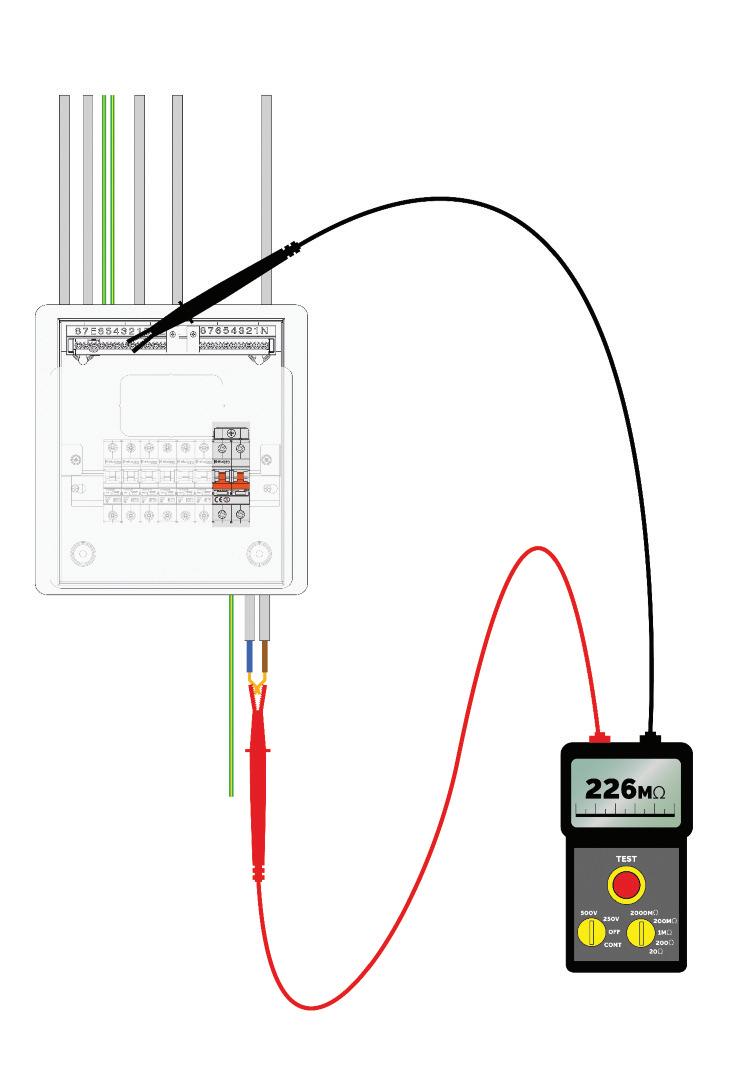

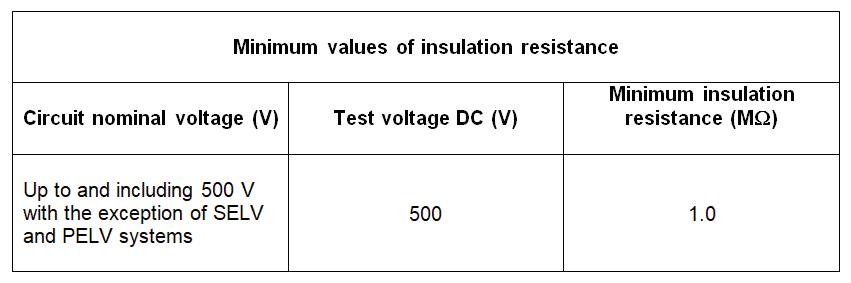

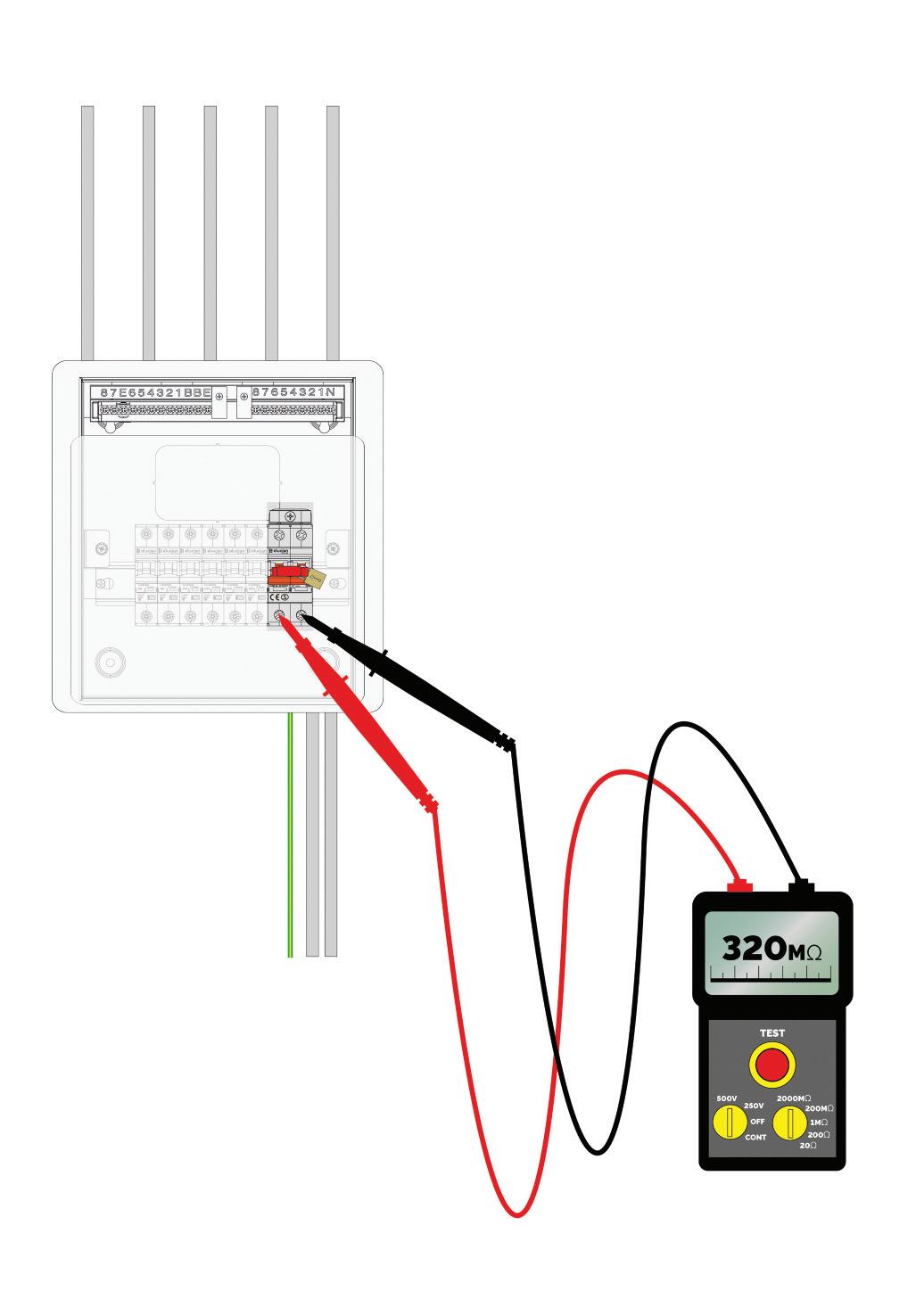

As stated previously, BS 5839-1 clause 38 1 states that all installed cables with a manufacturer’s voltage rating suitable for mains use should be subject to insulation testing at 500 V DC Insulation resistance should be measured between each conductor and earth and achieve no less than 2 MΩ.

It continues to say that on completion of the installation work, where maximum circuit resistance for any circuit is specified by the

manufacturer or supplier, measurement of the resistance of every such circuit must be documented

At Zzeus Training, this is standard day three practical electrical testing, but it may appear that some training providers are not doing this The standard is very clear: if you install a fire cable, you must test it

Insulation resistance testing

Resistance is a measure of how difficult it is for current to flow and is measured in units called ohms (Ω)

The insulation resistance test definition is the measurement of total resistance between any two points separated by electrical insulation This measurement identifies if, down the length of the tested cable, the insulation between the cores is in good condition The higher the reading, the better the insulation is.

The standard allows 2 MΩ as a minimum reading; however, on brand new soft skin fire cable, I would expect to see a reading greater than the meter

can calculate The new cable with a 2 MΩ reading has got a serious problem

This test needs to be done with no devices on the circuit because it will put 500 V DC through the cable, which may damage equipment or indeed shock a person

Testing for insulation resistance is very simple with a multifunction tester:

Step 1

Attach the live lead to your first core and attach the earth lead to the second core

Step 2

Select ‘Insulation Testing’ on the meter and ensure the test voltage is set at 500 V DC

Step 3

Press the test button, keeping your fingers away from the test leads and cable

The results will measure the resistance in megohms (millions of ohms) Remember, the higher the number, the better the insulation!

DO YOU HAVE A QUESTION YOU'D LIKE ANSWERED? EMAIL YOUR QUERIES TO: TOM@ZZEUS.ORG.UK

GET MORE DETAILS ABOUT ZZEUS TRAINING AND THE RANGE OF COURSES ON OFFER AT: WWW.RDR.LINK/EAZ014

Steve Dunning, Managing Director of Martindale Electric, explains the importance of safe isolation and why using the right equipment is an absolute must.

Safe isolation procedures are necessary to ensure that workers on-site are not exposed to danger when working on or near live electrical systems There have been incidents where failure to use safe isolation procedures has resulted in injury or, in the worst cases, death

Selection and use of the right equipment is one of the most important parts of the procedure. Firstly a voltage indicator with the means to prove it is operational, usually by using a dedicated proving unit Secondly, lock off items suitable for the circuit being tested and signage to warn others Failure to use the correct equipment and procedures can result in a circuit inadvertently remaining live.

Locking off devices are either supplied as individual items or, more generally, as kits There are many kits and combinations available, however a basic starter set should always include a selection of MCB and breaker locks, a padlock with a unique key or combination, a hasp for when more than one person is working on a system, plus an array of lock out tags and warning labels

For the locking off procedure itself, where a distribution board switch or other means of disconnection is used, this should be locked in the ‘off ’ position using a suitable lock with the addition of signage to advise others of the activity The key or combination lock should be the responsibility of the person doing the work or someone delegated by them.

It is important that any padlock must have a unique key or combination held by the person carrying out the work to prevent anyone else from removing the lock and inadvertently activating the circuit A unique key lock provides the safest solution Once the breaker has been locked off correctly, a warning tag should be attached to clearly identify that

to voltage detectors to be used in contact with electrical systems up to 1000 V AC and HSE Guidance GS38 Electrical test equipment for use on low voltage electrical systems.

Proving dead needs to be done because the circuits to be tested may not be labelled correctly (or labelled at all) and it should never be assumed that a circuit or nearby circuits are dead because the isolation device is set to off.

Best practice is to use a dedicated voltage indicator and a voltage compatible proving unit when carrying out this procedure Importantly the voltage indicator must comply with BS EN61243 There is a variety of suitable equipment available on the market, including test lamps or more commonly voltage

Martindale VI-13800

or VI-15000 Both these units include a high wattage resistor in the probe to limit the current in the event of damage to the cable. It is important to note that the voltage indicator must be able to work without the need for a battery If a device needs a battery and is flat, you cannot prove the circuit is dead

The procedure for proving dead is to take the voltage indicator and check it against a known source, such as a proving unit, then test the circuit before testing the voltage indicator against the known source again to prove the tester has not failed during testing Whilst you can use a known live source to test your voltage indicator, a much safer method is using a dedicated proving unit matched to the

ng used. The reason is wn live source will only the LEDs on the tester, oving unit will ensure that anges are working, ding against incorrect a faulty LED. In addition, s a suitable live source icated proving unit is

ses against the use of and non-contact devices Multimeters are not oving dead process as it elect the wrong range a multimeter relies on unction fully, thus there aking a false “dead” circuit Non-contact also require a battery in and are often sensitive gnals, such as static It’s also not possible to y are working correctly ndard proving unit se units can be used to cables, they cannot used to prove dead.

elines well established solation kits readily mplementing safe cedures is neither pensive and has been es and avoid injury It’s pliance with Electricity at Work Regulations for safe working when installing and maintaining electrical equipment and systems

Electrical Safety First, in association with other industry bodies such as SELECT, has produced a guidance document that covers best practice for safe isolation (Best Practice Guide 2) This includes guidance on proving isolated equipment or circuits are dead by using suitable test lamps and voltage detectors, and is an extremely useful reference document

GET MORE DETAILS ON MARTINDALE ELECTRIC’S ALIVE CAMPAIGN AND ITS RANGE OF PROVING DEVICES AT: WWW.RDR.LINK/EAZ012

For every installation, regardless of the technology, there are requirements placed on the contractor to furnish the client with information on the products and how to use and maintain the system It is important to note that certain items are covered by legislation, British Standards, scheme requirements and consumer protection laws.

During any estimation or quotation for installation contracts, the client may request documentation to demonstrate that you have the relevant skills, insurance and accreditations to satisfy them that you would be suitable to carry out the

This may then form part of the handover documentation as a record that the client has selected the appropriate contractors, which they may need to demonstrate to third-party organisations, such as finance or planning departments

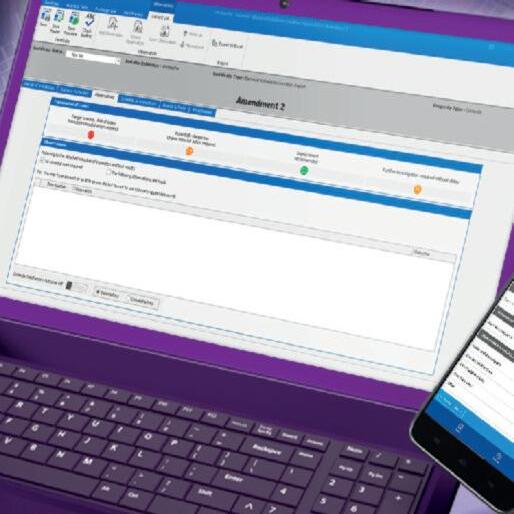

Once the quotation has been accepted, this is often followed by a purchase order and subsequent confirmation by the contractor The client would then expect a programme for the works, risk assessments and method statements for each task, as well as any particular site requirements, such as power shutdowns, delivery and access, as shown in Fig 1

The Construction Design and Management Regulations 2015 (CDM) are statutory regulations that are enforced under the Health and Safety at Work Act The creation of CMD was to establish higher standards in the management and control of construction and demolition work

CDM 2015 has been in force since 6 April 2015, replacing the 2007 CDM Regulations They lay out what people involved in construction work need to do to protect themselves from harm, including anyone the work affects, and for the first time, these regulations are also applicable to domestic installations The aim of CDM 2015 is to improve health and safety in the industry by helping you to:

● Sensibly plan the work so the risks involved are managed from start to finish,

● Have the right people, for the right job, at the right time,

● Cooperate and coordinate your work with others,

● Have the right information about the risks and how they are being managed,

● Communicate this information effectively to those who need to know,

● Consult and engage with workers about the risks and how they are being managed

Members should be aware that:

● All builders, whatever their size, will

have to create a construction phase safety plan for all building projects,

● All domestic projects will have to meet the same basic standards for the provision of welfare facilities as commercial projects,

● Any domestic projects where there has been more than one contractor must have a Health and Safety file presented at completion,

● There is a Health and Safety file/handover pack available, which should include ‘as built’ drawings or specifications of components that have been installed Conveyancing solicitors are likely to request this when a property is bought and sold,

● For home owners, CDM duties are passed to the contractor where there is only one, or to the principal contractor if there are more than one

Where there is more than one contractor, a principal designer will be appointed, and they will coordinate all matters relating to health and safety Where the principal designer changes or is not engaged to the end of a project, any responsibility for the file moves on and may rest finally with the principal contractor.

The principal contractor is responsible for operational site safety and passing information to the principal designer for the Health and Safety file On completion, the principal contractor will hand over the Health and Safety file/handover documentation to the client

There are some caveats associated with CDM, such as the duration and labour associated with the contract, such as:

● Lasts more than 30 days, and

● Has more than 20 people on-site, or

● Lasts more than 500 days

Although these types of contracts would not fall under CDM, as a contractor you will still be required to provide similar handover documentation to the client.

This is to allow them to have the information to enable them to operate, maintain and replace any components

The handover documentation, see Fig 2, should include all documentation relating to the contract, such as:

● Quotations,

● Variations,

● Payments and final settlement,

● Specifications,

● Detailing the extent of the work carried out,

● Health and Safety risk assessment and method statements,

● Certification/commissioning – this is dependent on the scheme ,

● Building Regulation Notifications, where applicable,

● Manufacturers’ warranties (all installed products, including software),

● Manufacturers’ instructions, including maintenance requirements,

● Diagrams and layout drawings for more complex contracts,

● COSHH data sheets for any products used within the installation

This information can take the form of a printed copy, PDF, shared file software or digital file There will also be a requirement for information to be retained in case the client seeks documentation or has a complaint or question regarding the work carried out

Another important area is the case of product recalls, which on occasions may affect a range of equipment and accessories.

As the installer of these products, the manufacturer will contact you regarding product recalls, so having information about where the equipment or accessories were installed is important

The handover pack should include details about product recalls.

It is extremely important that the client is provided with information on how the installation functions, maintenance procedures and replacement of equipment and accessories. Providing the handover pack allows you to discharge your duties to the client and maintain the essential ongoing client relationship

Have you dealt with problems with USB socket-outlets that have been faulty following insulation resistance testing? Jake Green, Head of Technical Engagement with Scolmore Group, aims to shed some light on the issue.

With USB socket-outlets, the charging unit is built into the back of the socket and this is sometimes fixed to the ‘on’ position This means that the switches on the socket that control the 13 A plug element have no connection to the USB charging point, with the result that it is permanently connected

This can cause problems when carrying out insulation resistance testing, as the electronic components of the USB charging unit are part of the circuit and therefore the 500 V that electricians use to test them could damage those components, resulting in a faulty charging port

The Click range of USB sockets has been designed to withstand the 500 V insulation test due to the nature of the circuitry built within the USB socket Chapter 64 of BS 7671 details the general requirements for initial verification, and Section 643 deals with the requirements for testing

Here we briefly consider the requirements for insulation resistance testing and the care that should be taken when testing after second fixing has occurred:

Insulation resistance testing

Insulation resistance testing is carried out to confirm that there are no inadvertent connections between live conductors, and between live conductors and Earth before

the installation is energised (643 3 1)

The insulation resistance test is a ‘dead’ test, and the normal supply should not be ‘live’ To this end the person carrying out the test should ensure that the circuits to be tested are isolated and the normal power cannot be energised inadvertently

The minimum required insulation resistance values in megohms is detailed in Table 64, although a value significantly in excess of these stated values is preferred (643 3 2)

Regulation 641 1 requires that every installation is tested both during erection and on completion before being put into service Insofar as this relates to insulation resistance testing, this means that tests should be carried out after first fixing (after cables have been installed and prior to equipment being connected) This test confirms that the installed cables are in a fit state.

The final insulation resistance test needs to be carried out after second fixing has taken place However, after second fixing it may be that connected equipment may influence the measurement or result of the test (643.3.3). Where this is the case, following the connection of equipment, it is permitted to reduce the test voltage to 250 V DC and to test between the live conductors (connected together) and Earth

Sensitive electronic equipment

The note attached to Regulation 643.3.3

indicates that manufacturer’s instructions may recommend some equipment needs to be disconnected, even when the test voltage is reduced to 250 V DC This may apply, typically, to accessories such as socket-outlets with USB connections and the like

Scolmore’s Click socket-outlets with USB ports do not require disconnecting

and may be tested between live conductors (connected together) and Earth at a test voltage of 500 V DC whilst still connected in circuit

Conclusion

Insulation resistance testing is an essential part of ensuring that prior to energisation the installation is safe. The tests verify that there are no inadvertent connections between live conductors and between live conductors and Earth

Care should be taken to ensure that any connected equipment is capable of withstanding the test voltages applied

Where there is a risk of damage or test results outside of the permitted range, it may be necessary to disconnect equipment prior to any test being carried out.

What is the ‘Electrician Plus’ campaign that I keep hearing about? Is it a new scheme I will need to join?

In short, no, it’s not an individual accreditation scheme

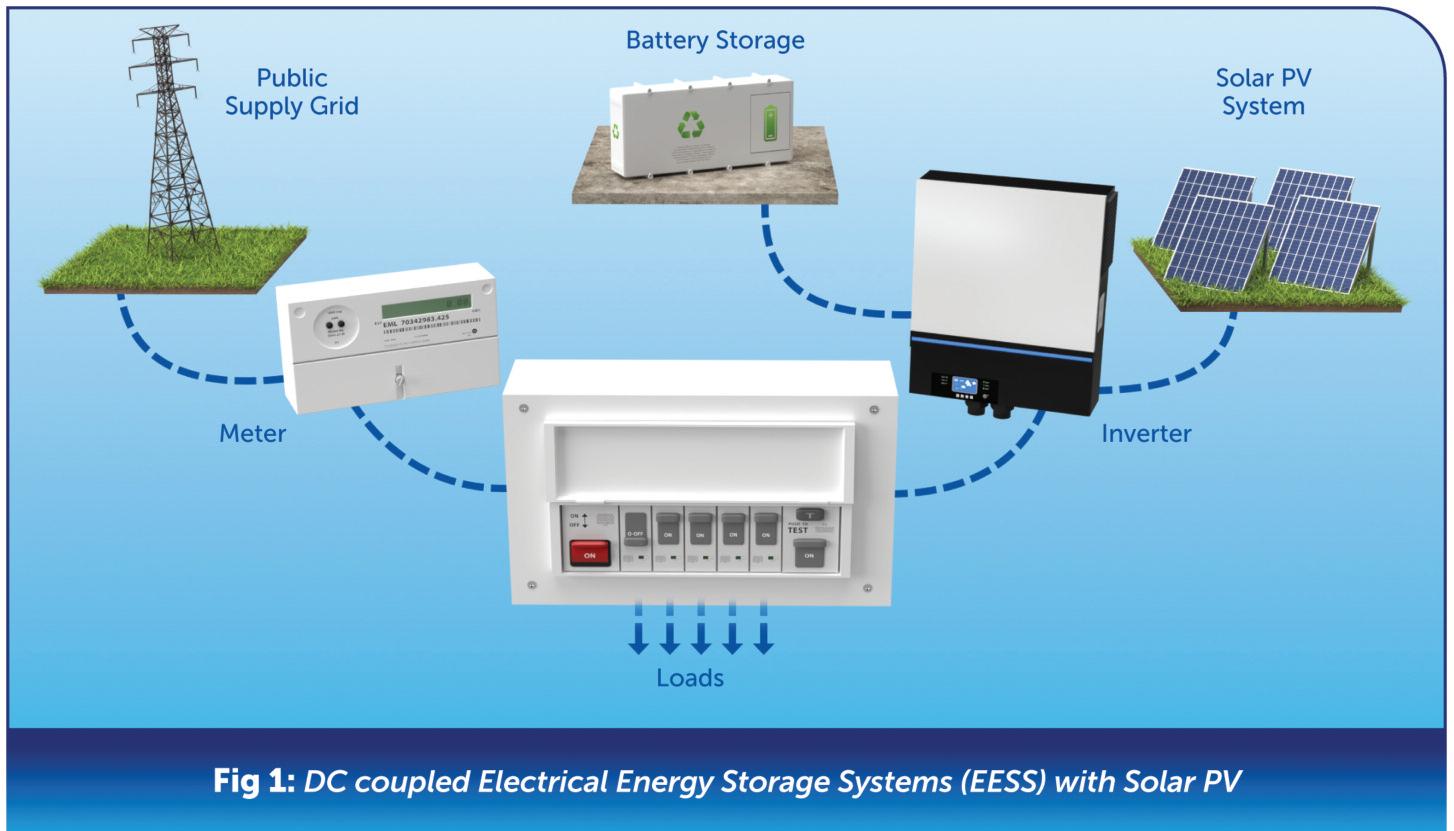

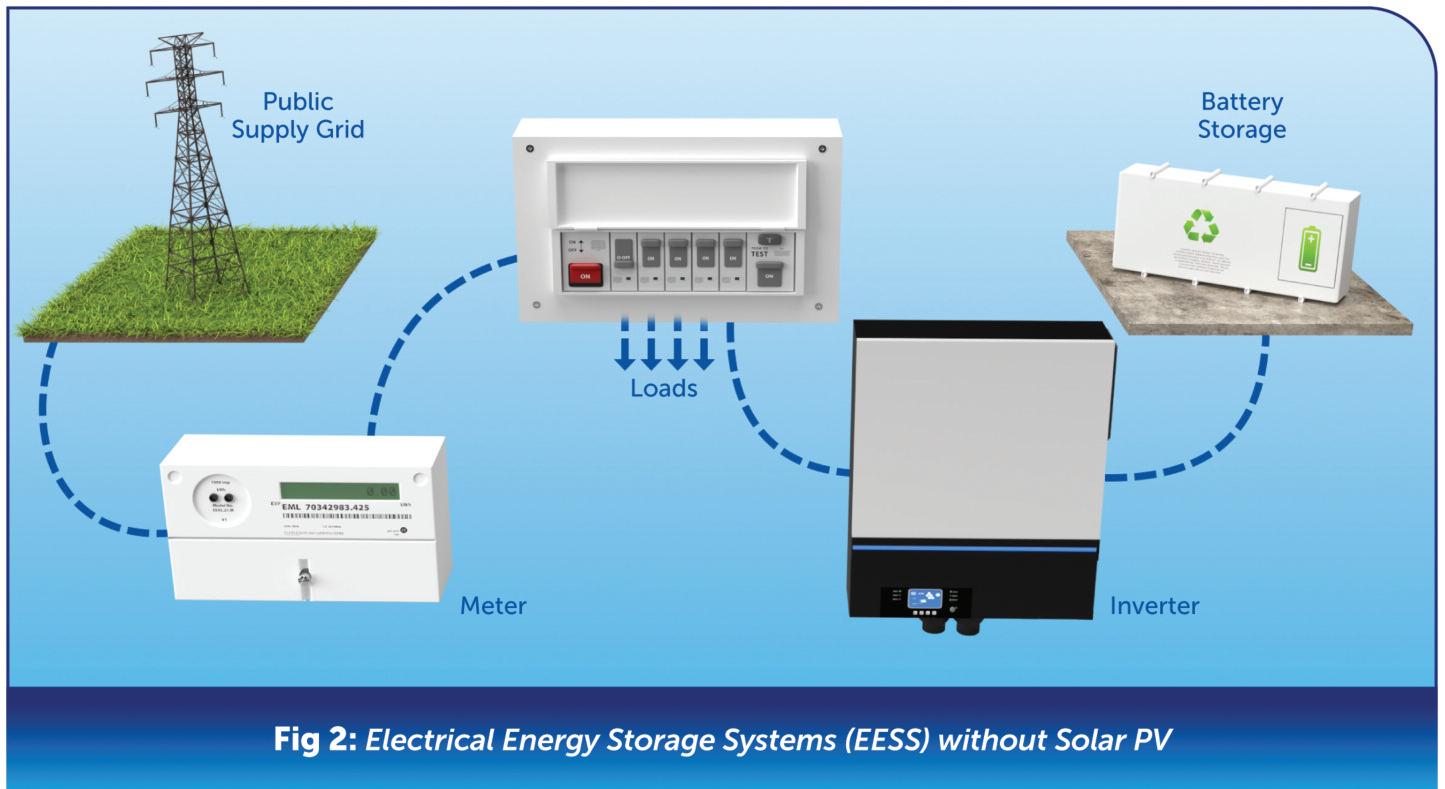

The term ‘Electrician Plus’ is a concept developed to highlight how the core skills of a qualified electrician are essential to low carbon technology installation. With underpinning core electrical competence, all that is needed is to top-up qualifications in relevant areas such as solar PV, electrical vehicle charging equipment (EVCE) and energy storage systems

It’s essential for public safety that anyone installing such technologies is properly qualified and competent Terms like ‘solar installer’ are not recognised as a separate occupation – those who undertake short courses in these areas without the underpinning core electrical competence can pose a public safety risk, and these people will be installing without robust training and assessment of their electrotechnical skills or knowledge

TESP is working closely with the Building Safety Regulator to finalise the development of the Mandatory Technical Competencies (MTCs) that underpin Competent Persons Schemes New low carbon MTC categories will align with the Electrician Plus model, supporting installation by qualified electricians

Once the MTCs are updated, the Electrotechnical Assessment Specification will also be updated The accompanying EAS Qualifications Guide will also reference valid low carbon qualifications

If you’re already a qualified electrician, there are top-up solar PV, EV and energy storage qualifications from awarding bodies such as City & Guilds, EAL and BPEC They’re designed so that only electricians who meet the industry Level 3 standard can enrol on these courses

The Electrician Plus logo will be used to endorse relevant qualifications to show they are industry approved in terms of content and assessment

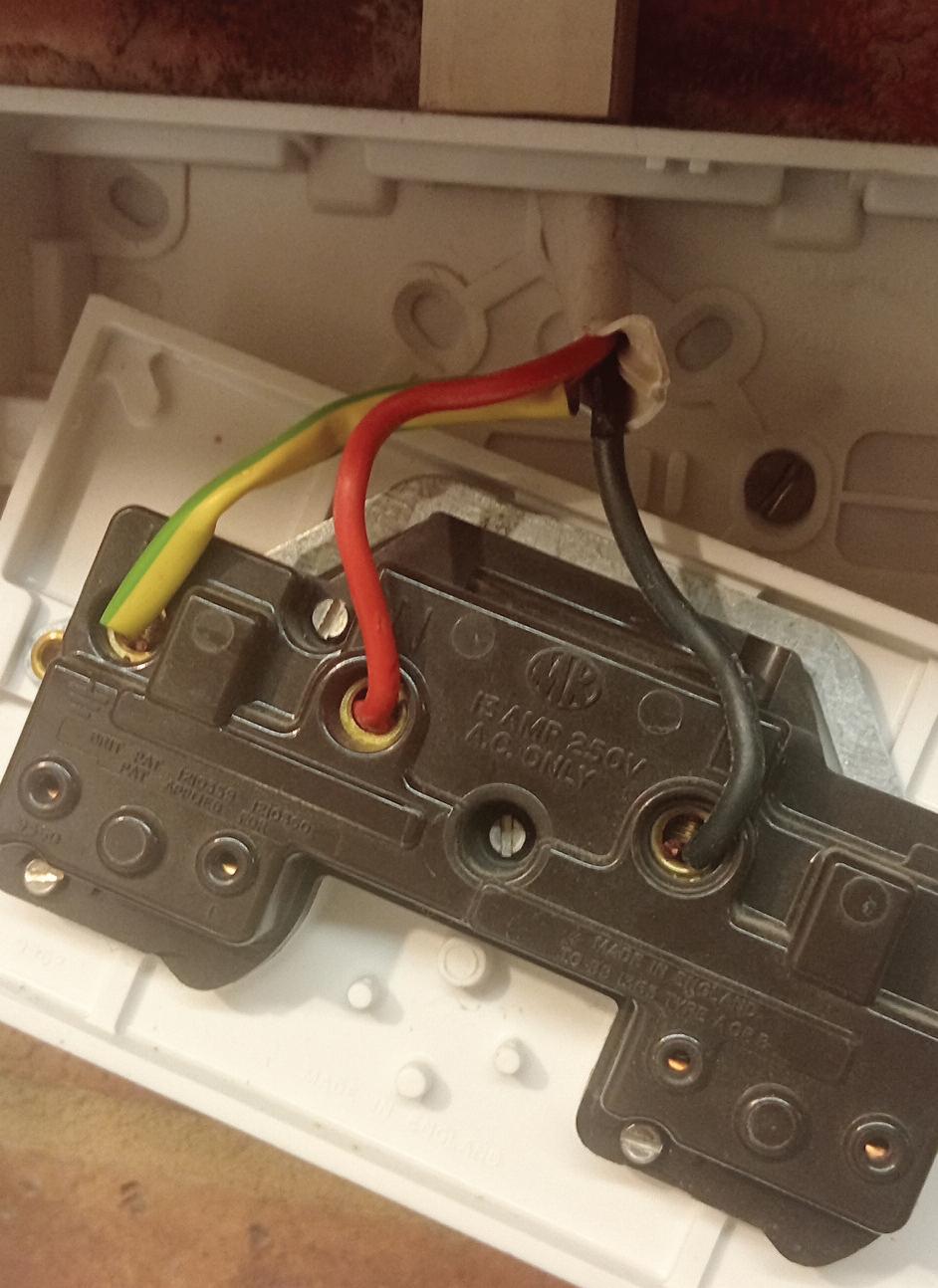

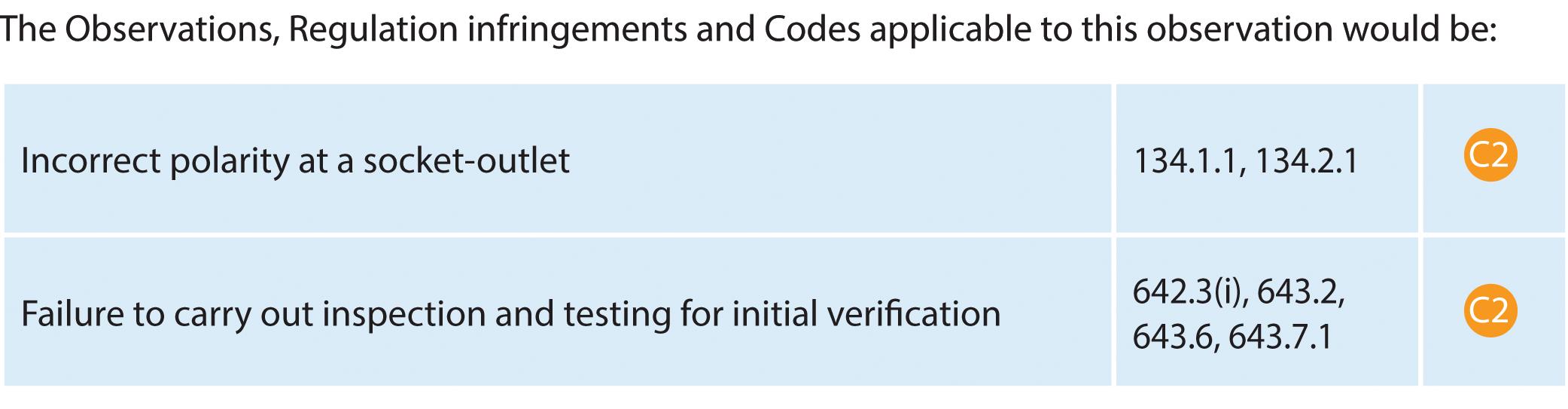

CHRISTOPHER ORTHODOXOU: THE CUSTOMER WAS WONDERING WHY EVERY TIME SHE PLUGGED SOME THING INTO THIS SOCKE T IT WOULD TRIP THE RCD!

This is a failure of the initial verification of the socket- outlet where the correct sequence of inspection and testing has not been carried out Par t of the requirements for inspection under Par t 6 for initial verification Regulation 642 3 (i) requires the check ing of the connection of conductors If this had been carried out then the incorrect termination of the line conductor into the neutral terminal and vice versa would have been noticed and corrected

The requirements for testing under Section 643 should have revealed the cross-polarity under several of the Regulations as follows:

● Regulation 643 2 Continuity of Conductors – R1 + R2 testing would have revealed the issue.

● Regulation 643 6 Polarity – this test would have shown that the line and neutral conductors were incorrectly connected at the socket- outlet

● Regulation 643 7 1 Ear th Fault Loop Impedance – this test would have highlighted that the polarity was incorrect

Unfor tunately, there are occasions when DIY enthusiasts dabble in electrical work without the k nowledge or experience, instead often relying on guidance from “How to Guides”

What would be inexcusable were if this work was carried out by a sk illed electrical person as they have paid lip ser vice to the requirement of Electricity at Work Regulations and BS 7671 requirements for electrical installations.

Updated for BS 7671:2018+A2:2022, NAPIT ’s EICR Codebreakers publication is purpose -written to aid contractors, inspectors and clients, and now includes updates to align with Amendment 2 of the IE T 18th Edition Wiring Regulations The book is the per fect technical aid for electrical professionals and their customers.

Need help with cracking those all-impor tant EICR codes? Ever y month the technical team at NAPIT will be studying your latest ‘Caught on Camera’ photos and offering advice on the next steps, should you find a similar installation. If you want the team at NAPIT to help crack your codes then send your pic tures through to us at: pe@hamer ville.co.uk

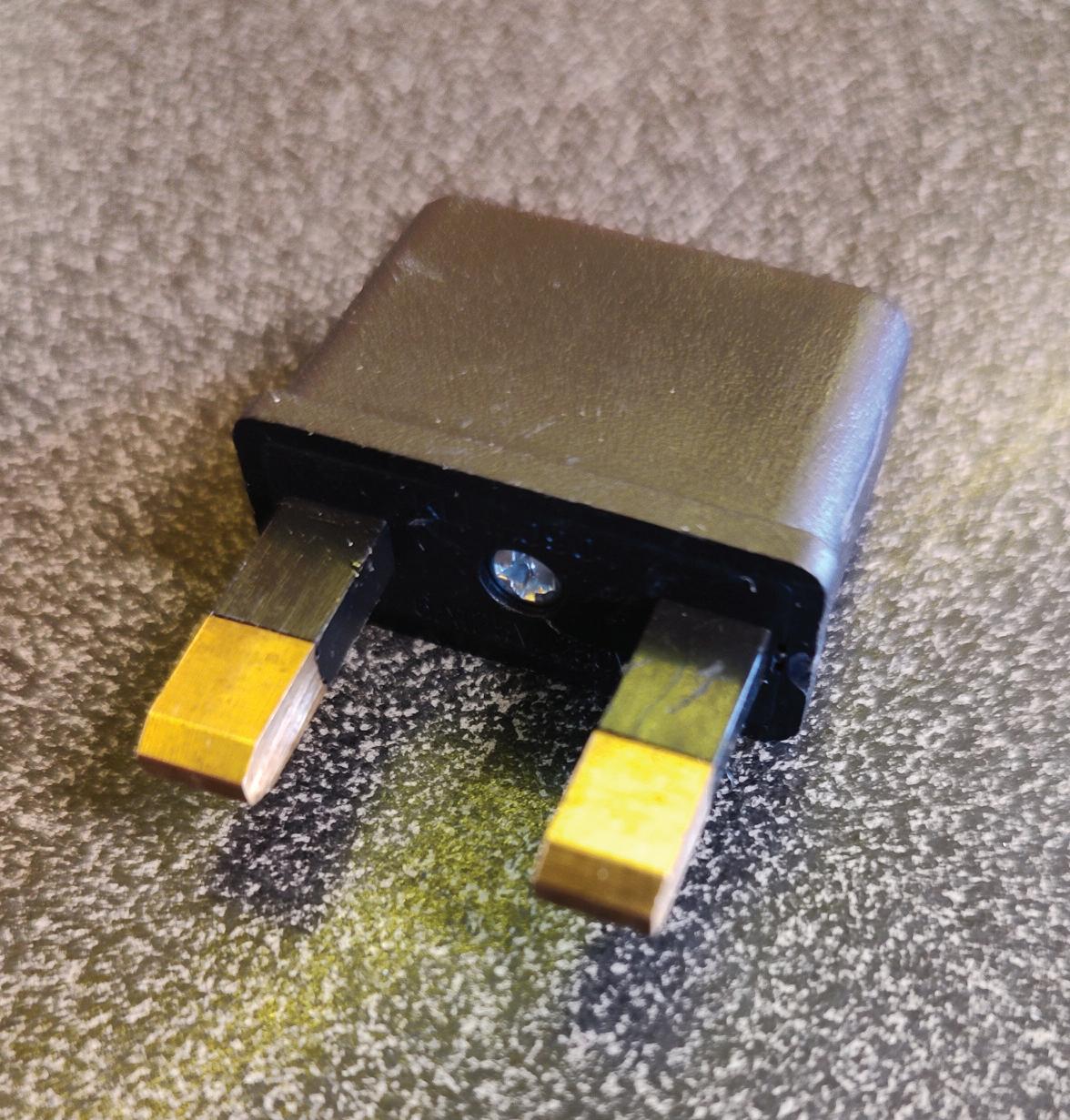

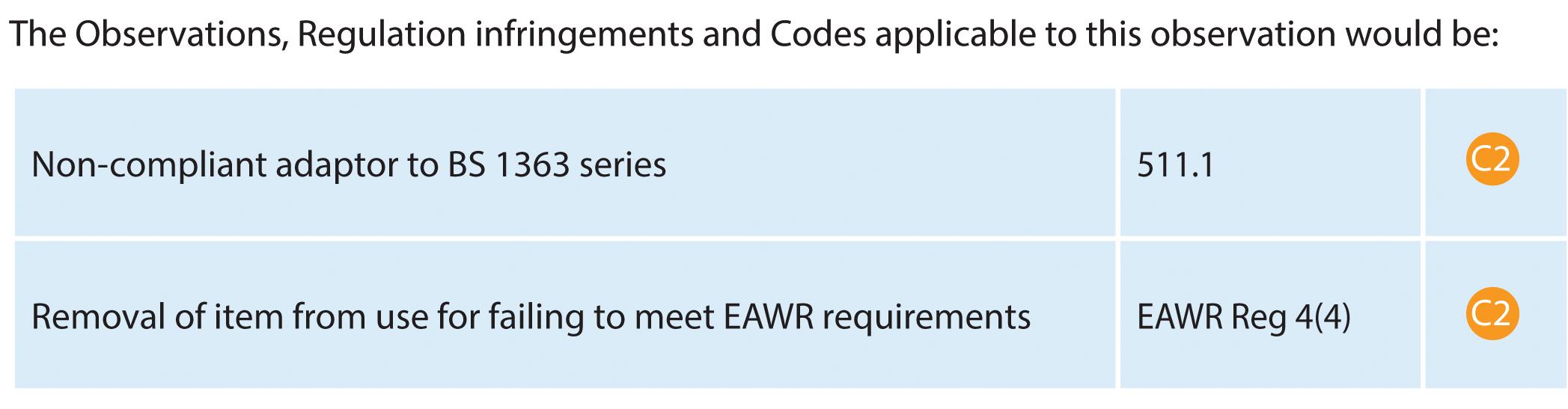

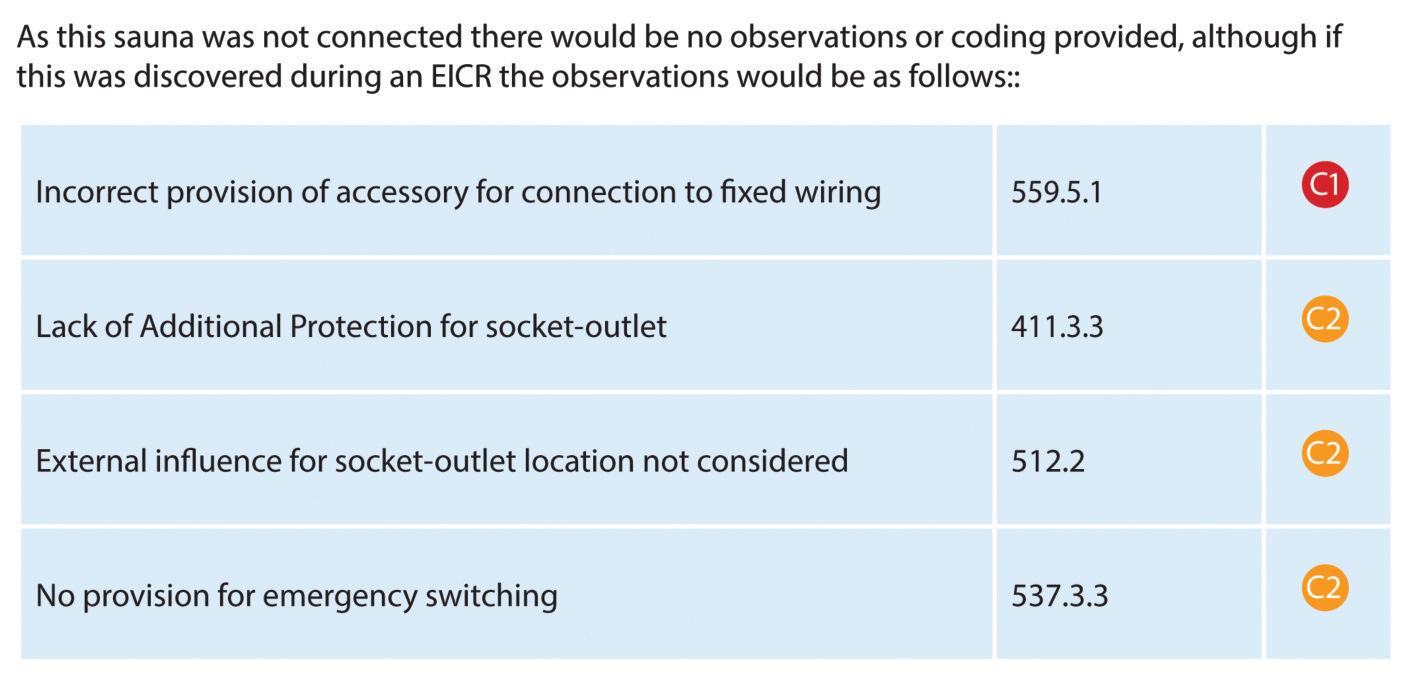

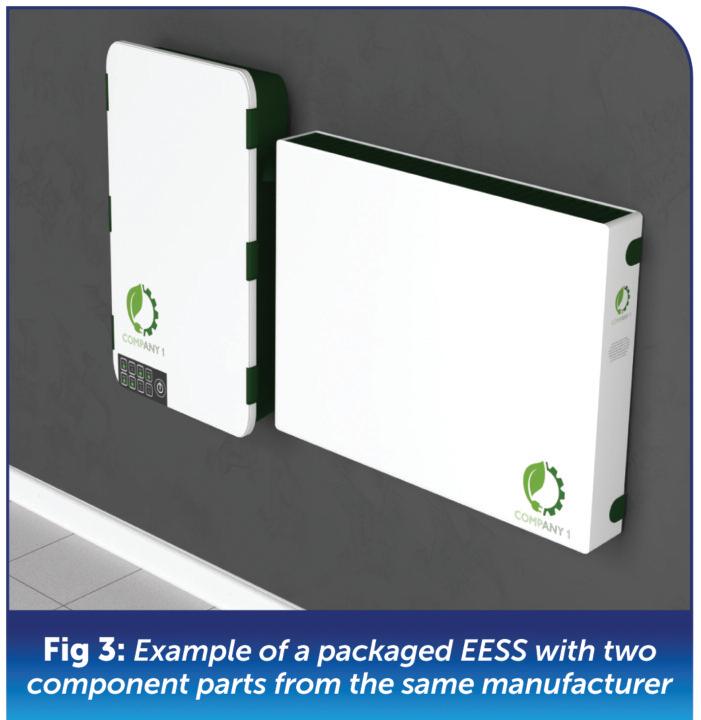

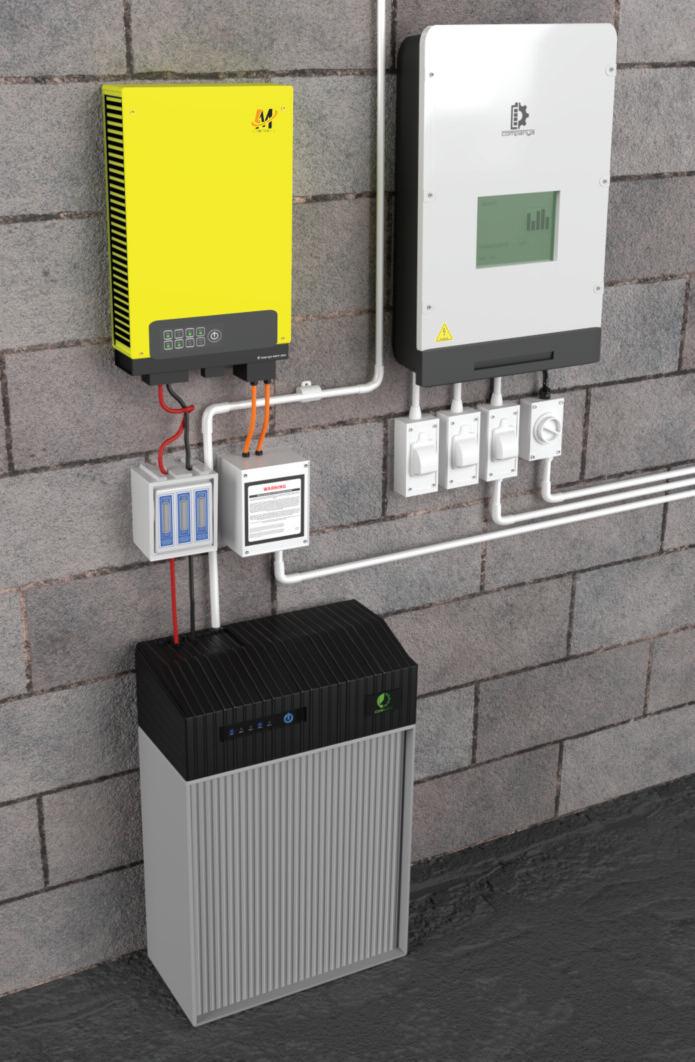

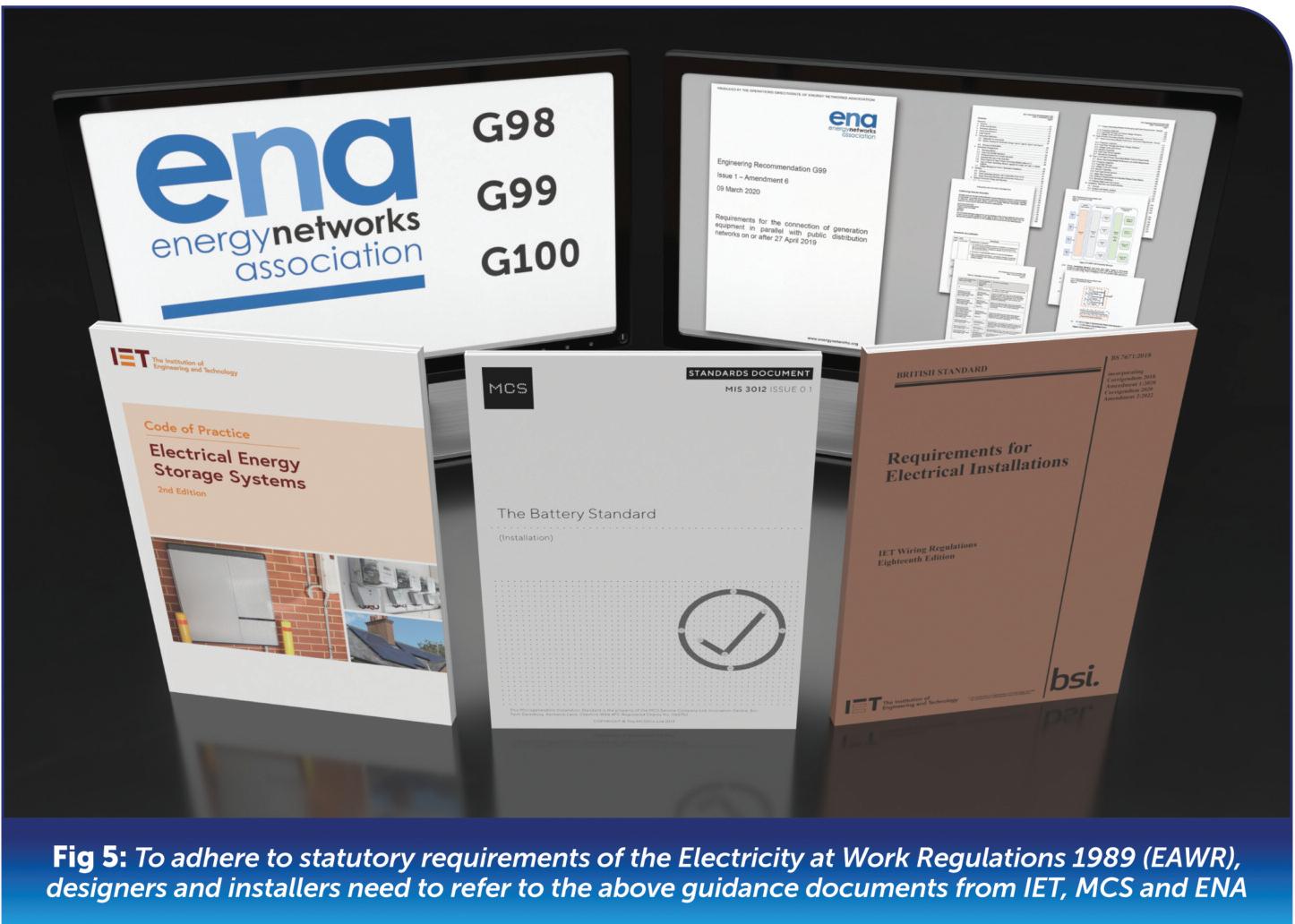

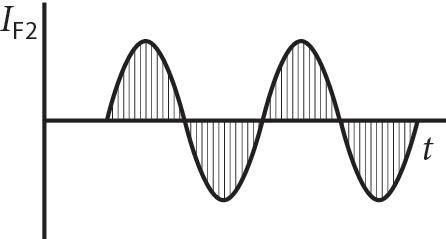

DARREN OVEREND: I SAW THIS UK CONVERTER PLUG ON SOME CHRISTMAS LIGHTS THAT HAD A EUROPEAN ST YLE TRANSFORMER PLUG HOW'S THAT SUPPOSED TO WORK THEN?