ELECT RICIAN &INSTALL ER

THE BUSINESS MAGAZINE FOR THE ELECTRICAL TRADE

THE C P D B OOK I VOLUME TWO

PROFESSIONAL

SECTION 1

8 ‘Codebreaking’ the latest on-site finds from electricians on the job

11 The requirements for the installation of equipment in meter boxes

14 Looking at the relationship between the Electricity at Work Regulations and BS 7671

16 LS0H cable: how does it work and how should you tackle it?

18 The importance of surge protection in complex installations

21 A look at some of the changes that were introduced with the May 2023 Corrigendum

22 What tests should be carried out as part of routine fire alarm maintenance and checks?

25 Overvoltage protection: how does the Corrigendum alter things?

SECTION 2

29 Recommendations around the use of insulation piercing connectors on meter tails

32 The requirements that apply to the design and maintenance of emergency lighting systems

34 ‘Codebreaking’ the latest on-site finds from electricians on the job

36 What does the Open Charge Point Protocol (OCPP) mean for EV installations?

39 Which cable management systems will help avoid corrosion in certain environments?

42 Getting the full details on the May 2023 Corrigendum

44 The implications of voltage imbalance on the electrical supply of an installation

SECTION 3

47 A look at the problems facing designers who may be specifying heavy current using equipment connected to consumer units

50 The considerations that electrical professionals need to make when installing equipment in medical locations

52 Earthing and bonding: understanding their different, but equally important, functions within an installation

54 Advice on the best ways to avoid false alarms

56 Earth electrodes and the relevant code of practice associated with their application

58 ‘Codebreaking’ the latest on-site finds from electricians on the job

60 The importance of providing additional fire protection following the mandated use of AFDDs

SECTION 4

62 Identifying some of the real hidden costs of inefficient cable calculations

64 How to verify the electrical continuity of protective bonding conductors in commercial and/or industrial locations

66 ‘Codebreaking’ the latest on-site finds from electricians on the job

68 How do fire rated downlights work and what is the legislation governing their use?

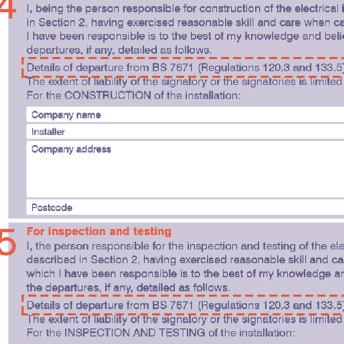

70 When do you need to use an intended departure?

72 What are inrush currents, who do they cause problems, and how can they be measured?

SECTION 5

75 Key considerations when installing RCDs

78 Addressing some of the common questions around EV charge point installations and maintenance

80 Earthing and bonding: what are the differences?

83 What is interoperability lighting and why is it important?

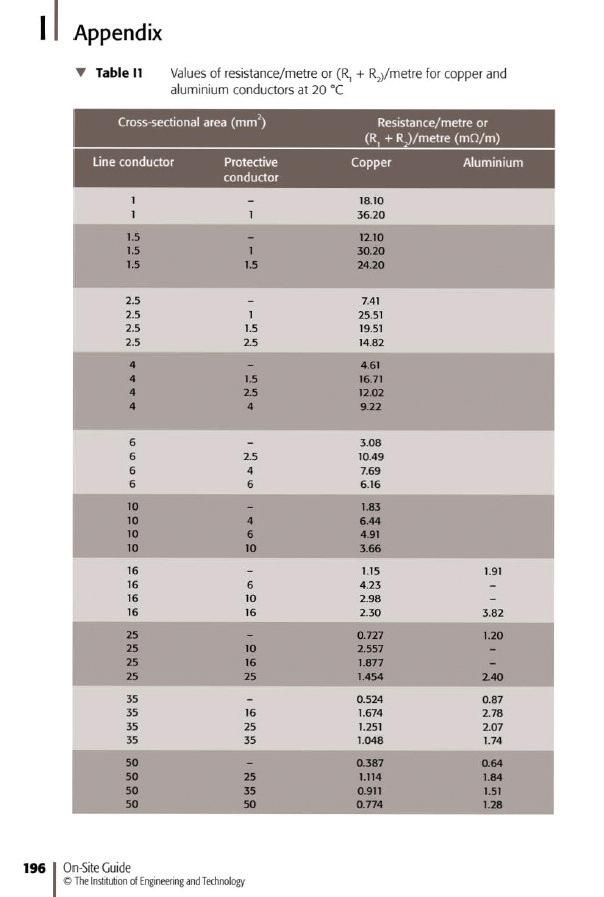

84 How do you measure the resistance of a cable, and how do you calculate the resistance of a standard 1.5 mm fire alarm cable?

86 ‘Codebreaking’ the latest on-site finds from electricians on the job

88 A look at the safety considerations installers should be aware of when dealing with Li-ion battery energy storage systems (BESSs)

O O K I V O L U M

2023

T H E C P D B

E TWO

Image References (Adobe Stock): Pg 7 CPD sign © TreenaBeena Pg 16 Train station © Vhoke Pg 16 Cable © VectorWin Pg 32 Emergency exit © Ambrozinio Pg 62 Ready for work © 9DreamStudio Pg 88 Renewables future © HN Works PROFESSIONAL ELECTRICIAN I CPD Book 3 32 88

W O R K T H R O U G H E A C H S E C T I O N A N D E A R N 5

C P D C R E D I T s ( o r 5 h o u r s o f l e a r n i n g )

T O WA R D S YO U R P R O F E S S I O N A L R E C O R D !

continuing professional development (CPD) can be broadly defined as any type of learning you undertake which increases your knowledge, understanding and experiences of a subject area or role

To help professionals to better document and prove this process, the CPD Book contains content and articles that have been checked, verified and accredited by a third-party specialist organisation

Collectively, the content within this specially designed publication has been deemed worthy of 5 CPD credits, or 5 hours’ worth of CPD, with each individual section providing 1 credit, or 1 hours’ worth of CPD.

Once this content has been consumed, readers will have the

opportunity to scan a QR code which will provide a bespoke, downloadable certificate that can be used as part of a professional’s ongoing CPD record

DO NOT SCAN THE QR CODE UNLESS YOU HAVE READ ALL OF THE CONTENT WITHIN EACH SECTION!

A large element of CPD involves self-certification and relies on professionals being honest about what they have actually read, consumed and digested A QR code has been placed with the final article in each of the five learning sections within this publication and ONLY once you have read ALL of the articles within each section, should you then scan the code to receive your bespoke certificate

By skipping any of these steps, you’re not just cheating the system, but yourself and your fellow professionals at the same time!

NEW USERS – ACCESS YOUR BESPOKE CPD CERTIFICATE IN FIVE STEPS

1. Read ALL of the content and articles included within the five sections

2. Find the QR code with the last article in each section and scan

3 Enter your email address

4. Fill out your details on the contact form

5. Download your certificate for use as part of your annual CPD record

PREVIOUS USERS – ACCESS YOUR CPD CERTIFICATE IN FOUR STEPS

1. Read ALL of the content and articles included within the five sections

2. Find the QR code with the last article in each section and scan

3. Enter your name and email address.

4. Download your certificate for use as part of your annual CPD record

All certificates are valid for one year from the issue date If you’re having any issues with downloading your certificate or using the system, please email us at: pe@hamerville.co.uk

introduction

PROFESSIONAL ELECTRICIAN I CPD Book 7

THE CODEBREAKERS

Unfor tunately, we see these used quite frequently these days. They ’re of ten used instead of Henley blocks or similar termination points to split meter tails for numerous reasons Correc tly named ‘I nsulation Piercing Connec tors’ or ‘Line Taps’, they ’re designed to be used where they ’re at height and out of reach.

Although there are many different manufac turers of this type of connec tor, this manufac turer states clearly that they ’re to be used for specific overhead LV cables and should also be used in conjunc tion with cable suppor t equipment to reduce mechanical stress. The requirements and protec tive measures that can be used on overhead lines and tak ing advantage of out- of-reach caveats differ greatly from those that can be used where terminations can be readily accessed Placed out of reach is a protec tive measure that sk illed persons must control or super vise

understand that its improper fitting has lef t access to live par ts, which is an immediate danger. Anyone in contac t with this – the client or future engineers –could receive a fatal shock

Before we consider that this equipment is not being used as its manufac turer envisaged, we need to

Secondly, we need to look at the need for any terminations in a cable to be suppor ted and taken into an adequate

enclosure Understandably tak ing into an adequate enclosure may not be where this equipment was designed for, as this may not be possible when dealing with overhead lines, however. I n this case, they ’re not being used as the manufac turer designed them for, and so must be taken into an adequate enclosure

8 CPD Book PROFESSIONAL ELECTRICIAN ADAM LUBKOWSKI: T H I S WA S C A R R I E D O U T BY A S O L A R S P E C I A L I S T CO M PA NY I N A C U P B OA R D T H AT WA S V E RY M U C H I N U S E A N D F U L L O F B R O O M S , H O O V E R S A N D OT H E R S T U F F. N OT I C E T H E B A R E CO P P E R P O K I N G O U T O F T H E L I N E TA I L …

.

GET THE BOOK AND CRACK THOSE CODES! Updated for BS 7671:2018+A2:2022, NAPIT ’s EICR Codebreakers publication is purpose -written to aid contractors, inspectors and clients, and now includes updates to align with Amendment 2 of the IE T 18th Edition Wiring Regulations The book is the per fect technical aid for electrical professionals and their customers.

Need help with cracking those all-impor tant EICR codes? Ever y month the technical team at NAPIT will be studying your latest ‘Caught on Camera’ photos and offering advice on the next steps, should you find a similar installation. If you want the team at NAPIT to help crack your codes then send your pic tures through to us at:

This is a prime example of why we must ensure that EICRs are carried out and that any elec trical work is under taken by adequately qualified, sk illed and registered persons

M ixing different manufac turers' equipment in one manufac turer ’s enclosure without the main manufac turer ’s consent has long been unacceptable – and for a good reason Different manufac turers design their equipment to operate and discharge gasses etc , in different direc tions When we mix different manufac turers' equipment, there is a danger that those gasses can be discharged onto conduc tive par ts where they aren' t designed, or type tested, to be and can cause a fire or other damage

I n this case, the two manufac turers (Eaton and MEM) merged and are now one entity, or ac t as subsidiaries.

3-phase Eaton MCB fit.

Not only is it now unlikely to be adequately terminated to the busbar, but the MCB’s off/on switch direc tion is also different from the rest of the devices in the DB This could cause confusion in the event of required emergenc y isolation

There are single -phase Eaton devices in the board that appear to be a replacement for possibly unavailable MEM devices and look to fit as they should

Although some manufac turers will allow retrofitting of newer devices in older boards, some do not, and some different ranges of manufac turers' equipment may not be compatible. I f in doubt, always consult the manufac turer to ascer tain if the devices fitted are acceptable

Although they are, in effec t, the same manufac turer, the original MEM DB is clearly older than the newer Eaton MCBs that have been fitted This means that the original DB has been butchered to make a

“Mixing different manufacturers’ equipment in one manufacturer’s enclosure without the main manufacturer’s consent has long been unacceptable – and for a good reason.”

ORDER YOUR COPY OF NAPIT CODEBREAKERS BY VISITING: WWW.RDR.LINK/EAT012

A2:2022 18th Edition Codebreakers publication is priced at £22.00 (members) and £24.00 (non-members). It is available in both hard copy and digital versions * Price is VAT exempt and excludes postage and packaging.

The

pe@hamer ville.co.uk JOE PERKINS: T H I S WA S F O U N D W H I L E C A R RYI N G O U T A N E I C R AT A LO R RY M OT W O R K S H O P. “ W E ’ L L MA K E I T F I T ” T H E Y S A I D

GUIDA NCE ON EQ UIP MENT IN METER BOXES

The experts at NICEIC provide more detail on the installation of equipment in meter boxes.

Electrical equipment associated with the consumer’s electrical installation is increasingly being found within the meter cabinet of domestic and similar premises The space within such cabinets is limited and typically allocated for specific usages by the distributor and energy supplier and therefore, should not be used to house other equipment

If this guidance is ignored and inappropriate equipment is installed within an enclosure, restricting the activities of the distributor or supplier, customers may incur financial penalties to have such equipment relocated This is likely to lead to customer complaints against the contractor originally responsible for the installation and result in reputational damage for the installer

Introduction

Industry

guidance on meter enclosure provision

The Energy Networks Association (ENA) is the body representing energy networks in the UK and Ireland. The ENA provide guidance within Appendix B (Spatial requirements for whole current metering) of its publication Energy Recommendation G87

When an electrical supply is laid on to a domestic or similar premises, the host Distribution Licence Holder will require the provision of a suitable enclosure at the service position to house the intake and metering equipment Although this enclosure is provided with the property, the distributor will specify that only equipment belonging to the distributor and meter operator (MOP) should be installed therein.

Issue 2: 2015 – Guidelines for the Provision of Low Voltage Connections to Multiple Occupancy Buildings (EREC G87) on the minimum provision of space in meter enclosures This is summarised in Fig 1 It should be noted that the arrangement of equipment as laid out in EREC G87 and as shown in Fig 1 is for illustrative purposes only The ENA recognises in its guidance that a “best use of space” approach may be adopted based on particular circumstances and equipment required to be installed

Nevertheless, the guidance also highlights that these minimum space requirements do not allow for the inclusion of any other additional customer equipment

Individual Distribution Network Operators (DNOs) will issue their own guidelines on

the provision of space in meter enclosures as a condition in their “Connection Offer” to customers This guidance, although based on the information given in EREC G87, may vary Typically, the space is divided into four, as shown in Fig 2 However, the guidance on additional customer equipment does not differ from that of EREC G87, as can be seen in Fig 2.

This advice has increased significance because of the smart meter rollout program, as some modern meters and associated equipment can take up more space than the meters they replace Additionally, it is becoming increasingly common for domestic or similar premises to be provided with three-phase intakes to facilitate future developments in the supply of electricity, such as “prosuming” and the introduction of networks operated by Distribution System Operators (DSO) This will inevitably result in more demand for space for equipment at the intake position.

PROFESSIONAL ELECTRICIAN CPD Book 11

section one

Fig 1 ENA EREC G87 guidance on the installation of whole current metering equipment at the ser vice position

Fig 2 Typical DNO recommendation for space allocation within a meter box enclosure

Installation of electrical equipment in the meter enclosure

Increasingly, contractors are installing equipment other than that directly associated with the supply and metering arrangements in meter enclosures at the service position. Evidence shows (see Fig 3) that installers of electric vehicle charging equipment find external meter enclosures to be a convenient location to install equipment such as joint boxes/connections in the meter tails, isolating switches, and small consumer units

In some cases, carrying out the work in this way may have been encouraged by the property owner or occupant, as it avoids the need to install often aesthetically unpleasing electrical enclosures on the exterior of the property

Implications for the customer

If the DNO or MOP need to attend a domestic or similar premises and encounter equipment other than that used for supply or metering purposes within an approved meter enclosure, this may prevent work activities such as:

● the replacement of lifetime-expired equipment;

● the installation of smart metering equipment;

● the installation of new cut-outs to provide enhanced supply capacity to allow for:

● an extension to the property;

● the connection of embedded generation; or

● the provision of electric vehicle charging equipment or other equipment which increases the maximum demand at the premises.

In such cases, where there is insufficient space within the meter enclosure, the planned replacement or upgrading work cannot proceed until sufficient space is made available therein.

The ENA have issued the following statement:

“While the meter cabinet is the customer’s, it is a space designed for the use of electricity industry apparatus only and no allowance is made for additional equipment. For safety reasons, we would

not recommend that any internal wiring, including a consumer unit, is installed within the cabinet ” Energy Networks Association

Furthermore, this is supported by guidance from the Department for Business, Energy & Industrial Strategy in Section 2.9 of its publication Smart Meter Guidance for Domestic New Builds – Guidance for Developers and Architects, and relevant to all those involved in the specification of metering locations in new-build premises, which is reproduced below:

“External meter boxes/cupboards should only contain equipment required to enable an electricity (or gas) supply to be provided to the premises safely, as defined by relevant regulations.

● Items permitted to be installed within electricity meter boxes/cupboards include: the local isolating device (e.g. main cut-out fuse), the electricity meter and communications hub, and may include a single- or double pole-isolation device (installed between the electricity meter and consumer unit).”

Therefore, where the guidance of the organisations discussed in this article is ignored, preventing any future upgrade work, the customer will be instructed by the DNO/MOP to employ a suitably competent person to remove and relocate

the inappropriate equipment – all at the customer’s expense and potentially incurring reputational damage for the previous installer

Summary

A meter enclosure may be provided at the service position of a premises to allow for the installation of the intake and metering equipment

The space allocation for this enclosure allows for the replacement of lifetime-expired equipment, installation of Smart Meter equipment and for some degree of future supply capacity upgrade

Only intake and metering equipment should be installed in the meter enclosure, as there is no allowance of space for housing additional equipment not associated with those functions

If a DNO or MOP attends the premises to carry out work on their equipment and insufficient space is available within the meter enclosure, work will not be able to proceed The customer will need to organise (at their expense) the removal of unrelated equipment to create the space needed for the work to be carried out

NICEIC strongly recommends that electrical contractors do not install any other equipment within meter enclosures.

section one 12 CPD Book PROFESSIONAL ELECTRICIAN

G E T M O R E D E TA I L S A B O U T N I C E I C R E G I ST R AT I O N AT: W W W. R D R . L I N K / E AT 0 1 3

Fig 3 Equipment associated with provision of electric vehicle charging points installed within external meter enclosures

EAW R AND B S 7671: C A N O N EHELPT HE OT HER?

In this article, the late Paul Skyrme looks at the relationship between the Electricity at Work Regulations and BS 7671.

This article intends to explain the inter-relationship between standards and legislation, using BS 7671 and the Electricity at Work Regulations as the reference point Firstly, it should remembered that standards are not compulsory They may be considered best or good practice, or even the bare minimum (BS 7671, I’m looking at you), but they’re not mandatory for compliance with the law.

For work being undertaken by electricians in the UK, one of the most important pieces of law is the Electricity At Work Regulations 1989 (as amended), referred to from here forward as EAWR

EAWR applies to all electricians or anyone undertaking electrical works, regardless of where those works are being undertaken – a private home, a shop, a hospital, a railway, or the Houses of Parliament.

If we look at EAWR in a little more detail, we’ll see that some of the requirements will fall under the the designer of the installation, under the remit of the installer, under the remit of the person u the inspection and testing

Even with this quick glance, see that the legislation is far-re hopefully, if we follow BS 7671, meet the requirements of EAWR is this so?

We have the legal requireme EAWR (Legislation), and our me to comply with this when at wo in whatever capacity we work with the installation in BS 7671 (Non-mandatory standard)

BS 7671 even has an introductory note written by His Majesty’s Health and Safety Executive (HSE) suggesting and endorsing the use of BS 7671 to meet the requirements of EAWR

In a nutshell, this gives us a piece of legislation – EAWR – and the means to meet it – BS 7671

If we now consider BS 7671, we will find Appendices in there labelled ‘Normative’ and ‘Informative’. Only one Normative Appendix – Appendix 1 – lists the standards referenced in BS7671

Why are they in there and why is this important?

They are there to illustrate that these standards relate to the products we purchase to complete our electrical installations under BS 7671 This ensures that the products are safe to use and that a product made to these standards

should be safe to use anywhere in the European Economic Area – not just the EU, but slightly further afield.

What does Normative mean?

In this situation, applied to this Appendix, Normative means that the Appendix itself forms part of the requirements for BS 7; that is, to comply with BS 7671, one must comply with the requirements of Appendix 1

Much of what is listed in Appendix 1 are product standards, so the designer, constructor, inspector and tester have little or no control over them. Is that important? Perhaps, perhaps not

If the designer is also specifying equipment, then to comply with BS 7671, the equipment specified must meet the requirements of the product standard listed in Appendix 1

Before you ask, this doesn’t mean the designer needs to start by buying the product standard and then getting their hands dirty to check that the selected product meets the requirements The electing the product to be used nstead satisfy themselves that the s compliant by using the tools in the legislation which facilitate is often known as ‘undertaking ence’

ols are available and how do we m?

s are the CE/UKCA (I will use CE is point forward to mean both CE KCA) marking and the eclarations of Conformity (DoC) Electrical products must be safe to be placed on the market or otherwise made available in the marketplace

section one

14 CPD Book PROFESSIONAL ELECTRICIAN The legal status of documents surrounding BS 7671 and their available volume Legislation in layers!

This requirement extends not only to items for sale to paying clients but also to any equipment made internally to meet the needs of the business. So, a test adaptor made internally within the company should be CE-marked.

For now, we’ll ignore internally designed and manufactured products and will only consider products selected and purchased on the open market to construct an electrical installation, such as isolators, light fittings, switches etc

How would we check these?

Firstly, we need to get hold of the DoC for the product The structure and content of the DoC are defined in the law This law is the Low Voltage Directive (LVD), as amended, and is transcribed into UK law, mirroring the safety requirements of the LVD, as the Electrical Equipment Safety Regulations (EESR) On the DoC, a requirement is to list the standards used for compliance with the legislation

So, in this case the due diligence called for would be to verify that the product standards listed on the DoC meet those required by the legislation and that this standard is also listed in BS 7671

The product manufacturer is responsible for compliance, following the product standard and completing the DoC. There is, therefore, the possibility of the information being incorrect or misleading on the DoC or that the product will not meet the requirements of the product standard

There’s nothing that the specifier can do concerning this except, perhaps, selecting products from reputable and reliable manufacturers with a good reputation in the supply chain and procuring these items from reliable and reputable sources

In conclusion

The aim of this article has been to provide a brief overview of how a standard (BS 7671) can be used to meet a piece of legislation (EAWR), what a Normative reference in the standard is, and how this Normative reference can be used to assist in ensuring that products selected for use under BS 7671 meet the relevant product legislation (EER) and assist in compliance with the EAWR

Further information and background on this subject can be found at the following links:

● Health and Safety at Work etc. Act 1974 (legislation gov uk)

● The Electricity at Work Regulations 1989 (legislation.gov.uk)

● The Electrical Equipment (Safety) Regulations 2016 (legislation gov uk)

● Directive 2014/35/EU of the European Parliament and of the Council on the harmonisation of the laws of the Member States relating to the making available on the market of electrical equipment designed for use within certain voltage limits (europa eu)

● The Electricity at Work Regulations 1989. Guidance on Regulations (hse gov uk)

WHAT IS LS 0H CABL E?

QI find myself working with LS0H cable on a more regular basis these days. Is this going to become the norm, and if so, how shall I tackle it? I find it very difficult to work with.

Use of LS0H (low smoke zero hydrogen) cable is indeed on the rise in the UK. While it isn’t a new product, a heightened awareness of fire safety, coupled with its growing prevalence in the USA, Ireland, and Europe, has seen the fire-safe material come into more common usage in the UK recently

Made from thermoplastic material, LS0H was first developed in 1979 It is an incredibly tough cable jacketing that’s resistant to fire and fumes, and – critically – doesn’t produce smoke when it burns This has a dramatic impact on how it reacts to fire and high temperatures While PVC may be cheaper, it produces a thick, acrid, highly toxic, and corrosive smoke This smoke kills We know that smoke inhalation is a bigger cause of death than fire itself in fire-related emergencies

The Kings Cross Fire in 1987, for example, claimed the lives of 31 people and injured 100 more The fire took hold for several varied reasons It began with a lit match on an escalator, but thick black smoke filling the ticket hall claimed the lives of almost everyone present. In response, cables containing halogen ceased to be used on the London Underground, and awareness and usage of LS0H cables grew

Now, with the legacy of the Grenfell Tower tragedy looming large, we’re seeing a further rise in LS0H cable jacketing In any area where smoke and toxic fumes could pose a risk to life, LS0H should be used. In public buildings and high-density housing in particular, use of LS0H is critical Should a fire take hold, fumes from LS0H cabling will emit less than 0 5% HCL gas, dramatically cutting toxicity What’s more,

a lack of smoke will result in enhanced visibility, enabling easier evacuation

It's also important to distinguish between LS0H and LSF (low smoke and fume) cable LSF is made from a modified PVC compound and emits 15 – 22% HCL gas upon burning. That’s 8 – 13% less than standard PVC. However, toxic fumes and thick black smoke will still pose significant danger to life While is marginally safer than PVC, SF should not be confused with S0H which emits 0 5% HCL gas and therefore does not produce toxic fumes or black smoke Nor does it pose a danger to life.

Cost-cutting measures –such as specifying PVC or LSF cable when LS0H is safer and more appropriate – are rightfully falling out of practise New regulations around the use of LS0H are anticipated But LS0H is more

section one

Brinley Buckley-Roberts, Brand Manager at Carl Kammerling International, answers a common contractor query related to the use of LS0H cable.

16 CPD Book PROFESSIONAL ELECTRICIAN

Use of LS0H cable in rail applications has increased in recent times

“Critically, LS0H doesn’t produce any smoke when it burns.”

difficult to work with than PVC cable The material is stronger and less flexible than its PVC or LSF counterparts Many electricians have reported challenges in stripping the LS0H, as standard cable strippers fail to meet the strength of the thermoplastic material.

Working with LS0H cable may be more challenging and time-consuming, but choosing this cable over PVC or LSF could save lives Armed with the right tools and equipment, and knowledge of its excellent fire safe credentials, tackling LS0H can and can be straightforward and worthwhile process

WHAT EQUIPMENT IS RECOMMENDED FOR USE WITH LS0H CABLE?

Specialist strippers, made from toughened materials and with multiple blades, should be used when working with LS0H cable Using the correct bracket size for the width of the cable, LS0H cable strippers peel the cable along its length, like a banana skin, allowing for simple stripping.

Due to its tougher nature, LS0H can also be less flexible This can lead to cracking during installation To prevent this, specialist lubricant is recommended to reduce friction Of course, it’s important to also choose non-toxic, non-flammable, and non-corrosive lubricant

CK Tools’ LS0H cable stripper includes two titanium nitrade coated blades and four cable brackets to tackle any size of LS0H cable

GET MORE DETAILS ON C.K’S LS0H CABLE STRIPPER AT: WWW.RDR.LINK/EAT014

A SURGE IN C O MP L E X I TY

What is a complex installation?

When we talk about complex installations, we generally mean those that aren’t simple domestic dwellings or basic commercial installs.

That doesn’t mean that all domestic installations are simple installations, nor does it mean all commercial and industrial installations are complex When an installation becomes more complex, it may have the following:

● Multiple sub-boards

● Sensitive equipment (general)

● Sensitive equipment rooms or Zones (specialist)

● High-value equipment (individual electric vehicle charging)

● High-value equipment (multiple electric vehicle charging systems)

● Data collection and holding systems

● Life safety and support systems

● Emergency egress systems

● Surveillance systems (security)

● Surveillance systems (critical safety)

● Security entrance and exit systems

● Multiple surge inlet threat areas (anything that can import a surge or overvoltage threat to an installation)

● TV aerials and satellite coax

● Overhead telephone lines

● Solar PV array (roof-mounted)

● SolarPVarray(ground-installedPV farm)

● CCTV equipment (generally taken to be those on purpose-built columns, etc )

● Outside lights (generally taken to be lamp posts, etc )

● Electric gates.

This list isn’t exhaustive by any means, but we can see the type of installation that can easily slide from simple to complex, with the emphasis now placed on SMART integration

It’s possible that many future installations could easily fall within the

remit of being classified as complex, especially where SMART applications can have a lower voltage withstand (Uw), with more Category 1 equipment present

Why do we need to look carefully at these installations?

If we take the standard requirement of BS 7671 Regulation 443 4 1 and its three bullet points aside, which are in place for indirect stokes on the incoming supply, we are left with Regulation 443 1 1 This requests that we take into account switching overvoltages where atmospheric protection is not installed

As well as Regulation 443, Regulation 534 4 1 6 requires that we consider not only switching loads but also where overvoltages can be introduced from other services feeding into secondary buildings on a site, or from them if they represent areas of multiple inlet threats

Where atmospheric protection is omitted, it’s prudent to look at protecting against switching damage We need to do this because the magnitude of switching surges tends to be less than those of an atmospheric nature, but they can be just as costly

While atmospheric protection will generally afford switching protection as a side effect, there are issues with this in both complex larger installations and those with multiple surge inlet threat areas.

What are the threats?

It stands to reason that we need to look at switching overvoltages more as an industry. From a magnitude of occurrences perspective, the most damage to sensitive equipment comes from switching overvoltages, not atmospheric These overvoltage switching threats can come from any number of different sources, both internal and external

Examples of internal switching overvoltages are:

● Large motors

● Lifts

● Air Handling Units (AHUs)

● Air conditioners

● Pumps

● Process and/or manufacturing equipment

● Production line evolution operations

● Welding equipment

● Large lighting banks

● Commercial or industrial ovens

● Multiple EV charger systems

● CNC machines

● Autoclaves

● Alternative sources of supply

Again, this list isn’t exhaustive, and the sensitivity of the equipment that needs to be protected may be affected by much smaller overvoltages

External to the installation, where National Grid operations may switch or changeover equipment, this can also affect sensitive equipment within an installation

External switching is harder to predict, pinpoint or prove, so there is a feeling that it could be best practice to look at the consequences at the design stage and discuss with the client what their expectations or risk to their business could be and design accordingly

If a client risk assessment highlights a high cost to their business model from lost

section one 18 CPD Book PROFESSIONAL ELECTRICIAN

NAPIT’s technical experts look at the importance of surge protection in complex installations.

production, lost data, or damage to equipment, there may well be a need to include switching overvoltage protection within the installation design criteria

What to think about at the design stage

As with all designs, there are a few things we need to consider when specifying surge devices. Firstly, each manufacturer’s device is tuned or manufactured to specific attenuation values

This means we can’t mix and match between manufacturers, as the device protection trail-off zone from one manufacturer may not favour the activation zone of the downstream device of a different manufacturer I mention downstream because, in physically larger installations, the protection afforded by a single device starts to lapse at about 10 metres, in most scenarios, due to resonation or oscillation, causing the overvoltage surge to pick up in magnitude

This reduction in effectiveness means that the designer may need to incorporate multiple devices along a circuit, especially where very sensitive or essential equipment needs to be protected

Where this is impractical due to the length of the circuit, SPDs placed at the load end of the circuit to protect particular equipment types may be prudent and more budget friendly

Although any increase in the magnitude of an overvoltage 10 metres after a surge protective device due to resonance is often associated with high-energy lightning stroke events, they can still be caused by manmade/switching loads, albeit with lesser degrees of magnitude

A lesser degree of magnitude can still cause significant damage to sensitive

electronics and equipment, and the designer needs to understand that manmade/switching overloads are more frequent than atmospheric overvoltages

The accumulation of damage and degradation to both equipment and SPDs over time by manmade or switching overvoltages mustn’t be overlooked or underestimated by the designer.

We also need to reduce overvoltages from multiple surge inlet threat areas Although the supply cable may be protected, surge inlet threat areas can still introduce an atmospheric event that can cause significant damage. For this reason, careful thought also needs to be given to the input and output signal lines of control cabinets or controls to roof mounted plant

Overvoltage protection devices will stop downstream surges from an atmospheric stroke (lightning), but they can’t protect the upstream equipment. This is because the sheer destructive force of an atmospheric stroke, even with lightning protection, will cause some damage What we are looking to do here is reduce the devastation within the installation

We can see this by looking at Fig 1, which shows a more complex installation.

If, for example, there were a lightning stroke on the CCTV equipment, the resultant energy would be directed into the installation and cause massive damage If there were appropriate surge protection here, the rest of the installation would be saved if the overvoltage devices were specified correctly; the CCTV camera, however, would be destroyed

There is no absolute protection from lightning; any Lightning Protection System (LPS) or associated Surge Protective Devices (SPDs) will only mitigate or reduce

the effect of an atmospheric event, which is why the CCTV mentioned earlier would become sacrificed

However, overvoltage devices or SPDs will protect totally against switching overvoltages, as the magnitude is significantly reduced

The only trade-off that the designer needs to understand is that each time a surge device operates, its effectiveness is reduced to the extent that it will need to be replaced when it reaches a pre-designed level This can be via the modular devices often found within consumer units or complete replacement where compact Type 3 devices are used in back boxes for fire alarm panels, etc

What’s available to help with the possible threats?

There are many different types of SPDs on the market, not just for inclusion into the mains voltage side of an installation They are available for coax, data and everything else in between

If in doubt, speak to the manufacturer you are looking to specify before confirming your design or ask them to be involved –they’re more than willing to help.

How to keep up to speed

If you feel that you need more guidance or would like to gain a more in-depth level of design knowledge, NAPIT Training can provide both electrical installation design and surge protection courses. Either would greatly enhance your understanding of two very complex subjects

PROFESSIONAL ELECTRICIAN CPD Book 19

GET MORE DETAILS ABOUT NAPIT’S TRAINING OFFERING AT: WWW.RDR.LINK/EAT015

B S 7671:2018 The cor rigend um explained

Following the announcement from the IET and BSI, that a corrigendum to BS 7671:2018+A2:2022 would come into effect, Jake Green, Head of Technical Engagement at Scolmore Group, provides some more detail on the changes.

Under the auspices of the IET/BSI, JPEL64, the committee responsible for BS 7671, have issued a corrigendum to address issues raised after the publication of Amendment 2 of BS 7671: 2018 These issues fall into three specific areas:

● Protected escape routes – amendment to Regulation 422.2 to clarify the scope of the provision in general installations, and a new provision for medical locations (710 422 2)

● Birthing pools – amendment to Regulation 701 1 removing the reference to birthing pools

● Provision of protection against overvoltage for safety services

Protected escape routes

Regulation 422.2 has been amended to provide clarification on its application The regulation now states:

‘Cables or other electrical equipment shall not be installed in a firefighting lobby, shaft or staircase of a protected escape route ’

The text in bold italics is the amended detail This change enables designers to better understand the scope of application of this requirement. Note 2 to Regulations 422.2 has been similarly amended, however, there are no changes to the guidance given in Appendix 13

Further to this change to Regulation 422 2, a new regulation (710 422 2 201) has been added to Section 710 covering medical locations This new text takes account of the specific concerns of the

health sector and points towards the guidance issued under HTMs (England), SHTMs (Scotland) and WHTMs (Wales)

Birthing pools

Regulation 701 1 in Section 701 (Locations containing a bath or shower) has been amended to remove the reference to birthing pools This change supports the work of designers in the health sector

Protection against transient overvoltages of atmospheric origin

Regulation 443 4 1 now limits the requirement for transient overvoltage protection to two conditions, (serious injury to, or loss of human life, and significant financial or data loss) by removing the reference to ‘safety services’

However, the rest of the regulation remains the same, and protection against transient overvoltages (typically using SPD) should still ‘ … be provided unless the owner of the installation declares it is not required due to any loss or damage being tolerable ’

As a consequence of this change, Table 443 2 has been amended by deleting the references to alarm panels, computers and home electronics

Furthermore, the note attached to Regulation 534.4.1.1 has been amended to remove the example of ‘fire/security alarm systems’

All of these changes became ‘live’ on May 15th 2023

SECTION ONE

DOWNLOAD THE CORRIGENDUM BY VISITING: WWW.RDR.LINK/EAT016 PROFESSIONAL ELECTRICIAN CPD Book 21

Dr. Zzeus

IN THIS REGULAR COLUMN, ‘DR. ZZEUS’ TOM BROOKES, md of zzeus training and CHAIRMAN OF THE FSA, WILL ANSWER YOUR QUESTIONS RELATED TO FIRE SAFETY COMPLIANCE. THIS COLUMN COVERS INSPECTION PERIODS AND PROCESSES...

We’ve just changed fire alarm service companies to save money in the current climate. When I questioned why the new company was not testing voltages, batteries, and some other checks at the six-monthly service that the old company did, they said the old company were doing too much testing and that what they were currently doing met the standard. Is there a checklist of what should be done?

It sounds very much like the new service provider either does not know the standard or is trying to get away with not completing a service correctly BS 5839-1:2017 Clause 45 3 covers the six-monthly inspections, and 45 4 covers the yearly inspection I have listed the minimum checks that should be carried out at the six-month visit; your provider can do more than this, but not less Changing suppliers entirely based on price can be a wrong move; for a fire alarm company, the most expensive part is the employees’ wages, so cutting the price down often involves the engineer doing less, cutting corners or missing parts of the service

Review the system logbook for recorded faults and ensure appropriate action has been taken.

Visually inspect for any structural or occupancy changes affecting compliance with the standards:

a. Check unobstructed and visible manual call points and any new fire exits that have been created have a manual call point adjacent to exits that

lead to a place of “Ultimate safety”

b. Assess any new partitions or ones that may have been moved within 500 mm of automatic fire detectors

c Ensure no storage encroaches within 300 mm of ceilings

d. Check clear space (500 mm) below automatic fire detectors

e. Evaluate the suitability of existing detectors for changed areas

f. Check additional fire detection and alarm equipment that may be needed for alterations or extensions.

Check false alarm records, note the rate in the past 12 months, and take appropriate action

Measure battery voltage with mains power on, ensuring it aligns with manufacturer recommendations before other tests (without additional load)

Disconnect the standby battery, activate alarms, and verify the power supply output voltage close to the nominal value Simulate full load if necessary (minimum 95% nominal voltage)

Inspect batteries and connections and load test without mains power

Test fire alarm functions of the Control and Indicating Equipment (CIE) using at least one detector or manual call point per circuit Record devices used in the logbook

Confirm the fire alarm signal upon at least one manual call point or fire detector operation

Verify proper operation of CIE controls and visual indicators

Check the automatic transmission facility for alarm signals to an Alarm Receiving Centre, ensuring the correct transmission of each signal type.

Test all ancillary functions of the CIE

Where feasible, check fault indicators and circuits through simulated fault conditions

Test printers for functionality and legibility and ensure sufficient consumables until the next service visit.

Service all radio systems as per the manufacturer's recommendations

Perform additional checks and tests recommended by the manufacturer for the CIE and other system components

Report any remaining defects to premises management, complete the system logbook, and issue an inspection and servicing certificate

DO YOU HAVE A QUESTION YOU'D LIKE ANSWERED?

EMAIL YOUR QUERIES TO: TOM@ZZEUS.ORG.UK

22 CPD Book PROFESSIONAL ELECTRICIAN

OV ERVOLTA GE PROTEC T ION: THE LATES T UPDATE

Electrium provides a brief overview of one specific update in the Corrigendum: overvoltage protection.

it’s now well documented that the IET has updated certain requirements in Section 443 of BS 7671 Amendment 2 Those requirements relate to providing protection against transient overvoltages of an atmospheric origin or due to switching

The revised requirements of Regulation 443.4.1 are as follows:

Protection against transient over-voltages shall be provided where the consequence caused by the overvoltage could result in:

● Serious injury to, or loss of, human life

● Significant financial or data loss

● And in all other cases protection against transient over-voltages shall be provided unless the owner of the installation declares it’s not required.

Previous references to overvoltages causing the failure of a safety service, as defined in Part 2 has been removed by the revised wording to Regulation 443 4 1

All other cases

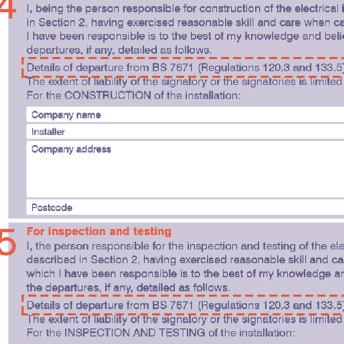

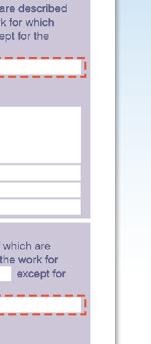

Ironically the clearest part of Regulation 443 4 1 is item 3 which says that overvoltage protection is required in all other cases This catch all scenario requires the installer and the installation owner to have a conversation on the basis that overvoltage protection is automatically included in the design, and if after that conversation an owner says “no thanks” then the contractor should record that decision on a departure note and the completion certificate

Owner responsibilities

While Regulation 443 4 1 takes account of circumstances where the owner of the installation could choose to declare that overvoltage protection is not required (which may be because any loss or damage is considered tolerable and the owner is willing to accept all risks of damage to equipment and any consequential losses) the benefits of protection in any modern installation with its plethora of sensitive electronic equipment will far outweigh any up-front SPD costs

“This scenario requires the installer and the installation owner to have a conversation on the basis that overvoltage protection is automatically included in the design...”

Specific situations

Although Regulation 443 4 1 refers to some specific situations it does not provide any guidance as to which types of premises are considered as ones where overvoltage can cause “serious injury to, or loss of, human life”. Nor does it advise which types of installation are susceptible to “significant financial or data loss” from an overvoltage fault Designers and installers must use their own judgement

However, the types of premises that come to mind – hospitals, care homes, banks and financial institutions may well already have the subject covered in their electrical installation specifications

SECTION 1

ENDS!

SCAN THE QR CODE TO CLAIM

YOUR CPD CREDIT FOR THIS SECTION OR VISIT: WWW.RDR.LINK/EAT017

SECTION ONE

Surge Protection device includes a status indicator and volt-free contacts for remote monitoring as well as replaceable cartridges that are securely locked into place and cannot be removed without use of a tool Wylex single module SPDs are designed, manufactured & tested to BSEN61643-11 and certified as compliant by Intertek

The Wylex single module SPD is fully rated at 100 A and does not need MCB protection It connects directly onto the busbar ( just like an MCB) in way number one It uses fewer cable links than some alternative products and

fits all Wylex consumer units & SP&N distributions boards This Type 2

WYLEX SINGLE MODULE SPD

PROFESSIONAL ELECTRICIAN CPD Book 25

T HE USE OF INSULAT ION PIERCING CONNECTORS ON MET ER TAILS

It has come to the attention of the NICEIC that some contractors installing EVCPs are using insulation piercing connectors (IPC) in order to provide a branch from the meter tails to supply an EVCP. This article looks into the use of such types of connectors for this purpose and strongly recommends that they’re not used.

When an electrical supply is laid on to domestic or similar premises, the host Distribution License Holder (DLH) will require the provision of a suitable meter cabinet at the service position to house the intake and metering equipment.

Although this meter cabinet is provided with the property, the distributor will specify that only equipment belonging to the distributor and meter operator (MOP) should be installed therein

The space within such cabinets is limited and therefore allocated for specific

usages by the distributor and energy supplier, and therefore should not be used to house other equipment relating to the consumers installation

IPCs are not designed for use on insulated and sheathed meter tails If encountered by Distribution Network Operators (DNOs) or MOPs when attending to carry out work, some will, with the customer’s permission, remove the IPC and remake the connection with a more suitable method In the event that the customer will not allow this replacement work to be carried out, the DNO or MOP may refuse to carry out their planned updating or improvement works.

Concerns relating to the use of insulation piercing connectors in meter cabinets

IPCs are a type of connector in which electrical contact with the conductor is made by metallic protrusions which pierce the insulation of an aerial bundled cable core. The relevant product standard for such connectors is BS EN 50483-4:2009

Test requirements for low voltage aerial bundled cable accessories - Part 4: Connectors

The scope of BS EN 50483-4 states that the standard applies to connectors used for the electrical connection of aerial bundled cables (ABC) only.

PROFESSIONAL ELECTRICIAN CPD Book 29 SECTION TWO

A number of concerns have been raised in respect of the use of IPCs to provide a connection to types of cable other than ABC, and in particular meter tails

Effectiveness of connections

When an IPC of the type seen being used in meter cabinets is tightened down onto an XLPE insulated conductor of an ABC, the core behaves like a solid conductor However, when installed on a typical double insulated copper meter tail the individual circular shaped strands of the conductor spread under compression, reducing the effective contact area of the connection while increasing the termination resistance

Where installed in the meter cabinet neither the meter tails nor the IPCs are fixed, which may allow movement in the connection. This could result in heat build-up, which may lead to joint failure

Further, if the IPC is not correctly aligned with the conductor when installed, the IPC will not clamp down as intended, which may also contribute to a poor connection

These factors raise concerns as to whether the requirements of BS 7671 for effectiveness of joints and connections have been met (134 1 4, 134 1 5, 522 8 5 and Section 526)

The combined thickness of the insulation and sheath of a meter tail is noticeably thicker than the insulation on an ABC conductor As a result, it is unlikely that the ‘teeth’ of the connector will engage fully The IPCs are being employed outside of the scope of their product standard, but electrical contractors are not in a position to determine which IPCs might be suitable

for use to provide a connection that is no less safe than using other recognised means of connecting into meter tails, as required by BS 7671 (See regulations 120 3, 133 1 3 and 511 2)

The possibility of poor connections is a particular concern, given the high currents that may be drawn by an EV during certain periods of its charging cycle.

Protection against electric shock

BS 7671 states that a protective measure shall consist of:

● An appropriate combination of a provision for basic protection and an independent provision for fault protection, or

● An enhanced protective provision which provides both basic and fault protection (410 3 2)

Typically, the protective measure employed is automatic disconnection of supply (ADS), in which basic protection is provided by basic insulation, barriers or enclosures and fault protection is provided by protective earthing, protective equipotential bonding and automatic disconnection in the event of a fault (411 1)

However, this protective measure is not typically applied to the meter tails situated before the first fault protective device of the electrical installation (434 3)

More typically, the protective measure of double or reinforced insulation is used for the meter tails, and other equipment between the service fuse and the first protective device of the installation Double or reinforced insulation is a protective measure in which:

● Basic protection is provided by basic insulation and fault protection is provided by supplementary insulation, or

● Basic and fault protection are both provided by reinforced insulation between live parts and accessible parts

Although the meter tails are insulated and

sheathed, so meeting the requirements of regulation 412 2 for basic and fault protection for double insulation (412 2 4 1), the IPC is not When IPCs are used in an aerial application the danger of inadvertent contact is minimal given the mounting height above ground effectively placing them out of reach

However, where IPCs are installed within a meter cabinet they are in a readily accessible enclosure to which it is not possible to prevent unauthorised access As a result, the conditions for protection by double insulation are not met.

Summary

Currently, there are no IPCs designed specifically for use on double insulated meter tails As it is not possible for a contractor to confirm that the use of IPCs in this manner is no less safe than using a recognised means of connecting to the meter tails, such use is a non-compliance with the requirements of BS 7671

Attitudes of Distribution Network Operators (DNOs) or Meter Operators (MOPs) on encountering IPCs used to connect to meter tails may vary

Some will advise the customer of their concerns regarding the use of this means of connection and, with the customer’s permission may remove the IPC and remake the connection using a means recognised as suitable for such use.

In the event that the customer refuses to allow this replacement work to be carried out, the DNO or MOP may issue an Electricity Deficiency Notice and decline to carry out their planned updating or improvement works

In either case, the customer may raise complaints in respect of the original use of IPCs on the meter tails, causing reputational damage for the contractor who installed them initially

As a result, NICEIC strongly recommends that electrical contractors do not use IPCs to provide a branch connection in meter tails.

SECTION TWO 30 CPD Book PROFESSIONAL ELECTRICIAN

G E T M O R E D E TA I L S A B O U T N I C E I C M E M B E R S H I P A N D BENEFITS BY VISITING: WWW.RDR.LINK/EAU015

Fig 1 Constructional differences between typical ABC and meter tail cables

The requirement for emergency lighting in non-domestic premises is laid out in legislation throughout the UK. Here Matt Tighe, Technical Service Manager with ESP, briefly considers the requirements of legislation and the British Standards and Codes of Practice that apply to the design, installation, commissioning and maintenance of emergency lighting systems.

EMERGENCY LIGHT ING IN NON-DOMESTIC P REMISES

Legislation

The Regulatory Reform (Fire Safety) Order 2005 (FSO) in England and Wales, Fire (Scotland) Act 2005, Fire Safety (Scotland) Regulations 2006, Fire and Re s c u e S

O r d e r 2006 and the Fire Safety Regulations (Northern Ireland) 2010 detail a series of legislative requirements for persons having responsibility for occupants of a building

The FSO uses the term ‘responsible person’ and ‘nominated person’ is used in Scotland and Northern Ireland

Under the FSO, the responsible person must take such general fire precautions as will ensure the safety of his employees and those persons who are not employees but who are using his premises (clause 8 FSO)

Amongst other things, clause 14 of the FSO requires that:

● Emergency routes and exits must be indicated by signs

● Emergency routes and exits requiring illumination must be provided with emergency lighting of adequate intensity in the case of failure of their normal lighting

u i r e s t h a t t h e b u i l d i n g i s d e s i g n e d t o i n c l u d e, ‘ a p p r o p r i a t e m e a n s o f e s c a p e i n c a s e o f f i r e ’ S i m i l a r r e q u i r e m e n t s e x i s t i n S c h e d u l e 5 , c l a u s e

2 1 0 o f t h e B u i l d i n g ( S c o t l a n d ) Re g u l a t i o n s Le g i s l a t i o n d e t a i l s t h e r e q u i r e m e n t s f o r e m e r g e n c y e s c a p e l i g h t i n g ; h o w e v e r, i t i s t h e v a r i o u s B r i t i s h St a n d a r d s a n d c o d e s o f p r a c t i c e t h a t p r o v i d e t h e n e c e s s a r y g u i d a n c e o n h o w e m e r g e n c y e s c a p e l i g h t i n g s y s t e m s s h o u l d b e d e s i g n e d a n d i n s t a l l e d

G u i d a n c e

T h e g u i d a n c e a v a i l a b l e f o r t h o s e d e s i g n i n g , i n s t a l l i n g a n d m a i n t a i n i n g e m e r g e n c y l i g h t i n g s y s t e m s i s v a r i e d H o w e v e r, t h e p r i m a r y g u i d a n c e i s f o u n d i n t h r e e r e l a t e d B r i t i s h St a n d a r d s :

● B S 5 2 6 6 - 1 : 2 0 1 6 E m e r g e n c y l i g h t i n g –

Pa r t 1 : C o d e o f p r a c t i c e f o r t h e e m e r g e n c y l i g h t i n g o f p r e m i s e s

● B S E N 5 0 1 7 2 : 2 0 0 4

● Health Technical Memorandum 05-02: Firecode (HTM 05-02)

● Health Technical Memorandum 06-01 –Electrical services: supply and distribution

● LG2: Lighting for healthcare premises (2019) – CIBSE

● LG12: Emergency lighting (2022) – CIBSE

BS 5266-1 – pre-design

BS 5266-1 is the principal code of practice for emergency lighting systems. The scope of BS 5266-1 is threefold:

● To assist occupants to leave a building during an emergency – Escape route lighting

● To help protect occupants if they stay in a building during an emergency –Emergency safety lighting

● To help occupants to continue normal operations in the event of failure of the supply to normal lighting – Standby lighting

Figure 1 in BS 5266-1 highlights the types of emergency lighting systems and the associated activity(ies) It is important that the designer is aware of the specific nature of the emergency lighting system

SECTION TWO

e r v i c e s ( N o r t h e r n I r e l a n d

)

I n a d d i t i o n t o t h e r e q u i r e m e n t s o f t h e F S O a n d o t h e r l e g i s l a t i o n , Pa r t B 1 o f t h e B u i l d i n g Re g u l a t i o n s ( E n g l a n d a n d Wa l e s ) r e q

/ B S 5 2 6 6 - 8 : 2 0 0 4 E m e r g e n c y e s c a p e l i g h t i n g s y s t e m s ● B S E N 1 8 3 8 : 2 0 1 3 L i g h t i n g a p p l i c a t i o n s – E m e r g e n c y l i g h t i n g F u r t h e r g u i d a n c e c a n a l s o b e f o u n d i n :

32 CPD Book PROFESSIONAL ELECTRICIAN

There are, for example, differences in lighting levels and times associated with each of the arrangements detailed in the table (pictured, right)

Clause 4 of BS 5266-1 makes it clear about the need for consultation between the responsible person, the owner/developer (occupier), the architect, the lighting engineer, the installation contractor, the enforcing authorities, the electricity supplier/distributor, and any other relevant persons at an early stage

The purpose of the consultation stage is to define the way in which the system is intended to operate

Clause 4 of BS 5266-1 further recommends that plans of the premises are available early in the process to assist with the consultation stage Clause 5 1 of BS EN 50172 details the plans should include, escape routes, open areas, high risk task areas, safety equipment (e g fire safety equipment etc ), and details of normal lighting and its control systems

Records of the emergency lighting system must be kept, including the location and type of system components, including luminaires, test devices, and any control power units (clause 4 3 BS 5266-1 and clause 6.1 BS EN 50172).

Conclusion

Legislation requires emergency lighting systems in non-domestic premises The responsibility for such systems falls to the ‘responsible person’.

The guidance issued under British Standards, HTMs and CIBSE give designers, installers, commissioning engineers and maintenance personnel help in ensuring that a suitable and sufficient system can be selected, erected and maintained

ESP provides a design service for emergency lighting systems However, it is important that any designers are part of the early consultation process to align

with the recommendations of BS 5266-1 and other associated standards

ESP can offer a team of dedicated design engineers who are trained and qualified in all relevant British Standards, including BS 5266. They can provide an in-depth solution to any challenges a building offers, through a combination of site visits and the study of site drawings

GET MORE DETAILS ABOUT THE EMERGENCY LIGHTING

SYSTEM DESIGN SERVICE

AVAILABLE FROM ESP BY VISITING: WWW.RDR.LINK/EAU016

THE CODEBREAKERS

Well, what can I say? This is absolutely horrendous and in a special location as well This is exactly the reason the Client should always use a competent and registered electrician.

I can’t pass comment on why the fan doesn’t work; it may be damaged and need replacing, or it may have a circuit fault which has meant there is no longer a live feed to it Both of these things are easy fixes for a competent electrician

I can only guess that the circuit has developed a fault, and the person called to repair it either couldn’t carr y out fault finding or didn’t k now how to I’m going to take the route that they didn’t k now how to on this occasion.

I could say the cable is at risk from premature collapse, but it seems to have beaten me to it! There is some merit, however, for suggesting this could be an entanglement issue for fire safety ser vices entering the building in the event of a fire

By rigging a power feed from a light fitting, using an unsuppor ted cable is ver y dangerous I t won’t take much for the twin and ear th cable to become detached from a terminal securing a conductor, potentially initiating a shock risk scenario. There is a potential for an IP infringement, but we can’t determine that from this photo.

This is a ver y dangerous and foolhardy repair/modification that is only going one way from a coding perspective

34 CPD Book PROFESSIONAL ELECTRICIAN NICK JAMES: A FRIEND OF MINE HAS A LANDLORD WHO TOLD HIS MATE TO COME ROUND AND FIX A FAULT Y FAN THIS IS THE RESULT!

The Observations, Regulation infringements and Codes applicable to this observation would be: N Cable not supported throughout its length, subjected to mechanical stress on terminations, and presenting an entanglement threat 134.1.1, 522.8.5, 521.10.202 C2 GET THE BOOK AND CRACK THOSE CODES! Updated for BS 7671:2018+A2:2022, NAPIT ’s EICR Codebreakers publication is purpose -written to aid contractors, inspectors and clients, and now includes updates to align with Amendment 2 of the IE T 18th Edition Wiring Regulations The book is the per fect technical aid for electrical professionals and their customers

Need help with cracking those all-impor tant EICR codes? Ever y month the technical team at NAPIT will be studying your latest ‘Caught on Camera’ photos and offering advice on the next steps, should you find a similar installation. If you want the team at NAPIT to help crack your codes then send your pic tures through to us at: pe@hamer ville.co.uk

STEVE BRENNAN: OVER RECENT MONTHS I’M FINDING MORE AND MORE ‘BANJOS’ BEING EARTHED USING SELF-TAPPERS. I WAS WONDERING IF THIS IS ACCEPTABLE OR IS THERE A PROHIBITIVE REGULATION?

We often consider it wrong when we see something we aren’t used to seeing. Sometimes it is, sometimes it isn’t, and sometimes it ’s a subjective take on a new practice This could well be one of those occasions

The BS 7671 take on this is that connections should be of sound mechanical strength and electrical conductance; Regulation 134 1 4 is the one to look at The use of nut and bolt fixings on SWA ear thing tabs, or ‘banjos’, has long been the go -to method. That said, the type of self-taper used in metal enclosures probably wasn’t around or too prevalent when SWA cables were first used.

This doesn’t make them unusable, but there are some questions you need to ask yourself :

1. Does it afford the same mechanical and conductance proper ties?

2 Does it present a damage risk to other cables?

3 Is it really any less effective?

4. What does the SWA gland manufacturer say?

The first one can be checked by measuring for continuity and possibly an IR test. After that, if we look at the possible damage to other circuits, the cable is distanced quite well from the self-tapper, and to be completely fair, there are just as many sharp edges on some nut and bolt screw threads, so I don’t see that as an issue in this case. Additionally, we can see that the enclosure manufacturer has used something similar to fix the top access panel in place.

Something to consider also is that the self-tapper will dig into the bare metal of the enclosure and may have more effective contact and continuity proper ties, as opposed to the nut and bolt, although both should have some of the enclosure paint removed to ensure good electrical contact.

After all of those things are looked at, we need to see what the SWA gland manufacturer says This can be tricky as there are many, and pinpointing the actual one could prove fruitless

For me, this is an inspector ’s engineering judgement call as to whether this is coded at all, and if it is, it may only be a C3 rising to something more if there is visible damage to a cable, which there doesn’t seem to be here. So, in this case, I wouldn’t code this at all, but I may note on the obser vations that it should be monitored at its next EICR to confirm that the contact sur face is adequate

The A2:2022 18th Edition Codebreakers publication is priced at £22.00 (members) and £24.00 (non-members). It is available in both hard copy and digital versions

* Price is VAT exempt and excludes postage and packaging.

ORDER YOUR COPY OF NAPIT CODEBREAKERS BY VISITING: WWW.RDR.LINK/EAU014

I T ’s ‘OPEN’ SE ASON!

The Open Charge Point Protocol (OCPP) is an application protocol that enables communication between electric vehicle (EV) charge points and a smart back-office management system

Originally invented by Joury de Reuver and Franc Buve, the protocol has since been promoted globally by the Open Charge Alliance and become an industry-wide standard that allows seamless interoperability between the hardware, software, and electrified vehicles In addition to that, it means you can change the charging network without ever having to change the original infrastructure.

Why is OCPP important to the EV industry?

Since the number of drivers making the switch has dramatically increased over the last few years, it is crucial the

charging infrastructure is always accessible and available. Having an OCPP-compliant EV charge point will allow for future advancements and requirements in the industry to ensure an accessible charging experience

As technology evolves and new features or capabilities emerge, the network will be able to complete over-the-air updates and create those changes This ensures scalability and futureproofing of the charging infrastructure, minimising the need for costly replacements or upgrades

What are the overall benefits of OCPP to EV drivers and CPOs?

There are several benefits that both EV drivers and charge point operators can take advantage of due to the standardisation of OCPP Drivers will gain access to a wider charging network and be able to use EV charge points from different manufacturers and service providers This means they will not be tied down to just one manufacturer or service provider and can even choose a preference when it comes to charging at home or in public Communication between the charge point and vehicle

will also ensure drivers benefit from a smooth and reliable charging experience.

Charge point operators will also benefit from the freedom to choose from a range of hardware and software providers Again, this will be futureproofed due to the open protocol having the ability to update as/when new features or regulations are introduced which will maximise the initial investment.

The standardised communication provided by OCPP simplifies the management and control of EV charge points, meaning CPOs can benefit from remotely monitoring every charging activity which will reduce maintenance costs and improve the overall operational efficiency.

What are the benefits of OCPP to installers?

Installers aren’t limited to a certain brand or supplier thanks to OCPPs compatibility This means they can offer customers a wider range of EV charging solutions, increasing profits and customer satisfaction Benefits for installers also include scalability, remote management capabilities, data access and future-proofing These benefits contribute to more efficient installation processes and the ability to build and manage charging infrastructure networks effectively

SECTION TWO

The team at Sevadis provide more detail on the Open Charge Point Protocol (OCPP), its standardisation and what this means for EV charge point installations.

36 CPD Book PROFESSIONAL ELECTRICIAN GET MORE DETAILS ABOUT THE SEVADIS RANGE OF EV CHARGEPOINT EQUIPMENT AT: WWW.RDR.LINK/EAU019

IT’S A MATERIAL CHOICE

Before you install a cable management system you need to understand where you will install it and make sure that you select the right material to avoid corrosion. In this article Paul Nolan, Projects Director for the Hudson Group, takes a closer look at what factors you should consider.

We’ve all seen rusty or corroded cable management and containment systems due to someone selecting the wrong material But equally there is little point in choosing a more expensive corrosion resistant material if you’re installing the system in an office

And there are a lot of materials and treatments to choose from. So, when would you choose pregalvanised and what about powder coated, stainless steel or GRP? There are dozens of choices that you can make

Clearly the first step is to understand where you will be installing it Thankfully there is guidance and we can refer to EN ISO 12944-2 which classifies corrosion and gives examples of where you may find it (see the table in Fig 1).

The right material for the job

Looking at the table in Fig 1, let’s go through what materials you might use

Where there is a very low corrosivity, or C1, you will most likely be indoors in an office, school, hotel or perhaps a shop Here you would typically choose electro zinc plated or pregalvanised steel

Raising the stakes higher to a low to moderate, or C2 environment, you will be installing product in places such as industrial

premises, sports halls, warehouses or partially covered outdoor areas. Here we would suggest you install a pregalvanised

PROFESSIONAL ELECTRICIAN CPD Book 39

SECTION TWO

Fig. 1

steel cable management system

For C3 and moderate corrosivity, think outdoors or in a light industrial area, then you need to go beyond a pregalvanised solution. For these applications you would use hot dip galvanised, CPC or powder coated steel or PVC systems

For seriously corrosive applications where there is a high humidity or significant pollution, such as in chemical plants, dockyards or swimming pools, you will need hot dip galvanised, powder coated steel, stainless steel, PVC or GRP systems This is a C4 environment from the table in Fig 1.

And when the going gets really tough, where there is almost constant condensation and/or high pollution such as you might see in chemical or water treatment plants, heavy industry and dockyards, then you need to install a material that will stand the test of time

Known as a C5I classification you should consider stainless steel, deep galvanised steel or GRP cable management systems for these jobs.

And finally, there are marine environments where high moisture salinity, or salt, will add to the corrosion Here you really do need to use 316L stainless or a GRP system.

Some additional pointers

Corrosion is only one factor to consider when selecting your cable management material We’ve already talked about balancing corrosion resistance against price, but there are some other things that you should think about

In projects where there are a lot of electronics, perhaps in a data centre or where there are lots of computers, you need to know about zinc whiskers. These are very thin zinc strands that form on the underside of galvanised products They grow over time and will eventually break off, causing problems for electronics

Also, not all galvanised products are the same Pregalvanised steel will typically have a coating of between 8 - 20 microns while hot dip galvanised will give a standard coating of between 45 - 65 microns, but this is an average and the product will not be coated equally

For greater protection manufacturers can provide deep galvanised solutions where different carbon steels attract more zinc when dipped to provide an even thicker coating of greater than 160 microns But if you hear the term “double dipping” then take no notice because someone is trying to fool you. Dipping steel a second time will make no difference to the thickness of the coating

Equally not all stainless steels are the same – 316L is more corrosion resistant than 304L The ‘L’ means that it is a low carbon version of the standard stainless so it is more easily weldable, but 316L, which is known as “marine grade”, has more Molybdenum which makes it more

corrosion resistant to chlorides and therefore salty environments

New materials and treatments

Remember also that material science does not stand still – new and better materials and treatments are constantly being developed A good example is a new finish called Magnelis This offers better corrosive resistance than galvanised options, it is self-healing for cut edge protection and is more cost-effective It’s certainly something you should consider in the future

And for really extreme environments many turn to GRP, or glass reinforced polymer, as a go-to material. Even here you need to be aware of what you’re installing since the mechanical properties of this material can vary

Delving deeper there are four main resin types of GRP cable management products which will suit different specific atmospheric environments, but that is a whole new subject

Getting the material right for your next cable management or containment installation is vital if you want to provide a long lasting and cost-effective solution for your customer

There is a huge range of materials available to choose from Remember that if you are in doubt, you can always phone the manufacturer to ask for advice, especially if they offer a wide range of different materials

This article is based on a CPD seminar run by the Hudson Group – ‘Selecting the Correct Environmental Material’

GET MORE DETAILS ON THE RANGE OF CABLE MANAGEMENT SOLUTIONS

AVAILABLE FROM HUDSON GROUP AT: WWW.RDR.LINK/EAU017

SECTION TWO

40 CPD Book PROFESSIONAL ELECTRICIAN

PART ING THE FOG

2023 Corrigendum.

On 9th May 2023, IET and BSI announced the release of a Corrigendum to BS 7671:2018+A2:2022 The Corrigendum was published on 15th May 2023 and makes changes to six areas of BS 7671 that came into effect immediately

There is often a Corrigendum issued after BS 7671: Requirements for Electrical Installations, is published in a new edition or amendment.

What is a Corrigendum?

The word is derived from the Latin word corrigere, which means to correct

In this case, with regard to BS 7671, it refers to text or information that should be removed and/or alternative wording that should be added within the next release of the printed or electronic version of BS 7671 This will be the second Corrigendum since the publication of BS 7671:2018 in July 2018 The first Corrigendum was published in December 2018

The Corrigendum is available on the IET website and is free to download, but you’re not permitted to create further electronic copies without permission The reason for this is that the IET is the joint publisher of BS 7671 with BSI BSI is the