Securing our future with smart tech and sustainable practices

Dear Reader,

Innovation, consumer preferences and demand, and food security are all interconnected.

With monsoon rains and flooding affecting regions in Asia and the Pacific, millions of crops and livestock can be lost, which can create an imbalance in our food supply. Without innovation, addressing the demand for food and achieving food security can’t happen.

As discussions about food security continue to loom, it’s about time we actively participate in achieving a more food-secure nation. With changing consumer preferences and growing demand for healthier food alternatives, manufacturers and food producers should invest in research and development and innovation. Partnerships with stakeholders and the application of technology should take us a step closer to our quest for a food-secure nation.

We hope you enjoy this month’s issue of the Asia Food Journal!

EDITORIAL/PUBLISHER

Keen Whye Lee Publisher

Cath Isabedra Editor editor-afj@harvest-info.com

Danico Acosta Layout and Design OPERATIONS

Mari Vergara Head of Operations mari@asiantvawards.com

SALES

Simon Lee Hong Kong, U.S.A. sales@harvest-info.com

Chua Chew Huat Asia Pacific sales-sg@harvest-info.com

Erhardt Eisenacher Europe info@eisanacher-medien.de

MARKETING

Lali Singson mktg@harvest-info.com

Coy Nazario production@harvest-info.com

TECHNICAL SUPPORT

Michael Magsalin tech@harvest-info.com

150 Orchard Road #07-05 Orchard Plaza Singapore 238841

Cath Isabedra Editor

AsiaFoodJournal AsiaFoodJourna1 asia-food-journal-magazine

Nektium launches organic elderberry extract as demand for natural immune health ingredients continues

became a top-selling ingredient, having experienced a 150% jump in sales compared with 2019. We are proud that we have been able to develop our portfolio to offer our customers higher standardisations of anthocyanins as well as an organic variant, which we believe will tap into the increasing popularity of all things organic and ingredients with a proven positive immune effect.”

Nektium is also confident the company can meet the ongoing demand for elderberry, despite reports of global raw material shortages.

Adler said: “The sudden and significant increase in demand for elderberry since the onset of Covid-19 led to a temporary shortage of raw materials for many producers and we have also seen a rise in inferior low-quality products hitting the market. At Nektium, we have a trusted source of raw materials because long-term partnerships are important to us. We also ensure our suppliers comply with the highest of standards. Therefore, we are confident we can continue to supply our high-quality elderberry extract to meet the ongoing popularity of this ingredient.”

Protein in every layer: Arla Foods Ingredients launches new solution for bars

Arla Foods Ingredients has developed a plug-and-play solution to help manufacturers create indulgent bars with high-protein content in every layer.

Equinom is improving plant-based food with the help of its Manna technology

Scientists from NTU Singapore’s Food Science and Technology (FST) programme have developed a technique to cultivate a fungi-based food product that could serve as a healthier, better tasting and greener alternative to plant-based protein.

The fungi used to cultivate the product are grown from a base of nutrient-rich common food waste, which infuses the fungi with more essential nutrients, such as protein, iron, and amino acids. This makes them more nutritious than ingredients commonly used in plant-based alternative meat, such as peas, chickpeas, wheat gluten, and soy

Nektium will launch its organic elderberry extract as consumer demand for natural ingredients with antiviral properties continues to rise. The botanicals specialist is also releasing a more concentrated version of the product.

The global market for organic food and drink products is expected to expand at a CAGR of 11 percent per year, reaching a value of $220 billion by 2024, while the popularity of organic supplements is also on the rise.

Alongside this, demand for elderberry has been growing since the start of the pandemic, with consumers increasingly seeking natural ingredients that have a positive immune effect. Elderberries contain a high concentration of active ingredients, including phenolic compounds such as anthocyanins, which have been shown to reduce oxidative stress and ease flu-like symptoms.

To meet the demand for more concentrated extracts, Nektium is now adding a new grade of its elderberry line, containing 10 percent anthocyanins. The 10 percent variant will join the existing 6 percent grade in the company’s portfolio, which will now also be available in organic form for the first time. Nektium’s elderberry portfolio comprises ingredients made from Black Elderberry (Sambucus nigra), which has been scientifically proven to treat upper respiratory symptoms effectively.

Thomas Adler, Chief Business Officer at Nektium, said: “Demand for elderberry rose significantly when the pandemic hit, and it

With 80 percent of consumers saying they are interested in protein (up from 69 percent in 2014), protein bars are increasingly common in retail outlets.

However, most have a more uniform mass than indulgent confectionery options, which can offer a wider variety of layered textures. This is a challenge in the increasingly saturated bar market, where texture is a major driver of consumer purchasing decisions.

Now Arla Foods Ingredients has launched a protein bar concept that allows brands to raise the protein content of every part of their bars – including the mass, filling and coating – without increasing size or compromising on taste or texture.

The new recipe is based on high-quality whey and milk protein ingredients from the company’s Lacprodan® range. It ensures that rich chocolate mass retains its flavour and softness throughout its shelf life and offers 30 percent protein per bar, allowing for high-protein claims. As a “plug-and-play” solution, it can be used by brands as it is or as the basis for their own formulations.

Laima Liepinyte, Sales Development Manager, Health & Performance Nutrition at Arla Foods Ingredients, said:

“In the crowded bar market, manufacturers need to capture the attention of consumers seeking high-protein options that are just as appealing as their confectionery counterparts. With Lacprodan® ingredients, they can create multi-layer protein bars with a palette of textures and a soft, light and creamy mouthfeel. As well as delivering pathways to success for wellness-focused manufacturers, this new concept opens new doors for highprotein confectionery products.”

Equinom, a food technology company, is now transforming the plant-based food sector by offering top-notch, non-GMO ingredients made with artificial intelligence (AI). The tech uses an automated matching concept where plant-based food developers are matched with optimized, high-quality ingredients.

Established in 2012, Equinom combines its AI and food development expertise with its patented Manna technology. The Manna Ingredient Platform utilises AI to analyse more than 50 million breeding combinations inside the company’s seed vault. The vault house over 250,000 varieties of seeds.

The Matchmaking Process

Food companies can send their requests for plant-based ingredients with the sensory traits they wish to develop for their food products. The Manna tech will start analysing the breeding combinations and recommend seeds for cross-breeding.

Chosen seeds undergo breeding. Equinom collaborates with farmers to plant, test, and harvest crops. These Equinom grains will be transformed into food ingredients with the help of ingredient processors.

Since most seeds are of high quality, they require minimal processing, resulting in excellent, non-GMO ingredients that plant-based enthusiasts can enjoy.

The company, with headquarters in the US and Israel, has several partners they’ve been collaborating with to bring only the best plant-based products to the market. What used to take years to perfect can now be done much faster, with minimal trial and error. The Manna platform is critical in helping companies develop and improve their product line by harnessing the power of artificial intelligence.

“As a result of minimal processing, Equinom ingredients tend to have more beneficial nutrients intact (e.g. fibre) and less detrimental ones (e.g. sodium),” Equinom founder Gil Shalev shares. “They also have a much better carbon footprint, using no chemicals and significantly less water and energy in their production.”

What food developers lack, such as understanding the biochemical properties of crops to attain their preferred flavours, is what the Manna technology addresses.

“Food developers rely on anecdotal experience and much trial and error to hone in on a successful ingredient for any given application,” Shalev explains. “We saw an opportunity to provide metrics that correlate to desired functional and sensory traits to make the application development process more efficient and turnkey—and that unique ability remains a core differentiator for us today.”

The cultivation of the NTU-developed food product would also offer an opportunity to reuse common food waste and byproducts of agriculture and the food and beverage industry, such as soybean skin, wheat stalk, and brewers’ spent grain, a by-product of the beer-making industry.

To scale up their fungi-cultivation method, the NTU team, which also includes PhD student at NTU’s FST programme Miss Malsha Samarasiri, is collaborating with The FOODBOWL, part of New Zealand Food Innovation Network, a national network of open-access food processing facilities supported by the New Zealand government to help food businesses and startups globally innovate, scale up and commercialise new products – ultimately to the international scale.

One New Zealand startup collaborating with NTU’s FST programme to implement fungi cultivation technology in its food products is Off-piste Provisions, a plant-based meat company.

Besides playing an advisory role to startups, the researchers at NTU’s FST programme hope to develop their product to boost its nutritional profile further and reduce food waste. They also hope to commercialise their solution by the year 2024.

Fungi-based protein healthier and greener alternative to plant-based meat

This will accelerate the company’s vision of establishing ProfilePrint’s digital fingerprint as a global standard for the industry.

Singapore’s ProfilePrint, a pioneering solutions provider to grade food ingredients using A.I. technology, has added U.S.-based Cargill (one of the world’s leading global food suppliers) to its panel of strategic shareholders through its Series A funding round.

To date, the other strategic shareholders are Louis Dreyfus Company (Netherlandheadquartered world leading merchant and processor of agricultural goods operating in 100 countries), Olam International (Singapore-headquartered major food and agribusiness company operating in 60 countries), Sucafina (Switzerlandheadquartered multinational coffee merchant operating in 32 countries) and Sinar Mas (one of Indonesia’s conglomerates that operates in seven business areas including food and agribusiness), as well as institutional venture capital funds.

Together they will accelerate the company’s vision of establishing a common digital standard based on its patented food fingerprinting technology. Cargill’s investment signals confidence in the Singapore-based deep-tech start-up, with its solution deployed in over 26 cities globally across five continents (North America, Latin America, Africa, Europe and Asia).

ProfilePrint is an A.I.-driven predictive and prescriptive profiler, providing users with accessible, affordable, and portable solutions to ascertain and predict the quality and profile of a food ingredient at the point of use within seconds. Today, enormous resources are required to physically grade food samples across multiple stages of the global supply chain. ProfilePrint’s solution redefines transaction standards and offers sellers and buyers an unbiased reference point, expediting existing quality assessment processes – from the farm to end-buyers.

Over the last six months, Cargill has completed successful pilots with ProfilePrint, which validated an array of practical applications of this disruptive technology across its portfolio of ingredients, such as cocoa and chocolate, which will accelerate ProfilePrint’s strides in establishing cocoa as a core vertical, after strong traction in coffee.

“ProfilePrint’s digital food fingerprinting technology holds the potential to transform the global food ingredient supply chain, strengthening the sensory innovation capabilities of our ingredient portfolio without compromising on taste and quality. This can help Cargill deliver against our high standards for food quality and enable faster and more precise product development for our customers,” said Francesca Kleemans, Managing Director for Cargill’s Cocoa and Chocolate business in the Asia Pacific.

Alan Lai, CEO and Founder of ProfilePrint, adds, “Cargill continues to strengthen our solution and accelerates our vision of establishing ProfilePrint as the industry’s digital standard for food ingredients globally. Our solution allows users to ascertain the agreed quality of food ingredients in an online transaction, saving time and money by transforming the current onerous process of sending samples for physical checks. We enable our clients to co-create a sustainable ecosystem with their partners to overcome the challenges of supply chain risks, while increasing their competitive edge for growth and resiliency.”

“We warmly welcome Cargill joining our strategic shareholder ecosystem. Cargill’s investment and partnership further solidify our investment thesis on ProfilePrint’s team and technology as the leading disruptive company in this market,” added Dr Wong Mun Yew, Managing Partner of Greenwillow Capital Management.

In June 2021, ProfilePrint was selected as the winner of the Cargill Health Through Nutrition Award at Future Foods Asia 2021 (Singapore). ProfilePrint also bagged numerous other awards, including winning the National Innovation Challenge for Supply Chain Resiliency 2020 (Singapore), International Grand Champion of Vietnam Startup Wheel 2021 (Vietnam), and 2nd runner-up at the International Suzhou Jinji Lake Startup Competition 2021 (China).

The funds will be used to invest in product development, talent acquisition and team expansion.

Fresh milk and cream: increasing capacities for returnable bottles

Fresh milk produced using traditional methods is the cream of the crop. The Berchtesgadener Land dairy fills this precious commodity in glass bottles. To meet the soaring demand for milk in returnable bottles, the cooperative has replaced its returnable-glass line, which fills organic and mountain farmers’ milk and cream.

‘The cows are our key staff,’ say the folks at the Berchtesgadener Land dairy. And you immediately notice that they mean it. A life-size plush cow stands in the reception lobby of the modern, welcoming administration building, and in the seating area you feel a bit as if you were sitting on a mountain pasture. Large photos on screens in the canteen showcase cows in artful settings, and in the meeting room cow bells are used as lamp shades.

Everything here revolves around the cows, or to be more precise their milk, which is supplied by the approximately 1,800 farmers who own the cooperative. When you talk to the people working for the dairy, you cannot help but notice the deep sense of attachment they feel to “their” farmers and the top-quality milk they supply.

The cooperative’s paramount business target is clearly perceptible: to preserve the existence of their farms, by fetching the best-possible milk price with high-grade products and smart marketing. The key priority is to preserve the smallholdings in the mountainous area between Watzmann and Zugspitze, in particular, where the average farm has 27 cows. They’d do almost anything here for their mountain farmers, even if that means driving a milk collection truck along winding mountain tracks to pastures located at elevations above 1,000 metres. They do that every other day in the summer season when the cows are up there.

Soaring demand for milk in returnable bottles

The Berchtesgadener Land dairy cooperative was founded in 1927, almost 100 years ago. Today, it has a payroll of 500 and processes 1.1 million litres of milk per day, turning them into more than 150 different products, ranging from a number of yoghurt and fromage-frais variants and cream right through to UHT, ESL and fresh milk. The dairy makes all those articles in-house at its Piding facility, most of them in conventional and organic quality. The cooperative was the first dairy in Germany to launch organic products in 1973, at that time working with five Demeter farms. The number of the cooperative’s organic farms has since grown to around 600, of which 100 belong to Demeter, Germany’s oldest organic farming association, and 500 to Naturland – Registered Association for Organic Agriculture.

“Traditional fresh milk is the most difficult product to make in our field,” says Paul Althammer, deputy production manager at the dairy. “We want to preserve everything

we can in the milk and treat it to maximised standards of gentleness. This premiumquality product must be filled in premiumquality packaging, the glass bottle.”

The dairy has filled its fresh milk into returnable glass containers since 1990. Soaring demand for milk in returnables caused some bottlenecks in the previous line, which was rated at 6,000 containers per hour. The situation even got so critical that the dairy had to temporarily cease production of the bottled conventional cream.

In 2019, the cooperative decided to change its plans and to use a building that had originally been erected to accommodate filling lines for beverages cartons for a new returnableglass line. This enabled the dairy to promise its customers that the popular bottled cream would return. The half-litre bottles with the green label then reappeared in the refrigerated display cases just in time for the 2022 strawberry season.

Altogether, the Berchtesgadener Land dairy has invested a sum in the two-digit millions into new buildings and the new line. For the cooperative’s farmers, that means having to do without the maximum possible milk money today, in favour of safeguarding their future. The expectations for the lines and systems are correspondingly high, as is the responsibility shouldered by project manager Paul Althammer.

The right stuff: traditional fresh milk in returnable bottles The most important requirement for the new line was quality, both in regard to the machines and systems and the products made on them. “Production lines for traditional fresh milk must always give reliable service. We don’t have time for long maintenance routines,” emphasises Althammer.

The milk is delivered to the dairy every day and must be dispatched fast, in order to guarantee retailers a minimum shelf life in the cold chain of eight days. What’s more, complying with stringent cleanliness standards in production is the top priority for filling this unsterilised milk. Germs carried in from outside result in faster milk spoilage, meaning the required shelf life would then not be met.

When filling into returnable bottles, moreover, contaminated empties must not be allowed to enter the filling zone. That entails stringent requirements for the bottle washer, the filler and overall hygiene standards for the line.

ProfilePrint closes series A1 with Cargill, bringing five of the world’s largest food ingredient corporations together as investors

Mondi opens laboratory that tests paper product recyclability

recycling facilities but on a smaller scale. The results generated provide concrete evidence that the material can be recycled.

Elisabeth Schwaiger, Head of R&D and IP Flexible Packaging, Mondi says:

“The ability to provide our customers with information on the recyclability of our products will be a key enabler in our efforts to develop more sustainable solutions and enhance our value proposition for customers. Currently, 78 percent of Mondi’s group-wide portfolio is already either reusable, recyclable or compostable. This recycling lab enables us to move closer to our MAP2030 goals of making 100 percent of our products fulfil these requirements by 2025.”

New study shows supermarkets could add ecolabels to foods

A new study conducted by Oxford University researchers shows that it could be possible for shoppers to check the environmental impact of their purchases by stamping food items with eco-labels.

Majority of Canadians oppose eliminating “best before” dates on food products to reduce food waste, according to new report

“The results of the survey open up some rich perspective into Canadian consuming habits. It really depends on the subcategory of food, with greater perceived risk of animal-based foods and prepared foods perishability, which can carry greater health threats if the items are going bad,” said Dr Juhasz, Research Associate at Dalhousie University’s AgriMark Food Analytics Lab.

• Mondi opens an in-house recyclability testing laboratory in Frantschach, Austria

• Laboratory speeds up testing of paper and paper-based material

• The lab determines how the packaging will perform in a large-scale recycling mill, on a smaller scale

Mondi, a global leader in packaging and paper, opened the Group’s first recycling laboratory at its Frantschach mill in Austria to test the recyclability of paper and paper-based packaging using non-paper components such as coatings.

Conducting recycling tests in-house speeds up the process of developing sustainable packaging. While paper packaging offers many sustainability benefits, it also has certain barrier functionality limitations for products like perishable food.

To enhance its functionality, non-paper components such as barrier coatings may need to be added, which in turn can impact recyclability. The data collected at the laboratory can be used to improve existing products and provide reliable information about their environmental impact.

Mondi will also use the results to determine how the design of new packaging can be improved as well as how best to improve the circularity of [our] material flows.

The tests are carried out on various paper and paper-based packaging products developed by Mondi and can determine whether the packaging can be efficiently recycled. The laboratory works in a similar way to industrial

With the new study, shoppers can make intelligent purchases since UK manufacturers will have to list their main ingredients by percentage, not the amount. The scientists addressed the issue of using public databases by estimating the composition of food products and their environmental impact.

Professor Peter Scarborough shared that the research can lead to an eco-labelling system for consumers, specifically those conscious of how their weekly visits to the shop impact the environment. But beyond this, Scarborough believes that a more significant impact needs to come from the food industry. They should use the research on eco-labels to cut their environmental footprint.

He shared, “It fills a huge gap. Manufacturers, caterers, and retailers have targets for reaching net zero [emissions], and they don’t have the tools they need to get there.” He added, “Now they have this data, and some of them are talking to us about things they can do to help people move towards more sustainable food purchasing. The data could help manufacturers adjust their formulations.”

The research has been published in the Proceedings of the National Academy of Sciences.

The Agri-Food Analytics Lab at Dalhousie University, in partnership with Angus Reid, is releasing a new report on “best before” dates and food waste.

It has been suggested numerous times that “best before” dates will generate more food waste. Consumers will be influenced by dates shown on food packages, whether they are expiry or “best before” dates. In recent months, several grocers in Europe like Morrison’s and Waitrose have opted to eliminate “best before” dates with the intention of reducing food waste.

Despite the fact that our food safety regime here in Canada is a little different, our lab wanted to know how important these dates are to Canadians and if consumers here would be willing to purchase products without them.

When Canadians are asked how often they look at “best before” dates, the frequency will vary greatly depending on the food category. While a total of 73 percent of Canadians will always check dates for dairy products, only 32 percent will look at dates for packaged foods/non look at “best before” perishables.

Women and older consumers are more likely to always look at “best before” dates. The survey probed how consumers consider “best before” dates when purchasing or consuming different food products. While a total of 44 percent of Canadians had bought a discounted food product for which the “best before” date had passed, 78 percent consumed food after the date had passed. A total of 65 percent had thrown out unopened food because the date had passed.

Consumers have different ways to manage risks and will do different things to determine whether a product is safe to eat or not. While 28 percent of Canadians will look for the presence of mould, 25 percent will rely on “best before” dates as an indicator of food safety. A total of 20 percent will rely on smell, and 17 percent will rely on the appearance of the food product itself. It is important to note that most microorganisms that can make people sick do not change the smell or the look of the food.

“There is a broad spectrum of Canadian consumer habits taking place, some more inclined towards trusting the food product, and others more risk averse. This is fertile ground for more research, maybe even comparing perceptions of ‘best before’ compared to expiry dates.” The results really point to food safety contradictions in Canada. While many Canadians are willing to buy and consume food after the “best before” date has passed, many will throw away unopened food products.

The willingness to buy a product in Canada without a “best before” date will again vary greatly, depending on the food category. While a total of 68 percent of Canadians would be willing to buy produce without an expiry date, only 15 percent would be willing to do the same with dairy products.

There are minimal statistical variations between provinces, but men are more likely to be willing to buy food products without a “best before’’ on them, except for produce. Younger consumers are more willing to buy food without a “best before” date, except for dairy. When asked specifically about whether Canadians support eliminating “best before” dates to reduce food waste, most Canadians are against such a measure.

Only 27 percent of Canadians either strongly support or support eliminating “best before” dates. The highest is Quebec at 36 percent, followed by Saskatchewan, where the level of support for such a measure is at 28 percent. The lowest support is in Alberta, at 22 percent.

“In light of these results, it is obvious that the food safety culture in Canada is quite strong,” stated Dr Syl vain Charlebois, Director of the AgriFood Analytics Lab. “Unlike for grocers in Europe, removing ‘best before’ dates will likely be viewed as an unpopular gesture, at least for now,” said Charlebois.

When it comes to food safety, Canada is the 7th most food secure country in the world in the world, followed by the United States and Ireland. The focus on food safety in Canada has been historically higher in comparison to other countries.

3D line design by KHS: customers already benefit during the offer phase

• Systems provider makes the full switch to 3D planning

• Possible drawbacks in the production environment detected early on

• New digital system speeds up the 3D planning process

Additional security of investment: thanks to the use of 3D software, the KHS Group now provides a timely virtual overview of all newly procured technologies at the offer stage.

With it, the systems provider can illustrate in detail and in advance how a client’s potential new line or single machine can be integrated into the production environment, taking all prevalent conditions on-site into account. By making a full switch to the three-dimensional planning method, KHS is successively expanding its portfolio of reliable services.

“Depicting machinery in 3D helps customers to pinpoint any geometric interference during the early offer phase. This improves planning security, as any spatial conflicts in the production shop are recognised and corrected right from the start,” says Patrick Bürger, head of Plant Design at KHS.

Unnecessary loops in the planning process – and consequently additional costs – are thus avoided early on. “We show customers how the line or machine fits into their existing environment. If required, we include the operators in the advance planning process and show them how they can later move around between the machines. Their feedback is of great value to us and enables us to devise an optimum layout,” he continues.

3D planning also shows machine heights New software is used to this effect that speeds up the entire 3D planning process as it is easy to use. At the same time, the system depicts the relevant machines and conveyor elements in greater detail than in the previous 2D variants. Production environments spread across several floors or located in extremely confined spaces can be simply and clearly visualised. 3D line design can be applied to all machines in the KHS portfolio – regardless of the container or beverage segment.

KHS offers laser scans that can be easily integrated using the new software to further improve planning security. Here, a 360°

“These individual images are then superimposed. This creates what’s known as a scatterplot that takes all geometries into account. Interferences and disruptive elements are reliably detected,” Bürger explains. This is particularly advantageous when integrating new systems into parts of buildings that already contain machinery as it prevents possible collisions with existing equipment.

3D models for further processes

Moreover, the use of 3D line design is also helpful to further processes. According to Bürger, customers are increasingly requesting rendered images for system visualisation so that they can display and process live data from their MES on a production monitor. “This enables plant operators to track what’s happening on the line in real-time and to see how high the current output is, for instance. We can provide these images as an option,” states Bürger.

3D data can also be used to build information modelling (BIM). This describes a networked planning method in which all assets – from data on the building through piping and ventilation systems to the energy supply and, ultimately, the filling line –can be compiled and displayed in a single line design model.

“We have quite a bit of experience with BIM projects. We’ve had plenty of very positive responses regarding the data quality here, for example. Our optional support program not only includes the provision of this data in various exchange formats but also enables plant operators to take part in regular BIM coordination meetings,” Bürger adds.

Another advanced 3D planning option is to use mobile VR goggles. Bürger claims this is particularly beneficial in confined spaces as it shows where and how operators can move from machine to machine. “VR simulation helps to provide simpler access to complex areas and to clearly visualise these. We’re hoping to find a number of prototype customers by the end of the year who we can test this form of visualisation with in specific offer planning processes and present the benefits on the ‘live’ object.”

In Bürger’s opinion, 3D line design by KHS is currently setting standards on the market. “We’re moving into the future together with our customers. The feedback we’ve had so far has been extremely positive.”

Large scale sustainable rice project improves incomes of smallholder farmers and makes positive impact on environment

• 10,000 farmers on the Mekong Delta see incomes increase by 17% through a successful public-private partnership between Olam Agri, GIZ, and MARD

• Farmers in the programme’s trial plots saw a reduction in water usage by up to 40% and N-P-K fertiliser by up to 15%

• Improved quality of rice meets international standards and opens up new markets in EU and US

Vietnam, 21 September 2022 – 10,000 smallholder farmers have made significant improvements in farming practices and the quality of rice as part of the Market Oriented Smallholder Value Chain (MSVC) programme.

Established in 2018, MSVC is a multi-stakeholder initiative between Olam Agri, German development cooperation Deutsche Gesellschaft für Internationale Zusammenarbeit (GIZ) GmbH, and Vietnam’s Ministry of Agriculture and Rural Development (MARD).

Through this programme, up to 150,000 tonnes of paddies that meets international standards is produced, creating new growth opportunities for Vietnam’s rice exports to markets such as the EU and US. Most smallholder farmers in the programme recorded more than 50 percent increase in scores verified by the Sustainable Rice Platform (SRP), the world’s first voluntary sustainability standard for rice production.

Additionally, some farmers in the programme’s trial plots reduced their water usage up to 40 percent and N-PK fertiliser up to 15 percent as they moved from traditional flood irrigation to more modern alternate wetting and drying (AWD) and drip irrigation techniques.

“We owe the great success of MSVC to the resilience of the farmers and the strong support we have received from the MARD, Department of Cooperatives and Rural Development, and local government authorities. We are strongly committed to the development of agriculture in Vietnam, and we are pleased that the increase

in quality and safety standards of the rice varieties produced has opened the doors to more markets globally, including EU and US,” said Mohit Agarwal, Country Head of Olam Agri Vietnam.

“Sustainable rice benefits farmers, communities, and consumers while providing nutrition for 97 million people in Vietnam. In line with our purpose to transform agriculture for a more sustainable future, Olam Agri is working closely with a consortium of partners to advance the quality of rice produced in Vietnam and improve the livelihood of Vietnam’s farmers by strengthening their links to the global value chain where there is strong demand for safe, high quality and responsibly-produced rice,” said Paul Nicholson, Vice President for Rice Research and Sustainability, Olam Agri, one of the world’s largest rice merchants and a founding member of the SRP.

Olam Agri is one of the world’s largest rice merchants and a strong advocate of sustainable rice cultivation. In the MSVC Vietnam programme, Olam Agri provided farmer incentives and created market linkages between cooperatives and millers to buy paddy directly from the farmers in Mekong Delta. With proven expertise and knowledge in sustainable farming practices, Olam Agri will be producing and packing private-labelled rice that carries the SRP-Verified Label from Vietnam‘s SRP-certified farms in the Mekong Delta.

“We highly appreciate the efforts of the partners in building a comprehensive set of solutions from improving farming techniques to access to markets, including developing the capacity of farmers, and farmer organizations in improving the quality and value of rice. The successes and lessons learned from the project will contribute to supporting state management agencies at all levels in the process of directing, formulating, and adjusting policies to promote the development of production and market linkages for agricultural products in the country,“ said Mr Le Duc Thinh, General Director of the Department of Economic Cooperation and Rural Development, MARD.

As an ongoing effort to continue advancing sustainable farming practices in Vietnam, Olam Agri will continue to work with the Vietnam government to train farmers on techniques to protect soil health and create more support for the inclusion of women in agriculture.

Waiting for the storm to pass: Will climate resilient agriculture finally address food security issues in Asia and the Pacific?

WILL WE SEE A FOOD-SECURE ASIA AND THE PACIFIC SOON?

of dry and wet seasons can reduce food productivity. Farms in susceptible areas, such as those near coastal waterways, can suffer from a sudden rise in sea levels, land subsidence, and erosion.

These challenges aren’t only limited to rural areas. Urban areas also suffer the consequences.

According to the Singapore Food Agency (SFA), local food production in the country helps buffer against import disruptions. “With global pressures (e.g. adverse weather due to climate change, urbanisation) and evolving market conditions (e.g. changing consumer diet/ demand), our future food system would be different from what it is today, especially for an urban city like Singapore.

So what can be done to address these looming agricultural issues in the region? Climate-resilient agriculture.

Climate-resilient agriculture and food security

The concept of climate-resilient agriculture (CRA) isn’t new. However, it’s only recently that more and more stakeholders are looking at its impact on food security. We asked Dr Uday Nidumolu, a principal research scientist at Commonwealth Scientific and Industrial Research Organisation (CSIRO), about CRA and its implications for food security. He explains,

Countries that belong to Asia and the Pacific, particularly the Philippines, Indonesia, India, and Kazakhstan, are considered to be highly agricultural. They are also among the areas with tremendous seasonal changes in recent years.

Climate resilient agriculture, as the term indicates, aims to build resilience in agricultural systems. This includes information-rich farming systems, such as improved and reliable climate forecasting, capacity building from the bottom-up at a community level, improved use of inputs, appropriate use of crop choice (such as low water demanding crops), and varieties, for example, short season varieties for when a monsoon season is delayed. ”

Agriculture remains a key economic industry in Asia and the Pacific. Market research shows the region is the largest producer of agricultural products globally, taking up more than 50 percent of the region’s land area.

As Asia and the Pacific population continue to grow amid the pandemic, demand for sustainable, safer, and healthier food increases. Asia Food Challenge revealed that food spending will double to $8 trillion by 2030 from $4 trillion in 2019.

This should be seen as a positive sign. However, at present, that’s not the case. The region continues to face food security issues. Countries that rely heavily on agriculture can’t even provide enough food for their current population. While there may be consumption growth, more than 700 million people in Asia and the Pacific live in poverty and suffer from undernourishment.

The region has limited land area they can

till to produce more agricultural products. Some countries have poor water and resource management. And then there’s also the issue of climate change – which may very well be the region’s greatest threat to food security for the next two decades.

Historically, when conditions remain stable, productivity follows. Consumers can enjoy high-quality products at reasonable price points. Today, with the impact of climate change, erratic wings

In the Philippines, the adoption of technology and CRA remains a challenge. The majority of farmers are old and considered risk-averse. They tend to refuse training to improve crop management and leverage innovative agricultural practices, and this can have a long-term impact on the agricultural sector.

But it doesn’t mean movements aren’t there. Several organisations are now using technologies and approaches to planting stress-tolerant crop varieties, utilising water harvesting technologies, and integrating crop and pest management.

Dr Nidumolu also shares that many

countries actively invest in CRA technologies.

He adds, “There is a renewed interest in managing climate risks in agriculture in the Asia and Pacific region. For example, in

India, climate-smart villages are a concept that is being developed and scaled up. Climate Information Centres (CLICs) are applied to communities in many large-scale agricultural developmental projects.”

Partnerships with stakeholders play a crucial role “CSIRO and the Australian Centre for International Agricultural Research (ACIAR) have partnered with in-country institutions to develop this idea. In the Philippines, there is significant work to improve the use of seasonal climate forecasts to manage risk in agriculture. Australian scientists have contributed to these efforts as well,” Dr Nidumolu says.

In areas where land use remains an issue, discovering different smart agriculture technologies has become more important than ever. With less than one percent of agricultural land, Singapore deals with food production issues. Reliance on importation can cause major disruptions to food security.

SFA explains, “Today, we import food from more than 170 countries/regions. The food industry is encouraged to explore new sources and maintain existing sources, which allows importers to tap on alternatives if there is a disruption to any one source (e.g. intense storms, drought,

and staffing shortages).”

The agency furthers, “An example would be reduced vegetable yield from Cameron Highlands due to bad weather in 2020, where the food industry was able to switch to other sources such as China, Indonesia, and Vietnam.”

There’s a great need to adopt sustainable practices and technologies to mitigate the effects of climate change. With this, consumers could expect high-tech farms with controlled environments to produce the food they eat.

Addressing the roadblocks

We’re still far from fully implementing CRA. Challenges still abound. Dr Nidumolu says, “Localised-contextualised information generation, access, and applications at a farm level is a challenge.”

He further explains, “For example, climate info needs to be made meaningful for use at a community scale. Another roadblock is access to inputs at the required time,

such as access to short season varieties when the break of the season is delayed, as well as availability and access to cold storage to reduce spoilage and get remunerative price for their produce.”

SFA understands the importance of support. The agency continues to work with industry partners to discover opportunities where they can diversify sources and increase local food production through technology.

As part of their support towards a highly productive, climate resilient, and sustainable world, SFA has implemented several strategies. The agency is actively doing holistic planning of older farmland areas to optimise food production on farmland and expand sustainable fish farming in the deeper southern waters of Singapore.

The agency launched the Agri-food Cluster Transformation (ACT) fund to financially support farms’ needs in innovating, upgrading, and upscaling their agricultural processes. SFA also invests in innovative research projects focusing on sustainable urban food production innovation through the Singapore Food Story R&D Programme. Reliance on local farmers is also promoted by rallying citizens to promote local produce and encourage producers to embrace sustainable farming.

For CSIRO, addressing the roadblocks mean investing in smart agriculture.

“Improved forecasting methods over the short, medium and seasonal scales will provide valuable data that can be translated into decision-making tools for use on-farm.”

Dr Nidumolu adds, “At CSIRO, we’re also looking at improved crop genetics that is drought tolerant and high yielding and food processing technologies. We’re also looking at soil moisture management capacity building for communities, helping farmers with using simple-to-use soil moisture probes.”

He further adds, “CSIRO’s Virtual Irrigation Academy (VIA) (via.farm) is a good example of a technology that is very farmer friendly and has proven mature technology that is being applied in many countries in Asia and Africa.”

Smart agriculture and the future of farming

Thanks to technology and collaboration from different organisations, climateresilient agriculture can help farmers affected by climate change to continue farming and bringing food to consumers.

In Singapore, high-tech indoor and floating fish farms are becoming increasingly common. These farms, because they’re not exposed to the changes in the weather, are climate resilient. They’re also notable for using innovative concepts to raise productivity and sustainability.

Achieving food security Will food security be achievable soon?

Dr Nidumolu believes we’re a step closer. Farmers in climate-risk regions have long incorporated innovative ways in their agricultural practices.

“For example, Australian farmers operating in low rainfall regions operate with great efficiency to optimise water use. There is deep knowledge of the farming system accumulated over centuries. However, with a changing climate, there is a need to develop information-rich farming systems that can cope with change and manage using new technologies and information being developed globally, including in Australia.”

With insights from Dr Uday Nidumolu, principal research scientist at CSIRO and the Singapore Food Agency.

“For example, Singapore Aquaculture Technologies (SAT), is one of the first to adopt closed containment aquaculture systems on a floating structure, which separates the culture water from the sea, enabling fish production to be resilient to external environmental conditions. Their farming system consists of selfcleaning fish tanks, automated fish selection systems to harvest and count fish, and solar panels to tap on solar energy to power the farm,”

”

INGREDIENTS

Backed by science: zeroing on the microbiome and gut health

With improving life expectancy, the interest has shifted from adding years to life but more about adding life to years. And this has led to the desire to search for practices that promote good health.

Several studies have clearly established how consumers have increasingly become more health conscious. They are now critical when it comes to the impact of what food, drinks, and supplements they feed their body with. Recent research shows that consumers are actively seeking food items with health benefits. In ADM’s

53% of consumers find brain-health products appealing.

Source:

latest Global Consumer Trends Report, 53 percent of consumers find products that support brain health appealing. Consumer preferences have changed dramatically, with many looking into food products that can provide holistic health benefits.

The microbiota benefit

Each individual has a unique set of microbiotas based on their DNA. First exposure occurs in infancy, during delivery and from breast milk. The microbiome changes as the individual get exposed to their environment and diet. These changes in microbiomes can be either one of two things: symbiotic or pathogenic.

In general, this microbiota can coexist. A healthy person’s microbiome make-up can offer protection against diseaseinducing organisms that enter the body. However, once there’s an imbalance, dysbiosis can occur, making people more susceptible to developing diseases.

Digesting microbiome

Is the food and beverage industry ready to “digest” microbiome?

Lois Mo, Marketing Director, Health &

Wellness for APAC at ADM shares, “We are seeing convenient foods, beverages and supplements with enjoyable sensory experiences coming to the forefront in the specialised nutrition sector, including fortified drinks, sparkling waters, stick packs, powders and more. These new formats are also opening the door for more personalization and consumer enjoyment, resulting in more specialized nutrition products that support consumers’ personal wellness goals.”

The F&B industry is continually evolving–driven by consumer demand and technological advancements. With increasing awareness about beneficial bacteria, it’s no longer surprising to see manufacturers incorporating microbiome

solutions into everyday food items. “Formulating with well-documented, branded ingredients makes sound business sense for more than one reason. As well as addressing regulatory requirements, it helps manufacturers to create innovative foods and beverages that consumers want, and it delivers on the consumer demand for researchbacked products they can trust,” Murphy comments.

Backed by science

In the past decade, we’ve seen an explosion of microbiome research. Many of these studies revealed valuable insights into how bodily microbes can impact human health and disease, from gut to brain health.

According to Aoife Marie Murphy (PhD), Nutrition Business Development Manager at Kerry, “the deepening scientific understanding of the relationship between the microbiome and the immune system and the gut-brain axis is driving research, innovation, product development and consumer interest in gut health, and probiotics in particular.”

She adds, “As a result, the probiotic market has grown considerably, and we are seeing probiotics feature in a wide range of food and beverage products beyond the traditional dairy offering. For example, innovation in probiotic stability means that we can now see certain strains feature in ice cream, tea bags, energy bars, gummies, snacks, juices and many more, delivering health benefits to

consumers in a variety of formats.”

Mo shares the same sentiment. She says, “The emerging scientific evidence connecting the gut microbiome to aspects of cognitive function is leading to new applications that will offer consumers new ways to support the function of the gut-brain axis.”

Addressing food safety concerns

With food-borne diseases in the equation, food safety remains a valid concern. This can impact how consumers can be more welcoming of probiotic products.

Probiotic stability is a challenge. Probiotic strains in the market mostly have vegetative cells with high vulnerability against gastric acids, decreasing their ability to provide optimal health benefits.

While most products undergo microbial content analysis before they hit the shelves, quantifying total microbial content can be challenging for probiotics. Some bacteria strains have a shorter shelf life.

Murphy shares, “Probiotics can contribute to the total microbial count. Therefore, analytic identification methods to characterise specific probiotic strains from other microbial counts within a food have been developed.”

“Food technologies can influence aspects of convenience, design and probiotic protection,” says Mo. She shares that “ADM’s spore-forming probiotic Bacillus

subtilis DE111® has also demonstrated survival through processing as well as excellent stability throughout the shelf-life even in high-water activity formulations. Bacillus subtilis DE111® can protect itself through manufacturing and digestion, and it is well suited for challenging processing conditions that may otherwise damage conventional lactic acid bacteria-based probiotics.”

In the midst of regulatory policies Entering the microbiome food development means awareness of the different regulatory compliance policies in place.

As consumer demand for functional foods grows, regulatory environments are changing in response. This has created challenges, but also opportunities to innovate with clinically supported ingredients that clearly communicate benefits. In recent years, the regulation of probiotics has been a particularly contentious area. ”

“As consumer demand for functional foods grows, regulatory environments are changing in response. This has created challenges and opportunities to innovate with clinically supported ingredients that clearly communicate benefits. In recent years, the regulation of probiotics has been a particularly contentious area,” Murphy shares.

She adds that most would heavily rely on health claim legitimacy rather than the actual efficacy and quality of the products. But this shouldn’t always be the case. She reiterates that regulatory policies should focus on research.

Conversely, Mo advises would-be manufacturers and developers to be more critical when offering products. Knowing the local and regional regulations is a must. Some countries have different ingredient permissibility.

“Some countries will need to do a caseby-case registration (e.g., China’s health food, Malaysia’s health supplement, etc.), while others can apply for a product license in a straight-forward manner (e.g., Health functional foods in Korea, Japan’s

Foods with Function Claims (FCC)),” Mo adds.

Personalisation and scalability

Diving into microbiome food development can be tricky. The goal is to provide the best gut health to consumers. With microbiome make-up unique to each individual, how does one ensure the product matches them? A tailored approach to gut health is the cornerstone of a microbiome diet. Personalisation can come at a cost, and this can impact the widespread adoption of embracing a microbiome diet.

“Another consideration is that the health benefits of probiotics are strain-specific. Many probiotics have digestive benefits, but some strains have specialised benefits such as immune support, heart health, mood balance or protein utilization. No two strains of bacteria are identical; the safety and clinical data from one strain cannot be used to support the safety and efficacy of another strain,” Murphy explains.

“As the personalised nutrition phenomenon gains hold, new technology is enabling consumers with microbiome

testing kits to benchmark the make-up of their microbiome,” Mo explains. “ADM is continually identifying new synergies between biotics to meet their different health and wellness needs. Developers can get ahead of the curve with our cutting-edge solutions and deep technical expertise to meet consumers’ evolving needs and expectations.”

Embracing gut health

Consumers proactively support health and wellness beyond traditional diet. More and more are looking at holistic health support.

This is likely to be an enduring behavioural lifestyle change, even after the global pandemic is over. We respond to this by helping food and beverage companies develop customised solutions to meet evolving consumer needs to support healthier living. ”

“This is likely to be an enduring behavioural lifestyle change, even after the global pandemic is over. We respond to this by helping food and beverage companies develop customised solutions to meet evolving consumer needs to support healthier living,” Mo believes.

Food experts are doing their share in supporting studies that link live microbe intake to human health and whether this can be part of daily recommendations. Kerry Health and Nutrition Institute recently held a live webinar to discuss the topic and how that could impact the consumer and food industry landscape.

With scientific research shedding more light on the health impact of the microbiome, we might just uncover the secret to optimal immunity.

With insights from Lois Mo, Marketing Director, Health & Wellness, APAC at ADM and Aoife Marie Murphy (PhD), Nutrition Business Development Manager at Kerry

AUTOMATION

How to harness the data hidden in your production line

How to harness the data hidden in your production line

Discover why the food and beverage industry players can benefit from leveraging big data in their operations

End-of-line inspection is a standard part of the quality control process in any food and beverage production facility. Checkweighers, metal detectors, X-ray inspection systems and vision systems all monitor production to ensure quality and conformity of products.

But what is often missed is the hidden value of the data produced by such inspection systems. Although they typically make binary decisions – an item is either good or bad – the data used to make those decisions is far more complex. It is usually discarded immediately after the quality control decision has been made. Yet it could hold the key to valuable production line optimisation. A dramatic reduction in the costs

Big data can hold the key to valuable production line optimisation. ”

associated with data collection, storage and analysis – along with new tools such as machine learning – have made it possible, for the first time, to capture ‘fastmoving’ data on the production line and analyse it to yield valuable benefits.

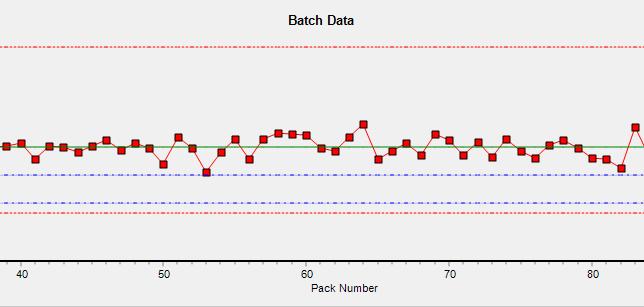

By capturing each measurement made from a checkweigher, for example, trends can be identified before a product becomes out of range. If four filling machines are involved in producing packets of rice and a fault means that one bagger consistently produces a product that is overweight, when analysing the batch averages across the four machines, the high-level data does not suggest anything is out of range. However, if the individual weights were analysed, a periodic pattern would emerge – allowing

the issue to be identified and resolved.

Alternatively, a chocolate enrober may coat multiple lanes of chocolate bars. If the flow rate is non-uniform across the belt, then the chocolate layer on the central bars will be thicker than that on the outer bars. Identifying and rectifying this non-uniformity allows for the coating to be run closer to the optimal level – ensuring all bars meet the required weight. Without this insight, the enrober will be adjusted to ensure the outer bars meet the minimum weight, resulting in a ‘give-away’ cost of the additional chocolate on the inner bars. Data at a batch level will not resolve this variation – but data on individual weights will. Similarly, if there are missing wafers in some of the bars, they will be rejected by X-ray inspection technology as it will detect that they are solid chocolate. If one of the moulds or lanes has an issue, that particular lane might have a higher reject rate.

But the overall reject rate may not give cause for concern, so the problem will not be addressed. If the process control system is supplied with statistics for each lane, however, the situation can be constantly monitored – and the alarm raised before any issue becomes critical.

The linking of a weigh price labeller to a vision system is a simple example of the power of linking equipment to uncover hidden data. As well as ensuring labels are properly applied, vision systems are often used to check that information such as weight and price has been printed correctly and legibly. By analysing the contrast of the print, a warning can be generated if the print head is failing. This allows for preventative maintenance to occur, rather than waiting until the print quality falls below an acceptable standard – at which point an unplanned stoppage will be required.

Similarly, an increase in the frequency of product rejections can indicate an issue with upstream equipment. But data from X-ray inspection technology can provide clues to the specific issue. If a filler valve becomes blocked on a yoghurt production line, for example, one of the pots in a four-pack will be repeatedly underfilled. The underfill may not be sufficient for a checkweigher to identify

the overall product as being underweight. But, by measuring the mass of each pot individually using X-ray zone mass inspection, the four individual masses can be reported to the supervisory system and any deviations from the production norms can be identified rapidly.

Zone mass inspection is also frequently used to detect missing items in boxes of chocolates – by highlighting discrepancies below the sensitivity of a checkweigher. But, on its own, this will just lead to the box being rejected. Whereas if data is collected about the frequency of rejects – and, specifically, which chocolate is missing – it can highlight a potential issue in the process, whether the boxes are put together manually or by a machine.

In a connected environment, the frequency of breakages in products such as boxes of biscuits can also be monitored and flagged up, with warning thresholds set lower than automatic reject thresholds. If a misaligned tool is causing a high proportion of biscuits to be broken when placed into the packaging, data from X-ray inspection technology can highlight the issue before customer complaints start flooding in.

As the quantity of data increases, so does the value of combining data from a variety

of sources. Does the operation of one piece of equipment affect the behaviour of a neighbouring machine, for example, leading to a nonconformant product?

By bringing a broad range of data into a single location, in real time, temporal and environmental factors can be more easily correlated with issues. And this interconnected data can be harnessed to reveal unprecedented hidden value in the production line.

Dr David Bosworth is the Head of Product Development at Sapphire Inspection Sys tems, a manufacturer of end-of-line X-ray inspection equipment. Along with a PhD in Material Science, David has industry-lead ing knowledge of X-ray inspection at both a technical level and as it relates to solving customers’ problems.

Wrapping the packaging industry in a circular economy: Is it possible?

Food packaging accounts for 5 percent of the energy in a food’s life cycle, making it a significant contributor to greenhouse gas emissions. For some products, the use of packaging contributes even more.

This is why there are calls for strengthening circular economies. More and more manufacturers and producers are called out to design product packaging with circularity in mind. According to the World Economic Forum, it’s estimated that half of the global plastic packaging can still see economic opportunity after its first use.

One of the ways food packaging companies address this is through flexible packaging. Compared to other forms, it’s believed to be more sustainable and contributes a lesser carbon footprint.

We connected with Claire Kneller, Head of WRAP Asia Pacific. WRAP is a climateaction NGO with global operations that

tackles the climate crisis. Their efforts aim to change products’ production, consumption, and disposal to protect the planet.

Waste from packaged food has a substantial environmental toll, but turning to sustainable new technologies has the potential to lessen its carbon footprint. Do you think flexible packaging is something that could help address this?

Packaging of all kinds does an amazing job of protecting the food we buy and ensuring it stays fresher for longer. In some cases, our research has found that removing the packaging altogether is better to help prevent food waste. For example, we found that allowing people to buy unpackaged fresh, uncut fruit and vegetables means they can buy exactly the amount they need rather than buying too much and wasting it. In other cases, innovative packaging can

help food last much longer. Many of these can be recycled at the front-ofstore supermarket locations, but this is an interim measure. Some of these plastics could be removed, like those on some fruit and veg items. But some are necessary. Therefore, systems must be in place to collect and recycle them. Nonmechanical recycling will have a key role to play in recycling food contact flexible plastics and enabling them to be put back into food packaging.

Reducing food waste is a key part of reducing the carbon emissions from our food system alongside switching to more sustainable diets that include more plantbased foods and lower carbon intensity meat. The right kind of packaging in the right place can help prevent food waste, but we must ensure that we’re designing packaging with circularity in mind. Packaging should stay in the economy, not the environment.

Do you recommend flexible packaging as a means to fight food waste?

Flexible packaging in the right place and on the right products can help prevent food from being wasted, but flexible plastics remain the biggest challenge when we look at the shift to a circular system. Flexible packaging is difficult

WRAP’s goal is to work with packaging designers, retailers and brands, local governments, and the reprocessing sector to figure out how we capture and reprocess these materials in the same way we do for PET and HDPE. ”

to collect and recycle using our current methods and leaks into the environment more easily than rigid plastics.

We can eliminate or change the way these materials are manufactured and used. One early step we have taken is to produce guidance for retailers on running effective in-store collection points for flexible plastics. This has led to 4,000 stores UK-wide now collecting materials from bread bags to crisp packets –but still, these remain tricky items to recycle, so the infrastructure needs to be developed further.

What are your thoughts on the current regulations on food packaging? Do you think it’s effective in reducing food waste?

WRAP works with governments and businesses to provide independent evidence supporting regulation and voluntary approaches. Our experience shows that voluntary approaches to food waste, packaging, and clothing can deliver impact. Policy and legislation are useful for creating a level playing field for businesses and ensuring the stragglers are moving too.

Policy tools like extended producer responsibility and product stewardship can work hand in hand with voluntary approaches, and sometimes legislation can be a useful way to increase the impacts. A good example of this is the carrier bag levy in England which

Do you think the private sector’s contribution to sustainable packaging is enough? What are their hits and misses?

The private sector is driving the changes in the packaging sector, and there have been some incredible success:

Our UK Plastics Pact members have shown a 46 percent reduction in problematic and unnecessary plastic items since 2018 and an overall reduction in consumer plastic packaging of 10 percent since 2018.

Fifty-two percent of plastic packaging is recycled, up from 44 percent in 2018. Seventy percent of plastic packaging is reusable or recyclable, and average recycled content levels in plastic packaging are 18 percent, doubling from 9 percent in 2018.

But there is more to be done. Plastic bags and wrappings like bread bags and crisp packets remain our biggest challenge, and some plastics on the market that, although technically recyclable, have no

end market.

WRAP calls on businesses to adopt the good practice generated through the Plastics Pacts around the world to deliver a circular economy for plastic packaging.

The work of UK Plastics Pact members in reducing plastic packaging levels by 10 percent equates to a 335kt CO2e reduction, equivalent to taking 150,000 cars off the road.

The doubling of recycled content in plastic packaging from 2018 equates to saving just over a million barrels of virgin oil production and 140,000 tonnes of CO2e. The crucial work Pact members do to include recycled plastic in their packaging is crucial.

For example, it takes 75 percent less energy to make a plastic bottle from recycled plastic than using “virgin’ materials.

Morrisons announced the removal of plastic bags from bananas. Once rolled out, this will reduce unnecessary plastic by 180 tonnes, that’s 45 million bags each year. Additionally, Sainsbury’s removed plastic film from its ‘By Sainsbury’s’ broccoli, saving 49 tonnes of plastic annually. It has also removed lids from its own brand cream pots saving 106 tonnes of plastic annually.

Nestlé UK & Ireland has redesigned its confectionery sharing bags to use significantly less packaging. Narrower pouches for its brands, including Milkybar, Aero Bubbles, Munchies, Rolo, Yorkie, and Rowntree’s Randoms, will save 83 tonnes of plastic, the equivalent area of 131 football pitches.

What are the current challenges in the packaging industry that make it harder to contribute to sustainability?

There remain huge challenges in the packaging industry across the region. In some cases, the lack of infrastructure to capture and reprocess packaging is not there, allowing plastics to leak into the environment. In other cases, the industry lacks cohesion, enabling businesses to work together to tackle technical issues.

WRAP works with the World Economic Forum to support the implementation of their Global Plastics Action Partnership which is aimed at turning commitments into concrete action, as well as with the Ellen Macarthur Foundation to implement Plastics Pacts around the world.

These initiatives aim to translate global and national commitments to reducing plastic waste into actions that are right for the national context and can help address local challenges.

What are the current projects of WRAP focused on mitigating food waste through sustainable packaging?

We have exciting projects in the pipeline. Our research shows that 67 percent of consumers are willing to explore refill options as their personal motivation for sustainable shopping. However, they also have reservations due to the lack of resources.

With this, WRAP has forged an industry partnership with Asda and Unilever to educate consumers on changing their shopping habits. But we go beyond the awareness part. We want to make things happen by providing the resources they need—for example, the use of refill stations and reusable packaging in UK shops. We’re also leveraging technology as part of the intervention. Online shoppers can receive prompts and reminders to use reusable packaging.

We’re also continuously encouraging businesses to join us in our whole chain

food waste reduction plans to reduce farm-to-fork food waste effectively. This initiative is part of the UK Food Waste Reduction Roadmap and Courtauld Commitment 2030.

Our Guardians of Grub is a campaign that addresses the growing problem of food waste in the hospitality and food service sectors. We actively engage with professionals on how they reduce food waste in their operations.

The Australian Food Pact brings together various farm-to-fork food supply chain organisations. We hope to halve Australia’s 7.6 million tonnes of food waste by 2030.

Our operations extend to North America with our Pacific Coast Food Waste Commitment. We’re currently working with WWF, ReFED, and Cascadia to call on supply chain partners, food retailers, manufacturers, hospitality, and food service industry players to collaborate on efforts to tackle food waste.

WRAP is actively working with industry leaders to initiate change, and we have no plans of stopping.

Do you want to share any other thoughts about the future of food packaging and its relation to sustainability?

Tackling our food system is one of the biggest challenges we have about climate change. Food waste is responsible for around 8 percent of global emissions alone. Packaging can play a critical role in preventing food waste, but we must consider its role in the context of a circular economy.

Our use of packaging should be carefully considered – What materials are we using? Can they be captured and economically recycled? Do we need the packaging at all? How do we engage consumers to fulfil their role? All of these are questions the packaging industry, in collaboration with brands and retailers, should consider when planning for the future.

It’s time for businesses to think of ways how to contribute to combatting climate change. Packaging should communicate not only the product’s contents but also the values and its impact on the planet.

Trade Show Calendar