Our latest issue explores the intersection of sustainability, clean-label processing, green packaging, and digital innovation. We aim to showcase how these different areas of expertise are coming together to create a greener, more sustainable future.

Sustainability is not just a buzzword but a way of life we must adopt to preserve our planet for future generations.

We talked to Didier Toubia, CEO and Co-Founder of Aleph Farms, and Francisco Codoner, CEO of Scale Up Bio, who gave us valuable insights about cultivated meat and precision fermentation.

Eric Lai, Regional Managing Director for Grundfos’ Industry Performance Unit for the Asia Pacific region and Country Director for Singapore, also shared how their company responds to calls for water and energy efficiency. Alan William Smith, Chief Supply Chain Officer, Suntory Beverage & Food Asia Pacific, discussed how they contribute to a circular economy.

Ian Scott-Mance, Technology Manager at Mettler-Toledo Product Inspection, provided us with an informative article about digitalization in the product inspection space.

Finally, John Jose, Marketing Director of Tetra Pak Malaysia, Singapore, Philippines, and Indonesia, gave us a comprehensive rundown of how end-to-end sustainability is possible in the food processing and packaging industry.

We hope you enjoy and get valuable insights in our latest issue of the Asia Food Journal!

Sincerely,

EDITORIAL/PUBLISHER

Keen Whye Lee Publisher

Cath Isabedra Editor editor-afj@harvest-info.com

Danico Acosta Layout and Design OPERATIONS

Mari Vergara Head of Operations mari@asiantvawards.com

SALES

Simon Lee Hong Kong, U.S.A. sales@harvest-info.com

Chua Chew Huat Asia Pacific sales-sg@harvest-info.com

Erhardt Eisenacher Europe info@eisanacher-medien.de

MARKETING

Lali Singson mktg@harvest-info.com

TECHNICAL SUPPORT

Michael Magsalin tech@harvest-info.com

150 Orchard Road #07-05 Orchard Plaza

Singapore 238841

AsiaFoodJournal AsiaFoodJourna1 asia-food-journal-magazine

Innovation enhances palatability and production of ready-to-eat food as market demand grows

SINGAPORE, March 2023 – Kemin Industries, a global ingredient manufacturer that strives to sustainably transform the quality of life every day for 80 percent of the world with its products and services, has developed VALTEQ™, a unique line of quality improvers for instant noodle manufacturers.

The liquid product line uses emulsifier solutions to increase consumers’ overall instant noodleeating experience by addressing some of the everyday challenges facing manufacturers.

• VALTEQ™ T merges instant noodles’ smooth texture with sought-after bounce and chewy mouthfeel. Research demonstrates that the innovative emulsifier system performs similarly to sodium tripolyphospate (STPP) on parameters such as color, flavor, smoothness, and elasticity. It also accelerates the hydration process, shortening noodles’ soak time by at least 20 percent and making it a valuable alternative to STPP.

• VALTEQ™ AS prevents noodles from sticking during processing, cooking, and serving using antioxidant-protected emulsifiers that allow for increased production efficiency and quality to maximize profits while satisfying

consumers. The blend, directly applied to air- or freeze-dried noodles, improves instant noodles’ quality and palatability while reducing waste.

• VALTEQ™ AO enhances instant noodles’ quality with an all-in-one solution of natural antioxidants and emulsifiers that extends shelf life and protects against sticking to production molds. Effective oxidation control improves the overall quality of instant noodles.

The VALTEQ portfolio helps food manufacturers increase production efficiency, contribute to quantity output optimization, reduce unnecessary waste and maximize profits,” said Michelle Lim, President of Kemin Food Technologies – Asia. “The product line brings two new-to-theindustry iterations—VALTEQ T and VALTEQ AO—which can be applied directly to noodle cakes. VALTEQ AS also offers an alternative application for instant noodles, which can be sprayed or dipped in the solution. ”

The instant noodles sector was significantly impacted by COVID-19, which led to higher-than-anticipated demand across all regions compared to pre-pandemic levels. The global market is projected to grow from USD$54.60 billion in 2022 to US$81.84 billion in 2029.1

“Instant noodles are one of the most internationally recognized food products consumed across both developing and developed countries,” said Joanne Tan, Associate Marketing Director, Kemin Food Technologies – Asia. “Market reports show that convenience, taste, nutrition and affordability all contribute to instant noodles’ increasing popularity among consumers. The VALTEQ suite of products answers all these demands, making it the ideal solution for instant noodle manufacturers.”

1(2021). Fortune Business Insights. Food Processing & Processed Food; Instant Noodle Market. Retrieved from Fortune Business Insight.

Protein from BSY is significantly more resource-efficient as a basis for burger patties than pea or beef protein

Brugg/Switzerland, March 2023 – A study at the University of Applied Sciences Northwestern Switzerland (FHNW) recently aimed to evaluate the environmental impact of burger patty production. A patty made with proteins sourced from

brewer’s spent yeast (BSY) was compared with conventional beef and a vegan one as benchmarks. The ISO 14040 ff Life Cycle Assessment (LCA) showed that Yeastin® can reduce the environmental footprint of a 113g burger patty by 74–81 percent, depending on the indicator examined.

The research results of the Institute for Ecopreneurship at the FHNW are impressive: a vegan burger patty made from Yeastin® protein by Yeastup has an even smaller ecological footprint than one made from pea protein. The production of pea protein had the greatest environmental impact on the conventional vegan patty (19–45%), with the meat in the beef patty producing a figure of 84–98 percent. Compared with the beef patty, the environmental ramifications of the Yeastup alternative were significantly lower across all impact assessment methods — possibly because of the elevated global warming potential (GWP) of beef production.

However, Daniel Gnos, founder of Yeastup AG, sees another huge advantage: “Thanks to the use of an industrial by-product, Yeastin® requires no arable land, no cultivation, no irrigation and no pesticides. This is a clear ecological benefit over animal and plant sources.”

Of the environmental footprint of Yeastin®, 56 percent was attributable to the animal feed substitution that replaces the brewer’s spent yeast in its previous use, which must be taken into account in accordance with the requirements of the general guidelines for the preparation of an ecological footprint (PEF). Compared with the benchmark pea protein, Yeastup protein has an approximately 81% lower environmental impact, 74 percent fewer greenhouse gas emissions and an 80 percent lower cumulative energy demand. Yeastin® has the potential to become a promising alternative to animal and vegetable proteins due to its significantly lower environmental footprint and excellent nutritional properties.

It is a high-quality protein powder that convinces in terms of purity and quality and, importantly, has a neutral taste. Furthermore, its excellent nutritional profile matches that of animal proteins. Protein formulations containing Yeastin® also showed promising functional properties in initial laboratory scale trials. There are numerous application

possibilities, too, from meat substitutes and cheese alternatives to sports nutrition products.

Gnos believes his team is offering the food industry a trail-blazing sustainable and vegan alternative protein: “In our LCA study, we investigated the environmental impact of producing protein from BSY and using it as an ingredient in burger patties,” he explains.

With these results, we aim to demonstrate the potential environmental benefits of using proteins derived from a high-quality brewery residue to our current and future project partners in the food industry using a global benchmark. ”

Peptigen® IF-3080, one of Arla Foods Ingredients’ protein hydrolysates for infant formula, has received final EU approval.

In February 2022, the EU introduced new regulations requiring evaluation of the safety and suitability of all protein hydrolysates used in formulas.

Shortly afterward, the European Food Safety Agency (EFSA) published an opinion that Peptigen® IF-3080 was safe and suitable for use in formulas and follow-on formulas in the EU. It was one of only a few milk protein hydrolysates to achieve this status.

The product has been included in the Commission Delegated Regulation (EU) 2016/7 – the final step necessary for it to be used in infant and follow-on formulas sold across the EU.

Anders Steen Jørgensen, Head of Arla Foods Ingredients’ Paediatric Business Unit, said:

“

It’s great news that Peptigen® IF-3080 has completed its journey to market in the EU. Safety and quality are of course paramount in infant nutrition, and this decision reflects our absolute commitment to the highest possible standards. We believe it will benefit manufacturers developing innovative products, as well as increasing the choice of high-quality formula available to parents. ”

Mollet del Vallès (Spain), March 2023: At Vitafoods Europe, Euromed will showcase its certified organic herbal extracts, as well as a growing portfolio of natural ingredients inspired by the health-promoting properties of the Mediterranean diet. Two presentations during the show – online and in-person –will provide nutraceutical professionals with in-depth knowledge about the benefits of botanical ingredients for a healthy body and mind.

Mediterranean fruit and vegetable extracts™ from lemon, pomegranate, olive, artichoke, fig, and spinach contain valuable nutrients that play a key role in the Mediterranean diet. They have been proven to support cardiovascular, metabolic, digestive, immune, and skeletal muscle functions, all of which are vital for healthy ageing. In addition, Wellemon®, Pomanox®, Mediteanox®, Cynamed®, ABAlife®, and Spisar® are all gently processed with an eco-friendly, proprietary extraction technology that uses only purified water as a solvent.

Euromed will also showcase its Earth Harmony Organic Extracts®. The 16 available ingredients, from artichoke leaf to valerian root extract, are produced following sustainable practices and full traceability from seed to the

final organic-certified extract.

During a lecture at 3 pm on May 10 in the New Ingredients Theatre, attendees will discover the power of botanicals from the Mediterranean diet for mental and physical health. Under the title “Mens Sana in Corpore Sano: Unlocking the Active Nutrition Potential of Mediterranean Extracts for Mind-Body Health,” Andrea Zangara, Head of Scientific Communications & Marketing at Euromed, will give insights into botanical traceability, sourcing, quality control, research findings and formulations for holistic health products.

Another digital presentation will dive deeper into the topic and provide product developers with insightful information on selecting appropriate botanical ingredients. Entitled “Beyond the Plant: How Our Bodies Process and Benefit from Botanical Extracts,” the presentation will explore the digestion, bioavailability, and effectiveness of specific botanical extracts and will be available on-demand from 1 May at the Vitafoods online platform.

Andrea Zangara explains:

Considering chemical complexity of plants and all the external variables, it’s increasingly relevant to investigate both efficacy and bioavailability of certain extracts, such as those high in polyphenols like pomegranate and lemon. From mental wellbeing to active ageing, our standardized botanical compounds provide a broad range of clinically validated health benefits which are specific to the extracts tested, and cannot necessarily be applied to other extracts. Our vertically integrated supply chain and strict quality protocols ensure the development of high-quality functional foods, supplements and other products for active nutrition and holistic health. At our booth and during our presentations, visitors will learn more about that botanical journey from seed to final extract. ”

Epax has reinforced its position as a leader in highly concentrated omega-3 with a major upgrade to its facility and the launch of next-level molecular distillation technology.

The Norwegian marine lipid specialist was already one of the few companies guaranteeing omega-3 with 90 percent minimum triglyceride content as standard. Now, a $40 million investment in its facility in Aalesund has increased its distillation capacity and further improved its ability to offer premium-quality omega-3 concentrates.

The upgrade includes the introduction of highly sophisticated quality process technology. Branded EQP+Tech allows individual fatty acids to be separated from fish oil and ultra-concentrated without excessive heat or harsh chemicals.

The black box-protected technology is the result of years of research and development. Using data from over a thousand test runs and analyses, Epax’s process engineers studied the performance of various fatty acids in the company’s high-tech molecular distillation equipment. By finding the optimum balance between pressure, temperature, and time, they identified the best possible way to separate each fatty acid from fish oil while retaining its natural quality.

Based on the research, Epax fine-tuned its re-esterification process and invested in new customised equipment. It includes highly sophisticated digital technology, with sensors monitoring thousands of data points and making constant adjustments, allowing in-depth tracking of the re-esterification process and ensuring consistent high quality.

EQP+Tech will help Epax continue to guarantee a minimum 90 percent triglyceride content across its range of EPA and DHA ingredients, as well as develop new highly concentrated omega-3 products for a range of health needs. The speed and gentleness of the process mean there are particular application opportunities in delivery systems where sensory properties are important.

Bjørn Refsum, CEO of Epax, said:

In omega-3 production, the big question is how you balance the never-ending quest for higher concentration with the need for quality and reproducibility. Epax was already a leader in ultraconcentrated omega-3, but this upgrade takes us to a whole new level. To our knowledge, no one else is using technology as sophisticated as this and the possibilities for manufacturers are huge. They’ll benefit not just from high concentration, purity and consistency, but also great sensory properties, allowing them to create products that meet the growing consumer demand for high-quality omega-3.

The upgrade concludes a major phase of Epax’s investment in its facility, with further improvements and investments already in progress.

Part of Norwegian fishery giant Pelagia AS, Epax Norway AS is a leading manufacturer of concentrated marine oils.

Epax® has been an innovator for over 180 years. Since 1838, when it began producing premium quality cod liver oil, Epax has transformed the marine ingredients sector. It invented the technology to concentrate fish oil as an ethyl ester and to re-esterify oils back to TG-form. It was also the first company to create condition-specific EPA/DHA ingredients backed by science. Today Epax continues to deliver omega-3 products of unmatched purity and quality.

The Epax production facility in Aalesund, Norway, has, in addition to all standard manufacturing certifications/approvals, been approved by the US FDA for the manufacture of Pharmaceutical Intermediates and by the Norwegian Medicines Agency (Legemiddelverket) for the production of Active Pharmaceutical Ingredients (APIs).

Next-level distillation technology creates new opportunities for ultra-concentrated omega-3

The new Alfa Laval ThinkTop V20, the next generation of hygienic valve indication units, is driving digital transformation within the process industries. Moving valve position monitoring into the Industry 4.0 era delivers a competitive advantage. With automation, digitalisation and real-time communication, the ThinkTop V20 raises the bar on process control, making it more reliable and accurate while saving time and money on installation, commissioning, operation and maintenance.

The ThinkTop V20 is the first pure valve-sensing unit that is maintenance-free and does not require manual adjustment or programming. It enables 360° LED visual status indication from all directions. It also provides convenient control-room monitoring of the real-time status of Alfa Laval hygienic valves used across dairy, food, beverage, home and personal care, biotechnology, pharmaceutical, and many other industries.

Purpose-designed to digitalize essential on-off valve monitoring, the ThinkTop V20 sensing unit provides a pragmatic approach to enhancing valve status and position reliability. This new addition to the advanced Alfa Laval ThinkTop V-series paves the way to a higher level of process control for manufacturers who rely on visual and signal feedback of the open or closed valve positions.

The intuitive ThinkTop V20 is a faster, more intelligent valve indication unit than what is available today,” says Ebbe Bundesen, Portfolio Manager, Valves and Automation, Alfa Laval. “It brings reliable process control to a higher level with fast, accurate, intuitive live setup, the convenience of real-time valve position monitoring, and access to real-time and historical data from the control room. Overall, it is an invaluable time- and money-saver considering the efficiency demand factories are facing. ”

A few seconds is all it takes to commission the ThinkTop V20 by simply installing, activating and deactivating the unit. Live setup is fast and intuitive. Sensors automatically recognise the valve type and size, calibrate and record valve opening and closing distances, and complete setup without requiring manual interaction. Moreover, replacing or hot swapping the valve top is easy without disrupting production. No expertise, training, adapters or special tools are required. Anyone can correctly install a new ThinkTop V20 or replace an older valve indication unit while safeguarding hygiene, productivity, and uptime while saving time and money.

Part of the proven ThinkTop V-series family, the ThinkTop V20 shares the same look, maintenance-free housing and enhanced 360° LED visual status indication as the best-selling ThinkTop V-series control tops. Its compact, robust design makes it suitable for tight installations. Manufacturers select the communication protocol – digital, AS-Interface or IO-Link – that best suits their processing needs. The V20 is hermetically sealed to ensure reliable readings of the valve position and prevent the risk of water, dust and other unauthorised access into the unit. Using the point-to-point IO-Link communication protocol allows the connection of sensors to automation systems. IO-Link also makes access to meaningful realtime data easier, improving diagnostics and simplifying configurability and control while supporting Industry 4.0.

The real-time visibility and remote monitoring capabilities of the ThinkTop V20 unit will provide a competitive advantage to those who rely on hygienic valve status data. The V20 stretches beyond what manufacturers thought possible from conventional valve position indicators through faster setup time and more reliable process control.

March - April 2023

New Alfa Laval ThinkTop V20 pushes the boundaries of valve position indication to Industry 4.0

SEALPAC invites you to Interpack in Düsseldorf!

As a leading manufacturer of high-tech traysealers and thermoformers, we have used the event break caused by the Corona pandemic to present exciting innovations in all of our machine segments at the upcoming edition of the world’s largest trade fair for the packaging industry, which will take place from 4th - 10th May, 2023.

Under our motto “GO sustainable!”, we will be presenting a flexible, semi-automatic traysealer that can package a large variety of products in small quantities, as well as our high-output traysealers and thermoformers that are fully prepared for Industry 4.0. Whether it concerns our entry-level model or performance class, each of these energyefficient machines produces attractive packs that combine maximum product safety with particularly economical use of materials.

World premiere: SEALPAC’s all-round, semiautomatic M-Flex traysealer

Highly flexible, extremely compact, and suitable for our entire range of packaging solutions: with the innovative, semi-automatic M-Flex traysealer, SEALPAC’s renowned tray-sealing technology is now also available for smaller production processes. Craft workshops, small business startups, laboratories, test kitchens, and catering suppliers can use it to produce the entire spectrum of packaging solutions in an extremely small space and with only short set-up times. The high-performance,

versatile M-Flex traysealer processes all prefabricated packaging materials, such as plastic, foil, and cardboard, with the highest degree of precision to produce secure and attractive packaging, ranging from standard solutions to innovative SEALPAC packaging concepts like FlatSkin®, FlatMap®, TraySkin®, EasyLid® and more.

SEALPAC Amax traysealer: state of the art

The SEALPAC

Amax-series sets new standards in high-performance tray-sealing. Depending on the application, these intuitively operated machines are up to 50 percent faster than previous generations. They are characterized by their particularly low-wear, low-maintenance design. They are driven by high-quality servomotors that allow for extremely smooth production runs, unrivalled in the market until today. The integrated EnergyManager ensures optimal use of energy. Furthermore, the air consumption of the Amax traysealer has been reduced by up to 90 percent.

In addition to the conventional modified atmosphere or TraySkin® packaging, these flexible traysealers produce particularly resource-saving solutions. For example, they process ultra-light trays, the weight of which has been reduced by 20 percent compared to conventional MAP trays. Hybrid packaging concepts with a reduced plastic and high cardboard content, such as eTray®, FlatSkin®, or FlatMap®, can also be handled by the SEALPAC Amax traysealers. At request, we offer you an all-inone solution allowing you to run all these concepts on the same base machine.

The intelligent drive management of the SEALPAC Amax traysealer reduces the maintenance effort and thus ensures optimal availability at all times. All in all, the new series succeeds in optimally combining product safety, performance, and efficient operation with more resource conservation.

Also within SEALPAC’s portfolio of high-quality thermoformers, the focus is on combining flexibility and performance with improved sustainability and less usage of resources. Next to the compact PRO thermoformer, outstanding in its flexibility, we will be demonstrating our high-output RE thermoformer by producing striking packs made from demanding mono-PP film. As such, this machine supports our customers in meeting the latest sustainability requirements in the packaging industry. The pack is equipped with SEALPAC’s unique EasyPeelPoint opening system, which is less subjective to cold sealing, common in existing thermoformer applications.

All SEALPAC thermoformers reliably process a wide range of materials, including recyclable films made from mono-PP, mono-APET, or mono-PE, as well as innovations like paper-based film. Each thermoformer stands for first-class quality in packaging design, hermetic sealing and user-friendly opening behaviour, especially when applying our EasyPeelPoint system.

There will be numerous other highlights at the SEALPAC stand at Interpack, such as machine monitoring. We will show you that, for example, by using OPC/UA, our equipment is easily integrated into the line control software. This lets our customers see in real-time if the machine is running, in stop, in error, or waiting for up- or downstream equipment. As such, it simplifies operational planning and increases efficiency in every detail. In addition, it supports maintenance, service, and error diagnosis, optimally meeting Industry 4.0.

Anyone looking for new ideas from the world of packaging will also find answers at the SEALPAC stand. In our Supermarket of Innovations, we will present an exciting selection of new, creative packaging concepts from all over the world, inspiring any packaging expert.

SEALPAC is exhibiting at Interpack 2023 in hall 5, stand F38.

March 2023 – Minebea Intec, a major manufacturer of weighing and inspection technologies, will be presenting its products and innovations at interpack 2023. The company will be attending the leading trade fair for the packaging industry from 4 to 10 May and presenting its solutions which help manufacturers to increase their product safety and efficiency.

With systems for visual product inspection, like the VisioPointer®, through to a new checkweigher, the company expects to generate a lot of interest. The checkweigher Flexus®, also available as a high-speed version, will be on display along with the X-ray inspection system Dylight. T

hese products, which together formulate a complete, efficient production process, will be on show for attendees to discover the range of features. Visitors to the stand will also be able to see the company’s established, highprecision products live alongside innovations. This includes the automatic weigh price labeller WPL-A, which provides a complete package for customers in the food industry.

These days, flexible and efficient production processes are digital and interconnected. However, face-to-face interaction is now firmly back on the agenda and Minebea Intec is looking forward to taking advantage of this opportunity at interpack after a six-year hiatus due to the coronavirus crisis.

Industry 4.0 is a key focus, and with its smart weighing and inspection technologies, the Hamburg-based company provides optimal solutions to take production lines to a whole new level. This means Minebea Intec’s products perfectly align with the key topics at interpack 2023, which will focus on the best possible performance, sustainability, and digitalisation.

From checkweighers, metal detectors, and X-ray inspection systems, to platform scales and the applicable software solutions, through to the new automated image processing technology: visitors to Minebea Intec’s stand at the trade fair can look forward to expert advice

to help make their production processes even more efficient.

With its new range of vision systems, Minebea Intec is adding a fourth pillar of quality assurance products in the form of a range of end-of-line inspection devices. Those who visit the stand at interpack 2023 will be able to experience the VisioPointer® live.

With three cameras as standard, multiple lighting options, and optional side and satellite cameras for multi-angle inspection, the product delivers high-precision results when checking labels, print, or the expiry date. It also provides reliable seal inspection.

This is an extremely important visual quality check in the food industry, as the product’s expiry date is only valid if the packaging is absolutely leak-tight.

“The seal inspection is performed by cameras and is fast, non-destructive and configurable,” says Dr Thorsten Vollborn, Senior Product Management for Product Inspection at Minebea Intec.

“Conventional methods do not offer these advantages. We are proud to now be able to integrate this outstanding solution into our customers’ production processes.” The machine can also inspect products such as bruising and blood spots in salmon, bread bake colouration and dimensioning, and shape recognition for products like biscuits in various packs. For hard-to-see applications, hyperspectral cameras can be used to distinguish between products.

Alongside this new inspection technology, Minebea Intec will also share its expertise and experience from over 150 years in industrial weighing with visitors to its stand at the trade fair. Before products are sent for shipping, they often need to be labelled in some way. The automatic weigh price labeller WPL-A is a reliable solution for products that have variable weights such as cheese, meat or fish.

This not only facilitates product tracing, it also increases throughput and productivity. The WPL-A meets directives and standards such as the Measuring Instruments Directive (MID) and the National Type Evaluation Program (NTEP) of the National Conference on Weights and Measures (NCWM). The system is produced in Europe to the highest quality standards and offers maximum modularity and connectivity. The device is the ideal automatic labelling system and can be configured to individual requirements to meet all kinds of challenges.

In the checkweigher range, Minebea Intec will be presenting its Essentus® Performance L Combi, the latest version of one of its best-sellers. The innovative design combines the checkweigher Essentus® Performance L and the metal detector Vistus® in one base frame. This makes the system extremely compact and highly efficient.

The combi system is used to check weights, perform integrity checking, control upstream filling systems, and check for metallic foreign objects at the same time. The Essentus® Performance L Combi is also verifiable and features a stainless steel conveyor system, which is ideal for meeting hygienic requirements, particularly for wet applications or unpackaged products.

Minebea Intec at interpack 2023: New weighing and inspection solutions for more efficient production

10th INTERNATIONAL TRADE FAIR FOR METAL PACKAGING www.metpack.de

The jury for the recent Global Wine Masters awards, organised by the Drink Business magazine, showed a spirit of activism that reflects a fundamental trend and a radical change of mentality.

The 2023 Masters awards introduced a new category, “Design & Packaging,” with Maison Telmont awarded the gold medal for its “Réserve de la Terre.” Like Telmont’s other cuvées, this fully organic cuvée follows the House’s “no packaging” programme.

With its “In the Name of the Mother Nature” project, aimed at drastically reducing its carbon footprint, Maison Telmont decided to turn away from the dominant practices in the sector and to eliminate gift boxes, as well as another packaging, to focus on what counts: the wine. We make champagne, not gift boxes. This initiative has already

reduced the carbon footprint of every bottle produced by 8 percent.

The jury specifically praised the eco-responsible design, the pared-back beauty of the bottle, and the wealth of information provided on the main label. This innovative label is the wine’s identity card, presenting in full transparency detailed information about the variety of grapes and the blend of vintages used.

“This gold medal is a recognition of the occasionally-radical choices the House has made, and confirmation that our insight was right: sometimes, no packaging is the best packaging. It encourages us to continue further down this path, always “In the Name of Mother Nature.” We decided to eliminate gift boxes in June 2021. The good news is that, based on over 20 months of sales figures, we can say that this has had no negative impact on our sales. There has even been a positive effect.

Indeed, there is clearly a new generation of customers who no longer want gift boxes, nor even “ecological” packaging, a new generation for which ‘the best packaging is no packaging’,” shares Ludovic du Plessis, President of Maison Telmont.

ProfilePrint, a Singapore-based company that provides AI-driven solutions to ascertain and predict the quality and profile of food ingredients, officially announced the signing of commercial contracts to deploy the ProfilePrint technology with three of Brazil’s largest food companies - Louis Dreyfus Company Brasil, Olam Agrícola Ltda (Brazil) and Sucafina Brasil.

Latin America is responsible for 16 percent of total global exports of food and agricultural products. However, one of the industry’s main challenges is not being able to ascertain the quality of the food ingredients produced and traded, as production conditions vary across high-tech farms and small producers.

ProfilePrint has managed to address this struggle faced by many in the food ingredient supply chain and has caught the attention of industry giants, including Cargill, Olam, Sucafina, Louis Dreyfus Company, and Sinarmas. The agrifood tech startup developed an AI technology, which predictively and prescriptively analyzes food ingredients such as coffee, cocoa, grains, sugar, and juices, with a portable analyzer and a software platform in just a few seconds. Such a technology solution can potentially revolutionize the food ingredient supply chain by empowering human graders and speeding up the assessment process, thereby significantly reducing the sales cycle by 10 times.

The signing of the commercial contracts with Louis Dreyfus Company Brasil, Olam Agrícola Ltda (Brazil), and Sucafina Brasil was witnessed by Desmond Ng (Head of Mission of the Singapore Embassy in Brazil), Josiah Choy (Regional Director, Enterprise Singapore Brazil), as well as key industry players at the Agrifood Tech Networking Reception on February 27 that brought together some of the biggest names in the food industry.

“We are delighted to hear of ProfilePrint’s entrance into Brazil, one of the world’s largest agrifood economies. The Singapore Embassy and Enterprise Singapore will continue to support the strengthening of technology

collaboration and trade relations between the two countries,” says the Head of Mission of the Embassy of Singapore in Brazil, Mr Desmond Ng.

“We are excited to see ProfilePrint establishing their footprint in Brazil and across Latin America, coming from a country where less than 1 percent of our land is used for agriculture, ProfilePrint developed a solution to empower agribusinesses across the supply chain to be more effective and efficient,” says the Regional Director for Enterprise Singapore (South America), Mr. Josiah Choy.

“Our technological solution powers people to be more effective and advances agribusinesses across the entire chain in Brazil, initially with coffee and cocoa. Without prior training, producers will be able to rapidly ascertain the quality of their crop and get a fairer price on their sales based on its true quality. The buyer on the other hand will be able to instantly and digitally assess the quality of the crops, thereby minimizing the need for sending samples as he will be able to access the independently trusted ProfilePrint report online. As a result, carbon footprints will be significantly reduced with less onerous physical grading as well as a reduction of samples shipped. Beyond rapid assessment, agribusinesses will also be able to use the ProfilePrint AI solution to propose blends based on tailored flavor requirement of their clients,” comments Mr. Alan Lai, CEO and founder of ProfilePrint.

Also, in the month of February, ProfilePrint officially formalized an alliance with Anacafé, the National Coffee Association of Guatemala, to empower more than 125,000 Guatemalan coffee growers using cutting-edge AI technology to classify and grade coffee without prior cupping training.

In addition, the company officially unveiled its Global SCA cupping A.I. predictor and participated as an official evaluator in the 19th edition of Let’s Talk Coffee in Honduras, empowering human experts to more objectively and efficiently ascertain the quality of all participating coffee samples during the three-day event.

Apart from being a profiling tool, ProfilePrint can also provide a prescriptive analysis of food ingredients and offer recommendations to its clients to achieve the optimal blend for its products. ProfilePrint managed to help a major client in the cocoa industry establish an acceptable tolerance for its product and recommend a different set of beans for its blend, which resulted in savings of US$1.64 million annually.

ProfilePrint’s AI solution benefits the producer, trader, and industry by enabling them to ascertain the quality of food ingredients rapidly

A new technology-driven agrofood ecosystem, the FarmByte Food Hub, has been established to consolidate and build the resilience of the agrofood sector, increase agricultural output, and uplift the livelihoods of farmers and the wider community.

Developed by FarmByte Sdn Bhd (FarmByte), a subsidiary of Kulim (Malaysia) Berhad (KULIM), the FarmByte Food Hub aims to transform Johor’s agrofood sector through its digitalfirst approach as part of Johor Corporation’s (JCorp) vision to strengthen food security both at the state and national levels.

Located in Ulu Tiram, the FarmByte Food Hub was officially launched today by the Chairman of the Agriculture, Agro-based Industry and Rural Development Committee, YB Dato’ Zahari Sarip as the official representative of YAB Datuk Onn Hafiz Ghazi, Menteri Besar Johor.

Datuk Syed Mohamed Syed Ibrahim, President & Chief Executive of JCorp, also the Chairman of FarmByte, said the newly launched FarmByte Food Hub would further bolster Johor’s food supply chains and create a sustainable agrofood ecosystem that will contribute to the national and state food security agenda.

“The FarmByte Food Hub will allow for the sustainable production of high-quality and high-value agrofood products. Through digitalisation and innovation, it will also help uplift the livelihoods and standards of living of our smallholder farmers while encouraging the participation of the younger generation in the agrofood sector.

“It is a key part of the state’s strategy to develop a sustainable agrofood industry that can compete at the international level in terms of production and product efficiency and quality,” said Datuk Syed Mohamed.

At the heart of the FarmByte Food Hub is a fully networked ecosystem of farmers, processors, distributors, retailers, and wholesalers – all connected via a hybrid setting of physical and digital hubs. This seeks to integrate all the activities throughout the value chain – from production to distribution – while creating efficiencies, transparency, and trust.

To meet the expected increase in production, a new Collection Processing Packaging Centre (CPPC) and two new Collection Distribution Centres will be built by FarmByte.

Datuk Syed Mohamed shared FarmByte will use innovative technology as an enabler to equip farmers with simple digital tools, market intelligence, and real-time production schedules to allow them to navigate the currently fragmented agrofood sector seamlessly and accelerate their growth.

Our mobile app, for instance, provides farmers with access to personalised advice and analytics and helps to expand their knowledge of expert farming practices.

One of the farmers in the trial, Yusaini Ali, who owns 6.3 hectares in Felda Ulu Tebrau, said many smallholders struggle to navigate the complex agrofood business.

“Until now, many smallholder farmers like me have relied on experience and the limited market knowledge we have as to what we produce for market and when it will be ready. Being part of the FarmByte Food Hub will give us certainty about what to plant and when demand will be highest so we can get the best price,” Yusaini Ali said.

“The tools and analytics provided will enable us to maximise our production and make our businesses more efficient. It will enhance our farming skills and knowledge and make us even better farmers.”

About the FarmByte Food Hub

FarmByte is pioneering a new innovative era in Malaysia’s agrofood industry. A subsidiary of Kulim (Malaysia) Berhad, FarmByte uses technology as an enabler to provide end-to-end solutions to players in its agrofood ecosystem – the FarmByte Food Hub – to enhance national food security, production efficiency and product quality.

Driven by a commitment to modernise and uplift the agrofood industry in Malaysia, the company works together with trusted partners throughout the value chain to create greater business and economic opportunities for the entire farm-to-fork ecosystem.

The 26th Food Ingredients China is held at Shanghai National Exhibition and Convention Center from March 15 to March 17. With the theme of “Unlocking nature’s potential, Building a healthier future”, Cargill, who is participating for the 15th time, is not only presenting a large number of health & nutrition focused innovative food and solutions, but is also releasing its latest proprietary “TrendTracker” study concerning Asia and the globe. Committed to acting as a “connector,” Cargill provides Chinese consumers and customers with industry insights and trends, helping customers to maintain a competitive advantage in the ever-evolving food market.

With forward-looking market insights and a deep understanding of its customers, Cargill is showcasing more than 40 products and solutions from its starches, sweeteners, and texturizers, as well as cocoa & chocolate businesses. These products and solutions are in line with the consumer trends highlighted in Cargill’s “TrendTracker 2023” study, with a strong focus on Health & Nutrition, and Indulgence, which reflects Cargill’s comprehensive solutions and new solutions innovations. Product highlights at this year’s FIC include:

• Oliggo-FiberTM chicory root fiber - It is the very first time for Cargill to unveil the Oliggo-FiberTM brand and OliggoFiberTM chicory root fiber products in China. A prebiotic, Oliggo-FiberTM chicory root fiber is rich in dietary fiber.

• Portfolio of stevia sweeteners - pure steviol glycoside brand Truvia®, compounded steviol glycoside sweeteners Unistevia. The products are nature origin and extracted from stevia leaf with Non-GMO Project Verified and are good for oral health.

• EpiCor® postbiotic - Backed by over 75 years of expertise, EpiCor® postbiotic is an ingredient resulting from a specialized anaerobic fermentation process. Eight human clinical studies and seven preclinical studies have demonstrated that EpiCor® postbiotic can beneficially modulate the gut microbiota.

• RadipureTM pea protein - uses Canada-origin non-genetically modified (nonGMO) peas as materials, with excellent digestibility and balanced amino acids profile.

• Cocoa and chocolate - including Gerkens® DL68 cocoa powder and Ghana liquor GHA24. Gerkens® DL68 is a flavorful light alkalized cocoa powder made with carefully selected cocoa beans from Asia and West Africa, with high colorability and long-lasting chocolatey flavor. The excellence of Ghanaorigin cocoa liquor is made possible by carefully selecting the single-origin cocoa beans and further enhancing the flavors during a fully controlled lowroasting process, resulting in a rich and long-lasting chocolatey flavor for your confectionary creations.

In addition to Cargill’s product exhibition booth, Cargill’s “TrendTracker 2023” report released during FIC is another highlight. Based on the study derived from the analysis of various market research reports, there will be greater purchases of health & wellness food, as well as a focus on food safety, convenience and a rise in e-commerce. Cargill’s “TrendTracker 2023” report shares its proprietary insight into macro trends globally and in the APAC. The report spotlights 4 key macro trends:

1. Healthy For Me. Today’s consumer is taking a more holistic, proactive, and preventative approach to health. A holistic approach considers not just physical health but also mental and emotional well-being. There seems to be a rising tolerance or even appreciation for science, expertise, and food technology. In addition, more and more consumers seek traditionally indulgent food & beverages with a healthier spin.

2. Experience It. Consumers place a high level of importance on experiences. They want to take control of their own diet, enjoying the products they love without feeling guilt or shame. Regarding food and beverage, the taste is table stakes, but the experience can be elevated in many creative ways as consumers appreciate surprise and delight.

3. Conscious Consumption. Consumers today seek to maximize value as they make food and beverage purchases. In addition, many consumers view their purchases as a reflection of their values, and they want to make decisions that support the environment and other societal causes they care about and they expect transparency from brands to help them do that.

4. Simplify My Life. With consumers staying closer to home these days, they are looking for faster and easier ways to procure, prepare, and clean up food. Omnichannel shopping has accelerated in recent years and there’s no turning

back because consumers have gained a better understanding of how technology can make their everyday tasks more convenient.

Since the Plan of Health China 2030 was published and implemented in 2016, “Health China” has become a national strategy. Besides, due to the COVID-19 pandemic, consumers are paying much more attention to nutrition and health than before, and their preference for healthy food has significantly improved, which corresponds with the results from Cargill’s “TrendTracker 2023” report.

Based on a deep insight into consumer preferences and business opportunities, Cargill is locally based and globally oriented. By combining extensive global capabilities with deep regional expertise, Cargill provides its food industry customers with the latest technology, research results, risk management, and industry-best solutions, and constantly develops customized portfolios to help customers win in the local market.

Innovation is another key factor in realizing the customer’s vision. Cargill local market teams are a source of inspiration, co-creation, and innovation that help customers unlock the future with speed and agility. With unparalleled food solutions by their side, Cargill enables customers to stay ahead of the competition and regulatory environment today – and tomorrow. Cargill has two Innovation Centers in Shanghai and Beijing to drive innovation around new products, new flavors, and new menus in the areas of food ingredients, animal protein, etc. Beyond China, Cargill also has Innovation Centers in Singapore and India to support its Chinese customers’ growth ambitions across the APAC region.

“The capabilities and innovation we are bringing to FIC will help customers better meet consumer needs in China market,” said Ming Peng, Managing Director of Cargill Food Ingredients for North Asia and Australia. “Having been in the Chinese market for over 50 years, Cargill has been working hard to share the expertise we have accumulated in our global practices with the Chinese market. Looking ahead, Cargill will continue to play the role of “connector” in the food industry, leveraging our extensive product portfolio, production and innovation capabilities, and global insights to help our customers develop healthy, delicious, innovative and sustainable products that meet changing consumer trends. We want to remain not only the leading food ingredient supplier that our customers trust, but also their partner of choice for innovation and growth.”

Bühler has a long heritage in Saudi Arabia and is well-positioned to assist with the national food security drive by the government.

The Bühler Group (www.BuhlerGroup.com) supports Saudi Arabia’s aim to achieve national food security, also considering the international challenges impacting this vital sector. “We provide unique and innovative solutions, aligning the highest technical standards and sustainable developmental concepts in line with the national goals of the Kingdom’s 2030 Vision,” comments Country Manager Eng. Mohamed Jebabra. Projects developed to date cover staple food products like wheat, rice, and other grains and extend to the feed industry.

Bühler has a long heritage in Saudi Arabia and is well-positioned to assist with the national food security drive by the government. It was established in 1978 in Jeddah, partnering with a local company to gain insight into the grain, mill, and silo sectors.

Barely a decade later, Bühler relocated to Riyadh and qualified for a Foreign Investment (FI) licence in 2001. It quickly became recognised as an essential partner in food security projects in the Kingdom.

From a global perspective, Bühler has over 145 branches and offices worldwide. Bühler is a family business established 160 years ago, with the fourth generation of founders still on the board. “Our heritage and passion is to serve society and industry, supplying high-quality products that comply with global specifications,” highlights Eng. Jebabra.

Bühler’s high-capacity equipment ranges from extruders to mixers, grinders, coolers, plan sifters, conveyers, belts, and hammers. Bühler has collaborated with some of the biggest private sector companies in Saudi Arabia, including Arabian Agricultural Services Company (ARASCO) and Al Marai, for their value chain from grains to meat production and other food products.

“For many years, General Food Security Authority (GFSA) ex SAGO was our main and biggest customer in the Middle East and Africa in terms of grain terminals and modern mills operating with the highest production parameters, modern technologies and best quality,” notes Eng. Jebabra. This relationship has seen Bühler being responsible for over 60 percent of SAGO projects.

From the early stages of any project, Bühler assembles an experienced team to determine the project requirements and specifications. It designs and delivers high-quality machines and installs and commissions all equipment. It provides a manager to oversee any aftersales requirements and 24/7 maintenance.

Bühler also contributes to youth training and skills development in the Kingdom and developing the capabilities of local citizens. “We have a social responsibility to uplift and empower Saudi society,” says Eng. Jebabra. Bühler has developed a three-year technical programme to equip the youth with the necessary qualifications and training to enter the labour market.

Food safety and regulatory compliance are hot topics for food manufacturers. Ian Scott-Mance, Technology Manager of Mettler-Toledo ProdX™ considers how digitalized product inspection technologies can help them to meet these demands.

Food safety is of critical importance, and the food industry has become increasingly heavily regulated. Success for food manufacturers, both now and in the future, comes from being adept at producing safe, high-quality food and in being able to demonstrate beyond question that the processes used to make that food meet regulatory demands.

Today, technology is helping manufacturers to align themselves with these requirements. Food safety and quality standards in production can be improved using product inspection

systems for x-ray, metal detection, checkweighing, and vision inspection. In parallel, the digitalization of much production line equipment – and product inspection technology, in particular – is making compliance with food safety regulations both simpler and easier.

Digital inspection technology can continuously monitor and record production line performance, which manual processes simply cannot match. In addition, standards owners and regulators are placing an increasing focus on food safety digital transformation. Not only is digitalization better able to support food safety compliance, but it is quickly becoming an expectation that food manufacturers embrace it.

So, the digitalization of product inspection has a direct bearing on the capacity of food manufacturers to demonstrate food safety compliance. Improved compliance comes through a variety of different aspects of the operation. In this article, we consider five ways in which food safety compliance is improved by digitalized product inspection.

Digitalized product inspection systems constantly monitor and record performance data, compile authenticated activity as it happens, and apply appropriate security features to ensure the data gathered cannot be tampered with. This gives food manufacturers, auditors, regulators, and customers confidence that optimum product inspection performance is being maintained.

This is especially true around system verification activities. When a test is carried out on the equipment, a range of data is recorded automatically, verifying that a test took place and storing the test results and other relevant information with a digital timestamp that cannot be changed. There is nowhere to hide here. Testing results cannot be falsified or altered without the culprit leaving evidence, and auditors examining the records will be able to identify anomalies. The confidence this inspires in the data is vital for food safety compliance.

Product inspection is most effective when used at Critical Control Points (CCPs) in the production line, where it can identify issues impacting product quality and food safety. Digitalized product inspection performs this function in real-time and can immediately warn of production line issues. This allows the manufacturer to quickly intervene and address any problems, potentially saving a large volume of products or ingredients from being wasted or quarantined, and reworked.

As well as improving production efficiency, reducing waste, and helping to ensure that only good quality products leave the factory, this capability also provides data supporting compliance with food safety regulations.

Across the world, food manufacturers must adhere to national, regional, and industry regulations to make sure their products are safe. This helps food manufacturers to focus on a wide range of areas, including HACCP, traceability, food fraud prevention, management commitment, and food safety culture.

Digitalization of product inspection means that data related to procedures such as system testing, managing rejected products, and checking all products are correctly packaged and labelled, is collected automatically, removing the need for manual collection or handwritten records. This makes food safety compliance both easier and cheaper for food manufacturers.

The industry-wide push from regulators and standards bodies for better food safety compliance will lead to more transparency in food manufacturing. Digitalization plays a critical part in developing this transparency. It enables

food manufacturers to gather meaningful production line data automatically, and this data can populate databases and track and trace systems within the digital supply chain.

Food safety data captured by by-product inspection machines can be captured and shared with ERP and factory management systems via a range of secure and industry-standard machine-to-machine connectivity protocols. This makes record-keeping and compliance with food safety regulations much easier for food manufacturers to achieve.

There is another factor to transparency: by embracing it, food manufacturers are opening their factories and processes up to a higher level of scrutiny. This requires a different mindset from their employees, which takes us to the fifth example of how the digitalization of product inspection helps food safety compliance.

With digitalization and transparency, there is nowhere to hide. Food safetyrelated processes such as regular testing of product inspection equipment must become part of the culture of the factory rather than potentially being seen as a boxticking exercise. Indeed, the requirement for such a culture is increasingly included within standards and regulations.

Digital records can be made tamper-proof, introducing a greater level of process governance. Crucially, all stakeholders have to be aware that non-compliance is also recorded.

Effecting this culture change requires proactive management strategies to keep people engaged and motivated. Training workshops might be required, in which objectives and goals are presented and business benefits explained. Concerned employees also need to be reassured. One way might be to highlight how new ways of working might deliver new opportunities and new skills that could increase their value to the business and possibly their salary.

Most importantly for the food manufacturer, getting the culture right means it can better comply with food safety regulations, helping to strengthen its reputation and its relationships with customers and regulators.

Improved food safety compliance is both a journey and a destination, and digitalization of product inspection is a critical part of both the process and the objective. There has to be a higherlevel reason to undertake the journey, though. The automation, the real-time monitoring of processes, the harnessing of digital data, the increased openness and transparency and the imperative of managing a new culture internally, are all worthwhile because they help to make a food manufacturer’s business and its key supply chain relationships both stronger and better.

About the Author

Ian Scott-Mance is the Technology Manager at MettlerToledo Product Inspection. With over 25 years’ experience in digital marketing, Ian is one of the main driving forces behind developing MettlerToledo’s digital presence. This entails overseeing the development of the company’s web presence plus customer digital solutions such as ProdX™ data management software. ProdX™ records all product inspection activities, helping manufacturers develop their digitalization plans and achieve digital maturity for food safety.

In an ever-evolving food and beverage industry haunted by various challenges, is end-to-end sustainability a reality we soon shall have?

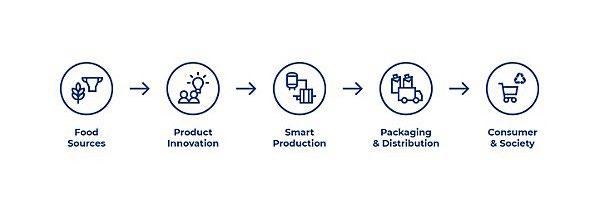

End-to-end sustainability is a concept that involves the entire supply chain, from production to consumption. It focuses on the environmental, social, and economic aspects of sustainability in order to create a holistic approach to green business practices.

The food and beverage industry has been increasingly adopting this concept as it helps them reduce their environmental footprint, improve their social responsibility and increase their economic efficiency. By taking into account all stages of production, from sourcing ingredients to packaging and distribution, end-to-end sustainability helps the F&B industry create sustainable production

processes that are beneficial for both the environment and society.

Where are we now?

The food and beverage industry is at the forefront of sustainability and circular economy efforts, as it is one of the most influential industries in adopting these practices. However, the industry is still facing some bottlenecks when it comes to creating a comprehensive, closed-loop system to encompass the entire value chain.

The F&B industry is challenged by the need to design a circular approach to the food system from farm to fork to achieve true sustainability. Furthermore, the industry currently faces a lack of resources to bring the circular economy to fruition, as well as difficulty in transitioning current business models to a more sustainable one.

There is a lack of consumer awareness and education in the circular economy, which makes it difficult for businesses to implement the transition successfully.

The sustainability environment has become a big issue. Even if brand owners don’t have sustainability as part of their agenda, they need to look into it. However, one plausible reason why it isn’t part of their commitment is they don’t have a starting point because this is something new to them.

But hope is not lost. Multinational companies are now taking the helm and providing end-to-end support. Tetra Pak, for one, offers end-to-end solutions to its partners, from processing to packaging. They can also be a critical starting point for product innovation.

Jose explains, “A customer can come to us. They want to address a customer’s need but don’t know how to address it. We can discuss, organize a workshop, and collaborate on research.” He adds, “Our work is proactive. We’ve done a lot of work on sustainability. So, we can help brand owners to see how they can start on sustainability. It can be as simple as putting messages on one-liter packaging. If brand owners want to increase potential with consumers, they can work with Tetra Pak on the side panel of the packaging.”

In a sense, this strategy can be a brand’s way to increase their consumers’ sustainability awareness. It’s also an excellent way for brands to convey their social responsibility, which is big among consumers.

Jose continues, “Now, one liter of milk sits on the breakfast table with a lot of consumers. The family sees the message they can associate it with the brand. In a way, it might help increase the credential. From a consumer perspective, there is a brand that cares for the environment because we put tips on how you can take care of the environment.”

But Tetra Pak’s work is more than just plastering sustainability commitment messaging on the packaging. They are also working with partners in recycling the products–bridging the gap between brands and partners.

End-to-end sustainability should include both the production of the product as well as its use and disposal.

To ensure sustainable production, it is important to consider the entire lifecycle of the product. This includes sourcing the right materials, minimizing waste, and utilizing environmentally friendly production processes. The packaging materials should be optimized to reduce waste and promote recyclability.

To ensure sustainable use of the product

focuses on educating consumers about the product’s environmental impact. This includes providing facts, figures, and data regarding the product’s environmental footprint.

Proper disposal of the packaging is paramount. This can be done using eco-friendly disposal methods, such as recycling and composting.

“We can collaborate with brands, and refer them to our collection and recycling partners. For example, in the Philippines, we’ve been running the Care and Share program. It’s a program that we do in schools. And we’ve been doing this for a number of years, with the aim of educating kids about how you dispose of carton packs.”

He adds, “Aside from education, we collect these used beverage cartons, and then we transplant those to our recyclers. At any point of the journey, whether it’s actually taking care of post-consumer waste or using beverage cartons, we can come in and support the customer.

Evaluating your food and beverage business for sustainable practices is essential for success in the modern world. With the increasing demand for an ecofriendlier approach to production, it is important to assess how your business can contribute to this goal. Fortunately, there are many opportunities to help companies evaluate their F&B business and develop a sustainable model that meets the needs of both customers and the environment.

Tetra Pak emphasizes its commitment to providing integrated solutions to their partners. Jose shares, “Manufacturers can come to us, and we can offer full solutions, end-to-end. We can connect all the machinery in the factory to make sure customers are able to see how the machines are running in real time. See the efficiency and know where the bottlenecks are or where the issues are coming from.”

“With all the data, they can address and predict which areas that they should be focusing on, especially when it comes to sustainability,” Jose concludes.

With insights from John Jose, Marketing Director at Tetra Pak. John has over 26 years of work experience with Tetra Pak in local, regional, and global roles across marketing, sales and product management. Currently leading the Marketing Function in Tetra Pak Malaysia, Singapore, Philippines, and Indonesia; John is responsible for the overall direction of Tetra Pak in the Philippines, providing strategic insights and leading expansion efforts. John was Tetra Pak’s Cluster Portfolio Manager from 2008 to 2010 and was based in Malaysia. During his tenure as portfolio manager, John supported the new packaging portfolio development for Southeast Asia and South Asia. He also ensured the smooth introduction of Tetra Pak’s new products and innovations to local markets. From 2005 to 2008, he was Tetra Pak’s Global Product Manager and was based in Lund, Sweden. As a global product manager, John was focused on the worldwide deployment of Minute Maid Tetra Wedge Aseptic. John graduated from De La Salle University with a degree in Marketing Management.

Food security is a complex issue that involves many factors, including population growth, climate change, natural disasters, political instability, and economic challenges. Significant progress is in ensuring food security, but much work still needs to be done.

Food engineering has played a crucial role in developing new technologies and methods for food production, and one that prominently pops into the conversation is the development of cultivated meat.

Didier Toubia, CEO and Co-Founder of Aleph Farms, shares,

Didier Toubia, CEO and Co-Founder of Aleph Farms, shares,

“

And that’s one aspect that we’re very serious about. We’re solid on sustainability issues. The second pillar is food security. Providing a food system that is resilient. Resilient to shocks, resilient to climate change, which is distributed, and production with short production cycles, shorter supply chains, close to the consumption areas, and a giant and reactive production system which can provide secure high-quality protein, animal protein independently to the climate or the availability of land and water.”

One of the most significant challenges facing the world today is the need to

produce enough food to feed a rapidly growing population. The United Nations estimates that the global population will reach 9.7 billion by 2050, meaning we will need to produce 70 percent more food than we currently do.

Aleph Farms works closely with different countries, specifically those that face the challenge of food security.

Toubia adds, “We’re working closely with Singapore on the 30 by 30 and with Abu Dhabi, in the UAE. It’s also why we’re backed by the State of Israel. In Israel, we import 88 percent of our beef, either before or after slaughter. And this issue of being unable to farm cattle locally is shared between the Middle East and a large part of Asia for the same reasons: resource scarcity, climate, and water. It is the food security issue. So sustainability, on the one hand, and food security, on the other hand, the different configurations or potential benefits of cultivated meat, are related to the public.”

Cultivated meat is one of the most resourceful ways to produce protein. ”

Precision fermentation is a technology that involves using microbes to produce specific ingredients or compounds through controlled fermentation processes. In the context of the cultivated meat industry, precision fermentation plays a crucial role in producing animalfree proteins that can be used to create meat-like products without the need for actual animal slaughter.

The method creates essential ingredients for cultivated meat production, such as plant-based proteins, fats, and flavorings. These ingredients are produced by genetically engineered microbes, such as yeast or bacteria, to produce specific proteins or compounds that mimic the taste and texture of animal meat.

One of the significant advantages of precision fermentation is that it allows for producing large quantities of these ingredients in a highly controlled and consistent manner. This makes it possible to scale up production quickly and efficiently, essential for meeting the demand for cultivated meat as it becomes more widely adopted.

Another significant advantage of precision fermentation is that it is a much more sustainable alternative to traditional animal agriculture.

various environmental

such as deforestation, greenhouse gas emissions, and water pollution.

fermentation. Precision fermentation has revolutionized the food industry by allowing for the production of various ingredients and compounds, such as proteins, fats, and flavorings, through controlled fermentation processes using microbes such as bacteria or yeast.

The precision fermentation industry is rapidly growing, with many startups and established companies investing in the research and development of new products and scaling up production. Investors and venture capitalists have also shown significant interest in the potential of precision fermentation, with many funding rounds and partnerships being announced in recent years.

One of them is ScaleUp Bio, a joint venture of ADM and Temasek’s Nurasa. During the Agri-Food Summit held in Singapore in October of 2022, I had the opportunity to talk to ScaleUp Bio’s CEO, Francisco M. Codoner, who shared insights about the precision fermentation industry and how ScaleUp Bio aims to provide stateof-the-art precision fermentation physical labs and facilities, technical and business assistance and access to potential investors/funders, targeted to support global food tech start-ups.

Precision fermentation also benefits the distribution and processing of cultivated meat products. Since the ingredients used in cultivated meat production are produced in a controlled fermentation environment, they are free from contaminants and pathogens that can be found in traditional animal agriculture. This makes processing and distributing the products more accessible, essential for consumer acceptance.

Many experts in food and biotechnology consider today to be the era of precision

Codoner explains, “Precision fermentation relies on classical fermentation. You have naturally fermenting things—for example, cheese. In precision fermentation, what you are doing is trying to exactly and precisely produce one protein. So, I precisely design an organism that is going to be able to provide calcium. And then, with that casein, I can build different products that will be on the market or whey protein for making other products. So precision fermentation is like targeted fermentation, using fermentation technology to produce an ingredient.”

Precision fermentation has been instrumental in developing plant-based meat substitutes and cultivated meat, offering a sustainable and ethical alternative to traditional animal agriculture.

Producing meat depends on how many cows are slaughtered. In precision fermentation, you don’t need cows to be present. With fewer cows, the elimination of greenhouse emissions from farming is possible. Plus, it allows cows to graze on good land.

The production of animalbased proteins is associated with

issues,

In contrast, precision fermentation produces ingredients that have a much lower environmental impact and can be made with significantly fewer resources.

Codoner adds, “What we’re trying to do in ScaleUp Bio is set up an infrastructure to help companies that need to produce the final ingredients. We are going to have all the downstream processing that they need to fortify that problem for the end to have as much as possible. He explains, “It will be like an end-to-end process. They only need to take care of having the idea and the good microorganisms to produce what they want to produce.”

ScaleUp Bio will provide a lending hand. “We want to be enablers and work in a collaborative way. We don’t want to be taking ownership of anything. We want to be an integral part of the team to see how they can improve the process, how they can improve the downstream processing, how they can improve even the strain if it’s needed, and what they needed to be changed to get a real good foot at the end of the like the entire ecosystem,” Codoner comments.

name a few.

Since the production of cultivated meat does not involve animal slaughter, it eliminates the need for complex supply chains and transportation logistics associated with traditional meat production. This can significantly reduce the costs and environmental impact of the meat industry.

“It’s not just the fact that we can adjust supply and demand and delivery attractive in terms of product delivery. Customers can come to us strict requirements, which is not possible with conventional meat because of the variability in traditional cattle raising,” Toubia explains.

Toubia adds, “And there are always differences between two animals. In our case, we can provide a product exactly one million times. It’s also a tremendous advantage for customers.”

But it does come with challenges.

main caveats that they need to overpass.”

And this is where ScaleUp Bio hopes to make a difference. The organization can connect and guide them on what else they can do for the product.

Codoner says,

With food supply a significant issue, cultivated meat can be the answer to addressing the gaps in the supply chain. Traditional cattle raising variability is a common issue. Various factors can impact cattle raising, such as climate, farming conditions, and cattle feeds, to

Codoner claims, “The first one is funding. So, venture capital needs to fund these companies to put that idea into a working idea. Most of the venture capitals are mainly willing to develop IP, not invest in infrastructure, and try to reduce the cost of infrastructure.”

He adds, “Infrastructure is difficult to maintain, and you will use it for a short period because whenever you are in big volumes, you will need that bigger infrastructure. So, these two things are the

In conclusion, precision fermentation is a game-changing technology for the cultivated meat industry. It allows for the production of animal-free proteins and other ingredients that mimic the taste and texture of animal meat in a highly sustainable and efficient manner. As technology continues to evolve, we expect to see even more innovation and improvements in the cultivated meat industry.

Is precision fermentation the key to sustainable meat production?

We can avoid them spending money on that. And we can take care of the fermentation expertise and the infrastructure required for the downstream processing. ”

“With insights from Didier Toubia, CEO and co-founder of Aleph Farms and Francisco Codoner, CEO of ScaleUp Bio.

The beverage industry, like many others, is under increasing pressure to adopt sustainable practices that minimize their impact on the environment. As consumers become more aware of the environmental impact of their purchasing decisions, there is a growing demand for sustainable products and processes. This has led many companies across the beverage industry to focus on sustainability as a core part of their business strategy.

One of the ways is by adhering to a circular economy. This means moving away from a linear model of production and consumption, where resources are used and then discarded, to a more

circular model that promotes the reuse and recycling of materials.

Adopting a circular economy approach can bring many benefits to the beverage industry. It can help companies reduce waste, lower costs, and create new revenue streams. It can also help reduce the environmental impact of production, from reducing carbon emissions to conserving water resources.

In this context, companies in the beverage industry must take a holistic approach to sustainability, looking at their entire supply chain from raw materials to consumer disposal. The adoption of circular economy principles can help create a more sustainable and resilient beverage industry that benefits both the environment and the bottom line.

As we continue to face global challenges such as climate change and resource depletion, the beverage industry and other industries must take a proactive

approach toward sustainability. Adhering to circular economy principles can be a powerful tool in achieving this goal and creating a more sustainable future for all.

Asia Food Journal had the opportunity to interview Alan William Smith, Chief Supply Chain Officer, Suntory Beverage & Food Asia Pacific, who shared how their company is making huge strides in sustainability.

Over the last few years – buoyed by the rise of the conscious consumer and regulatory movements – we have seen a concerted push across beverage companies to scale green efforts, with a recent IDC industry report indicating

nearly 30 percent of F&B decision makers putting eco-friendly products as a top factor for organisational change.

This has undeniably fuelled great changes in bringing sustainable packaging to the masses, including integrating materials like compostable paper and monomaterial plastics that make recycling processes, or the circular economy, more seamless and cost-efficient.

For the most part, amendments to food packaging standards by authorities across Thailand, Vietnam, and South Korea, have supported ongoing efforts to make recycled polyethylene terephthalate (rPET) bottles become a mainstay in the industry. These nationwide changes will likely create steady investments to bolster manufacturing and recycling infrastructures within the F&B ecosystem to support its heightened production.

At Suntory Beverage & Food Asia Pacific (SBFAP), we recognise the immense potential that rPET has in supercharging climate change efforts – giving rise to our goal to implement 100 percent sustainable PET bottles globally by 2030 have since steadily climbed, with efforts made by Suntory PepsiCo Vietnam Beverage, our joint venture with PepsiCo, to launch the first-ever rPET, in addition to producing

our Pepsi and Pepsi Zero bottles in 100 percent recycled materials.

Our efforts to bolster the groundwork in Vietnam’s sustainability journey with greener packaging innovations have already succeeded. In 2022 alone, we have reduced up to 20 percent plastic weight in the packaging of products such as Oolong Tea+ and Aquafina, etc., saving about 2,435 tonnes of plastic.

At the same time, we are also working closely to pave the way for rPET in Thailand. This includes trying out different recycled resins to put quality, cost-friendly, and safe products on the shelves.