2

INTRODUCTION AND GENERAL INFORMATION

LICENSE DATA The following method of numbering vehicles and their engines will be used on the 1970 models. The starting vehicle number will be as follows: Coronet Models

Coronet Series

WE21B9A-100001 Charger

Charger

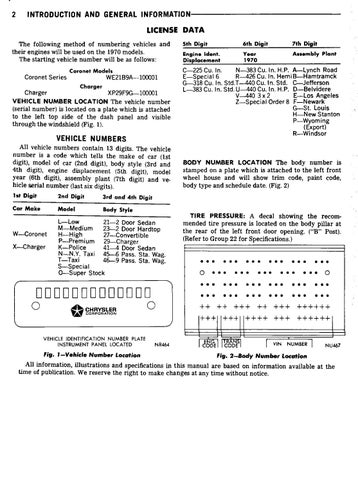

XP29F9G-100001 The vehicle number (serial number) is located on a plate which is attached to the left top side of the dash panel and visible through the windshield (Fig. 1). VEHICLE NUMBER LOCATION

VEHICLE NUMBERS All vehicle numbers contain 13 digits. The vehicle number is a code which tells the make of car (1st digit), model of car (2nd digit), body style (3rd and 4th digit), engine displacement (5th digit), model year (6th digit), assembly plant (7th digit) and vehicle serial number (last six digits). 1st Digit 2nd Digit 3rd and 4th Digit Car Make

Model

5th Digit

6th Digit

7th Digit

Engine !dent. Displacement

Year 1970

Assembly Plant

N-383 Cu. In. H.P. A—Lynch Road C-225 Cu. In. R-426 Cu. In. Hem i B—Hamtramck E—Special 6 G-318 Cu. In. Std.T-440 Cu. In. Std. 0—Jefferson L-383 Cu. In. Std. U-440 Cu. In. H.P. D—Belvidere E—Los Angeles V-440 3 x 2 Z—Special Order 8 F—Newark G—St. Louis H—New Stanton P—Wyoming (Export) R—Windsor

BODY NUMBER LOCATION The body number is stamped on a plate which is attached to the left front wheel house and will show trim code, paint code, body type and schedule date. (Fig. 2)

Body Style

L—Low 21-2 Door Sedan M—Medium 23-2 Door Hardtop W—Coronet H—High 27—Convertible P—Premium 29—Charger X—Charger K—Police 41-4 Door Sedan N—N.Y. Taxi 45-6 Pass. Sta. Wag. 1—Taxi 46-9 Pass. Sta. Wag. S—Special 0—Super Stock

DODOE0000000111 a CHRYSLER

VEHICLE IDENTIFICATION NUMBER PLATE INSTRUMENT PANEL LOCATED Fig. 1 —Vehicle Number Location

0

NR464

TIRE PRESSURE: A decal showing the recommended tire pressure is located on the body pillar at the rear of the left front door opening. ("B" Post). (Refer to Group 22 for Specifications.)

• • •• 0 ••• ••• ••• ••• ••• 0 ••• ••• • • • • •• ••• • •• • • • • •• • • • ••• ••• • •• •

• •

• • •

• • •

• • •

• •

++ ++ +++ ++ +++ ++++++ +++ +++ ++++ +++ ++++++ ENG I ITRANSI CODE CODE

VIN NUMBER

NU467

Fig. 2—Body Number Location

All information, illustrations and specifications in this manual are based on information available at the time of publication. We reserve the right to make changes at any time without notice.