9 minute read

SMOOTH MOVES

BEGINNER TIPS TO CREATE A SMOOTH, GLASSY FINISH WITH WOOD EPOXY.

By Matt Weber

Bars, countertops, and table tops are among the most popular projects to feature a smooth, glass-like finish that highlights and

preserves the wood beneath it. This durable finish is created by using a two-part epoxy resin that self-levels upon application. The epoxy can provide a clear transparent protective layer to see the wood underneath or can be tinted with powdered or liquid pigment colorants. The right coloring effects can produce intriguing designs or even faux granite or marble-like epoxy countertops.

The job requires high-quality epoxy resins. I chose WiseBond Epoxy Systems and their Bar & Table Top epoxy, which is known for its ease of use and its high-shine, crystal clear transparency. My plan was to preserve the color and grain character of a coffee table I made from reclaimed tongue-and-groove pine that I salvaged from my grandparents’ old barn.

This article shows how I completed my first epoxy project and offers a few tips to help guarantee success on your projects at home.

PREP STEPS

The Bar and Table Top epoxy is designed to harden over and preserve whatever it coats, so make sure you’re fully satisfied with the look of your project before application. Also, make sure the surface you’re coating has no “leaks.” For example, the coffee table shown had a hole in the trim at one corner, and when I poured the epoxy flood coat over the table, the epoxy drained through the hole rather than pool and achieve

the self-leveling effect (which forced me to seal the leak from the underside of the table then reapply the coating).

If you’re working with a very porous wood or other material subject to epoxy flowing through it, you can build a form to completely surround the object like a pan and catch the epoxy so it pools over the surface.

Prior to application, it’s extremely critical to clean the entire surface carefully. Any lint, wood dust or debris left on the surface will be stuck like a fly in amber if you don’t clean it off first. Avoid using tack cloths or other fabric that can leave small fibers which can get caught in the finish. Surfaces with rough texture and high relief can be cleaned of dust by using compressed air. Thoroughly wipe the surface with acetone or denatured alcohol, then wipe dry with clean shop towels.

WORK SITE

The coating process involves flooding liquid epoxy over the entire table top, including the edges. This means epoxy will be dripping off the sides. To limit the mess, I placed the coffee table over a large 4x8 sheet of plywood covered with a plastic drop cloth to catch the runoff. Make sure to arrange a similar worksite for your project to retain the excess product and facilitate cleanup afterward.

It’s also important to work indoors in a dustfree environment, so airborne particulates don’t float down onto your crystal-clear coating before it has fully cured. Keep in mind fluorescent lights in your work area can create static electricity which can attract dust to the bulbs. Then, when the lights are turned off, the dust can fall because there is no static attraction. This dust can fall right into your epoxy, destroying the glossy finish. Another trick is to use a pop-up tent covering your project to eliminate as many falling particles as possible.

The two-part epoxy product should be stored between 70°F and 85°F before mixing, and the work space air temperature should be no warmer than 85°F. If the parts A and B are cooler than 70°F, warm the containers in hot tap water. If crystals are present in A or B, place the closed containers in 120°F tap water until crystals dissolve, then let the containers cool. You should only use A and B when the liquid temp is 85°F or under to prevent premature curing.

Knowing the porous nature of the reclaimed wood would be susceptible to air pockets that could form bubbles in the epoxy finish, I took the opportunity to seal the boards with a water-based poly when constructing the table. Epoxy application requires a very clean, dust-free work environment. It’s a messy job, so arrange drop cloths to catch the spill. Thoroughly wipe and clean the surface before a pour with acetone and wipe dry with shop towels.

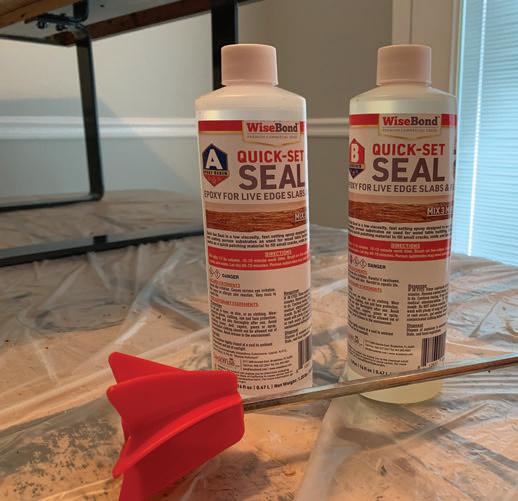

The first coat is a seal coat to prep the work surface. I used Wisebond’s Quick Set Seal product, which is a two-part epoxy that dries in just a few hours.

MIX IT UP

Carefully mixing the two-part product is a critical step. Use a clear mixing bucket with exact measurements printed on the side. Measure one part Resin-A to one part HardenerB and mix thoroughly for 3 minutes with a paint stick or paddle mixer attached to a drill until the swirls and tails disappear. Swirls and tails floating around are a sure sign the epoxy isn’t yet completely mixed. Be careful not to over mix and whip air into the epoxy.

Next, pour the mixed epoxy into a second clean mixing container and mix for 1 minute. This will ensure no unmixed A or B will contaminate the final pour. (Add colorants if applicable when epoxy is completely mixed.)

Note that improperly mixing the epoxy is the number one problem people face. Your measurements must be exact, because a hard epoxy cure is completely dependent on proper mixing.

SEAL COAT

In order to prevent air from escaping out of the project’s surface and creating a bubble when the epoxy is applied, you need to apply a seal coat prior to the final flood coat. In fact, for extra protection, I coated the wood with waterbased poly prior to the seal coat, because I knew my reclaimed boards were especially porous.

The same two-part epoxy you’ll use on the flood coat can be used to apply the seal coat. (However, I used Wisebond’s Quick Set Seal for the seal coat, simply because it cures in 2-3 hours and saved time on this project).

If using a drill paddle, mix very slowly so as not to impregnate the epoxy resin with air bubbles.

When applying the seal coat, make sure to coat any surfaces with high relief that could form an air pocket when the epoxy is poured on.

I used a paint brush to apply the seal coat epoxy as a thin layer, paying close attention to the table edges and areas with low spots and heavy relief. Next, I used a smooth plastic scraper to spread a skim coat over the entire surface that will later have a flood coat applied. Multiple seal coats may be needed depending on porosity of the wood, countertop or bar top material.

Note that epoxy in a mixing container may last 15-20 minutes before it begins to gel. Prior to that, work time may be as long as 30 minutes as a thin layer, depending on air temperature, width, length and the overall surface area. The epoxy in a mixing container also heats up as it cures. Pour as soon as possible and do not let the epoxy sit in the mixing cup.

If you need multiple seal coats, recoat as soon as the first epoxy seal coat is at a hard tack. If the seal coat is older than 24 hours, sand with 220-grit between coats and clean away the sanding dust. It might seem counterintuitive to sand between coats, because the abrasion scratches up and whitens the clear finish. However, once you follow up with further coats, the epoxy will bond to the sanded surface and return it to its crystal-clear appearance.

FLOOD COAT

The final flood coat is so named because you’ll pour it onto and spread it over the entire project surface, allowing it to spill off the edges.

Use quality mixing containers with the proper mix ratio. Never let the epoxy sit in the mixing container too long, because it will heat up in mass.

Apply the seal coat to the edges of the project to facilitate the flow of epoxy during the upcoming flood coat. Two or more seal coats may be needed, depending on porosity of the wood.

After applying a thin seal coat over the entire project, allow it to completely dry. Scuff the hardened surface with 220-grit sand paper to ensure adhesion between epoxy layers.

Wipe away sanding dust with denatured alcohol.

Make sure you mix up enough product for full coverage in a single pour. Flood coat coverage is 12 sq. ft. at 1/8-in. thick per gallon.

Spread the mixed resin evenly using a 1/4-in. notched plastic trowel. Use thin pours of no more than 1/4 inch. Apply epoxy to the sides and edges of the table material surface before pushing epoxy over the edges. This “wets” the sides and edges, allowing the flood coat to smoothly flow in sheets over the edge instead of wandering drips. Continue to pour the remaining material to achieve the desired thickness, allowing the resin to flow evenly over the project’s sides. As you comb through the resin with the notched trowel, you’ll see the epoxy fill into the grooves and level as a smooth, even 1/8 in. surface. Do not use a squeegee to spread epoxy. It will not produce an even thickness.

Keep an eye on the project for the next couple of hours in case it requires any maintenance. For example, table top epoxy will have bubbles in it from mixing, and tiny bubbles might form if air escapes from the wood. However, you can easily eliminate (pop) those bubbles with a heat gun or propane torch.

Allow the resin to cure for 72 hours before handling. Seven days of cure is good for light use, and 30 days will achieve a full hard cure.

For the flood coat, I used Wisebond Bar and Table Top Epoxy, which must be mixed in exact 1:1 ratio. For the best coverage, apply epoxy to wet the edges and sides of the material surface before pushing epoxy over the edges.

FINAL THOUGHTS

This coffee table was a sentimental project for me because it served as a memento of my grandparents and the time I spent at their home. Since this was my first foray into working with wood epoxy, I was worried I might screw up the finish. However, by carefully following the mixing and application instructions, I was able to give my rustic table exactly the clear, glass-like surface that I’d hoped to achieve, and I couldn’t be happier with the results.

Apply the flood coat using a 1/4¨ notched plastic trowel to spread evenly.

H

Find out more about the Wisebond brand of wood epoxy products at www.wisebond.com.

During the flood coat, tiny bubbles might form if air escapes from the wood, but you can easily pop those bubbles with a heat gun. Allow the epoxy to cure for 72 hours before handling.