Unrolla SL700X|SL700 Bale Feeder Original Instruction

IMPORTANT Read this manual before operation HUSTLER EQUIPMENT INTERNATIONAL LIMITED

CONTENTS

Introduction................................................................................. 2 Important..................................................................................... 2 Specifications............................................................................. 2 Warranty ...................................................................................... 3 Warnings...................................................................................... 4 Warnings Cont............................................................................. 5 Maintenance................................................................................ 6 Operational Instructions........................................................... 7 Adjustments................................................................................ 8 Options......................................................................................... 9 Trouble Shooting...................................................................... 11 General Issues.......................................................................... 11

1

INTRODUCTION Thank you for purchasing a HUSTLER SL700X|SL700 BALEFEEDER. Please read through this manual as it contains important information which you need to know. Please take special note of the warnings on page 4-5, routine servicing on page 6 and trouble-shooting on page 11. Correctly maintained and operated this machine will give many years of service. If you have any questions please contact the dealer who supplied you this machine. They have trained technicians who will be able to help you.

IMPORTANT • Please ensure this booklet is read and understood by every operator of this machine. • Also ensure that this booklet goes with the machine if it is resold and is read and understood by owner.

SPECIFICATIONS Pressure:

2250 - 3000 PSI.

Flow:

25 - 60 Litres/minute (our recommended minimum flow is 25 Litres/ minute)

Hydraulic Requirements:

2 x set of double acting hydraulics.

Tractor size:

Large enough to safely handle the SL700X/SL700 bale feeder (980 kg’s) and 2 bale up to 1000kgs each. (One on the platform and one on the loading tynes.)

2

WARRANTY

(SL700X|SL700 Bale feeder) The goods specified in the Instruction Manual as designed and supplied by the Manufacturer are warranted against faulty workmanship and defective materials for a period of 24 months from the date of purchase. Such warranty is subject to the following conditions: 1. This warranty covers the repair or replacement of parts or machinery sold by the manufacturer and damaged as a result of the faulty workmanship or materials in such parts or machinery. It does not extend to any other loss or damage including consequential loss or damage or loss to other property or persons. 2. Without limiting the senerality of paragraph 1 above, this warranty does not cover the following: a. Travel expenses. b. Damage caused by accident, misuse or abuse. c. Damage to any goods which have been altered or modified by someone other than the manufacturer or its authorised agent d. Damage or loss to the goods due to their unsuitability for any particular use or for using with any particular tractor except where such use or tractor had been specifically approved by the manufacturer. e. Damage or loss where the fitting and installation of the goods were not carried out By the manufacturer or its authorised dealer. f. Paint damage or wear. g. Wear and tear where Hustler deem the product to be in a high wear environment 3. Procedure for recovery under warranty. No loss or damage will be covered by this warranty unless the following procedure is followed by the purchaser a. The loss or damage should be reported immediately to the dealer (who will contact the manufacturer who will advise whether it is covered by the warranty and undertake the necessary action). “This warranty shall be interpreted according to the laws of New Zealand and the parties agree to submit to the jurisdiction of the Courts of New Zealand.”

3

WARNINGS • ALL persons and animals must be keep WELL CLEAR of the machine in operation and when traveling • Shut off the tractor BEFORE trying to clear feed material or cut strings/ net from anywhere around the machine. • BEFORE attempting maintenance or any work, ensure the tractor engine is shut off, the handbrake is applied and no one is near the hydraulic controls. • DO NOT allow any person(s) to ride on the machine at any time. • EXTREME CARE must be taken when traveling on uneven ground or hill country. A steep or slippery slope may cause the feeder or tractor to rollover. This could cause INJURY or DEATH. • EXTREME CARE must be taken when traveling on hill country with a bale in the cradle, so it doesn’t roll out Optional side bars can be purchased from Hustler. • ENSURE the jack stand is PROPERLY latched in place before driving the tractor away. • This machine is designed for off-road use ONLY. If towing on the road, two safety chains rated to at least 3.2 metric tons each MUST be used and securely fastened in the correct cross over technique. Tail lights and a registration plate may be required. It is the owner’s responsibility to adhere to the law in their country/state. • Take CARE when travelling with a bale up on the rear forks as this lessens the stability of the machine. The closer the bale to the ground to lower the centre of gravity. • ALWAYS ensure the rear loading forks are pointing up approximately 45 when travelling without a bale • NO alteration or modification is to be done on this machine unless undertaken by Hustler or its authorized dealer. This will void the warranty • Vehicle must be operated no more than 30km/h when the bale feeder is attached. • KEEP CLEAR of moving feed chains and bars DO NOT use for transporting anything other than a bale. • KEEP CLEAR of feed bars. These have sharp points which are needed for teasing the bale • ENSURE axles are adjusted to the correct width setting for the terrain. Wide for hilly terrain • ENSURE the jack pin is securely in place so the jack doesn’t move in either the stand or transport position.

4

MAINTENANCE (also do this before initial operation)

• Grease all points regularly. • These are: - 4x main shaft bearings (do not over grease). - 2x drive couplings - 6x pivot points in rear loading mechanism - Inside the hook latch contact surface • Keep the 2 drive chains oiled. Use non-tacky black or brown chain lube monthly. • Grease the wheel bearings annually or earlier depending on conditions. If the machine is travelling through water occasionally, we recommend ADR High Tech Lithogrease 3 or equivalent. • After the first 10 hours of operation: • Check the wheel nuts are tight (x12)-220Nm • Check the notes on the tynes are tight, (x2)-600Nm • Check the drawbar bolts are tight. (x3)-200Nm • Check the axle bolts are tight. ( x4)-200Nm • During routine servicing check that the grub screws and bolts are tight. • In a salty atmosphere keep grease on parts that are likely to rust i.e. pins and cylinder shaft.

5

OPERATIONAL INSTRUCTIONS Connecting bale feeder onto tractor/telehandler etc. • Connect the bale feeder to the drawbar of the tractor. Ensure its securely fastened with a strong pin and retainer clip to stop the pin jumping out. • NOTE: The drawbar height can be adjusted by rotating the towing eye 180 degrees, (M16 Bolts should be torqued to 200Nm dry) • Connect the hoses so that: Lever 1 – lever back – loading frame lifts. (2 small hoses. Inside lever closest to driver.) Lever 2 – lever back – chains feed out on the right side. (2 large hoses. Outside lever.) • The hydraulic flow rate should turn the top rotor 1 turn/2-3 seconds. Many high flow rate tractors have an adjustable control. Use this to reduce the flow to the required rate. If there is no flow adjustment, simply operate the tractor at low rpm. • Some bales are just plain difficult for any feeder, however the Unrolla SL700X/SL700 series will generally feed these out. If you experience a problem, try feeding the bale out the other side. This will unroll the bale instead of trying to pull it a part. • The hydraulic flow should actuate the chains at a smooth, controlled rate i.e. not too jerky or sudden. • Familiarise yourself with the hydraulic controls on the machine. Using your 2 hydraulic hand controls.

6

Loading Hay/straw Round Bales • Use lever 1 to adjust the height of the rear forks till the top of the tyne frame is just below the top of the bale, then back the forks into the bale. (A good rule of thumb is: if the bale is 4’(1220mm) round, drop the forks fully down. If it is bigger that 4’(1220mm) raise the forks so the top og the tyne frame is below the top of the bale.) • For hay/straw bales with strings, lift the bale so its above the feed chamber and remove the strings. Then lower on to the bed. • Always return the forks back immediately after loading the bale. Lower the forks right down to the ground, to reset and then back up to the 45-degree position, unless loading another bale. • If loading a second bale, raise forks to selected bale height, then back the forks into the bale and raise to the transport position.

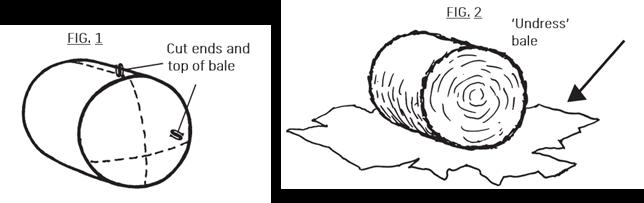

Loading Wrapped Round Bales • For loading wrapped bales - first remove the plastic wrap only (fig. 1). DO NOT remove string or net-wrap at this stage. NOTE: In most cases it does not matter which way the bale has been rolled up. • Use lever 1 to adjust the height of the rear forks till the top of the tyne frame is just below the top of the bale, then back the forks into the bale. (A good rule of thumb is: if the bale is 4’(1220mm) round, drop the forks fully down. If it is bigger that 4’(1220mm) raise the forks so the top og the tyne frame is below the top of the bale.) • Still using lever raise the bale up off the ground and over towards the platform. To facilitate easy removal of the net on bales with net-wrap we recommend to stop just before the bale settles on to the platform (try not to let the bale start falling apart while removing the net). With the removed finish lowering the bale onto the platform. • Now withdraw the forks and lower the forks right back down to ground level. Once you hear the ‘clack’ of the loading mechanism resetting, you can re-adjust the forks to pick up another bale if required. • If loading a second bale, raise forks to selected bale height then back the forks into the bale and raise so the bale is off the ground but not too high as this lessen the stability of the feeder. • If a second bale is not required lift the tyne frame to the 45-degree position (this keeps the fork safely away from animals etc.) 7

Transporting • Always ensure the rear loading forks are point up 45 degrees when travelling without a bale. • Take care when travelling with a bale up on the rear forks as this lessens the stability of the machine. The closer the bale to the ground to lower the centre of gravity. • Side bars are available from HUSTLER to keep the bale more secure on hilly country and to keep cattle away from the moving mechanism. Order code – 7207148

Feeding Out Round Bales • Keep the tractor in a low gear and using lever 2 start feeding the bale usually the bale will feed out one way better than the other. TIP: drive in a circle slightly to the right. This helps to see the hay feeding onto the ground. Select a higher gear to achieve a thinner feed-out line if required.

8

ADJUSTMENTS Adjusting wheel width • The SL300X/SL700 has an adjustable wheel track. This can be achieved by simply removing two bolts, sliding the axle across then tightening the bolts again. Ensure the rear of the bale feeder is lifted off the ground before removing the axle bolts. Both M16 bolts must be torqued to 200Nm. If the bale feeder is being used on the hill country axles must be in position 3 (wide).

9

OPTIONS String box For storage of bale wrap and net Order Code # 4004814 (includes all covers)

Wide tyres Ideal for softer terrain Order Code #5105532

Tractor Grip tyres Ideal for hillsides where more grip is required Order Code #5105536

Side bars For keeping the bale more secure in the feeder and assists in square bale feeding Order Code # 7207148 (Pair)

10

TROUBLE SHOOTING General Issues ISSUE I need to feed square bales

Bales not staying in the feeder

The chains won’t turn

POSSIBLE CAUSE Aside bar kit is required

•

Purchase an optional side bar kit for the bale feeder. Order code 7207148

•

Feed bars turning too fast

•

Slow down the feed bars they don’t need to turn fast

•

Feeding on hill country

•

Purchase an optional side bar kit from your nearest Hustler dealer

•

A string still left in the bale, wrapping around the shaft causing it to jam

•

Remove the string

•

Lubricate chain - see Maintenance secti on

•

Check hydraulic pressuresee Specification section for recommended pressure

•

Feed bale out the other side so it unrolls correctly or pick up feeder from the other end

•

Bend feed teeth to a more aggressive angle forwards

•

Chains may need lubricating Hydraulic pressure to low

•

Chain tensioner is to tight

•

Bale on the feeder ‘backwards’

Bale rotates but will not feed

•

The bale isn’t speared in the correct place for its size

•

Spear into the bale lower down before loading.

•

Fine chopped bale

•

Remove the covering Just before lowering the bale onto the platform.

•

For very difficult bales, lower bale onto platform and remove the covering around the bale where you can, and collect the rest afterwards.

The Bale is dropping hard onto the platform

Bale starts falling apart after removing the plastic or the net wrap, even when I try removing it carefully.

11

SOLUTION

•

NOTES

12

NOTES

13

NOTES

14

UNROLLA SL700X|SL700 BALE FEEDER

Hustler Equipment LTD PO Box 2127, 1416 Omahu Road Hastings, 4153, New Zealand. Phone +64 6 879 7926 www.hustlerequipment.co.nz

15