Tentative Certification Review Training

IFPS offers onsite review training for small groups of at least 10 persons. An IFPS accredited instructor visits your company to conduct the review. Contact kpollander@ifps.org for details of the scheduled onsite reviews listed below.

HYDrAUliC SpECiAliST

May 1-3, Mukwonago, WI, MSOE. Written test: May 4.

May 8-11, Fairfield, OH, CFC Industrial Training, Written test: May 12.

CFpE Certified Fluid Power Engineer

CFpS Certified Fluid Power Specialist (Must Obtain CFPHS & CFPPS)

CFpHS Certified Fluid Power Hydraulic Specialist

CFppS Certified Fluid Power Pneumatic Specialist

CFpECS Certified Fluid Power

Electronic Controls Specialist

CFpMT Certified Fluid Power Master Technician

(Must Obtain CFPIHT, CFPMHT, & CFPPT)

CFpiHT Certified Fluid Power Industrial Hydraulic Technician

CFpMHT Certified Fluid Power Mobile Hydraulic Technician

CFppT

Certified Fluid Power

Pneumatic Technician

CFpMM

Certified Fluid Power Master Mechanic

(Must Obtain CFPIHM, CFPMHM, & CFPPM)

CFpiHM

Certified Fluid Power

Industrial Hydraulic Mechanic

CFpMHM

Certified Fluid Power Mobile Hydraulic Mechanic

CFppM

Certified Fluid Power

Pneumatic Mechanic

CFpMiH

Certified Fluid Power

Master of Industrial Hydraulics

(Must Obtain CFPIHM, CFPIHT, & CFPCC)

CFpMMH

Certified Fluid Power

Master of Mobile Hydraulics

(Must Obtain CFPMHM, CFPMHT, & CFPCC)

CFpMip

Certified Fluid Power Master of Industrial Pneumatics

(Must Obtain CFPPM, CFPPT, & CFPCC)

CFpCC

Certified Fluid Power Connector & Conductor

CFpSD

Fluid Power System Designer

Aug. 14-17, Fairfield, OH, CFC Industrial Training, Written test: Aug. 18.

Dec. 4-7, 2023, Fairfield, OH, CFC Industrial Training. Written test: Dec. 8, 2023.

ElECTrONiC CONTrOlS SpECiAliST

July 24-27, Fairfield, OH, CFC Industrial Training. Written test: July 27.

pNEUMATiC SpECiAliST

June 19-22, Fairfield, OH, CFC Industrial Training. Written test: June 23.

Nov. 13-16, Fairfield, OH, CFC Industrial Training. Written test: Nov. 17.

CONNECTOr & CONDUCTOr

May 23-24, Fairfield, OH, CFC Industrial Training. Written and JP test: May 25.

Nov. 15-16, Fairfield, OH, CFC Industrial Training. Written and JP test: Nov. 17.

MOBilE HYDrAUliC MECHANiC

June 26-29, Fairfield, OH, CFC Industrial Training. Written and JP test: June 31.

Oct. 23-26, Fairfield, OH, CFC Industrial Training. Written and JP test: Oct. 27.

Online Mobile Hydraulic Mechanic certification review for written test is offered through CFC Industrial Training. This course surveys the MHM Study Manual (6.5 hours) and every outcome to prepare you for the written test. Members may e-mail for a 20% coupon code off the list price. Test fees are not included.

iNDUSTriAl HYDrAUliC MECHANiC

June 5-8, Fairfield, OH, CFC Industrial Training. Written and JP test: June 9.

iNDUSTriAl HYDrAUliC TECHNiCiAN

April 17-20, Fairfield, OH, CFC Industrial Training. Written and JP test: April 21.

MOBilE HYDrAUliC TECHNiCiAN

Sept. 18-21, Fairfield, OH, CFC Industrial Training. Written and JP test: Sept. 22. pNEUMATiC TECHNiCiAN and pNEUMATiC MECHANiC

For dates, call CFC Industrial Training at (513)874-3225 or visit www.cfcindustrialtraining.com/.

JOB pErFOrMANCE TrAiNiNG

CFC Industrial Training offers an online Job Performance Review that includes stations 1-6 of the mechanic and technician Job Performance tests. Members may e-mail IFPS for a 20% coupon code off the list price. Test fees are not included. CFC also offers live distance learning Job Performance Station Reviews. To register or purchase, contact CFC Industrial Training at (513) 874-3225 or visit www.cfcindustrialtraining.com/.

HS Test Available in Spanish

»IFPS RECENTLY RELEASED a Spanish-language version of the Hydraulic Specialist certification test.

The new version was developed to provide greater accessibility to the certification program and to ensure a more equitable opportunity for Spanish-speaking professionals to obtain certification.

For more information or to take the test, visit www.ifps.org/hydraulic-specialist-3.

Mark Your Calendar

UPCOMING TRAINING

Fluid Power Basics

When: April 27, 12-1 p.m. [ET]

Valve Manifold Design

When: May 4, 12-1 p.m. [ET]

For more information, visit www.ifps.org/web-seminars.

WWW.IF p S.O r G • WWW.FLUID p OWE r JOU r NAL.COM Apr IL 2023 23

Certified Fluid Power Authorized Job Performance Proctor CFpAJppCC Certified Fluid Power Authorized Job Performance Proctor Connector & Conductor

IFPS UPDATE

ON TARGET LUBRICANTS Reliable hydraulic performance depends on fluid choice; it’s not just about viscosity grade. EQUIPOWER HYDRAULIC OIL For more about LE’s high-performance lubricants, contact us or visit our website today. www.LElubricants.com | 800-537-7683 | info@LE-inc.com | Wichita, KS LE’s line of Equipower™ Hydraulic Oils are engineered to ensure smooth performance and superior protection for your equipment. Ability to maintain viscosity Thermal and oxidative stability Friction reduction capability Nonfoaming characteristics Detergency Demulsibility Hydrolytic stability Considerations when choosing hydraulic oil: PUSHBUTTONS JOYSTICKS ROCKERS GRIPS TOGGLES HALL EFFECT SOLUTIONS CONTROLS www.otto-controls.com @OTTO.Controls

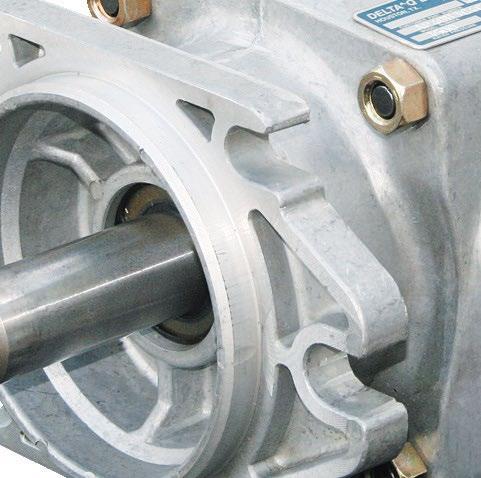

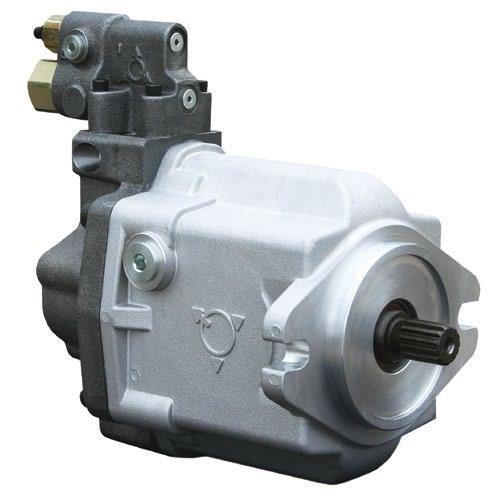

Simplified hose configuration, less hose and adapters combine to reduce repairs and downtime cutting the overall cost of hydraulics. 1-763-784-5531 www.SuperSwivels.com No Kinks No Hose Twisting Quality Products Made In The U.S.A. Patent No. 5547233 Fax: 1-763-784-7423 Email: sales@superswivels.com Available In BSPP LiveHydraulicSwivels Inline & 90° Heavy Duty Ball Bearing Design • Available In 304 & 440 Stainless Steel • Rated To 10,000 P.S.I. • Custom Design & Sizes Available • Rebuildable Ball Bearing Design • Full Flow —Low Pressure Drop • Superior Quality Alloy Steel • Side Load Resistant • Heat Treated Sw i tc h Y o u r S w i v e ®l S w i t c h Y o u r S iw v ®le •Variable Displ. Piston Pumps from 28-65cc •Pressures Up To 5000 PSI •Multiple Control Options •Rear, Side, Thru Drive Port Options •Made in the USA for Over 40 Years “Short Lead timeS With exceptionaL QuaLity” Delta ˆ Q l t D . 14233 West Road Houston, TX 77041 info@deltaq.com www.deltaq.com 800-650-3110 Manufacturer of Hydraulic Piston Pu M Ps Made In The USA Don’t compromise! Use MAIN Manufacturing Products, Inc. as your source for hydraulic flanges Dependable - 60 yrs service Informed - members of SAE & NFPA tech committees Quick - Thousands in stock specials can be 3-4 days MAIN Manufacturing Products, Inc. Grand Blanc, MI USA 800.521.7918 Info@MainMfg.com MAINMfg.com SAE 4-bolt, JIS, DIN, ISO standard & special adapters Socket and Butt weld, NPTF BSPT, ORB, BSPP, 6149, etc. Materials: Carbon, 304L, 316L, duplex, Cu-NI, ductile, alum. etc. In-line, el, tee, F, blind, cross, reducing, flange heads Made in USA

1A Total Safety P.O. Box 100088 Pittsburgh, PA 15233

P: 412-262-3950

F: 412-262-4055

E: sales@1atotalsafety.com

W: 1atotalsafety.com

6K Products 1006 143rd Ave SE Tenino, WA 98589

P: 360-264-2141

F: 360-264-5105

E: sales@6kproducts.com

W: 6kproducts.com

A1 Manifold Supply PO Box 18 Spring Lake, MI 49456

P: 616-296-9165

W: a1manifolds.com

AAA Products International 7114 Harry Hines Blvd. Dallas, TX 75235

P: 214-357-3851

F: 214-357-7223

E: info@aaaproducts.com

W: aaaproducts.com

Aalborg Instruments 20 Corporate Drive Orangeburg, NY 10962

P: 845-770-3000

F: 845-770-3010

E: info@aalborg.com

W: aalborg.com

Aberdeen Dynamics 17717 East Admiral Place Tulsa, OK 74158

P: 918-437-8000

F: 918-437-8420

E: sales@aberdeendynamics.com

W: aberdeendynamics.com

Ace Pump Corporation

1650 Channel Avenue PO Box 13187 Memphis, TN 38113

P: 901-948-8514

E: sales@acepumps.com

W: acepumps.com

ADACONN

538 Township Line Rd. Blue Bell, PA 19422

P: 215-643-1900

F: 215-643-4017

E: sales@adaconn.com

W: adaconn.com

Adsens Tech, Inc.

18310 Bedford Cir. Industry, CA 91744

P: 626-854-2772

F: 626-854-8183

E: sales@adsens.net

W: adsens.net

Advance Hydraulics

3073 S. Chase Avenue Milwaukee, WI 53207

P: 414-481-1545

F: 414-744-1667

E: mail@advancehydraulics.com

W: advancehydraulics.com

Advanced Cylinders, LLC

8966 Benson Ave. Ste C Montclair, CA 91763

P: 909-920-6437

F: 909-498-3712

E: sam@advancedcylindersllc.com

W: advancedcylindersllc.com

Advanced Fluid Systems, Inc. 245 Campbell Rd York, PA 17402

P: 717-757-1068

F: 717-757-4915

E: sales@advancedfluidsytems.com

W: advancedfluidsystems.com

Advanced Machine and Engineering 2500 Latham St. Rockford, IL 61103

P: 815-962-6076

F: 815-962-6483

E: info@ame.com

W: ame.com

Aggressive Hydraulics Inc. 18800 Ulysses St N.E.

P.O. Box 187 Cedar, MN 55011

P: 763-792-4000

F: 763-792-4400

E: sales@aggressivehydraulics.com

W: aggressivehydraulics.com

Aignep USA 7121 Loblolly Pine Blvd Fairview, TN 37062

P: 615-771-6650

F: 615-771-0926

E: service@aignepusa.com

W: aignepusa.com

Air and Hydraulic Equip 821 E 11th Street Chattanooga, TN 37404

P: 800-277-4466

F: 423-756-2084

E: airandhydraulicequipment@ aheinfo.com

W: aheinfo.com

Airline Hydraulics 3557 Progress Dr. Bensalem, PA 19020

P: 215-638-4700

F: 215-638-1707

E: sales@airlinehyd.com

W: airlinehyd.com

Airmo Inc. Pressure Technologies 9445 Evergreen Blvd. NW

Minneapolis, MN 55433

P: 1-763-786-0000

F: 1-763-786-4622

E: airmo@airmo.com

W: airmo.com

Airotronics

2747 Route 20 E.

Cazenovia, NY 13035

P: 315-655-8476

F: 315-655-3862

E: info@pelcocaz.com

W: airotronics.com

Airoyal Div. of Delta Sales

1355 Route 23

Butler, NJ 07405

P: 973-838-0371

F: 973-838-2638

E: info@airoyal.com

W: airoyal.net

Air-Way Manufacturing Company 586 N. Main St. Olivet, MI 49076

P: 800-253-1036

F: 269-749-2025

E: sales@air-way.com

W: air-way.com

Aitech Defense Systems

19756 Prairie Street Chatsworth, CA 91311

P: 888-248-3248

F: 818-718-9787

E: dpatterson@rugged.com

W: rugged.com

AKG Thermal Systems

809 Mattress Factory Road Mebane, NC 27302

P: 919-563-4871

F: 910-640-2233

E: sales@akgts.com

W: akgts.com

ALA Industries Limited (Yuken/Settima/Vivoil/Fluid Press)

1150 Southpoint Circle, Suite D Valparaiso, IN 46385

P: 877-419-8536

F: 219-477-4194

E: info@alaindustrieslimited.com

W: alaindustrieslimited.com

Alemite LLC

5148 North Hanley Rd. St. Louis, MO 63134

P: 866-4-alemite

F: 800-648-3917

E: feedback@alemite.com

W: alemite.com

Allenair Corporation

255 East Second Street Mineola, NY 11501

P: 516-747-5450

F: 516-747-5481

E: steves@allenair.com

W: allenair.com

Allied Electronics, Inc.

7151 Jack Newell Blvd. S. Fort Worth, TX 76118

P: 800-433-5700

F: 817-595-6444

E: quotes@alliedelec.com

W: thinkallied.com

Allied Fluid Conditioners

536 Township Line Road Blue Bell, PA 19422

P: 215-643-0966

F: 215-643-4017

E: sales@alliedfluidconditioners.com

W: alliedfluidconditioners.com

Allied Metrics Seals and Fasteners, Inc.

2 Wilson Drive Sparta, NJ 07871

P: 973-383-2487

F: 973-383-3329

E: alliedmetrics@nac.net

W: alliedmetrics.com

Alloys & Components, SW

2525 Sea Harbor Rd. Dallas, TX 75212

P: 214-637-9301

F: 214-637-9303

E: sales@alloysandcomponents.com

W: alloysandcomponents.com

Almo Manifold & Tool Co. 777 Aulerich PO Box 112 East Tawas, MI 48730

P: 989-984-0800

F: 989-984-0830

E: sales@almomanifold.com

W: almomanifold.com

Alumi-Tec Inc. PO Box 753 Grand Haven, MI 49417

P: 800-327-7558

F: 616-846-1984

E: Service@alumitecmanifolds.com

W: alumitecmanifolds.com

American Chemical Technologies, Inc. 485 E. Van Riper Rd. Fowlerville, MI 48836

P: 800-938-0101

F: 517-223-1703

E: sales@americanchemtech.com

W: americanchemtech.com

American Cylinder Co., Inc. 481 S. Governors Hwy. Peotone, IL 60468-9116

P: 708-258-3935

F: 708-258-3980

E: amcyl@americancylinder.com

W: americancylinder.com

American Sensor Technologies, Inc. (AST) 450 Clark Drive Mount Olive, NJ 07828

P: 973-448-1901

F: 973-448-1905

E: sales@astsensors.com

W: astsensors.com

Ametek Factory Automation

1080 N. Crooks Rd. Clawson, MI 48017

P: 248-435-0700

F: 248-435-8120

E: gemco@ametek.com

W: ametekfactoryautomation.com

Ametek US Gauge

820 Pennsylvania Blvd. Feasterville, PA 19053

P: 215-355-6900

F: 215-354-1802

W: ametekusg.com

AMETEK Vehicular Instrumentation Systems (VIS)

287 27 Road Grand Junction, CO 81503

P: 970-242-8863

F: 970-245-6267

E: info.dixson@ametek.com

W: ametekvis.com

Amphenol Industrial Operations

40-60 Delaware Ave. Sidney, NY 13838

P: 607-563-5088

F: 607-563-5157

E: mhartman@amphenol-aio.com

W: amphenol-industrial.com

Anchor Coupling Inc.

5520 13th St. Menominee, MI 49858

P: 906-864-1117

F: 906-863-3242

E: clark_gail_r@anchorcoupling.com

W: anchorcoupling.com

Anchor Fluid Power 5553 Murray Road Cincinnati, OH 45227

P: 513-527-4444

F: 513-527-4449

E: Sales@Anchorfluidpower.com

W: AnchorFluidPower.com

Anderson Fittings

4325 Frontage Rd. Oak Forest, IL 60452

P: 800-323-5284

F: 708-535-9083

E: dchristensen@andersonfittings. com

W: andersonfittings.com

Anderson Metals Corporation, Inc.

P.O. Box 34200 Kansas City, MO 64120

P: 800-821-5672

F: 816-472-8700

E: info@andersonmetals.com

W: andersonmetals.com

APEM, Inc.

970 Park Center Vista, CA 92081

P: 760-598-2518

E: info@apem.com/us/

W: apem.com/us

Apex Hydraulic & Machine, Inc.

2859 Philipsburg Bigler Highway Philipsburg, PA 16866

P: 814-342-1010

F: 814-342-9732

E: apexhyd5@gmail.com

API Heat Transfer 2777 Walden Ave. Buffalo, NY 14225

P: 716-684-6700

F: 716-684-2155

W: apiheattransfer.com

API Heat Transfer – Airtech Division 91 North Street Arcade, NY 14009

P: 585-496-5755

F: 585-496-5776

E: froy@apiheattransfer.com

W: apiheattransfer.com

APM HEXSEAL 44 Honeck Street Englewood, NJ 07631

P: 201-567-5700

F: 201-567-4106

E: info@apmhexseal.com

W: apmhexseal.com

Apple Rubber Products Inc. 310 Erie Street Lancaster, NY 14086

P: 716-684-6560

F: 716-684-8302

W: applerubber.com

Application Equipment W209N17341 Industrial Drive Jackson, WI 53037

P: 262-238-9900

F: 262-674-1682

E: apemeq@appequip.com

W: appequip.com

Applied Energy Company, LLC.

1205 Venture Court Suite #100 Carrolton, TX 75006

P: 214-355-4200

F: 214-355-4201

E: mark.scott@appliedenergyco.com

W: appliedenergyco.com

Applied Industrial Corporate Headquarters One Applied Plaza Cleveland, OH 44115

P: 877-279-2799

W: applied.com

ARGO-HYTOS Inc. 1835 N. Research Dr., PO Box 28 Bowling Green, OH 43402

P: 419-353-6070

F: 419-354-3496

E: info.us@argo-hytos.com

W: argo-hytos.com

OFF-H

2023 D ir ECTO rY Check out the online matrix at www.fluidpowerjournal.com 26 Apr IL 2023 WWW.FLUID p OWE r JOU r NAL.COM • WWW.IF p S.O r G #

i GHWAY

A

Eskridge 1900 East Kansas City Rd.

Olathe, KS 66051

P: 913-782-1238

F: 913-782-4206

E: sales@eskridgeinc.com

W: eskridgeinc.com

European Industrial Products, Inc. 5785 Advantage Cove Memphis, TN 38141

P: 901-375-0011

F: 901-375-4002

E: info@eip.us.com

W: eip.us.com

Evonik 723 Electronic Drive Horsham, PA 19044

P: 215-706-5800

F: 215-706-5801

E: oil-additives@evonik.com

W: dynavis.com

Exair Corporation 1250 Century Circle N Cincinnati, OH 45246

P: 513-671-3322

F: 513-671-3363

E: techelp@exair.com

W: exair.com

ExpresSeal Div. of Apple Rubber 204 Cemetery Road Lancaster, NY 14086

P: 716-684-6560

F: 716-684-1678

E: exinfo@expresseal.com

W: expresseal.com

Fabco-Air, Inc. 3716 NE 49th Ave. Gainesville, FL 32609-1699

P: 352-373-3578

F: 352-375-8024

E: service@fabco-air.com

W: fabco-air.com

Fairfield Manufacturing Company, Inc.

P.O. Box 7940 Lafayette, IN 47903

P: 765-772-4000

F: 765-772-4010

E: sales@fairfieldmfg.com

W: fairfieldmfg.com

Fairview Fittings and Manufacturing

3777 Commerce Court

Wheatfield, NY 14120

P: 800-688-4088

F: 716-614-0329

E: ussales@fairviewfittings.com

W: fairviewfittings.com

Famic Technologies Inc. 9999 Cavendish Blvd., Suite 350 St. Laurent, QC

CANADA H4M 2X5

P: +1 514-748-8050

F: +1 514-748-7169

E: sales@famictech.com

W: automationstudio.com

FasTest, Inc.

1646 Terrace Drive Roseville, MN 55113

P: 800-444-2373

F: 651-645-7390

E: fastsales@fastestinc.com

W: fastestinc.com

FEMA Corporation 1716 Vanderbilt Avenue Portage, MI 49024

P: 269-323-1369

F: 269-323-0108

E: sales@fema-corp.com

W: fema-corp.com

Feroy Company, Inc. 3220 B Street SE Auburn, WA 98002

P: 253-939-1363

F: 255-939-0810

E: glenn@feroy.com

W: feroy.com

Ferry, Inc.

3179 Walden Avenue Depew, NY 14043

P: 716-684-1703

F: 716-684-1706

E: sales@ferryinc.com

W: ferryinc.com

FHI – Sioux City 623 W. 7th St. Sioux City, IA 51103

P: 712-279-8086

F: 712-279-8071

E: dharder@fhi.siouxcity.com

Filtration Products Corporation 18151 Territorial Road

Dayton, MN 55369

P: 763-428-6418

F: 763-428-8659

E: sales@filtrationproducts.com

W: filtrationproducts.com

Filtrec North America PO Box 1222 Sault Ste. Marie, MI 49783

P: 888-345-8732

F: 705-256-6064

E: information@filtrec.net

W: filtrec.net

Fisher Gold Star 603 Highway 10 West, Box 164 Laurens, IA 50554

P: 712-845-2634

F: 712-845-2571

W: fishergoldstar.com

FlangeLock, LLC

57 Old Post Road #2

Greenwich, CT 06830

P: 203-861-9400

F: 203-622-1238

E: sales@flangelock.com

W: flangelock.com

Flaretite Inc.

4036 Shadow Oak Fenton, MI 48430

P: 810-750-4140

E: sales@flaretite.com

W: flaretite.com

Flint Hydraulics, Inc. 4099 B.F. Goodrich Blvd.

Memphis, TN 38118

P: 901-794-4884

F: 901-794-1618

E: sales@flinthyd.com

W: flinthyd.com

Flint Hydrostatics, Inc. 4084 E. Shelby Drive Memphis, TN 38118

P: 800-238-0155

E: sales@flinthydrostatics.com

W: flinthydrostatics.com

Flodraulic Group 45 Sinclair Ave. Georgetown, ON CANADA L7G 4X4

P: 905-702-9456

F: 905-702-9457

E: flodraulic@flodraulic.com

W: flodraulic.com

Flodyne Controls, Inc.

48 Commerce Drive Murray Hill, NJ 07974-1142

P: 908-464-6200

F: 908-464-1553

E: sales@flodynecontrols.com

W: flodynecontrols.com

Flo-tech

A Division of Racine Federated, Inc.

2200 South St., P.O. Box 1404 Racine, WI 53404

P: 800-433-5263

F: 800-245-3569

W: hedland.com

Flow Ezy Filters Inc.

P.O. Box 1749 Ann Arbor, MI 48106

P: 734-665-8777

F: 734-665-4332

E: flowezy@flowezyfilters.com

W: flowezyfilters.com

Flow Technology 8930 S. Beck Avenue, Ste. 107 Tempe, AZ 85284

P: 480-240-3400

F: 480-240-3401

E: ftimarket@ftimeters.com

W: ftimeters.com

Flow-Tek, Inc., A Subsidiary

Of Bray Int’l. Inc.

8323 N. Eldridge Pkwy #100 Houston, TX 77041

P: 832-912-2300

F: 832-912-2301

E: steve.johnston@flow-tek.com

W: flow-tek.com

Fluid Design Products, Inc.

3516 E. Main Spokane, WA 99202

P: 509-533-0479

F: 509-534-2998

E: steves@fluiddesignproducts.com

W: fluiddesignproducts.com

Fluid Energy Controls

6431 Flotilla Street Los Angeles, CA 90040

P: 323-721-0588

F: 323-721-8368

E: JC@fecintl.com

W: fecintl.com

Fluidtechnik USA, Inc. PO Box 715 Uwchland, PA 19480

P: 610-321-2407

F: 610-321-2409

E: sales@fluidtechnikusa.com

W: fluidtechnikusa.com

Geartek 1506 S. Fulton Drive PO Box 2160 Corinth, MS 38834

P: 662-286-2252

F: 662-287-6580

E: haisales@geartek.com

W: geartek.com

Gefran, Inc. 8 Lowell Avenue Winchester, MA 01890

P: 888-888-4474

F: 781-729-1468

Fluid Gear Products, Inc.

115 Market Street

Marcus Hook, PA 19061

P: 610-200-6045

F: 610-200-6046

E: sales@fluidgearproducts.com

W: fluidgearproducts.com

Fluid Line Products, Inc.

P.O. Box 1000 Willoughby, OH 44096

P: 440-946-9470

F: 440-946-9472

E: flp@fluidline.com

W: fluidline.com

Fluid Power Connections

P.O. Box 475 Englishtown, NJ 07726

P: 732-792-0411

E: info@usa-4u.com

W: fluidpowerconnections.com

Fluid Power Inc.

534 Township Line Road Blue Bell, PA 19422

P: 215-643-0350

F: 215-643-4017

E: sales@fluidpowerinc.com

W: fluidpowerinc.com

Fluid Power Service Corp.

4474 Walden Ave. Lancaster, NY 14086

P: 716-681-8474

F: 716-681-8514

E: kjirak@airlinehyd.com

W: fluidpowerservice.com

Fluid Power Training Institute

2170 South 3140 West Suite B

West Valley City, UT 84119

P: 1-888-222-3421

F: 801-908-5734

W: fpti.org

FluiDyne Fluid Power 31915 Groesbeck Hwy Fraser, MI 48026

P: 586-296-7200

E: sales@fluidynefp.com

W: fluidynefp.com

FORCE America 501 East Cliff Road Burnsville, MN 55337

P: 952-707-1300

E: marketing@forceamerica.com

W: forceamerica.com

Freelin-Wade 1730 NE Miller St. McMinnville, OR 97128

P: 503-434-5561

F: 503-472-1989

E: sales@freelin-wade.com

W: freelin-wade.com

Galland Henning Nopak, Inc. 10179 S. 57 Street Franklin, WI 53132

P: 414-645-6000

F: 414-645-6048

E: info@nopak.com

W: nopak.com

Garrod Hydraulics 1050 Locust Point Road York, PA 17406

P: 717-767-6429

F: 717-764-4490

E: Brian@Garrod.com

W: garrod.com

Gates Corporation PO Box 5887 Denver, CO 80217

P: 303-744-1911

F: 303-744-4540

E: gatesmail@salessupport.com

W: gates.com/fluidpower

Gator Hose 12327 E. 1st St.

Tulsa, OK 74128

P: 918-794-2550

F: 918-794-2560

E: info@gatorhose.com

W: gatorhose.com

E: info.us@gefran.com

W: gefran.com/en/us

Gemels North America, Inc. 775 Dillon Drive Wood Dale, IL 60191

E: northamerica@gemels.com

W: gemels.com

Gems Sensors & Controls One Cowles Road Plainville, CT 06062

P: 800-378-1600

F: 860-793-4531

E: info@gemssensors.com

W: gemssensors.com

Global Servo Hydraulics, Inc. 609 Corry A Edwards Drive Kennedale, TX 76060

P: 800-673-4745

F: 817-478-4958

E: servovalve@yahoo.com

W: globalservo.com

Goodway Technologies Corp. 420 West Avenue Stamford, CT 06902

P: 203-359-4708

F: 203-359-9601

E: goodway@goodway.com

W: goodway.com

Goodyear Engineered Products 703 S. Cleveland-Massillon Road Fairlawn, OH 44333

P: 330-664-7091

F: 330-664-7145

E: randy-kish@veyance.com

W: goodyearep.com

GPM Controls 1607 Industrial Dr. Carlisle, PA 17013

P: 717-218-6565

E: info@gpmcontrols.com

W: gpmcontrols.com

OFF-H i GHWAY 2023 D ir ECTO r Y WWW.IF p S.O r G • WWW.FLUID p OWE r JOU r NAL.COM Apr IL 2023 29

F

G

Hyvair Corp. 31341 Friendship Drive

Magnolia, TX 77355

P: 866-449-8247

F: 281-259-7249

E: svairin@hyvair.com

W: hyvair.com

IC-Fluid Power, Inc 63 Dixie Hwy. Rossford, OH 43460

P: 419-661-8811

E: ben@icfluid.com

W: icfluid.com

IFH Group, Inc., The 3300 East Rte. 30 Rock Falls, IL 61071

P: 800-435-7003

F: 815-626-1438

E: info@ifhgroup.com

W: ifhgroup.com

igus Inc. PO Box 14349 East Providence, RI 02914

P: 401-438-2200

Toll free: 1-800-521-2747

F: 401-438-7270

E: sales@igus.com

W: igus.com

IHD, Inc.

6830 N. Eldridge Pkwy, Unit 102 Houston, TX 77041

P: 713-849-2949

F: 713-849-5638

E: info@ihd-usa.com

W: ihd-usa.com

IMO USA Corp.

4000 Faber Place Drive, Suite 300 North Charleston, SC 29405

P: 843-813-4219

E: americas@imo.us

W: imo.us

Industrial Hardchrome, Ltd. 501 Fluid Power Dr. Geneva, IL 60134

P: 630-208-7000

F: 630-208-7035

W: industrialhardchrome.com

Industrial Nut Corp.

1425 Tiffin Ave. Sandusky, OH 44870

P: 419-625-8543

F: 419-625-5517

E: sales@industrialnut.com

W: industrialnut.com

Industrial Servo Hydraulics, Inc.

17650 Malyn Blvd. Fraser, MI 48026

P: 586-296-0960

F: 586-296-0375

E: klamberti@indservo.com

W: indservo.com

Industrial Specialties Mfg. 4091 S. Eliot St. Englewood, CO 80110

P: 303-781-8486

F: 303-761-7939

E: sales@industrialspec.com

W: industrialspec.com

Innovative Hydraulics LLC

305 S. 84th Avenue Wausau, WI 54401

P: 715-803-2600

E: sales@innovativehyd.com

W: innovativehyd.com

Inserta Products

538 Township Line Rd. Blue Bell, PA 19422

P: 215-643-0192

F: 215-643-4017

E: sales@inserta.com

W: inserta.com

Integrated Hydraulics, Inc.

7047 Spinach Dr. Mentor, OH 44060

P: 440-974-3171

F: 440-974-3170

E: usinfo@inthyd.com

W: intergratedhydraulics.com

Interface Sealing Solutions, North American Sales Office

22260 Hagerty Road

Northville, MI 48167

P: 248-596-2810

F: 248-596-2880

E: vkburriss@sealinfo.com

W: interfacesealingsolutions.com

International FPA (Fluid Power of America)

43123 Business Park Drive

Temecula, CA 92590

P: 951-676-2155

F: 951-676-2154, 2156

E: info@intlfpa.com

W: intlfpa.com

Inventive Resources, Inc.

5038 Salida Blvd PO Box 1316

Salida, CA 95368

P: 209-545-1663

E: info@jpce.com

W: sealndry.com

IQ Valves 425 West Drive Melbourne, FL 32904

P: 321-729-9634

F: 321-768-8732

E: sales@IQValves.com

W: IQValves.com

J.R. Merritt Controls Inc.

55 Sperry Ave. Stratford, CT 06615

P: 203-296-2272

F: 203-381-0400

E: jgurliacci@jrmerritt.com

W: jrmerritt.com

Janatics USA, Inc.

2654A Lehigh Street Whitehall, PA 18052

P: 610-443-2400

F: 610-530-8439

E: seshb@janaticsusa.com

W: janatics.com

JARP Industries

1051 Pine Street Schofield, WI 54476

P: 715-359-4241

F: 715-355-4960

E: sales@jarpind.com

W: jarpind.com

Jason Industrial 221 South Westgate Drive Canul Stream, IL 60188

P: 630-752-0600

F: 630-752-0662

E: Miguel.valazquez@ammega.com

W: jasonindustrial.com

Jem Technical Marketing 550 N Old Crystal Bay Road Orono, MN 55356

P: 952-473-5012

F: 952-473-6930

E: sales@jemtechnical.com

W: jemtechnical.com

JH Technology Inc. 4233 Clark Road, Unit 9 Sarasota, FL 34233

P: 941-927-0300

F: 941-925-8774

E: jhtek@jhtechnology.com

W: jhtechnology.com

John Deere Cylinder Division

909 River Dr. Moline, IL 61265

P: 309-765-7596

F: 309-765-7379

JWF Technologies 6820 Fairfield Dr. Fairfield, OH 45014

P: 513-769-9611

F: 513-769-0109

E: info@jwftechnologies.com

W: jwftech.com

Kaeser Compressors, Inc.

P.O. Box 946

Fredericksburg, VA 22404

P: 540-898-5500

F: 540-898-5520

E: info.usa@kaeser.com

W: kaeser.com

Kaiser Aluminum Fabricated Products, LLC

27422 Portola Pkwy. #200 Foothill Ranch, CA 92610

P: 562-754-1677

W: kaiseraluminum.com

Kavlico 14401 Princeton Ave. Moorpark, CA 93021

P: 805-523-2000

F: 805-523-7125

E: sales@kavlico.com

W: kavlico.com

Kawasaki Precision Machinery (USA)

3838 Broadmoor Ave. SE Grand Rapids, MI 49512

P: 616-975-3100

F: 616-975-3103

E: rachelle.kaltak@kmp-usa.com

W: kpm-usa.com

Kee Safety Inc

100 Stradtman St Buffalo, NY 14206

P: 716-896-4949

F: 716-896-5696

E: info@keesafety.com

W: keesafety.com

Keller America Inc.

351 Bell King Road

Newport News, VA 23606

P: 877-253-5537

F: 757-596-6659

E: sales@kelleramerica.com

W: kelleramerica.com

Kepner Products Company

995 North Ellsworth Ave. Villa Park, IL 60181

P: 630-279-1550

F: 630-279-9669

E: wkokum@kepner.com

W: kepner.com

Keystone Fluid Power

120 Unico Drive – Valmont Industrial Park West Hazelton, PA 18202

P: 570-454-9759

F: 570-454-9789

E: neilc@keystonefluidpower.com

W: keystonefluidpower.com

Kocsis Technologies, Inc.

11755 South Austin Ave. Alsip, IL 60803

P: 708-597-4177

F: 708-371-6560

E: service@kocsistech.com

W: kocsistech.com

Kracht Corp.

6552 Weatherfield Court

Maumee, OH 43537

P: 419-874-1000

E: s.zahn@krachtcorp.com

W: krachtcorp.com

Kraft Fluid Systems, Inc.

14300 Foltz Parkway Cleveland, OH 44149

P: 800-257-1155

F: 440-238-5266

E: csdept@kraftfluid.com

W: kraftfluid.com

KTR Corporation 122 Anchor Rd. Michigan City, IN 46360

P: 219-872-9100

F: 219-872-9150

E: j.krueger@ktr.com

W: ktr.com

Kuriyama of America Inc.

360 E. State Parkway Schaumburg, IL 60173

P: 847-755-0360

F: 847-885-0996

E: sales@kuriyama.com

W: kuriyama.com

Kurt Hydraulics

5280 Main St. NE Minneapolis, MN 55421

P: 866-257-7995

E: kurthyd@aol.com

W: kurthydraulics.com

KYB Americas Corporation 140 N. Mitchell Court

Addison, IL 60101

P: 630-620-5555

F: 630-620-8133

E: hyd@kyb.com

W: kybfluidpower.com

La-Man Corp.

P.O. Box 328

Mazeppa, MN 55956

P: 507-843-4413

F: 507-843-4953

E: sales@laman.com

W: laman.com

Lee Company, The 2 Pettipaug Rd.

Westbrook, CT 06498

P: 860-399-6281

F: 860-399-2270

E: inquiry@theleeco.com

W: theleeco.com

Lehigh Fluid Power, Inc.

Rte. 179, P.O. Box 76214

Lambertville, NJ 08530

P: 800-257-9515

F: 609-397-0932

E: sales@lehighfluidpower.com

W: lehighfluidpower.com

Lenz Inc.

P.O. Box 1044

Dayton, OH 45401-1044

P: 937-277-9364

F: 937-277-6516

E: rwagner@lenzinc.com

W: lenzinc.com

Lexair, Inc. 2025 Mercer Road

Lexington, KY 40511

P: 859-255-5001

F: 859-255-6656

E: jjennings@lexairinc.com

W: lexairinc.com

Lillbacka USA Inc. 619 Estes Ave.

Schaumburg, IL 60193

P: 847-301-1300

F: 847-301-2562

E: sales@lillbackausa.com

W: lillbackausa.com

Linde Hydraulics Corporation 5089 W. Western Reserve Rd. Canfield, OH 44406-9112

P: 330-533-6801

F: 330-286-0741

E: info@linde-hydraulics.co

W: linde-hydraulics.us

Liquid Controls 105 Albrecht Drive Lake Bluff, IL 60044

P: 847-295-1050

F: 847-295-1057

E: lc-info.lcmeter@idexcorp.com

W: lcmeter.com

LNA Solutions 3924 A Varsity Drive Ann Arbor, MI 48108

P: 734-677-2305

F: 734-671-2339

E: inquiries@lnasolutions.com

W: lnasolutions.com

Logic Hydraulic Controls, Inc. 6616 Windmill Way Wilmington, NC 28405

P: 910-791-9293

F: 910-392-5621

E:Scott.Oxjr@logichyd.com

W: logichyd.com

Lynch Fluid Controls Inc.

1799 Argentia Road

Mississauga, ON CANADA L5N 3A2

P: 1-905-363-2400

F: 1-905-363-1191

E: sales@lynch.ca

W: lynch.ca M

M & M Rogness Equipment Co.

1941 W. County Road C-2 Roseville, MN 55113

P: 651-633-0550

F: 651-633-6797

E: sales@mmrogness.com

W: mmrogness.com

Machinery Service and Design

W232 N 2960 Roundy Circle Dr. Pewaukee, WI 53072

P: 262-513-8040

F: 262-513-8044

E: les@ms-d.com

W: ms-d.com

Mack Corporation 3695 E. Industrial Drive Flagstaff, AZ 86004

P: 928-526-1120

F: 928-526-0473

E: info@mackcorp.com

W: mackcorp.com

Macro Sensors

7300 U.S. Route 130 N., Bldg. 22 Pennsauken, NJ 08110

P: 856-662-8000

F: 856-317-1005

E: positionsensors@macrosensors. com

W: macrosensors.com

Macrotech Polyseal Inc. (MPI) 1754 West 500 South Salt Lake City, UT 84104

P: 801-973-9171

F: 801-973-918

Madison Company 27 Business Park Drive Branford, CT 06405

P: 203-488-4477

F: 203-481-5036

E: info@madisonco.com

W: madisonco.com

Magister Hydraulics 175 Christie Street Newark, NJ 07105

P: 973-344-5313

F: 973-344-5167

E: info@magisterhyd.com

W: magisterhyd.com

Magnetek N49 W13650 Campbell Drive Menomonee Falls, WI 53051

P: 262-783-3500

E: radio.sales@magnetek.com

W: columbusmckinnon.com/ magnetek

Main Filter, Inc. 188 Industrial Park Cres. Sault Ste Marie, ON P6B5P2

P: 800-465-6246

F: 705-949-9431

E: information@mainfilter.com

W: mainfilter.com

Lubrication Engineers, Inc.

1919 E. Tulsa St. Wichita, KS 67216

P: 800-537-7683

E: info@le-inc.com

W: lelubricants.com

Lubriplate Lubricants Co.

129 Lockwood Street Newark, NJ 07105

P: 800-733-4755

F: 800-347-5329

E: lubexpert@lubriplate.com

W: lubriplate.com

Lydall Filtration (Filter Media)

PO Box 1960

Rochester, NH 03866-1960

P: 603-332-4600

F: 603-332-9602

E: info@lydall.com

W: lydallfiltration.com

Main Mfg. Products, Inc. 3181 Tri-Park Dr. Grand Blanc, MI 48439

P: 800-521-7918

F: 810-953-1385

E: info@mainmfg.com

W: mainmfg.com

Manifold Center, The 12 Commercial Blvd. Medford, NY 11763

P: 631-736-2275 X1

E: kathya@manifoldcenter.com

W: manifoldcenter.com

Maradyne Corp. 4540 W. 160th St. Cleveland, OH 44135

P: 216-362-0755

F: 216-362-0799

E: mwalsh@maradyne.com

W: maradyne.com

OFF-H i GHWAY 2023 D ir ECTO r Y WWW.IF p S.O r G • WWW.FLUID p OWE r JOU r NAL.COM Apr IL 2023 31

i

J

K

l

Marco Rubber & Plastic

35 Woodworkers Way

Seabrook NH 03874

P: 603-468-3600

F: 603-468-3490

E: sales@marcorubber.com

W: marcorubber.com

Marion Mfg.

Div. of Maradyne Corp.

4540 W. 160th St. Cleveland, OH 44135

P: 216-362-0755

F: 216-362-0799

E: walsh55@sbcglobal.net

W: maradyne.com

Marken Manufacturing / Uniflex of America

2081 E. Center Circle Plymouth, MN 55441

P: 763-577-0111

F: 763-577-0112

E: info@markenmfg.com

W: markenmfg.com

Marmon/Keystone LLC

P.O. Box 992 Butler, PA 16003

P: 724-283-3000

F: 724-283-0558

E: jevans@marmonkeystone.com

W: marmonkeystone.com

Marmon/Keystone LLC

225 East Cunningham Street Butler, PA 16001

P: 724-283-3000

F: 724-283-0558

E: sales@marmonkeystone.com

W: marmonkeystone.com

Mars Labs, LLC

29 C Street

Laurel, MO 20707

P: 301-470-3278

F: 301-470-4749

E: mars.sales@marslabs.com

W: marslabs.com

Marzocchi Pumps 905 Albion Ave. Schaumburg, IL 60193

P: 1-800-924-5404

F: 847-923-9937

W: marzocchipumpsusa.com

Email: pumps@marzocchipumpsusa. com

Max Machinery, Inc.

33A Healdsburg Ave.

Healdsburg, CA 95448

P: 707-433-2662

F: 707-433-1818

E: info@maxmachinery.com

W: maxmachinery.com

MB Dynamics, Inc.

25865 Richmond Road Cleveland, OH 44146

P: 1-216-292-5850

F: 1-216-292-5614

E: sales@mbdynamics.com

W: mbdynamics.com

Men Micro Inc.

24 North Main St. Ambler, PA 19002

P: 215-542-9575

F: 215-542-9577

E: Stephen.cunha@menmicro.com

W: menmicro.com

PASSION TO PERFORM

www.mpfiltriusa.com

(215) 529-1300 sales@mpfiltriusa.com

Metal-Matic, Inc.

629 2nd Street S.E. Minneapolis, MN 55414

P: 612-378-0411

F: 612-392-3399

E: sales@metal-matic.com

W: metal-matic.com

Metaris Corp. 1519 Hwy. 35 North Forest, MS 39074

P: 601-469-1987

F: 601-469-2120

Toll Free: 1-800-962-2703

E: sales@metarisusa.com

W: metaris.com

Metaris Inc. 101 Canarctic Dr. Toronto, Ontario CANADA M3J 2N7

P: 416-638-6000

F: 416-638-9365

Toll Free: 1-888-477-2737

E: sales@metaris.com

W: metaris.com

Metro Machine and Engineering 8001 Wallace Rd. Eden Prairie, MN 55344

P: 952-937-2800

F: 952-937-2374

E: gpautsch@ metromachine.com

W: metromachine.com

MFP Seals (A Division of Martin Fluid Power) 84 Minnesota Troy, MI 48083

P: 248-585-8170

F: 248-585-4398

E: sales@MFPseals.com

W: MFPseals.com

Micheller and Son Hydraulics, Inc. 534 West First Ave. Roselle, NJ 07203

P: 908-687-1545

F: 908-241-0934

E: michellersonhyd@aol.com

W: michellerandsonhydraulics.com

MICO, Inc. 1911 Lee Blvd. North Mankato, MN 56003

P: 507-625-6426

F: 507-625-3212

E: micomail@mico.com

W: mico.com

Micro Mini Hydraulic 536 Township Line Road Blue Bell, PA 19422

P: 215-542-2198

F: 215-643-4017

E: sales@microminihydraulics.com

W: microminihydraulics.com

Midland Industries 3145 Oak St. Kansas City, MO 64111

P: 800-821-5725

F: 800-888-5391

E: sales@midlandindustries.com

W: midlandindustries.com

Milton Roy Company 201 Ivyland Road Ivyland, PA 18974

P: 215-441-0800

F: 215-441-8620

E: info@miltonroy.com

W: miltonroy-americas.com

Milwaukee Cylinder 5877 S. Pennsylvania Ave. Cudahy, WI 53110

P: 414-769-9700

F: 414-769-0157

E: sales@milwaukeecylinder.com

W: milwaukeecylinder.com

Milwaukee School of Engineering

Fluid Power Institute™ 1025 N. Broadway

Milwaukee, WI 53202

P: 414-277-7191

F: 414-277-7470

E: wanke@msoe.edu

W: msoe.edu/fpi

MOCAP

409 Parkway Drive Park Hills, MO 63601

P: 800-633-6775

F: 314-543-4111

E: sales@mocap.com

W: mocap.com

Moog

300 Jamison Road East Aurora, NY 14052

P: 716-652-2000

F: 716-687-4989

E: jmarsh@moog.com

W: moog.com/industrial

Morris, S. G. 699 Miner Road Cleveland, OH 44143

P: 866-746-6774

F: 866-746-2556

E: SGMMail@SGMorris.com

W: sgmorris.com

Motion Industries Inc.

1605 Alton Road Birmingham, AL 35210

Toll free P: 800-526-9328

F: 1-205-957-5290

E: mimarketing@motionindustries. com

W: motionindustries.com

Nachi America Inc. – Hydraulics Div.

17500 Twenty-three Mile Rd. Macomb, MI 48044

P: 800-622-4410

F: 800-383-8665

E: hydraulics@nachiamerica.com

W: nachihydraulics.com

Napoleon Engineering Services 1601 Johnson Street

Olean, NY 14760

P: 877-870-3200

F: 716-372-1448

E: sales@nesbearings.com

W: nesbearings.com

Nass Controls LP 51509 Birch Street New Baltimore, MI 48047

P: 586-725-6610

F: 586-725-5802

E: jim.rosenbury@nasscontrols.com

W: nasscontrols.com

NRP Jones, LLC 302 Philadelphia Street

LaPorte, IN 46350

P: 800-348-8868

F: 800-207-2221

E: sales@nrpjones.com

W: nrpjones.com

Nutron Motor Co., Inc. 102 Dow Hwy., P.O. Box 370

Eliot, ME 03903

P: 207-439-5272

F: 207-439-8611

W: nutronmotors.com

OEM Controls, Inc. 10 Controls Drive

Shelton, CT 06484

P: 203-929-8431

F: 203-929-3867

E: ContactUS@OEMControls.com

W: OEMControls.com

Oerlikon Fairfield US 525

Lafayette, IN 47903

P: 765-772-4200

F: 765-772-4001

E: gmoreland@fairfieldmfg.com

W: fairfieldmfg.com

National Tube Supply 925 Central Avenue University Park, IL 60484

P: 800-229-6872

E: sales@nationaltubesupply.com

W: nationaltubesupply.com

NC Servo Technology

38422 Webb Dr. Westland, MI 48185

P: 734-326-6666

F: 734-326-6669

E: sales@ncservo.com

W: ncservo.com

New Pig One Pork Avenue

Tipton, PA 16684-0304

P: 814-684-0101

F: 814-684-7690

E: hothogs@newpig.com

W: newpig.com

MP Filtri Inc.

380 Four Valley Drive Concord, Ontario Canada L4K 5Z1

P: 905-303-1369

F: 905-303-7256

W: mpfiltricanada.com

MP Filtri USA Inc.

1181 Richland Commerce Dr Quakertown, PA 18951

P: 215-529-1300

F: 215-529-1902

E: sales@mpfiltriusa.com

W: mpfiltriusa.com

MTE Hydraulics

4701 Kishwaukee Street Rockford, IL 61109

P: 815-397-4701

F: 815-399-5528

E: sales@mtehydraulics.com

W: mtehydraulics.com

MTS Systems

3001 Sheldon Drive Cary, NC 27513

P: 919-677-0100

F: 919-677-2343

E: sensorsinfo@mts.com

W: mtssensors.com

Muncie Power Products

201 East Jackson Street Muncie, IN 47305

P: 800-367-7867

F: 765-284-6991

E: rmiddleton@munciepower.com

W: munciepower.com

Murrelektronik, Inc.

1400 Northbrook Parkway, Ste. 300 Suwanee, GA 30024

P: 770-497-9292

F: 770-497-9391

E: ahenry@murrinc.com

W: murrinc.com

Myron L Company

2450 Impala Dr Carlsbad, CA 92010

P: 760-438-2021

F: 760-931-9189

E: info@myronl.com

W: myronl.com

NewAge Industries Inc. 145 James Way Southampton, PA 18966

P: 215-526-2300

F: 215-526-2191

E: info@newageindustries.com

W: newageindustries.com

Nike Hydraulics Inc.

3980 West Albany, Unit #1

McHenry, IL 60050

P: 815-385-7777

F: 815-385-7776

E: info@nikehydraulics.com

W: nikehydraulics.com

Norman Filter Company 9850 S. Industrial Drive

Bridgeview, IL 60455

P: 708-233-5521

F: 708-430-5961

E: sales@normanfilters.com

W: normanfilters.com

North Coast Seal, Inc.

5273 West 137th St. Brook Park, OH 44142-1810

P: 216-898-5000

F: 800-435-5533

W: northcoastseal.com

Noshok, Inc.

1010 West Bagley Rd. Berea, OH 44017

P: 440-243-0880

F: 440-243-3472

E: jscott@noshok.com

W: noshok.com

Nott Company 4480 Round Lake Road W Arden Hills, MN 55112

P: 800-634-3301

F: 651-415-3632

E: nottfp@nottco.com

W: nottco.com

Novotechnik U.S., Inc. 155 Northboro Road

Southborough, MA 01772

P: 508-485-2244

F: 508-485-2430

E: info@novotechnik.com

W: novotechnik.com

Oetiker, Inc. 6317 Euclid Street Marlette, MI 48453

P: 989-635-3621

F: 989-635-2157

E: info@us.oetiker.com

W: oetiker.com

Ogura Industrial Corporation 100 Randolph Road Somerset, NJ 08873

P: 732-271-7361

F: 732-271-7580

E: jandes@ogura-clutch.com

W: ogura-clutch.com

Ohio Fabricators Company 111 North 14th Street Coshocton, OH 43812

P: 888-354-0291

E: info@ohfab.com

W: ohfab.com

Oilair Hydraulics, Inc. 11505 West Little York Houston, TX 77041

P: 713-937-8900

F: 713-937-0438

E: sales@oilairhydraulics.com

W: oilairhydraulics.com

Oilgear Company 2300 S. 51st Street Milwaukee, WI 53234

P: 414-327-1700

F: 414-327-0532

E: sales@oilgear.com

W: oilgear.com

Oil-Rite Corporation

P.O. Box 1207 Manitowoc, WI 54221-1207

P: 920-682-6173

F: 920-682-7699

E: sales@oilrite.com

W: oilrite.com

O’Keefe Controls Company P.O. Box 316 Monroe, CT 06468

P: 203-261-6711

F: 203-261-8331

E: info@okeefecontrols.com

W: okeefecontrols.com

Olsen Manufacturing Company, Inc. 4353 Delemere Blvd. Royal Oak, MI 48073

P: 248-549-4200

F: 248-549-4250

E: olsenmfg@aol.com

W: olsenmfg.com

Omega Engineering 800 Connecticut Avenue Norwalk, CT Suite 5N01

P: 203-359-1660

F: 203-359-7700

E: sales@omega.com

W: omega.com

OFF-H i GHWAY 2023 D ir ECTO r Y 32 Apr IL 2023 WWW.FLUID p OWE r JOU r NAL.COM • WWW.IF p S.O r G

N

O

BEST PERFORMANCE, BEST RESULTS.

Omnex Control Systems Inc.

74-1833 Coast Meridian Rd.

Port Coquitlam, BC Canada V3C 6G5

P: 604-944-9247

F: 604-944-9267

E: sales@omnexcontrols.com

W: omnexcontrols.com

Ono Sokki Technology, Inc.

2171 Executive Dr. # 400 Addison, IL 60101

P: 630-627-9700

F: 630-627-0004

E: info@onosokki.net

W: onosokki.net

Orange Research 140 Cascade Boulevard. Milford, CT 06460

P: 203-877-5657

F: 203-783-9546

E: jgill@orangeresearch.com

W: orangeresearch.com

OTTO 2 East Main Street

Carpentersville, IL 60110

P: 847-428-7171

E: info@ottoexcellence.com

W: otto-controls.com

Pace Mfg., Div. of Atlas Hydraulics Inc. 600 S. Sioux Brandon, SD 57005

P: 605-582-7221

F: 605-582-7222

W: pacemfg.com

Pamark, Inc.

1730-B Olson N.E. Grand Rapids, MI 49503

P: 616-456-6043

F: 616-456-8849

Panagon Systems, Inc. 51375 Regency Center Macomb, MI 48042

P: 586-786-3920

F: 586-786-7331

E: sales@panagonsystems.com

W: panagonsystems.com

Parker Fluid Control Division 95 Edgewood Ave. New Britain, CT 06051

P: 860-827-2300

F: 860-827-2384

E: skinnervalve@parker.com

W: parker.com/fcd

Parker Hannifin Accumulator and Cooler Division 6035 Parkland Blvd. Cleveland, OH 44124

P: 800-272-7537

F: 216-896-4410

E: c-parker@parker.com

W: parker.com

Parker Hannifin Hydraulic Filter Division 16810 Fulton County Road # 2 Metamora, OH 43540

P: 419-644-4311

F: 419-644-6205

W: parker.com/hydraulicfilter

Parker Hannifin, Racor Division 3400 Finch Road Modesto, CA 95353

P: 800-344-3286

F: 209-529-3278

E: racor@parker.com

W: parker.com/racor

Parker Sterling Hydraulics 850 Arthur Ave. Elk Grove Village, IL 60007

P: 847-690-1333

F: 847-690-1334

E: shi@sterling-hyd.com

W: sterling-hydraulics.com

Peninsular Cylinder Co.

27650 Groesbeck Hwy. Roseville, MI 48066

P: 586-775-7211

F: 586-775-4545

E: stevev@peninsularcylinders.com

W: peninsularcylinders.com

Pepperl+Fuchs 1600 Enterprise Parkway Twinsburg, OH 44087

P: 330-425-3555

F: 330-425-4607

E: sales@us.pepperl-fuchs.com

W: pepperl-fuchs.com

Peter Paul Electronics Co., Inc.

480 John Downey Drive New Britain, CT 06051

P: 860-229-4884

F: 860-223-1734

E: info@peterpaul.com

W: peterpaul.com

PHD, Inc. 9009 Clubridge Drive

Fort Wayne, IN 46809

P: 800-624-8511

E: phdinfo@phdinc.com

W: phdinc.com

Piher International Corporation 1640 Northwind Blvd.

Libertyville, IL 60048

P: 847-918-9300

F: 847-918-9433

E: paul.cain@meggitt.com

W: piher.net

Pinnacle Systems, Inc. PO Box 100088 Pittsburgh, PA 15233

P: 412-262-3950

F: 412-262-4055

E: sales@pinnaclesystems.com

W: pinnaclesystems.com

Pirtek USA 501 Haverty Ct. Rockledge, FL 32955

P: 321-504-4422

F: 321-504-4433

W: ownapirtek.com

Pisco USA Inc. 100 Leland Ct., Unit A

Bensenville, IL 60106

P: 630-521-9920

F: 630-521-9927

E: inquiry@pisco.com

W: pisco.com

Plymouth Tube Co. 29 W. 150 Warrenville Rd.

Warrenville, IL 60555

P: 630-393-3550

F: 630-393-3551

W: plymouth.com

Pneumadyne Inc. 14425 23rd Ave. N Plymouth, MN 55447

P: 888-559-0177

F: 763-559-0547

E: sales@pneumadyne.com

W: pneumadyne.com

Poclain Hydraulics 1300 Grandview Parkway PO Box 801 Sturtevant, WI 53177

P: 262-321-0676

F: 262-321-0703

E: info-america@poclain-hydraulics.com

W: poclain-hydraulics.com

Polymer Molding, Inc.

1655 West 20th St. Erie, PA 16502

P: 800-344-7584

F: 888-257-5566

E: pmi@polymermolding.com

W: polymermolding.com

Power Drives Inc.

133 Hopkins Street Buffalo, NY 14220

P: 800-888-1373

F: 716-824-4817

E: solution@powerdrives.com

W: powerdrives.com

Power Drives Inc. 3003 Pittsburgh Ave.

Erie, PA 16508

P: 812-344-4351

F: 716-822-1714

E: e.knechPhone@powerdrives.com

W: powerdrives.com

Power Systems AHS, LLC 8325 Commerce Drive

Chanhassen, MN 55317

P: 952-361-6800

F: 952-361-6801

E: sales@powersystems-mn.com

W: powersystems-mn.com

Power Valve USA 222 S. Navigation Blvd. Corpus Christi, TX 78405

P: 713-869-1064

F: 361-883-3893

E: service@powervalveusa.com

W: powervalveusa.com

Poweram, Inc.

150 North 18th St. Barron, WI 54812-0153

P: 715-537-9050

W: poweram.com

PowerTech Hydraulics

305 Island Avenue Mahwah, NJ 07430

P: 201-934-9354

F: 201-934-9480

E: customer.service@p-Tech.com

W: p-Tech.com

Precision Filtration Products PO Box 218

Pennsburg, PA 19087

P: 215-679-6645

F: 215-679-6648

W: precisionfiltration.com

Precision Instrument Corporation

3295 Cobb International Blvd. Kennesaw, GA 30152

P: 888-650-6923

F: 770-429-0795

E: sales@picgauges.com

W: picgauges.com

Precix, Inc.

744 Belleville Ave. New Bedford, MA 02745

P: 508-998-4030

F: 508-998-4100

E: sales@precixinc.com

W: precixinc.com

Premier Thermal Solutions

209 W. Mt Hope Ave. Lansing, MI 48910

P: 517-485-5090

E: sales@premierthermal.com

W: premierthermal.com

Preso Flow Metering Equipment

8635 Washington Ave. Racine, WI 53406

P: 800-632-7337

F: 262-639-2267

E: info@preso.com

W: preso.com

Pressroom Electronics

PO Box 99875

Pittsburgh, PA 15233

P: 412-262-1115

F: 412-262-1197

E: sales@pressroomelectronics.com

W: pressroomelectronics.com

Pressure Components Inc.

5101 Naiman Parkway Solon, OH 44139

P: 440-349-4020

F: 440-349-3653

E: sales@pressurecomponents.com

W: pressurecomponents.com

Pressure Connections Corp.

610 Claycraft Road Columbus, OH 43230

P: 614-863-6930

F: 614-864-1327

W: pressureconnections.com

Pressure Systems Inc.

34 Research Dr. Hampton, VA 23666

P: 757-865-1243

F: 757-865-8744

E: denise.topping@pressuresystems. com

W: pressuresystems.com

Prince Mfg. Corp.

612 North Derby Lane P.O. 7000

N. Sioux City, SD 57049

P: 605-235-1220

F: 605-235-1082

W: princehyd.com

Proportion-Air, Inc.

8250 N. 600 West McCordsville, IN 46055

P: 317-335-2602

F: 317-335-3853

E: wwhite@proportionair.com

W: proportionair.com

PTI Technologies, Inc.

501 Del Norte Blvd. Oxnard, CA 93030

P: 805-604-3700

E: filters@ptitechnologies.com

W: ptitechnologies.com

PVS Sensors Inc.

2816 Blue Ridge Blvd. West Union, SC 29696

P: 800-831-8217

F: 864-653-1047

E: sales@pvssensors.com

W: pvssensors.com

PWM Controls Inc

185-911 Yates St Victoria, BC V8V4Y9

P: 866-719-2561

E: info@pwmcontrols.com

W: pwmcontrols.com

Q

Quaker Chemical Corporation One Quaker Park 901 Hector St. Conshohocken, PA 19428

P: 610-832-4173

F: 610-832-8652

E: zinkm@quakerchem.com

W: quakerchem.com

RAM Industries Inc.

33 York Road E, PO Box 5007 Yorkton, SK Canada S3N 3Z4

P: 1-877-799-1005

E: estimating@RAMindustries.com

W: ramindustries.com

RAMCO Innovations

1207 Maple St. West Des Moines, IA 50265

P: 515-225-6933

F: 515-225-0063

W: ramcoinnovations.com

RB Royal Industries, Inc.

1350 S. Hickory Street Fond du Lac, WI 54937

P: 800-892-1550

F: 920-921-4713

E: sales@rbroyal.com

W: rbroyal.com

Reed Switch Developments Corp.

2524 Norwood Court

Racine, WI 53403

P: 262-883-9060

E: marketing@ reedswitchdevelopments.com

W: reedswitchdevelopments.com

Reelcraft Industries, Inc.

2842 East Business Hwy. 30 Columbia City, IN 46725

P: 260-248-8188

F: 260-248-2605

E: reelcraft@reelcraft.com

W: reelcraft.com

Rehobot, Inc.

3980 W. Albany St., Unit #1

McHenry, IL 60050

P: 815-385-7777

F: 815-385-7776

E: info@rehobot.us

W: rehobot.us

Reid Tool Supply Company

2265 Black Creek Rd. Muskegon, MI 49444

P: 800-253-0421

F: 800-438-1145

W: reidtool.com

Reidville Hydraulics & Mfg., Inc. 175 Industrial Lane Torrington, CT 06790

P: 860-496-1133

F: 860-496-1166

E: info@reidvillehydraulics.com

W: wwwlreidvillehydraulics.com

Reverso Pumps, Inc. 201 SW 20th St. Fort Lauderdale, FL 33315

P: 954-522-0882

F: 954-522-0456

E: contact@reversopumps.com

W: reversopumps.com

RHEINTACHO Messtechnik GmbH

Waltershofener Str. 1 Freiburg, Germany 79111

P: +49(0) 761 4513 0

F: +49(0) 761 445 274

E: info@rheintacho.de

W: rheintacho.com

Ritepro, Inc., A Subsidiary of BRAY Int’l, Inc. 12200 Albert Hudon Blvd. Montreal, Quebec Canada H1G 3K7

P: 514-324-8900

F: 514-324-9525

E: strudel@bray.qc.ca

W: ritepro.com

R J Hydraulic Inc. 967 New Castle Road Butler, PA 16001

P: 724-865-9883

F: 724-865-2501

RL Hudson & Company 2000 W Tacoma Broken Arrow, OK 74012

P: 918-259-6600

F: 918-259-6700

E: info@rlhudson.com

W: rlhudson.com

Rockwell Automation, Inc. 1201 South Second St. Milwaukee, WI 53204-2496

P: 1-414-382-2000

1-888-382-1583

F: 1-414-382-4444

E: webmaster@rockwellautomation.com

W: rockwellautomation.com

Rosedale Products, Inc.

3730 W. Liberty Ann Arbor, MI 48103

P: 734-665-8201

F: 734-665-2214

E: filters@rosedaleproducts.com

W: rosedaleproducts.com

OFF-H i GHWAY 2023 D ir ECTO r Y WWW.IF p S.O r G • WWW.FLUID p OWE r JOU r NAL.COM Apr IL 2023 33

p

r

Grips ∙ Joysticks ∙ Pushbuttons ∙ Switches Controls Solutions www.otto-controls.com

Rota Engineering Ltd. Wellington Street

Bury, Manchester GB BL8 2BD

P: 972-359-1041

E: info@rota-eng.com

W: rota-eng.com

Rota-Cyl Corporation

136 Stauffer Rd.

P. O. Box 269

BechPhonesville, PA 19505

P: 610-845-8001

F: 610-845-8178

E: sales@rotacyl.com

W: rotacyl.com

Rotary Power Inc.

6009 West 41st Street, Suite 1A Sioux Falls, SD 57106

P: 1-605-361-5155

F: 1-605-362-1949

E: info@rotarypower.com

W: rotarypower.com

Rotor Clip Company, Inc.

187 Davidson Avenue Somerset, NJ 08873

P: 732-469-7333

F: 732-469-7898

E: sales@rotorclip.com

W: rotorclip.com

RR-USA Inc.

8 Creek Parkway Boothwyn, PA 19061

P: 610-497-0154

F: 610-497-6085

E: azanellotti@rrusainc.com

W: rrusainc.com

RT Dygert 12121 Nicollet Avenue South Burnville, MN 55337

P: 952-835-1700

F: 952-835-1701

E: sales@rtdygert.com

W: rtdygert.com

Rupe’s Hydraulics Sales and Service 725 N Twin Oaks Valley Rd. San Marcos, CA 92069

P: 760-744-9350

F: 760-744-7859

E: sales@rupeshydraulics.com

W: rupeshydrualics.com

RYCO Hydraulics 1616 Greens Road Houston, TX 77032

P: 281-821-4100

F: 281-821-4300

E: sales@ryco.us

W: ryco.com.au S

S.G. Morris Co., LLC 699 Miner Road Cleveland, OH 44143

P: 866-746-6774

F: 866-746-2556

E: sgmmail@sgmorris.com

W: sgmorris.com

SafeWay Hydraulics, Inc. 4040 Norex Drive Chaska, MN 55318

P: 952-466-6220

F: 952-466-6219

E: info@safewayhyd.com

W: safewayhyd.com

Scenery Hydraulic, Inc.

1939 S. Lake Pl. Ontario, CA 91761

P: 909-930-9586

F: 909-354-3181

E: kai@sceneryhydraulic.com

W: sceneryhydraulic.com

Schmalz, Inc.

5200 Atlantic Avenue Raleigh, NC 27616

P: 919-713-0880

F: 919-713-0883

E: schmalz@schmalz.com

W: schmalz.com

Schroeder Industries 580 W. Park Road

Leetsdale, PA 15056

P: 724-318-1100

F: 724-318-1200

E: sisales@schroederindustries.com

W: schroederindustries.com

Schunk Inc. 241 Kitty Hawk Dr. Morrisville, NC 27560

P: 919-572-2705

F: 919-572-2818

E: info@us.schunk.com

W: schunk.com

Scorpion Technologies Ltd. #953 Laval Cr. Kamloops, BC Canada V2C 5P4

P: 250-377-4399

F: 250-377-4036

E: bill@controlgrips.com

W: controlgrips.com

Seal Master Corporation 368 Martinel Dr. Kent, OH 44240

P: 330-673-8410

F: 330-673-8242

E: info@sealmaster.com

W: sealmaster.com

Sensor Data Technologies

50207 Hayes Road Shelby Township, MI 48375

P: 586-739-4254

F: 586-739-5689

E: sales@sensordata.com

W: sensordata.com

Sensor Systems LLC

2800 Anvil Street North St. Petersburg, FL 33710

P: 727-347-2181

F: 727-347-7520

E: sales@vsensors.com

W: vsensors.com

Sensotec Inc.

2080 Arlingate Ln. Columbus, OH 43228

P: 800-848-6564

F: 614-850-1111

W: sensotec.com

SERFILCO, Ltd.

2900 MacArthur Blvd. Northbrook, IL 60062

P: 847-509-2900

F: 847-559-1995

E: sales@serfilco.com

W: serfilco.com

Service Hydraulics, LLC.

222 S. Navigation Blvd. Corpus Christi, TX 78405

P: 361-883-3891

F: 361-883-3893

E: info@servicehyd.com

Servi Fluid Power Inc.

22240 Merchants Way, Suite #100 Katy, TX 77449

P: 281-347-8080

E: info@sfphyd.com

W: sfphyd.com

ServoTek Products, Inc.

8019 Ohio Riser Boulevard Newell, WV 26050

P: 304-387-1200

F: 304-387-1212

E: customerRFQ@marshbellofram. com

W: servotek.com

Seventy-Three Mfg. Co. Inc.

136 Stauffer Road, PO Box 269 BechPhonesville, PA 19505

P: 610-845-7823

F: 610-845-7824

E: sales@seventythreemfg.com

SFC KOENIG LLC

73 Defco Park Road North Haven CT 06473

P: 203-245-1100

F: 203-245-3072

E: info-us@sfckoenig.com

W: sfckoenig.com

Sierra Instruments, Inc.

5 Harris Ct, Bldg. L Monterey, CA 93940

P: 831-373-0200

F: 831-373-4402

E: info@sierrainstruments.com

W: sierrainstruments.com

SIKO Products, Inc.

2155 Bishop Circle East Dexter, MI 48130

P: 734-426-3476

E: sales.us@siko-global.com

W: siko-global.com

Silicon Designs, Inc.

13905 NE 128th Street

Kirkland, WA 98034

E: sales@silicondesigns.com

W: silicondesigns.com

Simerics, Inc. 303 Williams Ave., Suite 123 Huntsville, AL 35801

P: 256-489-1480

F: 256-489-1460

E: contact@simerics.com

W: simerics.com

Simonds Inc. 248 Elm St. Southbridge, MA 01550

P: 866-764-3235

F: 508-765-5125

E: sales@simonds-inc.com

W: simonds-inc.com

Simrit

2250 Point Blvd., Ste. 230 Elgin, IL 60123

P: 866-274-6748

F: 847-783-6519

E: information@simrit.us

W: simritna.com

SIWI, Inc.

P.O. Box 1415

Glendora, CA 91740

P: 626-963-7643

F: 626-963-3612

SKF/Lincoln Lubrication Systems

5148 N. Hanley Road St. Louis, MO 63134

P: 800-435-9599

F: 800-424-5359

E: brenda.hendricks@skf.com

W: lincolnindustrial.com

Smalley Steel Ring Company 555 Oakwood Road Lake Zurich, IL 60047

P: 847-719-5900

F: 847-719-5999

E: info@smalley.com

W: smalley.com

Snap-tite Quick Disconnect & Valve Div. 201 Titusville Road Union City, PA 16438

P: 814-438-3821

F: 814-438-3069

E: qdv_sales@snap-tite.com

W: Snap-titeQuickDisconnects.com

Solenoid Solutions, Inc

2251 Manchester Road

Erie, PA 16506

P: 814-838-3190

E: tmartin@solenoidsolutionsinc. com

W: solenoidsolutionsinc.com

Sonic Hydraulics/Sonic Tractor Parts

1780 NW 93rd Ave.

Doral, FL 33172

P: 305-594-0777

F: 305-594-7798

E: sales@stpusa.com

W: stpusa.net

Source Fluid Power 331 Lake Hazeltine Drive

Chaska, MN 55318

P: 952-368-3866

F: 952-448-3392

W: sourcefp.com

Spartan Scientific 8510 Foxwood Court

Youngstown, OH 44514

P: 330-758-8446

F: 330-758-3314

E: ptbyce@spartanscientific.com

W: spartanscientific.com

Specialty Fittings Incorporated

18151 Territorial Road

Dayton, MN 55369

P: 763-428-7137

F: 763-428-6487

E: sales@specialtyfittings.com

W: specialtyfittings.com

Spectroline Industrial 956 Brush Hollow Road Westbury, NY 11590

P: 516-333-4840

F: 516-333-4859

E: info@spectroline.com

W: spectroline.com

Spencer Fluid Power 19308 68th Ave. South Kent, WA 98032

P: 253-796-1100

F: 253-796-1101

W: spencerfluidpower.com

Spencer Fluid Power 2700 N. Hwy. 14-16 Gillette, WY 82716

P: 307-682-5858

F: 307-687-2040

W: spencerfluidpower.com

SPhonemi America Inc.

1601 Brooks Dr. Marshall, MI 49068

P: 269-781-6222

F: 269-781-7723

E: info@sPhonemiamerica.com

W: sPhonemiamerica.com

SPIR STAR, Ltd. 10002 Sam Houston Center Dr. Houston, TX 77064

P: 800-890-7827

F: 888-893-1255

E: sales@spirstar.com

W: spirstar.com

Sponsler, Inc. 2363 Sandifer Blvd. Westminster, SC 29693

P: 864-647-2065

F: 864-647-1255

E: dbourgeois@idexcorp.com

W: sponsler.com

Sprague Products 10195 Brecksville Rd. Brecksville, OH 44141

P: 440-838-7690

F: 440-838-7528

E: Sprague@curtisswright.com

W: sprague.cwfc.com

Stafford Manufacturing Corp.

P.O. Box 2370

Woburn, MA 01888

P: 800-695-5651

F: 800-649-5101

E: sales@staffordmfg.com

W: staffordmfg.com

Stanley M. Proctor Company

2016 Midway Dr. Twinsburg, OH 44087

P: 330-425-7814

F: 330-425-3222

W: stanleyproctor.com

Stauff Corporation

7 Wm Demarest Place Waldwick, NJ 07463

P: 201-444-7800

E: sales@stauffusa.com

W: stauff.com

Steelhead Composites 500 Corporate Circle, Suite 0 Golden, CO 83440

P: 720-524-3360

E: sales@steelheadcomposites.com

W: steelheadcomposites.com

Steffen Inc. 621 West 7th Street Sioux City, IA 51103

P: 712-279-8030

F: 712-279-8071

W: steffenhydro.com

Sterling Hydraulics, Inc. 850 Arthur Ave. Elk Grove Village, IL 60007

P: 847-690-1333

F: 847-690-1334

E: shi@sterling-hyd.com

W: sterling-hyd.com

Stiebel Drive Technology Inc.

319 Garlington Road, Unit B-11 Greenville, SC 29615

P: 864-286-7152

E: t.ruiz@stiebel-drives.com

W: stiebeldrivetechnology.com

Strong Forge & Fabrication, LLC 20 Liberty Street Batavia, NY 14020

P: 585-343-5251

F: 585-343-5829

E: info@strongforge.com

W: StrongForge.com

SUCO ESI North America 6560 W. Rogers Circle, Suite 22 Boca Raton, FL 33487

P: 561-989-8499

E: sales@sucoesi.com

W: sucoesi.com

OFF-H i GHWAY 2023 D ir ECTO r Y 34 Apr IL 2023 WWW.FLUID p OWE r JOU r NAL.COM • WWW.IF p S.O r G

Sun Hydraulics Corporation

1500 University Parkway

Sarasota, FL 34233

P: 941-362-1200

F: 941-355-4497

E: stevetberlin@sunhydraulics.com

W: sunhydraulics.com

Sunfab Hydraulics Inc.

6426 Hendry Road, Suite A

Charlotte, NC 28269

P: 704-509-6435

E: sunfab-us@sunfab.com

W: sunfab.com/us

SunSource

12800 Hwy 13 South #100 Savage, MN 55378

P: 952-563-1700

E: mecsolutions@sunsrce.com

W: sun-source.com

Super Swivels 7917 Beech St. NE Minneapolis, MN 55432

P: 763-784-5531

F: 763-784-7423

E: sales@superswivels.com

W: superswivels.com

SVF Flow Controls, Inc.

13560 Larwin Circle Santa Fe Springs, CA 90670

P: 562-802-2255

F: 562-802-3114

E: Jeanette@svf.net

W: svf.net

Swanson Industries

2608 Smithtown Road

Morgantown, WV 26508

P: 800-327-6203

F: 304-292-8151

E: industrialsales@ swansonindustries.com

W: swansonindustries.com

Switches Unlimited 34-11 56th Street Woodside, NY 11377

P: 800-221-0487

F: 718-672-6370

E: info@switchesunlimited.com

W: switchesunlimited.com

Switching Solutions Inc.

380 Four Valley Drive Concord, ON Canada L4K 5Z1

P: 905-303-8700

F: 905-303-7256

E: sales@switchingssi.com

W: switchingssi.com

Sync-Lok, Inc. 407 Newburg Avenue Catonsville, MD 21228

P: 410-869-3480

F: 410-869-3482

E: info@sync-lok.com

W: sync-lok.com

System Seals, Inc. 24202 Aurora Rd. Cleveland, OH 44146

P: 440-735-0200

F: 440-735-0288

E: info@systemseals.com

W: systemseals.com

Tahoma Engineered Solutions

532 County Road 1600 Ashland, OH 44805

P: 419-496-0964 x203

E: sales@ tahomaengineeredsolutions.com

W: tahomaengineeredsolutions.com

Taiwan PU Corporation

760 Oak Grove Dr. San Jose, CA 95129

P: 408-839-2919

E: sales@taiwanpu.com

W: TaiwanPU.com

Tapeswitch Corporation 100 Schmitt Blvd. Farmingdale, NY 11735

P: 631-630-0442

F: 631-630-0454

E: marketing@tapeswitch.com

W: tapeswitch.com

TE Connectivity 1050 Westlakes Drive

Berwyn, PA 19312

P: 610-893-9800

E: mary.manzo-ritchie@te.com

W: te.com

Terex Utilities, Inc.

3400 NE 37th Place

Wildwood, FL 34785

P: 352-330-4044

F: 352-330-4047

E: mike.shannon@terexutilities.com

W: terex.com

Texacone

4111 Forney Ave. Mesquite, TX 75149

P: 800-235-2727

F: 972-289-6285

E: information@texacone.com

W: texacone.com

Texas Hydraulics, Inc.

3410 Range Road Temple, TX 76504

P: 254-778-4701

F: 254-774-9940

E: sales@texashyd.com

W: texashydraulics.com

Texcel Rubber 4444 Homestead Rd. Houston, TX 77028

P: 800-231-7116

F: 800-759-4673

E: sales@texcelrubber.com

W: texcelrubber.com

The FPDA – Motion + Control Network 105 Eastern Avenue, Suite 104 Annapolis, MD 21403

P: 410-940-6347

F: 410-263-1659

E: aluckado@fpda.org

W: fdpa.org

Thermal Transfer Products 5215 21st St. Racine, WI 53406

P: 800-394-8330

F: 262-554-8536

E: thermal_transfer_sales@ thermasys.com

W: thermasys.com

Thomas Magnete USA, LLC

3225 Gateway Rd, Suite 350 Brookfield, WI 53045

P: 262-781-2900

E: heinz.strickler@thomas-magnete. com

W: thomas-magnete.com

Thomas Products

987 West Street Southington, CT 06489

P: 800-666-9101

F: 860-621-1470

E: thomsales@aol.com

W: thomasprod.com

Titan Inc.

9900 Durand Ave. Sturtevant, WI 53177

P: 262-884-2890

F: 262-884-8072

E: tevans@titansystems.com

W: titansystems.com

T-Lon Products, Inc. 1110 Richards Road

Hartland, WI 53029

P: 262-367-2333

F: 262-367-8159

E: dolson@t-lon.com

W: t-lon.com

Tobeyco Mfg. Co., Inc. Federal Brass Division 165 Cedar St. Corning, NY 14830

P: 607-962-6054

F: 607-962-8871

Tobul Accumulator, Inc.

61 Innovation Drive

Bamberg, SC 29003

P: 803-245-2400

F: 803-245-2636

E: sales@tobul.com

W: tobul.com

TR Engineering Inc. 1350 Green Hills Rd. #10 Scotts Valley, CA 95066

P: 831-430-9920

F: 831-430-9989

E: rromero@trengineering.com

W: trengineering.com

Transcom Inc.

3451 W. Burnsville Pkwy. Burnsville, MN 55337

P: 800-328-2840

F: 952-894-1588

Trelleborg Sealing Solutions

2531 Bremer Road Fort Wayne, IN 46803

P: 260-749-9631

F: 260-749-4844

E: tssusa@trelleborg.com

W: trelleborg.com/en/seals/yourindustry/fluid-power

Triad Technologies, LLC

985 Falls Creek Dr. Vandalia, OH 45377

P: 800-420-8575

F: 800-420-4324

E: sales@triadtechnologies.com

W: triadtechnologies.com

Trident

408 Defiance Ave. Hicksville, OH 43526

P: 419-542-7721

F: 419-542-8717

E: trident@ tridentconnection.com

W: tridentconnection.com

Triple R America

60/040 Industrial Pkwy. Cheektowaga, NY 14227

P: 800-668-8671

F: 416-413-9387

E: sales@triple-rrr.com

W: triple-rrr.com

Tubes n’ Hoses 820 N. Dallas Ave Lancaster, TX 75146

P: 972-923-0766

F: 972-332-4119

E: sales@tubesnhoses.com

W: tubesnhoses.com

Turck Inc.

3000 Campus Drive

Minneapolis, MN 55441

P: 800-544-7769

F: 763-509-7797

E: turckusa@turck.com

W: turck.us

Tuthill Coupling Group

1000 West Bagley Rd. Berea, OH 44017

P: 440-826-1115

F: 440-826-0115

E: hansencoupling@tuthill.com

W: tuthill.com

Tuthill Pump Group, Concord Operator

5143 Port Chicago Hwy. Concord, CA 94520

P: 925-676-8000

F: 925-676-8151

E: concord@tuthill.com

W: pumptales.com

Tuxco Corporation 4300 Grove Ave. Gurnee, IL 60031

P: 800-613-6979

F: 847-244-7335

E: moreinfo@tuxco.com

W: tuxco.com

UFI - Hydraulic Filter Division 9337 Ravenna Rd., Unit G

Twinsburg, OH 44087

P: 330-405-1800

F: 330-405-1801

E: sales@uhiltd.com

W: uhiltd.com

UHI LTD

9337 Ravenna Rd. #G Twinsburg, OH 44087

P: 330-405-1800

F: 330-405-1801

E: sales@uhiltd.com

W: uhiltd.com

United Electric Controls 180 Dexter Ave. Watertown, MA 02478

P: 617-926-1000

F: 617-926-4354

E: marketing@ueonline.com

W: ueonline.com

Universal Grinding Corporation 1234 West 78th Street Cleveland, OH 44102

P: 216-631-9410

F: 216-631-5264

E: monica@universalgrinding.com

W: universalgrinding.com

Universal Hydraulics Intl., Ltd. 9337 Ravenna Rd. Unit G Twinsburg, OH 44087

P: 330-405-1800

F: 330-405-1801

E: sales@uhiltd.com

W: uhiltd.com

Universal Hydraulik USA Corp. Fort Meigs Business Center 25651 Ft. Meigs Rd., Suite A Perrysburg, OH 43551

P: 1-419-873-6340

F: 1-419-873-6341

E: info@universalhydraulik.com

W: universalhydraulik-usa.com

V

V & P Hydraulic Products 1162 Peachblow Rd. Lewis Center, OH 43035

P: 740-548-5181

F: 740-548-6206

E: mikeueber@vphyd.com

Ultra Clean Technologies Corp. 1274 Highway 77 Bridgeton, NJ 08302

P: 856-451-2176

F: 856-453-4975

E: briley@ultracleantech.com

W: ultracleantech.com

Ultraflo Corporation, A subsidiary of BRAY International, Inc. #8 Trautman Industrial Drive

Ste. Genevieve, MO 63670

P: 800-950-1762

F: 573-883-8882

E: ultraflo@ultraflovalve.com

W: ultraflovalve.com

Unique Automation LLC 612 East Main Street Palmyra, NY 14522

P: 315-597-4900

F: 315-597-4953

E: C.Schaufelberger@ uniqueautomation.com

W: uniqueautomation.com

W: vphyd.com

Validyne Engineering 8626 Wilbur Ave. Northridge, CA 91324

P: 818-886-2057

F: 818-886-6512

E: sales@validyne.com

W: validyne.com

Van Air Inc. 2950 Mechanic St. Erie, PA 16506

P: 814-774-2636

F: 814-774-0778

E: info@vanairsystems.com

W: vanairsystems.com

Veethree Electronics & Marine LLC 2420 Trailmate Drive Sarasota, FL 34243

P: 941-538-7775

F: 941-755-1222

E: sales@veethree.com

W: v3instruments.com

OFF-H i GHWAY 2023 D ir ECTO r Y WWW.IF p S.O r G • WWW.FLUID p OWE r JOU r NAL.COM Apr IL 2023 35

T

U

Ventura Hydraulic and Machine Works, Inc.

1555 Callens Rd. Ventura, CA 93003

P: 805-656-1760

F: 805-525-2739

W: venturahydraulics.com

Vescor Corp. 50 North River St. South Elgin, IL 60177

P: 847-742-7270

F: 847-742-5187

E: sales@vescor.com

W: vescor.com

Vonberg Valve, inc. 3800 Industrial Ave. Rolling Meadows, IL 60008-1085

P: 847-259-3800 x227

F: 847-259-3997

E: dhenrich@vonberg.com

W: vonberg.com

Wainbee Ltd. 5789 Coopers Avenue Mississauga ONT Canada L4Z 3S6

P: 905-568-1700

F: 905-568-0083

E: marketing@wainbee.com

W: wainbee.com

Wandfluh of America, Inc. 909 High St. Mundelein, IL 60060

P: 847-566-5700

VEST, Inc.

3250 W. Big Beaver Rd., #440 Troy, MI 48084

P: 248-649-9550

F: 248-649-9560

E: sales@vestusa.com

W: vestusa.com

Viatran 199 Fire Tower Drive Tonawanda, NY 14150

P: 1-800-688-0030

F: 716-693-9162

E: solutions@viatran.com

W: viatran.com

Vogelsang Fastener Solutions 1790 Swarthmore Ave., Suite 1 Lakewood, NJ 08701

P: 732-364-4422

F: 732-364-8111

E: bpappas@vogelsangfastner.com

W: vogelsangfastner.com

Voith Turbo 25 Winship Road York, PA 17406

P: 717-767-3200

F: 717-767-3210

E: bob.snopek@voith.com

W: voith.com

Von Ruden Mfg., Inc.

100B First St. NE Buffalo, MN 55313

P: 763-682-3122

F: 763-682-3954

E: sales@vonruden.com

W: vonruden.com

F: 847-566-5733

E: sales@wandfluh-us.com

W: wandfluh-us.com

Warner Electric 449 Gardner St. So. Beloit, IL 61080

P: 815-389-3771

F: 815-389-2582

E: info@warnerelectric.com

W: warnerelectric.com

Warren Electric Corporation. 36 Franklin St., P.O. Box 86 Warren, RI 02885

P: 401-245-3700

F: 401-245-9331

E: luann@warrene.com

W: warrene.com

Waterclock Engineering 342 N. Water St. #600 Milwaukee, WI 53202

P: 888-902-2297

E: info@waterclockeng.com

W: waterclockeng.com

Weiss Instruments, Inc. 905 Waverly Ave. Holtsville, NY 11742

P: 631-207-1200

F: 631-207-0900

E: sales@weissinstruments.com

W: weissintsuments.com

Wen Technology, Inc. 8411 Garvey Drive, Suite 117 Raleigh, NC 27616

P: 919-954-1004

F: 919-954-1009

E: wentec@wentec.com

W: wentec.com

Wessel-Hydraulik GmbH

2144 Burbank Dr. Mississauga, Ontario CANADA L5L 2T8

P: 905-828-5579

F: 905-828-8189

E: wesselhydraulics@ rogers.com

W: wessel-hydraulik.de

West Coast Fluid Power 5370 S. Watt Ave. Suite 300 Sacramento, CA 95826

P: 800-532-8837

F: 800-370-0447

E: info@comoso.com

W: comoso.com

Western Hydrostatics, Inc.

1956 Keats Dr. Riverside, CA 92501

P: 951-784-2133

F: 951-784-8423

E: pjmaluso@weshyd.com

W: weshyd.com

Western Integrated Technologies, Inc.

13406 SE 32nd St Bellevue, WA 98005

P: 425-747-0927

F: 425-747-0940

E: jjohnston@westernintech.com

W: westernintech.com

Wetherell Mfg Co., Inc.

407 W. Grace St. Cleghorn, IA 51014

P: 712-436-2266

F: 712-436-2672

E: info@wetherellmfg.com

W: wetherellmfg.com

White Drive Products, Inc.

P.O. Box 1127

110 Bill Bryan Blvd. Hopkinsville, KY 42241

P: 270-885-1110

F: 270-886-8462

E: info@whitedriveproducts.com

W: whitedriveproducts.com

Whitman Controls Corp. 201 Dolphin Rd. Bristol, CT 06010