11 minute read

Case Study: Wireless Controls for Tracked Carrier

Case Study

Wireless Controls for Tracked Carrier

By Ben Stoller, Business Development Manager, Columbus McKinnon

As a family firm of crane specialists, John Taylor Crane Services of Bedfordshire, U.K., developed an innovative tracked platform intended to reduce the need for manual handling. This tracked carrier platform was designed to operate where forklifts and other machinery could not maneuver.

The challenge

Magnetek, a brand of Columbus McKinnon, was challenged by JT Cranes to provide a flexible wireless solution that had the capacity for future enhancements. This wireless solution needed to increase maneuverability and safety for lifted loads, allow operators better control of carrier speed, and decrease the footprint of existing controls.

The solution

Magnetek, working in concert with JT Cranes, designed a custom eight-button handheld wireless control system that improved directional accuracy by using buttons configured with proportional control and incorporated four modes of adjustable speed settings for precision control. The system’s transmitter and receiver occupied limited space on the carrier platform, which left a smaller footprint than traditional crane systems and could not handle a large control package.

The project

terrain and traverse ramps of up to 40°. It is able to carry loads up to four tons despite its compact design. Its load carrying platform can rotate 360°, allowing for enhanced maneuverability as compared to standard crane systems. JT Cranes looked to incorporate flexible and precise wireless controls into these carrier systems to enhance their versatility. The tracked carrier platform required the highest levels of maneuverability for lifting in small spaces, moving forward and backward, and getting around tight corners and through standard doorways.

While JT Cranes originally considered a larger bellybox transmitter for the application, they discovered a more compact, versatile option better suited to their requirements: the Magnetek eight-button Flex Pro transmitter. Flex Pro offers precise management and smooth control of all functions. Smooth movements are essential for successful carrier operation, particularly when moving fragile loads, such as art pieces. Any uneven lifts or unwanted movement while the carrier platform traverses an area or during a lift could mean dropped loads or damaged material.

The Flex Pro transmitter was customized by Magnetek to meet the carrier’s exact needs, providing adjustable speed control in a four-mode setting to deliver 25, 50, 75, or 100% output for precise machine movement. Additionally, the stepless variable speed control ensures that operators have an enhanced level of control over the carrier while it is in motion. With its tough nylon housing and NEMA 4 (IP66) rating, the Flex Pro is made to withstand shock and sealed to operate in a variety of harsh, industrial environments. The Flex Pro transmitter is paired with Magnetek’s patented MHR radio controller, which combines the components of a radio receiver and up to 16 hydraulic proportional valve controllers into a single convenient unit, reducing costs and freeing up valuable space on the equipment. The MHR utilizes an informative graphic display to easily view system settings and machine functions. Two-way feedback provides operators with precise information about equipment performance. The MHR’s rugged, waterproof design makes it ideal for outdoor use and harsh environments. Magnetek’s transmitter and receiver system improved HITACHI FLANGELOCKTM the level of control operators had over the tracked car-AND CAP KITS AVAILABLE rier. Proportional control provided smooth movements Part number for the safety of lifted loads and greater spatial control Part description Applicable machines Number of parts Weight (kg) SWINGFLGLCK2062 for maneuvering the D40 in tight spaces. Swing hose FlangeLockTM kit EX3600, EX5600, EX8000 16 x 2062U - red FlangeLockTM 6.7 The Flex Pro and MHR integrated so easily with SWINGCAP2062 the D40 that JT Cranes plans to install the system on Swing circuit cap kit EX3600, EX5600, EX8000 16 x 2062 - cap 4.5 TRAVELFLGLCK2462 additional tracked carriers. The systems’ flexibility also Travel hose FlangeLockTM kit EX3600, EX5600, EX8000 16 x 2462U - purple FlangeLockTM 7.7 makes future enhancements, such as engine start-up TRAVELCAP2462 buttons, a simple modification. • Travel circuit cap kit EX3600, EX5600, EX8000 16 x 2462 - cap 6.4

FRONTATTFLGLCK326162 Front attachment FlangeLockTM kit EX3600, EX5600, EX8000 14 x 3262U - black FlangeLockTM 4 x 3261U - black & silver FlangeLockTM 8.9

FRONTATTCAP326162 Front attachment cap kit EX3600, EX5600, EX8000 14 x 3262 - cap 4 x 3261 - cap 9.5

BOOMARCHFLGLCK3262 Boom arch hose FlangeLockTM kit EX3600, EX5600, EX8000 20 x 3262U - black FlangeLockTM 9.9 BOOMARCHCAP3262 Boom arch hose cap kit EX3600, EX5600, EX8000 20 x 3262 - cap 11.3

THE ULTIMATE CONTAMINATION CONTROL TOOL

SAVE TIME SAVE MONEY SAVE LABOR SAVE OIL

This product is Patented, other Patents pending. CONTAMINATION CONTROL

Routine and scheduled maintenance of hydraulic systems are vital to getting the most out of your Hitachi Mining Excavator. While maintenance plays the largest role in the prevention of unnecessary machine downtime, it can also expose the hydraulic system to high levels of contamination rapidly decreasing component longevity. The importance of contamination control is sometimes Stop the Mess overlooked when performing maintenance due to incorrect practices being used. THE FLANGELOCK™ TOOL AND CIRCUIT BLANKING CAPS The FlangeLock™ tool and caps are the ultimate contamination control tools for protecting your hydraulic system. The FlangeLock™ allows for the simple sealing of open hydraulic flanges without tools while the caps can be bolted in place of a flange connection. Easy on, easy off, they offer a leak-proof solution to hydraulic systems and environmental cleanliness. FlangeLock™ tools and caps stop the mess.

The FlangeLock™ Tool is the ultimate contamination control tool for protecting your hydraulic systems. It allows for the simple sealing of open SAE code 61, 62 HITACHI MAKING CONTAMINATION CONTROL EASY & CAT-Style hydraulic flanges without tools. Constructed from lightweight aluminum. Hitachi have packaged FlangeLock™ tool and caps specifically for Hitachi mining excavators. The Hitachi customised kits make sure no matter which component routine maintenance is being performed on, you will always have the exact Easy on, easy off. Offers a leakproof solution to hydraulic system and environmental number of FlangeLocks™* and caps to help reduce contamination. cleanliness. FlangeLock™ Tools stop the mess!*Note: FlangeLocks™ are not to be used under pressure

• No tools required • No expensive hardware needed • No more rags stuffed into hoses • No more messy plastic caps • The ultimate contamination control tool

• One hand installation • Eliminate hydraulic oil spills & clean up • Quick installation & ease of usage Call you local Hitachi Muswellbrook representative or the branch on 02 6541 6300 for more information. • Safe for personnel & environment • Industry acclaimed

For more information, call (203) 861-9400 or email sales@flangelock.com. www.flangelock.com

WANTED SURPLUS

Pumps · Motors · Valves · Servo/Proportional

Email, call or fax with a list of your Surplus. We’ll provide you with a price offer!

1-800-422-4279 | 586-949-4240 Fax: 586-949-5302 | surplus@hydraulex.com

HYDRAULIC FLANGES and COMPONENTS

THE “SPECIAL” YOU WANT IS PROBABLY ON OUR SHELVES

MAIN Mfg. Products, Inc.

800.521.7918 fax 810.953.1385 www.MAINMFG.com/fpj

HIGH FLOW PROPORTIONAL FLOW CONTROL

• 16MM to 50mm • Standard ISO 7368 and

DIN 24342 cavity • High performance 5,000 psi • On board amplifier • 0-10 volt command

almomanifold.com

Phone: 989.984.0800 Toll Free: 1.877.ALMO. NOW Fax: 989.984.0830

IN STOCK FROM 25MM TO 80MM

MANY COVERS IN STOCK

• Pressure, Flow, Directional • Large Flow 90° Valves • Single DIN blocks • Active Valves • Monitored Poppets

almomanifold.com

Phone: 989.984.0800 Toll Free: 1.877.ALMO. NOW Fax: 989.984.0830

The correct answers to Test Your Skills on page 10 are 1-d and 2-d.

10 & 15 mm Electronic Valves

Compact, quick, powerful! Technical Support

Large Inventory

Standard, High Flow, Latching & ISO Series

877-245-6247

ADVERTISER INDEX

Company.................................................................. Page ........................................................ Phone...............................................................................Web

Adaconn/Inserta..................................................... 5, 22 ..................215-643-1900, 215-643-0192......................www.adaconn.com, www.inserta.com AEM ....................................................Inside Back Cover ...................................................................................................................................www.IFPE.com Almo Manifold............................................................. 31 .......1-989-984-0800, 1-800-ALMO-NOW.......................................................almomanifold.com Assured Automation .................................................. 22 .........................................1-800-899-0553....................................www.assuredautomation.com CFC-Solar ..................................................................... 13 ............................................513-874-3225.......................www.CFCINDUSTRIALTRAINING.com Clippard.............................................24, 31, Back Cover .........................................1-877-245-6247........................................................www.clippard.com Flange Lock ........................................................... 23, 29 ............................................203-861-9400....................................................www.flangelock.com Fluidyne Fluid Power ............................................ 23, 31 .........................................1-586-296-7200...................................................www.FluidyneFP.com Hydraulex...................................................11, 24, 27, 31 .........................................1-800-323-8416.....................................................www.hydraulex.com Hydraulics, Inc. ...................................................... 14, 22 ............................................817-923-1965...............................................www.hydraulicsinc.com Main Manufacturing Products ...................... 11, 23, 31 .........................................1-800-521-7918......................................................www.mainmfg.com MOCAP INC ................................................................. 14 .........................................1-800-633-6775........................................................ www.MOCAP.com Norgren ..........................................................................3 .........................................1-800-514-0129........................................................ www.norgren.com Ryco Hydraulics..............................................................9 ............................................866-821-7926.........................................................www.ryco.com.au Tele Radio LLC ...............................................................9 ........................................... 866-629-0780..............................................www.tele-radio.com/us/ TEXCEL ....................................... Inside Front Cover, 22 ............................................800-231-7116................................................ www.texcelrubber.com West Coast Hydraulics & Repair ............................... 30 ............................................209-357-7360 Yates, Inc.................................................................. 1, 23 .........................................1-586-778-7860.......................................................www.yatesind.com

FILL OUT THIS CARD COMPLETELY, DETACH, AND MAIL OR FAX IT TO START YOUR SUBSCRIPTION MAIL TO: PO BOX 2548 • ORLANDO, FL 32802-9830 • FAX: 1-866-207-1450 YOU CAN ALSO SUBSCRIBE ONLINE AT WWW.FLUIDPOWERJOURNAL.COM.

01 YES! Please start/continue my complimentary subscription to the Fluid Power Journal 02 NO. Not interested.

Signature (required) Title (required) Date (required) / /

Telephone Fax E-mail

First Name

Please Type or Print Clearly:

Middle Initial Last Name

Company

Address Division

Mail Stop Web Address

City State Zip Code

Check here if you would like to keep your name, address, phone and fax numbers confidential, and not released to third parties The address above is my: Home Address Business Address

Which edition would you like to receive? Print Digital Both (View a sample of our PAPERLESS digital edition at www.fluidpowerjournal.com)

1. Do you specify, select or influence the purchase of components & systems, on new or existing machinery? 03 Yes 04 No.

If yes, which technologies? (check all that apply) 05 Hydraulic 06 Pneumatic 07 Vacuum 08 Electronic Controls 09 None of These

2. What is your primary job title? (check only one) 10 Administration: Chairman, President, V.P., Secretary, Treasury, General Manager, Owner, Business Manager, Director, etc. 11 Plant Operations: VP of Manufacturing/ Operation/ Production, Plant Management/ Director/ Manager/ Supervisor/ Superintendent/ Foreman/ Safety Director, etc. 12 Engineering: V.P. Eng., Eng., Design Eng., Director of Eng., Staff Specialist, Chief Eng., Senior Eng., Maintenance/Production Eng., etc. 13 Technical: Chief Tech., Fluid Power Tech., etc. 14 Mechanical: Chief Master Mech., Master Mech., Fluid Power Mech., etc. 15 Purchasing: VP/Director of Purch., Procurement Manager, Buyer, Purch., etc. 16 Other: (please specify)_________________________________________________________________________________________________

3. Number of employees at this location?

A 1-19 B 20-49 C 50-99 D 100-249 E 250-499 F 500-999 G 1000+

4. What is the primary business activity at this location?

In the Fluid Power Industry, Outside the Fluid Power Industry 56 Manufacturer 57 Distributor 58 Education 59 Original Equipment Manufacturer (OEM) 60 End User of Fluid Power Products 61 Other: (please specify)__________________________________________

5. Which of the following best describes your market focus?

A Aerospace A Marine & Offshore Equipment

B Agricultural Machinery B Material Handling Equipment

C Automotive C Mining Machinery

D Civil Engineering D Packaging Machinery

E Cranes E Plastic Machinery

F Drills & Drilling Equip. F Presses & Foundry

G Flame Cutting/Welding Equip. G Railroad Machinery

H Food Machinery H Road Construct/Maint. Equip.

I Forestry I Simulators & Test Equipment

J Furnaces J Snow Vehicles, Ski Lifts

K Gas & Oilfield Machinery K Steel Plants & Rolling Mills

L Heavy Construction & Equip. L Truck & Bus Industry

M Military Vehicles M Textile Machinery

N Construction & Utility Equip. N Woodworking Machines

O Machine Tools O Other (specify)_____________

P Government Related P Fluid Power Industry MY COMPANY SHOULD BE ADVERTISING IN OR SUBMIT AN ARTICLE TO THE FLUID POWER JOURNAL.

PLEASE CONTACT THIS PERSON:

NAME: _____________________________________

TITLE: ______________________________________

SCAN HERE

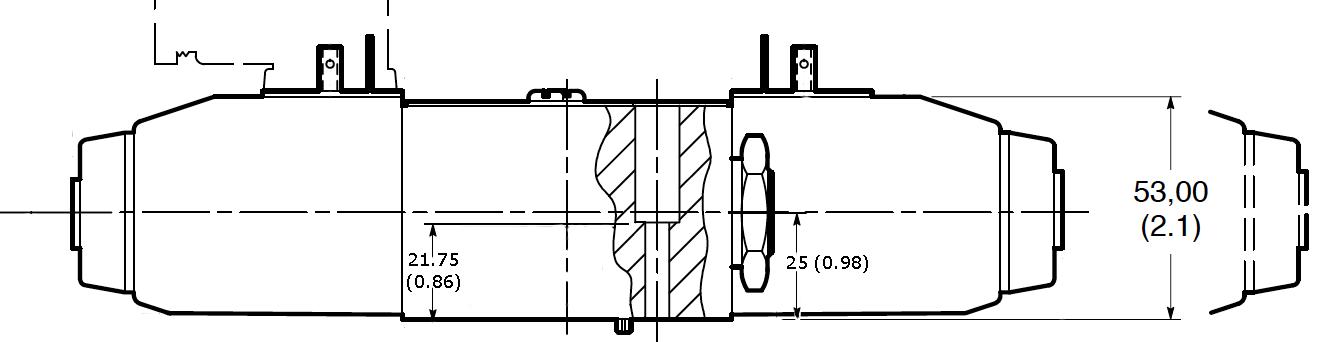

• Resolution ≤5 mV

• Accuracy ±0.25% of full scale • Real-time adjustable PID control • Integrated 0 to 10 VDC, 4-20 mA signal, or 3.3 VDC serial communication

• 0 to 10 VDC feedback pressure monitor • Virtually silent • No integral bleed required • Multiple pressure ranges from vacuum to 150 psig • 2.7 to 65 l/min flow control

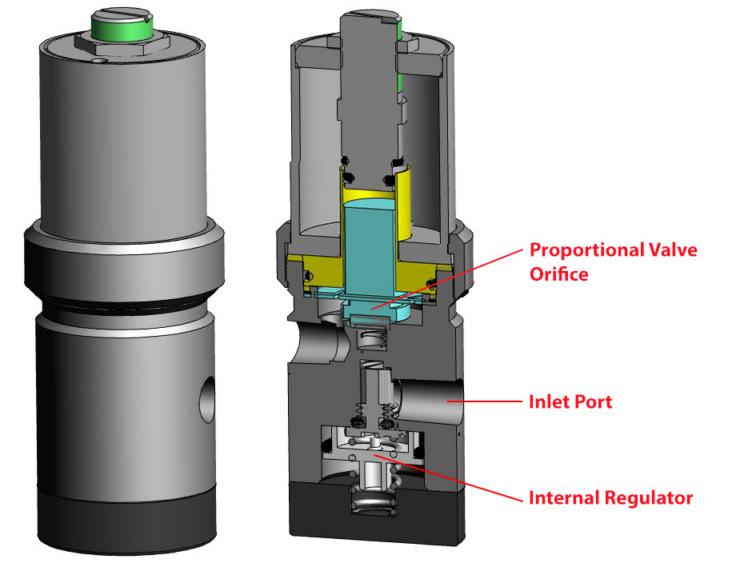

Take Control with Cordis

ELECTRONIC PRESSURE REGULATION

The future of proportional control has arrived— and it’s digital. The Clippard Cordis is a revolutionary microcontroller primed for escape velocity from a proportional control market that has grown stagnant.

With unparalleled performance and flexibility not possible with current analog proportional controllers, the Cordis makes everything from calibration, to sensor variety, to future development opportunities more accessible and less complicated.

Precise, Linear Digital Pressure Control

Contact your distributor today to learn more about how the Cordis can provide precise, real-time control for your application, or visit clippard.com to request more information.

877-245-6247

CINCINNATI • BRUSSELS • SHANGHAI