21 minute read

Test Your Skills

Replacing Hydraulic Valves

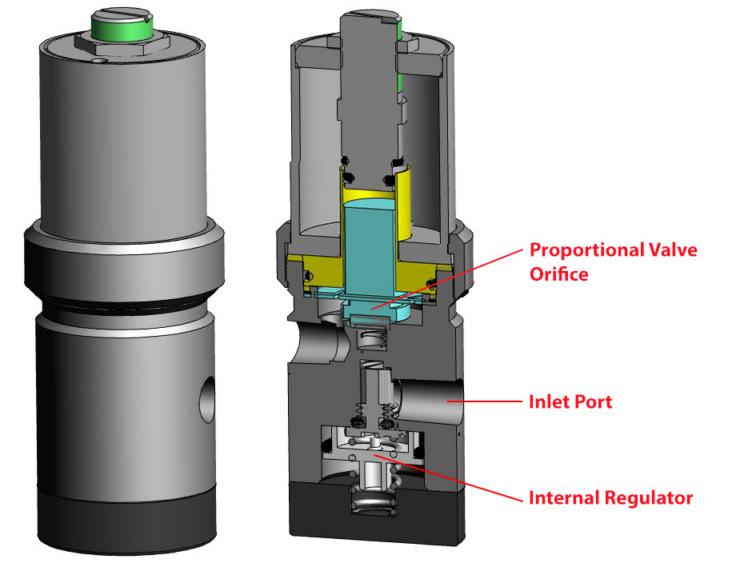

Even though hydraulic valves are relatively simple devices, often with only one or two moving parts, close attention needs to be paid when replacing them. Subplate-mounted solenoid-controlled valves can have a variety of spool conditions and solenoid voltage options. Even though the replacement valve may physically fit in place of the original valve, the function can be different and result in a potentially hazardous unintended movement when the machine is started. Mobile-style sectional valves not only can have different spool configurations but also multiple other options. These options can be in the individual valve sections as well as in the inlet and outlet sections. Cartridge-style valves, both the common cavity style that conforms to an ISO standard and valves that fit a proprietary cavity, can be flow control, directional control, or pressure control that fits into the same cavity. Cartridge valves may have the same mounting thread but a different cavity profile to accommodate the three or four flow paths compared to a simple two-flow path cavity. The extra paths connect to a third drain or pilot port. The same mounting thread can also fit a four-way directional valve or pressure valves with both separate drain and pilot ports with different cavity profiles.

When replacing any valve, all the O-rings should be replaced. Carefully inspect the mounting surface or cavity once the old valve has been removed to confirm the old seals have also been completely removed.

It is important when installing a new valve that the manufacturer's torque specifications are followed. Be sure the proper mounting bolts are used, as the use of incorrect bolts may affect valve operation (see drawing below).

Valve installation drawing.

In the drawing, note that the shoulder where the mounting bolt head rests is below the centerline of the valve to minimize the chance of spool binding due to uneven torque applied to the mounting bolts. When installing a new valve, special attention must be paid to ensure any O-rings remain in place and are not cut or pinched during the installation process. The O-rings should not be installed dry. A common practice is to use a small amount of hydraulic fluid, grease, Vaseline, or retaining compound specifically designed for retaining O-rings. Ensure the material is compatible with the O-ring material and the hydraulic fluid (see illustration).

Identifying the valve to be removed from a machine can be difficult, if not impossible, due to paint applied after the valve was installed, a buildup of dirt, or physical damage to the data tag. The repair manual or bill of materials should also be consulted. The part number of the replacement valve should match exactly with the valve to be replaced. Even a single digit change in the model code can indicate a significant difference, such as an open center versus closed center valve.

Before removing the old valve, the machine must be put into a safe state, with all supported loads lowered or blocked with a suitable support. Suitable containment must be in place. If shut-off valves exist, they should be closed to reduce fluid loss, but they must be opened again before starting the machine. Any hoses or tubes that are removed should be capped to minimize spillage and prevent introducing dirt into the hydraulic system.

Load-holding valves require special attention when being serviced. One manufacturer’s counterbalance valve pressure setting is increased by turning the adjustment counterclockwise, unlike most other pressure controls that increase the setting by turning the adjustment clockwise. Field adjustment of the setting on counterbalance valves is not recommended, especially if there are two parallel cylinders with counterbalance valves that move the load. Equipment builders may specify nonadjustable counterbalance valves to prevent improper or mismatched settings. Cylinders with integral dual counterbalance valves may have different settings for extend and retract. Identifying which counterbalance valve controls the extend or retract function may be difficult to determine without details of the cylinder plumbing.

Pilot-operated check valves do not have spring adjustments but may have an adjustment or manual override that will permit manually opening the valve without pilot pressure present. •

Not all valves have locating dowell pin. If no pin is present, verify proper valve orientation.

Ensure these O-rings remain in place during valve installation.

TEST YOUR SKILLS

1. Why would a counterbalance valve be used that is nonadjustable? a. Internal drain prevents valve adjustment. b. Valve is pressure balanced. c. Pressure is adjusted by second pilot. d. Prevent improper or mismatched field adjustment. e. Spring adjustment would interfere with check valve.

2. When replacing a cartridge-style valve, the replacement valve: a. Must exactly match the old valve. b. Can be shorter, as long as it fits into the cavity. c. May not have an adjustment screw because it is factory set. d. May have a solenoid instead of an adjusting screw indicating it is proportional. e. Will have the same function as long at it has the same number of ports.

See page 31 for the solutions.

Web

MARKETPLACE

www.orbitalmotors.net Hydraulex

Genuine Metaris® Orbital Motors are your best low speed high torque motor option in an economical and compact design. The motors are engineered with Roller-Star technology, come in a range of displacements and we offer multiple flange options including wheel mount. You’ll find that our motors are a perfect fit, form and function replacement for common OEM motors in the market today, such as Eaton®/ Char-Lynn®, Danfoss®, Parker® and White® .

Visit our website for more information (www. orbitalmotors.net), give us a call (1-800-3238416), or email us at seattlesales@hydraulex.com.

www.mainmanufacturing.com

Main's website provides quick access to the 120 page catalog that includes popular styles of MAIN Manufacturing’s extensive offering of carbon and stainless Hydraulic Flanges and Components – ready for immediate shipment. Metric ordering information, weld specs, and dimensional information included. The “Quick Reference Guide” helps specify less popular items often stocked or quickly manufactured (generally 3-4 days) at our US plant. “Create-AFlange” offers more parts than the catalog — by picture. If it’s not here, or for questions, E-mails may be sent to get your answer quickly.

1-800-521-7918 info@mainmfg.com

PRODUCT REVIEW

Danfoss Launches Aeroquip Dynamax Hose Line

»DANFOSS POWER SOLUTIONS, a global supplier of mobile and industrial hydraulics and electric powertrain systems, recently launched its Aeroquip EC881 Dynamax line of hose.

This two-wire braided hose offers higher reliability and extended service life, reducing maintenance time, costs, and waste.

EC881 hose outperforms standard EN 857 type 2SC hose specifications, with a 35% higher pressure rating, 26% higher operating temperature, eight times more abrasion resistance, 67% greater flexibility (⅓ SAE bend radius), and five times more impulse life (1 million qualified impulse cycles). These benefits are enabled by Danfoss’ patented Dura-Pulse inner tube technology, patented hybrid wire braid reinforcement, and Dura-Tuff cover.

With its higher pressure capabilities, EC881 hose can replace heavy, rigid four-wire spiral hose in certain applications, providing a direct cost savings of up to 30% as well as several design benefits. Braided hose is much more flexible than spiral hose, which may enable OEMs to reroute and reduce hose assembly lengths, contributing to further cost savings. Braided hose is also lighter in weight than spiral hose, which reduces the overall weight of the machine, improving fuel efficiency.

Aeroquip EC881 Dynamax hose is available in sizes -4 through -24 (0.25-inch to 1.5-inch inner diameter). The hose is ideal for a variety of applications, including compact construction equipment, agricultural equipment, forestry equipment, mining, oil and gas, refuse trucks, aerial lifts, and railway.

Executive Profile

Certification Empowers Opportunity.

Brian Kenoyer, CFPHS, Director of Engineering, Cemen Tech

Q. How did you get started in the fluid power industry?

A. I was hired as a hydraulic engineer with JLG Industries. I had little prior experience besides specifying hoses and fittings, but I was able to successfully learn on the job from some of the best and experienced engineers in the industry.

Q. How and why did you get involved in IFPS, and what have you gained professionally and personally?

A. [Getting involved with IFPS was] a condition of employment. I took the hydraulic specialist exam early in my employment with JLG and thankfully learned enough to pass. IFPS has provided me with fantastic educational resources for myself and my employees to overcome many engineering obstacles. I also have gained a substantial network of hydraulic professionals eager to promote the industry.

Q. Why did you pursue certification, and how has it helped your career?

A. I became certified as a condition of employment, and I do not regret the choice. To date, I have been successful in advancing my career partly due to the official certifications I hold and the knowledge and experience they represent.

Q. What have you learned by working in this industry?

A. The wide range of viable applications. There are many instances in which fluid power offers either the best power, control, or economical combination. It is flexible, cost-effective, and advancing.

Q. Where do you see the industry heading in the next 10 years?

A. I see the industry staying stable, as there are many applications in which fluid power is the optimal solution. I am often encouraged by new innovative solutions that hydraulic component OEMs unveil, and I actively direct my engineers to push the envelope and embrace these technologies. Q. What advice would you give someone starting out in the industry?

A. Get certified. Actively reach out to others and network. Do not be afraid to ask questions or say you do not understand. Be open and try new technologies. R&D is fundamental for advancement. Q.What are some of your hobbies and interests?

A.I enjoy home DIY projects and spending time with my family. When time permits, I enjoy pickup basketball and slow-pitch softball. Q. What is something people would be surprised to learn about you?

A. I am a Detroit Lions fan.

Upcoming Virtual Training

FLUID POWER MATH

Dan Helgerson, CFPAI, and Tom Blansett, CFPAI, conduct this seven-week series covering fundamental math skills and laying a foundation to calculate more complex formulas. When: Wednesdays, Oct. 5 through Nov. 16, 11 a.m. to 12:15 p.m. [ET]. Cost: $199 for members and $299 for nonmembers. The fee includes a calculator, the Fluid Power Math book, and two-year access to the IFPS learning management system.

DISCUSSING THE TYPES, DESIGNS, TERMINOLOGY, FUNCTION, AND USE OF VARIOUS AIR COMPRESSORS

Presented by Ed Rybarczyk, CFPAI. When: Nov. 11, 12-1 p.m. [ET].

THE CONSTRUCTION, OPERATION, SIZING, AND APPLICATIONS OF USING ACCUMULATORS

When: Dec. 21, 12-1 p.m. [ET]. Presented by Medhat Khalil, CFPAI, CPFHS.

Register at www.ifps.org/web-seminars.

IFPS recently launched a live chat option on its website. IFPS is available to answer questions and more. To see the feature and for more information, visit www.ifps.org. Have a chat while you’re there.

Mark Your Calendar IFPS Launches Live Chat

FLUID POWER TECHNOLOGY CONFERENCE

Oct. 12-13, Detroit, MI

2023 IFPS SPRING MEETING

Feb. 27-March 2, 2023, New Orleans, LA

INTERNATIONAL FLUID POWER EXPOSITION

March 14-18, 2023, Las Vegas, NV

2023 IFPS ANNUAL MEETING AND HALL OF FAME CEREMONY

Sept. 25-28, 2023, Milwaukee, WI

2024 IFPS SPRING MEETING

March 11-14, 2024, San Antonio, TX

For more information, visit www.ifps.org.

ONSITE

TRAINING

AND CERTIFICATION FOR: Hydraulic Techs & Engineers Electrical Techs & Engineers Pneumatic Techs & Engineers Multicraft Techs & Engineers

UPSKILL YOUR WORKFORCE!

CFC provides direct, Industry and/or Machine-specific training to companies the world over. Our Hands-On Training Equipment is mobilized directly to your facility with Certified Instructors traveling on-site. This turnkey approach includes all books, materials, equipment, and travel arrangements. We have the capability to upskill your entire workforce NOW!

CFCINDUSTRIALTRAINING.com 7042 Fairfield Business Drive Fairfield, Ohio 45014 +1 513.874.3225 info@cfcindustrialtraining.com

New Handbook Edition Released

»A SECOND EDITION of the Fluid Power Reference Handbook is now available. Highlights of the second edition include: • An expanded symbology section ISO 1219 compliant. • New and enhanced graphics. • Expanded topics. • Updated charts that are ISO, ANSI, and SAE compliant.

The 388-page Fluid Power Reference Handbook is the gold standard on-the-job reference tool of choice for any fluid power professional. IFPS has sold over 2,000 copies since its first publication in 2020.

Soft-cover: Members - $74.95 | Retail - $125.95

Hard-cover: Members - $149.99 |Retail - $165.99

The Fluid Power Reference Handbook second edition is the best resource I have seen for the fluid power industry. It contains all the formulas that you will use in our industry, including formulas needed for fluid power certification tests. It is much more than just a reference manual. The handbook explains many concepts, in reasonable detail, for an excellent overview of how various components work with both pneumatics and hydraulics. I have over 50 years of experience in the fluid power industry, and I still learned some things that I hadn’t thought about. I’m sure you will too. The handbook is also color-coded for easy reference, with no short-cuts taken. IFPS put its full effort into making this handbook for education and industry reference.”

—Ernie Parker, CFPAI

For more information and to purchase, visit www.ifps.org/training-resources-handbook.

Certification Empowers Opportunity.

Introducing!

9S SERIES INVESTMENT CAST SWIVELS

The “9S” Series swivels represent one of the most complete range of sizes and configurations available to the industry. This series has been redesigned to incorporate a one piece barrel arrangement thus eliminating the need for braze joints. These swivels are pressure balanced with operating pressures up to 5,000 psi. All configurations are designed with a 4:1 Safety Factor and include RoHS compliant zinc plating.

P.O. Box 6479, Fort Worth, TX 76115 V. 817/923-1965 www.hydraulicsinc.com

Newly Certified Professionals

July 2022

HYDRAULIC SPECIALIST

Joelle Andres-Beck, Airline Hydraulics Corporation Carlo Garcia, Applied Industrial Technologies Ray Haskins, Applied Industrial Technologies Daniel Sanchez, Applied Industrial Technologies Morgan Webber, Applied Industrial Technologies Isaac Boraas, SunSource Nicholas Youngers, Hyspeco Donald Steinhart, Gulf Controls Company

MOBILE HYDRAULIC MECHANIC

Freddie Bates, Altec Industries Maximino Sanchez, Altec Industries Josh Remmer, Altec Industries Conrado Rios, Altec Industries Robert Sullivan, Altec Industries Victor Cabrera, Southern California Edison Salvador Martinez, Southern California Edison Steven Price, Southern California Edison Jerry Rubio, Southern California Edison

PNEUMATIC SPECIALIST Elizabeth Walker

Chengwu Deng, Disneyland Resort Kamran Rostami, Transcanada Ian Klein, GCC Cassandra Ryan, Womack Machine Supply

SPECIALIST

Holds HS and PS certifications

Elizabeth Walker

Chengwu Deng, Disneyland Resort Kamran Rostami, Transcanada Ian Klein, GCC Cassandra Ryan, Womack Machine Supply

Certification Facts

»IFPS OFTEN RECEIVES QUESTIONS from fluid power professionals about certification and how to become certified. Here are 10 things everyone should know about IFPS certification.

1. IFPS has certified thousands of professionals since 1960. 2. Certification tests provide an objective, third-party assessment of an individual’s skill level. 3. All IFPS certification tests are psychometrically evaluated and meet defensible standards. 4. IFPS certifications are the industry standard for assessing the knowledge and skill level of professionals in fluid power and motion control. 5. IFPS certifications are highly recognized industry wide. 6. The IFPS certification designations that appear after your name are portable and remain with you wherever your career takes you. 7. IFPS certifications are approved through the NAM-endorsed skills certification system as a stackable credential that can be earned in postsecondary education. For more information, visit www.themanufacturinginstitute.org. 8. IFPS is approved by the U.S. Department of Veterans Affairs to reimburse certification test fees. The VA may reimburse eligible veterans for taking IFPS certification tests. 9. IFPS certifications are valid for five years, then you must recertify. While certified, you must accrue professional development points and work in the fluid power industry for at least three years. 10. IFPS certification empowers fluid power distributors, manufacturers, and end users to set standards for assessing the skill level of current or potential employees.

Written Certification Test Locations

Individuals wishing to take any IFPS written certification tests can select from convenient locations across the United States and Canada. IFPS is able to offer these locations through its affiliation with the Consortium of College Testing Centers provided by National College Testing Association.

Contact headquarters if you do not see a location near you. Every effort will be made to accommodate your needs.

If your test was postponed due to the pandemic, please contact headquarters so that we may reschedule.

TENTATIVE TESTING DATES FOR ALL LOCATIONS:

November 2022

Tuesday 11/8 • Thursday 11/17

December 2022

Tuesday 12/6 • Thursday 12/15

January 2023

Tuesday 1/10 • Thursday 1/26

February 2023

Tuesday 2/7 • Thursday 2/23

JOB PERFORMANCE TEST LOCATIONS

Arizona California Colorado Florida Georgia Maine Michigan Minnesota Montana New Jersey Nova Scotia Pennsylvania Texas Washington Wyoming Western Australia

ALABAMA

Auburn, AL Birmingham, AL Calera, AL Decatur, AL Huntsville, AL Jacksonville, AL Mobile, AL Montgomery, AL Normal, AL Tuscaloosa, AL

ALASKA

Anchorage, AK Fairbanks, AK

ARIZONA

Flagstaff, AZ Glendale, AZ Mesa, AZ Phoenix, AZ Prescott, AZ Scottsdale, AZ Sierra Vista, AZ Tempe, AZ Thatcher, AZ Tucson, AZ Yuma, AZ

ARKANSAS Bentonville, AR Hot Springs, AR Little Rock, AR

CALIFORNIA

Aptos, CA Arcata, CA Bakersfield, CA Dixon, CA Encinitas, CA Fresno, CA Irvine, CA Marysville, CA Riverside, CA Salinas, CA San Diego, CA San Jose, CA San Luis Obispo, CA Santa Ana, CA Santa Maria, CA Santa Rosa, CA Tustin, CA Yucaipa, CA

COLORADO

Aurora, CO Boulder, CO Springs, CO Denver, CO Durango, CO Ft. Collins, CO Greeley, CO Lakewood, CO Littleton, CO Pueblo, CO

DELAWARE

Dover, DE Georgetown, DE Newark, DE

FLORIDA

Avon Park, FL Boca Raton, FL Cocoa, FL Davie, FL Daytona Beach, FL Fort Pierce, FL Ft. Myers, FL Gainesville, FL Jacksonville, FL Miami Gardens, FL Milton, FL New Port Richey, FL Ocala, FL Orlando, FL Panama City, FL Pembroke Pines, FL Pensacola, FL Plant City, FL Riviera Beach, FL Sanford, FL Tallahassee, FL Tampa, FL West Palm Beach, FL Wildwood, FL Winter Haven, FL

GEORGIA

Albany, GA Athens, GA Atlanta, GA Carrollton, GA Columbus, GA Dahlonega, GA Dublin, GA Dunwoody, GA Forest Park, GA Lawrenceville, GA Morrow, GA Oakwood, GA Savannah, GA Statesboro, GA Tifton, GA Valdosta, GA

HAWAII Laie, HI

IDAHO

Boise, ID Coeur d ‘Alene, ID Idaho Falls, ID Lewiston, ID Moscow, ID Nampa, ID Rexburg, ID Twin Falls, ID

ILLINOIS

Carbondale, IL Carterville, IL Champaign, IL Decatur, IL Edwardsville, IL Glen Ellyn, IL Joliet, IL Malta, IL Normal, IL Peoria, IL Schaumburg, IL Springfield, IL University Park, IL

INDIANA

Bloomington, IN Columbus, IN Evansville, IN Fort Wayne, IN Gary, IN Indianapolis, IN Kokomo, IN Lafayette, IN Lawrenceburg, IN Madison, IN Muncie, IN New Albany, IN Richmond, IN Sellersburg, IN South Bend, IN Terre Haute, IN

IOWA

Ames, IA Cedar Rapids, IA Iowa City, IA Ottumwa, IA Sioux City, IA Waterloo, IA

KANSAS

Kansas City, KS Lawrence, KS Manhattan, KS Wichita, KS

KENTUCKY

Ashland, KY Bowling Green, KY Erlanger, KY Highland Heights, KY Louisville, KY Morehead, KY

LOUISIANA

Bossier City, LA Lafayette, LA Monroe, LA Natchitoches, LA New Orleans, LA Shreveport, LA Thibodaux, LA

MARYLAND

Arnold, MD Bel Air, MD College Park, MD Frederick, MD Hagerstown, MD La Plata, MD Westminster, MD Woodlawn, MD Wye Mills, MD

MASSACHUSETTS

Boston, MA Bridgewater, MA Danvers, MA Haverhill, MA Holyoke, MA Shrewsbury, MA

MICHIGAN

Ann Arbor, MI Big Rapids, MI Chesterfield, MI Dearborn, MI Dowagiac, MI East Lansing, MI Flint, MI Grand Rapids, MI Kalamazoo, MI Lansing, MI Livonia, MI Mount Pleasant, MI Sault Ste. Marie, M Troy, MI University Center, MI Warren, MI

MINNESOTA

Alexandria, MN Brooklyn Park, MN Duluth, MN Eden Prairie, MN Granite Falls, MN Mankato, MN

MISSISSIPPI

Goodman, MS Jackson, MS Mississippi State, MS Raymond, MS University, MS

MISSOURI

Berkley, MO Cape Girardeau, MO Columbia, MO Cottleville, MO Joplin, MO Kansas City, MO Kirksville, MO Park Hills, MO Poplar Bluff, MO Rolla, MO Sedalia, MO Springfield, MO St. Joseph, MO St. Louis, MO Warrensburg, MO

MONTANA

Bozeman, MT Missoula, MT

NEBRASKA

Lincoln, NE North Platte, NE Omaha, NE

NEVADA

Henderson, NV Las Vegas, NV North Las Vegas, NV Winnemucca, NV

NEW JERSEY

Branchburg, NJ Cherry Hill, NJ Lincroft, NJ Sewell, NJ Toms River, NJ West Windsor, NJ

NEW MEXICO

Albuquerque, NM Clovis, NM Farmington, NM Portales, NM Santa Fe, NM

NEW YORK

Alfred, NY Brooklyn, NY Buffalo, NY Garden City, NY New York, NY Rochester, NY Syracuse, NY

NORTH CAROLINA

Apex, NC Asheville, NC Boone, NC Charlotte, NC China Grove, NC Durham, NC Fayetteville, NC Greenville, NC Jamestown, NC Misenheimer, NC Mount Airy, NC Pembroke, NC Raleigh, NC Wilmington, NC

NORTH DAKOTA

Bismarck, ND

OHIO

Akron, OH Cincinnati, OH Cleveland, OH Columbus, OH Fairfield, OH Findlay, OH Kirtland, OH Lima, OH Maumee, OH Newark, OH North Royalton, OH Rio Grande, OH Toledo, OH Warren, OH Youngstown, OH

OKLAHOMA

Altus, OK Bethany, OK Edmond, OK Norman, OK Oklahoma City, OK Tonkawa, OK Tulsa, OK

OREGON

Bend, OR Coos Bay, OR Eugene, OR Gresham, OR Klamath Falls, OR Medford, OR Oregon City, OR Portland, OR White City, OR

PENNSYLVANIA

Bloomsburg, PA Blue Bell, PA Gettysburg, PA Harrisburg, PA Lancaster, PA Newtown, PA Philadelphia, PA Pittsburgh, PA Wilkes-Barre, PA York, PA

SOUTH CAROLINA

Beaufort, SC Charleston, SC Columbia, SC Conway, SC Graniteville, SC Greenville, SC Greenwood, SC Orangeburg, SC Rock Hill, SC Spartanburg, SC

TENNESSEE

Blountville, TN Clarksville, TN Collegedale, TN Gallatin, TN Johnson City, TN Knoxville, TN Memphis, TN Morristown, TN Murfreesboro, TN Nashville, TN

TEXAS

Abilene, TX Arlington, TX Austin, TX Beaumont, TX Brownsville, TX Commerce, TX Corpus Christi, TX Dallas, TX Denison, TX El Paso, TX Houston, TX Huntsville, TX Laredo, TX Lubbock, TX Lufkin, TX Mesquite, TX San Antonio, TX Victoria, TX Waxahachie, TX Weatherford, TX Wichita Falls, TX

UTAH

Cedar City, UT Kaysville, UT Logan, UT Ogden, UT Orem, UT Salt Lake City, UT

VIRGINIA

Daleville, VA Fredericksburg, VA Lynchburg, VA Manassas, VA Norfolk, VA Roanoke, VA Salem, VA Staunton, VA Suffolk, VA Virginia Beach, VA Wytheville, VA

WASHINGTON

Auburn, WA Bellingham, WA Bremerton, WA Ellensburg, WA Ephrata, WA Olympia, WA Pasco, WA Rockingham, WA Seattle, WA Shoreline, WA Spokane, WA

WEST VIRGINIA

Ona, WV

WISCONSIN

La Crosse, WI Milwaukee, WI Mukwonago, WI

WYOMING

Casper, WY Laramie, WY Torrington, WY

CANADA ALBERTA

Calgary, AB Edmonton, AB Fort McMurray, AB Lethbridge, AB Lloydminster, AB Olds, AB Red Deer, AB

BRITISH COLUMBIA

Abbotsford, BC Burnaby, BC Castlegar, BC Delta, BC Kamloops, BC Nanaimo, BC Prince George, BC Richmond, BC Surrey, BC Vancouver, BC Victoria, BC

Certification Empowers Opportunity.

MANITOBA

Brandon, MB Winnipeg, MB

NEW BRUNSWICK

Bathurst, NB Moncton, NB

NEWFOUNDLAND AND LABRADOR

St. John’s, NL

NOVA SCOTIA

Halifax, NS

ONTARIO

Brockville, ON Hamilton, ON London, ON Milton, ON Mississauga, ON Niagara-on-the-Lake, ON North Bay, ON North York, ON Ottawa, ON Toronto, ON Welland, ON Windsor, ON

QUEBEC

Côte Saint-Luc, QB Montreal, QB

SASKATCHEWAN

Melfort, SK Moose Jaw, SK Nipawin, SK Prince Albert, SK Saskatoon, SK

YUKON TERRITORY

Whitehorse, YU

UNITED KINGDOM

Elgin, UK

GHAZNI

Kingdom of Bahrain, GHA Thomasville, GHA

EGYPT Cairo, EG

JORDAN

Amman, JOR

NEW ZEALAND

Taradale, NZ

CFPAI

Certified Fluid Power Accredited Instructor

CFPAJPP

Certified Fluid Power Authorized Job Performance Proctor

CFPAJPPCC

Certified Fluid Power Authorized Job Performance Proctor Connector & Conductor

CFPE

Certified Fluid Power Engineer

CFPS

Certified Fluid Power Specialist (Must Obtain CFPHS & CFPPS)

CFPHS

Certified Fluid Power Hydraulic Specialist

CFPPS

Certified Fluid Power Pneumatic Specialist

CFPECS

Certified Fluid Power Electronic Controls Specialist

CFPMT

Certified Fluid Power Master Technician (Must Obtain CFPIHT, CFPMHT, & CFPPT)

CFPIHT

Certified Fluid Power Industrial Hydraulic Technician

CFPMHT

Certified Fluid Power Mobile Hydraulic Technician

CFPPT

Certified Fluid Power Pneumatic Technician

CFPMM

Certified Fluid Power Master Mechanic (Must Obtain CFPIHM, CFPMHM, & CFPPM)

CFPIHM

Certified Fluid Power Industrial Hydraulic Mechanic

CFPMHM

Certified Fluid Power Mobile Hydraulic Mechanic

CFPPM

Certified Fluid Power Pneumatic Mechanic

CFPMIH

Certified Fluid Power Master of Industrial Hydraulics (Must Obtain CFPIHM, CFPIHT, & CFPCC)

CFPMMH

Certified Fluid Power Master of Mobile Hydraulics (Must Obtain CFPMHM, CFPMHT, & CFPCC)

CFPMIP

Certified Fluid Power Master of Industrial Pneumatics (Must Obtain CFPPM, CFPPT, & CFPCC)

CFPCC

Certified Fluid Power Connector & Conductor

CFPSD

Fluid Power System Designer CFPMEC (In Development) Mobile Electronic Controls

CFPIEC (In Development) Industrial Electronic Controls

Tentative Certification Review Training

IFPS offers onsite review training for small groups of at least 10 persons. An IFPS accredited instructor visits your company to conduct the review. Contact kpollander@ifps.org for details of the scheduled onsite reviews listed below.

HYDRAULIC SPECIALIST

Oct. 25-28, Charlotte, NC. Contact mzanon@hydeparkpartners.us Livingston & Haven. Written test: Oct. 28.

CONNECTOR & CONDUCTOR

Nov. 15-16, Fairfield, OH. Contact info@cfcindustrialtraining.com. Written test Nov. 17.

MOBILE HYDRAULIC MECHANIC

Oct. 10-12, Fairfield, OH. Contact info@cfcindustrialtraining.com. Written and JP test Oct. 13. Online review for written test. Contact info@cfcindustrialtraining.com. IFPS members can email askus@IFPS.org for a 20% off coupon code. Test fees not included.

INDUSTRIAL HYDRAULIC TECHNICIAN

Onsite review training for small groups. Contact IFPS for details.

MOBILE HYDRAULIC TECHNICIAN

For dates, call 513-874-3225 or contact info@cfcindustrialtraining.com.

PNEUMATIC TECHNICIAN and PNEUMATIC MECHANIC

For dates, call 513-874-3225 or contact info@cfcindustrialtraining.com.

JOB PERFORMANCE TRAINING

Online review. Contact info@cfcindustrialtraining.com. Reviews includes stations 1-6 of the IFPS mechanic and technician job performance tests. Members can email askus@IFPS.org for a 20% coupon code. Test fees not included. To register, contact info@cfcindustrialtraining.com.

LIVE DISTANCE LEARNING JOB PERFORMANCE STATION REVIEW

Contact info@cfcindustrialtraining.com for information.