NoBitterAfterTaste

NoBitterAfterTaste

we do.

Delivering a drug when and where it’s needed results in better outcomes for both manufacturers and patients. Ashland is a global leader in excipient technologies for controlled release, film coatings, disintegrants, tablet binding, long acting injectables, and medical devices. We offer products that meet a wide variety of sophisticated needs: klucel™ hpc, viatel™ bioresorbable polymers, vialose™ trehalose, aquarius™ film coating systems, plasdone™ povidone, benecel hpmc, polyplasdone™ crospovidone, natrosol hec, pvpi™ povidone iodine

Learn more about how we can help with your formulations at ashland.com/contact

Chairman of the Board

ViveckGoenka

Sr.Vice President-BPD

Neil Viegas

Vice President-BPD

Harit Mohanty

Editor Viveka Roychowdhury*

Editorial Team

Lakshmipriya Nair

Kalyani Sharma

Kavita Jani

Neha Aathavale

DESIGN

Art Director

Pravin Temble

Senior Designer

Rekha Bisht

Senior Artist

Rakesh Sharma

Marketing Team

Rajesh Bhatkal

Ashish Rampure

Debnarayan Dutta

Production Co-ordinator

DhananjayNidre

Scheduling & Coordination

Pushkar Waralikar

CIRCULATION

Mohan Varadkar

P14 KANISHKDUGGAL COO,ICRI

20 CONTINUOUS MANUFACTURING: TRANSFORMING PHARMA MANUFACTURING

Driven bystringent regulations,rising investor expectations,consumer demand, and operational considerations,MSME pharma companies need to carefully balance their sustainabilitygoals with financial viability

By Viveka Roychowdhury

31 MANUFACTURING THE RIGHTTALENT

35

45 THE FUTURE OF PHARMA LOGISTICS: TRENDS, CHALLENGES,AND OPPORTUNITIES

Regd.With RNI No.MAHENG/2005/21398.Postal Regd.No.MCS/164/2022 - 24.Printed and Published byVaidehi Thakar on behalf of The Indian Express (P) Limited and Printed at The Indian Express Press,Plot No.EL-208,TTC Industrial Area,Mahape,Navi Mumbai-400710 and Published at Mafatlal Centre,7th floor,Ramnath Goenka Marg,Nariman Point,Mumbai 400021.

Editor: Viveka Roychowdhury.* (Editorial & Administrative Offices: Mafatlal Centre,7th floor,Ramnath Goenka Marg,Nariman Point,Mumbai 400021)

* Responsible for selection of news under the PRB Act.Copyright © 2017.The Indian Express (P) Ltd.All rights reserved throughout the world. Reproduction in anymanner,electronic or otherwise,in whole or in part,without prior written permission is prohibited.

Emcure Pharma became one of the first pharma companies to apply for and get some interim relief from the union health ministry's recent prohibition of sale and distribution of fixed dose combinations (“FDC”). Emcure had filed a writ petition before the Delhi High Court seeking the quashing of the August 12, 2024 notification, which prohibited the manufacture for sale and distribution of the company's pain relief FDC of S (+)-Etodolac + paracetamol for human use with immediate effect. Emcure's senior counsel stated before the Delhi High Court that the report of the sub-committee, on the basis of which the ban has been notified, has not been made public till date. The senior counsel also stated that it remains unclear why complete prohibition of the subject matter FDC has been recommended.

The court order shows that Emcure's senior counsel drew the attention of the Delhi High Court to an order dated July 3, 2023 regarding FDCs (Phenytoin + Phenobarbitone Sodium of Lupin) which had been prohibited under similar circumstances. The petition also referred to previous orders dated June 14, 2023 of the same court, which had under similar circumstances, granted interim protection for the drugs already in the distribution network. The June 2023 order specified that while drugs already in the distribution channel shall not be withdrawn, no fresh manufacture of the drug could take place till the next date of hearing. In addition, the order stated that no coercive steps would be taken against the petitioner for the drugs which are already in the distribution channel.

The Delhi HC order dated August 22, 2024 directed that the interim order of June 14, 2023 shall apply to Emcure's drugs which are part of the present writ petitions. The court also directed Emcure to file details of the stock of these banned FDCs as of the order date, within a week. The company also needs to give an affidavit of stock in circulation, within a week. The Union of India was granted four weeks' time to file a counter affidavit. Rejoinder affidavit, if any, needs to be filed before the next date of hearing, which has been listed as January 15, 2025.

The scene seems set for a repeat of previous prohibitions on FDCs, starting from 2016 with 344 FDCs prohibited. After a stay was granted, the matter was referred back to the Drugs Technical Advisory Board (DTAB), which stood by their decision on 328 drugs. The union ministry accepted their recommendation and banned these 328 FDCs in 2018. The next lot of banned FDCs in 2023 too saw similar litigation from several companies.

Pharma associations have gone on record to welcome the recent notification, with Sudarshan Jain, Secretary General, Indian Pharmaceutical Alliance pointing out that the discussion on FDCs is going on over a period of time with recommendation from Kokate committee and Nilima Kshirsagar

Putting the patient first, before granting licences seems the solution

committee. He feels this is a right step in the interest of patients and all aspects have been taken into consideration.

Industry associations are planning to file appeals along similar lines of the Emcure petition, to allow companies to exhaust stocks in the distribution network as well as stocks already manufactured that may be still within company premises. A future plan of action includes associations supporting their members should they contest the notification's premise that their FDCs are purportedly irrational combinations. If companies feel strongly that these are good products, have been in the market for over 30-40 years, and see no reason for a ban, associations will help them make their case.

While it remains to be seen whether more pharma companies challenge the notification, the recent ban revives the discussion on why such purportedly irrational combinations were approved in the first place. Industry discussion groups allude to cases where state licensing authorities took the stance that since individual molecules were licensed, it was fine to pass a combination of licensed molecules.

The gazette notification for each individual banned FDC stated, “There is no therapeutic justification for the ingredients contained in this FDC. The FDC may involve risk to human beings. Hence in the larger public interest, it is necessary to prohibit the manufacture, sale or distribution of this FDC under section 26 A of Drugs and Cosmetics Act 1940. In view of above, any kind of regulation or restriction to allow for any use in patients is not justifiable. Therefore, only prohibition under section 26A is recommended.”

The sentence, 'The FDC may involve risk to human beings' without specifying the reasons / extent and nature, puts the onus on the government to prove that a particular FDC is harmful to patients' health.

Going a step back, should not the authorities have examined whether there were therapeutic benefits of FDCs when licences were applied for? Similarly, should they have not examined whether there is no risk to patients, before they grant a manufacturing licence?

The list of banned FDCs include medicines for common illnesses like cold, fever, antibacterial and antifungal medicines, as well as antibiotics, anti allergy medication, painkillers and multivitamins. Medicines in India can be purchased very easily without a prescription, leading to potential long term misuse of many such irrational combinations. Given this reality, putting the patient first, before granting licences seems the solution.

VIVEKA ROYCHOWDHURY, Editor viveka.r@expressindia.com viveka.roy3@gmail.com

Elevateyourtabletcoating experiencethatofferssuperior protectionwithunmatched quality&innovation.

Kanishk Duggal,COO,ICRI in interaction with Kalyani Sharma emphasises how the availability of a skilled workforce is influencing the growth of clinical research in India and more

How do you perceive India's role in the global clinical research landscape evolving in the next five years?

India is set to become a central player in global clinical research due to its vast and diverse population, costeffective research capabilities, and evolving regulatory environment. Recent data shows a 25 per cent increase in registered clinical trials in India over the past year, positioning the country among the top 10 globally. The Central Drugs Standard Control Organization's new guidelines are streamlining the approval process, further attracting international researchers and sponsors. At ICRI India, we are excited about these developments and are committed to advancing clinical research education to support this growth. India’s expanding role will not only enhance its global standing but also contribute significantly to innovations in healthcare and treatment.

What specific regulatory reforms have significantly impacted clinical research in India, and what further changes are needed?

India has made significant strides in aligning its regulatory framework with international standards, such as those set by the US FDA and EMA. This alignment has made the country more attractive for global clinical trials. The introduction of the New Drugs and Clinical Trials

The adoption of digital tools in the clinical research sector has seen a significant acceleration post-pandemic.The COVID-19 crisis highlighted the need for faster,more efficient,and scalable solutions,leading to a rapid shift towards digital transformation

Rules in 2019 marked a pivotal moment, streamlining the approval process and ensuring higher ethical standards. Additionally, the Indian regulatory authorities have implemented fast-track approval processes for drugs, which has further bolstered the appeal of India as a clinical research hub. However, continued efforts to refine and enhance these regulations, particularly in areas such as patient safety and data transparency, will be necessary to maintain this momentum.

How is the availability of a skilled workforce influencing the growth of clinical research in India, and what measures are being taken to enhance this talent pool?

The availability of a skilled workforce is crucial for the growth of clinical research in India. Our educational programs at ICRI India are designed to address this need by providing comprehensive training in clinical research, pharmacovigilance, and clinical data management.

The landscape is evolving rapidly, with opportunities expanding beyond Contract Research Organizations (CROs) to include IT giants like IQVIA, Wipro, TCS, and Mahindra, each having a life sciences division. Currently, there are over 250,000 job vacancies globally in this sector.

To enhance the talent pool,

we focus on equipping students with practical skills and industry knowledge, ensuring they are wellprepared for these diverse roles. By offering exposure across these three critical areas, we aim to meet the industry’s demand for specialised professionals and support the sector's growth.

How has the adoption of digital tools accelerated in the clinical research sector post-pandemic?

The adoption of digital tools in the clinical research sector has seen a significant acceleration post-pandemic. The COVID-19 crisis highlighted the need for faster, more efficient, and scalable solutions, leading to a rapid shift towards digital transformation. Tools such as electronic data capture (EDC) systems, remote monitoring, and virtual trials have become integral to modern clinical research.

We have integrated these digital advancements into our curriculum, preparing our students to work with cuttingedge technologies. This shift not only streamlines research processes but also enhances data accuracy and participant engagement. As a result, clinical research is becoming more agile, transparent, and capable of addressing complex global health challenges with greater efficiency.

What are the key areas of

investment in building clinical research infrastructure in India?

Investment in clinical research infrastructure in India is focused on several key areas. Advanced technology plays a crucial role, with emphasis on electronic data capture systems, patient management software, and data analytics tools to enhance trial accuracy and efficiency. Upgrading clinical trial sites is equally important, ensuring they meet global standards with state-ofthe-art facilities and resources. Building a skilled workforce is another priority, with investment in education and specialised training programs in clinical research, pharmacovigilance, and data management to address the

Training programs and strategic partnerships are undeniably pivotal in bolstering capacity building within the clinical research domain

skills gap. Strengthening regulatory frameworks to align with international standards also facilitates smoother trial conduct and boosts India’s global competitiveness. Additionally, with the rise of digital tools, investing in infrastructure for remote and virtual trials is becoming increasingly vital. These investments collectively advance India’s position as a leading global hub for clinical

research.

How are training programs and partnerships contributing to capacity building in clinical research?

Training programs and strategic partnerships are undeniably pivotal in bolstering capacity building within the clinical research domain. our comprehensive approach encompasses

clinical research, pharmacovigilance, and clinical data management, providing a robust foundation for nurturing talent.

The burgeoning life sciences landscape has expanded opportunities beyond traditional CROs. IT giants like IQVIA, Wipro, TCS, and Mahindra, among others, have established dedicated life sciences divisions, creating a surge in

demand for specialised professionals. This presents a golden opportunity for skilled individuals to carve out successful careers.

By imparting in-depth knowledge and practical skills, our training programs equip aspiring professionals to excel in this dynamic industry. Moreover, our collaborations with industry leaders foster knowledge exchange, enabling us to stay at the forefront of emerging trends and best practices. Ultimately, these synergistic efforts contribute significantly to the growth of a skilled workforce, thereby strengthening the clinical research ecosystem in India.

Kalyani.sharma@expressindia.com journokalyani@gmail.com

September 2024

www.micronclean.in

DELIVEREDWITHAVERIFIEDANDEASILYACCESSIBLE PROCESSINGHISTORYASSTANDARD

MicroncleanIndiacandeliverdry,cleansterilereadytowearcleanroom garmentsdirectlytoyourpremiseswithaverifiedandeasilyaccessible processinghistory,whichallowsyoutobecompliantwithEUGMPAnnex1. Ifyouareinterestedinintegratingourcleanroomgarmentserviceinto yourcontaminationcontrolstrategy,pleasecontactus.

MicroncleanIndiaPvtLtd PlotNo.24&25|VemagalIndustrialArea Vemagal|Kolar|563102|Karnataka|India T.+917829111150 E.enquiries@micronclean.in

In an exclusive interview with Express Pharma, Zubin Zaveri,Managing Director of Transchem Corporation Pharma Pvt.Ltd.,discusses the company's evolution,market outlook,and investment plans in the Indian pharmaceutical excipients industry

How has Transchem evolved since its inception? What have been the major milestones in this journey?

Transchem started its operations in 1989 by collaborating with BASF. We started as a trader with a turnover of 29 lakhs in 1st year with 3 employees. Since then, we have grown into one of the major Pharma excipients distributors in India and achieved a milestone of 300+ crores in 2023. Since last few years Transchem is growing at CAGR of over 20 per cent. Over the years Transchem has added Elementis, G Sweet, BA’MEK, etc. as Principal partners. We at Transchem believe in “Quality of Quantity” which ensures that the quality standards are maintained. USP of our growth has been quality of service and transparency with both Principals and end customers. In 2022 Transchem was awarded for highest sales in Asia Pacific region by BASF.

How do you see Indian Pharmaceutical excipients market and how do you see the growth of Transchem going forward? What are Transchem’s investment plans considering the current Indian Pharma Excipients Industry?

The Indian pharmaceutical excipient market is growing at a rate of 10–12 per cent annually, which is higher than the global rate of 5–7 per cent. We are witnessing a growing interest in increasing export to developed markets from Indian Pharma manufacturers and hence we at Transchem believe that though there is competition from local and Chinese manufacturers we will grow at a good rate considering the quality of excipients we offer and

principals like BASF we are associated with.

Regarding investment plans, yes, we are open and wiling to invest if right opportunity comes. If you look at the current scenario, India is heavily relying on imports from Europe, US, China, Japan, etc. and that accounts to more than 70 per cent. So, we are open for collaboration if get the right partner who is willing to manufacture excipients in India.

In recent years we have witnessed quite a few acquisitions of Indian distributors by global distributors. What is you view on that and how do you see it impacting Indian Pharma companies?

As we know that Indian Pharma Industry is growing at a good pace, and this is generating the interest from global excipient distributors to increase their presence in India and capitalise on the growth. So, we are seeing lot of acquisitions either to get entry into India or increase the presence. But we see this as a challenge for Indian Pharma manufacturers because lot of money has gone into these acquisitions and there will be margin pressure of global distributors which in turn may increase the cost of excipients to end customers. So, we think these acquisitions may impact Indian Pharma manufacturers as it will increase the cost of their formulations. And that’s where we see the opportunity as we work on a very reasonable

margins and hence are very competitive. So, we are positive of the Transchem’s growth going forward.

What are Trans-Chem's plans for future market expansion or product diversification? What will be your growth strategies, both domestically and globally? How does Transchem plan to leverage Indian Pharma growth and emerging technologies to stay ahead of the curve?

Transchem offers a large basket of excipients for various dosage forms like oral solids, oral liquids, topicals, parenteral, etc. across the different applications like instant & modified formulations, solubilisation, biologics, etc. Indian Pharma is transforming from conventional formulations to concentrate more on specialty medicines, complex generics and expanding into biologics and biosimilars to enhance profitability. At Transchem we have a well-qualified and experienced sales and technical team who have the experience of working in Pharma research. Our team closely follow the industry transformations and work hand in hand with Pharma companies to understand their current and future requirements. So, we are aware of changing industry dynamics and prepared for it.

What is your view on Indian Pharma Industry and why are you so positive about it?

There are quite a few factors which favours India. India has emerged as a global hub for low price and high-quality medicines, thereby rightly making the country the ‘Pharmacy of the World’. The low cost of manufacturing and R&D along with cheap skilled

labour compared to US and Europe makes India a preferred destination. India has the largest number of USFDAcompliant plants outside the US and over 2,000 WHO-GMP approved facilities and supplying to more than 150+ countries worldwide.? Further government policy measures and increasing investments are making the growth conditions more favourable. Up to 100 per cent, FDI has been allowed through automatic route for Greenfield and up to 74 per cent for Brownfield pharmaceuticals projects. The government has launched PLI schemes to boost pharmaceutical manufacturing.

Are there any plans for Transchem to explore new markets or sectors beyond pharma in the near future? We’re witnessing an evolution in India’s pharma sector, and we are focussed to be part of the growth story. The Indian pharmaceutical industry is expected to grow at a CAGR of more than 10 per cent to reach $130 billion by 2030. With a robust base of drug manufacturers and a growing pool of R&D talent, India is a goto market for generics, contract services, coupled with a surge in the biological production of commercial drugs. India Ranks 3rd worldwide for pharmaceutical production by volume and 14th by value. About 20 per cent of the global exports in generic drugs are met by India. Hence considering the future growth in Indian Pharma we are currently focused on Pharma but yes, we are open to explore beyond Pharma and will be interested in collaborating with global manufacturer operating in cosmetics & Nutraceuticals where we see good growth.

Indu Bhushan,CEO & Director,STEERLife highlights how continuous manufacturing make production of pharma products more efficient and offers significant regulatory benefits.He also underscores the importance of technological advancements,regulatory compliance and strategic investments in driving the future of pharma manufacturing

The world massively relies on the developments that continue to take place in the pharma industry to experience an improved quality of life. From producing drugs for rare forms of cancer to generating highly effective vaccinations for various epidemics and pandemics, this industry has always played a pivotal role in safeguarding public health. Its response to COVID19 underscores its potential to effectively address every global health crisis and mitigate longterm health risks associated with them.

The pharma industry has undergone a monumental transformation over the last few years. One of the major factors responsible for its transformative journey has been Process Intensification (PI). Driven by the need to increase efficiency, reduce cost, and improve product quality, it has been at the core of pharma manufacturing. At the moment, it is being majorly applied in bioprocessing and small-molecule drug facilities through Continuous Manufacturing (CM) for rapid development of new therapies and to scale up the production of existing drugs in order to evade a health crisis.

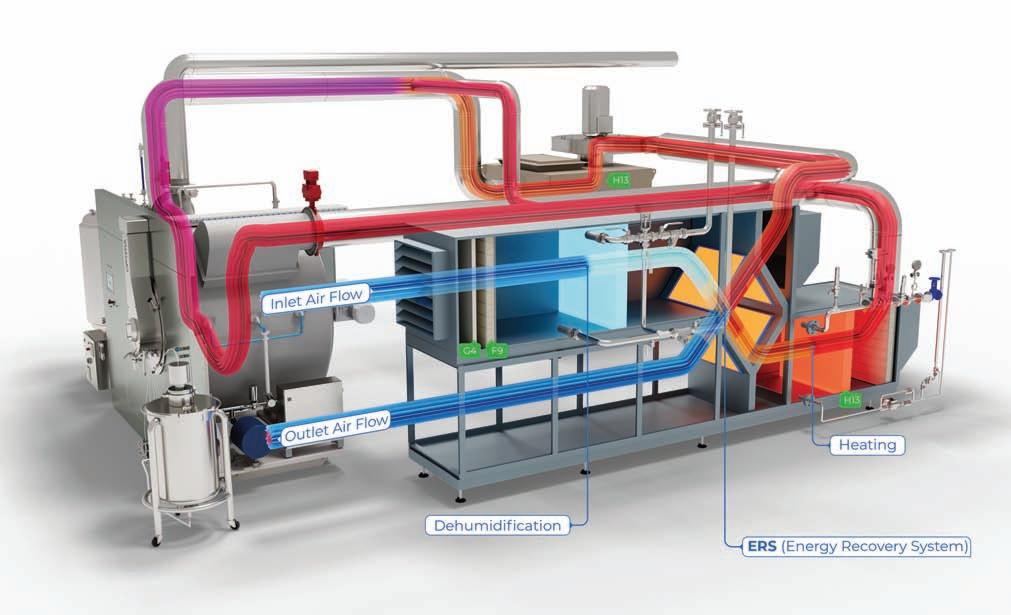

Continuous manufacturing and its benefits

There are three different approaches to continuous manufacturing (CM); fully end-toend continuous, a hybrid of batch and continuous, and individual continuous operations retrofitted in a batch process (mostly for legacy processes). The selection of any of these

approaches is guided by factors such as enterprise readiness, the product itself, processes involved, equipment, relevant regulations, available technology, demand in the market, and volume/value of the product. Irrespective of the approach, integration of CM in the pharma sector results in smaller factories, better process control, and environmental footprints, lower capital input, consistent product quality, modular manufacturing, and lower operating costs.

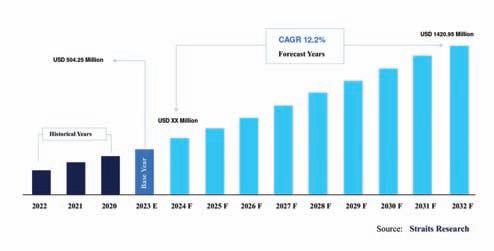

As per a report by Straits Research, a market research company, the global continuous manufacturing market was valued at $504.25 million in 2022 and is predicted to reach $1,4290.95 million by 2031, registering a CAGR of 12.2 per cent during the forecast period. It also highlights that with more and more manufacturers realising the number of benefits CM holds, there is a noteworthy increase in the investments in the R&D area, further leading to such positive predictions.

Out of many, one huge advantage is how CM renders drug sponsors the ability to rapidly respond to market opportunities. It can seamlessly accommodate scale-up and post-approval changes. For ex-

ample, increases in lot sizes are possible by simply running longer. This can be particularly beneficial during drug shortages and competitive market situations, as manufacturers can acquire additional market share immediately with little to no disruption in operations or product quality.

Along with availing benefits of continuous manufacturing, manufacturers must maintain regulatory compliance to ensure public health safety, build trust, and ethically run the business. They can do so by following the guidelines of the Food and Drug Administration (FDA) and European Medicine

Agency (EMA). Also, to establish a sense of transparency, especially for audits, and adhere to regulatory standards, manufacturers must have a Quality Management System (QMS) in place. This system assists in proper documentation and record-keeping.

However, some manufacturers have been hesitant to adopt CM due to perceptions of increased regulatory risks. They are primarily concerned about potential pre-market delays, greater inspectional scrutiny, and post-market hurdles.

Nonetheless, a recent FDA selfaudit comparing CM to batch manufacturing regulatory outcomes confirmed that manufacturers who submitted CM applications actually “had relatively shorter times to approval and market as compared to similar batch applications…translating to an estimated $171-537 million in early revenue benefit.” In addition, the assessment displayed “no substantial regulatory barriers” for CM applications related to manufacturing process changes or pre-approval inspections.

Over the last decade, companies like Pfizer, Eli Lilly, GlaxoSmithKline, and others have proven CM’s commercial success, which is also indicative of the kind of potential this process holds to drive future trends in pharma manufacturing. Over a half-dozen medicines have already been made by using CM and have been approved in the US.

Along with this, semi-continuous manufacturing is also growing in popularity. This technique combines the elements of both – batch manufac-

turing and continuous manufacturing. As a result, certain stages of the process are operated continuously, while others are carried out in batches. Nonetheless, CM continues to remain a popular choice.

Given the recent technological advancements, regulatory developments, and commercial products, continuous manufacturing is registering noteworthy growth in the pharma industry. Regulators are also pushing CM along with harmonised guidance development to ensure maximum clarity regarding various approaches and concepts associated with it.

But just like the two sides of a coin, along with CM's success and growth rate, the challenges associated with it demand equal attention. Manufacturers are facing economic and workforce capacity challenges associated with CM start-up activities, upfront investment costs, and regulatory uncertainties in certain geographies. Therefore, to successfully implement CM in every pharma manufacturing facility, the key focus should be key investments, advancing scientific and technical knowledge, and additional incentives.

References

1. https://straitsresearch.com/report/continuous-manufacturingmarket

2.https://www.sciencedirect.com /science/article/pii/S03785173220 03337#!

3. https://www.fda.gov/regulatory-information/search-fdaguidance-documents/q13-continuous-manufacturing-drug-substan ces-and-drug-products

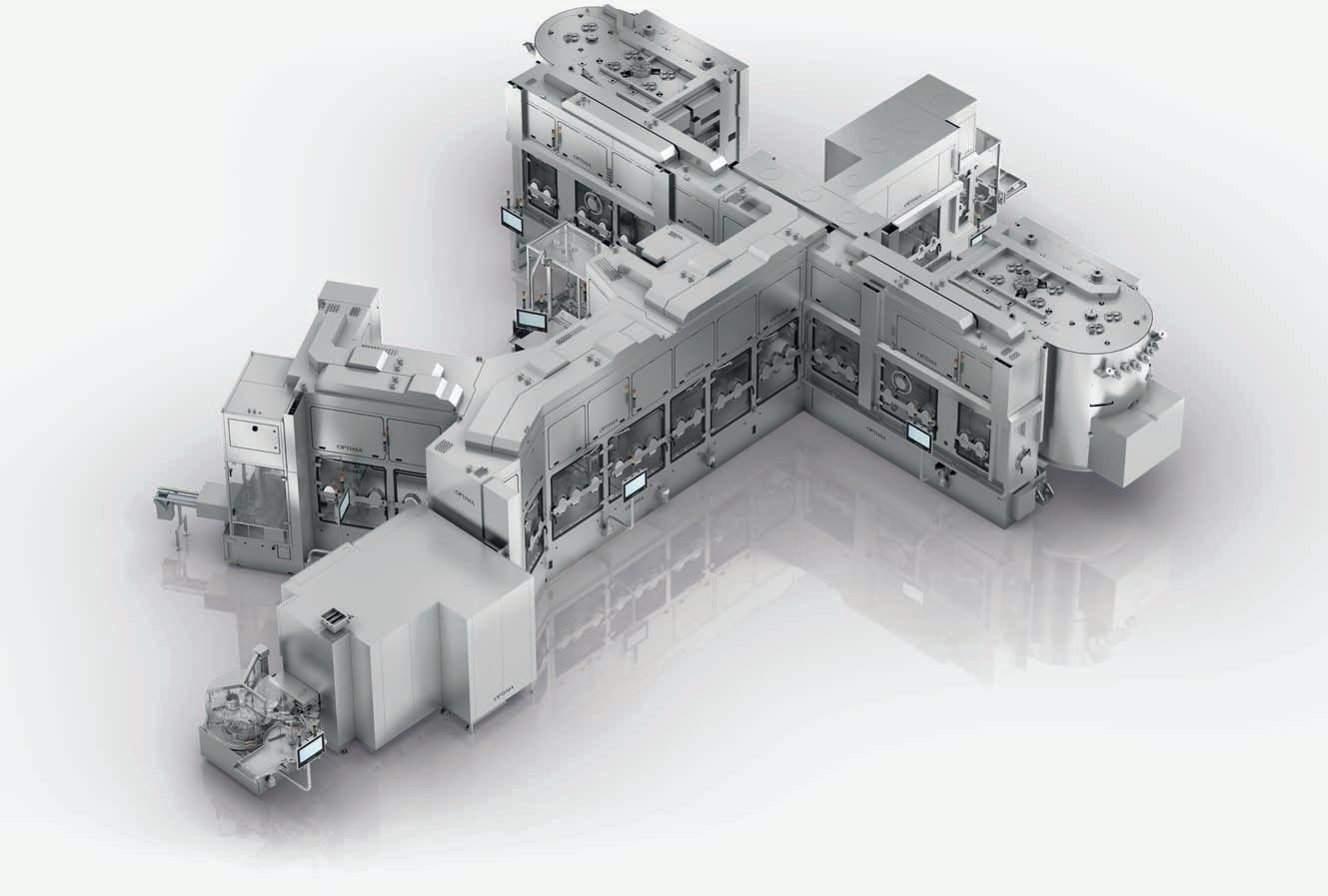

⚪ Turnkeyapproachforthecomplete filling linewithisolatorandfreezedryers

⚪ Weconsistentlyalignourprocessesto meettheneedsofourcustomers

⚪ Weassureourcustomerscompetence, safetyandreliability

⚪ OptimaPharmaisanexpert,partner andthehomeforturnkey

OPTIMApharmaGmbH |74523SchwaebischHall|Germany|pharma@optima-packaging.com|www.optima-packaging.com/pharma

OPTIMAIndiaPackagingMachinesPvt.Ltd. |unit110,1stfloor|BrigadeRubix,PlotNo.20|HMTmainroad|Bangalore560013 info-in@optima-packaging.com|Phone:+918046525900|www.optima-packaging.in

Driven by stringent regulations,rising investor expectations,consumer demand,and operational considerations,MSME pharma companies need to carefully balance their sustainability goals with financial viability

By Viveka Roychowdhury

Prime Minister Narendra Modi’s mention of ‘green jobs’ in his Independence Day speech this year re-emphasised his commitment to achieving the Net Zero emissions target by 2070. The question is how will India, arguably the world’s third-largest greenhouse gas emitter, achieve this target, with even the goal of limiting global warming to an increase of no more than 1.5 degrees Celsius (1.5°C) above pre-industrial levels, looking like a steep challenge?

As the market regulator, the Securities and Exchange Board of India (SEBI) has added heft to the net zero target, by expanding the disclosures that listed entities need to make related to Environmental, Social and Governance (ESG) factors.

A SEBI circular dated July 12, 2023 mandates that the top 150 listed entities (by market cap) had to undertake reasonable assurance of Business Responsibility and Sustainability Reporting (BRSR) Core from FY23-24, and this will extend to the top 1000 listed entities by FY26-27. The circular also requires the top 250 listed companies by market cap to disclose BRSR Core information for their value chain in their Annual Reports for FY24-25 on a comply-or-explain basis.

As Ramesh Swaminathan, Executive Director, Global CFO and Head of Corporate Affairs, Lupin points out, the pharma industry’s contribution to the climate crisis comes from its 4.4 per cent share of global CO2 emissions. Although this percentage is lower than that of other industries, without action, emissions are expected to rise. Thus, he points out that the pharma industry has a unique responsibility to take action and promote sustainability. While it needs to reduce its greenhouse gas (GHG) emissions through net-zero strategies, it also needs to address the adverse health effects of the climate crisis by providing affordable medicines.

Listed pharma companies in India have been reporting on their ESG initiatives for the past few years. Quoting from the

Our success in Sustainability within a short period of time is a solid example for companies wanting to start incorporating sustainability in business practices.We at Lupin did our basics right while we integrated sustainability into business operations

Ramesh Swaminathan Executive Director,Global CFO and Head of Corporate Affairs,Lupin

These steps not only reduce environmental impact but also improve operational efficiency,making them attractive to investors who are increasingly looking for companies that prioritise sustainability

Mehul Shah Promoter & Managing Director,Encube Ethicals

Pursuing green certifications,can enhance a company’s credibility and demonstrate a commitment to environmental responsibility,thereby, attracting investors and partners interested in supporting sustainable initiatives

Anil Matai

Director

General,Organisation of Pharmaceutical Producers of India (OPPI)

To further incentivise the sector,the government should introduce green subsidies,tax breaks,and low-interest loans for eco-friendly technologies.Focus on sustainability is fundamental for all organisations and this will contribute to sustainable performance from a longterm perspective

Sudarshan Jain Secretary General,Indian Pharmaceutical Alliance

EY-CII 2024 report ‘How can Sustainability and ESG be the microscope and telescope in the Indian healthcare sector?, Nitesh Mehrotra, Partner, ESG & Sustainability, EY India highlights increasing allocations towards environmental and social initiatives within research and development (R&D) and capital expenditure (capex). 21 per cent of spending is dedicated to environmental and social activities in R&D, showcasing a commitment to innovation and sustainable practices. Equally noteworthy is the allocation of 13 per cent of spending towards environmental and social initiatives within capex, affirming a strategic commitment to infrastructure and operational enhancements for bolstering sustainability performance.

Toeing the green line Larger pharma companies are toeing the SEBI line and are also prominent on global ESG ratings. In December 2023, Dr Reddy’s Laboratories became the first Indian pharma company to earn a place in the Standard & Poor Dow Jones Sustainability World Index (DJSI World) for 2023. Alongside its debut in DJSI World, the company retained its place in the Dow Jones Sustainability Index for Emerging Markets (DJSI EM) for the eighth year in a row. Dr Reddy’s scored 77/100 in the 2023 S&P Global CSA, achieving full scores in Innovation Management, Impact on Access to Healthcare, Climate Risk Management, and Resource Efficiency and Circularity. The company ranked in the top decile percentile and achieved the sixth-highest score out of 347 companies assessed in the pharma industry in the S&P Global CSA. Dr Reddy’s S&P Global ESG score, measuring the company's performance on and management of material ESG risks, opportunities and impact, is 78/ 100. Dr Reddy’s has been awarded ‘Gold Medal’ status by EcoVadis, the global sustainability ratings agency, for its score of 70/100 in its 2023 scorecard.

A Dr Reddy’s spokesperson’s

statement also informed that in 2022, the company’s largest formulations manufacturing facility in Bachupally joined the Global Lighthouse Network (GLN) of the World Economic Forum - a community of over 100 manufacturers that are showing leadership in applying Fourth Industrial Revolution (Industry 4.0 or 4IR) technologies to drive impact in productivity, workforce engagement, sustainability and supply chain resilience. In addition, five of the company’s manufacturing facilities are certified under Indian Green Building Council (IGBC). In FY2024, the company evaluated 26 products through chemistry gate clearance. Through the implementation of 17 cost improvement projects leveraging green chemistry principles, Dr Reddy’s successfully reduced nearly 22 per cent hazardous waste generation in the manufacturing of those products.

Lupin embarked on their sustainability journey four years ago, and made an entry in the S&P Global Sustainability Yearbook 2024, with a notable Corporate Sustainability Assessment (CSA) score of 65/100, and an S&P Global ESG Score of 69. Sun Pharma's CSA and ESG scores were both 68, Cipla's CSA was 67, ESG 70, and Neuland Laboratories had a CSA score of 60 and ESG score of 64. Similarly, Biocon’s S&P Global CSA score was 61, and ESG score was 63, placing it among the Top 10 global biotech companies.

Sudarshan Jain, Secretary General, Indian Pharmaceutical Alliance, which represents large Indian pharma companies, summed up this evolution, saying, “Sustainability is a strategic priority for pharma companies as the sector involves a significant environmental footprint. IPA members are advancing green practices including sustainable supply chains, efficient technologies, carbon neutrality, waste management, and energy and water conservation practices. Financial sustainability, achieved by integrating ESG principles, ensures long-term stability and growth.”

Anil Matai, Director General, Organisation of Pharmaceutical Producers of India (OPPI), which represents India subsidiaries of MNC pharma companies, believes that true

sustainability involves adopting a long-term perspective that prioritises the well-being of both the people and the planet. This entails a dedication to social, environmental, and civic

responsibilities that go well beyond immediate gains. OPPI’s publication titled, Putting the Country First Taking the Country Far, lists the efforts of OPPI member companies.

As an ESG consultant, Sunil Kumar, Director, SIPL also concurs that the pharma sector is increasingly making investments in sustainability, driven by a combination of regulatory

pressures (for instance, regulations like the European Union's Green Deal and the US Securities and Exchange Commission's ESG disclosure requirements are becoming more stringent), investor expectations, consumer demand, and operational considerations.

With +20 clients in the pharma and related intermediate sectors, SIPL has conducted life cycle Assessments (LCAs), and provided ESG solutions and SimaPro software to pharma majors like Novartis, Sun Pharma, Biocon, Ajanta Pharma, Dorf Ketal, Gharda Chemicals, Cardolite Specialty Chemicals, Anupam Rasayan India, SRF, etc.

Giving the equipment manufacturer’s point of view, Shivshankar SR, CEO, ACG Packaging Materials, reiterates that it is important for organisations to proactively set targets and focus on long-term initiatives that will provide value realisation and business transformation towards creating a more sustainable and resilient future. He mentions that within ACG’s business, their adherence to the Science Based Targets initiative (SBTi) through their recently announced strategic partnership with EY Parthenon, underscores their commitment to conscientious corporate stewardship.

Summing up, Shivshankar of ACG Packaging reminds us that the mission to reduce the overall carbon footprint remains a driving principle for the pharma sector, with a focus on making manufacturing ‘contained, continuous and connected’ - optimising raw material use and reducing waste.

Shivshankar singles out large-scale manufacturers who must expedite net zero objectives, thereby effectuating a meaningful reduction in their carbon emissions. While he concedes that embarking on the journey towards decarbonising entire processes will undoubtedly prove overwhelming for many, he reminds us that “ultimately it’s about looking towards the future and trying to understand wide-ranging

stakeholder needs to create long-term and effective solutions.”

MSME pharma sustainabilitypath

But MSME pharma companies are also a huge part of India Pharma Inc. According to the Confederation of Indian Industries (CII), there are around 8,000 small and medium enterprises (SME) units, accounting for about 70 per cent of the total

Transparent reporting of ESG metrics not only enhances investor confidence but also serves as a barometer of a company's resilience and adaptability in a rapidly evolving world.Integrating ESG into investment strategies not only aligns with ethical imperatives but also unlocks opportunities for sustainable growth

Nitesh

Mehrotra Partner,ESG & Sustainability,EYIndia

Government support is crucial for MSMEs to embrace sustainability.Key incentives include financial support, tax benefits,regulatory support,skill development and public procurement preference

Sayooj Thekkevariath,

Partner,Climate Change and Sustainability Services,EYIndia

highly regulated environment.

One of the primary challenges the industry faces is the inherent resource intensity of pharma manufacturing. The production of drugs requires significant amounts of water, energy, and raw materials, which contribute to a substantial carbon footprint. Furthermore, the management of pharma waste, especially active pharma ingredients (APIs), poses significant environmental risks if not handled responsibly. The complexity of global supply chains adds another layer of difficulty in ensuring that sustainability is maintained at every stage of production, explains Shah.

The energy requirement for continuous manufacturing goes down by 50-70 per cent in a few cases.That's very significant as a lower energy requirement translates to not just huge savings but also a huge reduction in the carbon footprint

Indu

Bhushan CEO & Director,STEERLife

number of the pharma units in India.

Forward looking mid size pharma companies have already committed to ESG goals realising that there are multiple benefits beyond compliance.

As Mehul Shah, Promoter & Managing Director, Encube Ethicals puts it, “Sustainability is more than a commitment, it's a path to operational efficiency and long-term value creation.”(https://www.

expresspharma.in/sustainabilityis-more-than-a-commitment-itsa-path-to-operational-efficiencyand-long-term-value-creation/)

Summarising the challenges, Shah points out that with growing awareness of the environmental impact of pharma manufacturing, such as pollution from toxic discharges, pharma companies face the challenge of balancing their sustainability goals with the economic pressures of operating in a

Drawing on his experience as an ESG consultant, Sunil Kumar comments that the sustainability journey for pharmaceutical companies, including smaller and MSME pharma clients, has varied widely depending on their size, resources, and initial practices. However, there are common outcomes and best practices that can guide MSME and smaller pharma companies in their sustainability efforts.

Enumerating some best practices, Sunil Kumar says that for MSME and smaller pharma companies, the way forward involves integrating sustainability into core business strategies and operations. “By starting with manageable changes, leveraging support, setting goals, and fostering a culture of continuous improvement, these companies can achieve significant benefits and contribute positively to environmental and social outcomes. As the industry evolves, ongoing adaptation and commitment to sustainability will be key to longterm success and resilience.”

Enumerating the early steps that MSME pharma companies can consider as they could result in quick gains to encourage more investments in sustainable manufacturing practices, Shah suggests that before making any major changes, the first step should be to optimise what the company has.

Operations can become sustainable if companies can enhance the lifespan and performance of machinery, reduce downtime and minimise resource use. This evaluation helps identify areas where simple optimisations can lead to significant improvements.

For instance, companies can start by improving energy efficiency and result in immediate reductions in energy consumption and costs. Implementing water conservation techniques, such as low-flow fixtures or rainwater harvesting, can reduce water consumption quickly. Companies can also explore the reuse of treated wastewater for non-critical operations like cleaning or cooling systems. Shah reasons that these steps not only reduce environmental impact but also improve operational efficiency, making them attractive to investors who are increasingly looking for companies that prioritise sustainability.

He also singles out ‘green financing’ as another popular avenue for quick gains in sustainability. Simply put, this is a type of loan designed to promote environmentally-friendly activities, encouraging companies to invest in projects that reduce their environmental impact. These loans come with reduced interest rates, providing financial incentives for companies to meet their sustainability goals.

For example, Shah points out that Biocon’s $1.2 billion green loan to fund its purchase of Viatris’ biosimilars business last year, was one of the largest green loans raised by a pharma company in the APAC region. The company agreed to meet certain sustainability targets that helped reduce the cost of the loan.

As EY India’s Mehrotra explains, “Transparent reporting of ESG metrics not only enhances investor confidence but also serves as a barometer of a company's resilience and adaptability in a rapidly evolving world. Integrating ESG into investment strategies not only aligns with ethical imperatives

but also unlocks opportunities for sustainable growth.”

Adding to the suggestions, OPPI’s Matai advocates that educating and training employees on sustainable practices fosters

a culture of sustainability within the organisation, which can have a ripple effect on overall operations. From the investability angle, he agrees that “Pursuing green certifications,

can enhance a company’s credibility and demonstrate a commitment to environmental responsibility, thereby, attracting investors and partners interested in supporting sustainable initiatives.”

Sayooj Thekkevariath, Partner, Climate Change and Sustainability Services at EY India goes further, stating that to make sustainability truly

Highprecision measurementswithmultiple channelsforreliable measurementatsites

Measurementdata memoryfor1million values

Robustmetalhousingand protectionagainstdustand waterjets

Automatedtemperature andhumiditymonitoring withconnectableprobes

Ÿ Easyinstallationsaves timeandeffort

Ÿ Dataaccessibilityfrom anywhereanytimeon

(Choosefromvarioussoftware-basictoCFR21part11compliant,exceptsaveris2)

sustainable in pharma, a holistic approach is essential. This involves adopting circular economy principles like recycling, reusing, and recovering materials which can significantly reduce waste and resource consumption. It also involves leveraging digital technologies for process optimisation, supply chain visibility, and energy management which can enhance efficiency and reduce environmental impact.

Similarly, collaborative partnerships with suppliers, academia, and industry peers can accelerate innovation and knowledge sharing whereas risk management, involving identifying and mitigating environmental risks can prevent costly disruptions and enhance resilience.

However Thekkevariath cautions that companies need to consider a long-term perspective, as viewing sustainability as a long-term investment rather than a cost can drive strategic decision-making.

In terms of early steps leading to quick gains, Thekkevariath opines that to incentivise early investments, the industry can focus on energy efficiency, waste reduction, water conservation and employee engagement.

Lupin’s sustainabilitystory

Swaminathan offers Lupin as an example of achieving success in sustainability within a short period of time. Lupin’s mantra: get the basics right while integrating sustainability into business operations.

Swaminathan touches on five aspects of this journey. Firstly, integrating sustainability into the core business strategy, “ensuring the integration of sustainability practices into the very fabric of our strategy and this accelerated our journey towards becoming a patient-centric sustainability organisation.”

Secondly, Lupin divided the goals into two pillars: aspirational short term ESG SMART goals and long-term Perpetual Commitments. Swaminathan explains that ESG SMART goals have specific targets and timelines, which are monitored

Companies that proactively addressed sustainability and regulatory requirements were better positioned to comply with evolving regulations and avoid potential fines or operational disruptions

Sunil Kumar Director,SIPL

The mission to reduce the overall carbon footprint remains a driving principle for the pharmaceutical sector,with a focus on making manufacturing ‘contained, continuous and connected’- optimising raw material use and reducing waste

Shivshankar S.R CEO,ACG Packaging Materials

Drawing on his experience as an ESG consultant, Sunil Kumar comments that the sustainability journey for pharma companies,including smaller and MSME pharma clients,has varied widely depending on their size,resources,and initial practices.However,there are common outcomes and best practices that can guide MSME and smaller pharma companies in their sustainability efforts

every quarter, whereas the Perpetual Commitments represent the company’s ongoing efforts to improve, track, and report monthly progress.

Thirdly, Lupin links executive pay to ESG goals, with all president-level personnel having ESG goals as their individual goals. Next, taking this down the line, the company integrates sustainability with employees, where every individual thrives and is valued and empowered to

contribute to the business ESG goals.

And fifthly, Lupin involves their supply chain partners,actively engaging with suppliers, partners, and stakeholders to ensure their environmental and social objectives are shared in pursuance of Lupin’s ESG goals. Sharing a few outcomes of this sustainability strategy, Swaminathan mentions that Lupin’s share of renewable fuel in the energy mix increased by

four times, contributing to 33.8 per cent of total energy derived from fuel sources in FY24. The company achieved a 21 per cent reduction in Scope 1 & 2 emissions from the previous year. Looking forward, the company has successfully committed and joined the “Science Based Target Initiatives” which will drive progress towards decarbonisation of the value chain.

On the water stewardship status, in FY24, 44 per cent of

total water withdrawn at Lupin facilities was recycled, and the company’s target is to achieve 50 per cent by 2025.

Giving an example of Lupin's green chemistry skills, Swaminathan explains how the manufacturing of a particular antiviral molecule previously involved a three-step process, which delivered an overall yield of 0.91 per cent with an e-factor of 88 and an atom economy of 35 per cent. Lupin transitioned into a single-step process, delivering a yield of 1.4 per cent along with an E-factor improvement of 90 per cent and an atom economy improvement of 58 per cent.

Pharma companies in India are in a transition phase, as they explore more sustainable manufacturing concepts. However cost remains a key consideration. Equipment makers however argue that while the initial cost to switch to more sustainable options does involve considerable capex, the long-term savings more than make up. Thus advocating short term pain for long term gain.

One such concept is the switch from batch to continuous manufacturing. Indu Bhushan, CEO & Director, STEERLife mentions that many pharma companies in India have shown keen interest to move from batch to continuous manufacturing, particularly for the granulation and blending stages. These large-volume pharma manufacturers are under tremendous competitive pressure and therefore are constantly on the lookout for ways to improve cost efficiency.

To put the cost pressures into perspective, Indu Bhushan says that with products like metformin, paracetamol, and ibuprofen, which are typically manufactured in tons every day, there is a significant energy cost involved. However, while these active pharma ingredients (APIs) are pretty cheap, there is a significant contribution from conversion cost.

For instance, according to

him, a certain amount of API is lost as dust in the manufacturing process. Even if 0.5 per cent is the dust or the material lost in the cleaning process, different kinds of effluent treatments need to be done, adding to the cost.

So how does continuous manufacturing prove to be more sustainable than traditional batch manufacturing?

For one, Indu Bhushan estimates that the energy requirement for continuous manufacturing goes down by 50-70 per cent in a few cases. That's very significant as a lower energy requirement translates to not just huge savings but also a huge reduction in the carbon footprint, reasons Bhushan.

Listing the other advantages, according to Bhushan, continuous manufacturing also generates less effluents than batch processes, where multiple steps and a larger processing surface area translate to cleaning equipment and effluent treatment costs at every part of the process. These costs are reduced in continuous manufacturing systems.

Continuous manufacturing systems have a smaller footprint and therefore need smaller clean room facilities, further cutting down on energy and other utility requirements.

As continuous systems are also automated, there is less chances of human error and therefore less reliance on quality control (QC) as most responses are measured online. And therefore, QC testing, which typically follows every step of the batch process, is not applicable in contiguous manufacturing, reasons Indu Bhushan.

He estimates that the gains would be greater when companies use continuous manufacturing right from the R&D and development stage, going to fullscale commercial manufacturing at a smaller scale.

As he reasons, “Lots of materials are saved during the development (phase) because whatever experience we gain, we (apply) it directly to the commercial scale. In fact, in the initial years of adoption,

companies have used R&D scale equipment even for commercial scale without involving any scale-up or tech transfer. That not only reduces carbon footprint, but the go-to-market

time also significantly reduces because you have all necessary data at one scale. And we are talking about various options available for a scale-up or increasing the batch size.”

On the time to get RoI, Indu Bhushan estimates that it takes between one and a half to two years for a manufacturer to get RoI on continuous manufacturing. Summing up, he mentions

that apart from RoI, continuous manufacturing offers better flexibility in terms of batch size, reduction in energy and effluents leading to better overall sustainability.

…but also more expensive

Indu Bhushan admits that continuous manufacturing is best applied to large volumes, with systems capable of producing 150-200 kg of material per hour, with STEERLife also providing very large commercial scale equipment producing 500 kgs to custom designing a system for one ton per hour line for a client. These systems are typically integrated and require expensive components, like gravimetric feeding and PAT tools, which are required for measuring loss on drying or content or uniformity from time to time. And that makes it more expensive than a batch processor.

Due to the high costs, he has observed two significant differences between how India and the West started adopting continuous manufacturing.

Firstly, in the evolution from batch to continuous manufacturing, while the West is working on end-to-end continuous manufacturing, India’s pharma companies are at a hybrid stage where continuous manufacturing and automation are currently being deployed for stages which are more prone to human error.

Secondly, Indu Bhushan refers to collaborations between

CONTRIBUTOR’S CHECKLIST

equipment manufacturers and contract development and manufacturing organisations (CDMOs) in the US. For example, GEA has collaborated with Hovione for continuous manufacturing of solid orals (continuous tableting). According to him, similar collaborations should happen in India because companies like STEERLife are not just equipment manufacturers, but also provide process solutions, enabling CDMOs which adopt continuous manufacturing to serve global clients.

Agreen government push

IPA’s Jain recommends that to further incentivise the sector, the government should introduce green subsidies, tax breaks, and low-interest loans for eco-friendly technologies. He believes that this will contribute to sustainable performance from a long-term perspective.

Given the financial constraints faced by MSME pharma companies, Thekkevariath also agrees that government support is crucial for MSMEs to embrace sustainability. Key incentives include financial support (like subsidies, grants, and low-interest loans for green technology adoption), tax benefits (tax breaks for in-

❒ Express Pharma accepts editorial material for regular columns and from pre-approved contributors / columnists.

❒ Express Pharma has a strict non-tolerance policy of plagiarism and will blacklist all authors found to have used/refered to previously published material in any form,without giving due credit in the industry-accepted format.All authors have to declare that the article/column is an original piece of work and if not,they will bear the onus of taking permission for re-publishing in Express Pharma.

❒ Express Pharma's prime audience is senior management and pharma professionals in the industry.Editorial material addressing this audience would be given preference.

❒ The articles should cover technology and policy trends and business related discussions.

❒ Articles for columns should talk about concepts or trends without being too company or product specific.

❒ Article length for regular columns: Between 1200 - 1500 words.These should be accompanied by diagrams,illustrations,tables

vestments in sustainable practices and R&D), regulatory support in terms of simplified regulatory processes for environmental compliance and green projects, skill development involving investing in training programmes to build a skilled workforce for sustainable operations and finally, public procurement preference, which involves giving preference to environmentally friendly products in government procurement.

OPPI’s Matai points out that the recently announced Revamped Pharmaceuticals Technology Upgradation Assistance (RPTUAS) Scheme is a significant step in the government's efforts to help upgrade the technological capabilities of our pharma industry and ensure its alignment with the global standards. Eligibility for the PTUAS has been expanded beyond MSMEs to include any pharma manufacturing unit with a turnover of less than Rs 500 crores that requires technology and quality upgradation.

Sunil Kumar also emphasises that policy incentives can help offset the costs associated with compliance and make sustainability upgrades more finan-

cially feasible for MSME pharma companies.

Light at the end of the tunnel?

Given the challenges, Mehrotra from EY India reminds us that the path towards sustainability is not a sprint but a marathon, demanding unwavering commitment and resilience. He believes that by embedding ESG principles into their DNA, Indian pharma can not only mitigate risks but also drive innovation and foster societal well-being. As he puts it, “The green pill beckons and the time to heed its call is now,” referring to R&D efforts that are yielding breakthroughs in sustainable drug delivery systems and biodegradable packaging. Going forward, Lupin’s Swaminathan projects that the company is aspiring to build a 'Transformational Journey in Sustainability'. “Our focus is to empower employees to drive sustainability not only by metrics or setting ESG goals; we are looking at fostering a sense of purpose, community, and urgency. We believe by creating a culture that supports sustainability, organisations can unlock the full potential of their workforce and make a lasting impact on the planet.”

Shivshankar believes that the industry is moving in the right direction, with visible gains already being seen. “We must continue to work collectively to achieve this goal (of reducing overall carbon footprint), ensuring clear communication and complete transparency” is his call to action.

Summarising the many benefits of embracing sustainable practices across production, R&D and supply chains, SIPL’s Sunil Kumar says, “In my opinion, those companies that proactively addressed sustainability and regulatory requirements were better positioned to comply with evolving regulations and avoid potential fines or operational disruptions.”

Thus while larger pharma companies are well on the sustainability path, mid-size and smaller companies can leapfrog early teething problems by exploring the learnings from these front-runners. Adapting and adopting best practices will need to become an urgent imperative to make sustainability part of their strategic growth plans.

viveka.r@expressindia.com viveka.roy3@gmail.com

and photographs,wherever relevant.

❒ We welcome information on new products and services introduced by your organisation for our various sections: Pharma Ally (News, Products,Value Add),Pharma Packaging and Pharma Technology Review sections.Related photographs and brochures must accompany the information.

❒ Besides the regular columns,each issue will have a special focus on a specific topic of relevance to the Indian market.

❒ In e-mail communications,avoid large document attachments (above 1MB) as far as possible.

❒ Articles may be edited for brevity,style,and relevance.

❒ Do specify name,designation,company name,department and e-mail address for feedback,in the article.

❒ We encourage authors to send their photograph.Preferably in colour,postcard size and with a good contrast.

Email your contribution to: The Editor, Express Pharma, Business Publications Division, The Indian Express (P) Ltd, Mafatlal Centre,7th floor, Ramnath Goenka Marg, Nariman Point,Mumbai 400021 viveka.r@expressindia.com viveka.roy3@gmail.com

As pharma manufacturing evolves to meet dynamic market demands,regulatory shifts and technological advancements, Kavita Jani highlights how effective skilling and training stratergies will be crucial to build a resilient and future-ready workforce

Known as the “Pharmacy of the world”, India is a hub for pharma manufacturing and occupies a hefty 20 per cent share in the global generics volume supply by manufacturing 60,000 different generic brands across 60 therapeutic areas. The industry is poised for considerable growth in the near future and is expected to reach $130 billion by 2030 (currently valued at $50 billion) (1).

With an aim to become more value-driven, India’s pharma in-

dustry is looking beyond generics, targeting innovations in drug development. Such ambitious goals will require robust strategies, and to implement those strategies, the pharma industry will require a resilient and future-ready workforce. India Pharma Inc., must therefore focus on optimising and refining its current processes and practices from the bottom up especially, as a sector that contributes greatly to public health and enhances the overall quality of life.

As a core component of the pharma industry, manufacturing and its associated practices need to constantly upgrade and adapt to the industry's changing trends. Minimising human errors, keeping up with the evolving market demands and regulatory landscapes and adapting to technological advancements are the paramount goals for manufacturing. Therefore, the industry needs to focus on upskilling its shop-floor workforce.

An article by CLR titled

“Skill Gap Analysis of Indian Pharmaceutical Sector” informs, that since a majority of the pharma manufacturing units are located in remote regions, not many are willing to relocate to these areas for employment. Therefore, securing and deploying a skilled workforce with highly specialised skills to ensure Good Manufacturing Practices (GMP) and Good Clinical Practices (GCP) becomes challenging.

Fortunately, recognising the imperative for skilled talent, the

industry is working on ways to plug the talent gap through skilling, reskilling and upskilling initiatives. As per a 2024 Employment outlook report by TeamLease, 86 per cent of Healthcare and Pharma employers have shown serious intentions of expanding their workforce driven by ongoing health demands, the surge in digital education and addressing growing industry needs (2).

Let’s look at a few measures that are crucial to nurturing a skilled workforce.

Bridging the industry-academia gap Industry and academic experts agree that industry readiness and job-specific skilling should begin from the academic level. But, they also admit that the current curriculum and teaching approaches need reform to put this into practice. Sumedha Nadkar, Pharmaceutical Consultant and NMIMS - Visiting Faculty Quality & Regulatory Affairs says that internship opportunities are provided to B.Pharm and M.Pharm students by pharmacy colleges. But, pointing out the challenges, she informs “NM College SVPTMhas a non-teaching staff member dedicated to look after placements. Most colleges are not so fortunate and some teaching faculty have to carry out this task while balancing their regular work (syllabus completion/exam paper setting /checking), and preparing for audits like NIRF, and NAAC.” Therefore, this becomes an arduous task.

Nadkar points out, “Rural pharmacy colleges need more attention. Students here lack the basic English communication skills and require direction on career options,” highlighting the need to improve skilling in institutes at the tier-2 and tier-3 levels. Recommending measures to deal with this issue, she says, “The Ministry of Education/ Rural Development/ Science and Technology can collaborate and invite applications from industry consultants and senior management to host sessions and internship programmes.” Simultaneously, Nadkar also stresses adequate training of the faculty, emphasising their lack of exposure to the industry. To aid industry-academia interactions, she suggests hosting student interactions with the alumni, depending on the alumni’s authority and influence in their organisation. Such interactions can also pave the way for internship or employment opportunities.

Explaining the initiatives that the industry must take to bridge the industry-academia gap, Dr Viranchi Shah, National President, IDMA, stated, “Practical training, classroom training, and involvement in cross-functional teams are some basic things that

the pharma industry does. Interacting and engaging with ITIs, pharmacy colleges and other academic institutions is also on the rise, to ensure that the new entrants to the industry are industry-ready. The overall principle is continuous training and engagement at the lowest possible level and continuous interaction with academic institutes.”

Need for apprenticeships

Sumit Kumar, Chief Strategy Officer, TeamLease highlights apprenticeships as a successful

The Ministry of Education/ Rural Development/ Science and Technology can collaborate and invite applications from industry consultants and senior management to host sessions and internship programmes

Sumedha Nadkar

Pharmaceutical Consultant and NMIMS - Visiting Faculty Quality & Regulatory Affairs

Providing on-the-job training alongside formal education,apprenticeships ensures that the workforce is well-prepared to meet future challenges

Sumit Kumar

Chief Strategy Officer, TeamLease Shop floor workers are the most fundamental contributor to the success or failure of any organisation

Dr Viranchi Shah

National President, IDMA

strategy to skill fresh talent for the pharma industry and bridge the industry-academia gap. “Unlike traditional education pathways, apprenticeships provide a unique blend of on-the-job training and theoretical instruction, ensuring that participants develop practical skills that are immediately applicable in the workplace,” says Kumar. This model is especially beneficial in the pharma sector, where roles like bioprocessing technicians, quality control analysts, and regulatory affairs specialists are be-

coming increasingly crucial. Kumar explains how major pharma companies in the UK have implemented apprenticeship programmes as an effective way to nurture a skilled workforce, ensuring that employees are well-trained and abreast with the latest industry practices. This model has proven to be cost-effective, allowing companies to tailor the training to their specific needs, resulting in a highly competent workforce that is ready to contribute to the industry's growth.

We have similar examples on the domestic front as well. For instance, Dr Reddy’s Laboratories’ concept of ‘Self Management Teams’ (SMT). The company informs that the initiative aims to “create an energetic, vibrant workforce capable of handling plant operations seamlessly.” A Dr Reddy’s spokesperson informs, “Since 2001, through SMT, we have trained over 4,500+ youth (10+2 candidates) from economically weaker sections to help them join mainstream professional life. SMT is an initiative aimed at building an agile and empowered workforce, by providing employment opportunities, appropriate education and training/skilling to create a more engaged and flexible workforce whilst providing livelihood opportunities.”

Thus, apprenticeship programmes act as a talent pipeline builder, providing a great model to address niche manpower shortages, and a steady stream of skilled individuals ready to take on the challenges of tomorrow. In India, the pharma sector has witnessed an expansion in apprenticeship programmes as well. According to TeamLease, the apprenticeship engagement in the sector has grown 25 per cent year-on-year in the last two years to reach 22,731 in 2023-24. Kumar says, “These programmes cover a wide range of roles including lab technicians, drug safety analysts, and retail pharmacy chemists, and have been supported by government initiatives such as the Skill India Mission and the National Apprenticeship Promotion Scheme (NAPS).” He emphasises that these programmes aim to not just fill up job vacancies but also aim to build capacity and capability within the life sciences sector.

“Providing on-the-job training alongside formal education apprenticeships ensures that the workforce is well-prepared to meet future challenges, particularly in areas like digital manufacturing, data analytics, and AIdriven drug discovery,” says Kumar.

Upskilling to build competency

The second stage of training is

September 2024

skilling the freshly acquired talent according to their job role and upskilling the long-term workers to enhance their adaptability to the dynamic and developing nature of the industry. Advancing technology, increasingly diverse demands and the changing regulatory landscape demand for the workforce to be adaptable, well-versed with the latest technological advancements, and regulatory compliance.

As per a USFDA Congressional report published in 2020, India stood the lowest among India, the EU, the USA, China and the rest of the world with only 86 per cent of drug facility inspections with acceptable outcomes (3). Moreover, during 2023 and 2024, 35 Indian companies re-

We aim to ensure that our manufacturing teams are not only prepared for current challenges but also equipped to handle future advancements and regulatory shifts in the industry

Rajendra B Chunodkar President – Manufacturing Operations, Lupin

”As a talent pipeline builder,apprenticeship programmes are a great model to address niche manpower shortages,providing a steady stream of skilled individuals ready to take on the challenges of tomorrow”

but also implement methods that can enhance the competency of regulatory compliance to the shop floor workers.

Highlighting the crucial role of the shopfloor workers, Shah says, “Shop floor workers are the most fundamental contributor to the success or failure of any organisation.” Considering that real quality is built by workers, operators and supervisors who work on the shop floor, Shah adds, “The major gap as far as manufacturing operations is concerned is in getting skilled machine operators, and also in skilled people on ground-level QMS implementation.”

With the increasing influence of automation, digitalisation, and the increasingly precise and technologically advanced equip-

Fortuitously, the industry is taking several measures to provide on-the-job training to its employees. Rajendra B Chunodkar, President – Manufacturing Operations, Lupin provides insights into what strategies Lupin implements to ensure its employees are prepared for audits. “We regularly conduct mandatory training sessions on regulatory standards, audit procedures, and the latest guidelines from regulatory bodies such as FDA, EMA, and CDSCO.” He highlights how Gemba walks and internal mock audits aid in simulating real-world scenarios and encourages quick thinking and cross-functional collaboration to ensure that all Lupin’s departments are aligned and prepared for audits and regulatory inspections.

Chunodkar adds, “We have taken a holistic approach to peo-

ple development for shop-floor personnel, including training on 5S Methodology and Six Sigma green belt and black belt training, language training for our shop floor operators, hyper-personalised communication coaching, and gamified learning for SOPs, GMPs, and Audit Interactions, among others.” This ingrains adherence to regulations into their daily operations.

Additionally, as per a 2024 employment outlook report by TeamLease, there’s a growing demand for niche skills in AI, ML, data analytics, and medical coding to derive healthcare insights and contribute to the ongoing transformation in manufacturing, precision medicine and diagnosis (2). These sophisticated tools can help focus on

lean manufacturing practices, reduce waste and improve production efficiency.

Shah explains, “The pharma industry is fast adopting automation and digitalisation, and the involvement of technology in equipment is also increasing. Continuous practical training of the shop floor teams to keep them in pace with the changes is therefore very important.” Therefore, as the pharma sector moves towards digitalisation, leveraging digital technologies to improve productivity, efficiency and innovation becomes increasingly important.

Explaining the methods that Lupin implements, Chunodkar adds, “Our employees receive extensive hands-on training on new technologies, including machinery, software, and automation systems. We also partner with technology providers for

continuous support, updates, and advanced training sessions to keep our teams ahead of the curve.”

Conclusion

Quality control, learning how to operate machinery and the competency of regulatory compliance are some of the governing factors of pharma manufacturing. Given the advancing state of technology, and increasing demand in society for quality medications and treatments leading to a consequential increase in production and evolving regulatory landscapes, the pharma industry must be equipped with a talented and competent workforce, from the ground up. Thus skilling this workforce from its root (i.e.) academia level, and continuing to upskill them as employees is an investment that can guarantee the benefits of an

agile and skilled workforce in the long run.

References

1.https://www.investindia.gov.in/ sector/pharmaceuticals#:~:text= The%20pharmaceutical%20industry%20in%20India%20is%20 currently%20valued%20at%20% 2450,all%20medicine%20in%20t he%20UK.

2. https://group.teamlease.com/ insights/employment-outlook-report-h2-fy24/

3. https://www.fda.gov/newsevents/congressionaltestimony/covid-19-and-beyondoversight-fdas-foreign-drug-man ufacturing-inspection-process06022020

4. https://blog.clrskills.com/skillgap-analysis-of-indian-pharmaceutical-sector/

kavita.jani@expressindia.com kavitanjani@gmail.com

Experts and leaders from the pharma industry congregated to highlight Aurangabad’s role in India’s pharma landscape and discuss issues that are vital for the industry's future growth and success

Express Pharma recently organised the inaugural edition of the Aurangabad Pharma Summit 2024 with a vision—to cocreate an ecosystem that fosters innovation, excellence, and growth within the pharma sector.

It brought industry leaders, innovators, and experts from the city to discuss and explore its rich legacy in manufacturing and industry, and its emergence as a hub of pharma excellence.

Over the course of this summit, experts explored key topics that are critical to the pharma industry’s progress—from advancements in digital technologies to sustainable practices, regulatory challenges, and beyond. These discussions are not just timely but essential as we navigate an era of rapid change and unprecedented challenges.

The event also offered opportunities galore for networking and interaction.

It kickstarted with a lamplighting ceremony and a welcome address from Express Pharma.

L-R: Dr SanjayToshniwal,Central Council Member,PharmacyCouncil of India; Pradipkumar N Patil,VP– Quality,Ajanta Pharma; Dr Prashant Musmade,Data ReliabilityOfficer,GlenmarkPharmaceuticals; Zoher Sihorwala,Senior VP& Head – Global Regulatory Affairs,Wockhardt; Dr Varda Bapat,COO,RVLifesciences; Sumeet Sharma,Sales Director,Cilicant; and Sunil Khera,Ex-President, Wockhardt Americas

Komal Bhavsar, AGM-Business Development, Cilicant, gave a compelling presentation on ‘Innovations in active packaging’ at the Aurangabad Pharma Summit 2024. The session focused on the latest advancements in active packaging technology and their impact on the pharma sector. Bhavsar highlighted how these innovations are crucial in ensuring product stability, extending shelf life, and improving patient safety.

Bhavsar emphasised the growing importance of intelligent active packaging solutions and elaborated on Cilicant's offerings to meet the evolving demands of the industry. The presentation provided an in-depth look into how active packaging not only protects but also interacts with the contents, thereby preserving their efficacy and safety.

Her presentation spotlighted Accuflip, a humidity regulator provided by Cilicant. She informed that this product plays a crucial role in maintaining the

Komal Bhavsar,AGM-Business Development,Cilicant

ideal moisture levels within capsules, preventing them from becoming too dry or overly moist. This control over humidity is vital for ensuring the stability, effectiveness, and efficiency of pharma products.

She also showcased Cilicant's FREXIL dust-proof canisters. Bhavsar explained that these canisters were developed in response to the common issue of dusting associated with activated carbon-based canisters. The FREXIL canisters are designed with a patented technology that not only safeguards pharma products from potential contaminants but also eliminates the dusting problem, which is a critical concern in maintaining the cleanliness and safety of packaging.

The session concluded with valuable insights on adopting Cilicant's smart active packaging solutions to optimise packaging strategies, enhance product quality and improve customer satisfaction.

The first panel discussion at Aurangabad Pharma Summit focused on Aurangabad's contribution to Maharashtra's leadership in the pharma sector.

This discussion was moderated by Dr Prashant Musmade, Data Reliability Officer, Glenmark Pharmaceuticals; Dr Varda Bapat, COO, RV Lifesciences; Anshu Manocha, Site Head (Executive GM), Indoco Remedies; Dr Sanjay Toshniwal, Central Council Member of the Pharmacy Council of India; and Manoj Patil, DGM-Production, Ajanta Pharma were the other other esteemed panelists for this discussion. They shared their insights on the region's strategic importance and future potential.