6 minute read

High pressure solutions

With over 60 years of experience in the business, LMF is the leading Austrian manufacturer of high-pressure piston compressor systems. Julia Snow spoke to the sales director, Günther Ognar, to find out about the company’s specialist solutions.

From engineering to manufacturing, testing, start-up and maintenance – Leobersdorfer Maschinenfabrik (LMF) provides the full range of services expected of a one-stop provider.

Located 30km south of Vienna, LMF employs 355 staff at its state-of-the-art engineering and production facilities. The company achieves an annual output of up to 200 specialised compressors – equivalent to a total weight of 3300 tons – and a turnover of around €80 million. The careful selection of raw materials and outsourced components guarantees the highly reliable operation of LMF compressor systems, even in the most demanding environmental conditions.

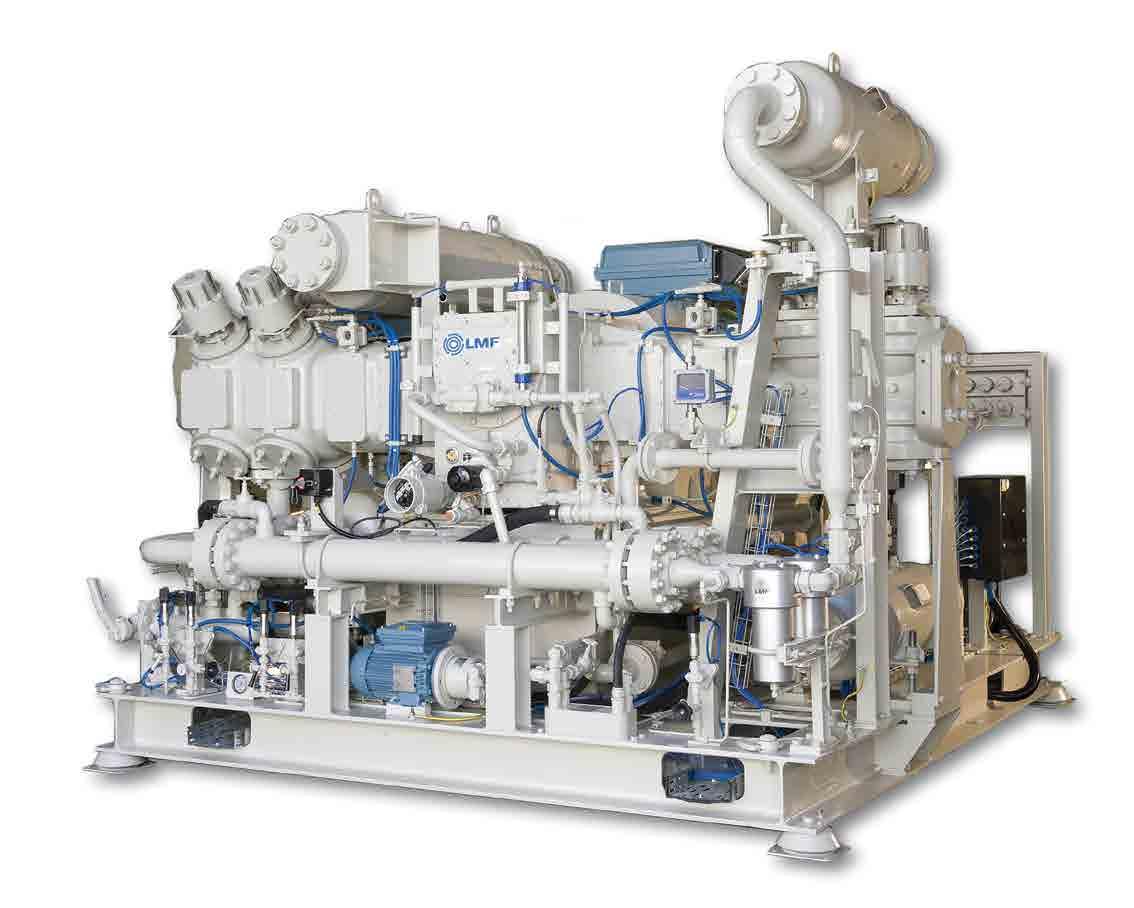

Systems for air and natural gas as well as technical and industrial gases, the modular structure of the product portfolio is ideally suited to respond to different technical and economic requirements. LMF specialises in high-pressure piston compressor systems

with a power range of up to 6200kW and final pressures of up to 10,150psi, developed exclusively to individual client specifications.

Long history as technology leader

The company was initially established as an iron foundry in 1850, producing raw castings and, later, parts for transmissions. In 1887 LMF was sold to Ganz & Co, Budapest, and transformed into an AG in 1907. During this period, water turbines were added to the product programme, while Viktor Kaplan, inventor of the Kaplan turbine, was employed as a design engineer. Another famous name associated with the company was Rudolf Diesel, who sold a licence for the manufacturing of Diesel engines to LMF at the end of the 19th century, resulting in the production of diesel engines from 1902.

After a period of Soviet administration from 1945 to 1955, LMF was bought by Egon Strager and renamed MAW Strager Maschinenfabrik in 1956. But the transformation into a worldwide operating company came with the take-over by the German division of Babcock in 1963, which gave LMF access to the resources of a global group. In 1998 an Austrian investor acquired the company which has since been in the ownership of various investors, thereby gaining independence in all operations.

In addition to European presences LMF operates sales offices in Mexico, Russia, the UAE, India and China.

Business units serve industry needs

The main business field for LMF is the oil and gas industry and the chemical/petrochemical industry, as well as applications in industrial and food technology settings.

LMF is well known for its tailor-made API compressors, which are produced for refineries, petrochemical and chemical plants, says Mr Ognar: “We sell to the end customers in this market as well as to EPCs who undertake plant newbuilds or refits.” Applications include underground storage for CO2 natural gas, desulphurization, flare gas, gas re-injection as well as boil-off gas.

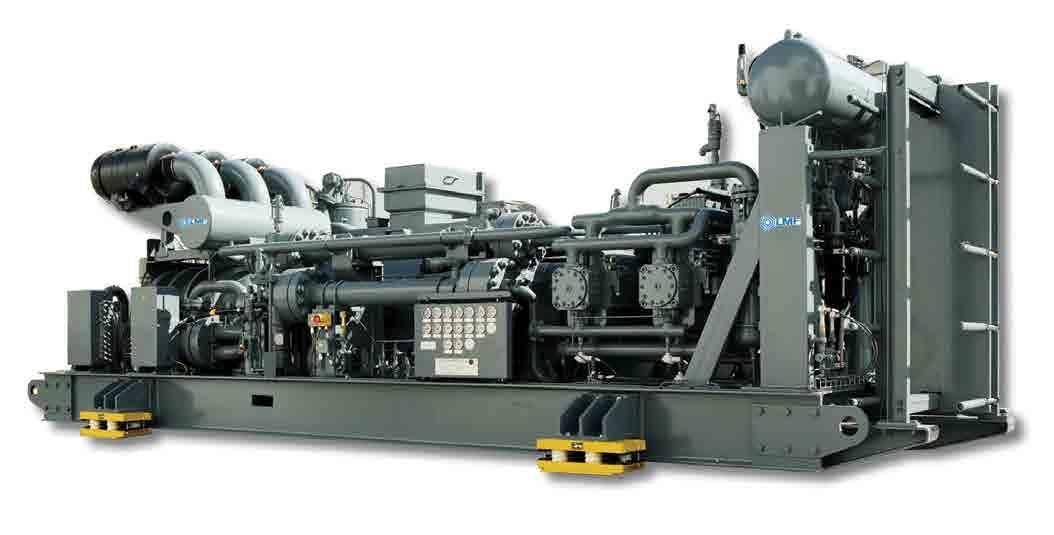

The second major business unit specialises in mobile systems for offshore applications onboard seismic survey vessels and for onshore applications. These systems are mounted on trucks or trailers for pipeline and oilfield service applications such as pipeline pressure testing, pipeline evacuation or on-site nitrogen production. “We have around 90–95 per cent market share in this field worldwide,” says Mr Ognar, “and we expect further growth due to our unmatched levels of know-how.”

Around 10–15 per cent of turnover is represented by the third unit, which provides standard compressors for gas in industrial

ELIN Motoren GmbH

With more than 120 years of experience in development and production of electrical machines, ELIN Motoren GmbH is one of the most traditional industrial enterprises in Austria.

Motors for low and high voltage applications from 400V up to 15,000V and from 50kW up to 35,000kW are produced as well as asynchronous generators from 500kW to 5,000kW and synchronous generators from 5,000kVA to 50,000kVA. ELIN Motoren GmbH offers support throughout the life cycle of the machine as well as an extensive scope of services, with central technical handling at Preding/Weiz and the support of an international network of certified service partners worldwide. The company’s strengths lie in the production of small and medium quantities, as well as custom-tailored products, designed precisely to customer’s specifications. Serial production is also covered by innovative partnerships (for example licences, joint ventures, outsourcings,…). The customers are offered all the advantages of a flexible business.

ELIN Motoren GmbH motors and generators are in use worldwide, especially in the following fields: Wind Energy, Industrial Plant Applications (cement, steel, metallurgy, paper, pulp, …), Power Plants, Decentralised Energy Systems and Small Hydro-Plants, Tunnel Boring and Mining, Plastics Industry and in the field of Gas & Petroleum.

applications, PET bottle processing and in the field of CNG and CBG, where the product portfolio ranges from bare blocks to compressor units with control systems and accessories up to turn-key CNG filling stations.

Engineering excellence

“LMF has a dedicated group of R&D engineers working on the further development of our products, but in addition the engineering departments of all business units draw on this know-how when fulfilling specific orders.” explains Mr Ognar.

Protecting natural resources is at the heart of the company, he adds: “We are in full compliance with the stringent European and Austrian legislation. It is in our utmost interest not to waste any material or natural assets, so one of our main driving factors in new product development is to increase the efficiency of operation for our end users, which leads to optimising energy-efficient operation of our products.” A dedicated aftersales service department supports customers for maximised performance. Global potential in specialist markets

LMF is aiming for profitable organic growth, with some geographical expansion also on the cards, says Mr Ognar: “Currently, our main markets are Europe, Asia and the Middle-East, but we are planning to increase our activities in China and develop the potential of the South-American markets.”

LMF intends to capitalise on its technology leadership in the industry. “One of our recent innovations is a new series of mobile pipeline evacuation units, which reduce the emission of methane during gas pipeline repair jobs. This not only salvages the valuable gas, but also protects the environment, given the fact that methane is 21 times more harmful than CO2.” And a second business field – the substitution of natural gas by bio-gas in the gas grid business – offers a future path to growth for the company: “We are among the two top world leaders in terms of technological advances when it comes to CBG applications, so we know that our activities will increase considerably here.” n