4 minute read

Driving into new markets Bharat Forge Kilsta

DRIVING INTO NEW MARKETS

Bharat Forge Kilsta is part of one of the world’s leading forging groups. Abigail Saltmarsh looks at its role within the Bharat Forge group and its plans for significant growth.

AT Bharat Forge Kilsta in Sweden, the drive is on for an increase in output and significant growth by 2016. The managing director, Juho Nömm, says that the forging company is seeking new markets and is investing in its equipment at its operation in Sweden.

“We have a strong market in Scandinavia and Europe and will not be seeking to go beyond that. We are part of a group that covers other regions and so we are very focused on where we already are geographically,” he says.

“However, we are keen to move into new markets. Most of our customers are from the automotive industry and we feel that we are too reliant on it. It would therefore be sensible for us to look at moving into other areas.

“We do have a plan to increase our output over the coming years. We are looking for organic growth and would like to expand by 30 per cent by 2016.”

A world leader

Bharat Forge Kilsta AB is a 100 per cent subsidiary of Bharat Forge Ltd, the world’s largest full service supplier of forged engine and chassis components, non-automotive components and systems. Headquartered in India, Bharat Forge Ltd has manufacturing operations across nine locations and six countries.

Bharat Forge, which is part of the Kalyani Group (a US$ 2.5 billion conglomerate with a 10,000 global workforce) has manufacturing facilities spread across India, Europe and China. It manufactures a wide range of safety and critical components for the automotive and industrial sector and is a leading manufacturer of powertrain and chassis components with market leadership in all major markets.

Bharat Forge’s customer base includes virtually every global automotive OEM and Tier one supplier, including the top five commercial and passenger vehicle manufacturers. Like Bharat Forge Kilsta, the group as a whole has embarked on an ambitious journey to redefine its already existing presence across several critical business verticals such as energy, oil and gas, aerospace, rail and marine, and other infrastructure-related businesses.

A specialist in Sweden

“Bharat Forge Kilsta is the only Swedish company within the group. We work closely with other companies within the group, especially CDP Bharat Forge, Germany,” Mr Nömm explains. “Being part of the largest forging group in the world does give us vital support.”

Bharat Forge Kilsta itself has a long tradition in the business. Today it specialises in heavy crankshafts, front axle beams, steering knuckles and other steering components.

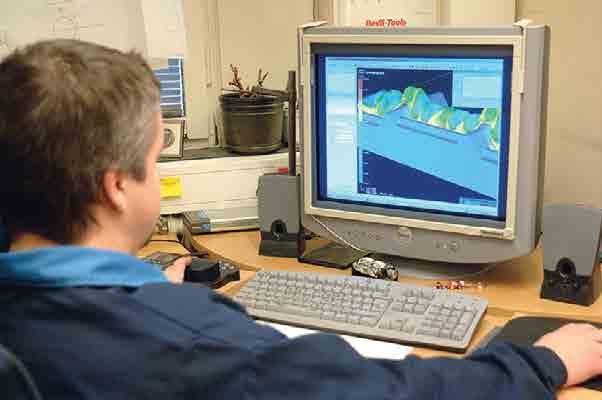

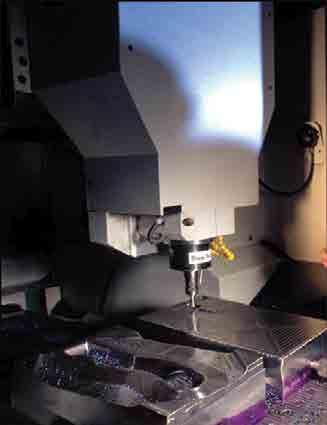

Its forge is equipped with the latest technology, in both the forging presses and ancillary equipment, in order to meet the high demands of the automotive industry with regards to quality, tolerances, drafts and design.

Among other equipment, it runs one of the most powerful and fully computerised forging presses in the world. This is used for the production of heavy diesel engine crankshafts and front axle beams for trucks and buses.

“We are currently making a large investment in this to upgrade it even further,” he says. “This coming summer we plan to replace the bed underneath it, as well as other parts.

“This is an investment of approximately €7 million. It is part on an ongoing upgrading and investment programme in our equipment and it will see us improve our production efficiency and increase volumes. Work should be finished by the beginning of August.”

An exciting future

The concept at Bharat Forge Kilsta is to cooperate closely with both customers and suppliers, he says. The aim is to find the best solution, and product development is carried out with the involvement of all parties.

“We use steel, and each and every product must be manufactured to the specified quality. The aim is always to develop our existing products, to reduce weight, for example,” he says.

As Bharat Forge Kilsta seeks to move beyond its reliance on the automotive industry, it is also looking to develop relationships with other manufacturers, says Mr Nömm. The plan is to make the most of all opportunities.

“We hope to move towards other industries, such as mining, for example, where the quality of products is essential.

“ We are working in a very demanding environment: automotive is a very demanding business and it is key that we and our suppliers always stay focused and stand on our toes!

“We have a very good relationship with our suppliers and we always look for continuous improvements. Lean thinking, do it right from the beginning and try to do things better every day – these are the keys to our success. “It is also important that there is a win-win situation for both parties. Important values for us are quality, flexibility and profitability, in order to reinvest in the organisation to become even better. We are confident that we can achieve the growth we are seeking and we look forward to an exciting future.” n