8 minute read

Fast materials solutions BIBUS METALS

mum rigidity and a high static and dynamic system load capacity.

In order to prevent dirt infiltrations and lubricant leakage the company’s technicians have mounted cross double-lip wipers on the front terminal plates. If the guideways have to be used in extreme external conditions, among the optional features that Schneeberger can supply, there are additional wipers, which can be inserted directly on the guideway, thus facilitating replacement or boost operations even in the spaces between the guide carriages.

The MR series guide carriages are equipped with several lubricating joints, in a variable quantity up to a maximum of 20, which can be used according to the applications. Special lubricating joints for short run systems are also available, as are a lubricating system with independent guides and a minimal air/oil lubricating system. The maximum length available for single piece rails in sizes 25, 35, 45, 55 and 65 is 6000 mm. The MR 100 guideway can have

a maximum length of 3000 mm. Greater lengths can be obtained, without encountering any difficulties, by joining several rail components with the utmost precision.

Schneeberger is extremely well-positioned on the market both from a financial and technological point of view. Its aim is that of maintaining sustained growth and continuing to shape its future. It intends to remain faithful to its mission of helping its customers build machines allowing them to manufacture innovative products, offering increased performances in technological, as well as in economic terms. The company is able to perform at these levels, thanks to the fact that it has at its disposal broad specialist knowledge, gained from many successful projects in various industries. In addition to this, it works closely with its customers, with whom it evaluates the optimum products from its standard range or alternatively defines project-specific solutions. Thanks to years of experience and consistent focus on linear technology, Schneeberger is in a position to continually develop its products and solutions and thus provide its customers with many technical advantages. FEM calculations and 3D simulations allow the company to determine whether the required specifications and characteristics can be achieved – all before the first prototypes are built.

Schneeberger products are manufactured in the company’s own production facilities, utilizing the most advanced manufacturing technology and highly skilled employees. The manufacturing process is subjected to demanding and applicationoriented checks and inspections, thanks to which the highest level of quality is guaranteed at all times. n

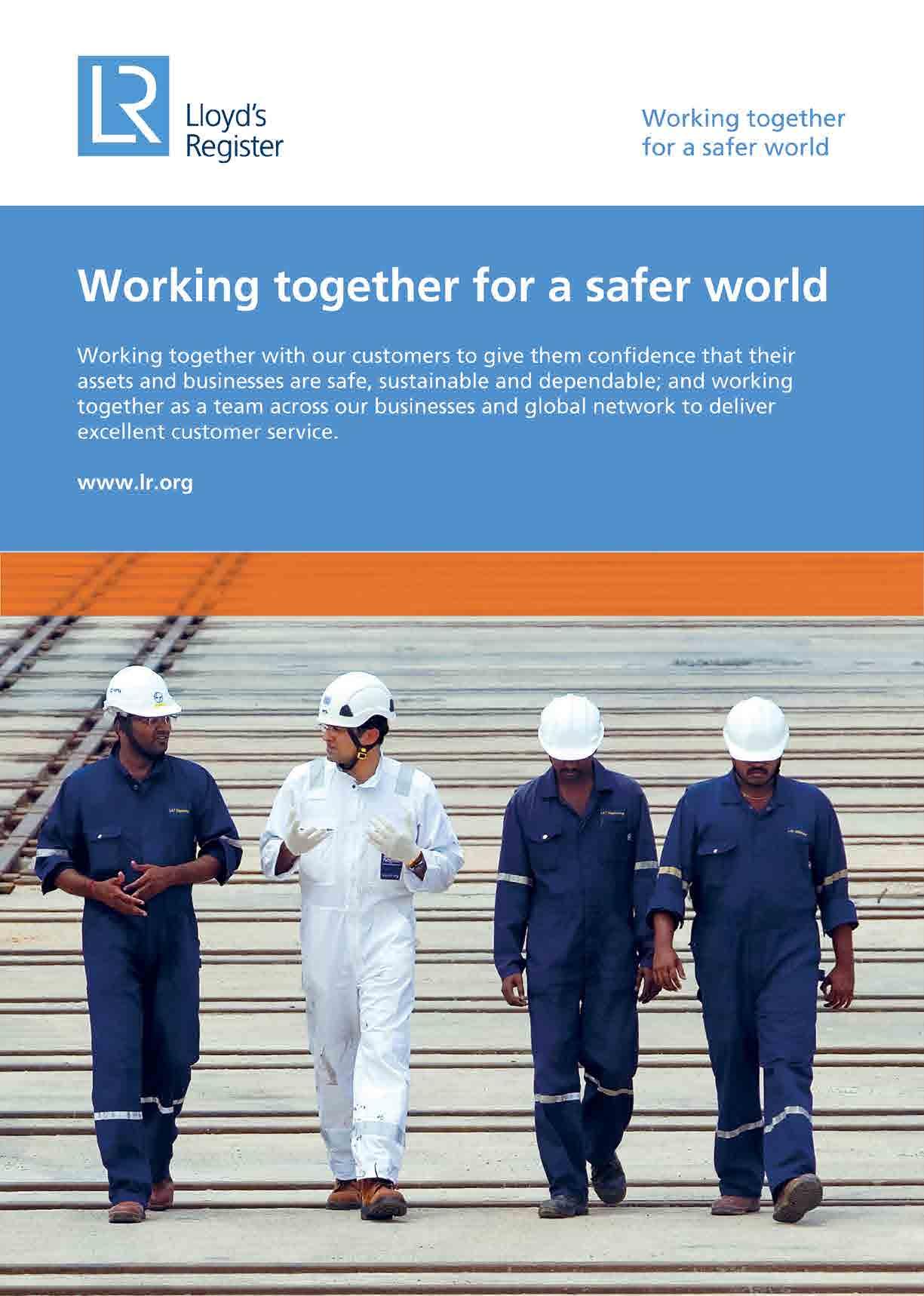

FAST MATERIALS SOLUTIONS

BIBUS METALS is a Swiss distributor for semi-finished products in nickel-based alloys, titanium, titanium alloys, zirconium, and tantalum. Marco Siebel spoke with Sales Manager Mike Zika about the company’s international expansion projects and latest investments.

BIBUS METALS’ warehouses stock large quantities of rods, bars, sheets, plates, tubes, pipes, wire, strip and welding material. State-of-the-art technologies and logistics procedures ensure extremely efficient clean processing. The sawmill connected to the warehouse cuts tubes and profiles in desired lengths - even two-sided mitre cuts can be produced.

Mike Zika: “Besides stocking semifinished products we also have warehouses where we cut on-site. We provide centrifugal products in different qualities and in the Czech Republic, Romania and Poland we have Jurid brake-pads in the portfolio. Our products are used in virtually every industry, worldwide: aerospace engineering, automotive engineering, chemical and process industries, electrical resistance heating, marine engineering, oil and gas extraction industries, petrochemical processing, pollution control and waste processing, power generation, thermal processing and heat treatment, and in welding.”

The family-run business is head-quartered in Switzerland, in Fehraltorf near the industrial city of Zürich. BIBUS METALS also maintains a large service centre and sales organisations in Switzerland, Germany, Poland, Czech Republic, Hungary and China. BIBUS METALS is known as a full service supplier, i.e. some customers only need metal sheets or tubes, while other customers come to BIBUS METALS because they need special profiles, in different metals and shapes.

Mike Zika: “Besides the service centres and sales organisation mentioned, BIBUS METALS has sales organisations in Austria, France, Great Britain, Romania, Ukraine and Russia. If you can communicate with people in their own mother tongue it is simply easier than if you are there as a foreigner.”

BIBUS MEATLS AG was founded in 1979 after becoming the exclusive distributor for Special Metals in Switzerland and Austria. Special Metals Corporation is the world’s leading developer and manufacturer of nickel alloys with production plants in the USA and the UK. BIBUS METALS AG belongs to BIBUS Holding AG.

Right from the start BIBUS METALS built and expanded the warehouse for large stocks of rods, bars, sheets, plates, tubes, pipes, wire, strip and welding material so that it rapidly became the foremost deliverer for heat and corrosion resistant materials.

In order to enlarge its portfolio BIBUS METALS added in the early nineties titanium and titanium alloys to its already extensive range of products.

In 2000 BIBUS METALS became the exclusive Special Metals distributor for all Eastern European countries.

Mike Zika: “As a supplier of nickel- and titanium alloys, quality has always been of great concern to us. We took the challenge in August 1994 and acquired the ISO 9001 and in 2013 the EN ISO 13485 Medical accreditation to the rules of the Swiss Association for Quality and Management Systems. All our material is purchased, stocked and controlled according to these rules.”

Titanium watches

In Switzerland, BIBUS METALS AG serves the watch-making industry by cutting a great deal of titanium watch housings, and anything up to 10 mm thick is cut in-house. Everything thicker than that is cut with water jet.

Mike Zika: “In Switzerland we work with the largest waterjet company in Switzerland, Waterjet AG in Aarwangen, near Zurich, to cut components to sketches or drawings, while in Poland we have our on-site waterjet cutting facility. With this additional service we can deliver extremely quickly custom cut metal products.

Traceability

In all machining steps, particular emphasis is placed on traceability of the products. This enables a mill test certificate to be supplied for all products, if required.

Mike Zika: “The energy, aerospace and medical industries are important clients for us. We also deliver to the space industry and chemical applications industry. Our core competence is that we have very large warehouses throughout the world, and together with the logistics departments BIBUS METALS can supply customers very quickly - either in standard sizes or cut to size - that is what distinguishes us” n

AAK 108 ACTEGA Colorchemie GmbH 148 Alfagomma SpA 43 Alpiq Energy SE 46 Aperam Alloys Imphy 96 Assag 156

Bibus Metals 167 Bilz Vibration Technology AG 167 Borghi Impianti Oleodinamici SpA 127 Buckeye 88

CAAC Pioneer Logistics Carlo Salvi SpA

5 139 C.Brandauer & Co. Ltd 96 Centrostal-Kujawy Company 39 CeramTec GmbH 24 Comelf SA 127 Crosswater Ltd 80

Curtis Machine Company 35

Decoleta a.s. 72

Delex Teknik

67 Diamon Sp. z o.o. 39 Dimontonate Floccati S.p.A. 70 Doceram GmbH 25

Emsclad Ernesto Malvestiti SpA ESEA Samrev Eumar 96 104 122 80

Faroil Srl 128

Fob-Decor Sp. z o.o.

118 FOR SpA 127 Fresche Bioscience Pty Ltd 151

G

G.B.I.E. Slip-Coat 70 Gebr. Winter GmbH & Co KG 32 GTP Company 108 GVB GmbH 25

H

Haas Food Equipment GmbH 109 Henkel Slovenija d.o.o. 63 Hühoco Group 71

I

Ilgomtubi Srl Industrial Technics Italpolimeri SpA

K

KAP IT Kardex Remstar Kawasaki Motors Europe Kovikor d.o.o. Krauss Maffei 127 124 93

76 57 34 63 59

L

Laufen Bathrooms 80 Lenze Pogonska Tehinka d.o.o. 115 Lloyd’s Register 174 LPL Scandinavia GmbH 135

M

MirTac BV MT Propeller

N

New Zinc Sp. z o.o.

O

Optima Packaging 131 32

140

89

P

Pantex International Perstorp Holding AB P.H.U. Solag Polimer Commerce d.o.o. 88 85 118 108

Q

QUIN Srl 159

R

R2 Group 151

S

Samo Purnat s.p. Shenzhen Taisu Material Technology Co. Ltd Sipac Sisu Worx 59 97

144 123

Smurfit Kappa

93 Spectra-Physics 173 Sundquist Components AB 66 Sunner World Trading 105 Synthopol Chemie 85

T

Tanatex Chemicals BV

153 Tehimpex d.o.o. 115 Thyssenkrupp Industrial Solutions 47

V

Varesina Stampi VFI 122 108

W

Woodtai Enterprises Ltd

Y

Yu-Label 50

108

Z

Zen Fonderie Srl ZPHU Paweł Mataśka 123 118