4 minute read

Staying strong Metalcam Group

staying strong

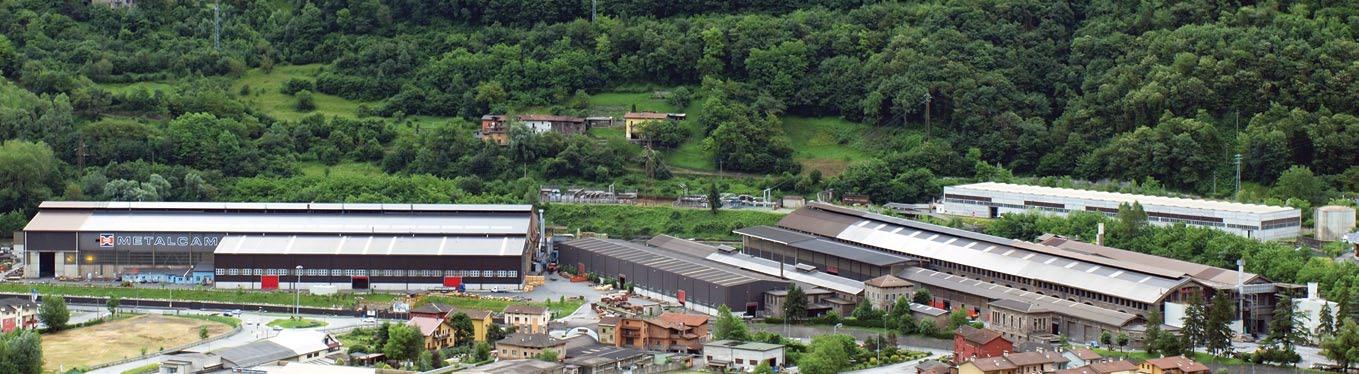

Italy-based Metalcam Group, headquartered in Breno, is a European leader in the production of open die steel forgings. Industry Europe talks to sales manager Massimo Cocchi about what makes the company unique in its sector and how it has fared in difficult market conditions since we last spoke to him in 2009.

When we last spoke to Metalcam, the company was experiencing steady growth of 10–12 per cent per year. However, as Mr Cocchi explains, the challenges it has faced over the past three years as a result of the international oil crisis have obliged it to seek alternative markets, such as Shipbuilding and Energy, in order to recover from the drop in its Oil & Gas business.

Fortunately for Metalcam, its years of experience and set of unique strengths have enabled it to remain positive during this time. As Mr Cocchi explains: “Metalcam has always been a fully vertically integrated company with a steel mill and forging shop under the same ownership and managed by a single team. Other competitors have tried to replicate this organisation in recent years but none of them is as fully integrated as we are. This aspect of our business is still highly regarded by many of our key customers.”

And it is this integrated structure that has enabled the company to grow far beyond the Italian market in the years since its establishment in the 1920s.

Today Metalcam’s main production facility is still located in Breno, but over the past 20 years it has integrated two other production companies that have enabled it to significantly increase the range of solutions it can offer its customers. These companies, both based in Italy, are: Valforge – a producer of small/medium forging components; and Adamello Steel – a producer of hot rolled steel plates.

Product development

As mentioned above, in light of the international oil crisis Metalcam has been looking to diversify its activities in recent years. Today it supplies medium- to large-size steel forged products for clients in the Mechanical, Oil & Gas, Energy and Shipbuilding industries, as well as supplying hotwork tools and raw material for forges and rolling mills.

According to Mr Cocchi, “Metalcam Group differentiates itself from other companies by being able to provide its customers with the most effective technical and metallurgic solutions by choosing the right materials and creating the optimal production cycle.

Normally in our business R&D means mainly identifying new ways to produce standard parts and optimise costs because the real R&D is carried out by our customers while developing and engineering their own equipment. However, over the past few years some key customers, appreciating our technical and metallurgical skills, are involving Metalcam during their product design phases. They consider us to be not only a supplier but a reliable partner able to establish deep collaborations with them.”

Global supply partner

When it comes to sales, today Metalcam looks well beyond the Italian market. According to Mr Cocchi, the European market has always been the most important for the company as it is, together with the domestic market, the most developed. Over the past 10 years Metalcam has also strongly developed its US market activities in parallel with the South American and Far Eastern Markets.

He tells us: “Metalcam Group is the everyday choice of hundreds of clients all around the world who value its huge production capacity as well as the highest expertise in the technical and metallurgic fields, its worldwide sales network, commitment, quality and care in looking after its customers.”

Of course, he acknowledges that none of this would be possible without maintaining relationships with the most reliable suppliers. “Considering how critical is our production cycle and considering we do not start from ‘free issue material’ (our main raw materials are metal scrap and ferroalloys), it’s fundamental to deal with suppliers who are highly qualified and conscious of being part of a strategic supply chain. Through collaboration with a few selected machining shops, we have been able to approach our clients to offer more and more advanced products.”

Future development goals

Moving forward, Mr Cocchi acknowledges that the continuing volatility of the market means Metalcam will have to find more strategic ways to stand out from its competitors. “The global market, despite showing better trends compared to last year, is still pretty unstable and driven by several uncontrolled factors including speculation on raw material and end products.”

For this reason, he says, Metalcam has always focused its investments on quality rather than quantity. “Such investments – concerned with doing better than doing more – are of course more complicated to identify but can strongly support the company to perform better and better from a technical, quality and service perspective.” And it is this long-term thinking that will help the company to stay strong during these challenging times and continue to diversify in the years to come.