6 minute read

Winning business New orders and contracts

NeWS

New contracts and orders in industry

British Steel secures new Catalonia rail contract

British Steel has secured a new contract to supply high quality rail for track renewals in Catalonia. The steel manufacturer has secured the agreement – for its R260 rail – with network operator Ferrocarrils de la Generalitat de Catalunya (FGC).

The announcement comes a short time after British Steel secured contracts with RFI, Network Rail, Infrabel and Translink.

Richard Bell, British Steel Commercial Director Rail, said: “We’re delighted to have secured this new contract with FGC. “Delivering with a short lead time is a great benefit to our customers and we look forward to supplying FGC with the high quality rail synoymous with the British Steel name.” British Steel has recently announced: • A two-year extension to supply Network Rail in the UK • A four-year deal with Infrabel in Belgium • An agreement for 68,000 tonnes of rail for Rete Ferroviaria Italiana in Italy • A contract for 18,000 tonnes of heat treated 108m Stress-Free rail to Rete Ferroviaria Italiana in Italy • An 8-year contract with Translink in Northern Ireland. Visit: www. britishsteel.co.uk

E.ON bids with ENGIE and EDPR for Dunkirk Offshore Wind Project in France

E.ON plans to enter the French renewable energy market and has joined the ‘Dunkerque Eoliennes en Mer’ consortium. Together with the energy companies ENGIE from France and EDPR from Portugal, E.ON is taking part in the auction of the Dunkirk offshore wind farm announced by the French government for March.

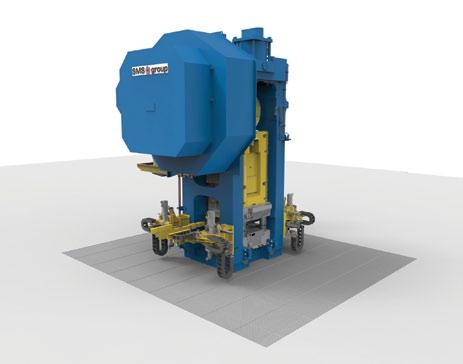

The 600-megawatt project is to be completed in the English Channel by 2025 and will supply more than 600,000 households with renewable energy. E.ON has been working as a technical advisor on the development of the project for two years now. The French government has now formally confirmed E.ON’s entry into the consortium. Visit: www.eon.com Dongfeng Forging Co., Ltd., part of the commercial vehicle manufacturer Dongfeng Motor Group, has placed an order with SMS group for the supply of an MP 5000 eccentric forging press with a forging force of 5,000 tons for its plant in Shiyan, Hubei Province, China. Founded in Shiyan in 1969, Dongfeng Forging Co., Ltd. operates a total of 26 forging lines at this site including, among others, a 12,000-ton wedge press supplied by SMS group.

Dongfeng Forging intends to use the new forging press to manufacture light-truck crankshafts with a maximum finished part weight of 21.5 kilograms. The new eccentric press will forge parts precisely, highly efficiently, and fully automatically with a nominal forging force of 50 MN. In addition to the press, the scope of supply includes process development services, sequence-controlled loading and unloading belt conveyors, an electrically operated automatic walking beam for parts handling, and an integrated die spraying system. Visit: www.sms-group.com

dongfeng forging orders 5,000-ton eccentric forging press from SmS group

Fortum’s Kalax wind power project in Närpes, Finland has been approved for the Finnish national renewables scheme. The effect of the wind power park is expected to be approx. 90 megawatts (mW) and the annual power generation around 300 gigawatt hours (GWh). The Kalax wind park will receive support of €2.87 per megawatt hour (mWh) if the market price for power is below €30 per mWh. The scheme was opened up for a total annual generation of 1,400 GWh. The projects are to be commissioned within three years from approval. The Kalax project still requires an investment decision by Fortum.

“The granted premium is very low, but will offer additional compensation on top of the spot price, should market prices be very low. It is time for wind power to become a part of the power market on the same basis as other production forms, without separate support. The support scheme is supposed to be a temporary solution and new support schemes are not needed,” says Joonas Rauramo, Vice President Wind Generation at Fortum. Visit: www.fortum.com

WINNINGBuSiNESS

fPT industrial powers new European Tractor brand mancel (yTo) with it Stage v Engines

FPT Industrial is powering new tractors produced in France by Mancel, a newly established manufacturer that represents the European interests of YTO, part of the China-based group Sinomach, which has activities in agricultural and construction machinery. Mancel has committed to using FPT Industrial’s reliable and powerful N45 Stage V engine.

The four-cylinder engine for Mancel offers peak power up to 115 kW and torque up to 640 Nm. The model is part of FPT Industrial’s proven NEF series, which totals 1.7 million engines produced since 2001.

FPT Industrial’s HI-eSCR2 technology is the Brand-patented solution to comply with Stage V emission regulations and its key elements are: Diesel Oxidation Catalyst (DOC), AdBlue injector and an integrated SCR system capable of limiting both NOx and PM. The system improves sustainability, performance and operating costs and it is maintenance free. Visit: www.fptindustrial.com

Meyer Burger awarded contract from leading Asian customer

Meyer Burger Technology Ltd (SIX Swiss Exchange: MBTN) has announced the successful conclusion of an order from an existing, major Asian customer for its high performance MAiA® 6.1 platform which delivers an impressive throughput of over 6,000 wafers per hour for mass production scalable PERC technology. By selecting Meyer Burger’s MAiA® 6.1, which launched in 2018, to drive the production expansion of its high quality PERC solar cells, this global leader in the PV industry has chosen today’s foremost standard in PERC manufacturing technology.

Meyer Burger’s industrialized MAiA® with its superior passivation technology played a key role in finally establishing PERC as the new global standard in mass manufacturing of solar cells. PERC delivered a much higher module performance while reducing production costs compared to the former Al-BSF standard technology. Dr Hans Brändle, CEO of Meyer Burger, stated: “Today’s announcement of a repeat order from a leading PV module manufacturer for our next generation MAiA® 6.1 signals the beginning of ambitious new PERC expansion plans by the solar industry.” Visit: www.meyerburger.com

wärtsilä to design and equip state-of-the-art transport vessel for aker biomarine

The technology group Wärtsilä has been awarded the contract to design a state-ofthe-art multipurpose transport vessel that will operate in Antarctic waters. Wärtsilä will also provide the vessel with a comprehensive package of integrated propulsion and hybrid solutions to ensure highly efficient and environmentally sustainable operations. The ship has been ordered by Norway-based Aker BioMarine and will be constructed in China, at CIMC Raffles. The ship design order with Wärtsilä was booked

The 168 metres long, 20,300 dwt vessel will comply with the International Maritime Organization’s (IMO) Polar Code. Because it will operate in the environmentally sensitive Antarctic, Wärtsilä’s sustainable technical and hybrid solutions, with high levels of safety and reliability, were considered as being the most suitable for this project.

“We are proud to have been selected to design and equip this ship. It will be a customised vessel designed specifically to meet the owner’s operational requirements in a challenging environment. It emphasises once again Wärtsilä’s comprehensive strengths and capabilities, as well as our broad offering to the marine market,” says Lilli Chi, Managing Director, Ship Design, Wärtsilä Marine. Visit: www.wartsila.com

SMS group to modernize gas cleaning systems at POSCO Gwangyang

SmS group), in cooperation with AeRIX Co., ltd., South Korea, has been commissioned to modernize the gas cleaning systems of the three BoF (Blast oxygen Furnace) converters at the integrated steel mill of PoSCo in Gwangyang, South Korea. Within the scope of a production increase in the converter shop, the gas cleaning systems will be adapted to deal with the higher process gas volumes. Primary gas cleaning is performed by means of easytomaintain dry electrostatic precipitators (eSP) which will be extended accordingly.

This will enable the gas cleaning systems to treat higher process gas volumes while, at the same time, their cleaning capacity is improved. The gas cleaning systems will each be designed for a capacity rating of more than 108,000 Nm³ per hour (dry). Visit: www.sms-group.com