4 minute read

The momentum of metal cans

Kathryn Fox, Global Marketing Manager at Videojet Technologies, looks at the continued rise in the use of metal packaging and the coding and marking challenges it presents.

Recycling, corporate social responsibility, and sustainability are all priorities for the beverage industry. In light of media attention with regard to certain packaging substrates and consumer demand for more responsible packaging solutions, there has been an increased focus on the use of materials that contribute in a positive way.

Materials that are a part of the circular economy – the ability to be recycled infinitely without any loss of properties – are of increasing importance. Metal packaging has seen a steady rise in the beverage industry in recent years due to its many positive attributes, one of which being functionality and another being sustainability. It is lightweight, easy to shape and size, offers a 360-degree billboard for advertising, and is integrated into the circular economy.

Globally, the market for metal cans is expected to reach a value of $56.38 billion by 2023 – growing at a CAGR of 3.2 per cent from 2018 - and there are a number of factors that are contributing to this rise in popularity such as convenience and hardiness.

The greatest quality of metal cans is its ability to be infinitely recycled without loss of product purity and quality. In contrast, a plastic product can only be recycled two or three times before its quality level decreases. The global recycling infrastructure is highly advanced to process cans. A recycled can could be back on a retail shelf within 60 days. The recycling rate for aluminium is above 70 per cen in many countries, while in the US – according to the Aluminum Association – the country processes enough ferrous scrap daily to build 25 Empire State buildings. Conversely, according to an article by Forbes, one million plastic bottles are purchased every minute globally, of which only 9 per cen are recycled.

Another valuable property of metal is the barrier to light and oxygen it creates which can negatively impact a product’s quality levels in terms of degradation. Metal is also strong in transit and throughout the supply chain and can be manipulated into a vast array of shapes and sizes. In addition, metal cans provide a 360-degree platform for branding and messaging with many decorative options available – from thermochromic technology that changes colour with the temperature of the liquid within, to matte, gloss and even fluorescent finishes.

metal gathers momentum in a number of beverage segments

While glass and plastic packaging has seen widespread usage for many years, metal is now becoming more commonplace in areas outside of its traditional market. Craft beers are a prime example here as many brewers are now informed that metal cans do not taint the flavour of the beer. Rather, metal cans protect beer from the very elements that contribute to its losing quality – namely light and oxygen.

Can manufacturers are finding ways to accommodate the smaller production runs required for these craft brews, which has led to some striking designs and some equally innovative packaging.

Sparkling waters are gathering momentum in metal cans, in addition to still water – which is far more familiar to consumers packaged in a plastic bottle. While some canned waters are

still aimed at the premium end of the market, one US based charity – CannedWater4Kids - is using aluminium cans to bring safe drinking water to those that lack access.

Finally, more alcoholic beverages – such as wine, Ready-To-Drink spirits and mixers – are being packaged in cans because of the convenience factor. It is not surprising that metal packaging is gaining market share.

The coding and marking challenges

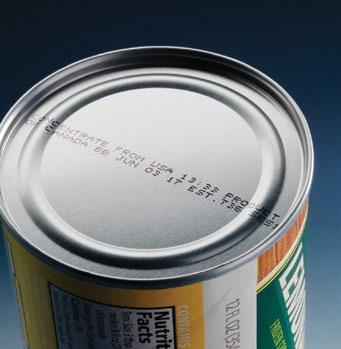

In terms of coding and marking, metal packaging presents a number of challenges for manufacturers, including metal finishes and curved surfaces. Printing a legible code onto a metal surface is not the same as printing onto a plastic bottle. Therefore, extensive testing must be carried out. Beverage canning lines run at incredibly high speeds – sometimes as fast as 2,000 cans per minute – and initial evaluations will ensure codes can be printed to the standard required.

Continuous inkjet (CIJ) and laser marking are the two technologies that dominate coding and marking in the metal packaging sector. Both technologies meet the needs of high-speed can applications, including coding on the concave bottom of aluminium cans. For continuous inkjet, advanced printheads require less frequent cleaning, allowing for longer run times, while smart cartridges feature an embedded microchip, allowing the printer to identify whether the correct fluid has been installed. For laser marking, fibre lasers are often recommended for metal packaging, as throughput is often higher. Laser coders have the advantage of not requiring consumables such as ink, and can therefore run for extended periods of time without the need for stoppage.

Regardless of your operational requirements, it is critical to engage with a specialist coding and marking supplier when looking to code onto metal. A detailed evaluation can be carried out to ensure maximum efficiencies are achieved and a system can be recommended and installed that will guarantee the very highest quality codes are applied to products that comply with the complex regulatory landscape of the food and beverage industry. n

- The author, Kathryn Fox, is Global Marketing Manager at Videojet Technologies, a leading company in the product identification market, providing in-line printing, coding, and marking products, application specific fluids and product life cycle services.