4 minute read

A european leader in electrical laminations Sitem

a european leader in electrical laMinations

New investment in advanced production equipment is keeping Italy’s Sitem at the forefront of the industry

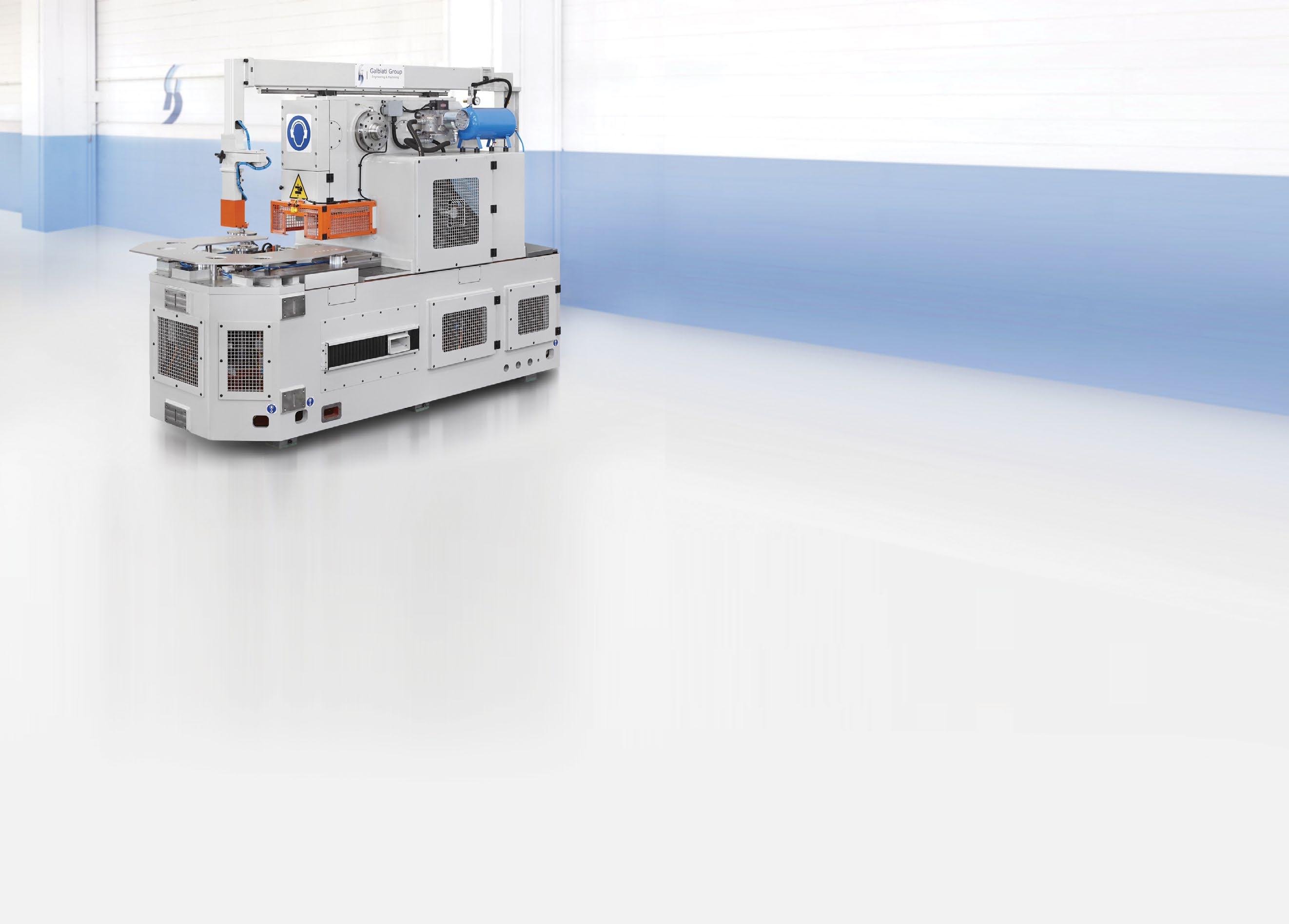

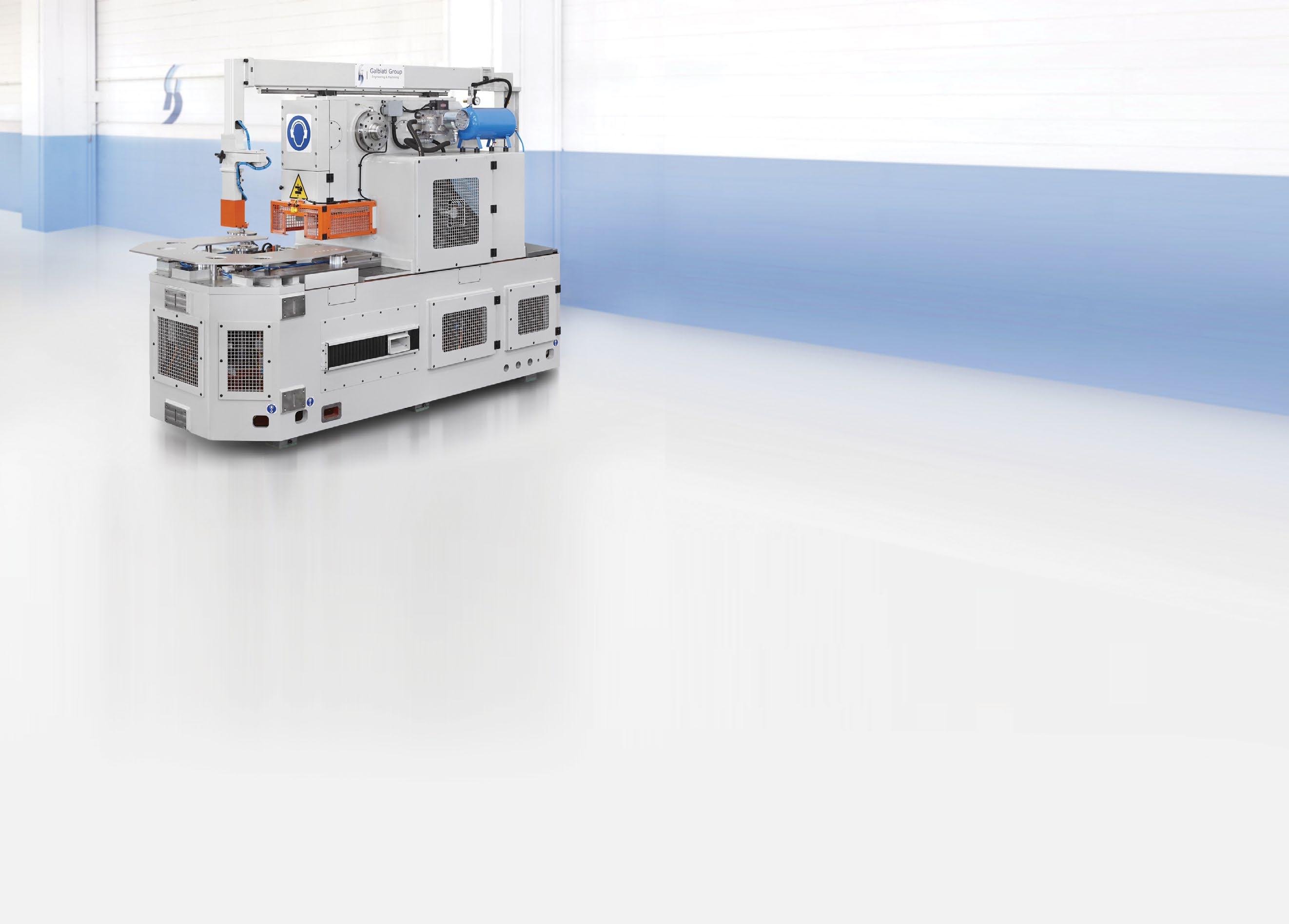

In June 2019, Sitem, the Italian family-owned electrical steel manufacturer, expanded its offering to customers with the installation of two Schuler Smartline high speed presses. The SA-135S presses are being used to punch motor packages for electric cars.

The 315 tonne press force of the machines is fully available over the entire output range from 100 to 400 strokes per minute. The new interlocked packet control increases productivity by up to 30 percent. Die life is also extended by 30 percent thanks to Schuler’s depth penetration control and slide guidance without play. Both developments also have a positive effect on the process reliability of the complex dies designed by Sitem itself.

The Sitem industrial group based in Trevi, halfway between Rome and San Marino, has two further locations in Italy and one each in France and Slovakia. With more than 700 employees and a turnover of over EUR 160 million, it is one of the largest providers in the market.

In 2016 Sitem took over Stanzwerk AG from Unterentfelden in Switzerland to prepare for the growing eMobility market. Stanzwerk specialises in the stamping and stacking of laminations. Using magnetic sheet metal, it manufactures stator and rotor stacks needed to

construct electric motors. The latter are then used in drives, steering systems, electric tools and ventilation systems.

The latest investment in Schuler’s high-speed presses marks Sitem’s continuing advance in this market as well as its continuing investment in increasing its production efficiency and quality standards.

extensive range

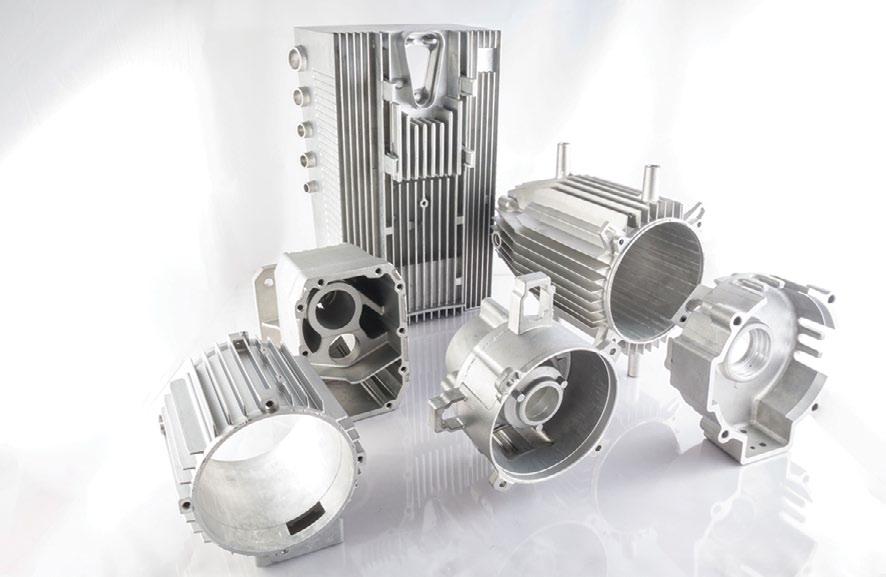

Sitem currently offers customers a large range of products and services, including electrical steel lamination stamping for electric motors and transformers, aluminium die-casting for rotors used in electric motors, lamination annealing heat treatment, design and construction of tungsten carbide tools for electrical lamination stamping, laser cutting of carbon steel or other materials reaching thickness up to 100mm and. Sitem produces a wide range of laminations for electric motors between 0,09 kW and 2000 kW, transformers and alternators.

Sitem products are employed in a wide range of applications including ventilation systems, industrial pumps, burners, wind generators, elevators, gear adapters, air compressors, refrigerators, brushless motors and transformers.

The company is a major force in the Italian market and has established strong positions in both the European and global markets. It is currently active in France, Spain, Portugal, Austria, Germany, UK, Denmark, Greece, Turkey, Poland, Hungary, Romania, Czech Republic, Croatia, Serbia, South Africa, Taiwan, USA, Argentina, China, Brazil and Mexico.

Production sites

Sitem’s main Trevi site covers an area of 82,000 m2, 19,000 m2 of which is covered, and is divided into six divisions. The Lamination stamping shop operates 30 production lines including stamping presses of several sizes, from 100 to 400 tonnes. The site also includes three ovens for heat treatment: and 16 die-casting production lines as well as automated lines for rotor machining, including inside and outside processing, polishing and heat treatment. There are 10 lines for stator production and more than 150 hard metal stamping tools.

The Trevi site also operates the latest laser cutting systems and a fully automated coil cutting line that can cut steel coils from 0.23mm to 2mm in thickness at speeds of up to 300m per minute.

Sitem’s Canegrate (Milan) facility operates 15 lamination stamping presses for electric motor and special components used in wind machines as well as seven stamping presses for transformer laminations.

There are also a total of 10 production lines for die-casting aluminium products such as electric motor housings and other aluminium components and nine fully automated production lines for aluminium die-casting for rotors.

The Sitem production site in Limbiate, Milan specialises in magnetic transformer laminations and small motor laminations. The 25 highly specialised workers, with years of experience in design and production of tools and rapid metal stamps, operate the latest generation machinery and work in the temperature-controlled rooms needed for the entire production.

Sitem’s Slovakia plant was established in 2004 at Spisska Nova Ves to enable the group to expand into the fast-growing eastern European market. It was an investment that proved to be strategic for the entire Sitem group and enabled it to serve customers such as Bosch-Siemens, Whirlpool, Aweco, Askoll, ACC (Nidec group), Best and Rosenberg.

The plant currently operates eight rapid metal lamination stamps, two heat treatment ovens, three lines used in die-casting of aluminium or other alloys for rotors and three lines for automated soldering.

Decoup, Sitem’s French production site, specialises in grain oriented magnetic lamination for single-phase and three-phase transformers.

Last September the SITEM Group continued its participation in major international trade fairs by presenting its latest offerings at COILTECH 2019 in Pordenone, Italy, COILTECH is an international exhibition focused on materials and machines for the production of electric motors, generators, power transformers and electric windings. n