5 minute read

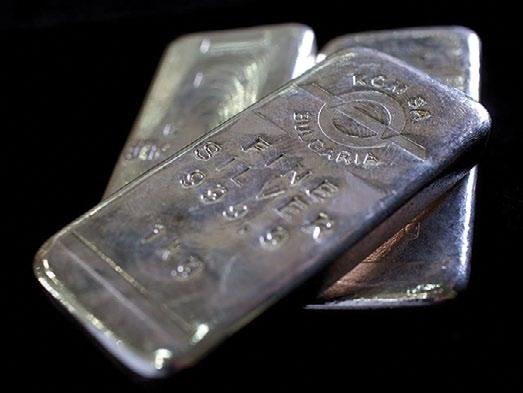

major boost for sustainable smelter development KCM Group

major boosT for susTainable smelTer developmenT

The KCM Group of Bulgaria is the largest producer of lead and zinc alloys in Europe. Its privatisation ten years ago heralded a new era of investment and a renewed commitment to the production of environmentally friendly products. The new 65-million-euro loan from the European Investment Bank (IEB) will increase the group’s production capabilities by more than 25 per cent and enhance its sustainable production processes, as Philip Yorke reports.

Europe’s leading non-ferrous metal smelter company, KCM 2000 is located on a 900,000 metre square site between Plovdiv and Asenovgrad in Bulgaria. The company was established in November 1961 as a state-owned business. However, in July 2000 a contract was signed between the country’s Privatisation Agency and KCM 2000 for the sale of an 80 per cent stake in KCM AD. Today KCM is the largest producer of lead and zinc in Europe and the acknowledged leader in the production of non-ferrous and precious metals in South Eastern Europe.

The group’s annual production capacity of lead is around 70,000 tonnes and almost 100,000 tonnes for zinc. The company employs over 2,000 people and is one of the largest industrial groups in Bulgaria. The KCM Group forms an integral part of the holding structure of KCM 2000 AD, which brings together its hightech affiliate companies to work for greater sustainability, smelting innovation and entrepreneurship.

eIB delivers key support

Recently the EIB delivered its most significant support to date for Bulgarian industry with a major contribution towards the expansion of more environmentally friendly production of lead and zinc. This is under its ‘Investment Plan for Europe’ strategy. This financial support amounted to a 65-million-euro loan to KCM AD in order to increase the company’s production capability by over 25 per cent.

This investment involves the construction of a new state-of-the-art lead refining plant and a modern zinc electrolysis unit. These will be designed to replace the existing outdated production plants. In turn, the investment will also ensure much improved environmental performance, as well as increasing the recycling rates of waste materials and providing improved working conditions for all.

The company’s use of recycled materials will also increase significantly, resulting in more efficient and sustainable production processes. KCM’s zinc is used in galvanised steel products, and the production of die-cast alloys as well as for brass and bronze components, whilst its lead-based products are primarily manufactured for the automotive and industrial battery sectors.

New sustainability levels

This significant new financial agreement is backed by the European Fund for Strategic Investments (EFSI), which lies at the heart of the Investment Plan for Europe. This is also known as the Juncker Plan. Thanks to its financial guarantees, the EIB is

in a position to support a patent-holding company in a ‘cohesion region’ in an effort to render its production processes more sustainable and more environmentally friendly.

“European support can do a lot to push heavy industry to new sustainability levels,” said EIB Vice-President Lilyana Pavlova. “Backed by the Investment Plan for Europe, our loan will help KCM to make better use of natural resources and decrease the energy intensity of its production cycles. Both measures will make the company more competitive, and will secure around 2,000 jobs in one of Europe’s top industrial regions. This shows that the circular economy and climate action go hand in hand with the ambitious social and employment targets of the European Union” she added.

Boosting energy-efficiency

Following the confirmation of the EIB loan, the European Commissioner for the Economy, Paolo Gentiloni said: “Making our traditional industries eco-friendlier and more modern is the key to boosting energy efficiency. With 65-million-euros in EIB financing under the Investment Plan for Europe, KCM can upgrade and update its manufacturing processes. This investment will help to support approximately 2,000 jobs in the region.”

KCM will use the EIB loan for its technological upgrade programme planned for 2020-2023. The programme provides for the modernisation and expansion of the company’s lead and precious metals refining unit and zinc electrolysis unit. The project will also increase the recycling capacity for different types of secondary waste lead and zinc materials by 15 percentage points.

Secondary materials currently make up some 20 per cent of the total refined lead and zinc output, whilst the project will bring the share of secondary materials to about 35 per cent. This is a high percentage by EU-standards, other European primary smelters currently report a recycling share of only 10 per cent to 15 per cent.

Prestigious Best-Practice award

At the 25th Annual Meeting of the EBRD Board of Directors, KCM 2000 Group received the regions’ prestigious Environmental and Social Best-Practice Award. Akfen Holding awarded first place to KCM AD, Plovdiv, and the award was presented to Mr Rumen

Tsonev, CEO of the KCM 2000 Group. KCM stood out among the 16 finalists for its commitment to the environment, safety and innovative energy-saving practices. The criteria was based on agreed performance indicators following the implementation of its largescale EBRD-funded investment project. This was called the ‘Process Innovation and Production Increase’ (PIPI) programme.

These ambitious sustainability projects meet the best European and world standards and guarantee the responsible and sustainable use of raw materials and resources. KCM’s Environmental and Social Best-Practice Award is an acknowledgment of its proven civil and corporate contribution to the environment and to society as a whole.

Focus on safety and health

The KCM 2000 Group strives continuously to improve the health and safety of its employees through safer and more modern working practices. A risk management strategy is in place that is based on the use of its own methodology for risk assessment, control and monitoring. The KCM Group also has its own Occupational Health Service where all practicable and reasonable measures are taken to improve the working environment and operating conditions for employees. The company also carries out its own regular educational programs, aimed at enhancing the health and well-being of its staff.

Health and safety training, as well as periodic medical examinations and risk monitoring, are also provided for all employees regardless of their role within the group. For more details of the KCM Group’s latest innovative products and services visit: www.kcm2000.bg