5 minute read

Innovation for a sustainable world Feralpi

innovation FoR a sustainable woRld

With a renewed commitment to sustainable production, Italy’s Feralpi Group confirms its position as a European leader in the production of steel for the construction industry

This summer, the Feralpi Group was proud to play a major part in the construction of the new Genoa bridge. The dramatic collapse of the Morandi Bridge in Genoa on 14 August 2018 claimed 43 lives and shocked the whole of Italy. Through its subsidiary Nuova Defim Orsogril, the steel company was able to help in the rebuilding of the bridge, despite the difficulties of the Covid-19 pandemic and lockdown. Steel gratings for the bridge were transported 200 kilometres from the Nuova Defim Orsogril plant to the construction site.

The Feralpi Group is one of Europe’s leading manufacturers of steels for use in building construction. The parent company Feralpi Siderurgica, which was set up in 1968 in Lonato del Garda, near Brescia, has developed steadily over the years to form a group of industries that currently turns out two million tonnes of steel and rolled products a year, and has a workforce of 1,500 permanent employees in Italy, Europe and North Africa.

In over fifty years of business, the company has expanded its foreign markets and has been highly successful in facing the challenges of an increasingly globalised steel industry. Building on its long tradition in steel manufacturing, the Group has developed according to a strategy of diversification into new products and markets, which has involved not only its internal organisation but also external transactions thanks to the acquisition of numerous enterprises operating in the steel industry.

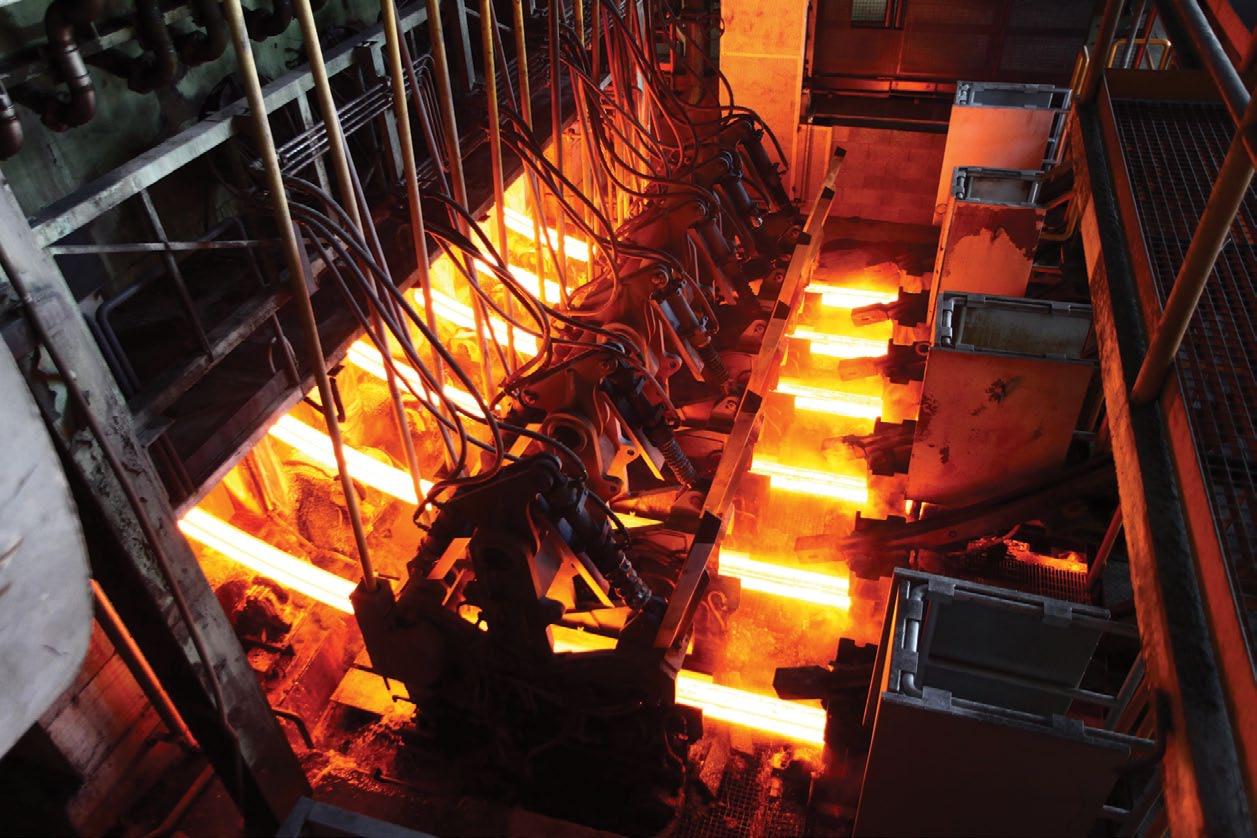

Today the Group’s main operation in Italy, Feralpi Siderurgica, is a leading manufacturer of reinforcing steel in bar, smooth and ribbed wire rod, recoiled, drawn and welded wire. The plant is equipped with high-tech systems for cutting up and shredding scrap and for the sorting of ferrous materials, which are delivered by road or rail.

The steel mill uses “mini-mills” electric-arc furnace technology for treating molten steel in ladles and the continuous casting of steel billets that feed downstream rolling mills in real time. The plant turns out rebar meeting various national and international specifications as well as reinforcing steel in coils and wire rod.

Still on track

Before this year’s lockdown, 2019 was another positive year for Feralpi, with profit, turnover, margins and production holding up following a good 2018. Investments remained high at 54.5 million euro and was targetted not only at achieving maximum efficiency, but also at contributing to the decarbonisation of production activity, reducing consumption and emissions, and developing new circular economy models to facilitate the optimisation of resources and the adoption of energy-efficient technologies.

With regard to the circular model, particularly important is the experimental furnace recovery project, with products generated by reusing plastic materials/polymers as reduction agents to replace

coal to reduce the use of fossil fuels and other natural, by capitalising on recovered materials.

“The positive results achieved in 2019 strengthen our Group, even in a situation where the market slowed down, especially in the second half of the year”, commented Giuseppe Pasini, Chairman of the Feralpi Group. “What didn’t slow down was our inclination towards investments, which continued to be robust to remain competitive, and picking up on what the UN 2030 Agenda and the European Green New Deal are asking of manufacturing companies.”

Continued expansion

In April 2020, the Feralpi Group took over full control of Leccobased Caleotto SpA by acquiring 50 per cent of the share held by Duferco Italia Holding.

Caleotto is now fully incorporated and vertically integrated in the Feralpi Group, thereby guaranteeing full support in the business plan development of this company, which has been producing wire rod for the drawing sector for over a century. Caleotto, Feralpi and Duferco will continue to work together to guarantee continuity in production, to achieve the highest quality standards and to support the major technological investments made.

“Following the business continuity policy adopted over the last five years, the Feralpi-Duferco synergy plan has effectively relaunched the production plant both technically and commercially,” explains Giovanni Pasini. “Clearly, in this period deeply affected by the global pandemic, our utmost priority is safeguarding people’s health, but as soon as conditions allow, we will have to start up immediately with renewed energy”.

Developing sustainability

This year the Feralpi Group became the first steel manufacturer in Italy to obtain a ‘green’ loan of 20 million euro to finance sustainable investment.

The finance is made available by BNL-BNP Paribas Group, and combines business development with environmental sustainability. This type of loan comes with conditions linked to specific sustainability indices that are measured and monitored. For Feralpi, this means further lowering greenhouse gas emissions in the next five years. “Not only does the arrangement attest to the company’s commitment and awareness of its responsibility, it is also a clear sign that the availability of green finance and a structured offering is an accelerator of sustainable development“, says Alberto Messaggi, the Feralpi Group CFO. “Supporting a company’s commitment, including financially, to focus on its environmental performance is a concrete sign of progress. We trust that the guidelines that focus on this model, which have also been supported in recent announcements by the Italian government, can be consolidated to quickly permeate businesses.” n