3 minute read

Corrosion in power plants TLT-Turbo

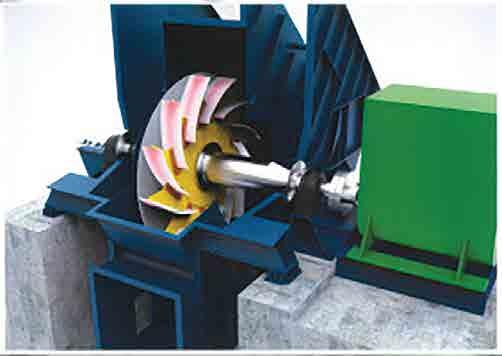

CORROSION IN POWER PLANTS

Energy technology is undergoing global transformation. Rapidly expanding renewable energy and other, more volatile power generation plants require significantly higher flexibility of conventional plants. This has resulted in a number of new challenges for ventilation equipment, including:

• An increased number of start and stop operations • Fewer full-load hours • Increased partial load operation • Lower exhaust gas temperatures due to residual heat utilization • Smaller gap to acid dew point

These factors cause an increased load on the systems which carries increased risk of corrosion during operation. This favors dew point corrosion, which can lead to total failure of fans and system components.

TLT-Turbo offers you a tailor-made solution for your plant by implementing effective corrosion protection measures to maintain uptime of your fans. Efficient Protection against Corrosion

TLT-Turbo Corrosion Protection for fans includes two key actions: Preventing corrosion where possible and protecting components where corrosion cannot be prevented.

Avoiding corrosive conditions:

• Preventing or reducing leakage of sealing air • Heating of fan components • Optimization of insulation

Use of corrosion resistant materials:

• Weather resistant steel • Polymers and polymeric coatings • Stainless steel • Ni-based coatings or base materials

In order to select the measures suitable to preventing and addressing corrosion on fans operating at your facility, TLT-Turbo

conducts an individual corrosion risk assessment. This assessment is based on your operational and environmental conditions.

TLT-Turbo provides further support by conducting an analysis of your specific operating conditions, e.g. on a dew point measurement based on a plant inspection.

Contact TLT-Turbo to discuss your corrosion protection needs and to find the right service package to suit your on-going requirements.

Optimal Protection against Corrosion for Existing Plants

TLT-Turbo conducts corrosion risk assessments and implements suitable preventative measures when designing and manufacturing new fans. These measures can also be carried out when retrofitting existing plants or as part of preventative maintenance during a scheduled shutdown.

Contact your service representative or the TLT-Turbo Service Department for more information on conducting a tailored risk assessment at your facility. About TLT-Turbo

TLT-Turbo GmbH builds radial and axial flow fans for virtually any application. First-rate engineering, tradition and progress in air handling technology and a worldwide support network have been the cornerstones of their excellent global renown as a fan and systems manufacturer for more than 140 years. TLTTurbo GmbH fans and the associated system components are deployed successfully all over the globe. To date over 10,000 fans have already been installed. Their subsidiaries, branches and agencies span the globe including TLT-Turbo offices in Germany, China, Austria, Russia, South Korea, USA, Chile, Hungary, Australia, India and South Africa. n

Visit www.tlt-turbo.com for more information.