5 minute read

Perfect packaging films Kablonex

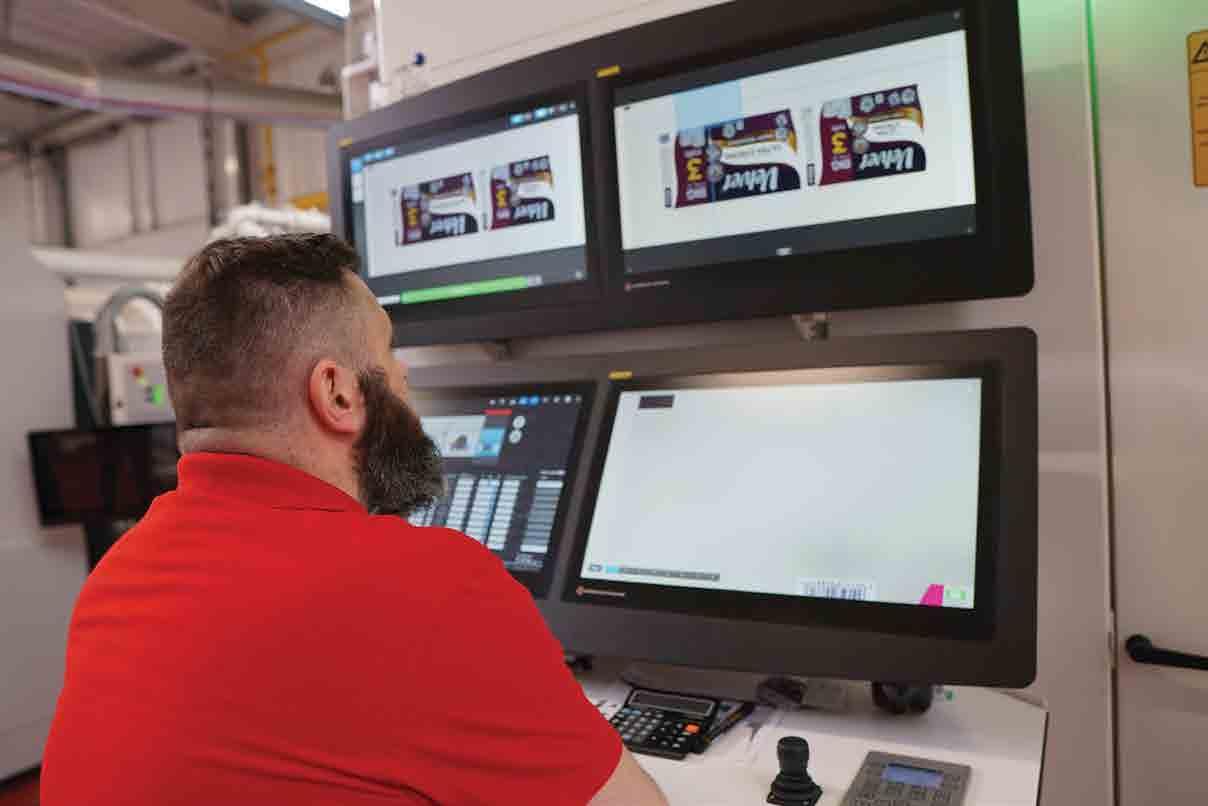

PERFECT PACKAGING FILMS

Kablonex, from Chodziez, Poland, is one of the leading European companies on the foil packages market. It boasts the breadth of experience and long, stable development. At the end of 2021 the company celebrated its 50th anniversary.

KABLONEX was founded in 1971 in Chodziez, a small town in Wielkopolska region. Since the very beginning it has been a family run business, nowadays managed by the third generation of the Nawrocki family. “The fact that the company is a family business makes our decision-making process very short. Moreover, our staff members are very close to each other, just like a sort of family,” points out Oskar Nawrocki, the company’s owner.

Initially, KABLONEX dealt with the production of cables, which is the source of the company’s name. The company’s greatest achievement from this period was to supply cables to the Warsaw Underground, which was being built in late 1980’s.

“Since then, a lot has changed: the technology, the market, the needs of our customers. The small company that KABLONEX was 50 years ago has grown into a producer, well established on the foil packaging market, with modern machinery, and a team of more than 120 people. I would like to emphasise the great role played in the company’s development by my father, Eugeniusz. He has devoted his whole life to KABLONEX, his hard work and strong work ethos have laid a solid foundation for the company’s current success”, adds Nawrocki.

In 1990 KABLONEX purchased its first machine for blowing film. Ten years later the first three-layer line was bought. In coming years, the company’s development would see even more purchases: a machine producing HDPE film (2008), the first five-layer line (2010), modern flexographic printer Novoflex and laminating machine Varex II from reputed German company W&H, an efficient bobbin cutting machine Jurmet, the computer processing of all processes, a new system – ERP, and six siloes for storing of raw materials (all these investments were performed in 2015).

Now, KABLONEX can be proud of its modern production processes, warehouse facilities and its own transportation system. The production of film is the company’s core business. With qualified, experienced staff, professional production and the latest technologies used at various stages of manufacture, the quality of its products can satisfy even the most demanding customers. KABLONEX is also very flexible. “We are the most versatile film producer and can meet each client’s needs with polyethylene film,” said Nawrocki.

KABLONEX’s annual sales are estimated at more than €30 million, whereas its annual production capabilities reaches more than 30,000 tonnes of plastics. Exports share more than 20% of the company’s total sales, with the main foreign markets being Germany, the UK, and Scandinavian countries.

Experts on packaging films

Foil packaging is used in many industries. It protects all types of goods from dirt and damage, against harmful atmospheric conditions. The size and thickness of the film is individually tailored to customer needs. KABLONEX is one of the most recognised brands on the shrink films market, it is also the leader in the production of multilayer films. The company specialises in the production of the following types of films: shrink films, packaging films, polyethylene bags, bubble film, shrink hoods, HDPE films and POD films. Polyethylene film producing technology is constantly being improved. Thanks to a modern, multi-layer blow moulding machine, the products are able to meet the extremely high demands of the market.

KABLONEX is also one of the leaders in production of thermoshrinkable sleeves for packaging machines. Its solutions are used by big companies that have automated packaging processes. Thermoshrinkable films are used for group packaging on automatic production line for packing domestic appliances, electronics, glass, ceramics, and loose products. The technology is adjusted to each packing machine and product. It can be widely modified. Thanks to modern machines the products fulfil expectations of the most productive packaging machines. The films are produced with three and five layer technology, using high quality materials.

Moreover, the KABLONEX offer has been recently extended and now provides also stretch-hood sleeves made from highly advanced and stretchy packaging film. In comparison to packing using thermo-shrining sleeve, stretchy film is efficient because of the fast process of stretching the sleeve on the pallet. The width and thickness of the foil is smaller than thermo-shrining sleeves. It is perfect for packing goods from building and chemical branches.

Laminating foils for the food industry, thanks to modern five-layer production technology, are perfect for laminating with materials of type: PE, PP, CPP, BOPP, BOPETmet. Usage of suitable resins allows for the production of laminated materials that can be processed on VFFS and HFFS packaging machines. They are available with additions adjusted to requirements of particular packaging lines, with or without dyes. Laminates of this type are generally used for packing frozen products (mix of vegetables, chips), animal feed, soaps, shampoos, and other liquids.

Investing for the future

KABLONEX lives up to the expectations of ecological production process and puts modern circular economy into its everyday practice. The company’s FFS (Form, Fill, Seal) films are 100% recycled. After investments totalling 13 million Euros, the ultra-modern technology used for the production of FFS films were a major hit on international markets, especially in the UK. They are perfect for packing ground, peat and other loose materials. New POD X films are fully made from used foil returned by the company’s customers. On top of this there is also new investments of up to 5 million Euros for a new state of the art recycling plant. n

Visit: www.kablonex.pl