8 minute read

Lighting

Multi-station test workstation illumination

Lighting up manufacturing

Advertisement

There are many economically and attractive solutions available for industrial lighting technology, including incandescent halogen lamps, High-Intensity Discharge (HID), fluorescent lamps and light emitting diodes (LEDs).

Understanding four key factors helps industrial users choose between the technologies to make the best lighting decisions.

1. Metrics

LED, fluorescent, and HID technologies are evaluated using the following metrics. Lumens (lm): The amount of light emitted, (in all directions) Wattage (W): Electrical power drawn by light and electronics (ballast or driver) Efficacy (lm/W): Lumens divided by wattage Lux (lm/m2): The intensity of light as it hits a surface in lumens per square meter Zonal Lumen Distribution: Lumen distribution in zones. Establishes spacing and mounting criteria

Correlated Colour Temperature

(CCT): Light colour appearance from about 2700K (warm) to 6500K (cool)

Colour Rendering Index (CRI):

How accurately a light source renders colours compared to incandescent light Rated Lifetime: For LEDs the projected number of hours until the light output drops to 70% of original. For traditional technologies the number of hours until 50% of lamps fail

Total Harmonic Distortion (THD):

Distortion of the electrical current waveform caused by non-linear loads Power Factor (PF): Ratio of real to apparent power

When creating a lighting solution, first select the proper illumination level. Lighting cannot be compared solely on wattage because new technologies can be more power efficient. Test methods for certain metrics are different for LED and non-LED products, so comparisons based on metrics can be problematic. LED directional light and non-LED omni-directional light with similar lumens can have very different levels of apparent brightness. Users should always evaluate samples of different lighting options in person.

2. Costs

Lighting is a small portion of electrical operating costs (est. 6.8% in 2010), but all savings help the bottom line. Good lighting solutions reduce costs and improve productivity, safety, and efficiency.

Total cost includes initial purchase cost, maintenance costs, lamp replacement costs and energy costs. Longer life and improved efficiency can provide significant overall savings, even if initial cost is higher.

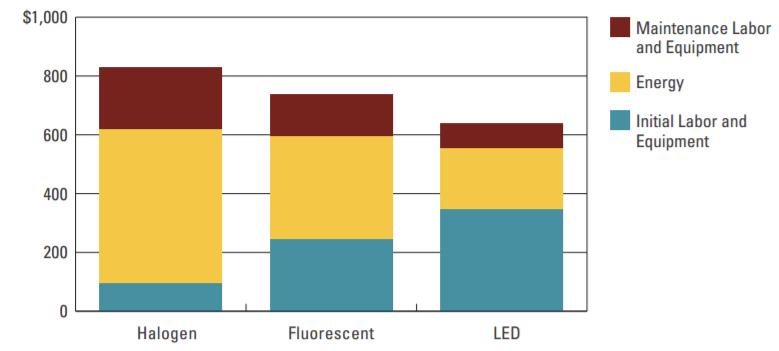

The graph below shows the costs of different lighting technology over a 15-year cycle, assuming typical costs for the different technologies.

Initial costs: Include housing, ballast or driver and the light (e.g. lamp or LED panel). LEDs usually have higher initial costs than other technologies but are often the most efficient option with the longest lifetime. Some products are better in challenging environments, which can increase the cost of the equipment, but reduce the risk of damage or injury.

Retrofit or redesign: Retrofits involve replacing existing lighting with more-efficient technology, while reusing existing housing, lighting pattern, and electrical equipment.

Redesigns involve new fixtures, modification of the existing lighting pattern, and partial or complete rewiring of the electrical system.

Both can involve technology upgrades, adjustment of illumination, and/or modified lighting controls.

Redesign is required if the existing lighting solution is in poor condition, has uneven light distribution, does

Lighting Technology Rated Lifetime (Hrs) Lamp Lumen Depreciation (LLD) at end of rated life

Halogen Incandescent 3,000 – 5,000 5 percent Linear Fluorescent 15,000 – 45,000 10 percent High Pressure Sodium 15,000 – 40,000 30 percent LED 20,000 – 50,000+ N/A

Source: Rated lifetimes from David L. DiLaura et al., eds., The Lighting Handbook, 10th ed., 13.7; LLD from Illuminating Engineering Society and International Association of Lighting Management Companies, Recommended Practice for Planned Indoor Lighting Maintenance: IESNA/NALMCO RP-36-03, 2.

not suit the uses of the space, or if the desired illumination or distribution is not achievable with retrofit options.

Operating costs: Small changes like downsizing area lighting and using lower power focused task lighting or controls that dim or turn off unneeded lights can create significant savings over the lifetime of a lighting solution. Efficacy ratings vary significantly across technologies and applications, from less than 15 lumens per watt (lm/W) for 60W incandescent lamps, to nearly 150 lm/W for some LED area lights. LED lighting often has better efficacy than other technologies, but high efficiency fluorescent and HID options provide better or similar efficacies in some applications.

Maintenance costs: Routinely replacing lamps and cleaning surfaces can reduce total maintenance labour and improve workplace safety and productivity. All technologies experience depreciation in lumen values over time, with some technologies depreciating more quickly than others and it is important to try to predict the technology lifetime and how and when deterioration will occur.

Maintenance schedules should reflect the amount of dirt and dust in the environment. Dirt accumulation lowers light output, can skew light distribution, and dirt on reflective surfaces, including walls and ceilings, can reduce illumination. Regular cleaning, painting, and upkeep ensures peak performance.

3. Environment and use

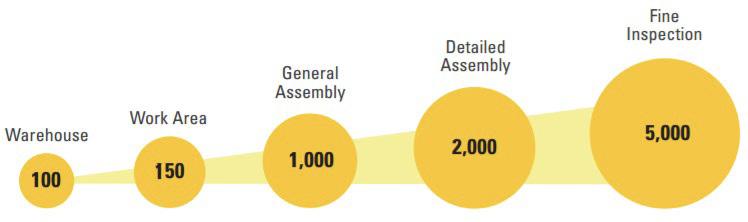

Area lighting includes wide-open, warehouse-type applications often needing high-power lights to provide adequate illumination over a large area. Troffers and downlights for area lighting are common in office environments where evenly spaced fixtures provide consistent illumination.

Task lighting augments area lighting by focusing illumination where the work occurs. Bringing the light source closer

to the work achieves recommended illumination with lower powered lighting. Task lighting is easier to maintain and replace than area lighting. Performance standards for: Determining the appropriate level of light is challenging. Not enough can be dangerous, too much creates glare and adds costs. Lighting design usually starts with an inventory of occupants and functions within the space.

Extreme conditions: Comply with standards for commercial lighting systems.

IP67 industrial lighting products suit typical industrial conditions, but sometimes IP69K products are required.

Vibration reduces the lifetime of lighting that uses fine filaments and other delicate components.

Glass fittings can shatter from impact, exposing workers and equipment to risk and product to contamination.

LED lighting is extremely resistant to vibration and impact.

LEDs are better in cold conditions making them ideal for applications with temperatures as low as -40°C. High temperatures can reduce the efficacy and lifetime of LEDs

Equipment and power quality:

Poor power quality can waste energy and capacity and can harm the system and its devices. Unexpected heat in equipment can indicate power quality issues.

In AC electrical systems the power factor (a number between 0 and 1) is the ratio between real power flowing to the load and the apparent power in the circuit. Low power factor loads draw more current than high power factor loads for the same amount

of useful power transferred. Power factors below 0.9 are considered low. Power factor should be assessed on each meter so, when adding or replacing lighting equipment, the lighting designer should make power factor corrections if needed.

Two performance metrics of lighting equipment are power factor and total harmonic distortion (THD). Power factor must be at least 0.90 for a manufacturer to claim a high power factor. New lighting should have a maximum THD of 20.

4. People

Lighting upgrades can save money with efficiency, but high quality lighting also produces substantial benefits by increasing worker comfort and productivity. The average cost of employee salaries and benefits can be 400 times that of lighting, so lighting that reduces eye strain, boosts mood, and protects safety is a good investment.

Multi station indication and lighting

Combined lighting and indication is achieved with LED fixtures that can emit multiple colours providing illumination or status information as required.

Lighting up manufacturing

Continued from previous page

Effect of Lighting on Mood and

Productivity: Environmental lighting affects the brain and nervous system, influencing alertness and mood. Studies show that the colour of light can have a positive effect, blue light being associated with calm.

While physiological and psychological impacts are important, workers want the brightness, colour, and quality of light that helps them do their jobs. If light levels are too low or too high the result can be eye strain and reduced productivity. Light with a poor colour rendering index (CRI) rating can increase the risk of errors where colour and contrast recognition are important.

Design Recommendations: We should provide enough light to illuminate large, open spaces in industrial facilities while avoiding glare. Solutions include lighting with diffused lenses and shielding and maintaining appropriate levels of reflectance on the ceiling, walls, and floors. Usually, ceilings should be the most reflective surface and floors the least reflective.

Distribution of light to maintain uniformity and vertical brightness ensures that light levels are consistent throughout the space and prevents the eye from needing to constantly adjust. This is especially important where vertical surfaces need to be illuminated. Because LED technology is directional, a wide variety of specialised lenses can be used to achieve different distributions.

Where areas have multiple tasks, the lighting should provide the most commonly occurring task with the highest recommended illumination. Where possible, adjust light levels for the time of day with automated lighting controls and/or daylight.

People perceive light and colour differently, so the occupants in a facility can have a range of colour preferences within the white light spectrum. LEDs have the widest range of CCT and CRI performance levels to cover all requirements.

Conclusion

Industrial users must balance many different considerations when selecting a lighting solution. Lighting industrial workspaces requires understanding the application and tasks in the space and the space’s physical conditions. Lighting solutions must provide appropriate illumination, and this often includes both area and task lighting. Using LED products to combine illumination and indication can save costs while also providing increased comfort, functionality, and safety.

Lighting upgrades must also make economic sense. Users should focus on full life-cycle costs of a lighting solution when choosing technologies, recognizing that solutions with high initial costs may be the least expensive overall due to efficiency and lifespan. Customers must also understand their own environment and choose lighting that matches their specific needs.

Balancing these considerations can make the selection process complicated, but the right lighting solution can help you ensure that your facility is appropriately lit, productive and safe for everyone who works there.

Extruded strip light SP wet application

Turck

turck.com.au

TENTE “SMILES” CASTORS

UNLEASH YOUR CREATIVITY

Award Winning Design

NEW

Panda

Bright and Colourful Faces

Bear

Cat 50mm Diameter Wheel

Cow

Plane

Range of “plug-in” fittings

Plate Circlip Threaded

Blind Hole

Faster assembly thanks to easy plug-in fittings.