MANUFACTURING GROWTH

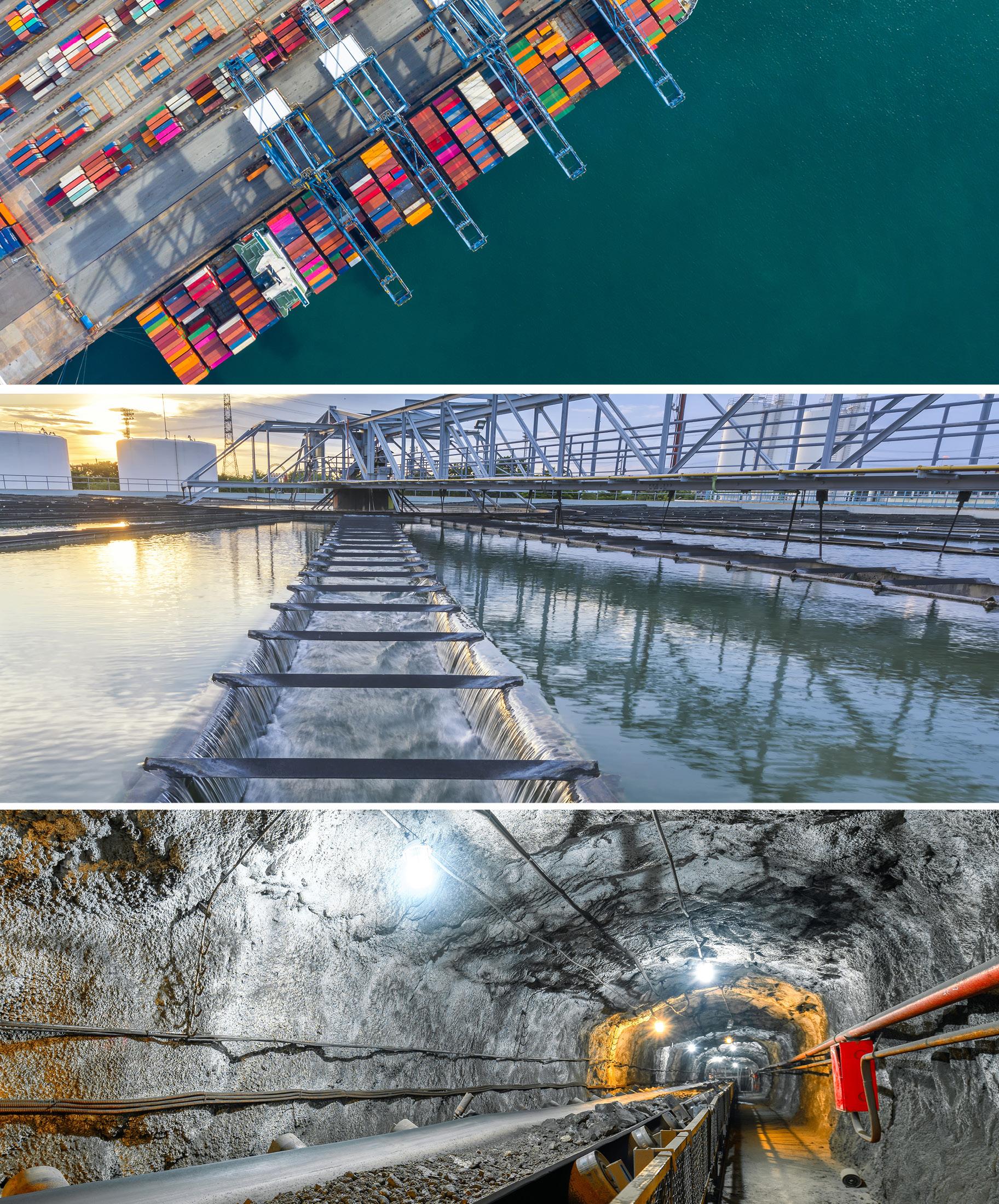

infrastructure projects – particularly in New Wales, and when you view this against a of robust global economic growth, opportunities are there for manufacturing to

Bizarrely, the threat of a global trade war have worked in favour of Australian the short term at least – by softening the Aussie dollar.

“More Australian manufacturers are exporting under the Coalition Government. For every $1 of revenue the sector generates, 28 cents comes from abroad. That’s up from 23 cents a decade ago,” says Senator Cash.

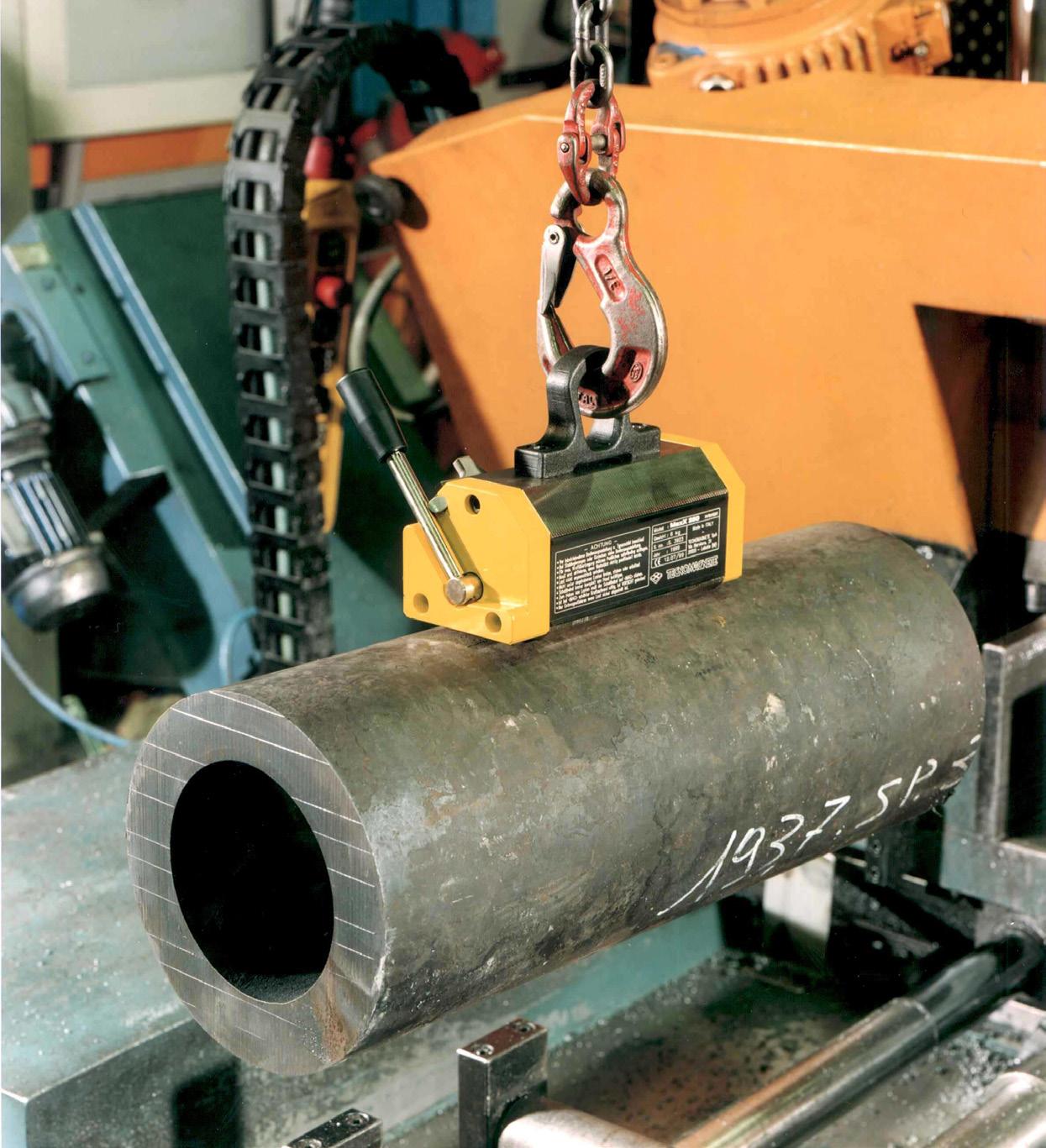

PRODUCTIVITY PLUS FOR SAFE MOBILE PLATFORM

How Espresso Displays beat supply chain issues to get their ‘crazy’ thin monitor to the world

By Margie Smithurst

By Margie Smithurst

Nonetheless, the nation’s reliance on export increased in recent years. According for Jobs and Innovation Senator Cash: “Australia’s access to global markets will be fundamental to continued health and success of our local manufacturing industry.

export more than $20 billion a year than we did a decade ago. Australian have, in fact, sold $2.7 trillion to the economy over the last decade.

Besa Deda from St.George also sees positives in the manufacturing employment statistics. “Although manufacturing employment as a proportion of the economy as a whole is in a long-term decline, the recent gains are encouraging,” she says, pointing to nearly 10,000 new manufacturing jobs and increasing capital expenditure plans in the sector.

One word of warning, though, comes from financial analyst illion, which noted in its most recent Australian Business Expectations Survey that one in three manufacturers had reported customers or suppliers become insolvent or unable to pay them in the preceding 12 months, highlighting cashflow as the second-biggest barrier to growth in the year ahead, after utilities and operating costs

t’s been lauded by the AFR as ‘the solution to working from home’, and earned praise from The Washington Post and Forbes magazine, as well as tech industry

Now available at a one-off price of $400 and with significant discount for quantity orders, the DarDeck safe step platform can pay for itself in efficiency gains. And the improved safety it brings to any warehousing, retail or maintenance environment could save a fortune in workers compensation and public liability payouts.

students Will Scuderi and Scott McKeon came up with an idea to make lightweight portable monitors that would sync with their devices and act as second displays.

For the young Sydney engineering graduates behind Espresso Displays, which makes the world’s thinnest portable monitor, the journey to success wasn’t smooth – but it was smart, and very ambitious. It was also a rare move by an Australian company into the consumer hardware innovation space.

In 2018, out of frustration with the limited screen space available on their laptops at uni, two UTS

Designed as a simple and more productive alternative to unstable stepladders and unguarded low work platforms, the Australian designed and manufactured DarDeck combines a solid working platform with safety rails to prevent the user from overbalancing and falling. There is also an integrated shelf to ensure both hands are free when mounting and dismounting.

They then added a hitherto untried element: they wanted the aluminium monitor to be just 5mm thick, 2mm thinner than an iPad.

The pair, joined by a third UTS engineering student Fabian Martitato, put together a prototype using Will’s own 3D printer at home. From there, Will and Fabian worked with vendors overseas to develop the prototype further. This led to them launching a Kickstarter campaign in

Continued page 52

AUSTRALIA'S LARGEST CIRCULATING MANUFACTURING MAGAZINE Issue 131 Apr/May 2023 $12.00 inc. GST

48

OVER 25,000 CABLES, CABLE GL ANDS & CONNEC ORS ONLINE. Make the right connection with L APP Australia. ralia.com.au sales@lappaustralia.com.au 1800 931 559 LEADER IN CABLE AND CONNECTIVIT Y SOLUTIONS Darling Harbour PRODUCT SOLUTIONS @ARBS industry Speaker Series product presentations precinct, IBTech@ARBS dinner celebration networking opportunities www.nationalmanufacturingweek.com.au Materials & Robotics Internet of Things *Based on 2016 attendance CAB Audited by AMAA ATTENDEES OVER 3 DAYS* EXHIBITION ZONES WHERE MEETS OPPORTUNITY LEADERS IN INDUSTRIAL AUTOMATION SUPPLY Treotham Automation Pty Ltd Phone: 1300 65 75 64 Email: info@treotham.com.au Website: www.treotham.com.au Offices in Sydney, Melbourne, Brisbane & Perth 1992 2017 Y CELE B R ATING B R Flexible Cables Linear Units Gearboxes Bearings Measuring Systems Sensors Safety Products Cable Accessories Flexible Conduits Connectors Energy Chains Chain ex Cables MTIQualos_Measurement 2015 IndUpd.indd 1 Industry Update MANUFACTURING MAGAZINE www.industryupdate.com.au

61

PAGE

NEW WORKPLACE HEALTH AND SAFETY SHOW PAGE 34 UPDATE VIDEOS WITH NATIONAL TV ICON TIM WEBSTER

HEALTHY & HAPPY AT WORK 5 EXERCISES TO KEEP YOU FIT 1707AMWMEL23INDUPDATE AUSTRALIA’S PREMIER MANUFACTURING SOLUTIONS EVENT SCAN HERE TO REGISTER A U ST R A L IANMANU FACT U R I NGWEEK.COM.A U T H E J O URNE Y T O I N T ELL I GEN T MAN U F AC TU R I N G DON’ T M ISS O U T ! R E GIS TER N O W 9 T H – 12 TH M AY 2 023 , M ELB O URN E • MC E C Continues on page 12 76 72

22 17

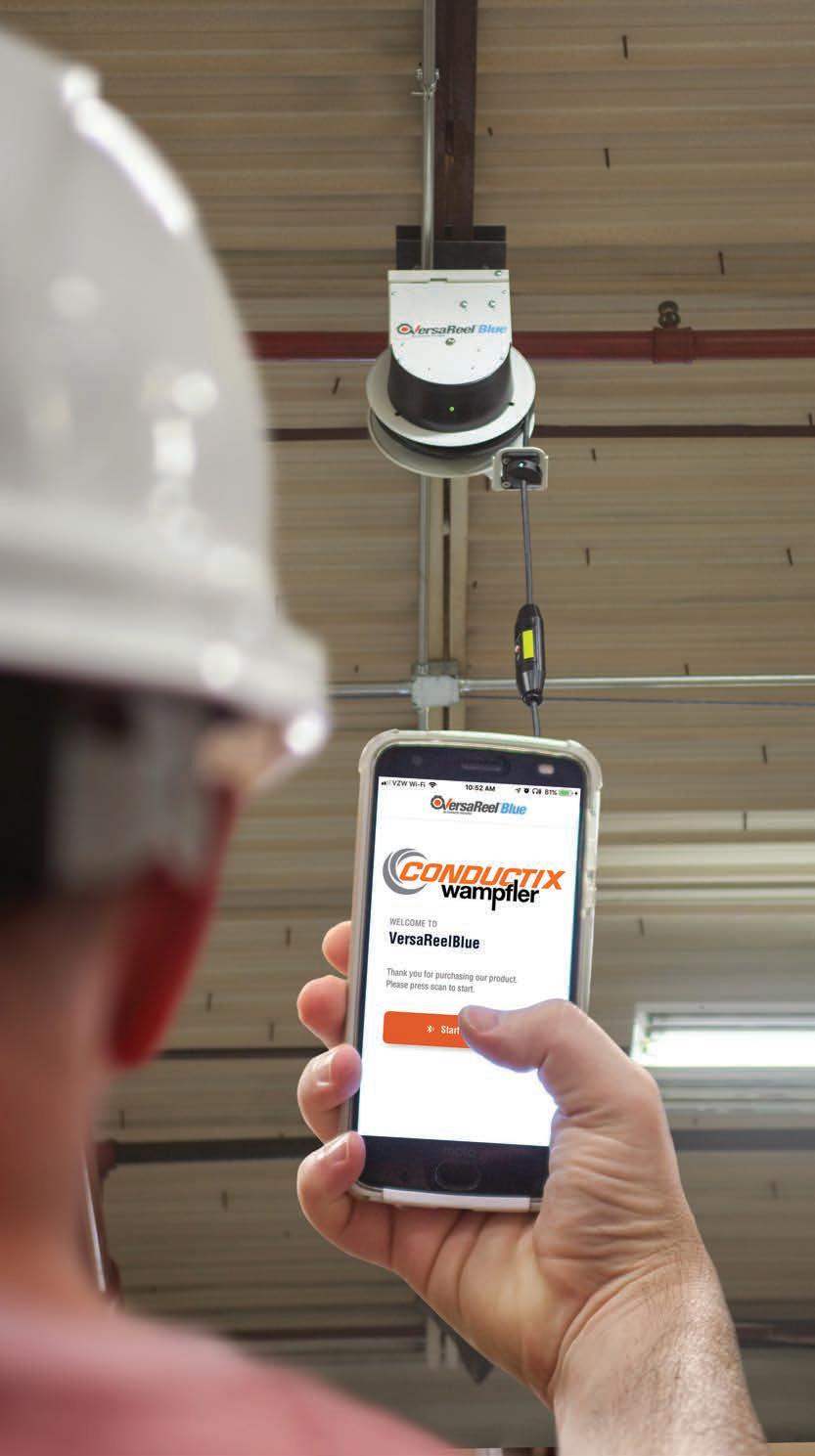

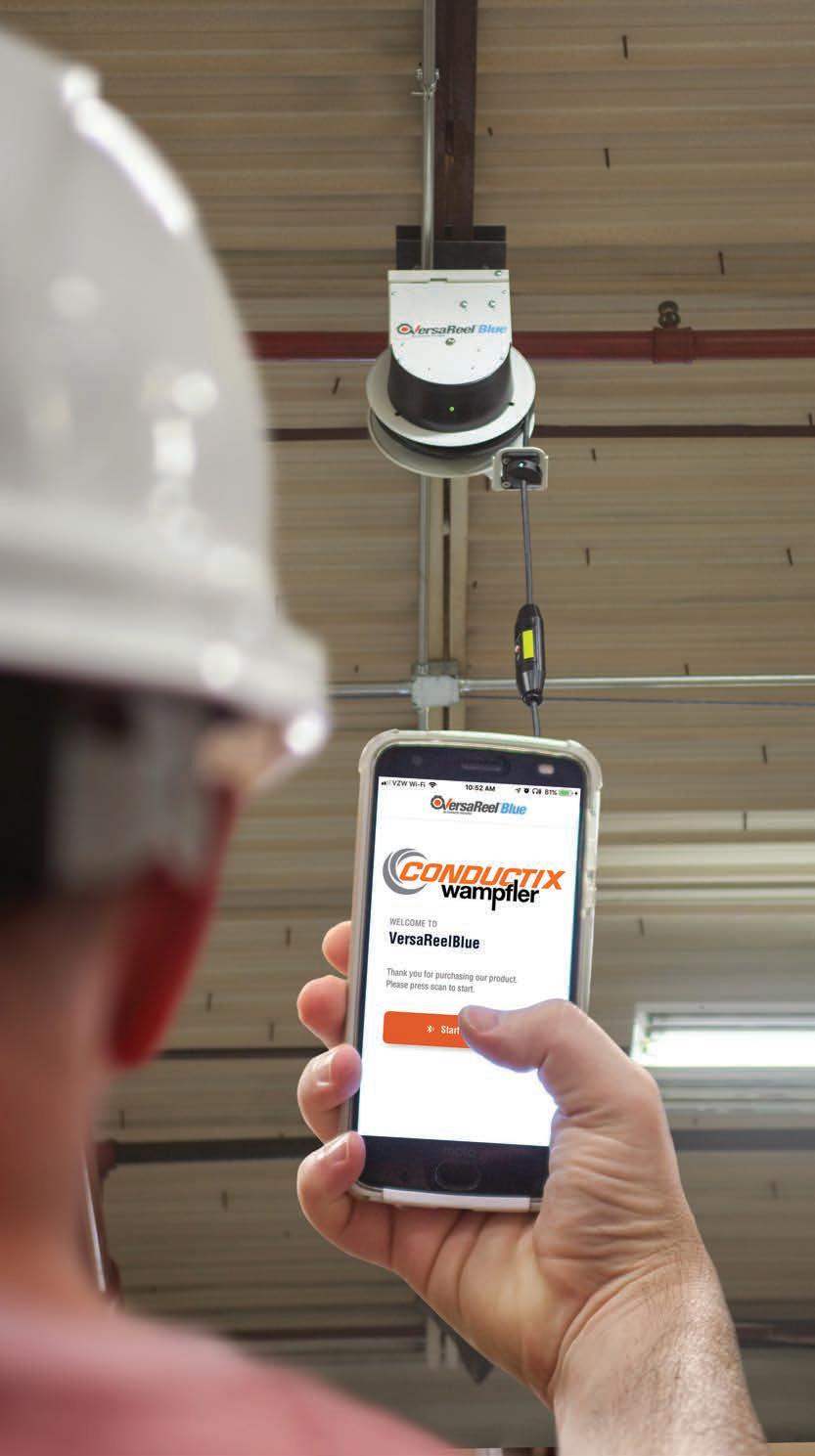

VersaReel® Blue

ersaReel Blue®

by Conductix-Wampfler

Key Features

• Quick and easy remote control lowering and raising the 240v power socket

ersaReel Blue®

by Conductix-Wampfler

When you have a temporary power requirement and Safety, Convenience and Reliability are important then the Versa Reel Blue may be your perfect option. The Versa Reel Blue mergers the proven reliability of the Conductix-Wampfler cable reel performance with the latest in simple to use Bluetooth technology. With the combination of the two Conductix-Wampfler have been able to produce a safe and reliable remote control cable reel system that works simply with your Bluetooth enabled mobile phone.

• Discreet ceiling mounting of the cable reel and control system offering quick and easy access to 240v power socket

• The option to select the height of the power socket keeping it at a safe height at all times

• Quiet and smooth operation, suitable for sensitive indoor applications

• Professional and discreet appearance, removing unsightly cables when not in use

• Improved safety with the cable tripping hazards removed

• Easy operation from any Bluetooth enabled mobile phone

• IOS and Android compatibility

• Remove the need for ladders to pull cable down from traditional spring cable reels

• Reduced wear and tear on cable and socket

• Removes the need for unsafe cable hanging arrangements

• Secure control features

cable reels require a lift or ladder to contrast, VersaReel® Blue has a rugged by Bluetooth® technology to do the control feature increases safety and takes to manage cables. your Android or iPhone to wirelessly control from a distance of up to 100 ft. Security unauthorized use. The quick-mount base the need to support the reel's weight safe way to manage drop-power cables VersaReel® Blue. Payout and retract the having to leave the ground. No need to find drag out unsafe ladders, or find an aerial unsightly cable dangling while not used. proudly made in the USA.

...when Safety, Convenience and Reliability are important.

Office Space

• Safe, easy and secure operation for staff/operators requiring minimal training

• Maintains a safe area reducing the risk from cable tripping hazards

• Keeps the power socket in safe location at all times

• Quiet and smooth operation not creating issues during operation

• Provides power when and where it’s needed and out of harm’s way when not required

Workshop/Warehouse

• Maintains a safe area reducing the risk from cable tripping hazards and ladder falls from spring reels

• Keeps the power socket in safe location at all times reducing wear and tear and risk from electrocution

• Provides power when and where it’s needed and out of harm’s way when not required

• Safe, easy and secure operation for staff/operators requiring minimal training

• Reliable 240v 10amp supply directly at your workspace

Factory Floor

• Maintains a safe work area reducing the risk from cable tripping hazards

• Removing the need for ladders with spring cable reels removing the risk of a ladder fall

• Keeps the power socket in safe location at all times reducing wear and tear and risk from electrocution

• Safe, easy and secure operation for staff/operators requiring minimal training

• Reliable 240v 10amp supply directly at your workspace

Service Centre

• Maintains a safe work area reducing the risk from cable tripping hazards and the impact on personnel and the service area.

• Removing the need for ladders with spring cable reels reducing the risk from a ladder fall

• Keeps the power socket in safe location at all times reducing wear and tear and risk from electrocution

• Safe, easy and secure operation for staff/operators requiring minimal training

• Reliable 240v 10amp supply directly at your workspace

SPECIFICATIONS

• Standard Australian 240v 10amps power outlet

• In built clutch prevents damage if cable gets caught

• Powerful enough to retract 10 metres of cable and socket

• Integrated Bluetooth® Technology - works from any Bluetooth® activated phone

• Safety protocols lockout second user while in operation

• One APP will operate up to 10 reels

1800 733 722 | e: sales.au@conductix.com | w: www.conductix.com.au

Commonwealth Government.

But he says when St.George came on board to offer finance, their Western Sydney manufacturing team not only brought expertise but also in-person introductions to the world of state government grants – in this case, NSW ones.

“They organised a meeting with about four different government entities all at once on our premises, and they went above and beyond to get them all in one spot,” Meyer told Industry Update

capability and more of an offering to our clients.

“We need to show that we have hired new staff over that period, and that we’re buying these new machines …and then the government basically funds dollar for dollar on the new capability purchases.”

“In rough numbers it’s over $2 million worth of equipment, which we’ve paid a million dollars for, and the government will contribute over a million dollars over the four year period as the staff are employed.”

With the new factory consolidation to be finalised by the end of the financial year, Meyer says the company will double volume in the foreseeable future, and expects to double that again in time with new plant and enhanced capability.

Value-adding

Meyer says St.George’s team, led by Matt Kelly, who they dub ‘Mr Manufacturing’, is very proactive with their manufacturing clients.

“He’s a go-getter. There’s a constant stream of different opportunities like networking, or industry experts and grants information coming from their office.

Networking helps sous-vide company bag significant grant

Navigating the world of grants isn’t a particularly dynamic one for companies, which usually interact with computer interfaces rather than people during the process.

But thanks to some prudent networking opportunities, Meyer Food Co, the sous-vide specialists once known as Bryopin, won a $1million NSW Jobs Plus grant, enabling them to roll out plans to significantly increase their capability and get the most out of their recent new factory build.

The Meyer family pioneered traditional sous-vide cooking in Australia. In 1988, brothers Nicholas and Michael

By Margie Smithurst

Meyer heard about the French cooking method (vacuum-sealing food in a bag and cooking it to a precise temperature in a water bath) and decided to establish their own business here, which included designing and fabricating the cooking and cooling equipment.

The brothers’ children now run the company, which is arguably the largest one in Australia dedicated to traditional sous-vide cooking.

No stranger to grants, Meyer Food Co Managing Director Anthony Meyer says the company had applied for a couple of Modern Manufacturing Initiative grants and understood the process with the

“It certainly helped us to understand the New South Wales grant opportunities. We were able to adapt our submission to ensure it was suitable and met the criteria for Jobs Plus.

“After a long time, probably at least 12 months, we had the grant approved. It was all off the back of St.George putting all those different people in a room with us, and showing us not only what we already knew, but a few different things that we didn’t know, which ended up being the key link to helping us get a Jobs Plus grant.”

More staff and capital investment

The Jobs Plus grant (now closed) was a NSW government initiative offering companies contributions towards training, infrastructure and payroll tax if they hire more staff full time.

Meyer says they’ll use the money to hire 30 people over four years and build extra capability in their new factory, a consolidation of 13 other sites.

“The grant enabled us to buy more machinery in order to have more

All Meyer Food’s banking business has now gone to St.George.

“Banking is the easy part,” says Matt Kelly. “What makes us different is that we partner with other providers to help our customers find ways to reduce costs, find money or enhance operations.”

“One of the best things you can do in banking is help clients succeed in a tangible way outside banking.”

Disclaimer: This information is general in nature and has been prepared without taking your objectives, needs and overall financial situation into account. For this reason, you should consider the appropriateness for the information to your own circumstances and, if necessary, seek appropriate professional advice. | © St.George Bank - A Division of Westpac Banking Corporation ABN 33 007 457 141 AFSL & Australian credit licence 233714.

St.George stgeorge.com.au

The Meyer Family at new factory construction, excluding Anthony. (L-R) Fiona Jordan (Human Resources, Credit Director), Michael Meyer (Co-Founder), Nicholas Meyer (Co-founder), Alex Meyer (Sales Director)

Matt Kelly (L) and Anthony Meyer with new cooling tanks

BUSINESS, FINANCE & ACCOUNTING

“What makes us different is that we partner with other providers to help our customers find ways to reduce costs, find money or enhance operations.”

4 | Industry Update Issue 131 Apr/May 2023 industryupdate.com.au

Anthony Meyer, Meyer Food Co Managing Director, Matt Kelly (R), St. George Bank at new factory

Ready, Set, Grow Transform your business with the help of our Manufacturing and Wholesale specialists, dedicated to connecting you with solutions that meet the unique needs of your business. If you’re ready to fire up your business, talk to us today. Things you should know: T&Cs, fees, charges and eligibility and credit criteria apply. © St.George – A Division of Westpac Banking Corporation ABN 33 007 457 141 AFSL and Australian credit licence 233714. COM 0348 0223 STG Manufacturing & Wholesale Matthew Kelly Head of Manufacturing & Wholesale 0412 265 197 manufacturingwholesale@stgeorge.com.au stgeorge.com.au/manufacturing

CONTENTS

www.greasemax.au

MANUFACTURING MAGAZINE

Industry Update Media Pty Ltd ABN 25 083 502 783 Suite 403, Level 4, 116-118 Christie Street, St. Leonards NSW 2065 +61 2 9439 1288 / sales@industryupdate.com.au

Circulation 17,754

Readership 71,016 as at September 2022

All material in this publication is copyright to the publisher and/or its contributors. No material may be reproduced in part or in whole without the written consent from the Publisher. It is a condition of purchase or acceptance of this magazine that the Publisher does not assume any responsibility or liability for any loss or damage which may result from any inaccuracy or omission on this publication or from the use of the information in this publication or from the use of the information and illustrations contained herein and the Publisher makes no warranties, express or implied, with respect to any of the material contained herein. © Copyright Industry Update Media Pty Ltd 2023

Publisher SCOTT FILBY scott@industryupdate.com.au

Editor CHRISTINE POWIS editor@industryupdate.com.au

Writer MARGIE SMITHURST writer@industryupdate.com.au

Universities & Collaboration Editor DAVID SLIGAR unieditor@industryupdate.com.au

Sub Editor WILLIAM POOLE subeditor@industryupdate.com.au

Advertising Sales Director SCOTT FILBY scott@industryupdate.com.au

Sales Assist JAMES ROBINSON salesassist@industryupdate.com.au

Marketing Manager DUMI UDESHIKA marketing@industryupdate.com.au

Creative Director EDWIN KWONG production@industryupdate.com.au

Production Manager DUMI UDESHIKA copy@industryupdate.com.au

Video Editor & Producer CHARLIE LOUGHLIN video@industryupdate.com.au

Office Manager NICOLE CHARLES nicole@industryupdate.com.au

Finance & Accounts MICHELLE ALCOCK michelle@industryupdate.com.au

Consultant TRACY FILBY tracy@industryupdate.com.au

Accounts Receivable LYN SLIGAR lyn@industryupdate.com.au

Subscription Assistant SAM HICKS info@industryupdate.com.au

Circulation Assistant JERIN BURZACOTT circ@industryupdate.com.au

Printer SPOTPRESS

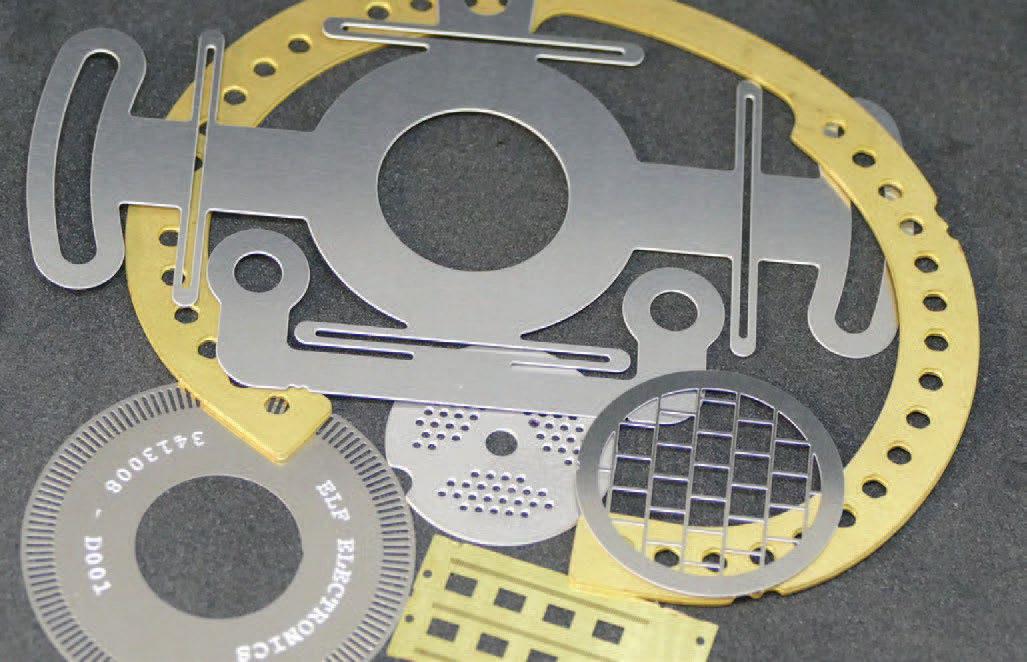

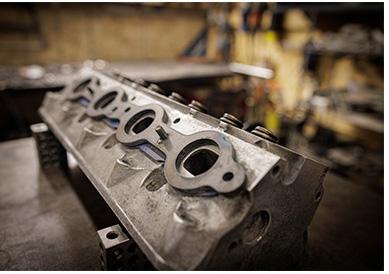

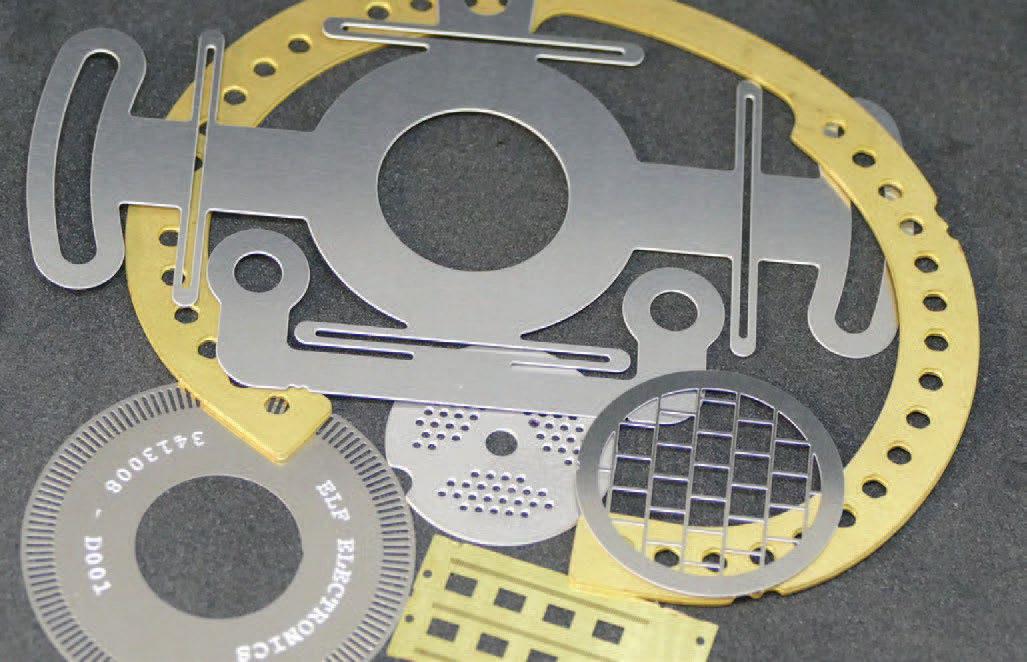

Unique metal manufacturing business for sale

including BAE Systems and Thales.

sions of interest from potential purchasers, as its owners prepare to retire.

Operating for more than 25 years, the company caters to a broad base of industries with its unique blend of capabilities in making thin metal parts, ID plates, signage and shim products to adjust machines levels and heights. It also customises shapes for clients’ applications.

Markets include original equipment manufacturers, defence, mining, oil, gas and electronics assemblers in Australia and New Zealand. Accredited with ISO-9001:2015, the company has been a long-standing supplier to Defence Department primes contractors

The company has expanded to service local councils with highly durable signage and nameplates. This broad customer base provides excellent resilience in changing markets.

The business is being offered as an asset sale and is clean, debt-free, and currently employs 16 staff with a turnover exceeding $3 million. This well managed company has shown steady growth and profitability, even through the pandemic.

Offers are expected to close 16 May 2023. In the first instance, interested parties should contact Scott Filby, Publisher of Industry Update by email scott@industryupdate.com.au

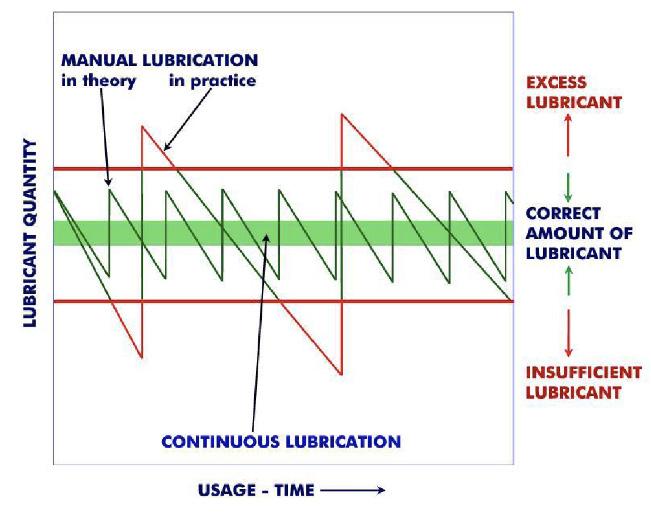

simply superior! single point lubrication WHAT’S POOR LUBRICATION COSTING YOU? MEDIAKIT2023 MANUFACTURING MEDIA AUSTRALIA’S NO.1 MANUFACTURING & INDUSTRIAL EQUIPMENT MAGAZINE & DIRECTORY DOWNLOAD MEDIA KIT Business, Finance & Accounting 4 From the Publisher 7 From the Minister 8 Industry News 10 Australian Made Week 22 Cyber Security 34 Automation 36 Australian Manufacturing Week 38 Electronex 66 Electronics 72 Workplace Health and Safety Show 76 Waste & Recycling 88 Events 94 Australian Made makes Australia Australian Made Week 15—21 May Certify your products as Australian Made australianmade.com.au/apply Web Developer JINI M R

Asouth-east Queensland manufacturing business specialising in thin metal products is inviting expres-

6 | Industry Update Issue 131 Apr/May 2023 industryupdate.com.au

Publisher Scott Filby

While Treasurer Jim Chalmers has warned of the grim international economic outlook and its impact on Australia, the government’s plan to invest in local manufacturing capability and technology comes as a welcome bolster.

The passing of the $15 billion National Reconstruction Fund, as noted in Minister Husic’s column on page 8, should help Australia improve our low ranking in manufacturing self-sufficiency, to which Covid drew startling attention. It also aims to advance manufacturers’ use of technologies in automation - something still lagging, as the latest Rockwell Smart Manufacturing Report points out (see page 37).

Australian Manufacturing Week in May in Melbourne (starts page 38) is a must-attend for manufacturers on the path to smarter production or thinking about it. It showcases the latest in production technology, including the newest 3D metal and carbon fibre printers.

Additive technology printers can bypass supply chain issues with their ability to locally produce parts of various shapes and sizes on demand, to high resolution and in large or small batches. On page 10, we tell the story of how Australian inkjet ingenuity combined with Swedish metal binder jet technology to make the latest in a high quality batch 3D printer, soon to be available here from Markforged.

Alongside AMW in Melbourne is

Australia’s largest electronics event, Electronex (page 66). Australian ingenuity in the electronics sphere is also on show in the magazine, with Sydney engineering graduates winning over fans around the world with their ultra-thin second display, made possible with manufacturing feats and supply chain determination.

Topping off the push for Australians to produce and buy locally, Australian Made Week is in May, and who better to represent the cause than tennis champion Ash Barty.

Meanwhile, with constant interest rate hikes biting both households and businesses, the Easter reprieve was most welcome. Manufacturers continue to face economic pressures, with new orders contracting, elevated prices, supply chain and labour challenges, as well as uncertain gas prices for east coast businesses.

But in my conversations with the sector, I hear the positive stories too. One measuring instruments specialist who supplies to Australia’s manufacturers, including the aerospace and defence sector, told me his sales have gone up since Covid, indicating that companies are increasingly making their products here.

This increase in onshoring is driven by a pragmatic need not to be caught short again, and is hopefully an enduring legacy of Covid.

Editor Christine Powis

Achievements by manufacturers more than justify the Federal Government’s focus and financial support for the sector via its National Reconstruction Fund — as this issue tells.

It’s fantastic to see local manufacturers solving problems, saving time and reducing risks in critical areas, and making inroads in the world’s core industries such as construction, and growth industries such as aerospace and defence.

One is Hypersonix Launch systems, an aerospace engineering and manufacturing firm since 2019 yet already successful in defence — and US ‘defense’ no less (story page 14).

This young hypersonic vehicle and scramjet engine specialist beat 60 contenders in a contract for testing hypersonic platforms, sensors, and comms, navigation, guidance and control systems.

Meanwhile, Western Australian robot maker FBR Limited is poised to set a fast building pace in the US (see page 29). FBR makes its stabilised Hadrian X robots here but offers them ‘on demand’ to developers to build walls faster and more safely than manual builders.

On the home front, Sydney steel fabricator All Metal Products has collaborated with a hospital and UNSW to create a life-support trolley which reduces risks, and saves time and

probably lives when patients get moved around a hospital. As the trolley fits many different bed designs, the market could be wide open for all hospitals and many clinics here and perhaps beyond (see page 32).

And there’s two business-minded series. One tells how getting familiar with tariff concession orders, run by Australian Border Force aka ‘customs’, can boost manufacturers’ bottom lines (see page 19). The third in a series from William Buck advises on revitalising your business in the wake of disruption (see page 42).

As government ramps up its fighting stance on cyber crime, we’re running the second part of our cyber crime story. It’s a guide on how to secure your operational tech – tailored to manufacturers’ OT — from Ashwin Pal, Partner, Cyber Security and Privacy Risk with RSM Australia.

The good news is that not all measures he advises incur downtime and, because businesses fail in basic ways, small things done properly can make a huge difference.

Unfortunately this is my last issue as editor and I want to thank Publisher Scott Filby and colleagues for the opportunity to work on Industry Update and get to know more of this vital and varied industry.

FROM THE PUBLISHER

Industry Update Issue 131 Apr/May 2023 | 7 industryupdate.com.au

Minister for Industry and Science Ed Husic

NRF through the lens of technology

The National Reconstruction Fund Corporation Bill passed the Parliament in March, bringing one of the largest peacetime investments in Australia’s industry and manufacturing capability one step closer.

Australians should be proud of our manufacturing history. We’ve made a wide range of sophisticated goods – and to very high standards.

But by 2015 we had slumped to last place in an OECD survey of manufacturing self-sufficiency.

Harvard University’s Atlas of Economic Complexity had Australia in 91st place in 2020, down from a modest 55 in 1995.

It’s clear that growing reliance on global suppliers has resulted in unwelcome impacts. For example, when the COVID pandemic happened, we couldn’t get the things we needed most at the most crucial time.

Becoming the last link in the global supply chain left Australia vulnerable.

Because we are now a price-taker rather than a price maker in manufacturing, we’re also more susceptible to global inflationary pressures.

That’s something no pragmatic Australian government can or should tolerate.

We’re confident the soon-to-be-established NRF –will empower our manufacturers to better withstand global shocks and diversify our industrial base.

Robotics Strategy for Australia.

We are a global leader in field robotics – robots that operate in large, unstructured outdoor domains carrying out aerial, land or underwater missions.

As technologies advance and mature, more and more Australian manufacturers will adopt robotic systems to improve their productivity and efficiency.

The NRF’s focus will help nurture and grow the industries and jobs of tomorrow, particularly in areas where we have natural and competitive strengths.

The NRF will dedicate $5.5 billion in funding for renewables and low-emissions technologies, medical science and advanced manufacturing for example.

There will be a targeted $1.5 billion for manufacturers to value-add to our resources and agricultural commodities.

I have also announced the development of a National

There is also immense potential for robotics and automation systems to make our workplaces safer and to help free up workers for more fulfilling and creative tasks.

Complementary to the strategy, the NRF will improve Australia’s critical technology capability, in areas such as quantum, robotics, and artificial intelligence; and there’s $1 billion for advanced manufacturing.

In terms of the research needed to underpin growth in these areas, Australia punches well above its weight.

From 2016-20, Australia ranked in the global top 10 in research across 36 technologies ranging from nanobiotechnology and additive manufacturing through to small satellites.

Our scientists will also be critical to addressing the challenges of putting our manufacturing sector on more sustainable footing.

We’re all aware that Australian scientists at the University of NSW invented the technology used in almost all the world’s photovoltaic arrays. It pains me to this day that we didn’t move quickly enough to manufacture it.

If we invent it here, then we should also make it here.

With our strong culture of innovation – and the NRF’s backing – more of our breakthroughs will be commercialised and scaled up here instead of overseas.

I’m especially excited by additive manufacturing and its potential to progress the Australian Government’s broader advanced manufacturing agenda.

The ability to build an object one layer at a time using 3D object printers is already revolutionising traditional fabrication methods.

Additive manufacturing technologies will allow our medical technologies, defence, and aerospace sectors to become even more competitive, particularly in global export markets.

These and other technologies will help create an advanced manufacturing ecosystem.

With our R&D expertise, our extensive raw materials and more cheap renewable energy coming on stream, the NRF is a historic opportunity to take manufacturing to a new level – one where the label ‘Made in Australia’ is synonymous with quality, reliability, and innovation.

FROM THE MINISTER

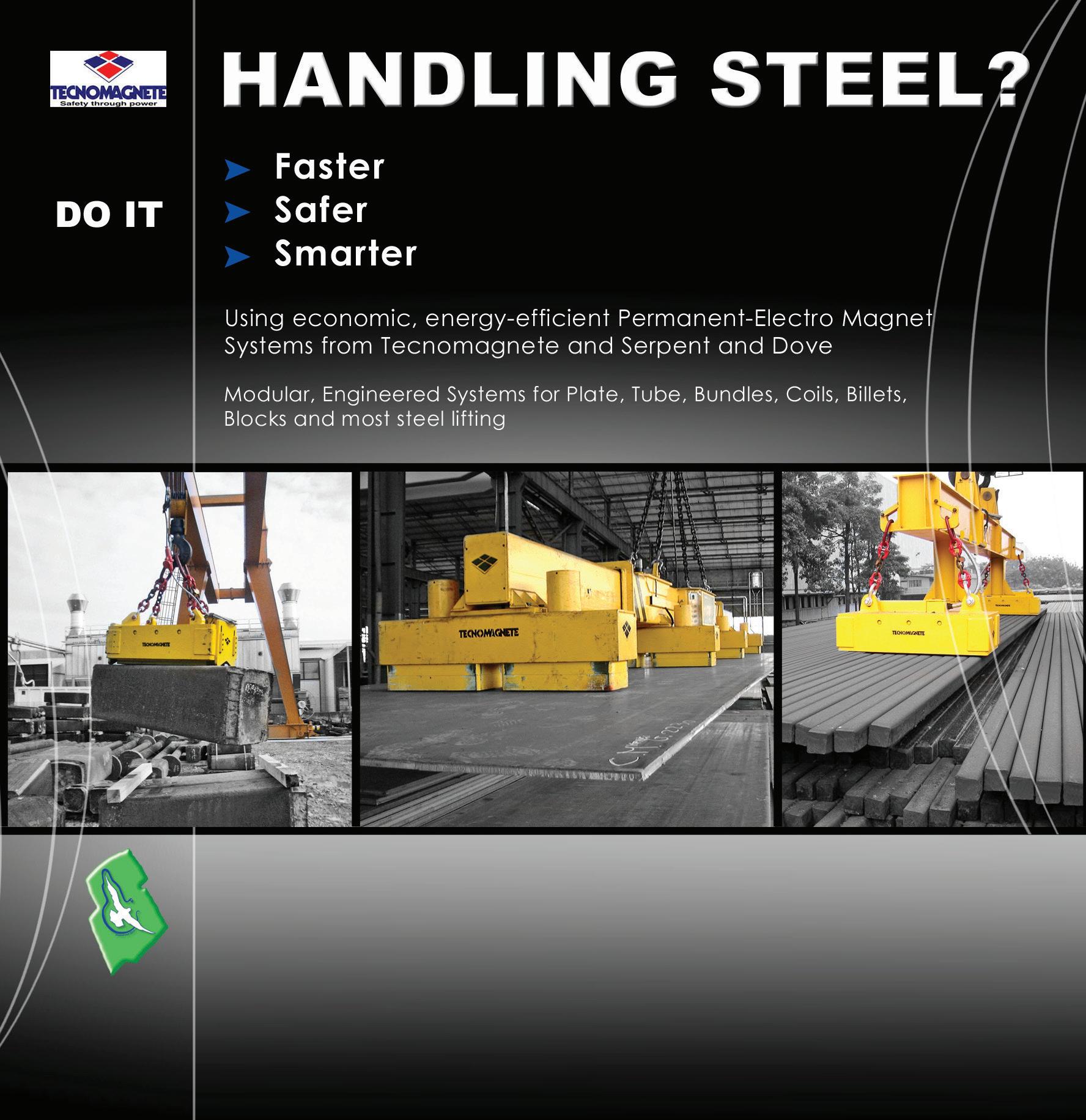

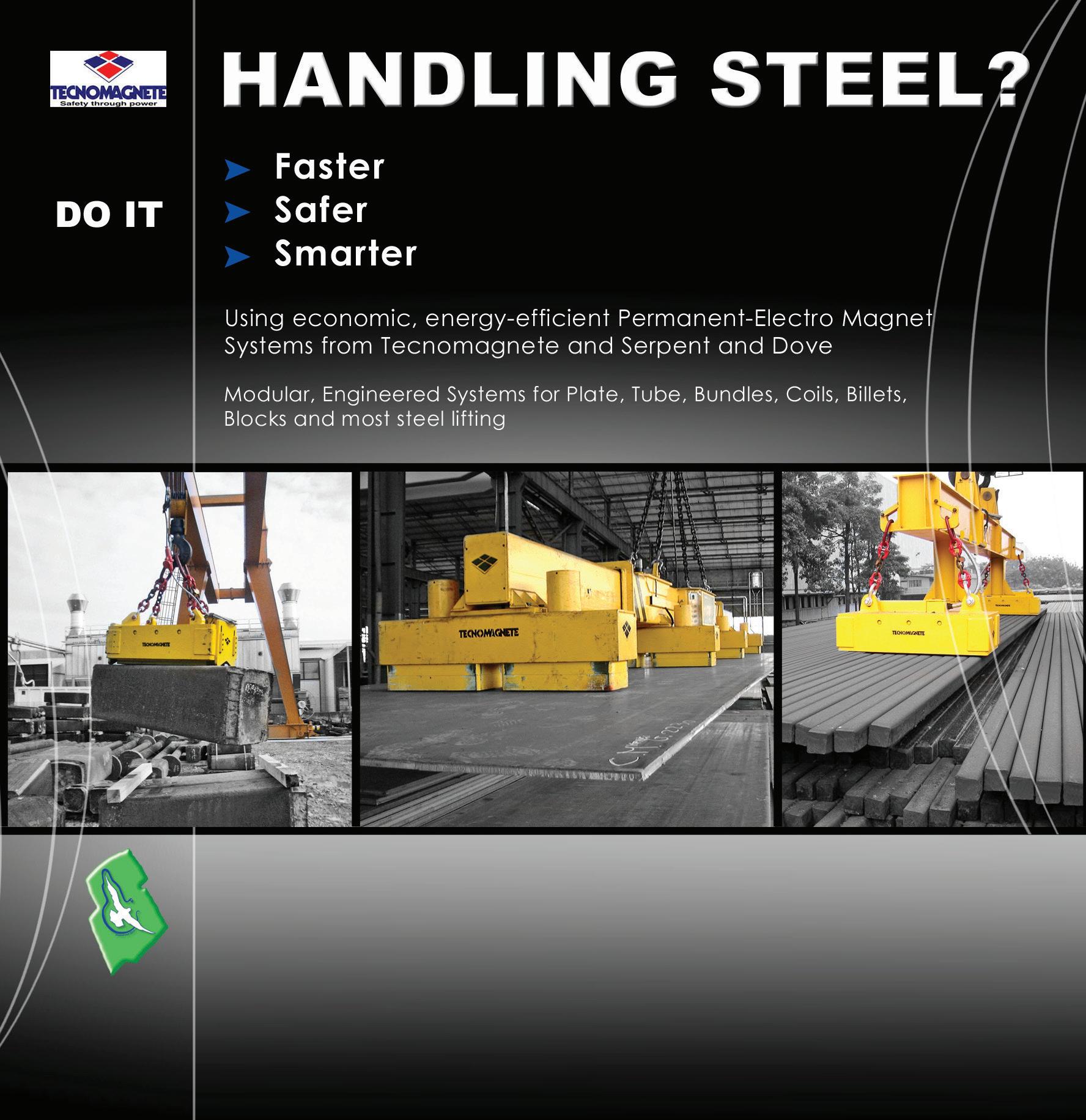

Phone 02 9971 7577 Email sales@serpent-dove.com 2/6 Taronga Place, Mona Vale NSW 2103 serpent-dove.com.au

“If we invent it here, then we should also make it here.”

8 | Industry Update Issue 131 Apr/May 2023 industryupdate.com.au

“I’m especially excited by additive manufacturing and its potential.”

sales@HydroInnovations.com.au www.HydroInnovations.com.au PERISTALTIC SLUDGE PUMPS Early leak detection Easy hose changes Pump thick sludge easily No corrosion issues Only one wearing part Very easy servicing ADVANTAGES

Swedish and Australian technology combine in ‘game-changing’

3D metal printer

by Margie Smithurst

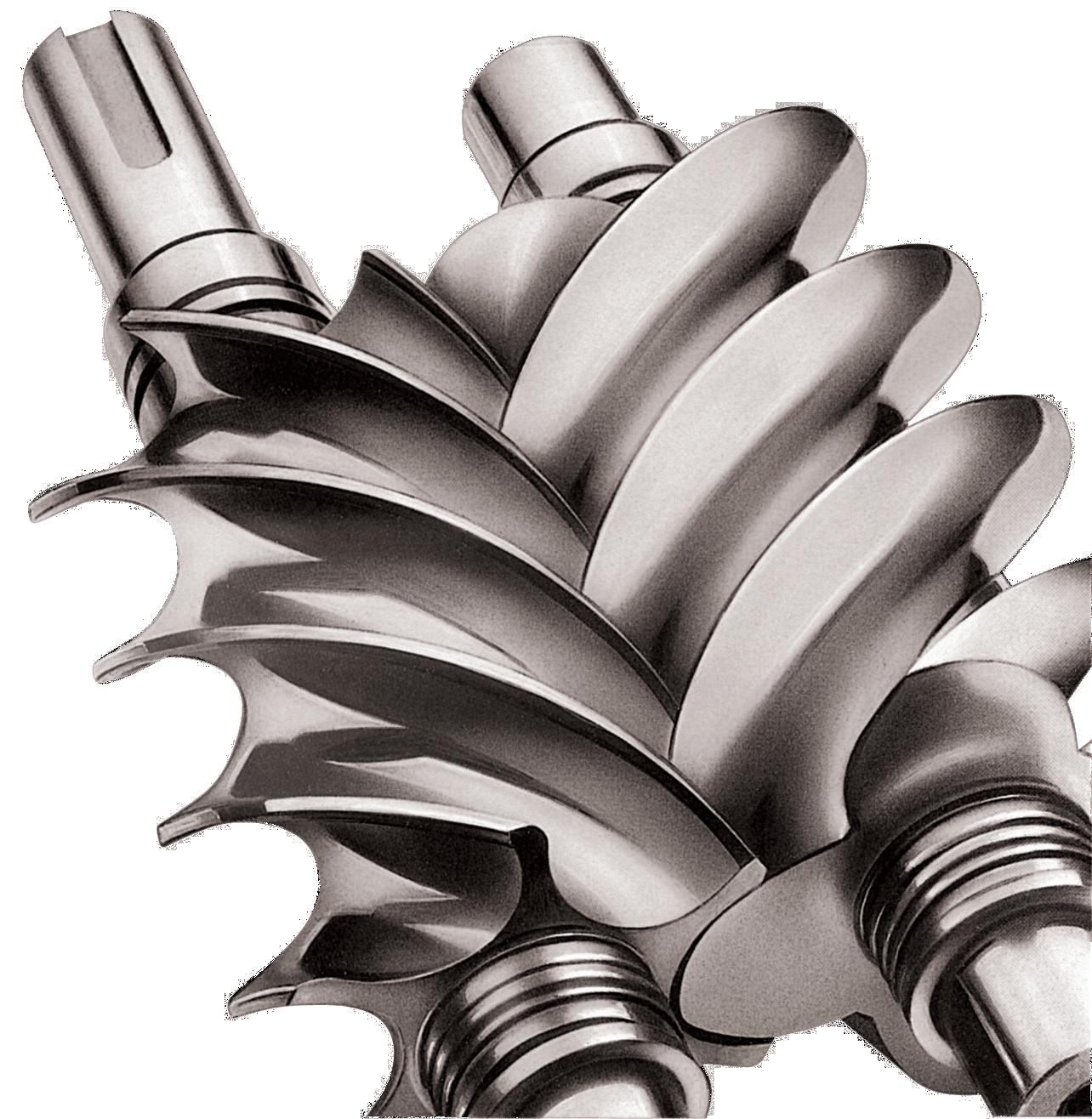

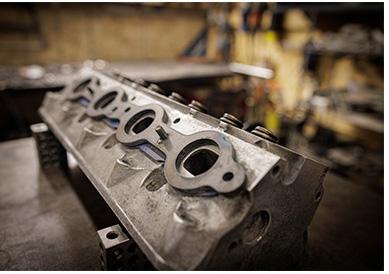

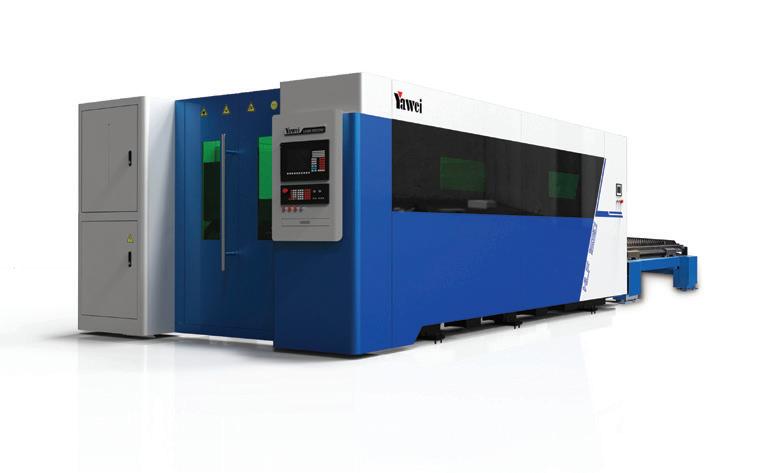

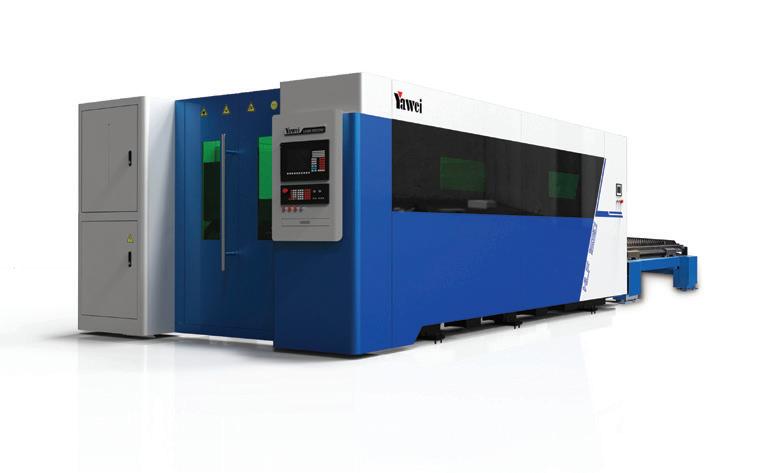

Australian manufacturers will soon be able to locally produce batches of high quality, complex parts with Metal Binder Jetting 3D printer technology, thanks to a collaboration between Swedish and Australian printing technology.

The PX100 Binder Jetting system, launched here in March by Swedish company Digital Metal, can produce large quantities of high-resolution parts at a time and on demand.

For Australian companies stalling on

supply chain issues, the ability to make their own metal parts locally is a win for sovereignty.

“Markforged Metal Binder Jetting 3D printing brings manufacturing home, offering supply chain resilience and capabilities to manufacture small to large scale serial production of metal parts at the point of need,” said Christian Lönne, CEO of Digital Metal, recently acquired by US 3D metals printer company Markforged.

Digital Metal has been developing metal powder printing technology for over 20 years.

Unlike laser-based technology, which is useful for prototypes and large parts, metal binder jetting uses liquid binder to join metal powder particles layer by layer, and is suitable for small to medium sized complicated parts where repetitive quality is required.

To build the PX100, the most advanced in its range, Digital Metal turned to Australian digital printing

company Memjet, which develops its own inkjet printing technology.

“The core of our technology is really inkjet printing. That’s how metal binder jetting works,” said Lönne, speaking to Industry Update after the launch at UTS’s Tech Lab in Sydney.

“You print on metal powder, where you inkjet a binder that binds the metal powder together to form a component. So the inkjet system is really the heart of our system, and the more advanced that is, the more advanced we can build the parts.

X INDUSTRY NEWS

10 | Industry Update Issue 131 Apr/May 2023 industryupdate.com.au

“The Memjet printhead that we have adapted for our Metal Binder Jetting printer is cutting edge technology and has around 70,000 inkjet nozzles. This is a huge increase of capacity and it makes our printer platform extremely capable and future proof.

“So you can imagine the scale up, the sort of possibilities that we get with this kind of technology. And that’s why we came to Memjet.”

Convincing Memjet to move into the 3D realm, however, took some work. Memjet’s core R&D is based in Sydney, but its headquarters are in San Diego, which is where Digital Metal’s team flew to in order to meet them.

“They were a bit sceptical in the beginning because they do 2D printing traditionally. We flew into their San Diego office and met with management and explained why this is going to be fantastic for 3D printing and I have to say, Memjet showed great openness and support from there onwards. I think it’s been a fantastic partnership journey together,” said Lönne.

Memjet’s Osama Abdul-Nabi worked on the project as the consultant engineer between the two countries’ teams.

“There was a lot of work to do on their side, I suppose to understand how they needed to use our technology to suit their needs. And of course, on our side, we needed to make sure we were doing things right for them.”

“I’m an applications engineer, so I work

on many different applications of our technology. And this 3D metal venture was just so unique. For me, it opens that door to showcase what Memjet is capable of.”

Abdul-Nabi says despite anticipating stability as a potential problem, it wasn’t one. And critically, say the collaborators, the printer’s stability makes it suitable for serial quality production.

“Variation kills manufacturing,” says Lonne, “you need to avoid variations to get a better yield.”

Game-changer

Markforged’s Richard Elving, Senior Director Australia, describes the PX100 technology as a game-changer “that will revolutionise high-volume metal production in Australian manufacturing.”

“With this innovative solution, our customers can eliminate third-party supplier risks and costs, insource critical production runs, and build large quantities of discrete or customised parts with precision and reliability,“ said Elving.

“We are confident that this technology will empower our customers to become industry leaders in Australian manufacturing.”

submarine, the USS New Hampshire, and has been performing well for more than six months, according to Markforged.

In Australia, Markforged says Sydney’s Garden Island Naval base has both composite and metal Markforged printers.

In terms of supplying to Australia’s aerospace industry, Markforged is working towards getting CASA quality-standard approval of its parts-printing process.

University collaborations

Australia has no metal binder jetting printing systems yet, and Digital Metal’s Christian Lönne hopes that once the technology does arrive, it is also installed at universities such as UTS Tech Lab or advanced manufacturing institutes where businesses can trial the technology.

“In Europe, we have several installations at leading universities and technical

For defence and aerospace industries, the ability to print quality parts locally, repeatedly and reliably is an obvious advantage.

3D composite and metal printers are already in use on US forces vessels to create spare parts on demand, as part of US Navy Command’s NAVSEA plan to transform digital capacity.

In late 2022, the first 3D metal printer was permanently installed on the US Navy warship, the USS Essex: an aluminium-printing Xerox ElemX.

In July 2022, a Markforged X7 3D carbon-fibre printer was installed on a Virginia class nuclear powered

institutes. This is important to us as it enables both engineering students/ researchers and industry to become a hub where the technology can be tested and tried out to understand what opportunities this technology represents for them.

“And then when companies see how they can leverage the technology they buy their own systems.

The PX100 printer will be commercially available in the second half of 2023 and it’s hoped the first printer will be in use in Australia soon after that.

INDUSTRY NEWS Markforged markforged.com/3d-printers/ px100

“Variation kills manufacturing,” says Lonne, “you need to avoid variations to get a better yield.”

Australian Made makes Australia Australian Made Week 15—21 May Certify your products as Australian Made australianmade.com.au/apply

“We are confident that this technology will empower our customers to become industry leaders in Australian manufacturing.”

Markforged PX100 - Metal Parts

Industry Update Issue 131 Apr/May 2023 | 11 industryupdate.com.au

Digital Metal CEO Christian Lönne with Memjet’s Osama Abdul-Nabi at the UTS Tech Lab PX100 launch

the design process”) and its robust functionality means it’s being used in OPSMs and Sunglass Huts as point-of-saledisplays, and within the optometrists’ rooms for eye exams on patients, which can be marked up on the displays during the consultation.

How Espresso Displays beat supply chain issues to get their ‘crazy’ thin monitor to the world

Continued from front page

2019, raising $600,000 to make 1500 units.

“We were probably defying physics, and any sane manufacturing person would say you guys are crazy to do it. But I think that’s what sets us apart - we’re ready to do the crazy,” Chief Operating Officer and fourth co-founder Gary Caldarola told Industry Update

The small screen challenge Caldarola, an experienced engineer, was working at ResMed when he met Scuderi, who he’d encouraged to join the medical equipment company.

The concept of an ultra thin portable monitor was “amazing” says Caldarola, who was immediately interested. With his experience in product development and manufacturing, he offered his help as a mentor just as the Kickstarter campaign kicked off in 2019.

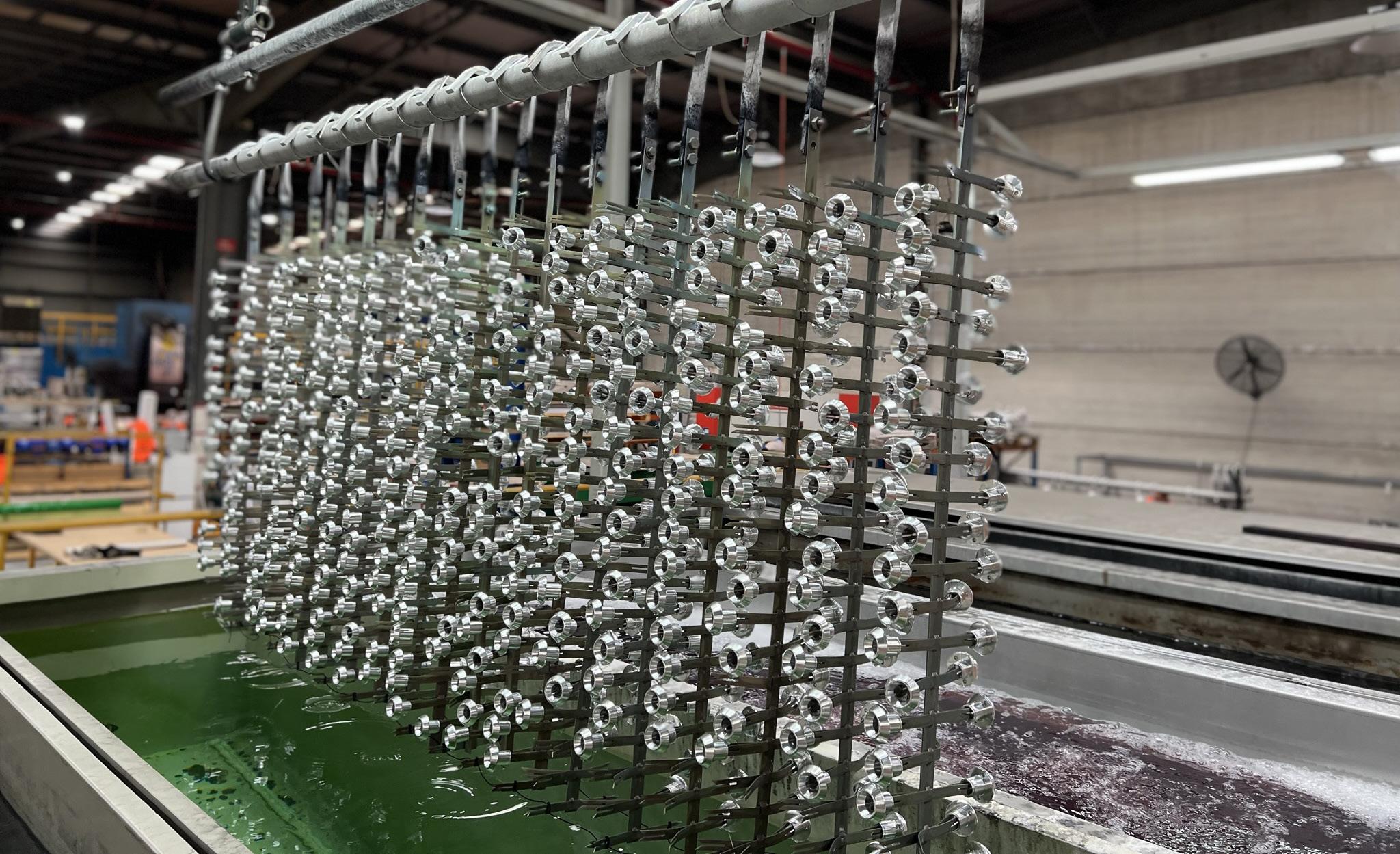

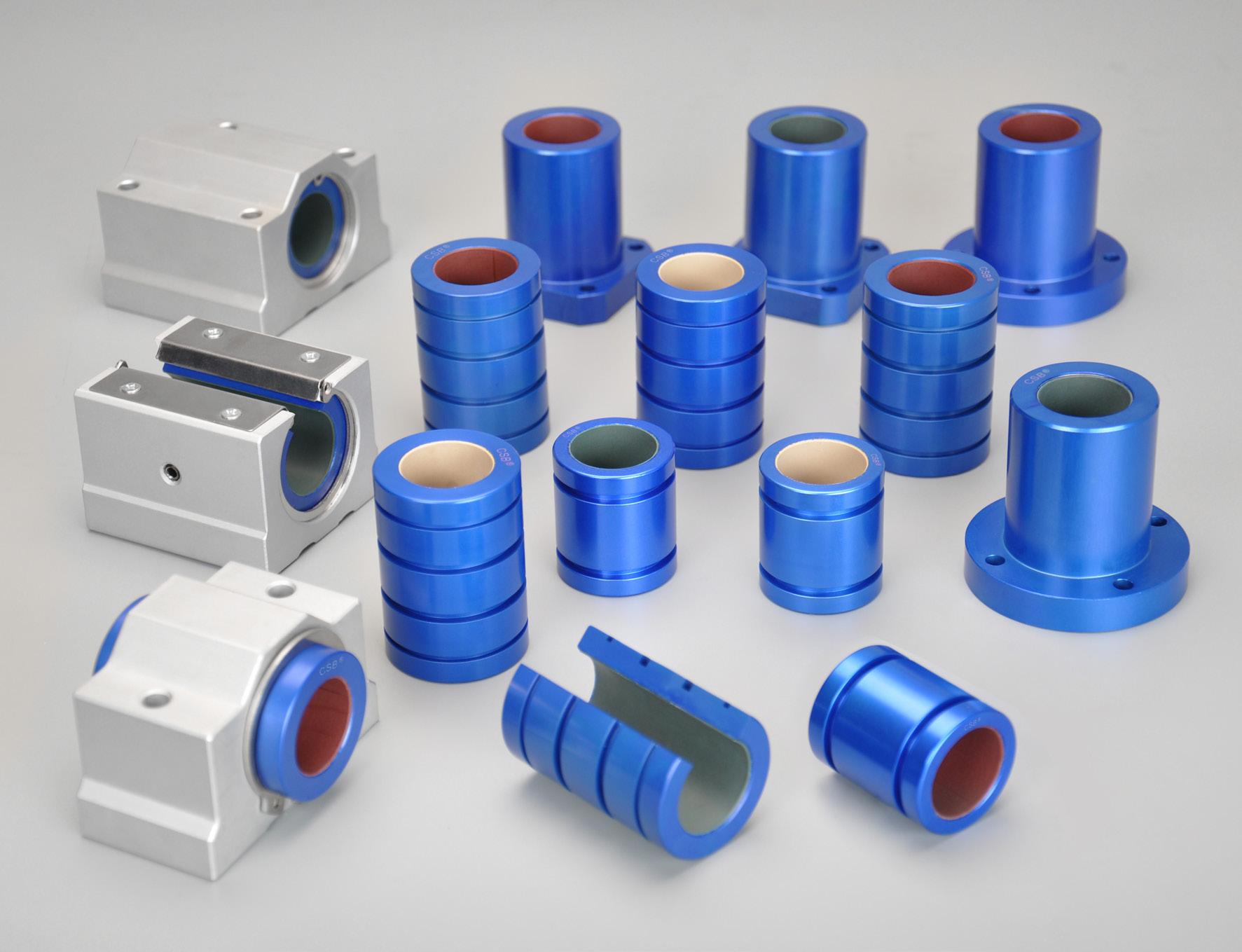

Manufacturing such a thin screen out of aluminium was a huge challenge, says Caldarola, and the team had to accept they’d be rejecting a lot of attempts.

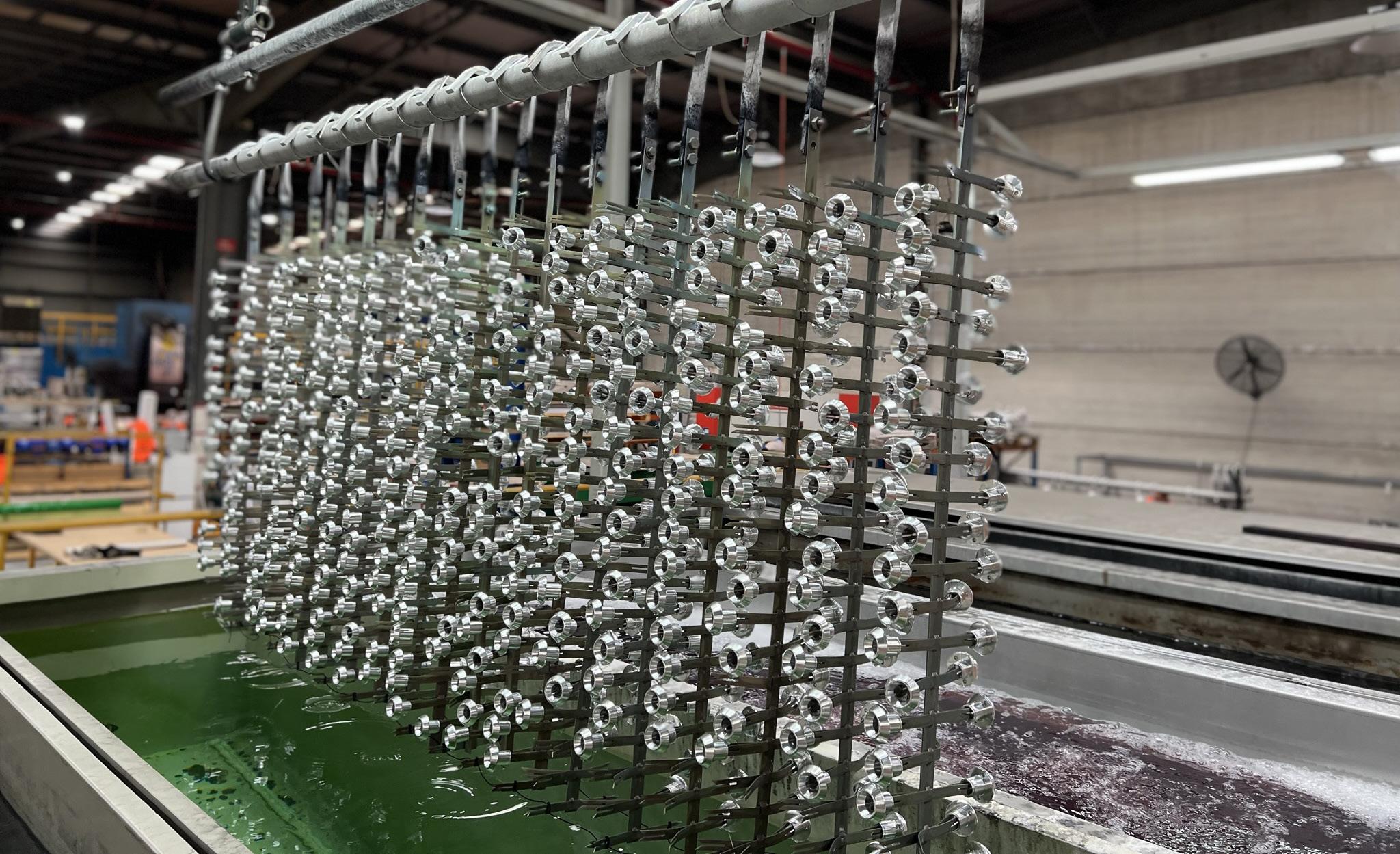

“It needed to be treated so carefully because… it’s essentially like an aluminium can and can get damaged along the production line. It goes from machining, to sandblasting, to anodising, to laser marking, and at each phase, there was a yield loss. And we had to optimise at each of the process steps to reduce that yield loss… That was a hell of a lot of work, a lot of pain.”

But by constantly optimising and iterating, Caldarola says they came very close to their 5mm goal, reaching 5.5mm for the V1. They’ve since beaten that: their latest V2 display is 5.3mm.

“We’ve still got 0.3mm to go before we’ve achieved Will’s original vision of being a five millimetre display,” says Caldarola.

Multiple site solution

Starting out during Covid threw a huge curveball, and Caldarola realised they needed some creative problem-solving for their manufacturing plans.

“Supply chains came to a grinding halt.

“The way we worked around that was to have manufacturing facilities and suppliers in multiple geographical locations within China, as well as having another

site in Malaysia that kept working and did the final assembly, building all the units for us while China was shut down. We also have suppliers in Japan.

“We were able to keep running, because we had multiple sites and dual sources. This meant that if one supplier was shut down, we could activate another supplier in a different geographical region. And that helped us a hell of a lot during the real peak of the lock downs.

With shipping costs and lead times skyrocketing, the team also built up their reserves internationally.

“We made sure that in each of the four major regions we sell in - Australia, USA, UK and the EU - we’d always have safety stock.”

“We could have died about 100 times,” says Caldarola.

“I think what’s enabled us to be still alive and going is that we would literally not take no for an answer, there was always another way to get something done.”

popular in the age of changing working habits, including office spaces, working from home and working from anywhere.

Their in-house software, espressoFlow, enables the touchscreen to sync with a Mac (“we are the first or one of the first to make a MacBook touch, essentially,” says Caldarola) as well as Microsoft and Linux systems. With Linux favoured by engineers, and Mac

The monitors are also being trialled in operating theatres by surgeons as a way of communicating with other surgeons around the world to get instant feedback while they’re operating, while marking up the touchscreen display at the same time.

Future iterations

With strong growth hopes, the team’s working on higher resolutions, higher colour specs and more sizes – “we’re always looking to optimise the experience for the user,” says Caldarola.

“We’re continuously updating the software to make drawing better, or

Since the V1 model, Espresso Displays has sold many tens of thousands of units, and 60% of their market is in the US.

Now supported by lead investor Richard White, CEO of WiseTech, the team’s grown to more than 30 people, mostly based in Sydney, but also in Asia and the US time zone.

System agnostic

Which brings us to the other remarkable feature of the product, which is that it’s “software and hardware agnostic” – it can work with any operating system and virtually any computing device. That compatibility includes Windows, Mac and Linux.

Espresso devices are also becoming

a favourite with artists and illustrators, both are large target markets along with corporate professionals and gamers.

The display is now much more than just a second monitor, says Caldarola.

“For example, [it] is now also a drawing tablet. It means the artists can also draw to the same standard on the 15.6 inch portable displays at home or remotely as in the office on their 27 inch drawing tablets.”

“Artists and designers have been coming to us saying they have been looking for a way to get creative from anywhere, and we are proud to support their needs with our display which acts as a fully featured drawing tablet when connected to Mac and Windows. It also supports apps like Adobe Photoshop and Illustrator.”

The display’s aesthetic qualities (“which we really focused on throughout

touch better, or the response time better, and to work with more devices. There’s just so many devices out there.

“For example, the Mac Mini M2 just came out and we needed to be compatible with that.

“We’re listening to the customers, we’re testing and we’re iterating all the time so that we can make the best possible product.”

The dream, says Caldarola, is to open production here in Australia, bringing the manufacturing home.

With an application in for the NSW government’s Future Industries Fund, if they’re successful, that may become a reality – and a win for Australian innovation and sovereignty.

Espresso Displays au.espres.so

(L-R)

Espresso Displays co-founders: Gary Caldarola, Scott McKeon, Will Scuderi, Fabian Maritato

“We were able to keep running, because we had multiple sites and dual sources”

INDUSTRY NEWS 12 | Industry Update Issue 131 Apr/May 2023 industryupdate.com.au

“We would literally not take no for an answer, there was always another way to get something done.”

Sweetener for Allen’s factory

Tonnes more lollies will be made each year at Nestlé’s manufacturing site at Broadford now that the factory’s $12 million expansion has the backing of the Victorian government’s Regional Jobs Fund.

More of Allen’s famous chewy lollies such as Minties and Sherbies will now be made in the Nestlé factory at Broadford which will add more than 2,000 tonnes each year to production.

“We’re proud to make Australia’s

favourite lollies right here in Broadford, thanks to our hard-working team,” said Factory Manager Emily Bradbury. “Our expanded facilities will allow us to scale up production – which is good news for lolly lovers, and for Broadford.”

The factory, which operates 24 hours a day, five days a week, is the biggest private employer in Mitchell Shire and the project is set to provide long-term job security for more than 200 existing employees.

Minister for Regional Development Harriet Shing, said workers at the Nestlé factory in Broadford have built a delicious and iconic legacy over the past 40 years and government support is helping the Allen’s brand continue to grow.

“Goulburn Valley is a food manufacturing powerhouse, and this investment is another example of what we’re delivering in the region – a strong economy, powered by secure jobs.”

Food manufacturing is one of the biggest industries in the Goulburn Valley, growing 15% faster than the Victorian average for industry growth.

The Labor Government reports that it has supported around 13,000 jobs since 2015 by contributing more than $48 million towards projects in the Goulburn Valley through the Regional Jobs and Infrastructure Fund and more than $700 million across the state.

INDUSTRY NEWS MODERNMANUFACTURINGEXPO.COM Transforming from traditional to modern manufacturing. 20 - 21 SEPTEMBER 2023 / SYDNEY SHOWGROUND REGISTER FOR THE FREE EXPO Join the global shift into the future of manufacturing. Learn how to harness the benefits of smart technologies and concepts for greater output. PLUS! ATTEND THE CO-LOCATED Industry Update Issue 131 Apr/May 2023 | 13 industryupdate.com.au

Australian hypersonics company wins US defence testing contract

Australian aerospace firm

Hypersonix Launch Systems is to provide its DART additive engineering hypersonic vehicles to the United States’ Defense Innovation Unit (DIU) for testing.

More than 60 aerospace companies were vying for the contract under the DIU’s Hypersonic and High-Cadence Airborne Testing Capabilities (HyCAT1) program. The first DART AE test flight is scheduled for 2024.

The Defense Innovation Unit (DIU) favours innovators but Hypersonix believes it’s unusual for DIU to award contracts to such a young organisation and that the deal shows the greater willingness from the US to source commercial, strategic technologies from allied countries.

Hypersonix was founded late 2019 to commercialise technology developed in previous decades by its co-founder Michael Smart in projects at NASA, in collaboration with the Centre for Hypersonics at the University of Queensland (UQ) and the HiFiRE program.

DIU’s late 2022 HyCAT solicitation sought vehicles for high-cadence, long-endurance testing of:

• hypersonic platforms and components

• sensors for detecting and tracking

• systems for communications, navigation, guidance and control.

DIU requested a vehicle to operate in a ‘representative environment’ that can maintain speeds above Mach 5 with a manoeuvrable/non-ballistic flight profile and at least a three-minute flight duration with near-constant flight conditions — and for these flights to be repeated at short intervals.

“Our vehicles are capable of non-ballistic flight patterns to at least Mach 7, which exceeds the HyCAT1 specification,” said David Waterhouse, Managing Director, Hypersonix Launch Systems.

“Our longer-term focus is to capture a slice of the emerging multi-billion-dollar commercial market for deployment of small satellites, but clearly Australia’s strategic defence allies see immediate potential in our technology.”

“This is our first major contract and a key step in our commercialisation process – we couldn’t be happier. This puts Australia one step closer to being a major player in the international space race,” David Waterhouse added.

Hypersonix’ DART Additive Engineering (AE) makes significant use of 3D-printing and is powered by a hydrogen-fuelled SPARTAN scramjet engine, capable of flying non-ballistic flight patterns at speeds of Mach 5 to Mach 7 and up to 1000 kms in range (400 seconds flight time). The DART AE has a modular payload bay of up to 20lbs and Hypersonix plans to fly it in early 2024.

The Australian government’s Department of Industry, Science and Resources has supported Hypersonix with several grants, recognising their

leadership in scramjet technology and adoption of modern manufacturing techniques.

DIU’s contract with Hypersonix permits DIU to ‘transition’ successful prototype projects into follow-on ‘production contracts’ under simplified rules and without need to again compete for a successful project.

Hypersonix Launch Systems is an Australian Aerospace engineering, design and build company specialising in scramjet engines and hypersonic technology.

Hypersonix

INDUSTRY NEWS TENTE LEVINA LIGHT CASTORS Healthcare Furniture – Bedside Cabinets – Medical Carts – Medication Carts, X Ray Carts, Ventilators – IV Poles Sterilisation Equiment – Surgical Equipment – Laboratory Equipment – Professional Furniture – Educational Furniture Janitor Carts – Audio Visual Equipment – Food & Catering Equipment – Store Fixtures – Display Tables – POS Display ONE CASTOR – 3 TYPES OF “PLUG IN” FITTINGS Plate Grip Ring Stem Threaded Stem Secure connection with four screws. Solid fitting due to threaded screw. Safe distance between castor and application due to collar. 75 - 82 kg 103 - 160 mm 75 - 125 mm 1300 836 831 | tente.com.au

14 | Industry Update Issue 131 Apr/May 2023 industryupdate.com.au

hypersonix.com

Brands worth €130 billion want EU to ban PFAS chemicals

AMS have been suppliers of instrumentation and calibration equipment to all industries since 1973 representing some of the world’s

The EU is proposing a ban on PFAS chemicals used in thousands of consumer products and brands worth more than €130 billion are supporting it.

Environmental NGO ChemSec says the chemicals look set to be one of the biggest environmental and health threats of our time and investors with assets in PFASproducing companies are calling for an end to production.

ChemSec and more than 100 corporate members of the PFAS Movement, are calling for comprehensive regulation of PFAS in the EU, which has invited the public to give its opinions on the proposed ban on these harmful chemicals. The chemicals are commonly used in fashion, furniture and homewares, cosmetics, electronics, and personal care.

The movement’s more than 100 members include well-known brands, such as Inditex, Urbanears and the Cookware Company, representing various industries.

“A European ban on PFAS chemicals will have huge repercussions for all manufacturing industries and require much work for companies in the global supply chain,” says Anne-Sofie Bäckar, Executive Director at ChemSec.

“However, some parts of the industry oppose this ban, claiming that the change is too big to be justified. That’s why the support for a ban from such influential consumer brands as those in the PFAS Movement is so important. It’s a strong sign that businesses want to eliminate PFAS chemicals in products and processes.”

Irreparable damage

PFAS chemicals have been used for decades in various consumer products such as cookware, clothes and electronics and are still used although researchers have linked them to a range of adverse health effects, including cancer, fertility problems and developmental problems. Also damaging is the fact that PFAS chemicals do not break down in nature — levels build up in humans and wildlife. Today people all over the world have measurable levels of PFAS in their bloodstreams and European media have reported the continent has over 17,000 PFAS-contaminated areas.

Alternatives

One of the most well-known products using PFAS are kitchen utensils and items such as PFAS non-stick pans are common despite the alternatives.

”At The Cookware Company, we eliminated PFAS from our products in 2007. We believe it is wrong to enjoy the fruits of doing business while leaving the toxic side effects to the next generations,” says Wim De Veirman, CEO at The Cookware Company.

“That’s why we fully support the ban on PFAS, which are known to be toxic, persistent, and bioaccumulative, and they pose a significant risk to human health and the environment. By taking a leadership position against PFAS, we are sending a clear message to our customers, stakeholders, and the broader community that we are serious about our commitment to sustainability and health”.

US lawsuits

ChemSec’s PFAS Movement is not only supported by the brands but also by Hollywood actor Mark Ruffalo who became a PFAS activist after his involvement in the film Dark Waters. The film depicts the real-life events following the massive uncovering of PFAS contamination in the USA. As a result, several PFAS producers in the USA are now involved in multimillion-dollar lawsuits.

The health and environmental threats of PFAS, along with all the lawsuits, have also created attention among another influential group: institutional investors. Last year, 47 institutional investors with US$8 trillion in assets sent letters to 54 chemical companies named by ChemSec, calling for them to halt the production of persistent “forever chemicals”.

EU ban on PFAS

The proposed EU ban, the first in the world was initiated by Sweden, Denmark, the Netherlands, Germany and Norway, which have spent almost three years mapping the implications of a ban on PFAS chemicals in a dossier of nearly 2000 pages. The proposal shows, among other things, that the emissions of PFAS were 75,000 tonnes in 2020. If this continues, the emissions are expected to sit at 4.4 million tonnes in 30 years. The emissions originate from both production and use of the many products that contain PFAS.

INDUSTRY NEWS

F l ow M e a suremen t Spec iali st s ww w .am s- ic. c om.a u s ale s @am s- i c c om.a u IN S T RU M E NT A TI O N & CALIBRATION PTY LTD SP E CI AL IST S

Scene from Dark Waters, the 2005 film depicting actual events after PFAS contamination was discovered in the US, where companies producing and using PFAS chemicals now face multimillion-dollar lawsuits.

ww w. a ms -i c.com.a u Industry Update Issue 131 Apr/May 2023 | 15 industryupdate.com.au

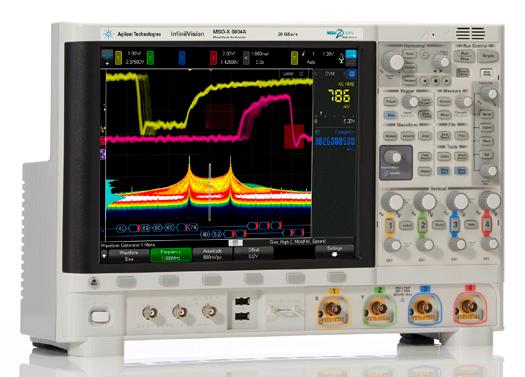

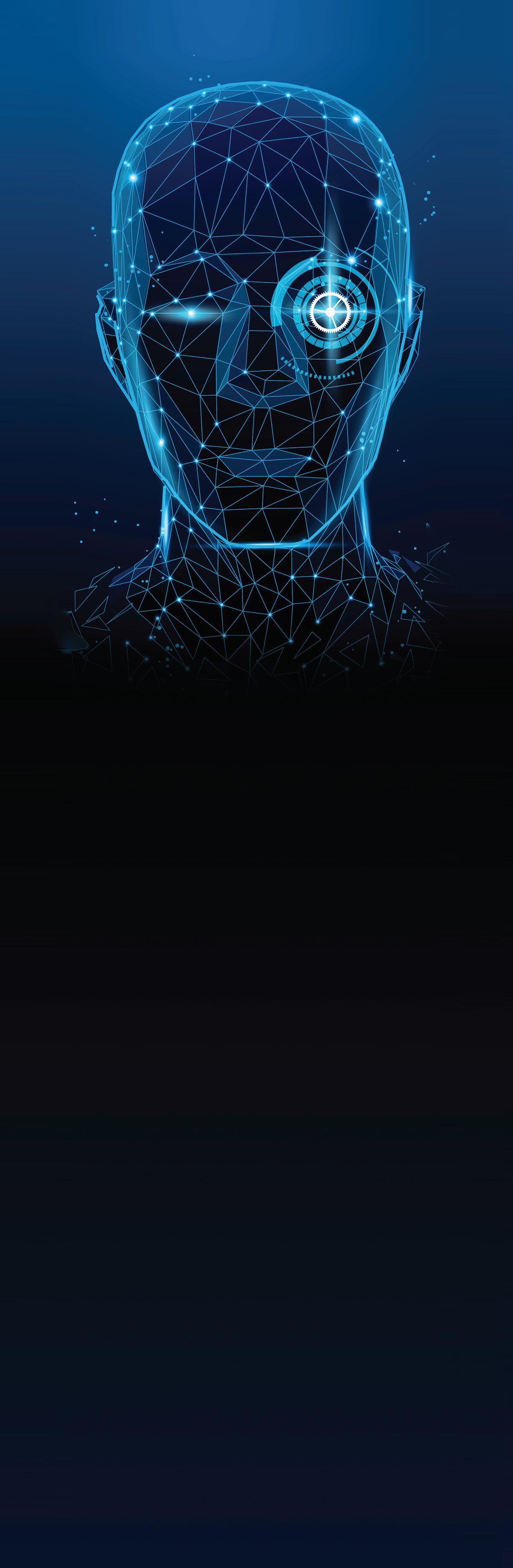

Australian AI in driver safety assistance systems

Long-haul driving and congested traffic are two scenarios where driver fatigue and distraction often occur and frequently cause accidents, resulting in injury or worse.

New and sophisticated advanced driver assistance systems (ADAS) are rapidly evolving to support safety across increasing, varied levels of autonomous capability.

Australian-based Seeing Machines is a world-leader in driver monitoring system technology, designing AI-powered operator monitoring systems to improve transport safety. It has collaborated with global semiconductor leader Analog Devices (ADI), in support of high-performance driver and occupant monitoring system (DMS/OMS) technology.

The collaboration pairs ADI’s advanced infrared driver and high-speed Gigabit Multimedia Serial Link™ (GMSL) camera connectivity solutions with Seeing Machines’ artificial intelligence (AI) DMS and OMS software to support powerful eye gaze, eyelid, head, and body-pose tracking system technology that more accurately monitors driver fatigue and distraction.

The solution meets European safety regulations and new car standards, which the rest of the world, including Australia, typically follows.

It is also conducive to enabling future occupant monitoring features and a range of in-cabin camera placement options, previously unworkable due to challenges related to power efficiency, functional safety, hardware footprint, and image quality.

“Cabin monitoring is complex and requires careful integration of infrared illumination, image capture, data processing, and algorithm layers to achieve a realtime response,” said Yin Wu, Director of Automotive Product Line Management at Analog Devices.

“Together with Seeing Machines, we are supporting the automotive industry with pragmatic solutions to help reduce collisions and save lives.”

ADI’s MAX25614 IR LED driver and GMSL serializer and deserializer (SerDes) connectivity solutions are supporting Seeing Machines’ FOVIO DMS and OMS solutions.

ADI’s Automotive Electrification and Cabin Experience Solutions

ADI’s innovations are making a positive planetary scale impact in automotive electrification and experience.

By leveraging technology synergies across Automotive and Sustainable Energy, ADI aims to accelerate the transformation of mobility and the grid towards Net Zero emissions.

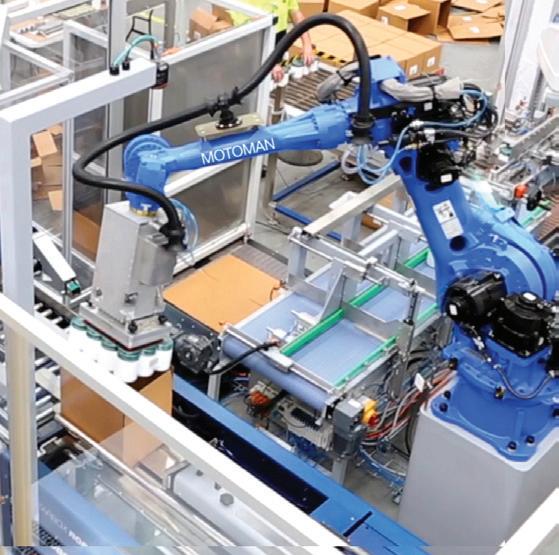

PBE Roboplas increase efficiencies and reduce operating costs by supplying new machinery, equipment, service and repairs from a strong background of technical experience including robotics, engineering and integration to the plastic industry.

Our Partners

Semi-autonomous driving systems rely on in-cabin DMS and OMS to recognize and address driver fatigue and distraction. These systems must operate in all lighting conditions and require proper infrared lighting to ensure image quality on a frame-by-frame basis necessary for eye tracking in real time. The combined solution from ADI and Seeing Machines leverages ADI’s industry-first infrared driver for DMS and OMS, capable of delivering up to 100W of peak power in a compact and functionally safe solution. This allows for a non-intrusive, smaller camera module in a vehicle’s cabin.

Seeing Machines’ AI software interprets signals from the optical hardware, monitors and diagnoses the problem, and combines with ADAS features to enable output signals to warn drivers and vehicle occupants when necessary.

“Seeing Machines exists to get people home safely, and our work with ADI aims to support semi-autonomous driving with increased safety levels to deliver what we call ‘supervised automation’,” said Nick DiFiore, SVP and GM of Automotive at Seeing Machines.

“ADI’s proven automotive-grade, near-infrared drivers and GMSL devices enable a sophisticated optical path to provide critical illumination and high-speed video bandwidth for real-world and real-time processing of interior cabin environments.”

ADI is also enabling the Digital Cabin and Safe Mobility revolution through its technology leadership in Audio Processing, Data, and Video Connectivity platforms which are advancing consumer applications and safety-critical ADAS in the vehicle.

ADI leadership in battery, power, and energy management solutions enables high performance, reliable, and safe operations across the entire electrification ecosystem—including EVs, energy storage systems, the clean energy grid, and more.

With a focus on measuring and advancing sustainability at every step, ADI innovations in software and wireless technologies allow for localized real-time mission-critical decisions to enable intelligence at the edge.

INDUSTRY NEWS

Temperature Control Units Robotic Automation & Ancillary Equipment Material Conveying, Dosing & Drying Systems Lubricants & Systems Blow Moulding Machines Injection Moulding Machines 60 – 3200 Tonnes Robot and Automation 02 9674 6511 pbe-roboplas.com.au Conveyor Systems 25 YEARS INDUSTRY EXPERIENCE

seeingmachines.com

analog.com 16 | Industry Update Issue 131 Apr/May 2023 industryupdate.com.au

Seeing Machines

Analog Devices

VersaReel Blue is the first phone-operated, temporary power system from Conductix-Wampfler

Convenient and safe power on demand

Whether it’s needed on the factory floor or a museum, the new VersaReel Blue’s retractable, 240v power system offers convenient, safe and reliable power on demand, and it’s likely to be needed in a range of settings.

It’s the first mobile phone-operated power system from ConductixWampfler, the specialist in mobile energy supply and data transmission, which usually supplies products and services to the mining, bulk handling and industrial sectors. The VersaReel Blue is also the first Conductix-Wampfler product for multiple settings including soft applications such as retail, education, and office — even entertainment and aesthetic venues such as museums, galleries and theatres.

performance with Bluetooth, ConductixWampfler has created a motorised electric cable reel which sits neatly at the ceiling and is operated by a phone app. This power source is ideal for warehouse, retail, service facility, factory, or just about anywhere that needs temporary, retractable power and also prioritises safety and convenience.

“We’re excited to offer a solution that our traditional cable reels have provided but, rather than our springreel which has to be manually retracted and released, the VersaReel Blue can be remotely operated by mobile phone,” said Kibbis.

easily, the reels are a permanent fixture that can be easily installed by an electrician to sit neatly mounted at the ceiling or within a ceiling space.

appearance, on which many organisations and public spaces pride themselves.”

“It’s the first product we’re aware of that’s a retractable, 240v power cable operated by a phone,” said Wayne Kibbis, Managing Director with Conductix-Wampfler.

Combining reliable cable reel

“An example might be an educational setting where a trainer wants to bring extra power into a space — by simply using a phone app to operate the reeler to lower a power outlet — say, the middle of the classroom or library where most power points are around the perimeter. Now they can lower the outlet from the ceiling safely and conveniently and then remove it the same way once it’s no longer needed. This can work for almost any setting.”

While the cables move up and down

The VersaReel Blue’s quick and quiet operation to lower or raise the power outlet to any safe height can be operated via secure controls on an IOS or Android phone app. It removes any need for traditional spring cable reels and ladders or messy cabling as well as wear and tear on cables. Like Conductix-Wampfler products for heavy industry, the VersaReel Blue is engineered for long-term, reliable operation.

“At the end of the day you can run power cords around, but you know that’s not as safe as it could be. And if you’re an organisation that prioritises safety and efficiency or convenience, this product ticks all the vital boxes,” said Kibbis.

“The VersaReel Blue also improves

Safety, minimal training requirements and ease of use make it ideal for all types of organisations. It looks equally professional in an office or industrial setting and VersaReel Blue’s discreet aesthetics and quiet operation also suit gallery, museum or other aesthetically designed leisure environments. In a nutshell (or its discreet ceiling mount), VersaReel Blue provides power whenever and wherever it’s needed and is out of harm’s way when it’s not.

Conductix

INDUSTRY NEWS

conductix.com

Industry Update Issue 131 Apr/May 2023 | 17 industryupdate.com.au

“At the end of the day you can run power cords around but you know that’s not as safe as it could be.”

AUKUS’ greatest challenge: skilled workforce

South Australia Premier Peter Malinauskas believes the workforce to deliver AUKUS submarines is the greatest challenge for Australia and his own state.

Yet he is confident about taking on the challenge and believes it will give Australia a sovereign submarine-building capacity.

“While I appreciate that many South Australians think the timelines seem long, the simple reality is there’s young people in schools today whose standard of living will be materially improved because of the step change in economic complexity that this task brings to our state and indeed our nation,” the Premier told ABC radio.

Following the Australian, UK and US governments’ announcement on March 14 of each country’s manufacturing and design responsibilities and which submarines they get to use and when, Malinauskas today set off for Barrow-in-Furness in north-west England where BAE Systems and Rolls-Royce are making the first of the joint UK-Australian submarines. Later submarines will be built in Osborne, SA, based on British design called ‘SSN-AUKUS’ and US technology, with the first vessels to be in the water in the 2040s.

Of the 20,000 direct jobs needed for the program, the government estimates up to 8500 will be in building and maintaining the submarines - from nuclear scientists and engineers to electricians, welders and metal-fitters.

AUKUS is estimated to bring more than 9,000 jobs of the expected total 20,000 Australian jobs, to Osborne,

South Australia, which Premier Peter Malinauskas says is the heart of naval shipbuilding in Australia. But, he says, creating the workforce with the right skills is “the single biggest challenge” of AUKUS for Australia. South Australia has full employment now and an ongoing agenda to create infrastructure.

“We’ve got a lot of work to do as a country to build up the skills base required to build what will be the most complex machines ever built in the history of our nation.”

“In Barrow-in-Furness, there’s a skills academy performing just that function for many years … I want to see that first hand and take learnings back to SA and apply them as quickly as possible.”

He believes Australia has the capability and just needed ongoing demand created by AUKUS.

“What we’ve always needed in Australia was continuity of work, a continuous demand for naval shipbuilding expertise that gives industry but also workers the confidence to build their lives around. We’ve now got that in South Australia and believe we can undertake this task.”

Asked if he thinks South Australia’s timeline for work and delivery of operational submarines in the 2040s is too far away, Malinauskas said many people think the government’s timeline is ambitious and it will take that time to get the workforce skilled up to be productively working on the submarines during the 2030s.

“It’s important to understand the level of complexity of building a nuclear submarine over and above conventionally powered submarines. Everything about it

is more technical, more complex and more demanding on our skills base. Reasonable people understand it will take time to build up [those skills ] up to the end of this decade.”

Malinauskas said South Australia’s ship-building experience is that production on a first type of nuclear submarine will take a long time. But once that first one is in the water, he believes we will see them built every three years.

The first workers needed are an estimated 4,000 people to design and build submarine construction yards at Osborne, with another 5,500 direct employees to build the submarines and MAlinauskas confirmed most would have to be South Australian and Australian.

“The security requirements for the infrastructure build — let alone submarine build — will be so substantial that in many instances they will necessarily have to be Australian citizens.

AFFORDABLE AUTOMATION SOLUTIONS.

Until now, adding automation to your production line could be an expensive exercise. But Enmin’s new Generate+ systems changes all that. A range of affordable modular systems that slot easily into an existing line; reducing labour costs, boosting

productivity and improving quality.

Designed and built right here in Australia they feature the same quality, reliability and safety that Enmin is renowned for. Plus, they can be added to and extended as your business evolves.

INDUSTRY NEWS T: +61 3 9800 6777 | W: enmin.com.au

South Australian Premier, Peter Malinauskas (left), and Deputy Prime Minister and Minister for Defence Richard Marles, sign agreement of co-operation for South Australia to deliver the AUKUS submarines

18 | Industry Update Issue 131 Apr/May 2023 industryupdate.com.au

Tariff Concession Orders: objecting to or revoking an order

The Customs Division within the Australian Border Force (ABF) is keen to draw local manufacturers’ attention to ways its Tariff Concession system can help local manufacturers maintain tariff protection.

In this second article of the series, ABF focuses on manufacturers’ ability to object to an otherwise imminent new Tariff Concession Order — or have an existing order revoked — to benefit their business.

The Tariff Concession System is a long-standing Commonwealth program designed to maintain or reinstate manufacturers’ tariff protection when an Australian-made product is a ‘substitutable good’ for a current import. This system aims to support local substitutable goods so it gives manufacturers the opportunity to object to or revoke an importer’s concessional rate of customs duty.

‘objection’ i.e. an importer has applied for a TCO but it is not finalised. In the case of an established TCO, when a local manufacturer applies for the order to be removed that is a ‘revocation’.

Identifying relevant TCOs

If a local manufacturer wishes to object to a recently applied for TCO, they must do so within 50 days of the date on which the relevant Commonwealth of Australia Tariff Concessions Gazette (the Gazette) announces the application. The Gazette is published weekly on the ABF website with all new applications for and successful submissions of TCOs included.

To revoke an established TCO, a local manufacturer can make an application at any time after the TCO is established. Should a manufacturer be unsure if a TCO is affecting their business, ABF’s tariff concession officers are available for consultation. The manufacturer must be confident it makes or has the capacity to make substitutable goods before contacting the tariff concession team.

Further, when the team administering the Tariff Concession System identifies a local manufacturer that could be affected by a TCO, they notify them of their right to review the TCO. This recently happened in the case of an Australian spectacle frames maker.

Corresponding use

Two key terms are involved when challenging a Tariff Concession Order (TCO): objection and revocation. When a local manufacturer challenges an application for a Tariff TCO, that is an

Where an Australian manufacturer objects to a TCO being made or seeks to revoke an established TCO, they need to demonstrate their goods have a corresponding use to the imported goods, and those goods are made here

or a substantial process of manufacture occurs in Australia.

Tribunal considered both heaters can heat a room.

• Goods are deemed to have been manufactured in Australia if at least one substantial process in their manufacture was carried out in Australia, i.e. a new and different product is made from various components.

It is irrelevant if the TCO goods are of a different quality, price and/or superior performance when considering whether substitutable goods can be put to a use subject to the TCO application. Furthermore, the goods do not have to even compete in the same market.

As long as the local manufacturer believes it can meet the above conditions, one of ABF’s tariff concessions officers can assist with the process to object or revoke the relevant TCO.

Meeting these conditions is not as difficult as it might appear. To clarify:

• Substitutable goods do not have to be identical to the imported goods. Substitutable goods means there is a corresponding use. Corresponding use can be considered as the overlap of uses of the two groups of goods. Simply put, consider all the uses of the substitutable goods and all the uses of the imported good; including their design use – wherever use overlaps, corresponding use exists.

• The wording of the TCO applies to the imported goods and it is largely irrelevant for the locally manufactured substitutable goods. For example, portable gas heater and electric wall heater. The Administrative Appeals

Successful TCO objections or revocations cover virtually every industry and a vast range of goods from complex machinery like transformers or trains to wooden barrels or tool boxes. It doesn’t matter if a manufacturer is big or small, nor does it matter where it is based. As long as they produce substitutable goods in Australia, it has a right to seek a revocation or object to a new TCO being made.

Successful objection or revocation of a TCO is published in the weekly Gazette. Visit www.abf.gov.au/importing-exporting-and-manufacturing/tariff-concessions-system for information on Tariff Concession Orders or to view the Gazette online.

BUSINESS, FINANCE & ACCOUNTING

“Meeting manufacturer objection conditions is not as difficult as it might sound.”

Industry Update Issue 131 Apr/May 2023 | 19 industryupdate.com.au

“It doesn’t matter if a manufacturer is big or small… as long as they produce substitutable goods.”

Tariff

Concession Orders Information

CSIRO to help SMEs with digital innovation and cyber security

Australian businesses will learn to innovate with AI and digital technology while understanding cyber risks via a free CSIRO program

The CSIRO, Australia’s national science agency, has announced that small to medium enterprises (SMEs) will be able to enhance their research and development (R&D) knowledge with a free 10-week online program focused on cyber security and digital technologies.

The Innovate to Grow program, connects businesses working on solutions in cyber and digital tech with knowledge, resources and mentors to advance their project or ideas.

After completing the program, eligible participants may be able to access continued support through CSIRO, being connected to national research expertise and/or dollar-matched R&D funding to keep moving their ideas forward.

CSIRO’s Data61 Research Director for Software and Computational Systems Dr

Liming Zhu said an Innovate to Grow program focused on cyber security and digital technology could not be more timely.

“The rise of generative artificial intelligence (AI) and large language models like ChatGPT are rapidly transforming the digital and cyber innovation landscape,” Dr Zhu said.

“Whether they’re creating knowledge-intensive products or seeking to add innovative features to interact with customers, companies can tap into new growth opportunities thanks to the increasing power of generative AI,” he said.

However, Dr Zhu warned that the rapid development and escalation of these applications comes with increased cyber risks and risks in digital trust, and that preparation is the key to mitigating these risks.

“This is a new territory, which is still evolving,” Dr Zhu said.

“Our aim with programs like this is to assist companies who are building solutions to these problems,” he said.

CSIRO’s Innovate to Grow Program Coordinator, Michelle Armistead, has

urged Australian SMEs to consider taking the opportunity to connect with like-minded mentors and companies to learn and grow.

“We know the critical importance Australia’s SMEs have in the growth and resilience of our economy, and likewise the large role they will play in growing these emerging industries of cyber and digital tech,” Ms Armistead said.

“One of the most valuable pieces of feedback we’ve had from participants in our previous cohorts is the deep value they have gained in working through the self-paced deliverables while connecting with our expert advisors,” she said.

Eligible companies can be working

directly in cyber security, digital technologies or adjacent industries and want to improve the cyber security and digital technologies aspect of their offering.

CSIRO’s Innovate to Grow: Cyber Security and Digital Technologies program commences 8 June and is available for 20-25 SMEs.

Expressions of interest to participate close 15 May.

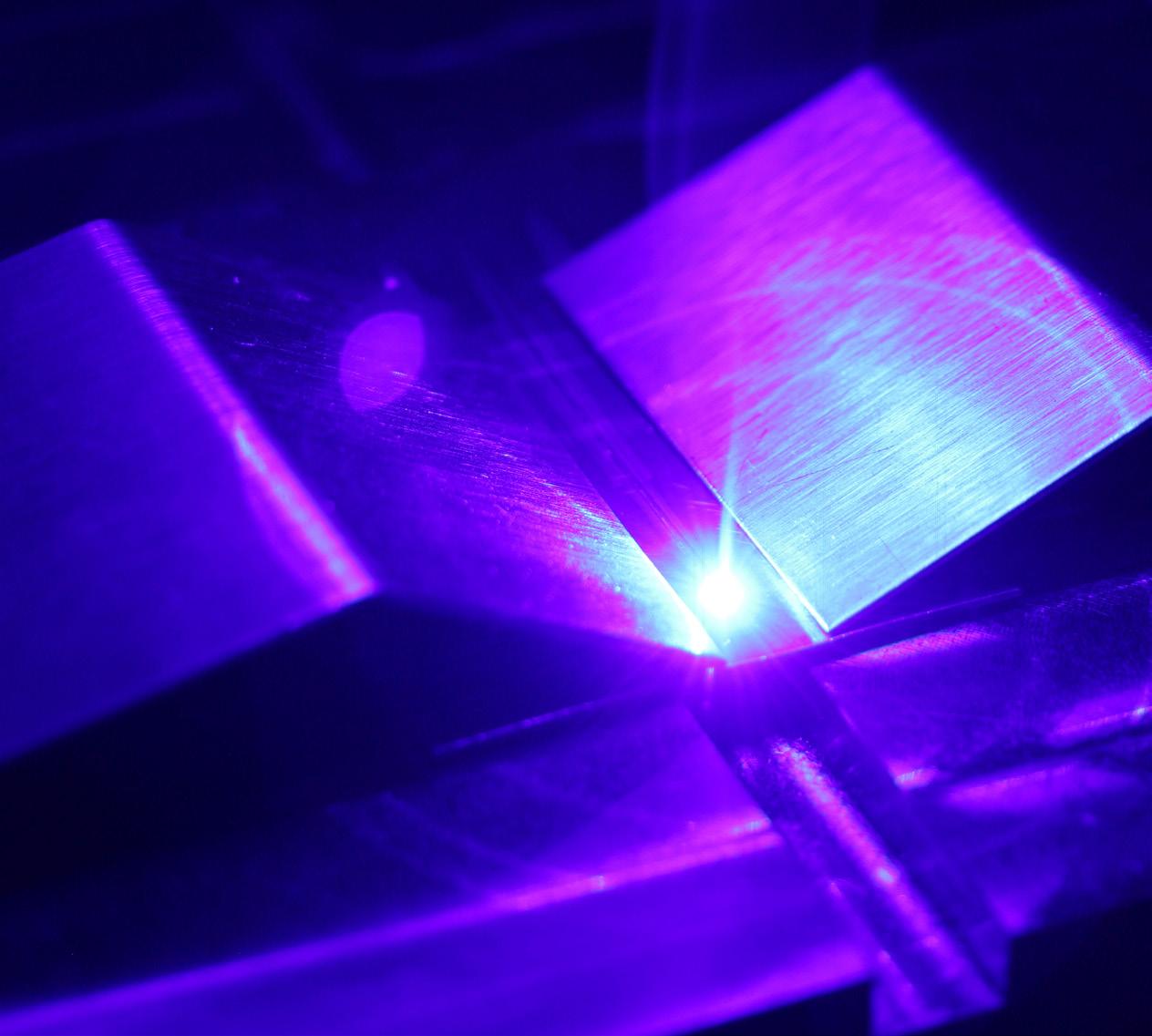

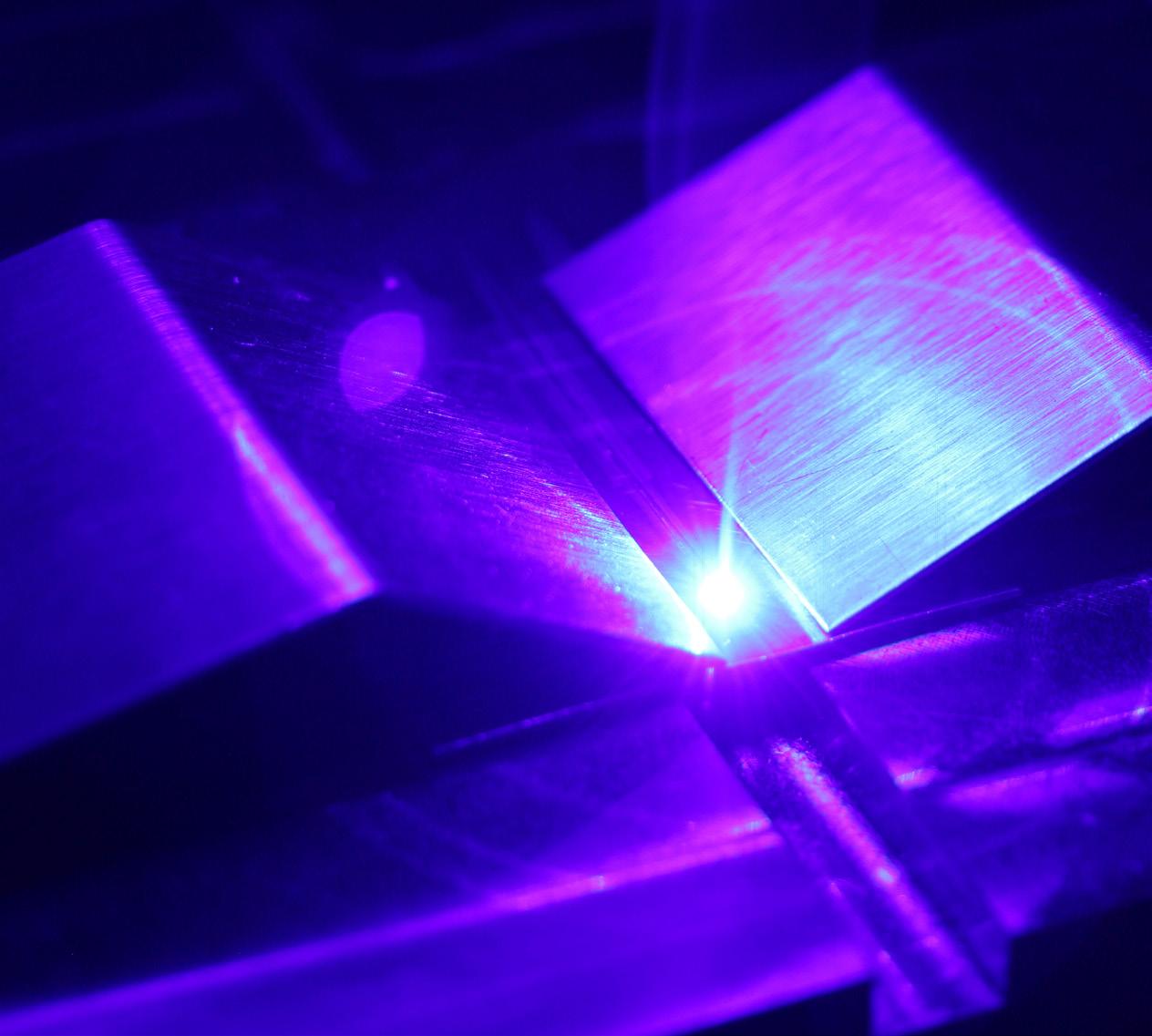

Powerful diode lasers solve welding challenges

High power diode lasers from the German company Laserline GmbH are widely used in Australia across a variety of sectors including copper welding, ship building, tape laying of fiber-reinforced plastics, joining pipes and machine parts.

Welding with these high-power diode lasers offers the highest energy efficiency of any industrial laser.

Good for wide gaps

Bridging wide gaps with metal welding is a significant challenge in machine

building, pipeline construction and ship building.

The main solution has long been gas shielded metal arc welding (GMAW) – a classic joining technology that uses an electric arc to melt the workpieces.

While this process is reliable, welding speeds are comparatively slow, with users often struggling to manage piece distortion due to the high heat input, as well as being time-consuming and costly because the straightening or reworking to repair unclean seams.

Laserline’s diode laser-based cold wire welding with multi-spot optics — which can be robot-driven — offers new processing options for joining symmetrical and asymmetrical seams.

Robotic control of lasers is an established practice in Australia - mostly for welding large items, and demonstrates their ability to weld in places that would otherwise not be accessible under normal welding conditions.

Electronic welding

With the need to extend battery life in cars, and improvements in semiconductor production, the demand from the electronics industry is increasing, and so the efficient welding of copper, gold and other non-ferrous materials is essential.

Copper is one of the most important raw materials for electrical signal transmission and a key component of

modern technologies found in battery cells of mobile devices, induction coils and accumulators in electric cars.

Often the parts are exposed to a high current, operate under high temperatures and strong vibrations, and where they comprise several parts, the joins must ensure efficient functionality.

This is where weld seams created by lasers are the best option. Laserline GmbH have developed a blue high power diode laser specifically for this task providing for high-quality, spatter free welding.

Using this new LDM platform, copper powder and thin copper foils can easily be joined to other materials such as steel and aluminium.

Recognising that not every piece of copper is the same, Laserline’s LDM blue lasers provide options for welders to adjust their processes, ensuring the most effective welding tool is available in whatever circumstance.

Raymax will be at stand MS 260 at Australian Manufacturing Week.

Expression of Interest csiro.au/cyberdigitech INDUSTRY NEWS

Raymax raymax.com.au 20 | Industry Update Issue 131 Apr/May 2023 industryupdate.com.au

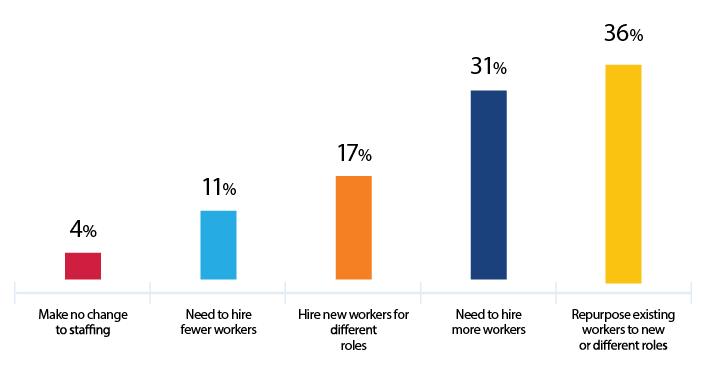

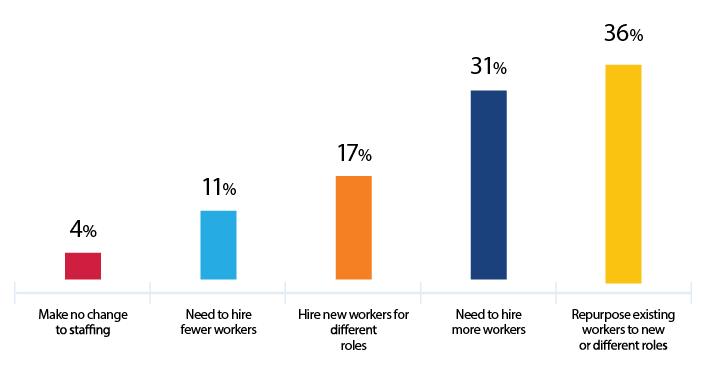

Equipment and technology investment top priority for food businesses

More than 60 per cent of Australian food industry businesses are looking to make capital expenditure investments in areas such as equipment and technology over the following 12 months, according to a recent survey.