MANUFACTURING GROWTH

www.industryupdate.com.au

projects – particularly in New Wales, and when you view this against a of robust global economic growth, opportunities are there for manufacturing to Bizarrely, the threat of a global trade war have worked in favour of Australian the short term at least – by softening the Aussie dollar.

“More Australian manufacturers are exporting under the Coalition Government. For every $1 of revenue the sector generates, 28 cents comes from abroad. That’s up from 23 cents a decade ago,” says Senator Cash.

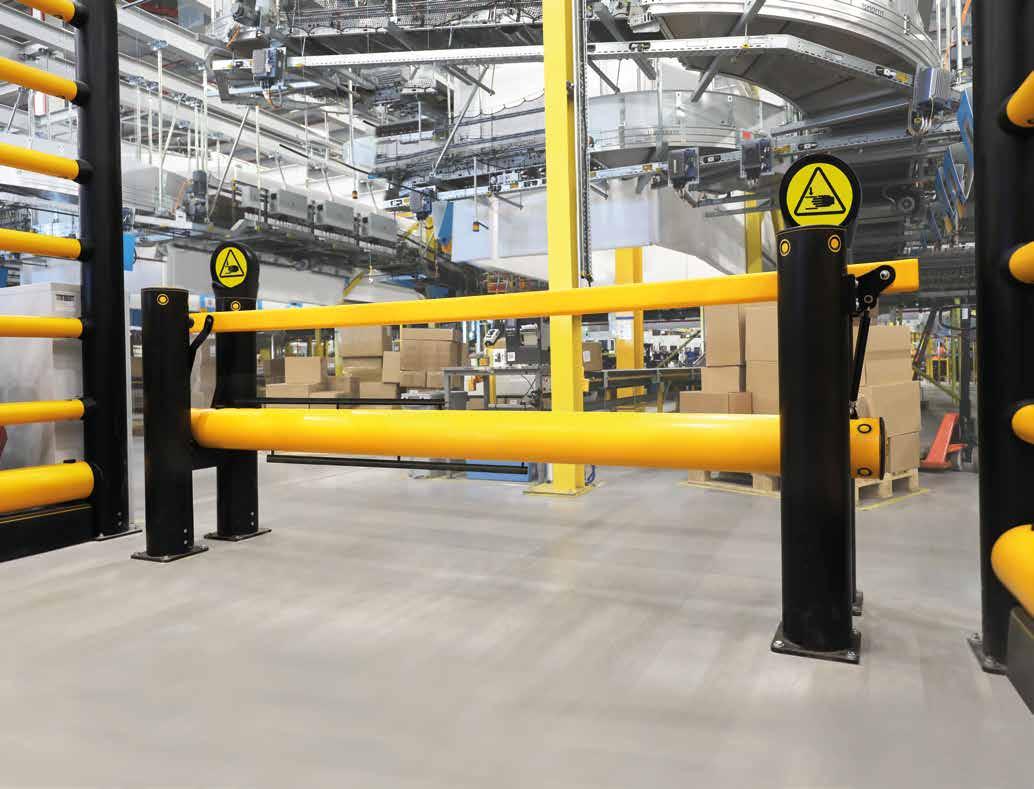

PRODUCTIVITY PLUS FOR SAFE MOBILE PLATFORM

NSW to rebuild manufacturing industry

Nonetheless, the nation’s reliance on export increased in recent years. According for Jobs and Innovation Senator Cash: “Australia’s access to global markets will be fundamental to continued health and success of our local manufacturing industry.

export more than $20 billion a year than we did a decade ago. Australian have, in fact, sold $2.7 trillion to the economy over the last decade.

Besa Deda from St.George also sees positives in the manufacturing employment statistics. “Although manufacturing employment as a proportion of the economy as a whole is in a long-term decline, the recent gains are encouraging,” she says, pointing to nearly 10,000 new manufacturing jobs and increasing capital expenditure plans in the sector.

fewer jobs, billions of government procurement dollars sent overseas and a poor skills base.

At a recent roundtable with manufacturers, one participant described NSW as the least hospitable state for manufacturers.

One word of warning, though, comes from financial analyst illion, which noted in its most recent Australian Business Expectations Survey that one in three manufacturers had reported customers or suppliers become insolvent or unable to pay them in the preceding 12 months, highlighting cashflow as the second-biggest barrier to growth in the year ahead, after utilities and operating costs

The NSW Labor government will

Now available at a one-off price of $400 and with significant discount for quantity orders, the DarDeck safe step platform can pay for itself in efficiency gains. And the improved safety it brings to any warehousing, retail or maintenance environment could save a fortune in workers compensation and public liability payouts.

By Courtney Houssos, the Minister for Finance, Minister for Domestic Manufacturing and Government Procurement and Minister for Natural ResourcesIn February, the NSW government announced $275 million for our Net Zero Manufacturing Initiative. The clean energy future will be built on the manufacturing of solar panels, storage and fuels.

The move to Net Zero will transform our economy and these grants ensure NSW

600 Machine Tools rebrands to Colchester

Designed as a simple and more productive alternative to unstable stepladders and unguarded low work platforms, the Australian designed and manufactured DarDeck combines a solid working platform with safety rails to prevent

NSW is home to a range of highly innovative, sustainable, competitive and world leading manufacturers and technology providers in industries such as fabrication and component production, health and life sciences, food and beverages, defence and space.

The NSW Government is committed to advancing our manufacturing sectors through programs to support workforce skills and development, exports, sustainability, innovation, research and development and much more.

Visit investment.nsw.gov.au/priority-sectors/advanced-manufacturing to learn more about how the NSW Government supports our manufacturing sectors to grow and embrace advanced manufacturing.

Visit the NSW Government stand RA350 to see great examples of the broad range of advanced technologies and products NSW businesses are using and making.

The NSW Government stand at Australian Manufacturing Week features organisations dedicated to supporting NSW manufacturers. Connect with industry experts and advisors from:

Facilitates economic development and attracts investment, reinforcing NSW as the most desirable place in the world to visit, study, invest and do business.

The WPCA’s Advanced Manufacturing Research Facility (AMRF) is the first of its kind in Australia, providing a unique offering that will bring industry, research, and education to the heart of the Western Sydney Aerotropolis.

Plays a crucial role in facilitating the planning, implementation and delivery of talent attraction and training initiatives. Its primary objective is to develop a skilled, work-ready pipeline of workers to meet the needs of NSW industry.

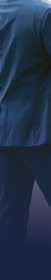

The workplace health and safety regulator in NSW.

Serves as a catalyst for business expansion, connecting local manufacturers with companies eager to enhance their supply chains, drive innovation, and explore new collaborations.

A not-for-profit innovation network funded by the NSW Government through the Office of the NSW Chief Scientist & Engineer. It brings together universities, industry, and government to translate world-class research into innovative smart sensing solutions that create value for the economy, environment, and society of NSW and beyond.

LAST CHANCE TO ATTEND OUR FUTURE VISION NEED LOW-COST AUTOMATION? DON’T

MISS THIS EVENT!

Far too big for any booth, a specially assigned 1,000 sqm area WITHIN OUR SYDNEY STORE, has been set aside to demonstrate how technical advancements in modern machinery and automation will increase your business efficiency and profit.

More than ten brand-new cutting-edge machines sourced from around the world will be on display and used over the three days, at our Sydney store. Unit 1, 2 Windsor Road, Northmead, NSW.

This is a strictly RSVP event, so please confirm your attendance quickly to avoid disappointment

RSVP NOW & ATTEND TO WIN $1,000!

Simply RSVP and attend Future Vision 2024, to win one of 5 x $1,000 Gift Cards

Meet Danny Sims, Head CNC Machinist from Brad Jones Racing, as well as representatives from UNIMIG Welders, Brobo Machinery, Bramley Manufacturing Equipment, Sutton Cutting Tools & Pilot Air Compressors.

Robotic Automation Systems

5-Axis Machining Centres

3 & 4

Axis Machining Centres

Multi Axis CNC Turning Centres

CNC Plasma Cutting Machines

Synchro CNC Pressbrakes RSVP HERE SYDNEY 2024 APRIL 17-18-19

MAKING IT IN MANUFACTURING IN NSW NSW to rebuild manufacturing industry

manufacturing is part of the revolution. The state’s leading critical minerals and high-tech metals deposits combined with the central role we play in Australia’s financial sector, makes NSW the perfect place to begin manufacturing these critical products.

We’re also investigating the best ways to invest government procurement dollars to stimulate growth in the state’s domestic manufacturing industry because every new job in manufacturing creates three-and-a-half more in the supply chain.

Last year, the government initiated a parliamentary inquiry into procurement to ensure the prioritisation of local content.

When we went to the election last year, we committed to creating a Jobs First Commission. It will oversee the implementation and growth of local industries, supporting and advocating for local firms bidding for government tenders.

We further committed to increasing local

“Every new job in manufacturing creates three-and-a-half more in the supply chain.”

content for tenders, including a target of 50% minimum local content for future rolling stock transport contracts.

Soon, we will start the procurement process for the next set of trains to replace the ageing Tangara train fleet. This will create at least 1,000 long-term jobs, including 200 apprentices.

Having a pipeline of skilled workers is crucial, and our new TAFE Manufacturing Centres of Excellence in the Illawarra, Hunter and Western Sydney will help create the workforce we need. This is a whole-of-government effort, being undertaken in collaboration with industry.

To boost opportunities, we are employing an additional 1,000 apprentices and trainees across the public sector.

We are delighted to be the main sponsor for Australian Manufacturing Week 2024 and to host the NSW government stand. It will highlight exciting new opportunities and connections with NSW government organisations to help businesses grow, including:

• Investment NSW, which develops and delivers the NSW government’s trade, industry development and investment programs. It focuses on business growth activities in emerging and established industry sectors

• The NSW Smart Sensing Network, which is helping companies gain an enduring competitive advantage by accessing expertise and technology from NSW’s leading universities. It’s exploring new frontiers in additive manufacturing, predictive maintenance in machines and infrastructure and optimisation of supply chains with new logistics models

• Training Services NSW is working with Investment NSW to provide skills training and award-winning workforce programs to help manufacturers meet their environmental sustainability obligations, the challenges of evolving digital skills and reimagining business models to align profitability with sustainability in the transformative move towards Net Zero

• SafeWork NSW, the workplace health and safety regulator in NSW is dedicated to working with businesses to ensure safe working environments. SafeWork Inspectors will be on hand to answer your questions

Over the next decade, Australia’s manufacturing sectors will undergo significant transformation. Driven by global technological and geopolitical trends, components of the

THIS IS

Continued from front cover

manufacturing value chain will evolve to be more automated, connected, repeatable and sustainable.

“A pipeline of skilled workers is crucial and our new TAFE Manufacturing Centres of Excellence…will help create the workforce we need.”

Unprecedented investment in NSW and in the manufacturing powerhouse that is emerging in Western Sydney, is already being leveraged to build a world class innovation ecosystem and drive domestic manufacturing.

In regional NSW manufacturing is diverse, shaped by the unique geographical strengths of each area and the close associations between innovators and primary producers in agriculture, mining and forestry.

The NSW government is committed to attracting further investment and to helping our existing manufacturers find new markets, embrace advanced manufacturing and grow their operations.

Welcome to the latest issue of Industry Update magazine, which is a special one. In co-operation with the NSW Government and Investment NSW, Industry Update is proud to present the largest feature that we have ever published at 62 pages and all on manufacturing in NSW.

In this edition we are highlighting the government initiatives and companies that have worked to make NSW the largest manufacturing state in Australia.

April is a big month for the industry, with Australian Manufacturing Week being held in Sydney April 17-19. More than 6,764 square metres of exhibition space will be dedicated to over 270 organisations showcasing the latest manufacturing technologies, processes and support services.

Not only is the must-visit event the nation’s premiere manufacturing solutions expo, it is also a celebration of all aspects of manufacturing.

The NSW Government’s decision to sponsor the event is a sign of its investment in the industry.

Minister for Domestic

Manufacturing and Government Procurement, Courtney Houssos recognises that every job in manufacturing creates three-and-a-half more in the supply chain, which is why she is committed to making NSW Australia’s leading manufacturing state.

Recent investments include $275 million for the Net Zero Manufacturing Initiative to build the state’s future on clean energy, including solar panels, storage and fuels. This was backed up by the federal government’s recent announcement of $1billion to manufacture solar panels in the Hunter Valley, a region previously known for coal mining.

Over the next decade, as Australia moves to become a key global player in the manufacturing of solar panels, its manufacturing sector will undergo a dramatic transformation.

Investment by government at all levels, which includes support and training as well as funding, means the future is looking bright when it comes to building a renewable future that’s made in Australia.

See you at AMW 24!!

NSW wind farm to power 700,000 homes

A1500 megawatt wind farm known as Yanco Delta is set to generate enough energy to power 700,000 homes in New South Wales.

Minister for Environment and Water Tanya Plibersek announced the farm today, saying it is one of the country’s biggest clean energy projects.

Yanco Delta will include the construction of 208 wind turbines, an 800 megawatt battery and grid connection infrastructure. Its site is ten kilometres north-west of Jerilderie on a 33,000-hectare site in the Murrumbidgee and Edward River Local Government Areas.

The project will save up to nearly 5 million tonnes of greenhouse gas emissions every year — equivalent to taking 1.5 million cars off the road — a big step in the government’s plan to make Australia a renewable energy superpower.

Minister Plibersek said years of political fights over climate change have cost Australia “big time” by keeping emissions higher for longer and postponing renewable energy projects for years.

“We want to unlock Australia’s potential to be a world leader in

renewable energy. It’s a huge task –we’re remaking our entire energy system.

“Our government has shown just how bright Australia’s future can be when there’s less political fighting and more action on climate change.”

The government says this project, while great for energy and the environment, will also support up to 300 jobs in construction and 30 ongoing jobs.

Minister Plibersek said the project has been approved under Australia’s environment law after careful assessment of the environmental impacts. It is able to proceed with strict conditions to protect nationally protected threatened species including the superb parrot and the plains-wanderer.

Element14 transforms product life cycle support

The new Design, Build, Maintain HUB from element14 will be a game changer for electronic components and solutions. It streamlines product development, saves time, and ensures operational efficiency for customers across industries.

This innovative platform was created to support how developers, OEMs

and industrial customers navigate every stage of the product life cycle, from conception to maintenance.

Element14 is a distributor of products and technology for electronic and industrial system design, maintenance and repair. Its Global Head of Technical Marketing Cliff Ortmeyer believes the HUB will set a new industry standard.

“Element14 distinguishes itself with our distinctive in-stock offerings, covering every aspect of OEM and EMS requirements. Our goal is to be the one-stop-shop for all electronic components and solutions required throughout a product’s lifecycle,” he said.

“This HUB will serve as a valuable resource to all customers, particularly OEMs and industrial clients, providing access to a diverse range of products and technical resources.”

The design phase is crucial for successful product development, so developers will be pleased that element14’s HUB provides them with

access to a vast array of in-stock components essential for design and prototyping, streamlining the development process and accelerating time to market.

It boasts over 13,000 development kits and evaluation boards, allowing customers to explore the latest technologies from leading suppliers across the globe. element14 consistently adds over 5,000 new products monthly on average, ensuring access to cutting-edge solutions.

To support the build phase, element14 offers a comprehensive selection of electronic components, including semiconductors, electromechanical parts, wires and connectors, hardware, and product build accessories. With products sourced from over 2000 leading manufacturers, customers can find everything they need in one place, saving time and resources.

Element14’s maintenance and repair solutions encompass a wide range of automation and control

solutions, production supplies, and industrial tests and tools to help ensure operational efficiency and safety. These essential products help customers keep their facilities running smoothly, ensuring employee safety and minimising downtime.

The HUB will also showcase new manufacturers, technical resources, and key industrial initiatives such as element14’s energy-saving solutions and Industrial minilog that features over 300 product highlights from suppliers, new technology and technical articles. The minilog includes categories like industrial automation and control, fans, power, relays and fuses, sensors, switches, test and measurement, tools and production supplies, SBCs, cables and connectors.

Training Services NSW supports transition to advanced manufacturing practices

The Workforce Development team at Training Services

NSW (TSNSW), a division of the NSW Department of Education, plays a vital role in facilitating the coordination and support of talent attraction and training initiatives. Its main goal is to foster the development of a skilled workforce that meets the needs of various industries in NSW. It achieves this by supporting apprenticeships and traineeships, providing subsidised training through programs like Smart and Skilled and offering adult and community education opportunities.

Navigating the Vocational Education & Training (VET) system can be challenging due to its complexity, including diverse training programs and funding options. To address this complexity, TSNSW collaborates with employers, industry stakeholders, training providers and government bodies to identify barriers and develop tailored solutions based on individual needs.

Driving digital skills

The Driving Digital Skills program, a collaborative effort between Investment NSW, TSNSW Workforce Development, and industry partners, aims to support NSW manufacturers in transitioning to advanced manufacturing practices.

This initiative is driven by the recognition of the industry-wide demand for digital skills, particularly in light of the transition to Industry 4.0. This program aims to help businesses understand the opportunities and benefits associated with Industry 4.0 and the adoption of digitalised operations.

Since its inception in early 2022, the program has undergone several pilot stages, incorporating continuous improvements based on industry feedback and consultation.

FutureMap and tailored training

The program starts with business leaders using a diagnostic tool called futureMap™ to assess their progress toward Industry 4.0. This tool provides insights and recommendations for improvement, helping businesses identify areas for growth.

Following this assessment, businesses can access a range of training options tailored to their specific needs in digital upskilling. These training opportunities are currently fully subsidised by the NSW Government through Smart and Skilled.

Climate impact reporting and ESG Building on the success of the

Driving Digital Skills program, a similar approach was adopted in response to the emerging need for climate impact reporting, particularly with impending mandatory carbon emissions reporting for large businesses across Australia from July 1, 2024.

Recognising the urgency, the Workforce Development team collaborated with Investment NSW and industry partners to develop the Driving Sustainable Advanced Manufacturing program.

Commencing in February 2024, this program offers training across three key operational areas within the manufacturing sector including:

• Business leadership

• Team management

• Shop floor operations

The training focuses on areas such as Environmental, Social, and Governance (ESG), carbon emissions tracking, sustainability, and energy audits. Businesses can utilise the futureMap™ sustainability tool to identify their training needs and access government-subsidised training in accredited units, including an introductory ESG course – a first of its kind in Australia.

For more information on the Driving Digital Skills Program or the Driving Sustainable Advanced Manufacturing Program, please contact tsnsw.workforce.development@det.nsw.edu.au

ANUFACTURING IN NSW

Manufacturing excellence the heart of our newest city, Bradfield City Centre

by Ben Kitcher, Executive Director of the Advanced Manufacturing Research Facility

New cities rarely happen. In Australia, the last major city to be built was Canberra100 years ago.

A new city built around advanced manufacturing technology is rarer still - a potential global first, in fact.

With this extraordinary foundation, we have the chance to make Bradfield City Centre, and Western Sydney more broadly, the place – globally – for manufacturing excellence.

The opportunity to participate in the development of a new advanced manufacturing centre at the heart of a new city is significant.

Across the Western Sydney Aerotropolis, unprecedented investment in world-class infrastructure will facilitate the growth of factories and related services, seamlessly linking them to local and global markets.

Bradfield City Centre sits at the epicentre, providing a great place to live,

work and innovate. The Advanced Manufacturing Research Facility (AMRF) will be the first organisation to open its doors in the new city, setting the tone for what is to come.

So, what can we expect from the AMRF?

The AMRF will activate the manufacturing ecosystem in Bradfield City Centre and across the wider Western Sydney region, targeting focus industries such as advanced manufacturing, space, defence, medtech, logistics, research and development, new energy, and the circular economy.

Connecting businesses with each other and further opportunities, the AMRF will provide services to manufacturers which want to implement next-generation manufacturing technologies, helping define, develop, and implement solutions which unlock greater productivity and new markets.

From its first facility, the AMRF will offer businesses the opportunity to develop capability and staff skills in advanced machining methods, additive manufacturing, composites production, process digitisation, and automation. AMRF machinery, systems, and facilities will all be of industrial scale, quality, and relevance, providing the perfect platform to develop methods which can be transferred easily into existing factories.

Providing front and back-end support with projects, the AMRF will ensure designs are optimised

projects, is what will set us apart.

The AMRF will also provide a platform to mentor a new generation of technology leaders that will proliferate people within businesses across the NSW manufacturing industry, helping to drive growth.

What’s next?

We are gearing up to launch the AMRF, with doors set to open later this year. All the essential parts are nearing readiness.

We have taken input and feedback from across industry to shape the capabilities to be offered. We have engaged suppliers across Australia and the world to work with us in the delivery of capabilities.

We have engaged universities across NSW to draw upon the immense expertise embedded within laboratories.

We are building the facility. And we have launched the Invitations for First Projects, with nearly thirty businesses expressing interest in collaborating with the AMRF.

for modern manufacturing methods and processes developed are qualified for their intended purpose.

The principles of collaborative manufacturing development centres which underpin the AMRF are not foreign to Australian institutions and businesses. However, until now limited investment has meant we could not create anything comparable to international centres of excellence.

To address broad industrial requirements and deliver meaningful impact, scale and commitment are key.

Building on the broad industrial shoulders of the Western Sydney manufacturing industry, the NSW government has invested more than $300 million in the AMRF, a significant investment that will provide the scale needed to achieve outcomes.

It will unify a wide range of advanced manufacturing capabilities under one roof, providing the seamless delivery of capabilities not yet seen in Australia.

The key to unleashing these capabilities, and to make them accessible and easy for businesses to adopt in a profitable and timely fashion, is the staff of the AMRF.

NSW government investment in the AMRF will build a team of manufacturing engineers who will be available to support a wide range of technical projects simultaneously, and with ongoing availability.

AMRF’s expert staff, with their industrial knowledge, experience of the latest technology, and readiness to guide businesses through their

Respondents have approached the AMRF with a huge range of concepts for projects, from modelling new factories to optimising investments through to the development of new and improved processes for additive, composite, and machined parts.

Areas of applications include space, medical devices, and sports goods.

One theme stood out strongly: our manufacturing industry recognises the value of technology and the AMRF’s potential to lower barriers and increase success in its implementation.

The AMRF’s objective for these businesses and others in future, is to provide the tools and methods necessary to generate industry growth, increase productivity, and ultimately, to re-establish Australia’s position as a leading manufacturing economy and trading partner for high-value manufactured goods. However, without manufacturing industry participation, the AMRF cannot achieve its objective.

The AMRF needs industrial partners to collaborate in the delivery of services to manufacturers, to support the strategic direction and growth of the AMRF, and most importantly to take up the capabilities and skills generated.

We cannot wait to unveil what we have to offer.

The unlimited opportunities to engage with the AMRF and use its network to engage with other industrial partners for supply, sourcing, or collaborative ventures is vast … get involved!

ICN NSW champions the manufacturing revival

At the heart of Australian Manufacturing Week lies Industry Capability Network (ICN), a pivotal force in driving manufacturing excellence across the state. ICN is a catalyst for industry growth, connecting local manufacturers with companies eager to enhance their supply chains, drive innovation and explore new collaborations.

Companies like Brumby Aircraft relied on overseas manufacturing in China for cost-effective production. Disruptions of the pandemic led to

soaring costs and delays, prompting a shift in strategy. Brumby Aircraft pivoted to local manufacturing in Cowra, leveraging ICN NSW’s support to streamline operations. Similarly, ICN assisted Ares Group in optimising its multi-million dollar projects by facilitating the movement of oversized cargo across Australia.

Small and medium enterprises are the backbone of Australian manufacturing, and at Australian Manufacturing Week, ICN showcases its range of tailored services and initiatives to support the sector. From its vast network of local manufacturers to its strategic specialists positioned in Western Sydney, regional NSW and North Sydney, ICN provides unparalleled expertise and support to businesses navigating the complexities of the manufacturing ecosystem.

ICN’s flagship offering, the ICN Gateway platform, streamlines supplier sourcing and facilitates connections between buyers and suppliers. Whether companies are

reshoring operations or exploring innovative solutions, ICN Gateway offers curated sets of suppliers and expert guidance to drive success.

Moreover, ICN’s collaboration with the NSW Government underscores its commitment to fostering economic growth and local manufacturing capabilities. As Australian Manufacturing Week unites industry leaders, innovators, and stakeholders, ICN stands poised to help shape the future of manufacturing.

Whether seeking to reshore operations or optimise supply chains, businesses can rely on ICN’s extensive connections, expertise and support to unlock the full potential of local manufacturing, driving success and prosperity across New South Wales.

Modern Manufacturing Manager, Marcus Batten said ICN aims to help bring together and build engagement between local suppliers and manufacturers.

“Our goal is to support local manufacturers in increasing their scale, justifying capital investments

for processes, expansion, or innovation. We aim to emphasise the value of ICN’s (alongside the NSW Government’s) contribution, helping manufacturers perceive ICN as an asset that facilitates supply chain matching services,” he said.

“We strive to foster a local and in-country manufacturing community that is interconnected, empowered and actively engaged in delivering advanced manufacturing as an Australian standard, led by NSW.

“Central to this endeavor is aiding manufacturers in discovering and nurturing local trade talent, while reassessing approaches to industrial automation and total quality management to align with business growth opportunities. The priority is to assist them in staying current with sustained, ongoing and optimised manufacturing practices, while being mindful of using the most suitable systems to ensure sustained output and profitability as desired outcomes.”

SVSR expands into bespoke manufacturing

When SVSR started in 2005, it was grounded in sewer vent installation solutions. It has since grown to servicing the building industry with steel frames and trusses, becoming an end-to-end manufacturer.

R&D Manager Duncan Reynolds said the company’s experience working with Sydney Water as well as Tier 1 and Tier 2 contractors has given SVSR important design and compliance experience.

“We are bespoke manufacturers,” he said.

“We guide clients through every step of the process from design to manufacture to installation. Our experience and knowledge means we can quickly navigate changes to adapt to clients’ needs.”

Covid was a turning point for the company. The problems with supply chain issues meant SVSR had to diversify the business.

“We had a lot of experience with compliance and certification. Covid meant we really needed to shift our focus from just importing materials, because the lead times were too long,” Reynolds said.

“The company broadened its supplier base and shifted to digitisation

and automation due to the skills shortage, like welding, design and drafting.

“We were getting asked by Tier 1 companies to do many of these jobs, so we took it upon ourselves to upskill. Within all of that we are trying to be more sustainable.

“Rather than focusing just on delivering a part for a process, we’ve used our end to end life experience to get into design, certification and installation. We know how things work onsite and it gives us feedback which informs design changes we can use further on.

“The whole of life approach to manufacturing is critical. We can’t necessarily compete on costs with imports, so our niche has to be our knowledge in these areas.”

Reynolds has worked in the manufacturing industry since he was 15 and said it’s unrecognisable to what it was in the 90s.

“It was all about cost and compliance. Now we are looking at digitalisation and automation,” he said.

“We need to learn all of this as mid-career professionals, which is quite the challenge.

“Manufacturing always amazes me. We are a SME, there are nine of

us, but when I have conversations with defence contractors and manufacturers who build submarines, I’m blown away by how much we have in common, no matter what we make.

“We all have the same issues, upskilling, shortages, compliance and cost. Manufacturing is definitely a way of thinking rather than just a job.”

M AKING IT IN M ANUFACTURING IN NSW

Regional NSW manufacturing: resilience, growth and grit

By Ian Smith, Department of Regional NSW, Executive Director Office of Regional Economic Development

Ian Smith, Department of Regional NSW, Executive Director Office of Regional Economic Development

The vast expanse of NSW, beyond the bustling metropolis of Sydney, is home to a thriving network of regional hubs thanks to a manufacturing renaissance. NSW boasts the largest manufacturing sector in Australia, with 25,000 businesses creating 30% of Australian manufacturing output.

Regional NSW is home to manufacturing powerhouses including Bega Cheese, Nestle, Sanitarium, Thales, Bisalloy, Bluescope Steel and many more.

Diversity defines manufacturing in regional NSW. Each area possesses its own unique strengths, shaped by geographical features, historical legacies and local expertise.

In the Hunter region, known for its coal mining heritage, manufacturing has evolved using the skilled workforce to drive growth industries such as defence, aerospace, clean technology, machinery and equipment manufacturing.

Meanwhile, the Riverina region, renowned for its agricultural abundance, thrives in food processing, packaging and agricultural machinery manufacturing. The Central West, with its rich mineral deposits, has fostered a strong presence in mining equipment, technology and services.

One of the driving forces behind manufacturing’s success in regional NSW is its close ties to the primary industries that dominate these areas. Agriculture, mining and forestry provide a steady stream of raw materials, creating a synergy between sectors.

This integration not only adds value to raw materials but also fosters innovation as manufacturers work closely with primary producers to develop cutting-edge technologies and processes. For instance, agricultural machinery manufacturers in the New England region collaborate with farmers to design equipment tailored

to the area’s specific needs, enhancing productivity and sustainability.

Furthermore, manufacturing in regional NSW thrives on the largest regional workforce in Australia with 58% holding tertiary qualifications. Of these, 22% have science, technology, engineering or mathematics qualifications. To leverage the strength of this mighty workforce, the team at the Department of Regional NSW has a range of workforce development programs to ensure the capabilities of local employees are aligned to the demands of rapid industry growth and business success across sectors with a focus on manufacturing.

Regional NSW is home to over 100 Technical and Further Education facilities and over 150 higher education science and research facilities.

The NSW government is committed to reducing red tape and planning timeframes for businesses

investing in regional NSW. At the forefront of this mission is the ongoing commitment to Special Activation Precincts. These worldclass business hubs in Wagga Wagga, Parkes, Moree and Snowy Mountains along with three regional job precincts in Albury, South Jerrabomberra and the Richmond Valley, offer streamlined planning approvals to enable infrastructure and are ideal locations for businesses looking to grow.

With well-established air, rail and road infrastructure, plus connectivity to deep-water ports at Port Kembla and Newcastle, regional NSW is strategically positioned to service some of the largest consumer markets in the world.

For example, the Wagga Wagga Special Activation Precinct located on the inland rail, houses the Riverina Intermodal Freight and Logistics (RiFL) hub, with overnight access to international ports along with 75% of Australia’s population.

‘With’ is confusing …. Can we instead say ‘The RiFL has overnight access to international ports along with 75% of Australia’s population.’

“Manufacturing in regional NSW is …. about building communities, fostering innovation and driving economic growth.”

The government continues to support manufacturers in regional NSW through its robust policy and funding initiatives, having just announced the $275 Net Zero Manufacturing Fund which complements the unprecedented $3 billion commitment to world-leading hydrogen strategy.

Manufacturing in regional NSW is not just about making products—it’s about building communities, fostering innovation and driving economic growth.

From the fertile plains to the rugged hinterlands, regional manufacturers embody the resilience and ingenuity that defines the Australian spirit. As they navigate the challenges of a rapidly changing world, they stand poised to seize new opportunities and continue shaping the future of manufacturing in regional NSW.

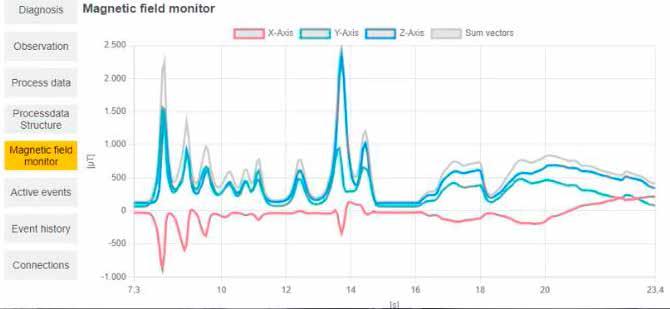

Smart sensors increase advanced manufacturing efficiency and productivity

NSW Smart Sensing Network’s Sam Ashby outlines how the agency helps companies unlock outstanding research capabilities for a competitive advantage.

Smart sensing is changing the way we manufacture, communicate, work, move and live.

For advanced manufacturers who want to count, sort, weigh, measure or monitor anything, smart sensing can provide increased efficiency and productivity.

To understand the technology, you first need to recognise that sensors detect, diagnose, monitor and respond to the world around them, allowing pre-emptive and predictive responses in a vast range of settings.

This technology is already part of our daily lives, found in even the most basic technology in our homes, offices and cars. But it is the next generation of sensors, known as smart sensors, where the exciting discoveries lie, which will shape our future economy and society.

Such sensors can be wireless, distributed, and networked to power the Internet of Things, Industry 4.0 and ‘smart’ cities.

The rapid progression of chip manufacturing has led to a surge in accessibility to compact computers that can perform complex calculations — in a single device that fits in

the palm of our hands.

The surge of AI also feeds into this. Certain tasks are best done autonomously on the device, rather than sending massive loads of information across the network.

Connecting this so called ‘edge-computing’ capability with traditional sensors, for example measuring temperature or air quality, provides deeper insights about how our environment is changing.

technology from across NSW’s leading universities and gain an enduring competitive advantage.

The NSSN is a not-for-profit Innovation Network funded by the NSW Government through the Office of the NSW Chief Scientist & Engineer.

“Smart sensors… will shape our future economy and society.”

Only the key important features need to be transmitted for decision making.

Some examples are classifying audio sensor data to look for endangered wildlife or analysing the movement of crowds without storing raw CCTV footage.

These applications drive the automation, AI and robotics that will revolutionise the way we grow food, generate energy and make things.

The additional data gathered has already allowed major advantages in tracking the supply chain of manufactured goods – and there is more to be done here.

Through partnering with the NSW Smart Sensing Network (NSSN), companies can access expertise and

cells, glucose biosensors, and energy conversion using renewable resources.

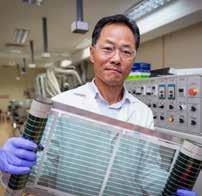

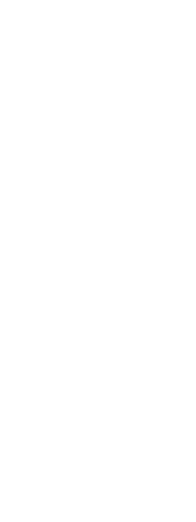

The manufacturing facility can develop materials and manufacture the printed solar cells using a new form of advanced manufacturing known as Functional Printing.

PEGRAS and the Key Centre for Colloids and Polymers (KCPC) at The University of Sydney are collaborating on an elegant multi-stage process to remove microplastics from laundry water.

In harsh settings where clothes are being repeatedly washed, like hospitals, a significant amount of microplastics end up in our waterways. They are a pollutant, potentially toxic, block and damage urban and natural spaces, and end up in the food chain. Taking cues from tried and tested techniques in other processing industries, they have developed a unique coagulant procedure to draw out the microfibres, leaving behind only pure water.

Sensing is an essential aspect. The project uses FT-IR spectroscopy and imaging techniques such as optical microscopy, transmission electron microscopy and scanning electron microscopy.

The KCPC laboratory can effectively characterise the presence of microplastics, and by doing this at various stages of the process, they have identified the performance of the operations.

It brings together universities, industry and government to translate worldclass research into innovative smart sensing solutions that create value for the economy, environment and society of NSW and beyond.

With an emphasis on collaboration between our member universities and industry, the NSSN facilitates the creation of projects implementing smart sensing, to bring innovative solutions to a broad range of industries.

There are many exciting R&D projects already taking place throughout the network.

Researchers at the University of Newcastle, in partnership with the Australian National Fabrication Facility and Newcastle Institute for Energy and Resources, are developing novel materials that are robust, flexible, recyclable, and low cost for innovative applications including solar

This NSW government funded project is now complete, and the innovation is in the process of commercialisation.

NSW universities are at the forefront of smart sensing research, exploring new frontiers in additive manufacturing, predictive maintenance in machines and infrastructure, data security in large sensor networks and optimisation of supply chains with new logistics models.

Artificial intelligence is unlocking next-generation smart sensing platforms for even greater optimisation.

Come and talk to us about how the NSSN can help give your company the competitive edge by unlocking the outstanding research capabilities in NSW.

The NSSN will be at The Investment NSW stand at AMW 17-19 April, Sydney International Convention Centre. To find out how the NSSN can help solve your challenges, contact Dr Sam Ashby at sam.ashby@nssn.org.au

NSW Smart Sensing Network

nssn.org.au

M AKING IT IN M ANUFACTURING IN NSW

$1 billion for local solar manufacturing supply chain

The Solar Sunshot program will supercharge Australia’s ambition to become a renewable energy superpower and capture more of the global solar manufacturing supply chain.

At the end of March, the Albanese government announced the $1 billion commitment in industry support such as production subsidies and grants, to help regions and industries deliver a renewable future made in Australia.

“We should be making solar panels here and that’s what we’ll do”

The news follows legislation establishing the Net Zero Economy Authority to catalyse investment in a clean energy future made in Australia’s regions.

Prime Minister Anthony Albanese made the announcement at the site of the former coal-fired Liddell Power Station.

“Australia should not be the last link in a global supply chain built on an Australian invention,” he said.

“I want a future made in Australia. And I want a future made in our regions. Places like the Hunter that have powered our nation for more than a century will power our future.

“We have every metal and critical mineral necessary to be a central player in the net zero transformation and a proven track record as a reliable energy producer and exporter.

“We can also invest in strategic manufacturing capability, particularly in components critical to the energy and economic transition, like solar panels.

“Historically, Australia has been good at going from the mining pit to port, and long may this continue. But the Australian government will also invest in the path from pit to panels and capture more value for our economy and workforce.”

Last week’s Climate Council report, which provides a roadmap to cut 75% of emissions by 2030, included recommendations to invest in clean technologies to stimulate economic growth in regions previously dependent on coal, oil and gas.

The Climate Council believes Australia can seize the decade by capitalising on its resources in renewable energy, and deep

industry and manufacturing know-how.

NSW to supercharge solar panels

While one in three Australian households have solar panels — the highest uptake in the world — only 1% of those have been made in Australia.

Parallel to Solar Sunshot, the NSW Labor Government is delivering the NSW Net Zero Manufacturing Initiative, with the $275 million first round now open to support workers, small businesses, manufacturers and innovators to take advantage of the transformation of the energy grid.

NSW Minister for Climate Change and Energy Penny Sharpe wants local homes to use local products to deliver long-term energy bill savings and a strong domestic renewable manufacturing sector.

“It’s great to align NSW and Commonwealth funding to support clean energy manufacturing, with this fund bolstering our $275 million investment in Net Zero Manufacturing.

“We know the world’s climate emergency is Australia’s jobs opportunity”

In the second round, the NSW Labor Government will work with industry to leverage government procurement to offer offtake agreements to local manufacturers of renewable products and low carbon materials.

Initiatives like Solar SunShot and the NSW Net Zero Manufacturing Initiative mean the regions that have long powered Australia will continue to prosper in the net zero economy by deepening the industrial base, largely in the regions.

NSW Minister for Domestic Manufacturing and Government Procurement Courtney Houssos wants to see government money spent locally.

“We will leverage our government procurement spend to build in offtake agreements with local solar manufacturers and foster the industry’s growth,” she said.

“For every job created in manufacturing there are a further threeand-a-half jobs sustained in the supply chain.”

Minister for Industry and Science Ed Husic said solar panels were our idea.

“We should be making solar

panels here and that’s what we’ll do. Aussie know-how is creating Aussie jobs, that’s what a future made in Australia is all about,” he said.

Independent think tank Beyond Zero Emissions has been calling for government investment in Australian manufacturing capability. CEO Heidi Lee believes Australia has an enormous opportunity to be a big part of the solar panel supply chain.

“The energy shift is a once-in-a-generation opportunity to build high-paid careers in regional Australia,” she said.

“Let’s not sit on the sidelines while other countries cash in on the energy shift…We’re not starting from zero in terms of manufacturing, we already have Australian companies doing bits and pieces, and we can scale this up and coordinate so we’re making the most of our natural advantages.”

Long-term commitment

The $1 billion federal investment in the Solar Sunshot program builds on more than $40 billion of investment committed by the Australian Government. Minister for Climate Change and Energy Chris Bowen believes Australia could become a renewable energy superpower.

“Australian research helped invent the modern solar panel –today’s announcement is about creating Australian jobs to help manufacture them,” he said.

“We know the world’s climate emergency is Australia’s jobs opportunity. The $1 billion to support Australian manufacturing in solar technology will help seize that opportunity.”

The Australian Renewable Energy Agency (ARENA) will now work with industry to design and deliver this initiative, along with the Australian Government. ARENA will look at the entire supply chain from ingots and wafers to cells, module assembly, and related components, including solar glass, inverters, advanced deployment

technology and solar innovation. This industry consultation complements other processes underway such as the Hydrogen Headstart program also administered by ARENA.

CEO Darren Miller said ARENA has been at the forefront of building Australia’s solar PV industry through its support for research, innovation and large-scale deployment and has helped make solar our cheapest form of energy.

“To date, ARENA has invested more than $830 million towards 233 solar PV projects. We are ready to take on the next step alongside others in the solar industry to create a domestic solar manufacturing industry.”

ARENA funded the Australian Photovoltaic Institute’s (APVI) Silicon to Solar Report to investigate solar manufacturing capability and potential in Australia. The report outlined a credible pathway for a domestic supply chain that could result in benefits such as securing access to solar PV components as Australia significantly scales up deployment of solar PV, creating local jobs, attracting significant private investment and unlocking potential export opportunities.

ARENA and the Department of Climate Change, Energy, the Environment and Water will publish a consultation paper outlining proposed specifications for the program, including objectives, funding mechanisms, timings and draft eligibility and merit criteria.

“Australia has the opportunity to build high quality products across the solar PV supply chain,” Miller said.

“Although we have a very small production capability today, we have the skills and the partnerships to establish a strong base that can be built on over the next decade.”

M AKING IT IN M ANUFACTURING IN NSW

Tente offers more mobility solutions

Tente Castors & Wheels has been manufacturing quality European castors, wheels and mobility solutions since 1923. Its smart mobility solutions noticeably improve people’s lives and working environments. They increase productivity, ensure greater safety and open up new horizons in matters of design, durability and environmental friendliness.

Whether it’s for industrial, commercial, medical technology, heavy goods transport, mechanical engineering, intralogistics, factory equipment or the furniture sector, Tente’s castors and wheels set new standards and put influential changes in motion.

Tente also manufactures and distributes quality trolleys for all types of applications, including removalist trolleys, warehouse trolleys, linen trolleys, platform trolleys and powered trolleys. It also does custom trolleys, which can be designed and built in any material fitted with suitable castors.

Tente’s E-Drive can be retrofitted to most trolleys and takes the pain of pushing heavy loads. It works like a fifth wheel and offers perfect

directional stability, especially when using four castors. The system is activated via the hand control unit, once the drive is lowered, it is ready for use. The stepless speed regulation (forward and backwards) enables optimal

use. The required energy is supplied by a powerful, rechargeable battery. There are three models available; E-Drive Flex for standard applications, E-Drive Optima for higher safety demand and E-Drive Ultimate for higher customisation demand.

Electric tugs are battery powered pedestrian operated machines designed to move heavy loads on wheels. They can be used in retail, healthcare, hospitality, supermarkets, airports, waste management and strata applications. The new range of Xsto Battery Electric Stairclimbers will make light work of moving heavy objects up and down stairs. There is an Xsto available for most items that need to be moved, ranging from 170kg-420kgs. These stairclimbers include folding handle models with tracked drive, track drive models with support wheel feature for heavy cargo, stairclimbing forklift which is capable of lifting itself and cargo into a van or ute, detachable drive units which function as a powered stairclimber or as a standard handtruck.

Tente also distributes a range of quality brands. Prestar trolleys from Japan are suited to offices, retail, stock

deliveries and schools. Prestar’s quality is superior and offers a fiveyear warranty.

The Tawi range of battery electric lifters offer efficient handling of goods with ergonomic lifting, full mobility and flexibility. The Tawi range includes Easy Squeeze which can squeeze, lift and rotate; Core Gripper which lifts and rotates; V Block which is a rotating turntable and lifter; Fold Up Platform which is a combined platform and forklift attachment. These units are available in zinc plated and stainless steel, which are ideal for pharmaceutical and food environments.

Nally plastic bins are food grade bins made to stack, nest or stack and nest. Nally products can be used in warehouses, restaurants, stock control, food processing and anywhere a quality, robust storage container is required. Tente can manufacture dollys to suit most Nally bins, these can be made from galvanised or stainless steel, all fitted with quality Tente castors.

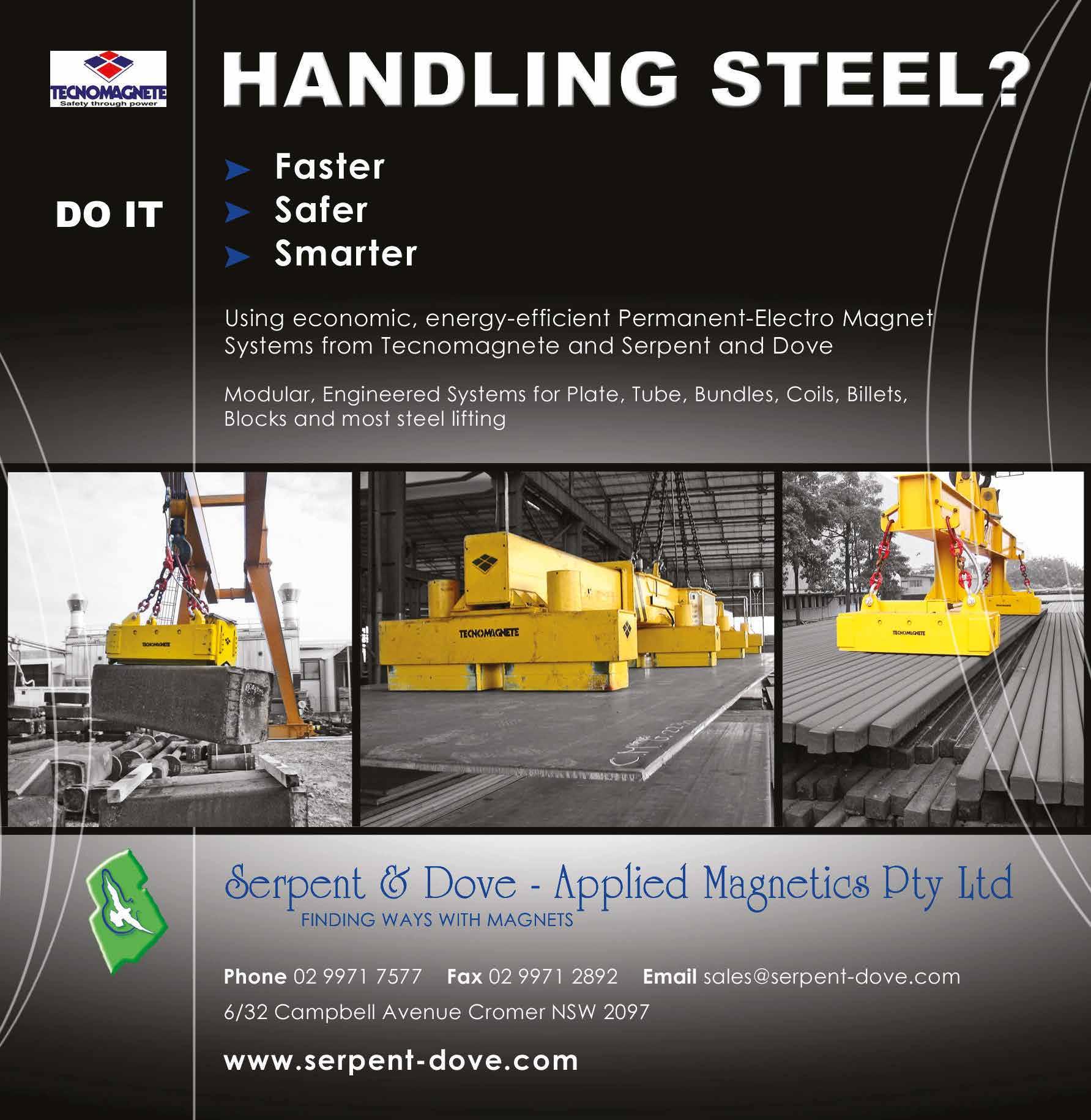

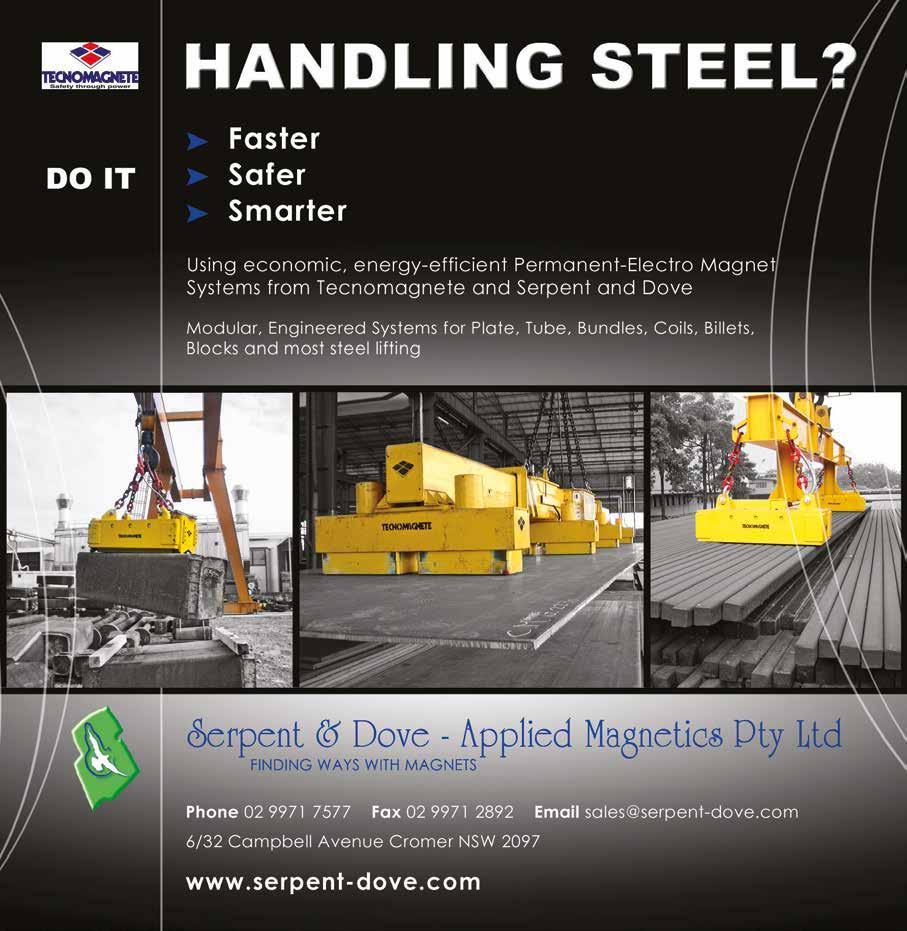

IPermanent-Electro lifting magnet technology

t’s taken a while to come to fruition, but the science has finally caught up with the goal. Lifting magnets that employ the immense gripping power of permanent magnets, which can be activated or deactivated at will, are now a reality.

The heart of the idea is that particularly designed permanent magnet elements can be magnetised and de-magnetised an infinite number of times without deterioration in effectiveness. Advances in rare earth and other permanent magnet manufacture have also contributed to the compactness and viability of the technology.

By using cleverly designed coils to ‘charge’, or activate these permanent magnet elements, steel of all types and shapes may be readily lifted. Similarly, a reverse pulse can de-activate the permanent magnets.

One of the pioneers in this specialised field was Italy’s Tecnomagete, now known as MagAutoblok Tecnomagnete. From the early 1970’s the company began to research and implement innovative magnetic solutions, among them the development of both permanent and permanent-electro lifting magnet apparatus with patents as early as 1975.

Today, thousands of installations around the world, lifting heavy steel loads of many sizes and shapes, demonstrate the telling advantages

of Permanent-Electro (also known as Electro-Permanent) Lifting Magnet design.

Once upon a time, electromagnets were considered the only real option for lifting steel plate, slab and billets, but this method has made lighter, stronger and more versatile magnetic lifting possible. Here’s why.

Conventional electromagnets consist of a relatively large steel or soft iron core and housing filled with a heavy copper or aluminium coil. A relatively large current is used in the coil to induce a magnetic field in

is here

the magnet core—usually the centre core is one pole (say North) of the magnet and the outer case forms the other pole (South).

“This method has made lighter, stronger and more versatile magnetic lifting possible.”

As the current flows in that coil, the whole core and housing

warms—and, as it warms there is a subsequent loss in magnet strength. This means the magnet must be sized to compensate for loss of magnetic strength that occurs over the period of a long lift, or series of lifts. That’s why lifting electromagnets are usually rated with a duty-cycle, for example maximum 30 minute ‘on’ time, followed by a cooling period.

Permanent-Electro lifting magnet technology offers various advantages. These include:

• There is no magnet efficiency loss due to temperature rise. The permanent magnets remain at ambient temperature for as long as a lift or series of lifts may take. They are activated or de-activated by a short, sharp current pulse only

• There is no need to duty-cycle the magnet/s

• The self-weight of permanent-electro magnetic lifters is usually considerably less than that of conventional electromagnets, so overhead crane or lifting equipment capacity requirements are reduced

• Whilst conventional electromagnets require back-up with batteries or other emergency systems to cover the eventuality of power-outages, there is no such requirement with permanent-electro systems, as the magnets continue to retain the load even during power outages. In addition, a load cannot be released inadvertently, because a fail-safe system, known as ‘Dautanac’ prevents release before the load is at rest

• Power is required only momentarily for the activate and de-activate operations, which means Mag-Autoblok Tecnomagnete

Permanent-Electro Lifters are far less energy-hungry—an important consideration in today’s green-conscious world

• Due to its relative lightness of weight, it can lift steel plates typically up to 16 metres in length and blocks up to 50 tonnes. Systems are also available to lift steel coils The technology not only applies to lifting, but is also used extensively in clamping operations such as chucks for machining operations as well as mould clamping in injection moulding operations.

Mag-Autoblok Tecnomagnete is represented in Australia by Serpent & Dove—Applied Magnetics Pty Ltd.

Intralogistics: Future signposts are clearly visible

By Simon Pullinger, LAPP Australia Managing DirectorAs long as the traffic is flowing and the shelves are full, the intralogistics sector is rarely in the spotlight. However, by flying under the radar, the significance of the industry can easily be overlooked.

The Australian intralogistics market was valued at AUD $780 million in 2022 and is expected to grow to AUD $2,319 million by 2030. By global comparison, Asia-Pacific is the fastest growing region for the freight and intralogistics market.

Intralogistics is essential to ensuring our day-to-day lives, all industries and many services can operate in the first place. Without a functioning flow of raw materials, goods or information, nothing can be produced, communicated or sold.

That’s why it’s unsurprising intralogistics is noticed precisely when something goes wrong, such as when a giant freight ship blocks the Suez Canal, work in warehouses is slowed down or even suspended by social distancing or traffic is paralysed by a strike over the consequences of Brexit.

Unfortunately, the intralogistics sector has a growing shortage of skilled workers. This will have significant consequences, because without personnel there are limitations to materials or goods flows.

Smart automated solutions

These global trends have also affected LAPP, the leading provider of integrated solutions and branded products in the field of cable and

connection technology. It has implemented smart solutions, such as using autonomous forklift trolleys to relieve employees of repetitive manual tasks, in factories across the globe.

Anyone thinking about the future of large logistics hubs and highrack warehouses will encounter the topic of automation: self-driving lift trucks, automated conveyor technology, robots that pick appropriate goods or artificial intelligence that handles all planning processes. The signposts for successful logistics in the future are clearly visible. Demographic change and the accompanying shortage of skilled workers are just two of the drivers of this development.

As a major global leader, LAPP recognised the trends in the sector at an early stage. It ranked itself among the most important companies in the sector for the first time in 2023 at LogiMAT, the largest intralogistics trade fair in Europe.

This shows how LAPP solutions enable comprehensive networking of data and processes and increase efficiency and transparency in intralogistics. The industrial-grade, robust and high-quality components for networking transfer data and power reliably. For cross-level communication between the various network participants, LAPP has smart solutions for the leading protocol standard PROFINET and all other standards.

There is a particular demand for solutions for the increasing number of high-rack warehouses, which are

growing in height due to an increasing lack of space. With the ÖLFLEX® CONNECT CHAIN, LAPP offers fully assembled cable chain systems that can be tailored precisely to the needs of customers. This applies both to applications requiring torsion and movement.

Data cables for logistics processes

For industrial data communication, LAPP has high-quality industrial cables in its portfolio with its HITRONIC® fibre optic cables and ETHERLINE® data cables, which enable reliable data communication in automated logistics systems.

LAPP also supports the integration of robotics and cobots into logistics processes. With special cables and connectors, these machines can be seamlessly integrated into the logistics environment. It means repetitive tasks can be automated, which eases the burden on human labour.

Future technologies also deployed at LAPP

At LAPP, these questions play a major role in all future projects. The Stuttgart-based company will be expanding its own logistics centre in Ludwigsburg over the coming months and bringing it up to date with the latest technology.

Rather than replace employees with machines, LAPP believes collaboration between people and robots and the use of other future technologies will increasingly become a matter of course. By optimising processes, LAPP uses its own products and solutions to ensure the current shortage of

professionals does not affect its own delivery capacity.

The conversion and expansion will allow LAPP to achieve significantly more warehouse capacity and increase its availability and throughput speed on site. This means that we will be able to rapidly supply all our customers. A modern IT system also reduces the error rate and, in the best case scenario, ensures that less waste is generated in the logistics centre.

This is just the beginning. In the future, intelligent technologies will make it possible to support what we call ‘best agers’ with age-appropriate work concepts. For example, the use of intelligent robots will reduce physical stress during standard activities including lifting, stacking and commissioning. Machines can relieve the arms and shoulders of logistics workers.

Working in logistics is becoming more demanding and less physical, but that doesn’t mean it can work without our employees and, in particular, without skilled personnel. That is precisely where we need well-trained professionals, of which there is an increasing shortage. We are focussing on training and retaining our own employees internally, according to their abilities and needs.

Human beings are not replaceable in intralogistics. Automation solutions from LAPP are available for the everyday work processes.

We keep your industry alive

We are your trusted partner for cable and connectivity solutions in the field of intralogistics.

AKING IT IN M ANUFACTURING IN NSW

Adept enters a new era

New owners have taken over Adept Conveyor Technologies and MRT Australia, creating Adept Conveyors Pty Ltd, a new business that’s set for growth and expansion in the Australian materials handling and logistics markets.

The new company will be steered by the Larsen family of Cowra, NSW, and the family’s long-time accountant, Stephen Henderson.

The Larsen family has a long history in Australian manufacturing,

particularly in the agricultural industry. They also bring extensive experience in marketing and finance. They look forward to building on the excellent work of the previous owners, Paul Johnson and Ross Simpson.

Adept Conveyor Technologies is a recognised leader in the materials handling industry, known for its expertise in the design and installation of conveyor systems throughout Australia. It also has distribution rights to a range of conveyor

componentry under the MRT brand.

Central to the decision to purchase the assets of these companies was the unique offerings of Adept Conveyor Technologies and the capabilities of its staff. Stephen and the Larsen family feel these benefits set up the company for growth and expansion in the Australian materials handling and logistics markets.

The history

In the early 1990s, Richard Larsen and his three sons decided to start manufacturing the farming implements they needed on the family farm. This soon grew into a profitable business manufacturing a variety of implements and was purchased by a multinational corporation in 2019.

Richard’s sons, James, Bill and David, were joined by their brotherin-law, David Trim, and their sons, Roly and Kurtis, when they started their next business. It was also based around Australian manufacturing, providing quality products and great customer service.

When they discovered Adept Conveyor Technologies, they realised it was an opportunity too good to pass up. Along with Stephen, who had worked with them since they first went into business, they made an offer. The assets of

Adept Conveyor Technologies and MRT Australia are now officially owned by their new business, Adept Conveyors Pty Ltd.

The future

Even before the sale was complete, it was decided that James and Kurtis would work with the previous owners to consolidate their knowledge of the company and the wider industry, so that they would be ready to take over immediately after the sale.

The other owners and Larsen family members are working part time for the company in various roles.

Paul Johnson continues at Adept Conveyors in an advisory role throughout the handover, to ensure the business continues running smoothly and provides the best possible value to all customers.

The new owners have great hopes for Adept Conveyors. They aim to build on the existing capabilities of the company to create a brand that is a renowned leader in the industry for quality products, outstanding customer service and comprehensive industry knowledge.

HELPING YOU DO WHAT YOU DO BEST

Warehouse order processing and fulfillment systems

Sanitary food production and processing conveyors

Freight and courier handling systems

Custom unique conveyor-based designs

HOW WE CAN HELP

The most favourable and exclusive pricing for all quality hardware

A flexible approach to conveyor design and manufacturing

The largest local stock holder of any conveyor supplier

Components sourced solely out of Europe

M AKING IT IN M ANUFACTURING IN NSW

Bespoke cranes rely on energy chains

Eilbeck Cranes has posted growth each year since the mid-1980s when current CEO Tom Eilbeck bought the 117-year-old company from his father.

In the last 30 years, turnover has jumped from $5 million in the mid1990s to $150 million today. Much of the success of the past decade has been due to igus energy chains which are key to Eilbeck’s standard German cranes and the bespoke cranes Eilbeck designs and builds here.

“Eilbeck had already delivered the first cranes … to South Australia to help build the French subs”

The company was based in Western Australia since being founded by Eilbeck’s grandfather in 1907 when it not only made cranes but also saws, winches, pulleys, tables, trolleys, wheels and rails for the local logging industry.

In 1994 Eilbeck expanded to Ingleburn, Sydney, where it now has four factories, plus two in WA, one in Truganina,Victoria, and one in MacKay, Queensland. Eilbeck’s ninth and biggest facility at 4,500 sqm in Moss Vale, NSW, was commissioned

last July. The tenth and by far largest facility at 9,000sqm is being designed now for Moss Vale.

The core business is cranes for construction and major infrastructure projects but Eilbeck also supplies to mining, aerospace, oil and gas, green energy, nuclear and medical. One of its four Ingleburn sites manufactures for defence: helicopter parts, tank components, among other defence and mining equipment. The massive new Moss Vale facility will also make for defence.

Operations Manager Peter Heinrichson says the Ingleburn facility winning defence work is the most state-of-the-art machine shop in the Southern Hemisphere. The French were not the only ones bitterly disappointed when the Australian government reneged on theFrench subs prior to AUKUS. Eilbeck had already delivered the first cranes it was to supply to South Australia to help build the French subs.

“All the big infrastructure project tunnels in Australia have had Eilbeck cranes on them, whether for rail or road.”

“Since the Airport link was built 1995-2000, an Eilbeck crane has been plant removing spoil from every major Sydney infrastructure project. Right now, we’ve got about 40 cranes out there around Sydney.” Eilbeck does the mechanics to specs of customers who do the civil work. A vital part of the success of

the festoon system to power cranes,” says Heinrichson. “They don’t ask for festoons any more.”

Festoons need much more space which is at a premium in tunnels, mining sites and other confined construction spaces. Yet energy chains offer many other benefits.

Being highly mobile, festoons can’t be mechanically housed. So they can get tangled or have problems with their pulling mechanisms.

“You get more than 10 years, maintenance-free, out of an energy chain”

Whereas an e-chain is fully housed, cannot tangle and unfolds only a small amount within the same space. Less movement by energy chains means fewer problems and far less maintenance.

Eilbeck’s customised cranes is the igus energy chain from Treotham, also known as an e-chain or dragchain, which Eilbeck uses in its locally custom-designed and built cranes.

Treotham, a supplier of electrical and mechanical components including cables, customises the cables and energy chain for Eilbeck to integrate into its bespoke cranes.

“A vital part of the success of Eilbeck’s customised cranes is the igus energy chain from Treotham”

Eilbeck is also an agent for ABUS Crane Systems’ standard cranes which use serial igus energy chains and sells up to 1,000 standard cranes each year. By value, Eilbeck’s business is split evenly between the far more expensive customised cranes using Treotham’s e-chains compared with the less expensive standard ABUS cranes it resells. Customers of bespoke cranes have found the initial outlay worth the price in the long term.

Twenty years ago, it was rare to use anything else but festoons but customers are now convinced.

“For a hundred years, people used

“Cranes with e-chains are a much more cost-effective solution,” says Heinrichson, “Because they reduce maintenance and downtime.

“The igus energy chain is maintenance-free and reliable. Our contracts, especially in construction, spell out performance guarantees we have to meet or be penalised. So we need reliable, proven equipment.”

“Maintenance is the biggest saving: festoons fail because trolleys pulling them fail within two to five years. That means downtime. You get more than 10 years, maintenance-free, out of an energy chain.”

Another cost benefit is that a much broader range of readily available cables can be used in an energy chain, and Treotham can supply and assemble them in the right configuration. This means Eilbeck has many more options for customers whose specs are always changing and demanding different performance levels for each project.

The latest is a 550-tonne crane with 50-metre lift height and 50-metre span for Victoria’s North-East Link.

“With an energy chain, we can make a crane as big as you want, say a hundred metres but you can’t do that with festoons; they’re very limited in length.”

“That’s why we’re successful — because we’re not bound by any limits.

The leading supplier of the BIGGEST names in Automation

Energy Chain

Flexible Cables

Secure supply of energy and data to moving industrial equipment.

• Large size range

• Vertical travels

• Energy tubes

• Hygienic chains

• Solutions for long travel

• Guide troughs

• Readychain

• Robotic, 3D

• Circular movement

Flexible Conduits

HUGE range of high quality flexible cables

• Control cables

• Single cores

• Data cables

• Sensor/Actuator

• Intrinsically Safe

• VSD/EMC cables

• Halogen Free cables

• High temperature

• Harsh Conditions

• Crane cables

• Profibus cables

• Bus/DeviceNet

• Solar cables

• Instrumentation

• Flat cables

• Curly cords

Connectors

Largest range of flexible conduits for cable protection

• Conduits

• Conduit fittings

• Divisible systems

• Jumbo systems

• Conduit Accessories

• Braided cable protection

• Fire barrier solutions

• Food and beverage

• EMC systems

• Ex, ATEX, IEC EX

Industrial connectors for many industries

• Rectangular multipole connectors from ILME

• Single pole Powerline connectors from TEN47

• EPIC connectors from Lapp Group

• M23 circular connectors from Hummel

• Circular connectors specifically for the entertainment/stage lighting industry from Socapex

Safety Sensors

Safety engineering solutions from EUCHNER

• Multifunctional Gate Box MGB

• Transponder-coded safety switches

• Electromechanical safety switches

• Magnetically coded safety switches

Sensor technologies for automation

• High-Precision Laser Distance Sensors

• Ultrasonic Sensors

• Inductive Sensors

• Fluid Sensors

East West Engineering

Ron King’s entrepreneurial journey began when he sold his beloved Ducati motor bike to buy tools and a van to start a residential fencing business in 1974.

By the end of the ‘70s, Kings focus changed to industrial fencing. Jobs installing temporary fencing at building sites gave King a toehold in the metalworking sector with requests for additional onsite metalwork such as handrails.

By the mid-1980s, Allmesh Engineering was being contracted on largescale metalwork projects for Darling Harbour’s public works including the Powerhouse and Maritime museums.

On these public works contracts, King saw an opportunity in the market for well-engineered and certified lifting equipment. With this he designed and manufactured a lifting jib he badly needed at the time, kicking off a habit of customising items which were to become bestsellers in East West Engineering’s range.

After Darling Harbour opened in 1988, recession hit the construction

industry. With 40 employees, King saw the business needed to pivot. Allmesh began designing and manufacturing forklift and crane attachments, such as jibs, and metal waste bins to meet Australian standards, and offered them with safety certification and documentation.

“In those days you couldn’t easily buy equipment with certification off the shelf, so it was a vital competitive edge for our initial products,” says King.

King attended equipment trade shows in Germany and returned brimming with ideas.

“The key to success was to get them onto the market quickly,” says King.

“We photographed the prototypes, made flyers which were sent out to 200 distributors of lifting equipment and advertised in trade publications” says King.

Established in 1993 as a specialised design division of Allmesh, East West Engineering was turning lifting and materials handling equipment ideas into prototypes.

A successful launch at a materials handling show in the mid 1990’s garnered many business leads. In 1998 the company’s catalogue boasted 100 products and, by 2000, East West stopped building work to focus solely on design, manufacture, and marketing its own products.

“In the early days we had to guess what the customer needed; now with an extensive range of over 300 standard products and more than 9,000 custom designs, customer demand helps guides our growing product range.”

Recent demand has led East West Engineering to the agricultural sector. Ag items now include a range of adaptors and attachments that increase the flexibility of a tractor to

handle different loads. This includes a cotton bale clamp, hay bale grab, hay bale spinners, log grabs, pole setters, bulk bag lifters and fork positioners that enables a tractor to do double duty as a forklift. A floor-mount bin tipper was designed to be customised to suit any bin and has been sold to grain

Lift-n-Tip wheelie bin tipper can require up to three prototypes, and might involve three months of testing.”

Before prototyping, there’s extensive research into market needs, competitive advantages, possible applications, then business case analysis. Design sketches are followed by detailed cad designs that must pass finite element analysis testing in accordance with the relevant Australian standards before moving forward.

While ongoing R&D is a substantial investment, the company’s 10,000 sqm of manufacturing equipment and facilities have substantial capital costs too. Finances have been kept under control by a company strategy to not expand too fast.

As King says, you can come up with new ideas but some may not work and that’s ok. Staying ahead of the competition requires more than great, practical ideas.

Copy-cats have been a problem for East West Engineering which often redesign old products because they have been copied. Our engineers design new features to compete with the copies.

companies, metal recyclers, and food producers. One customer wanted a bespoke stainless steel chute and removable safety barriers for its food production line; this new design is now part of their standard range.

Inspiration for this product designer is everywhere. King recently spotted a car being lifted into a shopping centre as a competition prize and decided to design a car carrier platform. Although time to market can vary depending on the product.

“Simple lifting platforms might take three to four weeks to prototype then another two weeks to build. More complex products, like our electric over hydraulic