From disadvantaged boys to work-ready young men: Clontarf’s success stories

by Margie Smithurst

by Margie Smithurst

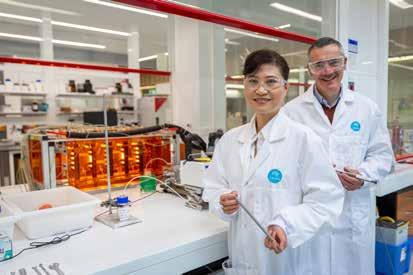

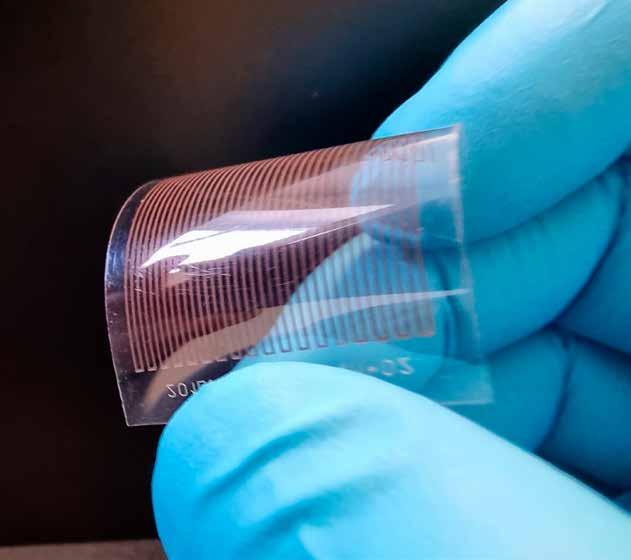

necessarily think about universities as a place to engage with,” UTS Strategic Partnerships Director John Szabo told Industry Update

“But with a facility like UTS Tech Lab, and across the 40 or so universities in Australia, there’s billions of dollars worth of infrastructure that is being underutilised by industry. So, we’re trying to lower the barriers to engagement and bring industry in to use it.

“Companies may not be able to afford to invest half a million dollars into certain pieces of equipment we have at UTS Tech Lab, but if we can establish a relationship and enable them to come in and use our facilities, whether it’s a per use or on a membership basis, that’s going to be an easier way for them to start developing proof of concepts and offers even low level manufacturing opportunities for them as well.”

Since launching in May 2021, UTS says 180 SMEs have had at least one engagement with the program, 65% of whom are manufacturers. Annette Dockerty leads the project to engage with the businesses.

“At a macro level, what we’re really trying to do is encourage SMEs to invest in innovation for modern manufacturing, which means improving their awareness about technologies, and making it easier... continues on page 23

“Setting the standard for Quality & Value”

METALMASTER ClearAir mobile welding fume bench is a compact all in one downdraft table with 1120 x 825mm work area (with fume shroud closed)

• HEPA H13 filtration ensures a safe & comfortable work environment

• Dual stage filtering

• High volume 2000 m3/h air filtering cap.Fume shroud with left & right hinged doors for larger work pieces

The Sunrise Punch & Shears are manufactured in Taiwan and the IW-60B is specially designed to include a 300mm wide multi-vee bending station.

• Punch, Shear & Bend

• ø22x20mm punching cap.

• 60 tonne, 5 work stations

• 350x15mm plate shear

• 100x100x8mm angle shear

• 300mm multi vee die block

$20,350 inc GST (P172)

$7,359 inc GST (W2715)

• 12.7 – 76.2mm OD Tube

• ½” – 2-1/2” NB schedule 40 pipe

• Double linear guide ways

• Adjustable notch angle up to 220 degrees

The Metalmaster Deburr1380 manual deburring machine is the ultimate cost-saving solution for deburring, grinding, edge rounding and finishing of metal parts.

$2,079 inc GST (P094)

A range of different types of pads and brushes for deburring, edge rounding, finishing, laser oxide removal and heavy slag removal are available.

• 1300 x 800mm TABLE with vacuum area to secure small parts in place

• Grinding head rotates 180° ensuring a quick and easy switch between processing steps

• Variable speed allows for easy speed adjustment to suit the tool and process

$14,795 inc GST (P7870)

The Metalmaster Synchro series pressbrakes adopt a heavy duty integral welded steel structure that is furnace tempered post welding to relieve residual stresses and ensure accuracy & longevity of the machine.

The hydraulic cylinders are manufactured from high resistance steel incorporating chromium plated ground & lapped pistons to ensure longevity of the Swedish brand SKF hydraulic seals

The hydraulics system consists of electronically controlled proportional valves with independent 3 point closed loop safety monitoring of the two cylinders as well as the main hydraulic system.

• 5 CNC Controlled Axis (Y1, Y2, X, R, V) as standard.

• Y1 & Y2 Axis is controlled by advanced safety monitored hydraulic proportional valves ensuring accuracy in movement.

• Bending compensation & accuracy is maintained using GIVI (Italy) Linear scales mounted on either end of the machine bed to measure any frame deflection

• CNC controlled auto crowning table (V) adjusts accordingly based on material, length & thickness specified in program.

The control features an intuitive interface with an advanced array of bending functions with vivid colour & large touch key interactive touch software. Interactive On-line help, and many other automatic functions that constantly guide the operator. CybTouch controllers are very easy to operate.

• Large, vivid and high-contrast fully touchscreen control mounted on a swivel pendant for optimal ergonomics

• Simple pages, clear display, large keys

• Intuitive 2D graphical touch draw part profile programming with auto bend sequencing

Electro-hydraulic servo synchronous control

The advanced Hydraulic system containing safety monitored proportional valves is integrated into the CNC control. Receiving real time feedback from the Y axis linear scales to the controller can compensate for deflection during bending, providing repeatable & precise control of the machine tool.

www.greasemax.au

MANUFACTURING MAGAZINE

Industry Update Media Pty Ltd ABN 25 083 502 783 Suite 403, Level 4, 116-118 Christie Street, St. Leonards NSW 2065 +61 2 9439 1288 / sales@industryupdate.com.au

Circulation 17,754 Readership 71,016 as at September 2022

All material in this publication is copyright to the publisher and/or its contributors. No material may be reproduced in part or in whole without the written consent from the Publisher. It is a condition of purchase or acceptance of this magazine that the Publisher does not assume any responsibility or liability for any loss or damage which may result from any inaccuracy or omission on this publication or from the use of the information in this publication or from the use of the information and illustrations contained herein and the Publisher makes no warranties, express or implied, with respect to any of the material contained herein. © Copyright Industry Update Media Pty Ltd 2023

Publisher SCOTT FILBY scott@industryupdate.com.au

Editor MARGIE SMITHURST editor@industryupdate.com.au

Sales Executive JAMES ROBINSON salesassist@industryupdate.com.au

Marketing Manager DUMINSHA UDESHIKA marketing@industryupdate.com.au

Finance & Accounts MICHELLE ALCOCK michelle@industryupdate.com.au

Consultant TRACY FILBY tracy@industryupdate.com.au

Writer CHRISTINE POWIS writer@industryupdate.com.au

Universities & Collaboration Editor DAVID SLIGAR unieditor@industryupdate.com.au

Sub Editor WILLIAM POOLE subeditor@industryupdate.com.au

Advertising Sales Director SCOTT FILBY scott@industryupdate.com.au

Creative Director EDWIN KWONG production@industryupdate.com.au

Production Manager DUMINSHA UDESHIKA copy@industryupdate.com.au

Video Editor & Producer CHARLIE LOUGHLIN video@industryupdate.com.au

Office Manager NICOLE CHARLES nicole@industryupdate.com.au

Accounts Receivable LYN SLIGAR lyn@industryupdate.com.au

Subscription Assistant TODD ALCOCK info@industryupdate.com.au

Circulation Assistant JERIN BURZACOTT circ@industryupdate.com.au

Printer SPOTPRESS

Downer has signed a $4.6 billion contract to deliver 65 passenger trains for South-east Queensland.

The six-car trains will be built at the state government’s purpose-built Torbanlea facility in Maryborough, with the first train set to be delivered in 2036, and all finished in 2032, when the state hosts the Olympic and Paralympic Games.

The government says the contract will support 800 construction and manufacturing jobs.

Queensland’s $7.1 billion Train Manufacturing Program is a key part of the state’s ‘Big Build’ $89 billion investment in infrastructure over the next four years, and is expected to create up to 3000 jobs in construction and manufacturing across Queensland.

Negotiations have been underway since Downer was announced as the

Prime Minister Anthony Albanese has sealed a deal for Australia to manufacture and export 100 Boxer armoured vehicles to Germany.

The PM made the announcement, one of the biggest defence deals in Australia’s history, en route to a NATO summit in Lithuania earlier this year.

The Boxers, all-terrain Combat Reconnaissance Vehicles (CRV), will be manufactured in Brisbane by German defence contractor Rheinmetall at its Military Vehicle Centre of Excellence in Redbank.

“This [deal] is worth over $1 billion to the Australian economy in the production and supply of these vehicles,” Albanese said.

“The agreement will boost Australia’s sovereign defence industry, secure local jobs and contribute to Australia’s economic growth.”

The PM said it was the first outcome of a few that he was going to announce “with our friends in Germany”.

Rheinmetall Defence Australia has a contract to supply 211 vehicles to the Australian military, and has already started manufacturing the Boxer CRVs.

The deal with Germany is expected to secure 1,000 jobs for Queensland over the next decade.

Delivery is set to begin in 2025.

preferred supplier for the program earlier this year. The contract involves construction, manufacturing and maintenance for the next 15 years.

The new trains will be more accessible for people with a disability, with the addition of Train Boarding Bridges and Electronic Levelling Controls to address the gaps between platforms and trains, as well as phone charging capabilities.

Construction is expected to start by the end of the year on both the manufacturing facility in Torbanlea and a new rail stabling and maintenance facility at Ormeau on the Gold Coast.

Queensland Premier Annastacia Palaszczuk said the government had promised to bring train building back to Maryborough.

“I saw how much this contract means to the men and women of Maryborough

when I visited Downer earlier this year – now we can get on with the job of building.

“Not only does this $7.1 billion program secure generations of job security, skills and training in Maryborough, but it sets our state up for a strong transport future.

“Because Queensland trains should be made in Queensland.”

“Campbell Newman sent rail manufacturing overseas,” said State Secretary of the Australian Manufacturing

Workers’ Union Rohan Webb.

“The billions of dollars in investment by the Palaszczuk Government will bring rail manufacturing back home, securing the future of hundreds of workers in Maryborough.”

The NSW government will build the biggest network battery in the Southern Hemisphere following more than $500 million raised by asset manager BlackRock.

This includes a $100 million equity investment from the federal agency Clean Energy Finance Corporation (CEFC).

The Waratah Super Battery, to be built on the former site of the Munmorah coal-fired power station on the Central Coast, will act as a giant ‘shock absorber’ for the electricity grid.

At 850 MW and 1680 MW, the battery project will be among the largest in the world. Up to 700MW and 1400MWh of the battery capacity will be contracted to buffer the system at peak periods and against disruptions such as power surges, lightning strikes or bushfires.

The 850MW battery will allow network operators to move greater amounts of electricity over existing transmission lines.

The government says this resilience will contribute to more reliable electricity supply and lower prices for consumers.

BlackRock’s Co-head of Climate Infrastructure for Asia Pacific, Charlie Reid believes the battery will boost reliability and Australia’s progress towards its renewable targets.

“We firmly believe battery storage is the critical technology of today — applied both on a small scale in homes, and for largescale battery platforms,” Reid said.

The project will be developed by battery company Akaysha Energy which BlackRock acquired one year ago. BlackRock is also planning other battery projects in Wellington, NSW and another in Queensland.

Ian Learmonth CEO of the CEFC said investments in both long- and short-duration storage assets are critical to the grid.

“Battery storage underpins a future balanced grid, ensuring more clean energy can reach more consumers and providing network stability as coal continues to exit

the network earlier than predicted.”

Minister for Climate Change and Energy Chris Bowen said the Waratah Super Battery will help stabilise the electricity network and help deliver more of the cleanest, cheapest form of energy for Australian businesses and households.

“The Albanese Government is already investing heavily through the CEFC on big battery projects in NSW, Victoria, South Australia and the ACT, as well as our $20 billion investment in Rewiring the Nation to upgrade and expand the grid to support Australia’s transformation to renewable energy.

NSW Energy Minister Penny Sharpe said the project is world-leading.

“The Waratah Super Battery is an excellent example of how our state can deliver clean, efficient and innovative infrastructure that benefits homes and businesses across NSW.”

The Waratah Super Battery is part of the Sydney Ring Project, which is a priority in the Australian Energy Market Operator’s 2022 Integrated System Plan (ISP) – the roadmap for investment needed for a reliable modern grid.

This announcement builds on the Albanese government’s Capacity Investment Scheme which will unlock around $10 billion in investment and add 6GW to grid reliability and security after a dearth of energy policy which resulted in less energy in the east coast grid.

The Albanese and state governments are set to improve energy affordability, security, reliability by attracting investment in the cheapest form of reliable energy – firmed renewables — through the Capacity Investment Scheme (CIS), a national framework.

A partnership between NSW and the

federal government announced at the end of June will deliver almost 1 gigawatt of dispatchable capacity, eliminating the forecast shortfall in 2028/29 flagged by the Australian Energy Market Operator (AEMO).

The CIS will more than double the 380MW of firmed capacity to 930MW in the NSW Energy Roadmap’s firming tender, through federal funding that will underwrite investment for up to an additional 550MW of firmed capacity.

Bids representing more than 3.3GW total capacity have already been submitted to the NSW 380MW firming tender round, meaning there is still a significant amount of firmed renewable projects ready to be unlocked by today’s announcement and support the grid over the long-term.

The NSW CIS will support grid-scale dispatchable generation and storage such as batteries, pumped hydro or other dispatchable capacity.

Minister for Climate Change and Energy Chris Bowen said the scheme would increase crucial investment in dispatchable renewable energy to improve the security and reliability of the NSW grid, as well as put downward pressure on prices.

“Today’s announcement will drastically improve energy security with largescale batteries and other zero-emission technology that can quickly dispatch cleaner, cheaper renewable energy when it’s needed, like when the sun isn’t shining and the wind isn’t blowing.”

Discover exciting automation trends and the latest innovations for I ndustr y 4.0 and the IIoT – with news, webinars, white papers and more.

Giving back to the community is an important ethos for business, which is why Industry Update magazine likes to cover worthy not-for-profits, charities or foundations when we can.

The Clontarf Foundation (story on p18) is one of those organisations that particularly deserves coverage by the manufacturing sector.

Set up by ex-Fremantle Dockers coach Gerard Neesham at a WA school in 2000, it has since established numerous ‘Academies’ at schools around Australia, and has already helped more than 6000 Indigenous boys complete year 12.

The boys are shepherded through school with a combination of discipline (the boys have to turn up to early morning footy training twice a week), dedicated Clontarf staff care and encouragement, and in turn learn public speaking, to contribute and participate in community projects, improve their footy, and finish their school years.

But that’s not all: those boys are taught ‘work-ready’ values, getting jobs while they’re at school, and receive dedicated support to get their CVs ready, tax file numbers, interview training and even drivers’ lessons.

And that’s where manufacturers or businesses looking for reliable labour come in.

I went to the recent Sydney event hosted by industrial and safety products supplier Blackwoods where Clontarf invited businesses to come and visit their school Academies, meet the boys and even consider them for employment.

It was an impressive event, and the stories the former Clontarf boys there told of going from disadvantage to university, or into one of the big construction companies, or roles at Blackwoods and Bullivants, were evidence that the Clontarf process really works.

Clontarf partners with businesses who in turn offer training and employment opportunities for the young men while they’re at school and afterwards.

To put more Indigenous boys through a Clontarf school program with the aim of getting them into jobs costs only $7000 per boy, with partnering businesses collaboratively funding the equivalent of $2000 of that.

But the money goes to much more – it helps to close the gap, but could also be one step in eventually bringing a young worker into your company who will contribute more than just a smile and a solid work ethic.

So I encourage companies to find out more about partnering with The Clontarf Foundation and help more disadvantaged boys become successful in their schooling and ultimately in their work and personal lives. In a time of a labour shortage, engaging and supporting the program and students in the longer term could be one of the simplest, most worthy solutions.

Also in this edition, a preview of the Modern Manufacturing Expo in September (from page 31). Industry Update is pleased to announce it is now the official magazine for the MME.

Eight new Australian Research Council (ARC) Industry Industrial Training Centres and five new ARC Industrial Transformation Research Hubs have received more than $64.8 million in funding. The funding will support partnerships between universities and industry to generate real-world outcomes, and mentor and train Australia’s next generation of research professionals.

Announcing the funding, awarded under the ARC’s Industrial Transformation Research Program, ARC Chief Executive Officer Ms Judi Zielke said it will provide innovative research benefits, new products and commercial opportunities for Australia.

“These new ARC Industrial Transformation Training Centres and Research Hubs will allow Australia’s best researchers to engage with critical industry partners to address current and future

challenges faced by industrial sectors,” Zielke said.

Universities and industry organisations will also provide over $227 million in additional funding for the new ARC Training Centres, as well as over $78 million for the new ARC Research Hubs, which will help increase collaboration between innovative researchers and industries vital to Australia’s social and economic future.

These contributions will allow researchers and students to access the latest technology, facilities, and to collaborate with leading industry experts to develop transformative solutions across government in industrial transformation priority areas, such as recycling and clean energy, and advanced manufacturing.

The 8 new ARC Industrial Transformation Training Centres commencing in 2023 are:

• ARC Training Centre for

Assisting Australian SMEs to upgrade their manufacturing technology and invest in automation is one of the ways the sector will remain resilient and productive in years to come. But talking to those who have that technology and expertise and who feel it’s underutilised, there appear to be a few barriers.

University of Technology Sydney’s SME@UTS program actively courts SMEs to encourage them to try out the world class UTS Tech Lab advanced manufacturing facilities in Botany, Sydney.

Dealing with a university isn’t often on an SME’s to-do list, but the advantages of using engineering, IT, biomedical and business students (often cost-free) and a range of high-tech testing equipment are obvious in their potential for research or solving specific projects.

As SME@UTS Program Lead Annette Dockerty told Industry Update: “At a macro level, what we’re really trying to do is encourage SMEs to invest in innovation for modern manufacturing, which means improving their awareness about technologies, and making it easier for them to get access to knowledge, expertise, talent, grants and our facilities.”

Australia’s central science and research agency CSIRO also wants to see more engagement with SMEs - in particular, in harnessing manufacturing’s digital future.

On page 24, CSIRO’s Christian Ruberg says that while the manufacturing sector already collaborates with peak

Automated Vehicles in Rural and Remote Regions ($5m): Led by Professor Sebastien Glaser, Queensland University of Technology

• ARC Training Centre for Whole Life Design of Carbon Neutral Infrastructure ($5m): Led by Professor Chun-Qing Li, RMIT University

• ARC Training Centre in Predictive Breeding for Agricultural Futures ($5m): Led by Professor Lee Hickey, The University of Queensland

• ARC Training Centre in Plant Biosecurity ($5m): Led by Professor Peter Solomon, The Australian National University

• ARC Training Centre in Critical Resources for the Future ($5m): Led by Professor Marco Fiorentini, The University of Western Australia

• ARC Training Centre for Radiation Innovation ($4.99m): Led by Professor Mahananda Dasgupta, The Australian National University

• ARC Training Centre for Battery Recycling ($5m): Led by Professor Shizhang Qiao, The University of Adelaide

• ARC Training Centre for Radiochemical Technologies and Precision Radiopharmaceuticals ($5m): Led by Professor Andrea Robinson, Monash University

The 5 new ARC Industrial

industry bodies, it needs to take advantage of other collaboration opportunities - such as those on offer by CSIRO.

CSIRO’s Future Digital Manufacturing initiative, for example, works with businesses to adopt new technology, funding leading-edge technologies within CSIRO to benefit Australian manufacturing.

As Ruberg says, ‘Australia has tremendous technical capabilities … CSIRO aims to contribute its hard-won intellect, ideas and resources to reduce the risks and costs associated with technology innovation.’

From the point of view of companies that sell the products SMEs need to step up to Industry 4.0, there appears to be a stalling.

On page 30, founder of Robotic Automation Colin Wells says he’s seeing a concerning reluctance to invest in automation processes, which he attributes to a number of factors including a broad lack of appropriate engineering skill in businesses, and the view that if no investment is made, no mistake can be made…

He also sees companies wanting to automate the wrong types of factory processes, indicating that the fundamentals behind the idea aren’t quite being grasped.

Showing small to medium manufacturers what’s out there in terms of lower cost and creative collaborations for trialling their ideas, as well as helping them see that investment in automation or higher-tech processes will at some point be necessary, is how media like Industry Update can help.

Transformation Research Hubs commencing in 2023 are:

• ARC Research Hub in Zeroemission Power Generation for Carbon Neutrality ($5m): Led by Professor Zhi-Gang Chen, Queensland University of Technology

• ARC Research Hub for Engineering Plants to Replace Fossil Carbon ($4.93m): Led by Professor Robert Henry, The University of Queensland

• ARC Research Hub for Smart Process Design and Control ($5m): Led by Professor Aibing Yu, Monash University

• ARC Research Hub for Value-Added Processing of Underutilised Carbon Waste ($4.96m): Led by Professor Lian Zhang, Monash University

• ARC Research Hub for Future Digital Manufacturing ($5m): Led by Professor Dimitrios

Georgakopoulos, Swinburne

University of Technology

More information about each of the successful 2023 Industrial Transformation Training Centres and Research Hubs is available on the ARC website.

ARC arc.gov.au

Core Additive, reseller of Markforged additive manufacturing equipment in Australia, has partnered with TAFE Queensland in a two-year collaboration to build 3D printing employment opportunities.

Additive manufacturing is forecast to be worth $37 billion globally by 2025, and is the more complex and industrial-scale implementation of 3D printing manufacturing techniques, which are increasingly being used in Australia. The agreement aims to accelerate the development of training programs specific to the 3D printing, composites, and additive manufacturing industries, ensuring Queensland and Australian businesses don’t fall behind.

TAFE Queensland is the largest training provider in the state, and Business Development Manager of Emerging Industries Shawn O’Sullivan said it has the resources required to support the growing need for training in the industry.

“Our teachers are experts with deep connections to their industries and they provide training across 60 campus locations from Cairns to Coolangatta and

William Illicic, Sales Manager Lianne Kelly, and TAFE Queensland’s Emerging Industries Business Manager Shawn O’Sullivan

out to Mt Isa with industry-standard equipment and materials,” he said.

“This partnership is one of many that TAFE Queensland holds across a range of industry sectors to develop the training needed to future-proof local industries.

“With a class-leading advisor in Core Additive, we can develop training safe in the knowledge that it is what serves Queenslanders best,” he said.

Core Additive’s CEO James Staples said TAFE Queensland was an obvious choice for developing top-quality training for Queenslanders looking to work in the rapidly growing additive manufacturing industry.

“We are proud to partner with TAFE Queensland, who deliver quality training to industry members across the State. To be involved in training development as an industry representative and subject matter expert is a testament to the work we are doing at Core Additive,” he said.

The Queensland government has funded $15 million for the Vocational Education and Training (VET) Emerging Industries initiative, which sees the money invested in new skills and training strategies across identified emerging industry needs in the manufacturing, energy, agribusiness, and screen and digital sectors.

Small and medium-sized enterprises, or SMEs, are the backbone of our economy.

In Australia, 99.8 percent of all businesses are small and medium-sized businesses and they employ more than half of the national workforce.

Understanding current economic conditions and how they might be impacting local businesses is important to us all.

Australian businesses have been hit with several setbacks in recent years: bushfires, the pandemic and the ensuing lockdowns, through to supply chain issues and labour shortages.

This year brings its own challenges, with higher operating costs and lower turnover as the cost of living stays elevated, consumer spending pulls back and economic activity slows further.

However, there’s some very good news in the readiness of businesses to weather tougher conditions before they improve.

According to St.George Bank’s new quarterly Business Snapshot, businesses in aggregate remain resilient, including manufacturing businesses. The business sector is financially strong as it heads into the downturn, according to internal business data drawn from St.George Bank and the wider Group.

Many businesses have been preparing for tougher times by improving their liquidity position, including through paying down debts where possible, increasing their liquid assets, maintaining credit lines and investing in their productive capacity.

Businesses have bolstered their cash positions. Some are looking to invest and are waiting for the right opportunity. Facing economic uncertainty and the possibility of further rate hikes, other businesses have opted to shore up their cash positions and preserved capital to weather the storm.

The Group’s measure of liquidity, comparing business deposits to possible calls on funds, puts the sector comfortably above pre-pandemic levels. Indeed, business liquidity is 30% higher than before the pandemic.

Depending on the industry, input costs have increased by as much as 30% since the December quarter of 2019. The lift in input costs reflects the inflationary pressures that have been prevalent since the reopening after the pandemic.

The Reserve Bank (RBA) has responded by raising the cash rate by four percentage points since May 2022 to take the cash rate to 4.10%. It has been the most aggressive tightening cycle since before the 1990s and reflects

the challenge policymakers have had in bringing down inflation.

At its August board meeting, the RBA kept the cash rate on hold, extending its pause for the second straight month. Indeed, the RBA has held the cash rate steady in three of the past five board meetings, demonstrating that they are at

faced by businesses.

Encouragingly, during the period since December 2019 where business costs have risen, business deposits have grown by about 15%.

A strong cash position is important in navigating uncertainty. It will also help businesses take full advantage of expan-

retail and wholesale industries are particularly well-placed to enter tougher times.

Another indicator of strength is seen in the composition of financing. We have recently seen an uptick in longer-term borrowing, and working capital loans have become less important in the funding mix. This is a strong signal that businesses have been borrowing to invest, rather than to operate.

Economic data shows that business conditions have started to become more challenging.

or nearing the end of the cash-rate cycle.

However, the full impact of interest rate hikes to date is yet to be felt and will continue to contribute to a slowdown in economic activity over the period ahead. As demand slows, so will conditions

sion opportunities and asset acquisitions that are likely to arise during this economic cycle.

Some industries have fared better than others. Our analysis shows that businesses in the education, health,

The impacts of inflation and rising interest rates are curbing consumer spending. Our economists expect this to continue over the next year or so. However, our data also shows the business sector is entering this downturn from a position of strength.

“The business sector is financially strong as it heads into the downturn.”

“A strong cash position is important in navigating uncertainty.”

Economist, St.George Bank

When developing a new website, marketers must address sales needs, changing technologies and platforms, as well as the challenges presented by legacy systems in IT and ERPs. Internal technical stakeholders often prioritise fulfilling important product and technical requirements on websites. This includes meeting legal obligations by housing specifications and providing ‘how-to’ and installation content. While these aspects are crucial, it’s important to ensure that effort put into presenting technical information is rewarded by high visibility in Google Search. To achieve this, the website development process needs to shift from a product-first approach to a user/solution-led approach.

Here are five ways to ensure your business’ new website delivers better growth outcomes for the business and provides the best user experience for customers:

Ask more questions: Conduct a discovery and planning stage at the beginning of a web project, even if it’s not an entire new build. Interview key internal personnel to understand their roles and challenges. Clarify the website’s role in the marketing conversation, define the target audience, determine what visitors need to understand about the company and its product line, and identify any third-party systems that need integration. The more

investigation and research you do upfront, the better the end product will be.

Reframe technical products through a customer/marketing lens: Instead of merely creating a repository of technical documentation, package the information so it’s useful for both industry users and consumers — to generate more qualified leads.

Highlight the technical literature visibly and accessibly through the top navigation bar/tool. Craft the technical elements of the product into a story that focuses on solutions. Support claims with news and case study content at the product page level. Provide a clear call-to-action (CTA) for visitors to connect with a business manager or engineer while browsing specific product pages.

Scale: Adopt a phased approach to developing the web presence when launching phase one and gathering feedback from internal stakeholders and the market before launching the finished product. Build web properties in a modular way that allows for future scalability, including the potential integration of eCommerce, IoT dashboards, and customer portals.

Improve lead generation: Make the website a primary method for lead generation by incorporating options such as general enquiry forms, CTAs at the product or case study page level, or gated content. Tailor the required information fields

based on the business objectives you want to achieve.

For general enquiry forms, ask for more information, such as name, company, email, phone, state, and comments. For gated content, limit the required information to just an email address initially. Once you have the email data, funnel it into your CRM system for ongoing marketing and communication strategies.

Consider Google Search upfront: Considering how your website will rank in Google Search is crucial, even if search engine optimisation (SEO) can be perceived as complex.

Conduct an audit of your site using tools like Google Analytics, Google Search Console, and SEMrush to assess rankings and identify desired keywords. Focus on providing new and useful content to be more competitive in search engine results pages.

Develop a content roadmap based on research and analysis, considering content type, length, keyword usage, and optimisation techniques such as including the primary keyword in the URL, page title, subheadings, and alt text for images.

By asking the right questions, reframing technical products, scaling effectively, improving lead generation strategies, and considering Google Search from the outset, manufacturers

can ensure that their website meets the objectives of both internal stakeholders and prospective customers.

Take advantage of free trial offers and available guides for tools like SEMrush, Google Search Console, and Google Analytics to enhance your website’s performance. Alternatively, reach out to a marketing specialist, technical or setup support.

*Jake Cush provides advice around growing market share, research, insights & corrective action, go-to-market strategies and brand awareness. He has delivered strategic programs and marketing solutions for Westfield, BOC Gas, Case IH and Siniat through to mid-sized manufacturing businesses and tech start-ups.

I.M.A.

A key aspect of customs work is education and communication with traders so that honest companies can better understand requirements and voluntarily comply with customs and tax law.

Australian Border Force has Voluntary Disclosures (VDI) teams in Melbourne and Sydney to help industry voluntarily comply with customs-related law for import and export declarations.

s243U (no revenue implications) of the Customs Act 1901 in Australia.

A voluntary disclosure provides protection from penalties and prosecution if it is given voluntarily, truthfully and fully.

• The VDI team was established as a separate team within Customs Division in FY 2014/15

• To date the total revenue identified by the VDI team is $857 million

• Since inception, VDI teams have actioned 629 cases where industry has been protected from penalties

• As a result of recent engagement with industry, there has been an increase in disclosures with 113 new cases

Any business needing to move more product out the door does have options. As frequency of parcel movement increases, any level of automation can only assist.

Handling freight and moving customer orders in greater numbers has certainly accelerated in recent times, and finding quicker, smarter ways has always been key to success. Certainly the rapid growth in e-commerce has exponentially multiplied the rate at which parcels need to get out the door and at ever-faster turnaround times.

To lodge a voluntary disclosure, a written notice to the ABF should detail the nature of previous errors and the relevant declarations required. Disclosures are usually lodged by email. Common types of errors or omissions that can elicit a voluntary disclosure include:

• valuation adjustments

• transfer pricing adjustments

• incorrect tariff classification

• incorrect application of a Tariff

Concession Order

The team regularly receives and assesses voluntary disclosure submissions from importers and exporters. Businesse which make voluntary disclosures can engage professional support so the team regularly deals with representatives including consultants, legal practitioners and customs brokers. Submissions are lodged by importers and exporters who seek protections for Integrated Cargo System reporting errors under s243T (revenue implications) and

The VDI team has focused on streamlining its processes to reduce its assessment times, effectively reducing a backlog from two years to six weeks, and actively marketing the benefits of voluntary disclosures to industry. The team recently received an ABF Australia Day award for its efforts.

Engagement at a range of industry forums, including trade exhibitions, and most recently the development of an E-learning Module released in partnership with the ABF’s Australian Trusted Trader Program are available to all businesses.

You can access the Voluntary Disclosures E-learning Module at australianborderforce.birchlp.com.au

The team seeks to share knowledge and get feedback from industry to further improve the voluntary disclosure environment. The VDI team can be contacted at abf.gov.au/help-and-support/ voluntary-disclosures

Australian Border Force abf.gov.au

Often we get a request to assist in sometimes quite simple, “low-target” solutions to lift performance to get the customer through a perceived temporary situation.

However most customers are very receptive to receiving an alternative and longer term solution that will give them broader and more sustained scope for growth. By providing “the alternative solution”, Adept Conveyor Technologies shows the customer much greater potential by looking in broader terms rather than just the temporary or initial request.

“VDI teams have actioned 629 cases where industry has been protected from penalties.”

Australia is a wonderful place to launch a new tech start-up and grow it into a thriving business. We have a world-class research ecosystem producing many important breakthrough ideas and processes. Our researchers and companies collaborate closely with their overseas counterparts on new and emerging opportunities.

But they also need support to grow and prosper – advice, expertise, finance, and investment.

To that end, the Australian government is moving quickly to implement our new Industry Growth Program (IGP).

We announced this new $392 million initiative in our May budget – and in June my department released a discussion paper to help shape its design and implementation.

Consultation ended on 30 July, giving a broad cross-section of views about the program’s design.

The IGP will take an agile and industry-led approach to supporting innovative SMEs to commercialise their ideas and expand their operations.

It will offer grant funding for some eligible projects as well as access to industry-led specialist advisory services from industry partner organisations.

It is anticipated the IGP will include the following design features:

• Industry Growth Program advisers

• Access to industry-led specialist advisory services from industry partner

organisations, and

• Grant funding for some projects.

The IGP also will align with other Australian government initiatives like the $15 billion National Reconstruction Fund.

Support will be focussed on projects in the NRF’s seven priority areas – value-add in resources; value-add in agriculture, forestry and fisheries; transport; medical science; renewables and low emission technologies; defence capability; and enabling capabilities.

Many Aussie tech start-ups have gone on to do important things, emerging as household names internationally.

Many others in sectors like medical science, quantum computing, robotics, and software – where we punch above our weight in terms of R&D – are on the verge of taking off.

But even the most promising of startups and SMEs can experience problems as they work to commercialise their ideas, grow, or scale up their operations.

The most common of these is when substantial efforts on a new enterprise have begun but self-sustaining revenues have yet to be generated.

That in turn can quickly lead to capital depletion.

Navigating this so-called valley of death can be testing, particularly given that angel and venture capital firms may be potentially unwilling to put more money into a business they consider

unproven.

Rebuilding Australia’s industrial and manufacturing capability will be contingent on the future success of our start-ups and SMEs.

It is vital therefore, that they have options available for navigating commercialisation and growth challenges.

Around the world, evaluation studies have shown that expert advice combined with matched grants enables earlystage companies to increase revenue, grow their workforce, and attract new investment.

Boosting commercialisation and entrepreneurship also increases

innovation, economic complexity, and productivity.

These are prerequisites to building sovereign capability and creating worthwhile jobs and career paths.

Encouragingly, the start-up ecosystem in Australia is now one of the fastest-growing globally, with the start-up rate being one of the highest in the world (Statista). By backing Australian ideas, enabling entrepreneurs to build their capability – and complementing other university, industry, and government initiatives – the IGP will help to nurture innovative companies to become the big employers of the future.

Aproject to develop new autonomous spacecraft using artificial intelligence (AI) has been launched by Australia’s leading space research centre, the SmartSat Cooperative Research Centre.

The three-year $7 million Spacecraft Autonomy and Onboard AI for Next Generation Space Systems, known as SCARLET-α, is a collaborative research effort with eight SmartSat partners: Airbus, Asension, Deakin University, Defence Science and Technology Group, Leonardo Australia, Saab Australia, Swinburne University of Technology, and University of South Australia (UniSA).

Spacecraft autonomy will be a key feature of the next generation of space

systems, said SmartSat CRC Chair of Artificial Intelligence, UniSA STEM Professor Ryszard Kowalczyk, who is leading the project.

“Spacecraft that can operate independently of ground contact will be able to respond to unexpected events in real time without needing to wait for commands from earth. This autonomy will improve Australia’s remote sensing capabilities and other vital services undertaken in space, allowing us to push the boundaries even further in orbit.”

“It will help increase the responsiveness and continuity of space-based observations, minimise communication and data access delays, and reduce the costs for both space and ground operations.”

Autonomy and AI SCARLET- α aims to create a set of autonomous algorithms that will enable small and distributed spacecraft to make decisions independently, optimise the use of available resources and capabilities, adapt to changing conditions, and handle critical situations, without intervention from earth.

The project will focus on high impact areas of spacecraft autonomy and onboard AI as identified and prioritised with industry and defence partners, including:

• Onboard processing and actionable intelligence

• Small spacecraft and constellation resilience

• Dynamic optimisation of constellation resources

• Real-time tasking and resource allocation

SmartSat CEO Professor Andy Koronios, said that, to date, onboard processing has been limited to data collection, but researchers hope the algorithms they develop will allow spacecraft to perform many tasks with less intervention from human operators.

“As autonomous technologies advance and are embraced, their place in space will expand and present new opportunities for applications here on earth. The next generation of satellite communications and earth observation will be achieved using integrated

and Wellness Australia and AgriFutures Australia, found the superior qualities in propolis scraped from honeybee hives across the country.

Beekeeper Murray Arkadieff, whose hives near Ipswich produced some of the most active propolis samples found in Queensland, said the positive findings provided opportunities for a new revenue stream for Australian beekeepers and more industry jobs.

“This will help to further reinforce the exceptionally high quality of Australian honey and our hive products both in Australia, and internationally,” said Mr Arkadieff.

The researchers’ paper in Nature Scientific Reports assessed the quality and chemical diversity of Australian propolis from Apis mellifera or European honeybees, common across the country.

systems of satellite constellations operating autonomously and performing multiple tasks in real time.

“Such AI-enabled technologies promise to transform the major sectors of our economy, such as agriculture, farming, and mining, and better serve our defence and national security objectives.”

“This investment is possible through the great support of the federal government CRC program and will help develop cutting-edge technologies in space autonomy.”

Professor Koronios said with next-generation space systems on the horizon, the possibilities for science, discovery and innovation are endless.

“SmartSat is well placed to progress Australia’s spacecraft autonomy capabilities to help our nation remain innovative and at the forefront of technology.”

SCARLET-α is the flagship of a suite of projects SmartSat will deliver under its SCARLET lab, a SmartSat initiative to develop innovative technologies across spacecraft autonomy, on-board Artificial Intelligence (AI) and data analytics. The lab provides a collaborative platform to bring together researchers and industry to advance autonomy and produce tangible outcomes for defence and civil pursuits, enabling Australia’s next space missions.

The UniSC team recently published three papers on propolis. Dr Tran said the next step would be tracing the plant sources of the samples, to inform plant biodiversity measures and hive locations.

“This study indicates Australia has the capability to produce unique and premium propolis types because of its unique and diverse native flora,” he said.

The paper was authored by UniSC’s Dr Tran and Dr Brooks with Chau Tran, Tahmikha Bryen and Dr Simon Williams, and Hive and Wellness Australia’s Jessica Berry, Fiona Tavian and Ben McKee.

It followed an AgriFutures Australia report in 2019 that recommended further research to help Australia grow its propolis production and market. It reported that the farm-gate value of propolis production to New Zealand beekeepers was averaging $NZ3.75 million a year.

Honeybees across Australia could generate a new homegrown health industry if researchers from the University of the Sunshine Coast are right about premium ‘bee-glue’ used in hive construction.

For the first time researchers have identified 16 types of high-grade Australian propolis as brimming with antioxidants and other chemical properties they believe could spark a new national industry for food and health products.

Sticky propolis is a mixture of beeswax, bee saliva and resin from the native and non-native plants that bees pollinate and, while the Australian honey industry has usually discarded it, Brazil, China and New Zealand harvest it for use in multi-million-dollar food, cosmetic and pharmaceutical industries.

The researchers, Dr Trong Tran and Dr Peter Brook, previously collaborated on national research that discovered exceptional antibacterial activity in Australian manuka honey. They believe their new findings have confirmed the chemical makeup of 16 propolis samples offered more potent antioxidant activity than some well-known international types generating big profits overseas.

“Established ‘cosmeceutical’ industries add propolis to products intended to have both cosmetic and therapeutic benefits, such as mouth sprays, soap, toothpaste, dietary supplements and skincare creams,” he said.

“In the food and beverage industry, propolis can be a preservative.”

Dr Tran said the latest two-year collaborative project, funded by Hive

Dr Tran said propolis had been used in many cultures for centuries as a natural antibiotic but research since the 1990s had increasingly found much more than antimicrobial potential, including the possibility of adjunct treatments for cancers and COVID-19.

Researchers and co-authors from Hive and Wellness Australia, owner of the Capilano honey brand, said the findings were encouraging for the Australian beekeeping industry, which has 530,000 honeybee hives.

“At the moment, we only have smallscale propolis production, mainly in South Australia,” said Dr Ben McKee, Chief Operating Officer at Hive and Wellness.

“More domestic harvesting would provide extra income for beekeepers and processors while reducing the reliance on imported propolis in manufacturing.

“This research could be a solid foundation to build a new industry across the country.”

AgriFutures Honey Bee & Pollination Program Research Manager Annelies McGaw said the findings could strengthen the industry.

“The annual contribution of the honey bee to our economy is $14.2 billion, however over recent years this industry has been severely impacted by bushfires, floods and pest incursions like Varroa mite,” Ms McGaw said.

“Although there is still more work to do to better understand the benefits of propolis, the potential commercialisation could provide a very welcome and timely income stream for Australian beekeepers.”

Australian Propolis Project

‘Bee glue’: a new industry beyond honey

By Greg O’Loan,

By Greg O’Loan,

RVP ANZ and Pacific Islands, Epicor

From pandemic to inflation, supply chain disruption to labour market shortages, the past two years have proved challenging for Australian businesses.

And yet the manufacturing sector has remained resilient.

With no sign of these challenges easing, the sector will remain tested as it continues to navigate an uncertain future.

The disruptions of the recent past – and more to come – have highlighted the need for manufacturers to streamline processes.

Here are three technology trends I believe will help manufacturers grow and overcome industry challenges:

The adoption of cloud technology by manufacturers is accelerating. Our most recent Industry Insights Report revealed 90 per cent of manufacturers plan on moving to the cloud. Despite this, there are manufacturers still reliant on outdated and unstable technology, restricting growth, innovation, and competitiveness.

Cloud solutions enable companies to integrate every aspect of their process seamlessly. Having data available on a

unified platform provides visibility over the whole production journey. This integration and ability to monitor processes in real-time not only enhances operations, but provides insights to streamline production, cut costs, and enable data-driven decisions.

Migrating to the cloud is already reaping rewards for manufacturers who have made the change. However, as our turbulent economy continues to create uncertainty, laggard businesses must consider investing in the right cloud solutions to help them consolidate and connect –otherwise, they risk being left behind.

Data is core to manufacturing and has become central to digitisation strategies and can be used to identify changes in customer behaviour, supply chain issues, and production or labour trends.

However, a recent survey by the World Economic Forum revealed insufficient skills are the biggest challenge to capturing value from manufacturing data. With this in mind, we expect an increase in hiring and valuing digital natives who

understand analytics and can adopt a data-driven approach.

We also expect an increase in reliance on digital work instructions and intelligent integrations. For example, Epicor Connected Process Control, formerly known as eFlex Systems, a provider of cloud-based Manufacturing Execution System (MES) technologies recently acquired by Epicor, helps manufacturers to increase productivity by modernising their production environments through digital work instructions, advanced

process control, and real-time visibility. Although the global economic outlook remains uncertain, the manufacturing industry recognises digital innovation is key to becoming more competitive, increasing growth, and improving profitability. We believe those who prioritise these technology trends will increase their chances of success for the remainder of 2023 and beyond.

It flies well under the radar, but the Clontarf Foundation is a standout example of how to actually improve the lives of Indigenous and Torres Strait Islander people – in this case, young boys and men.

By setting the boys up to attend school, receive an education, and then go into employment, Clontarf has seen more than 6300 boys across Australia finish year 12 since it began in 2000.

One of the main carrots at the end of the stick is footy: Aussie Rules and Rugby League. If you want to play footy, you have to turn up to school. And playing footy means two early morning training sessions a week, so you need to set your alarm, and get motivated to turn up.

Attendance, discipline, respect, and education – all within a welcoming environment of dedicated staff who support the boys from grade 7 right through to helping them get a job, and then on throughout their lives.

Started by former primary school teacher and ex-Fremantle Dockers coach Gerard Neesham at Clontarf Aboriginal College in Waterford, WA, there are now almost 150 Clontarf Academies around Australia, with 11,000 boys in the program and 580 staff.

The academies are onsite at schools, with a specific room for the boys and the Clontarf staff to use. But they’re more than that – from Monday to Friday the academies are a haven and even a family, when there may not be stability at home.

“Clontarf is helping to close the gap,” Neesham told a lunch for prospective corporate partners in Sydney in July, hosted by Blackwoods and Bullivants.

Neesham wants to see Clontarf academies increase in number so that more boys can have the same opportunities, and the foundation is looking for more businesses to come on board.

There’s more than just a good feeling to be gained from partnering with Clontarf. There’s also the opportunity to hire a young employee who understands what a work ethic is.

Clontarf sees its role as getting the boys ‘work ready’ with values that’ll keep them in employment for the rest of their lives.

Christopher Bron is Clontarf’s Sydney region Employment Officer, one of 30 around the country who focus on postyear 12 care.

Last year he looked after 50 boys. He does graduation plans, lines up jobs with companies, organises apprenticeships, helps them get their drivers’ licence, tax file numbers, resumes and practices work interviews with them.

while they’re at school, when they might work for organisations like Blackwoods, Kmart, Bunnings or Target – all Clontarf corporate partners.

In their school academy rooms, the boys’ work ethic is celebrated on a “working wall”, which shows photos of the boys at work.

“It gives them something to look up to,” says Bron.

The boys’ families are proud of them, he says. Often they aren’t that involved with the schools, but they are involved with Clontarf, and it’s not unusual that the boys are the first in their families to graduate from year 12.

If you don’t turn up, you can’t get paid Clontarf videos show the success stories of their ‘work ready’ approach.

Two young men talked of their time as Clontarf boys before joining Woodside Energy.

It costs $7000 to put a student through the Clontarf program. Federal and state/ territory governments pick up $5000 of that, and the other $2000 is funded by corporate partners.

“These young fellas haven’t chosen to be in this space. It shouldn’t be a lottery for the boys to get a Clontarf Academy at their school,” said Neesham.

“NSW currently has 3600 boys in Clontarf Academies. We want to scale that up to 7000 over the next five years.

“NSW has the largest Indigenous population in Australia. Imagine the difference it’d make if we could get between 1000 to 1500 boys per year into the workforce.”

“The job doesn’t stop,” says Bron of the amount of time he happily puts in to help the boys cross that gap between finishing school and finding a job.

But getting the boys ‘work ready’ starts

Sheldon, who works as a process plant operator north-west of Karratha WA, spoke of the leadership he takes within the company and how the Clontarf focus on attendance has helped him: “you can’t get paid if you don’t turn up”.

Despite once struggling to go to school every day, Sheldon said he graduated with some As and Bs because of the structure and ambition of his Clontarf cohort of boys.

Without Clontarf, said Sheldon, “I think I would have followed a pathway which would have led me to being locked up in jail.

“Clontarf helped me separate from a negative circle – where the bad guys were the majority, they became the minority,

Clontarf founder Gerard Neesham at at the Clontarf WA Central Region Year 12 Leadership Camp breakfast in Perth, 2023“Imagine the difference it’d make if we could get between 1000 to 1500 boys per year into the workforce.”

“It shouldn’t be a lottery for the boys to get a Clontarf Academy at their school.”

because I was surrounded by a bunch of good guys.”

Another young man who spoke at the Sydney lunch talked about how he’d fallen in with the wrong crowd at an elite Melbourne private school while on a footy scholarship, had to leave, and ended up back in country Victoria at a Clontarf Academy school with a sceptical headmaster.

Having the Clontarf discipline around him put him back on the right track, and he eventually topped the regional school and got into law at ANU. He is now working for one of the country’s top law firms.

For many of the boys, blue collar jobs are their preferred option.

There are five Clontarf academies in the Mt Druitt, Sydney area alone, and Western Sydney has big opportunities for jobs, says Bron.

Talented NRL player Samson Bennett graduated from year 12 at Chifley College’s Bidwill Clontarf Academy in 2022, and was a trainee at Blackwoods while at school.

A juniors player with Wests Tigers, he’s also working three days a week as a surveyor with construction company BMD Group at Western Sydney Airport, having done the requisite TAFE certificates.

The company, a Clontarf partner, is happy to give him a shorter working week at the moment because he and his older sister still look after their younger siblings, picking them up from school and running the household.

At one point, when he was 15, his mother had to leave the family for a few years, and he says he didn’t think he’d actually be able to finish school or keep playing footy.

But Clontarf stepped in, filling in the gaps where the system couldn’t or

wouldn’t. Staff helped Samson and his sister out with groceries and furniture, and dropped the younger ones to school when they couldn’t.

experience, he says.

That ongoing connection is why Bron says “once they’re Clontarf boys, they’re always Clontarf boys”.

And if the respectful, well-spoken young Clontarf men sitting at the tables at the Sydney lunch are anything to go by, Australian businesses could do worse than partner with Clontarf, engage in their program and local academies, and hire their school based trainees and graduates, helping close the gap even further.

With Clontarf’s help, Samson made it through.

At the end of year 12, Clontarf boys get to choose to go on a trip to anywhere in Australia. Samson’s group chose Cairns. It was “one of the best things in my life,” he says.

Recently, Clontarf organised a trip to watch the State of Origin game for a group of young Clontarf men, and Samson also went to that. Another “amazing”

To learn more about the work of The Clontarf Foundation, to visit their Academies and meet the boys and become a Clontarf corporate partner, visit the URL or scan the QR below.

Clontarfclontarf.org.au/

partnerships“..getting the boys ‘work ready’ starts while they’re at school..”

“Once they’re Clontarf boys, they’re always Clontarf boys.”

In the fast-paced world of manufacturing, an alarming trend has emerged: skilled labour shortages are persisting and posing significant challenges for companies across the country.

As the demand for qualified talent continues to outpace the available supply, it’s become imperative to explore the underlying causes behind this pressing issue. Why are we facing this shortage, and what measures can we take to address it effectively?

At the forefront of trying to address the skill shortages, Fuse Recruitment has identified challenges they are observing.

Melissa Kennedy, National Manager of Manufacturing at Fuse Recruitment, paints a holistic picture of the issue:

workforce, and global competition worsen the skill gap. To counter this, early exposure programs, educational reforms and industry partnerships are vital to equip the next generation for manufacturing.”

Leah Creswick, a manufacturing sector specialist at Fuse Recruitment, also offers her insights into the market’s flux:

“Initially dominated by a candidate-driven narrative, the market evolved with employers regaining a measure of control. This shift may be attributed to job-seekers’ challenges in adapting to the changing market conditions. As well, the surge in remote work presents hurdles for recruitment endeavours that require a physical presence.”

But it’s not only the recruitment industry that is feeling the burn. Australian manufacturing professionals within all sectors are seeing skill shortages ravaging their businesses.

Daniel Thompson, Chief Manufacturing Operator at Seer Medical, points out the enduring impact of the decline in automotive manufacturing on the talent pool:

long-term prospects/opportunities which may not pay as strongly right now.

“A lot of people I see coming out of their apprenticeships seem to be seeking mining or FIFO work chasing the higher salaries, leaving a shortage for everyone else. There are also changes in the apprenticeships themselves, so the skill sets coming out now are slightly different to the skill sets being asked for by employers”.

up the local manufacturing ecosystem by investing in educational reforms and aligning curricula with industry needs, ensures that graduates possess the skills demanded by the evolving sector.

Skill development and training: Skills development needs to be targeted. Collaborating with industry experts, comprehensive training modules can be designed to align with technological advancements. This approach not only addresses the dearth of skills but also equips professionals with the expertise needed to overcome the challenges of scaling up operations.

“Viewed through a recruitment specialist’s lens, the shortage of skilled trades in manufacturing is a result of intertwined factors. It starts with insufficient awareness among school leavers about the diverse career paths in the industry – the perception of manufacturing as unglamorous, limited career guidance, and trade stigma dissuade young talent.

“Rapid technology shifts, an ageing

“I have found it very difficult to get people with genuine skills. The dissipation of automotive manufacturing has greatly reduced the infrastructure of skilled manufacturing people coming through the pipeline. The off-set to this is that it holds back progress. This has impacted our ability to scale-up quickly, and hence delayed our growth trajectory and sustainability.”

Caleb Chiverton, Production Manager at Champion X, has also been affected:

“It seems that a lot of employers are ramping up their production and bouncing back from Covid – but there are more roles than people looking. Coupled with this, some employers are paying a premium for short-term staff, taking them away from

Nurture early exposure: Early exposure initiatives, such as internships and hands-on projects, provide students with real-world experiences that can shape their career choices. By weaving these experiences into their educational journey, they’ll be helped to make informed decisions about pursuing manufacturing careers.

Cultivate awareness and education: The slowing pace of trade apprenticeships and shifting skill sets underscore the need for early intervention. Collaborative partnerships with educational institutions directly address these concerns. By offering workshops, seminars and career fairs, students can see the diverse and rewarding pathways in manufacturing.

Seed long-term growth: Building

Revive apprenticeship programs: Collaborating with industry associations and government bodies to revitalise apprenticeship programs can create a sustainable pipeline of skilled professionals. Incentives like financial aid and mentorship, embedded within this strategy, address the challenges employers have in acquiring genuine skills and propelling growth.

Harmonise industry initiatives: More collaboration between industry players and governmental bodies, such as industry consortiums and alliances, provides a platform for sharing best practices, developing curricula, and collectively advocating for the sector’s growth.

Embrace flexible work: As remote work gains momentum, offering flexible work arrangements can mitigate the appeal of short-term opportunities and lure skilled professionals seeking a balance between work and life.

Enrich through diversity: By fostering an inclusive environment that welcomes voices from diverse backgrounds, preconceived notions are challenged and manufacturing horizons broadened.

The shortage of skilled labour in manufacturing is a multifaceted challenge, demanding united action from stakeholders. By dispelling misperceptions, fostering early exposure, and investing in education, the chasm between the workforce and skilled professionals can be bridged.

If you’re seeking assistance in confronting skill shortages head-on, the manufacturing specialists at Fuse Recruitment are ready to lend a hand. With decades of experience spanning sectors including industrial, packaging, FMCG, pharmaceuticals, medical devices, and chemicals, the Fuse team possesses the expertise to craft a workforce strategy that draws premier talent to your business.

FUSE Recruitment fuserecruitment.com

“Early exposure programs, educational reforms and industry partnerships are vital to equip the next generation for manufacturing.”

“Some employers are paying a premium for short-term staff, taking them away from longterm prospects/ opportunities..”

“Offering flexible work arrangements can mitigate the appeal of shortterm opportunities..”

Addressing skilled labour shortages in the manufacturing industry: insights and solutions

by Fuse Recruitment

The federal government has launched a $60 million fund to encourage businesses to recycle plastics that are difficult to recycle, particularly soft plastics such as shopping bags, bread bags, cling wrap and chip packets.

Businesses can apply for grants from $1 million to $20 million from the Recycling

Modernisation Fund Plastics Technology Stream (RMF) to support new or upgraded recycling infrastructure such as:

• advanced recycling to turn plastic back into oil for re-use in food-grade packaging

• commercialisation of trial technology targeting ways to keep using

hard-to-recycle plastics

• extraction and processing of plastics from e-waste into valuable products

• diverting more plastics from landfill by using advanced sorting, separation and decontamination technology such as optical or robotic machinery

Welcomed by the Australian Food and

Grocery Council, the new fund is part of the government’s push to a circular economy by 2030. Its projects will accelerate the shift away from virgin plastics towards a circular economy where materials are kept in use for as long as possible.

The Minister for Environment and Water, Tanya Plibersek, said Australia’s recycling record was not good enough.

“Australians use about 3.8 million tonnes of plastic a year and dispose of about 2.7 million tonnes. And we’re only recycling about 13% of it.

“We can do better. That’s why we’re investing $60 million to boost Australia’s recycling and recovery rates for hard-to-recycle plastics.”

Combined with contributions from state and territory governments as well as industry, the funding will add to the more than $600 million combined investment in recycling infrastructure the Albanese government has made so far. The government has already funded 57 additional plastic recycling facilities, 12 of which are running.

Applications for grants from the Recycling Modernisation Fund (RMF) Plastics Technology stream are open from 18 July 2023 to 13 November 2023.

Having just celebrated its hundredth anniversary this year, it’s no wonder that the products of German firm Tente-Rollen GmbH can be found among countless everyday items, such as shopping carts, furniture, hospital beds and industrial mobile applications.

Founded by Adolf Schulte in 1923, Tente’s first products were cast castors for industry and castors for pianos, made in Wermelskirchen, Germany, before the company moved to Tente in the mid-1950s.

The company’s first export markets were Belgium, France and Switzerland. Internationalisation continued after Dr. Dietrich Fricke took over management of the company from the late 1950s and founded its first subsidiary in South Africa in 1971.

Production and sales companies were added, including a subsidiary in Kentucky, USA, in 1979 and competitor Hufa Rollen in 1983 when the Fricke family acquired the company shares from the founder’s descendants.

In 1998 their son Peter Fricke joined the management and, with Peter Helmert, guided the family-run company to evolve into a highly automated production group and global brand.

With consolidated sales of more than

260 million Euros in 2022, Tente is one of the world’s three largest manufacturers of castors and wheels. With nine production sites, 30 subsidiaries and 1,600 employees, the company is represented by its own companies on five continents. It serves more than 50,000 business customers in more than a hundred countries.

Tente is one of the largest employers in the region and maintains good relations with schools, universities and other companies in the Bergisches Land region of Germany. Training and continuing education are a priority at Tente. With an average tenure of 14 years, welltrained professionals work throughout the company.

Tente supports local institutions through the Tente Foundation. For example, it regularly provides financial support to schools, the Wermelskirchen hospital, relief funds and other local social institutions. A high level of social commitment is also evident among Tente employees outside of the foundation.

Tente tente.com.au

In the “golden” 1920s, there was one piece of furniture that every middle-class household simply had to possess: a piano. TENTE expanded its castor product portfolio, and tea trolley castors were now joined by piano castors, which quickly became popular in foreign markets as well.

1940s

1930s

After WWll, materials were limited, and progress in developing the latest technologies came to a standstill. Nevertheless, TENTE succeeded in re-establishing itself on the market with hospital bed castors.

1960s

After the Great Depression and mass unemployment, the economy started to recover. The industry rebuilt and TENTE produced in larger quantities, even if a lot was still assembled by hand. The big seller at the time: our first heavy-duty castors

1950s

The 1950s was the decade of the economic miracle. The shortage of materials was overcome, and the consumption behaviour of the population increased drastically. The new economic development required new mobility solutions. Countless transport vehicles were equipped with the robust 348 series industrial castor TENTE-ROLLEN and TENTE France started producing castors for toy manufacturers - for rocking horses, for example.

In the 1960s, the concept of selfservice discounters spilled over from the USA to Europe, and within a very short time, self-service shops emerged. TENTE quickly recognised the potential for this development and entered the market with shopping trolleys.

1954: TENTE presented a range of products at national and international trade fairs under the firm’s logo of a Roman chariot.

1954: TENTE presented a range of products at national and international trade fairs under the firm’s logo of a Roman chariot.

anywhere else in Australia – citing the Anechoic Chamber, where as an example, air conditioner manufacturers come to do sound and vibration testing.

To work with SMEs, UTS offers a range of collaborative student programs.

continued from front page

of students working on a components database for future costing templates for Applied Robotics.

Ming was then hired by the robotics company, and he’s now back at UTS Tech Lab managing AR’s Optik cobot programming project.

... for them to get access to knowledge, expertise, talent, grants and our facilities.”

The indefatigable Dockerty describes herself as a “high-level concierge service”, visiting SMEs and their factories to find out what they need and who she can connect them with.

“I really try to dig into what their challenges are, and then I’ll think about how we can best help them… and that might be a project that I think will be great for a student group. Or, have you thought about an intern? Or, let’s organise a meeting between you and an academic expert – because I’m not an expert in manufacturing and warehouse automation, but we do have people in the Centre for Advanced Manufacturing, for example, who are the experts.

“It might just be a 30-minute chat, but it gives them a piece of knowledge that helps them make the next step in their decision.”

Dockerty says she aims to make the engagement with the companies a lengthy one, where she can come up with collaborative action plans, both short and long term.

“A lot of these businesses are so busy they don’t know what’s out there. So, it’s very much about awareness and keeping in touch with them to let them know about opportunities as they emerge.”

But UTS, she says, is just one university, so it can’t do it all – which is why they also have an ecosystem of 36 external partners, including other universities such as Newcastle, Wollongong, Western Sydney, ANU, TAFENSW, industry groups, state and federal departments and local councils, which might for example have the energy cost-reduction answers companies are looking for.

Without the academic onus of a sandstone university, UTS is regarded as the most industry-engaged university in Greater Sydney, says Szabo.

Young Henrys, Space Machine Company, Chaos1 (SMEs), along with large organisations like Nokia, Boral,

Sydney Water, NSW Transport, are among others who have leveraged UTS facilities and student talent.

“The universities who have focused on SMEs or have tried to work with SMEs, have typically done it through the lens of a research project.

“What these factory visits and consultations have uncovered is that it’s not just about research or innovation conversa-

They include the popular Optik Consultancy that gives undergraduates real-work learning opportunities. SMEs propose projects that need the help of skilled talent, and UTS provides four to six students at no cost, mainly from the university’s faculty of Engineering and IT, but also its biomedical and business disciplines.

The program has two intakes a year and projects run for 12 weeks, guided by academics and/or engineers. Apart from exam commitments, students work full time on them.

There are 13 Optik projects at UTS Tech Lab right now, and when Industry Update visited, small student groups were spread around the facility. One was working on a company’s biomedical device; another on programming a cobot to play blackjack at trade shows.

Isaac Roach, former Solutions Development Manager and now Head of Operations at Applied Robotics, was himself a UTS student.