SUMMARY VOLUME 5 2024

GLASS BRICKS

SOLAR PANELS MADE OF (MORE) SUSTAINABLE MATERIALS

LIGHTWEIGHT 3D-PRINTED ALUMINIUM PRESSURE VESSEL

ADVANCED MEASURING AND MODELLING OF THIN-FILM CORROSION

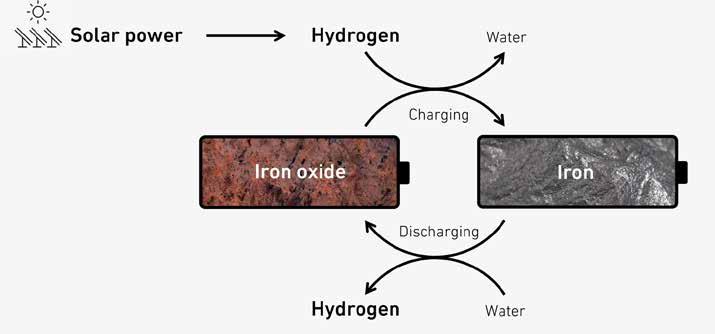

IRON AS A CHEAP STORAGE MEDIUM FOR HYDROGEN

GLASS BRICKS

SOLAR PANELS MADE OF (MORE) SUSTAINABLE MATERIALS

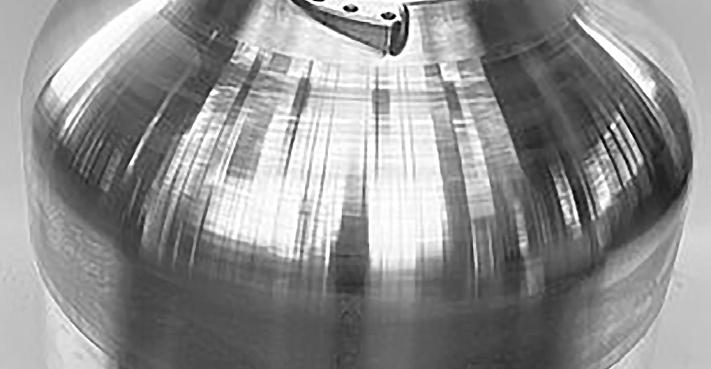

LIGHTWEIGHT 3D-PRINTED ALUMINIUM PRESSURE VESSEL

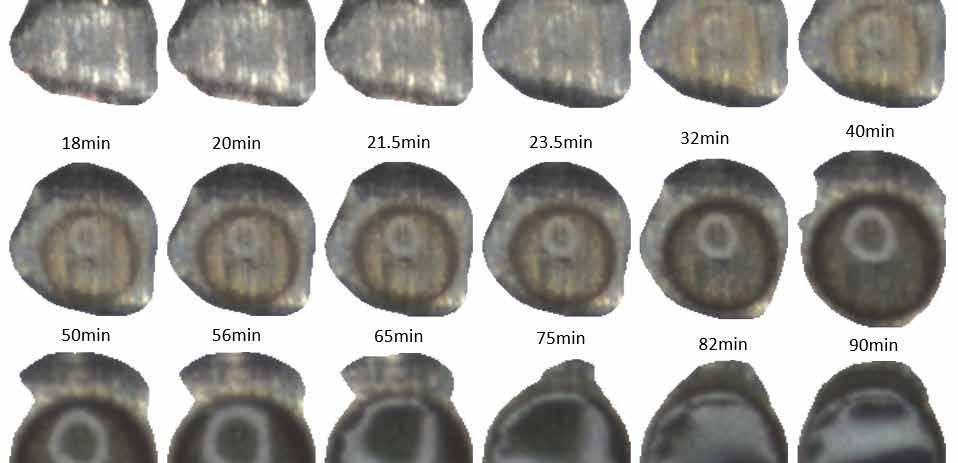

ADVANCED MEASURING AND MODELLING OF THIN-FILM CORROSION

IRON AS A CHEAP STORAGE MEDIUM FOR HYDROGEN

This is a summary of the most recent edition of Innovative Materials. Would you like to read the entire articles? You will find more information about subscriptions HERE.

Innovative Materials is an interactive, digital magazine about new and/or innovative applied materials in civil engineering sector, construction, architecture and design.

Researchers at ETH Zurich have developed a fast, cementless, robotic printing process for earth materials: impact printing. It’s a project by Gramazio Kohler Research at ETH Zurich and represents a new robotic construction method for building large- scale, free-form structures using modified earth materials.

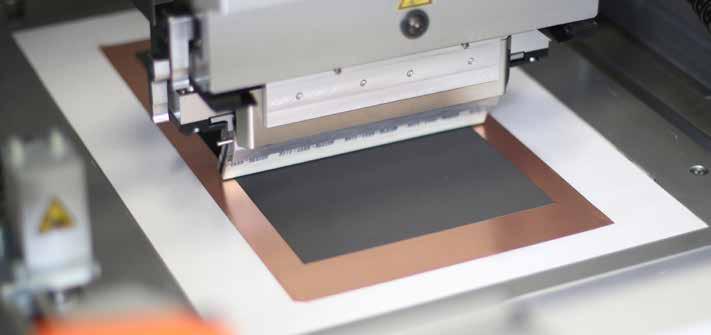

Fraunhofer IFAM now claims to have developed a sustainable alternative for the future of batteries: the ‘printed’ battery, produced using a screen printing process.

A research team led by James Tour of Rice University has developed a method to recycle valuable metals from electronic waste more efficiently than similar existing methods. It also has a much smaller environmental impact.

As the architectural industry increasingly shifts its focus toward sustainability and circular design, Pretty Plastic and FRONT (formerly StoneCycling) have teamed up. Pretty Plastic is the creator of Pretty Plastic Panels, used for facade and roof cladding, which are made entirely from 100 % recycled PVC waste.

German scientists have developed an innovative, eco-friendly method for soda production, based on a process called bipolar electrodialysis of brine. This new technology was created as part of the ‘Green Soda’ project, led by the Fraunhofer Institute for Ceramic Technologies and Systems (IKTS).

Car that can reuse four times more material

Phoenix is the newest and highly sustainable electric car developed by students at TU Eindhoven. Through smart assembly and the use of mono-material structures (structures made from a single type of material), the vehicle can be reused for up to 75 percent in the next generation of cars. In contrast, existing cars in Europe have a much lower so-called closed-loop recycling rate of only 21 percent.

Which is ecologically better: concrete or plastic pipes?

On behalf of the FBS (Bundesfachverband Betonkanalsysteme/ Federal Association of Concrete Sewer Systems), Fraunhofer UMSICHT prepared a life cycle assessment of the environmental impact of wastewater pipes made of (steel) concrete.

Scientists at the Deutsche Institute für Textil- und Faserforschung (DITF) now say they have developed a robust yet flexible glove coating made from environmentally friendly lignin and manufactured using a 3D printing process.

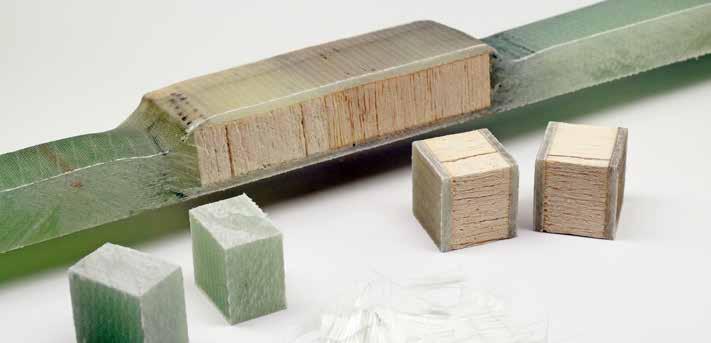

Researchers at Fraunhofer WKI are developing innovative material recycling processes to make wind turbines easier to recycle and construct from renewable materials. Their work focuses on designing wind turbines that are recyclable from the outset, including new methods for recovering balsa wood and foam plastic from rotor blades.

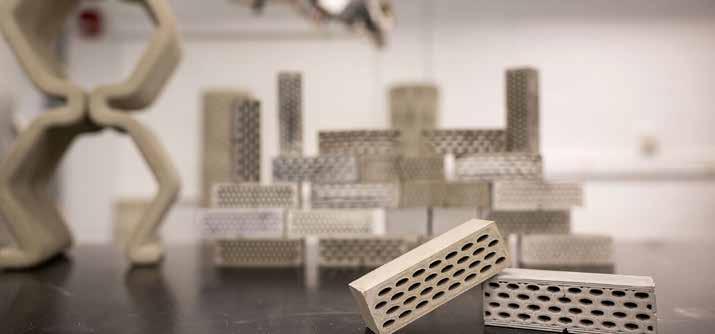

Now, scientists at the Massachusetts Institute of Technology (MIT) have developed a new type of reconfigurable brickwork made from 3D-printed recycled glass. They are strong, layered glass bricks, each shaped like a figure eight, and designed to interlock like LEGO bricks. They believe that 3D printable glass brickwork could be reused many times over as recyclable bricks for facades and interior walls.

Thermoelectric devices, or thermoelectric generators, are based on energy-harvesting materials that convert heat into electricity. This process relies on a temperature difference (gradient), with one side of the device being hot and the other side cold. Researchers from Kyushu University have now developed a new organic thermoelectric system capable of harvesting energy at ambient temperature.

Scientists from Finland have developed a binder based on biochar, that could replace carbon-intensive cement, potentially reducing emissions in the construction sector while turning infrastructure into carbon sinks.

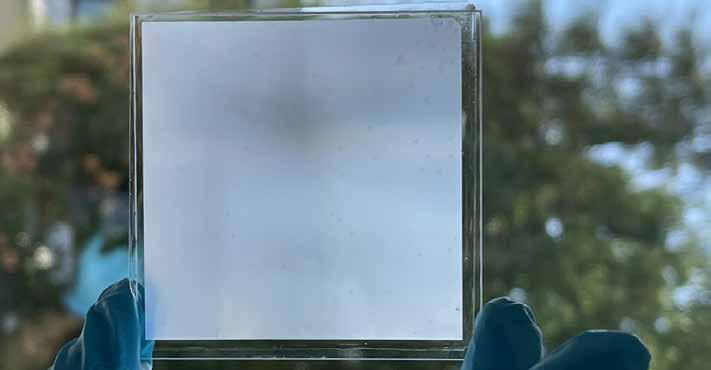

Researchers at the Karlsruhe Institute of Technology (KIT) have developed a new polymer-based mate-rial with interesting properties. The material allows sunlight to pass through, ensures a more comfortable indoor climate without additional energy, and has self-cleaning properties. The researchers believe that their new material is attractive for use in glass components in walls and roofs.

Rechargeable lithium-ion batteries are becoming increasingly popular, powering devices such as smartphones, laptops, electric vehicles, and energy storage systems. However, the supply of nickel and cobalt used in the cathodes of these batteries is limited. New research led by the Department of Energy’s Lawrence Berkeley National Laboratory (Berkeley Lab) suggests that manganese could play a key role.

Researchers at the University of Tokyo have developed concrete blocks made from waste concrete and atmospheric CO2 Their studies demonstrate that these blocks are strong enough for residential construction.

Researchers from Australia’s RMIT University (Royal Melbourne Institute of Technology) have designed an innovative tubular construction system that can be flat-packed for easier transport and ‘popped up’ into strong building materials.

Inspired by the structure of the hard outer layer of human bone, scientists at Princeton have developed a cement-based material that is 5.6 times more damage-resistant than standard concrete. The bio-inspired design makes the material resistant to cracking and sudden failure.

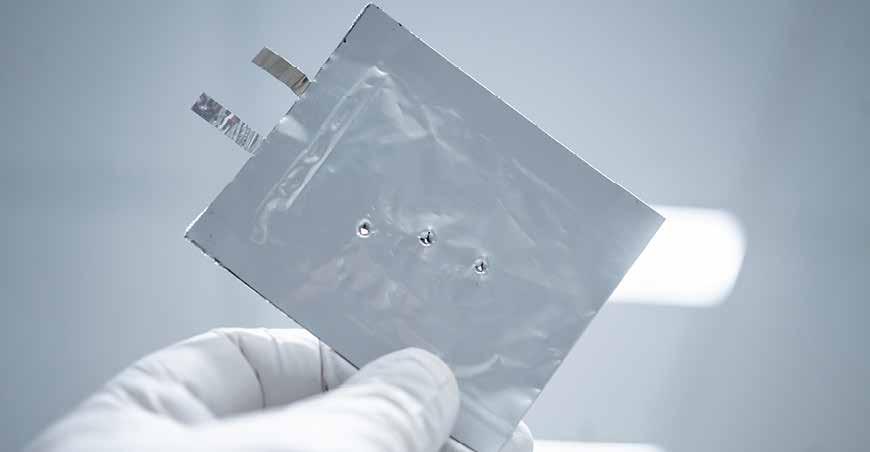

New process for high-performance lithium-metal battery

The Horizon 2020 SOLiDIFY consortium, composed of 14 European partners, has developed a high-performance lithiummetal solid-state battery. The prototype battery, produced in a state-of-the-art battery lab at EnergyVille, Belgium, was co-developed by imec, Empa, and SOLVIONIC.

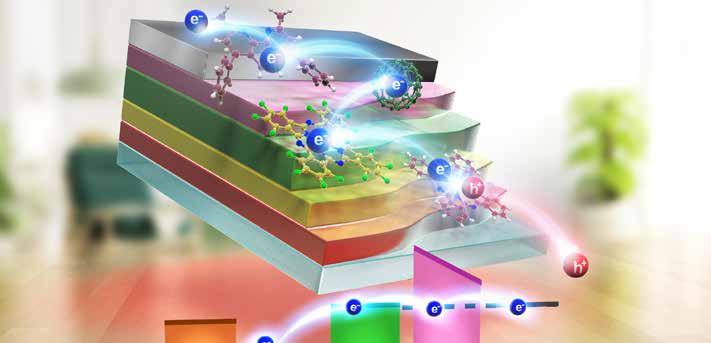

Recently, the ‘E2 - E-Quadrat - Renewable energies from renewable raw materials’ was concluded in Germany. With this project, the Fraunhofer Center for Silicon Photovoltaics CSP (and partners) developed a solar module in which the components that are not directly needed for the conversion of light into electricity are made of biodegradable, recyclable materials or renewable raw materials.

Hydrogen is seen as a promising alternative to fossil fuels to achieve the international environmental goals of 2050 - with zero CO2 emissions. The European aircraft manufacturer Airbus, for example, aims to produce hydrogen-powered passenger aircraft (‘ZEROe’) within fifteen years. However, technical challenges still need to be overcome, for example in the area of hydrogen storage

The ThinCorr project aimed to improve the understanding of the corrosion resistance of metallic systems under atmospheric conditions. With the project, it becomes easier to select suitable materials for the transport and civil sectors and to validate new material developments and surface preparations.

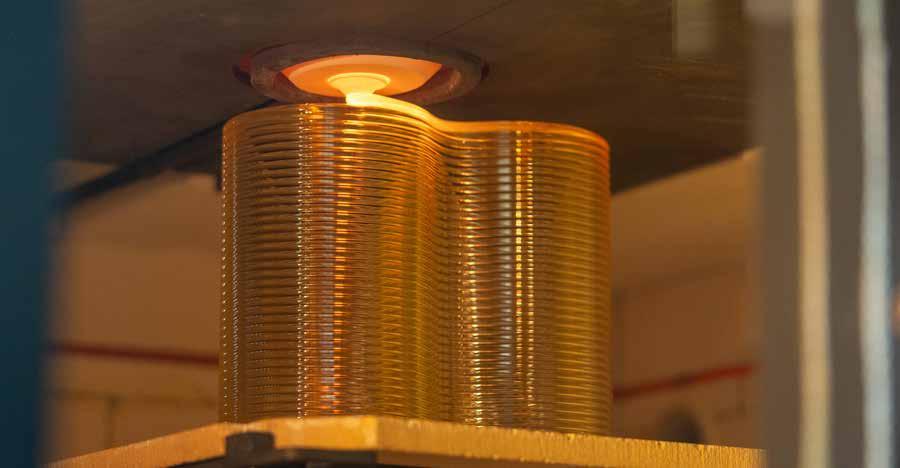

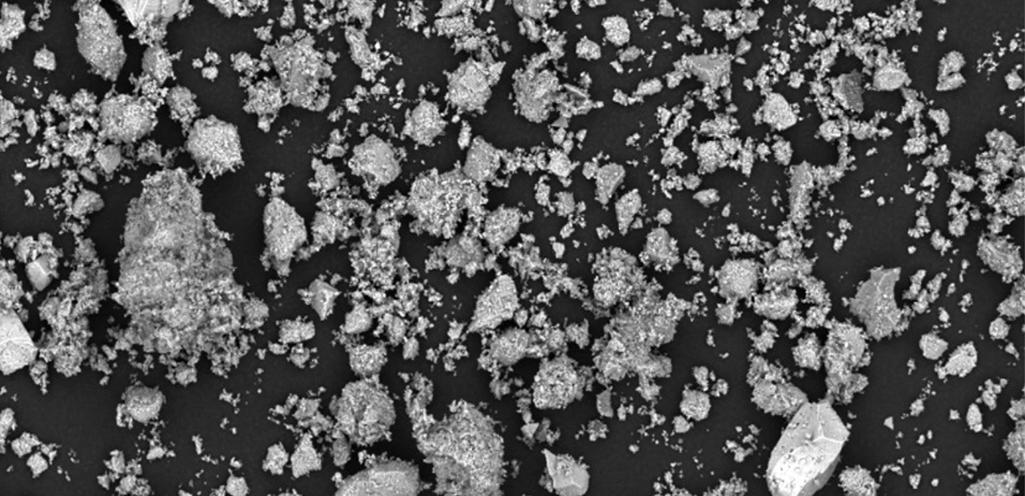

Iron as a cheap storage medium for hydrogen Hydrogen is seen as an interesting fuel for the future. However, storing hydrogen is complex and expensive due to the energy required, safety risks and storage problems. Researchers at ETH Zurich have developed a safer and cheaper alternative. They use iron to store hydrogen seasonally, which shows promise for solving these challenges.

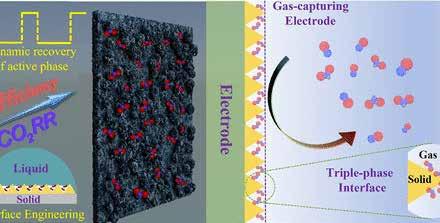

Lotus leaf-inspired technology to convert CO2 into fuels and chemicals

Researchers at the University of Central Florida (UCF) have developed a nature-inspired filtration and conversion system that converts atmospheric carbon dioxide gas into fuels and chemicals. The device extracts gaseous carbon dioxide through a micro-surface consisting of a tin oxide film and a fluorine layer.

Recycling 2024 12 - 14 November 2024, Gorinchem

Precisiebeurs 2024 13 - 14 November 2024 ‘s Hertogenbosch

Formnext 19 - 22 November 2024, Frankfurt am Main

Advanced Recycling Conference 20 - 21 November 2024, Cologne

Beton Event 2024 21 November 2024, Rotterdam

Lijm Event 2024

27 November 2024, Veldhoven

Münchener Forum Verbindungstechnologie

28 November 2024, Frankfurt am Main

Hagener Pulvermetallurgie Symposium 2024

28 - 29 November 2024, Hagen

Architect @ work Germany 2024 4 - 5 december 2024, Frankfurt am Main

MaterialsNL 9 - 10 December 2024, Arnhem

EBC 24 - The European Bioplastics Conference 2024 10 - 11 December 2024, Berlin

BAU 2025 13 - 17 January 2025, Munich

Gevel 2025 5 - 7 February 2025, Utrecht

Batibouw 2025 15 - 23 February 2025, Brussels

Maintenance Dortmund 2025 19 - 20 February 2025, Dortmund

Cevisma 2025 24 - 28 February 2025, Valencia

JEC World 2024 4 - March 2025, Paris

Beton Tage 2025 11 - 13 March 2025, Ulm

Innoteq 2025 11 - 14 March 2025, Bern

Cellulose Fibres Conference 2025 12 - 13 March 2025, Cologne

MaterialDistrict Utrecht 2024 12 - 14 March 2025, Utrecht

Silicone expo Europe 2024 19 - 20 March 2025, Amsterdam

Fastener fair global 2025 25 - 27 March 2025, Stuttgart

CO2-based Fuels and Chemicals Conference 2025

29 - 30 April 2025, Cologne

Wij leveren complete installaties voor ontstoffing, luchtreiniging en pneumatisch transport

Technieken voor o.a.:

- Ontstoffing van productieruimtes (MAC)

- Reduceren van geuremissies (NER)

- Reduceren van stofemissies (NER)

Componenten die wij o.a. kunnen leveren:

- Natfilters & Droogfilters

- Cyclonen

- Gaswassers

- Topsteen- / Frogreinigers

- Naverbranders

Projecten kunnen turn-key worden uitgevoerd

Wij garanderen de emissie & grenswaarden

Engineering, bouw en onderhoud in eigen beheer

Mesys Industrial Air Systems BV

Molenstraat 27, 6914AC Herwen

+31 (0) 316 248744

www.mesys.nl

Info@mesys.nl

Uniting industry leaders and stakeholders across all plastic waste value chains.

Topics of the Conference

• Markets, Investments & Policy

• Circular Economy & Ecology of Plastics

• Physical Recycling

• Biochemical Recycling

• Chemical Recycling

• Thermochemical Recycling

• Other Advanced Recycling Technologies

• Carbon Capture and Utilisation (CCU)

• Upgrading, Pre- and Post-treatment Technologies

• Digital Solutions (e.g. AI & Blockchain) Contact Dominik Vogt Conference Manager dominik.vogt@nova-institut.de Organiser

Gold Sponsor Bronze Sponsors

Geïnteresseerd in de onbegrensde mogelijkheden van keramiek? Word nu lid van de Nederlandse Keramische Vereniging (NKV)

Wat doet NKV?

• kennisoverdracht, samenwerking, ontmoetingen en informatie-uitwisseling met andere (keramische) organisaties, instituten en verenigingen, in binnen- en buitenland.

• stimuleren van onderwijs en onderzoek op het gebied van keramische materialen

• contactennetwerk bieden voor de leden

• actief kennis verspreiden over keramiek en keramische materialen

• collectieve promotie van de toepassing van keramiek.

Meer weten over lidmaatschap? www.ceramics.nl Klik hier>

Independent, dedicated, objective research and consultancy. ISO 17025 accredited. Center of expertise for materials characterization.

We are pleased to support you with research and analysis of your innovative materials. Call us on +31 26 3845600 or email info@tcki.nl www.tcki.nl