Theconceptofsupplychainmanagementanditsbenefitsarebespokeninthebusinessworld.

However,formanyyearstheconceptremainedonlyaputativeidea.Overthelastdecadeorso, supplychainmanagementhasconsiderablygainedsignificanttractionamongstvariousindustries; thereasonforthesamebeingquiteinterestingtodecipher.

Withtheshiftingfocusfrommanufacturingtocustomervalue,companiesarenotmuchconcernedabout manufacturingcostsorproducinghigh-qualityproducts.Onthecontrary,themajorchallengeistodeliver thecorrectproduct,atthecorrectlocation,atthetimethecustomersneed,intheappropriatequantity,and atthelowestpossiblecost.Itisquiteimpossibletomeetuptothesechallengeswithoutthehelpofaunit thatdevelopscomprehensivestrategiesandpreciselystrengthensbusinesschains.Thisentailstheneedof supplychainmanagement(SCM).

Supplychainmanagement(SCM)istheperfectblendofbusinessandtechnologydisciplinethatrefersto thewaysofco-coordinatingtheactivitiesinvolvedinpurchasing,designing,buildingandsellinga product.TheteamofanysupplychainmanagementproviderutilizesInformationTechnologytocreatea crossfunctionalinter-enterprisesystemcalledSCMinformationsystems.

Thesesystemsincorporatethebusinessprocessesofsuppliers,purchasingfirms,distributors,andcustom logisticsinordertoimprovetheefficiencyandeffectivenessofmanufacturinganddistribution.They maintainandstreamlinetheflowofinformationbetweenacompanyanditssupplychainpartnersto optimizethesourcing,procurement,manufacturinganddeliveryofproductsorservices.

Acompanycandeployasupplychainmanagementsystemin-houseorcanevenhireaspecialteam ofprofessionalsdedicatedtomaintainthebusinesschain.Mostoftheworld’sleadingbrandshave witnessednumerousbenefitsofhiringsuchteam,andmoreandmorecompaniesfromvarious industriesareshowinginterestinemployingthesame.

However,supplychainmanagementanditssolutionsvaryfromproducttoproductandservicesto services.Henceitbecomesprerequisiteforpotentialcustomertounderstandthedifferencebetween supplychainmanagementsolutionsandtheirabilitytochannelizetheirbusiness.

Toshedlightovertheindustryandrecognizesomeofthebestsupplychainsolutionproviders, InsightsSuccesshascuratedalistof“The10BestPerformingSupplyChainSolutionProviders, 2018”thatareexcellingtheirprovisionofbest-in-classsupplychainsolutionsandplayingavital partinthesuccessofassociatedorganization.

FeaturingastheCoverStorywehaveGlobal4PLisaleadingsupplychainsolutionsproviderthat specializesinhelpinghi-techcompaniespenetratenewregionalmarkets,optimizetheirsupplychain deliverymodels,andlowersupplychaincosts.

Inthisissue,wehavealsolistedAdexa’sAttributeBasedPlanningallowsuser-defineddynamic constraintsandsignificantlyenhancesthespeedofrunsbyordersofmagnitude;OnProcess Technologyanawardwinningmanagedservicesproviderspecializingincomplex,globalservice supplychainoperations;TersoSolutions,Inc.istheleadingproviderofautomatedinventory managementsolutionsfortrackinghigh-valuemedicalandscientificproductsinhealthcareandlife science;SourceIntelligenceisamarket-leadingSaaSmanagementcompany,focusedonsupply chaincompliance,dataanalytics,andriskmanagement;ChainSequenceiscommittedtohelping enterprisesidentifychallenges,createinnovativesolutions,andimplementlastingimprovementsin SupplyChainprocessestoadvanceSales&Operationsgoals;StateofFluxisaleadingprocurement andsupplychainconsultancyprovidingcontractlifecyclemanagement,categorymanagementand strategicsourcing,andsuppliermanagementservices;andRightChainofferssupplychainanalytics, consulting,researchandeducationtolargeandmedium-sizecorporationsinallmajorindustriesand inallpartsoftheworld.

Alsodon’tforgettoflipthroughsomeinsightfulCXO’swrittenbyindustryleadersandarticles pennedbyourin-houseeditorialteam.

HappyReading!

Kaustav Roy

We enable our clients’ top-line global growth strategy as they enter new markets, region by region, country by country. Along the way, we help them avoid costly trade compliance errors and the associated penalties.

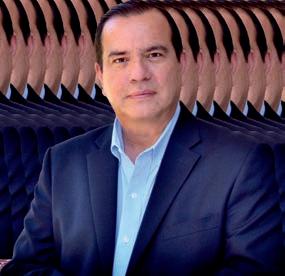

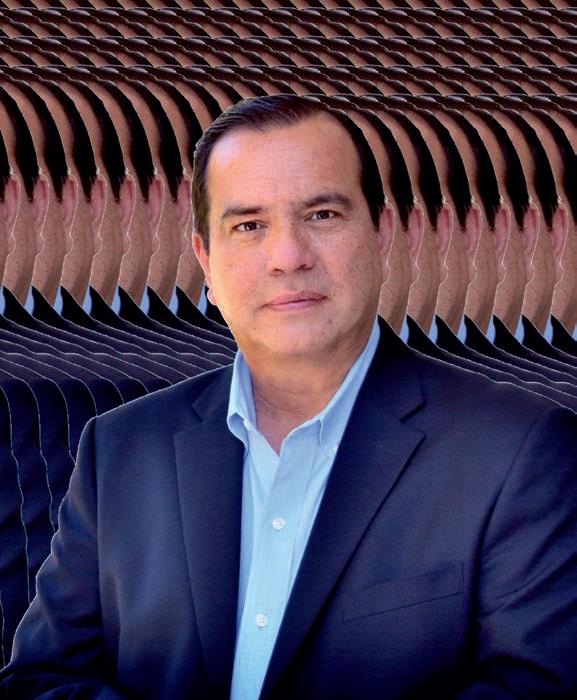

Sergio

Sergio

We

a team of high-performance, hands-on industry veterans that come to the table with proven experience. We deploy experts in import/export compliance, multi-mode transportation, partner negotiations, third party logistics, and general operations management to implement innovative solutions with immediate, measurable results.

Global4PLisaleadingsupplychainsolutions providerthatspecializesinhelpingcompanies penetratenewregionalmarkets,optimizetheir supplychaindeliverymodels,andlowertheirsupplychain costs.Theorganizationdeliverswithquickpayback innovative,software-backedsolutionstoitsglobalcustomer base.

Thecompany’sinternationalteamofindustryveteranshave anaccomplishedtrackrecordofdeliveringresults. Global4PLdeployson-siteexpertsinimport/export complianceandtradelaw,multi-modetransportationand 3PLnegotiations,andglobalsupplychainoperations management.

Itdeliversbest-in-class,end-to-endsolutionsbackedby leanprocessimprovementtechniquesandlaser-focused softwareanalytics.

TheDynamicLeader SergioRetamal,whosecareerspansamassive29yearsin procurementandsupplychainmanagement,istheCEOof Global4PL.Sergio’sprofessionalexperienceincludes managementrolesintheUnitedStates,Asia,Europe,and LatinAmerica.

Hehasbeenwidelyrecognizedforhisaccomplishments. Someoftheseaccoladesincluderecognitioninthe Top 50 Most Admired CEOs of 2017 andinclusiononSupply& DemandChainExecutiveMagazine’s Pros-To-Know from 2007to2011andfrom2013to2017.

Sergiohasalsobeenprofiledonthecoversof Technology Headlines Magazine and Logistics Tech Magazine in2017, andby Hispanic Magazine Executive in2015.

Mostrecently,Global4PLwasawardedwiththePresident’s “E”AwardforExportServiceataceremonyinWashington,

D.C.Muchofthiscanbeowedtotheunwavering contributionsofSergioandhisteamofprofessionals.

Additionally,SergioistheCEOofPOHorizon,aglobal tradecomplianceSaaScompanythathelpssmalltomidsize companiesimprovecomplianceandnavigatecomplex globalcustomsandregulatoryenvironment.Priorto Global4PLandPOHorizon,Sergiogainedconsiderable experiencemanaginglogisticsandimport/exportteamsin bothestablishedandearly-stagecompanies.

HehasledgloballogisticsforseveralFortune100 companiesandeventaughtlogisticsandheldboard positionsintheCaliforniaStateUniversitysystem.Sergio isfrequentlyinvitedtospeakatdomesticandinternational logisticsforums,andhassharedhisperspectiveatthe WorldDevelopmentCongressinHongKong.

HeholdsaMaster’sDegreeinChangeManagementfrom PepperdineUniversity’sGraziadioSchoolofBusiness.He earnedbothaMaster’sDegreeinBusinessAdministration inInternationalBusinessandaBachelorofSciencein InternationalBusinessfromCaliforniaStateUniversity, Northridge.

Global4PL’sarrayofservicessetitapartfromthe competition.Theyareofferedinaplug-and-playmodelto helpcompaniesgrowinternationally,andinclude consulting,completesupplychainmanagement,customs brokerage,transportationmanagement,andtradelaw services.

Thecompany’ssoftwareensurestradecomplianceaswell asthevisibilityofordersandrawsupply.On-sitepersonnel areavailabletosupportandrunoperations,inadditionto in-countrysupportneededtobesuccessfulbeyondnational borders.

are

Clientsbenefitfromanarrayofdifferentskillsand resourcesworkingsimultaneouslythatkeepcostslow whilemaintainingcompliance.

Global4L’sservicesinclude:

Ÿ

IOR/EOR: A global program that enables U.S.-based companies to export non-revenue international shipments to other countries without paying the taxes and duties associated with a Temporary Import License. Acting as the client’s in-country legal entity, Global 4PL can support the client’s sales and customer service departments with pre-sale marketing material and demo product shipments while also allowing the company to keep spares inventory near end-customer sites to support quick-turn repairs.

Ÿ Consulting: Global4PL’s Supply Chain Consulting services are flexible to the requirements of small and large organizations, high-tech and non-high-tech. It can create, implement or simply conduct a review of a client’s Supply Chain organization in benchmarking, cost analysis, operations, etc.

Ÿ

Trade Compliance: Global4PL is an award-winning consulting firm that has developed its own SaaS tool. Trade Compliance services are at the core of what it does, and it helps businesses of all sizes implement and improve their import and export compliance programs.

Ÿ Trade Law: Global4PL’s Legal Division helps clients manage risks and maximize opportunities associated with the CBP/BIS audit of their international trade in goods and services. The organization’s practice, centered in Silicon Valley and extending across the globe, provides a wide range of services designed to match the scope of global trade regulation and answer the needs of its clients.

Ÿ Customs Brokerage: Global4PL offers a comprehensive range of Customs Brokerage services for importers and exporters which go far beyond what other brokers provide.

Ÿ Technology Solutions: Global4PL provides a suite of professional services to ensure that its customers can succeed at implementing new IT and business initiatives. The organization focuses on SCM/Asset Management/CRM implementations and provides support in three key areas: Implementation, Development and Integration services.

Global4PLrecognizesthatthegloballogisticslandscape isundergoingmassivetransformation,largelyfueledby the“Amazoneffect”,whereclientsdemandservicesand productsbedeliveredintheshortestpossibletime.

We design and deliver holistic, end-to-end supply chain solutions including differentiated supply chain delivery models tailored to our clients’ true needs, and a fully transparent and aligned Sales & Operations Planning Process underpinned by our PO/Horizon proprietary supply chain software.

Thisdemandopensatreasuretrove ofpossibilitiesaswellaschallenges formanufacturers.Traditionally, manufacturershadtochoose betweenoneandthreegloballegal entitiesthatallowedthemtoconduct businessinothercountries.Many weredependentonValueAdded Resellers(VARs)whomanagedtheir operationsinthosecountries,acting asaliaisonbetweenthemandthe endcustomer.

Withtheemergenceofcloud computing,thattime-testedsales channelmodelisnolongereffective.

Asanexample,consideraFortune 1000companythatpurchasesa securityapplianceforglobaluse. Theyexpecttointerfacewithone entity,whichistheappliance manufacturer,andnotmanyofthe differentVARsthatareregion dependent.Thesecurityappliance companymustthenbeabletofulfill thisorderaroundtheglobe,often shippingnottoanOEM’sfacility, buttoacolocationdatacenter.

Theseshiftsincustomerpractices arecreatingaperfectstormthat requiresaneconomicalwayto deliverproductsgloballywithout channelsupport.Internationaltrade isripewithopportunitiesforthose whocannaildownthelogisticsof movingproductsinternationallyina predictable,compliant,andcosteffectiveway.

DoingbusinesswithGlobal4PL comeswithseveralbenefits,someof whichareasbasicashavingthe localrepresentationofaUSA-based corporationwithcoverageover85 countries.

We conduct a complete review of your supply chain management that spans all movement and storage of raw materials, workin-process inventory, and finished goods from point of origin to point of consumption.

approachmakesthecrucial differencewhenitmatters.

Oneofthebiggestchallengesfor Global4PLhasbeentoescalateits productsandservicestosupporta customerbasespreadovermorethan 85countries.Thecoveragehastobe bothefficientandcost-effective whilemaintainingthefocuson customers’needswhichliesatthe coreofGlobal4PL’svalues.

Global4PL’sIORexpertiseissought byagrowingnumberofclients, includinglargecorporationsthatsee theriskofimportingintoother countries.Theyaredrawnbyits servicescompliancewithworldwide regulationsandtherangeofservices whichaddresstheneedsofaglobal supplychain.

Global4PLalsohastherightmixof expertisetodelivertradecompliance, customsbrokerage,ImporterofRecord (IOR),ExporterofRecord(EOR), transportationservicesandafullsuite ofsupplychainservices.

Inoneword,theorganizationcantake careofallitscustomer’sglobalneeds withfullcomplianceandwithan award-winningteam.

Global4PL’semployeesareeagertobe partofeveryclient’slogisticsjourney andtohelpthemgrowandbecome morecompetitive.Itscustomized

Global4PL’ssuccessisdrivenbyits abilitytohelpcustomersnavigatethe difficultiesofdoingbusiness globallyandtohelpthemsucceed. Thecompanyonlyconsidersa projectsuccessfulifthecustomer’s businessgrowsanditachievesthe bestandmostefficientglobal footing.

Global4PL’stakespridein capitalizingonopportunities providedbycustomers,aswellasthe opportunitiesthatithasopenedto them.

Thecompanyiscurrentlyworking onexpandingitsglobalfootprint. Withinthenextfewyears,theyplan toexpandfromcovering85 countriestoover140.Itiswhat Global4PL’scustomerswant.

Adexa,Inc adexa.com

ChainSequence,Inc. ChainSequence.com

K.CyrusHadavi Founder BillMrzlak Co-founder& ManagingPartner

Global4PL global-4pl.com

SergioRetamal CEO

ManhattanAssociates manh.com

EddieCapel President&CEO

Adexa’sAttributeBasedPlanningallowsuser-defined dynamicconstraintsandsignificantlyenhancesthespeedof runsbyordersofmagnitude.

ChainSequenceiscommittedtohelpingenterprisesidentify challenges,createinnovativesolutions,andimplement lastingimprovementsinSupplyChainprocessestoadvance Sales&Operationsgoals.

Global4PLisaleadingsupplychainsolutionsproviderthat specializesinhelpinghi-techcompaniespenetratenew regionalmarkets,optimizetheirsupplychaindelivery models,andlowersupplychaincosts.

ManhattanAssociatesdesigns,buildsanddeliverssupplychain commercesolutionsthatdrivetoplinegrowthbyconverging front-endsaleswithback-end.

OnProcessTechnology onprocess.com

RightChain rightchain.com

SourceIntelligenceLLC sourceintelligence.com

MikeWooden CEO

Dr.EdFrazelle Founder&CEO JessF.Kraus Co-Founder&CEO

OnProcessTechnologyisamanagedservices providerspecializingincomplexglobalservice supplychainoperations.

RightChainofferssupplychainanalytics,consulting,research andeducationtolargeandmedium-sizecorporationsinallmajor industriesandinallpartsoftheworld.

SourceIntelligenceisamarket-leadingSaaSmanagement company,focusedonsupplychaincompliance,dataanalytics, andriskmanagement.

StateofFlux stateofflux.co.uk

TersoSolutions,Inc tersosolutions.com

AlanDay Chairman&FounderJoePleshek President&CEO

Vizient vizientinc.com

CurtNonomaque CEO

StateofFluxisaleadingprocurementandsupplychain consultancyprovidingcontractlifecyclemanagement, categorymanagementandstrategicsourcing,andsupplier managementservices.

TersoSolutions,Inc.istheleadingproviderofautomated inventorymanagementsolutionsfortrackinghigh-value medicalandscientificproductsinhealthcareandlifescience.

Vizientconnectsmemberswithknowledge,solutionsand expertisethatacceleratesperformancetoensurethatthey deliverexceptional,cost-effectivehealthcare.

Gordon VP & Product Lead SC Navigator AIMMS

Gordon VP & Product Lead SC Navigator AIMMS

WhenIfirststartedworking insupplychain,backinthe 90s,dataavailabilityand technologywerenowherenearwhat wehavetoday.Iwasfortunateenough toworkwithAlanBraithwaite,who createdtheinitialcost-to-serve methodology.Thereweresignificant challengesthen,butaftermonthsof hardwork,wegeneratedacost-toservemodelthatoftenledtosome surprisingresultsandstrategicchoices. Thiswassimilarforallsupplychain professionals.Projectswerelong, exhaustingandexpensive,involving largeteamsofconsultants.Collecting datawasahassletosaytheleast.Fastforwardto2018andweareattheonset ofadigitalsupplychain transformation.Howexactlyis technologysimplifyingthesupply chainforthebetter?

Gartnerpredictsthatby2020,over20 Billiondeviceswillbeconnected. WiththeInternetofThingsandIT

integrationprojects,datacollectionhasgottensomewhat easier.Butthishasalsocreatedotherchallenges:data overloadandqualityissues.Whenyoubuysupplychain optimizationsoftware,youstillneedtohuntaroundfordata tomakethetechnologywork.Itoftenfeelslikeyouwork forthetechnologyvendor,nottheotherwayaround.That’s why60%ofthetimespentinanalyticalsupplychain projectsisspentcollecting,cleansingandformattingdata.

Whatifinsteadoftryingtofityourdatatothetechnology, thetechnology’sarchitecturewouldbedesignedaround satisfyingyourbroadsupplychainneeds?Imaginebuilding acomprehensiveandrobustsupplychaindatasetwiththe helpofawizardthattellsyouexactlywhichdatayouneed toanswerthequestionsyouhave?Thisisnowwithinreach. AtAIMMS,we’resimplifyingthedatacollectionprocess withDataNavigator,anintegratedclouddatabasethat bringsstructuretocomplexityandenablesyoutosharedata acrossmultiplefunctionalareas.

Iexpecttoseedataarchitecturemovinginthisdirection,as itmakesiteasiertodeployadditionalsolutions,testnew things,andembedanewstrategyinyourbusinessvery quickly.

Inthepast,itcouldtakehoursor(dareIsay)daystosolve asupplychainmodel.Today,thankstoadvancedcomputing power,wecansolveamodelinseconds.Still,notall organizationsaremakinguseofthisspeed.Clunkysystems thatneedtobemanagedbyexpertsstillabound.The promiseofreal-time,self-serviceanalyticsiselusive.

TakeS&OPsupportsoftware,forinstance.Weheldan S&OPworkshopatarecentconferenceinAmsterdam wherewesimulatedaCapacityReviewmeeting.Duringthe workshop,welearnedthatvirtuallyallattendeeshadapain pointincommon:theyalwayshadtogobacktotheirdesk totestdifferentscenariosafteranS&OPmeeting.Nonewas abletoperformscenariocomparisonsinreal-timetodiscuss insightswithstakeholdersduringthemeeting.Somealso lackedadvancedanalyticsandoptimizationcapabilities.

Newself-servicetechnologiesenrichedwithprescriptive analytics,suchasAIMMSS&OPNavigator,allowyouto performeasyandreal-timescenariomanagementwithout datascienceexpertise.Withthiscapability,youcanrunand comparemultiplescenariosside-by-sideintheexecutive meetingattheendofS&OPandmakeconversationsricher, moreentertainingandfluid.Moreover,yourmeetingswill bemorestrategic,ratherthanfocusedongranular, operationalthings.

Besidesbringingdataanalysisclosertoend(business) users,technologyisalsosimplifyingcollaborationinsupply

chain.Mostorganizationsstarttheirsupplychainanalytics journeybyusingspreadsheets,usingdatafrom transactionalsystems.Spreadsheetsaregreatforpersonal productivityandtheytendtoworkwellforthepersonthat buildsthem,butwhathappenswhenyouworkinateamof 100spreadacrossdifferentregions?Asmoreandmore peoplegetinvolved,moreversionsofthesespreadsheets getshared. Sharingknowledgeisdifficultandtheoriginal logicbehindeachspreadsheetisoftenhardforothersto comprehend.

Cloudbasedanalyticalsystemsthatallowforversion controlaresimplifyingcollaborationacrossthesupply chain. Replacingspreadsheetswithacentraltoolallows peopletogainalotmoreinsightintotheirbusiness. Centralizingthisdataandprovidingwideaccesshasbeen oneofthebiggestbenefitsAIMMSclientslikeBPhave achieved.

Simplifyingdecision-making Basingcomplexsupplychaindecisionsoncommonsense hasitspitfalls,butorganizationsstilltendtorelyongutfeel toruntheirsupplychain.Withprescriptiveanalytics,they nolongerneedto.Aslongasthesystemisfedtheright data,theyshouldbeabletosupporttheirdecisionsonfact andpredictablebusinessoutcomes.Thankstomobile technologies,decisionscanalsobemadeonthego, regardlessofyourlocationortimeofday.Thanksto advancesinmachinelearning,itisnolongerdifficultto imagineasemi-autonomoussupplychain,werecertain decisionsaretakenautomaticallyandothersareleftto humaninsight.

Inshort,technologyhascertainlysimplifiedsupplychain throughouttheyears.Butasmuchasthatistrue, technologyaloneisnotgoingtorevolutionizesupplychain management.Thekeyfactorforsuccessispeople,andthe commitmentofsupplychainleadershipandteamsto leveragenew,intuitivetechnologiestoimprovetheirsupply chainstrategyandexecution.

Chris Gordon has worked in supply chain consulting and operations across Europe, the US and India for over 25 years. He’s driven dozens of supply chain initiatives in retail, consumer goods and manufacturing with a heavy focus on leveraging analytics to promote major business change. He is passionate about making supply chain analytics accessible to everyone to drive data-driven, factbased decisions to drive major strategic and operational impact.

Thegeographicalfootprintofcompaniesinvirtually everyindustryhasgrownexponentiallyoverthe pastfewdecades.Notonlydotheycatertomore clientsinmorecountriesbutalsomanagenetworksof suppliers,subcontractors,manufacturingsitesandinventory pointsspreadovervastdistances,bothnationallyand internationally.

Withoutpropermanagement,theincrediblecomplexityand unwieldinessofsuchasupplychainecosystemisthe perfectbreedinggroundforlostrevenue,lostassets,and lostreputations.

Adexa’stechnologyenablesyoulowertheoperationcost, minimizeinventorycostandensureon-timedeliveryof goods.

Foundedin1994,Adexahasgrowntobecomeoneofthe world’sleadingsupplychainplanningcompanies.ItsS&OP andS&OEsolutionsareusedbyFortune2000companies locatedacrossfivecontinents.

OneofAdexa’sstrongestfeaturesisthatitcreatesaunified environmentwhichincorporatesplanningsolutionsfrom demandplanningtoinventoryoptimizationandsupply planningtofactoryplanningandscheduling.

Adexafortifiesthissystemthroughtheuseofoptimization algorithms,heuristicsandMachineLearningtechniquesto deliveraccuratereal-timesolutionsacrossglobalnetworks.

Thecompanyisnotcontenttoletitsstatusasamarket leaderdetractfromitscontinuedcommitmentto adaptabilityanddexteritywherethenameisderivedfrom. Itisalreadyfomentingrevolutionarychangesinthe industrybyintroducinginnovativetechnologylikeAttribute BasedPlanning(ABP)andArtificialIntelligence.Adexa’s Self-Improving Supply Chain©technologyconstantly assessesunderlyingchangesinthedemandandsupply networkandadaptsitselftotheenvironment.

Adexa’scomprehensivesuiteofsolutionscaterstosupply chainessentialsfromtop-levelplanningtoexecution,allin aunifiedenvironment.Thisuniqueapproachoffers exceptionaladvantages:

Ÿ

Attribute-Based Planning (ABP) - Adexa’sproprietary technologythatenablesfastandflexiblemodelingofthe supplychainandtheabilitytoadapttosupplychain changeswithoutanyadditionalcodingandconsulting.

Ÿ Planning accuracy –theaccuracywithwhichtheycan modelasupplychainmeansthattheresultingplansare executableandreliable.

Ÿ

Low cost of ownership:WhenABPtechnologyisused, minimalresourcesarerequiredtomodelthe environmentandmakefuturechangesasthebusiness changes.

Ÿ

Single-environment S&OP and S&OE –Virtuallyevery otherplanningsolutiononlyusesS&OPtechnology basedonspreadsheet-typeplans,whichrequire extensivemanualinterventionand,thus,areproneto errors.Bycontrast,Adexa’shighly-accurateplansare completelyself-sustaining.

Ÿ

Financial and operations planning combinedFinancialsandanalyticsareembeddedineveryAdexa planningmodule,givingend-usersateveryleveltheir owndashboardtounderstandthefinancialconsequences ofeveryoperationaldecision.

Ÿ

Use of AI and Machine Learning technology –Supply chainsevolveconstantlyandstaticmodelsbecome increasinglyinaccurateovertime.Adexa’s SelfImproving Supply Chain©technologyallowsthesystem toconstantlylearnandadapttoitsenvironment.Their technologyrevealshiddentrendswhichcanbe leveragedtoconstantlymalegoodplansanddeliverontimeatlowercostofoperations.

Supply Chain pressures and challenges are ever present in good or poor economic climates. For over 20 years, Adexa has been dedicated to providing the most advanced planning technologies to help its clients rise above their competition and keep their customers happy regardless of the market conditions. I am proud to be an evangelist for Adexa’s solutions and its passionate people.

Risk management –AItechnology candetectpotentialharmfultrends beforetheyaffectthesupplychain. Forexample,excessinventory,and impendingshortagesorweather conditionsthatmayaffectfuture deliveries.

DecisiveLeadership

AdexawasfoundedbyDr.K.Cyrus Hadaviin1994.Dr.Hadaviisoneof theworld’sforemostexpertsonsupply chainmanagementandrelatedfields. Underhisleadership,Adexahas becomeoneofthetopsupplychain companiesintheworldwithapresence onfivecontinents.

Dr.Hadavi’sexperiencehasbeen instrumentalformanyFortune1000 companies,includingBlack&Decker, Solectron,Northrop-Grumman, Philips,Toshiba,GM,Boeing,Hanes andSeagate

Cyrusisoneofthepioneersof applyingArtificialIntelligenceto planningproblems.AtSiemens,he implementedthefirst-generationofhis AIplanningsolutionsattheirfacilities. Thisincludedsemiconductor fabricationlines,regardedasthe hardestplanningandscheduling scenario.

AsAdjunctProfessorofOperations ManagementatColumbiaUniversity, Dr.Hadavitaughtcoursesonthe applicationofcomputerscienceandAI tomanufacturing.Hehasperformed jointresearchatColumbiaUniversity, theWhartonSchoolofManagement, LoyolaUniversity,Clemson

University,andtheMaxPlanck InstituteinGermany.

Besidespublishingnumerousarticles andbooksonsupplychain management,manufacturing,andecommerce,Dr.Hadaviisapopular speakeratbusinessforums.

HeholdsaB.Sc.degreeinElectrical EngineeringandanM.Sc.degreein IndustrialManagementfromthe UniversityofBirmingham,UK.He alsoholdsanM.Sc.degreein ComputerEngineeringfromthe UniversityofSouthampton,UK,anda Ph.D.inElectricalandComputer EngineeringfromtheUniversityof Michigan,AnnArbor.

Dr.HadaviisontheECEAdvisory Council(ECEC)atMichigan University,agroupcommittedto positive,transformationalchange acrossallindustries. Heisanalsoan ExecutiveBoardmemberoftheCenter forGlobalSupplyChainManagement attheUSCMarshalSchoolof Business.

InnovativeSolutions,Always Developingathrivingbusinessina fieldwhichmovesandevolvesso rapidlyisnevereasy.Adexa’sstature todayisbuiltonitsabilitytoforesee andavoidpotentialdrawbacks,andto respondquicklyandeffectivelywhen thatisnotpossible.

Oneoftheissueswithwhichithashad tocontendsincetheveryfirstdaysis thedifferenceinculturesbetween clientcompanies.Becauseitdealswith

suchdiverseclientele,Adexahasto constantlyshiftandadaptsoits approachfitsperfectlyinevery situation.

Clienteducationcanalsobean obstacle.Becausechangeisnevereasy, C-levelexecutivesontheclient’sside havetobeconvincedoftheefficacyof Adexa’ssolutions.Adexahasto effectivelyconveyhowitstechnology simplifiestheroleofeveryoneinthe supplychain.

Finally,thereisagreatdisparityin termsoffunctionalitybetweenlegacy systemsusedbyclientsandthe cutting-edgeAdexaplatform.They havetoensurethattheirsophisticated algorithmsdonotaffectitsuserfriendlinessandthattheplatformdoes notrequireextensiveend-usertraining.

ItisAdexa’sabilitytoconsistently solvesuchproblemsthatunderscores itsreputationasoneofthebestsupply chainplanningcompaniesintheworld.

Thecultureofinnovationisasstrong asever.Adexaiscurrentlyinthe processofcombininganimation technologywithpredictiveanalyticsto producenotificationsforcritical informationacrossallmobiledevices.

Withsuchcutting-edgetechnologyin theworks,Adexaislayingthe foundationforcontinuedexcellence andmarketleadership.

www.Adexa.com

Forover20years,ChainSequenceprofessionals continuetodelivertransformativeSupplyChain projectdeploymentsonbehalfoforganizationsthat areseekingmeaningfulchangetooutdated,cumbersome processesintoday’sdigital,cloud-basedmarketplace.From bothanefficiencyandcompetitiveperspective, ChainSequence’ssupplychainplanningservicesintegrate best-practice,nimblerprocesseswithsalesandoperations objectives.Augmentingtheseserviceswithadvancesin benchmarkingsupportanalytics,thefirm’sclientsbenefit frommorestructured,enterprise-wideplanningcyclesto ensurenewsystemsarefunctioningatpeakperformance.

Withmorethan25yearsofexperienceinleading professionalteams,BillMrzlakistheCo-founderand ManagingPartnerofChainSequence.Equippedwithan encyclopedicknowledgeandaremarkableabilitytobuild supportforcommongoalsatmultiplelevels—C-suite, seniorleadership,andcross-functionaloperational teams—Billcontinuestodrivethedevelopmentand optimizationofbest-in-classsupplychainplanning organizationsthroughouttheU.S.,EuropeandAsia.He excelsatleadingtheseglobalteamsinthehighlytechnical arenaofbusinessprocessre-engineeringthroughfacilitated sessions,aswellasmanagingenterprise-widesystems developmentandprojectdeployments.

Billandhisteamspossessasterlingreputationforguiding clientgroupstowardgettingtotheheartofwhat’sreally holdingtheirenterprisesback.ChainSequence’sgoalisto

helpbusinesseslearnhowtofirstremovethese obstructions,andthenfocusenergyondevelopingand deployingamoreinclusiveframeworkforholisticsolutions goingforward.

OnekeyattributethatsetsChainSequenceapartisits knowledge-sharephilosophy,whichprioritizesgamechangingguidancetodevelopclientautonomy. Asa consultinggroup,ChainSequencefocusesspecificallyon businessprocessimprovement,organizationaldevelopment, andprocessownership,andthefirmhasbuiltastrong followingforitsworkineducatingclientsonthehow’sand why’sofbest-practicesupplychainplanningwithS&OPto improveoverallbusinessperformance.Byapplyingthese constructive,educationalcomponentswithtargetedmetrics toensurepositivechangemanagementandhealthyROI, clientsachievemoretransparentbusinessprocesses,tiedto robustsalesandoperationsprograms,thatallowfor continuousimprovementovertime.

E-commercehasfundamentallydisruptedthestatusquo, changinghowbusinesswillbeconductedforthe foreseeablefuture.Mrzlakstressesthatamongecommerce’skeytraitsisitseliminationofmuchofthe humanelementfromeverydaybusiness.Transactionsarrive atlightningspeed,andinnoparticularorder,which subsequentlydictatestheincreasedcompetitiveneedfor speedincustomerresponsiveness. Whenhumansaren’t involvedinelectronicsales,abusinesscouldquicklyfailif

thesetransactionsareprocessed withoutasoundplan.Recognizingthe challengesthisnewdynamicposedto itsclientsearlyon,ChainSequence successfullyadaptedandexpandedthe firm’sserviceframeworksto accommodateonlinesales,incorporate enhanceddatamodeling,developmore customer-centricsystems,integrate multiplesupply,inventory,anddemand channels,andaugmenteducational sessionstohelpclientteamsgaininhouseproficienciesintheseconcepts.

Toexecuterapid-fireresponsetimes fortheseprocessesmoreeffectively, ChainSequencehelpscompanies deployaclearlydefinedsetofrulesto supporttheirstrategicandfinancial goals.Thefirmemphasizesthatwhile it’snotpossibletoresolveevery uniquescenario,itisessentialtodefine keyrulessupportingthemostcommon situationsandminimizethenumberof exceptions.Thekeytoe-commerceis tobuildautonomyandfostergrowth potential,underscoringthatasan enterprise’sprocessmaturesandcycles oflearningcontinue,itcanadjustthe rulesasnecessarytocontinuously improveresults.

Fromtheverybeginning, ChainSequencehasfocusedon developingthebestbusinessprocesses

tosupportSupplyChainandSales& OperationsPlanninggoals. Alltoo often,Mrzlaksays,thefirm’spractice leadersencounterorganizationsor individualswhoassumethatsoftware suitesorsystemscansolvealltheir issues. Whileadvancementsin technologyandplanningtoolsallowus tooptimizeouroriginalmodelsand gainfasterROI,supplychainplanning andS&OPplanningimprovementsare stillinherentlyboundbyproven,rulesbasedbusinessprocesslogicand leadershipthatiscommittedtochange management. Byignoringthe imperativetoanalyzeandfixinherent processobstacles—notputtingthese rulesinplacefirst—thismindsetwill ultimatelyleadto1)gettingabad resultfaster,and2)achievingavery costlylessonlearned. Masteringthe “tools-before-rules”oppositioncanbe challenging,butbyworkingclosely withanorganizationthroughhands-on guidanceandconsensus-building,we greatlyimprovethechancesoflongtermsuccess.

PlanningforaProductiveFuture ChainSequenceprofessionalshave workedincountlessorganizations acrossdifferentindustrysectors

aroundtheglobe,experiencingvarying degreesofthesameissuesfromone organizationtothenext. Havingsaid that,itdoesn’tmeantheteamhasseen everything. Mrzlaksaysthatchanging customerdemand,theglobaldigital evolution,theroleofdataanalytics, andemergingRPA/AI-related innovationswilldrivenew requirementsandscenarios. ChainSequencecontinuesto incorporatethesenewrealitiesintoits businessprocessmodels.

ChainSequenceenjoysbroad partnershipswithotherservice providers,professionalassociations, andthoughtleadersintechnology solutiondeployment. These connectionshaveformedavirtual innovationlab,offeringabetter understandingofmarketconditions, techadvancements,andcustomer nuancesfromoneregiontothenext. Thefirmissuccessfullyexpandingits presenceintheconsumerproducts, retail,andservice-orientedindustry sectorsintheU.S.,Europe,andAsia regions.

all

One key attribute that sets ChainSequence apart is its knowledge-share philosophy, which prioritizes game changing guidance to develop client autonomy.

“

Thegratifying tool for companies to lead aheadIoT Technology” TheInternetofthings(IoT)isa revolutionarychangeformanysectorslike manufacturing,agriculture,retail,electronic,energyand healthcarewhichareprogressingtowardstheIoT phenomenontoconnectdigitally.Ithasplacedan opportunitytobuildunusualresultswhichincreasesa company’scompatibility.Enterprisesseeking developmentarefocusingontheuseofreal-timedata managementandIoTanalysis.Manyofthe companiesareadoptingthistechnologytoheighten theirpowerofconsumption.Companiesare mainlyconcentratingonIoTapplicationfrom “sensing”insteadof“doing”togrowits competitiveadvantages.Thiselementempowers organizationsbyallowingthemtotaketheIoT advantageandadoptamore‘innovative connectedapproach’.

Newapplicationsarenowenhancingtheirlevelof consumption.Likewise,manufacturingsectorisalso

gettingengrossedandachievingexcellencethroughIoT Techniques.Applicationsareliableformonitoringand controllingoperationsforurbanandruralmanufactures likebridges,farms,andrailwaytracks.Itisthekey featuresoftheapplicationswereIoTinfrastructureis alsousedformonitoringtheconstructionsafetyandrisk managementsystemandoperations.Thismajorfeature representsthemechanismofIoTapplicationwhich worksunderinfrastructuremanagement.BenefitsofIoT Technologyarecostreducing,timereducing,betterin quality,andincreaseproductivity.Ithelpstomakefast decisionsandsavemoneywithreal-timeanalysis.IoT deviceshelptogiveprominentresultsbymonitoringand controllingoperationsusedinallinfrastructurerelated area.

Inthemanufacturingsector,networkingandcontrolling havebeenusedwithIoTdevices.Itprovidesinformation aboutdataandoperationstability.Networkstatusandthe informationiscollectedinthesystembytrackingIoT device.Manufacturingcontrolprocessdeliver informationaboutindustryapplicationandsmart manufacturingdetailsreceivingformIoTdevice.IoT intelligentsystemenablessharinginformationabout productdemands,servicemanagement,supplychain networks,sensorsandcontrolsystemstogether.Small industriescanalsobeintegratedwithIoTtechnology thatenablesreal-timeoptimization,measurements, productioncompatibilityandsafetymanagement. However,intelligentsystemsaredeterminedasthe significanttechniquethatimpliesuserexperienceand systemsecuritywhichultimatelysavescosts.

TheAgriculturesectorisoneoftheindustryto implementIoTtechnologyforstabilityandbetter performance.IoTtechnologyhasbecomeasignificant methodoffarming.Italsooffersdurabilityand functionalitytothewholeprocess.Thecombinationof wirelesssensorswithagriculturalappsandcloud platformsbenefitsingatheringdefiniteinformation relatingtoenvironmentalconditionslike,rainfall, temperature,humidity,windspeedetc.Farmersare gettingcompetentresultsoutofit,andareabletofind real-timeinformationeasily.Linkedwithfarmland,it improvesandautomatesfarmingtechniqueslikeweather information,takingdecisiononqualityandquantity,and minimizesriskandwaste.WithIoTTechfarmerscan findoutdetailedinformationoffarmandsimilarlyknow

whichlandisfertileorwhichoneisdryandpredict futurefields.

IntegratedSensingandControlsystemhelpstooptimize energyconsumption.IoTdevicesareintegratedwith energyconsumptionsystemsinordertomaintain balancebetweenpowergenerationandenergyusage.IoT devicesoffertheopportunitytoremotelygather information.Itenablesadvancefunctionslikeremote controllingandchanginglightconditions.IoT Technologyworkforhome-basedenergysystemwhich providepowerrelatedinformation,energyconsumption andenergyusageathomes.IoTdevicessetgoalsto improveefficiency,reliabilityandsustainabilityofthe energysystem.

Environmentmonitoringapplicationhasbeeninvolved withsensorstoassistinformationaboutenvironment changesbyidentifyingwaterquantity,atmosphere,air pressureetc.Italsohasfocusonmonitoringmovements ofwildlifeandtheirhabitats.Devicesconnectedtothe internetalsoprovidestatisticsaboutearthquakeor tsunami-earlywarningsystems,andalsousedasan emergencysystem.IoTdeviceapplicationisusedto collectgeographicinformationandmajorlyinstructive information.Thisdevicealsousesstandardizedapproach tobringwirelesssensingtechniqueandgatherfinest information.

Withcertainty,IoTdevicesareusedtomonitorand controlthemechanical,electricalandelectronicsystems. IoTdevicesareusedinvarioustypesofhome automationandbuildingautomationsystems.Control andsensoryapplicationsofferunifiedinformation.The integrationoftheinternetwithbuildingcreatesan energymanagementsystemwhichwillallowprominent energyefficiency.

TherehavebeenmanywaysforIoTtechnologyto expandcompatibilityinthedigitalworld,anditwillbe implementedineachsectortoworkasanimportanttool, toenhanceitsaffinity.Afterall,theIoTnetworkmakes technologymoreunifiedandsatisfying,withitstoolsand applicationsandIoTwillbeastepaheadtowards numerousopportunities.

OnProcessTechnologyisamanagedservices providerspecializinginbusinessprocess optimizationforglobalserviceandsupplychain organizations.OnProcessdeliversimprovedbusiness outcomesbyidentifyinghiddencostsandoptimizingthe servicedeliverylifecycle.

MikeWooden CEOSinceitsinceptionin1998,whenitpioneeredpost-sale optimizationservices,thecompanyhasbeenhelpingmany oftheworld’sleadingbrandsintelligentlyscaleoperations, growrevenue,reducecapitalandoperationalcosts,and deliversuperiorcustomerexperiences.

Thecombinationofitsdomainexpertiseandtheunique wayithasembeddedpredictive,actionableanalyticsinto automateddecisiontreeprocessestodrivehigh-impact outcomes,hasmadeOnProcesstheservicetransformation partnerofchoiceforleadingcompanieslikeComcast, Philips,Cisco,Verizon,andAT&T.OnProcessprovides servicesin23languagesandoperatesinfourglobal facilities,includingitsMassachusettsheadquartersand centersinMaine,IndiaandBulgaria.

Mostcompaniesarenotabletomakedramatic improvementsintheirservicedeliverylifecyclebecause theylackend-to-end-visibility,anddon’thavetrueinsights intoupstreamcausesofinefficiencies,customer dissatisfactionandrevenueleakage.

SM

OnProcess’proprietaryapplicationsOPTvision and SMOPTiQ underlyallitsservices.OPTvision,anactionable

controltower,providesreal-timevisibilityintoanaggregate viewofthecomprehensiveservicedeliveryecosystem,to identifyintelligentinsightsandresolvehiddencostsand processbreakage.WithinOPTvision,embeddedanalytics andautomateddecision-treebusinessrulesdrivetargeted outcomesthatdeliverthestrongestreturnsforOnProcess’ clients.OPTvisionispoweredbyOPTiQ,OnProcess’ advancedanalyticsengine.

OnProcess’sservicesinclude: SM Ÿ

IntelliForce :Thecompany’snewestinnovationisthe industry’sonlyon-demanddigitalmarketplaceforfield servicemanagement.IntelliForcefeaturesadynamic variablelabormodelthatispoweredbyOPTiQand sourcedfromOnProcess’sselectnetworkofauthorized servicepartners.Clientsbenefitfrom100%field productivity,reducedcostsandimprovedcustomer experiences.

Ÿ

Reverse Logistics:OnProcessintelligentlyexpeditesthe returnofassetsfromthefieldorcustomer,andthe movementofdefectivepartsthroughtherepairchannel andintoinventory,ultimatelyreducingtheneedfor costlynewbuys.

Ÿ

Service Fulfillment:Thecompanymanagesthedispatch ofpartsandtechnicianstooptimizeservicenetworks andinventory,andrapidlycloseoutserviceevents,meet SLAs,andimprovecustomersatisfactionratings.

OnProcessassurestherighttechnicianandrightpartget totherightplaceattherighttime.

Ÿ

Revenue Enablement:OnProcessresolvessalesorder processbreakage,speedstimetorevenuerecognition, drivesservice/accountactivation,andprovidescustomer

educationinordertominimize remorsereturnsandincreasecrossselling.

Ÿ Triage/Customer Support: OnProcessimprovesthecustomer experienceateverypointof interaction,expeditingproblemsolvingwithmorefirst-contact resolutions,savinghigher-value techsupportresourcesfor escalations,andreducingcostly, avoidabletruckrolls.

Ÿ Warranty & Fraud Management: Thecompanyalsomanagesthe entirewarrantyprocess,from productregistration,repairorder diagnosis,andclaimsprocessing, withaspecialemphasisonfraud prevention,throughinvestigation andlossrecovery.

OnProcessrevealsthatbecause companieshavebeenfocusingonthe forwardsupplychain,theyareoften notawareoftheenormouscostsavings andrevenueenhancementsthatcanbe gainedbyoptimizingthepost-sale supplychain.

Theyarealsogenerallyunawareofthe hiddencomplexitiesandproblems inherentintheirownpost-salesupply chains,andhowmuchtheiroperations

aresufferingbecauseoftheseissues. BypartneringwithOnProcessto digitallytransformandoptimizetheir post-salesservices,businessessave millionsofdollarsannually,increase revenueandprofitability,vastly improveend-customersatisfaction,and streamlineandacceleratetheprocesses underlyingtheirservices.

Forinstance,byworkingwith OnProcess,aU.S.cableoperatorsaw itsNetPromoterScoreincrease250% whilechurndecreased,resultingin morethan$12Minsavedsubscriber revenue.Inaddition,Elekta,amedical devicecompany,centralizedits globally-fragmentedsparepartsorder managementsoitcouldeasilymeet SLAsforpartsdeliveryandrepair. Theysavednearly$14millionovera three-yearperiodbyboostingfield returnratesandensuringtheright levelsofinventory.

Inthecomingyears,OnProcesswill continueinvestinginnewcapabilities, advancedtechnologiesandinnovative services.Thiswillenablethe organizationtoaccelerateclients’ digitaltransformationsanddriveeven greatervaluefromtheirpost-sale supplychains.

MikeWoodenjoinedOnProcessas CEOin2015.Hehasbeenleading, growingandbuildingglobal enterprisesandstart-upbusinessesfor morethantwodecades.Fromthevery start,MikebelievedOnProcesshadall theingredientstobeasuperstarina globalpost-salesservicesmarketthat wasrifewithopportunities.

Heunderstoodthatbusinesssuccess dependsasmuchonwhathappens afterthesaleofaproductasitdoeson thesaleitself;thathowefficientlyand intelligentlycompanieshandlethe post-salesupplychainmakesahuge differencetotheirtopandbottomlines.

Evenso,untilrecently,moreattention hadbeenpaidtotheforwardsupply chain,essentiallygettingproducts manufactured.Butasbusinesseslook foradditionalwaystooptimize operationsandenhancecompetitive standing,thepost-salesupplychain offerstremendouspotentialsince opportunitiesforoptimizationarevast andlargelyuntapped.Becausemost companiesdon’thavetheexpertiseto fullyoptimizeitontheirown,thereare enormousgrowthopportunitiesfor OnProcess.

Our ability to consistently deliver strong results can be traced to our service supply chain expertise, advanced analytics-based services and actionable, intelligent control tower.

SupplyChainManagementistheartofdelivering therightproductattherighttimeattherightplace andattherightcosttocustomers.Excellingatthis artisoneoftheworld’spremierglobalsupplychain firms,RightChain.

RightChainofferssupplychainanalytics,consulting, researchandeducationtolargeandmedium-size corporationsinallmajorindustriesacrosstheworld. Amongthemajorcorporationscurrentlyusingitsmodel, methodologyandtoolkitsareHonda,Disney,BP, Hallmark,Nutrisystem,andUnitedTechnologies. RightChainisfocusedsolelyonhelpingclientsdevelop supplychainstrategiesthatmaximizefinancialand serviceperformance.

TheFounderandCEOofRightChainisDr.Ed Frazellewhoisoneoftheworld’sleadingauthoritieson supplychainstrategy.

Dr.Frazelle’sSupplyChainManagementbookseries withMcGraw-Hill,includingSupplyChainStrategy, InventoryStrategy,andWorld-ClassWarehousingisthe world’sleadinglibraryonsupplychainstrategyand operations.HeisalsotheExecutiveDirectorof

RightChainInstituteandtheinstitute’scurriculumisthe world’sleadingsupplychainprofessionaleducation program.

Dr.FrazellewasfoundingdirectorofTheLogistics InstituteatGeorgiaTech.Asaneducator,hehastrained morethan50,000professionalsintheprinciplesof world-classlogisticsand,asaconsultant,hehasassisted morethan100corporationsandgovernmentagenciesin NorthAmerica,SouthAmerica,Europe,AsiaandAfrica intheirpursuitofworld-classsupplychains.Dr.Frazelle isalsoaprofessorandhaslecturedatCornell, Northwestern,theUniversityofWisconsin,Waseda University,andtheNationalUniversityofSingapore. Hisbookshavebeentranslatedintosixlanguages, includingJapanese,Chinese,Korean,Spanish,Russian, andPortuguese.

Dr.Frazelle’sachievementshavebeenrecognizedwitha CSCMP’sDoctoralResearchGrant,WERC’sBurrHupp Fellowship,theMaterialHandlingInstitute’sMHEF Fellowship,Kodak’sEducationalGrant,andGM’s ScholarAward.HewasrecentlynamedGeorgiaTech’s OutstandingProfessionalEducator,inductedintothe NorthCarolinaStateUniversity’sISEHallofFame.He isaformerpresidentoftheInternationalMaterial ManagementSociety.

RightChainoptimizesacross financial,serviceandoperational implications;strategic,tacticaland executionalimplications;andthe long,middleandshort-term implicationsofthefullrangeof supplychaindecisions.Thisincludes supplychainservice,inventory, sourcing,transportation,and warehousing.

Customersincreasetheirbottomline by1%to5%,reduceinventoryby 25%to35%,elevatefillratesby3to 8points,lowertotalsupplychain costsby15%to25%,andintegrate theirsupplychainmetrics,planning, andteams.

Everycombinationofproducts, customerdemographics,andlogistics geographyrequiresauniqueoptimal mixofe-commerceandtraditional retail.Thewinnerswillberetailers whocandetermineandexecuteon thatmix.

RightChainhasdeliveredsolutions fortheaerospace,automotive, chemicals,consumerproducts,food andbeverages,healthcare,high-tech, naturalresources,pharmaceuticals, retail,semiconductor,andtextiles industriesaswellasmanyothers.

Theiranalystsandconsultantsare accomplishedinsupplychain strategy,inventoryoptimization, supplychainnetworkoptimization, salesandoperationsplanning assessments,benchmarking,metrics designanddevelopment, organisationdevelopment, warehouseoperationsdesignand logisticsproviderselectionand negotiation.

Supplychainsarebecoming increasinglycomplexandare expectedtobecomemoreintricatein thefuture.Tomaintainitsleadership andstatusintheindustry,RightChain hasdecidedtorequireeachofits employeestohaveaPhDaswellas advancedexperienceinthefield.

RightChainwillcontinuetodevelop itsproprietaryalgorithmsand artificialintelligenceapproaches. Newtechnologiesandtrendsemerge frequentlyinthefieldand RightChainiscommittedto providingitscustomerswiththebest solutionsfortheirbusinesswiththese developmentsinmind.Thecompany alsoassessestheirpotentialbenefits foritsownbusinessandprioritize implementationgoals.

AstheindustryofSupplyChain Managementmatures,trendsand technologiesareofgreatinterestto theirclients.RightChainisalways focusedonknowingwhatisgoingon inthemarketandwhichtrendsmay helptomakeprocessesmore efficient,savecosts,optimize capacityallocations,andultimately increasecustomersatisfaction.

In this data-driven world and with the modern complexities of global businesses, RightChain provides clients with innovative, reliable and effective supply chain solutions.

Thoughtheconceptofsupplychangevisibility(SCV)has existedforsometimenow,itsapplicationsanddefinition haveundergonemassivechanges.Thesupplychainisno longeracontrolledentitywithinthefourwallsofawarehouse. Today,thewholeprocessinvolvesanetworkofresources scatteredacrossfacilitiesandentitiesindifferentcitiesand countriesallovertheworld.Inorderforthemtobemanaged properly,supplychainresourcesneedtobelinkedtoeachother; theyneedtobeabletocommunicatewithoneanothertoachieve maximumbenefit.

Supplychainvisibility workswhensuppliers,partners,and customers,whoallplaydifferentroleswithinthesupplychain, operateasahubinthemovementofgoodsaswellasintheflow ofinformation.

Notverylongago,theideaoffullsupplychainvisibilitymay haveseemedautopianconcept.However,today,mostcompanies trytoaffordtheirenduserssomedegreeofvisibilityinorderto keepthemselvescurrentandofferthebestpossiblecustomer experience.Althoughitmaynotbefullvisibility,effortsarein placetoachievesomedegreeofvisibilityacrossthesupplychain. AchievingfullSCVinvolvesacustomer-centricapproachthat willentailtheperfectamalgamationoftechnologyandprocesses todeliverarichcustomerexperience.

“Supplychainvisibility(SCV)isthetrack-abilityortraceability ofproductordersandphysicalproductshipmentsfromthe productionsourcetotheirdestination.Thisincludeslogistics activitiesandtransportaswellasthestateofeventsand milestonesthattakeplacebeforeandduringtransit.

TheobjectiveofSCVistoenhanceandempowerthesupply chainbymakinginformationeasilyaccessibletoeachandevery stakeholder,includingcustomers.TheintegrationofSCVtoolsor systemsenablesdifferentsupplychaindivisionsinan organizationtoacquirereal-timeandpreciseinformation regardingstock,orders,anddeliveriesintheirincomingand outgoingnetworks.”

Supplychainvisibilitydoesn’tbeginorendwithjustthe transportationoftheproduct.Oneofthethingsthatisoften forgottenisthatahugeamountofefforthappensonthecargo procurementside.Withoutprocurement,theproductwouldnever makeittothesalesfloor.Theprocurementofcargoiscomplex andhistoricallytherehasbeena lackofaccessibledatatomake itmoreefficient.

According to a study that was carried out in June 2017,amere6 %ofcompaniesareabletoofferSCV.Whileeveryonewantsto

Katherine Barrios is the Chief Marketing Ofcer of Xeneta with close to 20 years of B2B international product marketing, enterprise sales, tech PR/communication and product management experience from various software industries.

Previously, Katherine was at The Qt Company (Digia, Nokia, Trolltech) as the Director of Global Marketing for the Qt cross-platform software development framework, where she led the global demand generation, communication, product and developer marketing strategy.

Prior to that, she worked at Unit 4 Agresso as Marketing Communications Manager with focus on product marketing and communication and at Opera Software as PR Manager. She also held positions earlier in her career as Account Executive at Weber Schandwick Worldwide PR (Tech Group) and Howard R. Miller Communications, both in Miami, Florida.

Katherine holds a Bachelors of Science in Communication from the University of Miami, graduate studies in Media and Journalism from the University of Oslo and Project Management Executive Studies (M.Sc) from Boston University. Barrios is a native of New Jersey, U.S.

achieveit,thereisstillsomewaytogobeforecompanies cancompletelydeliverfullSCV.A2017surveyof623 supplychainprofessionalsin17countriesdescribedtheir challengeswithvisibility:

Ÿ

70%offirmsdescribedtheirsupplychainas“very”or “extremelycomplex”

therefore,willenableacompanytocreateareputationand anedgeforitselfinthemarket.

Ÿ

6%saidtheyhave“fullvisibility”totheirentiresupply chain

Ÿ

74%saidtheyusefourtofivedifferenttransportation modesintheirsupplychain

81%offirmsareusingonetothreeKPIstoassess supplychainperformance Ÿ

Ÿ

84%outsourcetheirtransportationservices

Source:Geodis2017SupplyChainWorldwideSurvey

AchievingfullSCVistoughandisn’tachievedovernight. There’samisconceptionthatmerelyimplementing technologytoolswillsolvethechallenges.Thesupplychain ismuchmorecomplexthanthat.Variousmodesof transportcoupledwithalackofoperationalstandardsin manypartsofthechainmakeSCVhardtoachieve,butnot impossible.

ThisiswhatSCVlookslikeandcanaddtobusiness:

Anorganizationneedstofactorinvariousaspectsorderto achievecompleteSCV.Theseincludeanalysis, collaboration,information-sharing,andthemostcrucial aspect-efficientandquickdecisionmaking.Anefficient teamthatcanworkoptimallytodissectinformation, communicatewithsuppliersandbusinesspartners,and modeldifferentoutcomeswillcontributetothegreatest degreeofSCV.Adoptingananalyticalapproachtodata willensureimprovementincurrentsupplychain performanceandalsoaffordanunderstandingoffuture demands.Inturn,themoredatathatiscollectedwill extendfurtherimprovementtothesupplychainprocess, andoptimizedemandforecastingandbusinessplanning. Monetarybenefitscanbeachievedbybeingabletoreduce inventorywhendemandisexpectedtobelow,thereby improvingon-timedeliveriesandrespondingmorequickly topotentialissues.

Ÿ

Theabilitytoinstantlyaccessvitalinformation Ÿ

Anenhancedprocessefficiencywithrespecttoend-toendbusinessprocesses Ÿ

Customerrequirementsaddressedthroughreal-time visibility

Transparencyandtheabilitytoviewsupplychain“blind spots” Ÿ

Ÿ

Optimizedlogisticsandtransportationefficiency Ÿ

Greaterresponsivenesstocustomers Ÿ

Moreefficienthandlingandexecution Ÿ

Lowerlaborandmaterialcosts Ÿ

Efficientstockmanagement Ÿ

Improvedbusinessmetricmonitoringandoutcomes

Foroceanfreight,SCVcanbeachievedthroughconnected vesselsandcontainertracking,aswellasthroughrate benchmarkingwherecargobuyersgaininvaluableinsights onaspectssuchassupplierandcarrierperformance.

Suchvisibilitycanbeagamechangerwhenshippers choosewhichcompanytogowithtoshiptheircargo. Completevisibilityandtransparencywillamounttocost savings,anincreaseinreliabilityandproductivityand,

In2014,JeffDobbs,GlobalSectorChair,Diversified IndustrialsandapartnerwithKPMG,said,“obtainingrealtimevisibilityacrossalltiersinthesupplychaincan significantlyincreasespeedtomarket,reducecapital expendituresandmanagerisk.”Hewentontomakethis profoundstatement,“movingtowardademand-driven supplychainisprobablythesinglemostimportantstepa globalmanufacturercantaketoday.”AccordingtoForbes, “beyondvisibilityissupplychainorchestrationthattakes theserviceimprovementsandinventoryreductionstothe nextlevelwherebybalancingsupplyanddemandisnot merelyimprovedthroughfasterleadtimes,butthesupplydemandmatchingprocessisactivelyandcollaboratively managedonanongoingbasis.”

Itisimportanttonotethatbestinclasscompaniesare becomingquick,flexibleandusingtheirvisibilitywithin thesupplychainasacompetitiveadvantage.Intoday’s scenario,acrossindustries,supplychainvisibility consistentlyranksnearthetopasthemostnecessaryaspect topropelabusinesstoachievemaximumsuccess.

Today,businessesfunctionina globalenvironment.Buildinga brandthatdeliverstheright producttotherightbuyergloballyat therightpricerequiresdiligentSupply ChainManagement(SCM).Allareas ofoperationsareimpactedfromdesign toprocurementtomanufacturingand delivery. Multinationalcorporations, globallyexpandingbrandsand manufacturersrequiresupplychain riskassessmenttoensurelegaland ethicalsourcing.Ensuringacompany’s mostvaluableasset–it’sbrand reputation–isprotected.Leading corporationsseekstrategicSCMto maximizetheircustomers’valueand achievesustainablecompetitive advantage.Fornearlyadecade,Source Intelligencehasledtheindustrywitha solutionthatusestechnologyto simplifysupplychaincomplianceand bridgethegapbetweentraditionalonsitediligenceandascalablesupplier riskassessment.

SourceIntelligenceisamarket-leading SaaSsolutionscompany,focusedon supplychaincompliance,data analytics,andriskmanagement.The company’suniqueblendofexperts, technologyandprocessachieveshigh responseratesinsecuringand verifyingcriticalsupplierinformation. “Usingtechnologytocategorize suppliersbyriskallowsBlue-Chip Companiestooptimizetheiron-site auditresources”,commentedJess Kraus,CEOandco-founderat SourceIntelligence.Thecompany bringsvisibilityintotheSupplychains

ofcompaniesglobally.By doingso,itensureslegal andethicalsourcingwhile seekingtoeradicate atrocitiesthatharmpeople andtheplanetsuchas moderndayslavery,toxicwater,and deforestation.

JessF.Kraus,CEOandco-founder, underwhoseleadership,Source Intelligencehasbecometheleading providerofinnovativesupplychain compliancedataservicesandsolutions. Hehasover30yearsofexperiencein thefieldsofenvironmentalprotection andsustainability.PriortoSource Intelligence,Jessfounded3E CompanyandservedasaPresident, CEOandlastlyasaViceChairman.He isavisionaryandabuilderinmany businessandcivicorganizations, includingYoungPresidents Organization/WorldPresident’s Organization(YPO/WPO)andtheSan DiegoBusinessInnovationCenterand

JessF.Kraus CEO&Co-founder

wasrecentlynamedCEOoftheyear anda“ProtoKnow”.

TheSourceIntelligenceplatform deliversaflexibleandhighlyscalable globalsupplychainsolution.This centralizesasupplier’ssupplychain informationonasingleplatform, simplifiescompliance,enables transparencyanddrivesdecisionswith data.Suppliers,partners,vendors, smallbusinesses,andglobalbrands cansecurelyandproactivelyaddress theircomplianceandtransparency needs.

Thiscloud-basedplatformincludes:

Ÿ

Multi-tier supply network,where Companiesatanytierofthesupply chaincanconnecttotheir

customersandsuppliers,thus creatingatruesupplychain network.

Ÿ Supplier request workflow,which enablesquickandeasy implementationofanyprocessfor supplychaindatacollectionat corporateorproductlevel.

Ÿ Supplier Data Sharing,afully featuredmulti-languagesupplier platformthatincludesfeaturesfor usersgloballytoself-admintheir complianceprograms.

TransformingRoadblocksintoa RobustPlatform

Accordingtocompaniesworldwide, theproductsafetyandsocial compliancewithinthecontextofa cross-borderanddecentralizedmarket placeisakeychallenge.While traditionalretail,withfixedlocations andclearsalesterritoriesenables stricterenforcementofcompliance withinacountry’sregulations,a border-lessmarketplacehasledtoa supplierreviewchallengeofglobal proportions.Onlyatechnologyenabledapproachcancost-effectively addressthisproblem.

Compoundingtheissue,arapidly changingregulatorylandscapecreates significantroadblocksforbrandsto keeppacewithcompliance requirementsacrosstheglobe.To addressthisneed.SourceIntelligence conductedroundtableswithtop industryinfluencerstobecomeboth,an educatorandaleader,inbuildinga robustplatformthatwaseasily adaptabletoanyindustrystandard, customizedcompanyrequirementsor

regulatedcomplianceneedinany market.Itenablesallcompaniesto monitorandcontroltheproduct complianceandsocialcomplianceof thebrandstheyseektoprotect. Theplatformcomprisesoffeaturesthat covers:

Ÿ

Allowscustomerstomovepastthe collectionofhard,rawdataand allowsforautomation,evaluation, analyzation,andstreamlined implementation

SourceIntelligencehasa global network whichassistssuppliersto overcometheirresistanceandfatigue. TheteamatSourceIntelligence comprisesof dedicated experts with deepexperienceinsupplychain, complianceandtransparency.

Ÿ

Allowsforcustomizationby customer/industry,and implementingnewprogramsand collectingdataexactlythewayitis requested

Ÿ

Detailedsupplierengagement metricsallowingusersto understandsuppliersthatareatrisk andthosethatarehighlyengaged

TheSourceIntelligence platform that centralizescompliancesolutions. Throughthisplatformthecompany enablesitscustomerstooptimize supplierrelationshipbuilding,data collection,qualitycontrol& management,andcustomizable assessments.Apartfromthese,italso providessuperior&intuitivesupplier interfacetoitsclientshavingaliveand personalizedsupportwithproven, robustandaudit-testedprocesses.The company’s strategic data analytics and visualization processensures automatedflagsforreporting inconsistenciesandrisk.Bydoingso, customerscangetcustomizable programsandtailoredviewsfortheir riskcategoriesofinterest.

Theemergingtechnologiesare influencingbusinessestoadoptnew innovations.Similarly,theimpactof thosetechnologieshasstimulated SourceIntelligencetoo.Asaresult,the companyisworkingtobringArtificial Intelligence(AI)intothecompliance world.Although,itisacomplexand laborintensivetask,thereisanatural fitinbringingAItobeartohelpits customersachievegreatercompliance overalargersupplychainwithless resources.Leadingthewayinthisarea, thecompanyhascollectedamassive amountofdataandrawmaterials information.

Beyond2018,SourceIntelligenceis lookingforwardtoadoptblockchain technology.Thetokenizationsystemof blockchainagitatedcompanymore thanitsimmutableledgerfeature.This iswhereSourceIntelligencebelieves theblockchaintechnologyholdsgreat promiseforincentivizingcompliance activitiesinthesupplychain.

Our mission is to use technology to disrupt traditionally laborintensive approaches for bringing visibility and compliance to supply chains of companies around the world.

Nowdays,itisessentialfororganizationsto developavitalrelationshipwiththeirsuppliers toeffectivelymanagetheirsupplychain.Dueto primaryfocusoncustomerrelationshipmanagementand highersales,enterpriseshistoricallymayhave overlookedtheopportunitiesandbenefitsthatbetter SupplierRelationshipManagement(SRM)candeliver. Howeverthisischangingandmanyorganizationshave startedrealizingtheimportanceofbuildingstrong relationswiththeirsuppliers.Thisrealizationhasturned intotheneedforstreamlinedandimprovedprocesses betweenbuyers(organizations)andsuppliers,and organizationsarestrivingtocreateinnovativestrategies toeffectivelymanagetheirsupplychain.However,very fewcompaniesaroundtheglobehaveprovenexcellence indeliveringinnovativesupplierrelationship managementstrategies.OneofthemisStateofFlux,an expertindeliveringsupplychainandSRMsolutions.

HeadquarteredinLondon,UK,StateofFluxhasbeen supportingclientsinprocurementforover14years.It hasgrownintoaleadingprocurementandsupplychain consultancy,providingcontractlifecyclemanagement, categorymanagementandstrategicsourcing,and suppliermanagementservices.Itworkswithclients globally,andhasofficesacrossEuropeandAsiaPacific.

Thecompanyhelpslargeorganizationsachieveboth financialaswellasnon-financialbenefitbyworkingwith strategicsupplierstoidentifyinnovativeand

AlanDay Chairman&Founder

collaborativewaystocompeteinaneverchanging marketenvironment.

AnAdroitLeadership

AlanDay,ChairmanandFounder,isresponsiblefor StateofFlux’smajorclientaccountsanddevelopingits businessoutsideoftheUK.Havingenteredprocurement andsupplychainwithadesiretolearnabout organizationsoperationsfromcustomerneedto fulfillment,henowhasover25yearsofexperiencein designingandimplementingbestpractice.

PriortofoundingStateofFluxin2004,Alanheldroles asDirectorofProcurementandSupplyChainatCable& Wireless,andDirectorofAccenture’sSupplyChain EuropeanCentreofExcellence,wherehisclients includedBritishAirways,Shell,Microsoft,BSkyBand MorganStanley.

AlanstartedhissupplychaincareeratFisher&Paykel, theleadingNewZealand-basedmanufacturerof domesticappliances.Hispassionforlearningistruly appreciable.Toretainhispassion,heiscurrently undertakingacourseonblockchainatOxford University.

AnAwardWinningCollaborativePlatform StateofFluxprovidesacollaborativeplatformcalled Statessformanagingsupplierrelationships,performance andproductivity.In2012,itbecamethefirstSRM

softwaresolutiontoreceiveaGartner CoolVendorAward.Itwasalsothe firstcompanytointroduceafully integratedsupplierinnovation capabilityin2013.Morerecently, StateofFluxwaspresentedaSpend Matters‘CompanytoWatch’award andwasnominatedforthe ProcurementLeadersCollaboration Award.

Throughthisnovelplatform,Stateof Fluxenvisionscontinuingtofocuson growthandinnovationinsolutions thathelpdriveproductivityacross clients’suppliermanagement programs.Italsostrivestoexpandits partnerecosystemofbest-in-class providersofspendanalysis, sourcing,P2Pandsustainability/ corporatesocialresponsibility (CSR).

StateofFluxunderstandsthateach clientisdifferentandthereforetheir offeringsaretailoredtothe organizationstheyworkfor.They havelearnedsomethingnewand overcomenewchallengeswitheach andeverypastproject,supporting procurementfunctionswith procurementtransformation, navigatingcomplexorganizations, helpingtoraiseexistinglevelsof

maturity,readinessfordeployment andmanagingresistancetochange. Everyprojecthasaddedtoits experienceandstrengthenedits proposition.

StateofFluxisgrowing internationallyandenvisagehelping moreclientswithsupplier managementandsuppliertechnology challenges.Accordingtoasurvey carriedoutbythecompanyinits annualSRMresearch,8outof10 globalcompaniesarelookingto drivebenefitsfromsupplier innovation.Torespondtheseneeds, itscollaborativeplatform,Statess 2.0,licenseandsupportpackages offerflexibleplanswhichenable organizationstoapplytechnologyto theareasofutmostbusinessneed. Packagesstartwiththecoreelements ofrelationshipmanagement includingaspaceforcollaborative workingforbothbuyers’andsellers’ andadynamicdashboardoflivedata showingthestatusofthe relationship,whichistailored dependingontheuser.

StateofFluxhasmorerecently createdaflexiblechoiceofmodules foritscustomersintermsof performance,risk,contracts,

innovation,CSR,program management,benefitsmanagement andcategorymanagement.Thisisa scalableapproachwherean organizationcanstartwith performanceandaddriskor contractsmanagementlater.

Longerterm,StateofFluxbelieves thatsuppliermanagementis becomingmoreofaprofessional disciplinewithitsownsetof qualifications,structureandcareer path.Withtheemergenceof technology,thecompanyis observingthatmoreorganizationsare optingforsuppliermanagementasa serviceandembracingsupplier managementtechnology.Within thesetechnologiesthereisfurther emergenceofAIcapabilityandblock chainopportunitiesincludingsmart contracts.Thecompanyisinvesting intheseareasandenvisions deliveringsmarterprocurement solutionstohelpclientsmeetthese needsworldwide.

We have a mission to make SRM easier to implement and operate for our clients, helping them to become a customer of choice and reap the benefits from this.Cardenas President TOC Logistics

Thelogisticsandsupplychainmanagementindustry isonethatisconstantlyevolvingandoptimizing, andbecauseofthecompetitivenatureofthe industry,innovationiskeyforsuccess.Modern technologieshavenotonlyaidedinthestreamliningof supplychainsandcompanyprocesses,buthavealsosetthe industryonatechnologicallyadvancedpaththatmany couldnothaveevenimaginedfifteenortwentyyearsago. Fromroboticsinwarehousesandautonomousshipsand trucks,tocomputerizedshippingandtracking,technology haschangedtheindustryforthebetterandhasprovided newlevelsofvisibility.

Withtheaidoftechnology,supplychainsofthefuturemay beabitmorecomplex,butwillcertainlybemoreefficient andlessexpensive.Afewofthetechnological advancementsthathavechangedthegameforthelogistics andsupplychainmanagementindustryare:

ComputerizedShippingandTracking Moderntechnologyhasdrasticallyimpactedtheshipping industryandhasmadeformoreefficientandaccurate tracking.Withawidearrayofdifferentsupplychain managementsoftwareprogramsonthemarket,logisticsand supplychainprofessionalsandtheirclientsareabletokeep aneyeontheirshipmentsduringeverystepofthesupply chainjourney.Witheverysecondbeingcrucialintheworld ofsupplychainmanagement,theabilitytoprovide completetransparencytoclientsintermsofwheretheir packagesareandwhentheywillarriveissomethingthatis extremelyvaluable.

Computerizedshippingandtrackinghasalsolargely reducedtheamountoftimespentshipping,receiving, trackingpackagesandcompilingshipmentdata,asall necessarydatacanbestoredinoneeasy-to-accessplace. Andinthiscase,savingtimemeanssavingmoney.Being abletodigitallyorganizedataandmonitorshippingand trackinginformationalsoreducestheopportunitiesfor humanerror.Withdigitalrecordsthereisnolongeraworry thatsloppyhandwritingoramisplacedpieceofpaperwill throwawrenchinashipmentbeingdeliveredontime,orto therightplace.

Abigtechnologicalpushintheindustryrightnowisthe advancementofautonomousvehicles,electrification,useof solarpower,andenergystorage,allofwhichwillbeused acrosstheboardtobothreducecostandincreaseefficiency. Rightnow,energyandtransportationmakeupmorethan halfoftotalsupplychaincostsandlaboraccountsfora littlelessthanathirdofcosts.Withfurthertechnological

advancements,thetransportationandlaboraspectsof supplychainswilleventuallycostvery,verylittlecompared towhattheydotoday.

Theeventualimplementationofautonomouselectric vehicles,whichcanbeprogrammedtousethemostefficient routesandrunthroughoutthenightwithoutadriver,will drivedownthecostoflaborandincreasecapacityonthe roads.Autonomousvehicleswillalsoaddressthegrowing concernoftruckdrivershortagesthroughouttheindustry.

Alsoontheverynearhorizonistheuseofautonomous ships.Autonomousshipswouldaddresstheissuesofpiracy, talentshortageintheoceanshippingindustryandaccidents causedbyhumanerror.

Logisticsandsupplychainmanagementprofessionalslive anddiebydata.ArecentstudybytheCouncilofSupply ChainManagementProfessionalsshowsthat98percentof third-partylogisticsfirmsand93percentofshippersfeel thatdata-drivendecisionmakingiskeytosupplychain activities.Technologicaladvancementshavemadeit extremelyeasytogatherandanalyzekeypiecesofdata.

Datasurroundingshippingtimes,cargoweight,weather patterns,trafficroutes,andmorecanleadtogreater transparency,optimizedroutes,greaterreliabilityand automatedsupplychains.Havingateamthatisableto accuratelyinterpretbigdataiskeytosuccess,andwill likelysaveacompanybothtimeandmoney.Thereisa reasonUPSdriversdon’tmakeleftturns.Someoneonthe UPSteamanalyzedlargeamountsofdata,whichisnow availablethankstotechnology,anddeterminedthat eliminatingthemajorityofleftturnswoulduse10million lessgallonsoffuel,emit20,000tonneslesscarbondioxide intotheairandhelpdeliver350,000morepackagesevery year.

Technologyissomethingthatishardtopredictandoften difficulttowrapyourheadaround,butthelogisticsand supplychainindustryisbenefitingfromeverynew technologicaladvancementinourfield.Thesupplychains thatweareworkingwithtodaywillbedrasticallydifferent infiveortenyears’time,andalmostunrecognizablein twentyorthirtyyears.Technologyhasmadesupplychain managementmoreefficient,transparentandcost-effective. Itisimportanttohavemembersofyourteamthatare willingtoembracenewwaysofdoingthingsandthatare abletostayup-to-dateonnewformsoftechnology.This industryisconstantlychanging,andinordertobe successfulyouneedtobewillingtochangealongwithit.

Tocompetentlygrowandexcelinanever-changing market,organizationsarelearningtorelyonsupply chainmanagementandautomatedsolutionsin healthcareandlifescience.

TersoSolutions,Inc.providesautomatedinventory managementsolutionsfortrackinghigh-valuemedicaland scientificproductsinthehealthcareandlifesciences industries.

Tersohasover14yearsofRFIDproductdevelopmentand implementationexperience,anditsproductlineincludes RAINRFIDcabinets,refrigerators,freezers(-80Cto-20C), smartrooms,andmobilesolutions.Tersohasdeployedover 2,100RAINRFID-enabledsensorsworldwide.

JoePleshekisthePresidentandCEOofTersoSolutions. Hejoinedthecompanyin2007andhasoverseenrapid growthwhileprovidingstrategicdirectionandfinancial management.Joeiscommittedtoadoptingthemost advancedRFIDtechnologysothecompany’spartnerscan bettermanagetheirsupplychains.

PriortojoiningTerso,Joeheldseveralsales,marketing,and generalmanagementpositionsatAppletonPapers.During histenurethere,heledthedevelopmentofanRFIDtag convertinglinewhichcreatedanentirelynewbusiness

revenuestreamforthecompany.Healsomanagedan acquisitionforAppletonthatwasbasedintheUnited Kingdom.

Joehasworkedat3MCorporation,wherehewastasked withintroducingseveralnewproductandserviceofferings. Thatexperienceallowedhimtoexpandhisbusiness developmentskillsconsiderably.

JoeholdsaBachelorofSciencedegreeinIndustrial TechnologyfromtheUniversityofWisconsin,aswellasa MastersofBusinessAdministrationinMarketingfromthe UniversityofSt.Thomas.

TersodevelopsRFID-enabledtechnologyincluding hardwaresuchascabinets,refrigerators,freezers,mobile cases,handhelddevices,andsmartstockrooms.Italso maintainsaCloud-basedplatform,Jetstream,onwhichits partnerscandeveloptoolsformonitoringandmanaging theirRFID-enableddevices.

Theorganization’sultra-lowtemperaturefreezersarethe onlyoneoftheirkind.Theyprovidereal-timetemperature monitoringcapabilitiesforhealthcareandlifescience organizationstomanagehighvalueassetsliketissue, implants,andsupplies.

Tersoworkscloselywithallofits clientstoenablethemtomeettheir goalsandrespectivecustomerneeds. MostoftheseclientsofferRFID solutionsundertheirownbrand,while Tersocollaborateswiththemtodeliver therightsolutionstofurtherincrease theirefficiency.

Allpartnersreceiveextensivehands-on trainingandcontinuedsupportfrom thecompany.Tersobelievesin outstandingcustomerserviceandis constantlynavigatinguncharted territoryinordertodeliversmart, provensolutions.

Tersopridesitselfonacompany culturededicatedtocollaboration, opportunity,respect,andfun.It believesincultivatinganenvironment thatbreedspositiveenergy,onethat creditsinnovativesolutionstopeople whoworkwelltogetherandactively helpeachothersucceed.

Theorganizationiscommittedtothe developmentofcutting-edge technologyandfindingthebest possiblewaytosolvesupplychain issuesthataredetrimentaltoitsclients. Itemployssmart,creative,andhard-

workingindividualswhocontinuously strivetofindinnovativesolutions.

Theworldofhealthcareand technologyisalwayspushingthe boundariesofwhatispossible.As technologyandRFIDadoption continuestogrow,Tersostrivesto remainagileandcreative.The companyisevolvingwiththelatest technologyanddevelopingnew, innovativesolutionsthatdrivevalue andsolvecomplexproblemsforits customers.

Itwasonlyafterbigretailstoreslike WalmartandMacy’simplemented RFIDtechnologythatitbecamewidely known.Retail’suseofRFIDhas acceleratedtheadoptionofthis technologyinmanyothersectors.The growthofitsuseinhealthcareisstill onthecuspofthetechnologyadoption lifecycle,andthereisalotofroomto expandinto.

“I read a report by Intel that inventory distortion represents approximately $818 billion worth of lost retail sales per year. The stakes are even higher in healthcare. Imagine the impact of removing waste worth billions of

dollars from the healthcare supply chain annually!” Joeenthuses.

TersobelievestheInternetofThings (IoT)willcontinuetoexpandasa technologytrendandwilltransform healthcaremarkets.Internet-connected devicesandsensorswillautomatically providereal-timedataonthelocation andconditionofpeopleandthingsthat worktogetherinahealthcaresupply chain.

Thiswillcontinuetoprovidea seamlesswayforhealthcare organizationstomeetregulatory guidelines,increasesavings,and improvepatientoutcomes.

Thecompanyremainscommittedto providingsolutionsthathelpits partnersachieveefficiencyand optimizationfortheirsupplychains, throughthedevelopmentofbothnew hardwareandsoftware.

Joesumsup, “Technology will never stop advancing, and neither can we. Terso will always make sure we are offering the best and most useful solutions to help solve complex problems.”

We are committed to being the market leader in the development and application of RAIN RFID solutions that enable healthcare and life science organizations to better manage their supply chains.

Astechnologyplaystherolemodelinourlives,in thesameway,itisandwillbeundoubtedly,the drivingpowerofthebusinessworldtoo.Those, whowillprovetobeinnovative,canonlythinkaboutbeing inthecompetition,others,strictlyoutofit!

Innovationisthecurrencyofbusinesstoday.Noonecares aboutthepast,butlovestoflauntthenewinventionastheir asset.Soisthesameabouttheinnovativenessinthe business.Themoreinnovativeideaisplacedbefore,the morethecompanygetsapplaudedandgrabstheeyeofthe customer.

Well,thereareafewcommonquestionswhichhammerour mindwhennewslike,GoogleorAmazonhaslaunched somenewproductorsomenewbusinessmodelgetflashed. ButWhy?What’stheneedofnewinnovationswhenthey havesomeoftheirmasterproductsorservicessomuch applaudedbytheaudiences?

Well,theanswerresidesinthequestionitself,theclients needsomethingnew,somethinginnovative,andsomehighqualitystuffallthetime.Thisisthereasoneverycompany hastobealwaysreadywithsomerevolutionaryideasto luremoreclientstowardsthem.Thiscreatesthespacefor innovation.Butyes,thereisn’tjustonereasonbehindthe needforinnovationbutmany.

Itisveryobvious,andanyprojectmanagerwillsharewith you,thebuiltuppressureafterasuccessfullaunchofany newproduct.Immediatelyafteralaunch,fewweeksare spentoncollectingandanalyzingthedataaboutcustomers likesordislikesoftheproduct.Once,donewiththedata collection,customersstartrequestingforthefeatures.What

theprojectmanagerdoesafterthatistoreleasethemost desiredfeaturesofallforthecustomersandleavetheleast admiredforthefuture.

Now,thethingisthoughyouhavesatisfiedthecustomers withtheirdesiredfeaturesbutithasonlymadetheirwork easy.Now,it’stotallycompanies’dutytosearchfor somethingnewsomethinginnovativetomakecustomers’ lifetransferfromeasytoeasier.Ifcustomersgetoffered somenewfeaturesbysomeothercompany,obviouslythey willoptforthem.Thatisthereason;everycompanyneeds tobepromptwhenitcomestoinnovativeness.Stayingup todatewithinnovativenessforthecustomersdemandis whatcompaniescando.Companieshavetoinvestin innovativenesstosatisfythefutureneedsofthecustomers.

Well,therealcompletiontodayisnottherivalcompanies butthestart-upssproutingupeverysingleday,witha hilariousnewsolutionfortheclients.Onthisground,allthe companiesneedtogearupwiththeirbestinnovativeteams. Becausethesestart-upsknowsonlyonethingandthatisto servetheircustomerswiththebestinnovativeservicesto takeadiveinthecompetitionwiththeexperiencedones.

Now,thealreadysuccessfulcompaniesgetonlyoneoption andthatistobeinnovativewiththeirownproductsand servicestoretaintheirpositioninthefiercecompetition withtheyoungones.Well,thesecompaniesalsohave anotheroption,whichwehavewitnessedbeforeandthatis toacquirethestart-ups.Evenwiththisacquisitionthese companiesareonlyacceptingthenewinnovationandgoing onintheirjourneytosatisfytheneedsofthecustomers.’

So,thepointsdiscussedaboutcanbethe‘Why’of innovation.Now,let'sseesomeofthe‘How’ofinnovation. Allthebigcompaniesinthebusinessworldhavesome commoncharacteristicsinthem,whichis‘How’ofthe innovation.Itisonthebasisofthesecharacteristicsthat thesecompaniesareontopoftheinnovationchart.The innovationsmadebythesecompaniesaretotallycustomercentric.Theuseoflatesttechnologiesanduniquewayof solvingaproblemiswhatmakesthemontopofthe competitionchart.So,herearesomeofthecharacteristics oftheinnovativecompanieswhichmakethemstandoutof thecompetition.

Innovativecompaniesalwayscherishinnovativeculturein theircompany.Innovationisneveranaccident.So,the companieshavingrightprocesscanonlycomeoutwiththe rightideas.Itisnotatallnecessarythattheinnovative employeecanbeonlyamongtheR&Ddepartmentorthe onewhositsintheboardroom.Theemployeeswhoare actuallyimplementingtheplancanfetchthebestidea. Innovativeideascanusherfromanydepartment,letitbe

marketingorcustomercare.Thatisthereasonthese companiesgiveequalchancetoallnurturingthebest cultureforinnovation.

Innovativecompaniesdonotmeasurecustomersasonlythe usersoftheendproductbut,valuesthemtobeagoodidea enablertoo!Ifcustomersgetinvolvedintothedesigning processtheycansuggestanideawhichisreallyimportant andvaluableinmakingofaproductorsolution.Innovative companiestakecustomersinputinthewholeprocess.This helpstoknowthecustomerrequirementinadvancemaking theproducteasilyaccepted,assoonasitgetslaunched.

Yes,beinganinnovativecompanystartswiththestarting phaseofthecompany.Togetcountedamongthemdepends onhowwellyouknowthe‘Why’and‘How’ofthe innovation.