Aswestepinto2025,theglobalsupplychainindustrycontinuesto

undergoaseismictransformation,shapedbymajortechnological advancements,evolvingmarketdynamics,andanintensifiedfocuson sustainabilityandresilience.Thiseditionof TheCIOConnectspotlights The 10 Visionary Leaders Transforming the Supply Chain Industry, 2025 celebratesthetrailblazerswhoarenotjustnavigatingthesechangesbutleading thewaywithinnovativesolutionsandstrategies.

FromleveragingAIandIoTtorevolutionizelogisticstoembracingcircular economyprinciplesforagreenerfuture,theseleadersareredefininghow supplychainsoperate.Theirvisionextendsbeyondefficiencyandcosteffectiveness—theyarecommittedtobuildingecosystemsthatareagile, transparent,andethicallyresponsible.

Inthisedition,wedelveintothejourneys,achievements,andforward-thinking initiativesoftheseremarkableindividuals.Theirstoriesinspireustorethink possibilities,challengethestatusquo,andpushtheboundariesofwhatthe supplychaincanachieveintheyearsahead.

Wehopethiseditionservesasbothasourceofinspirationandatestamentto thepowerofvisionaryleadershipinshapingthefutureofglobalcommerce.

DeputyEditor AnishMiller

ManagingEditor PrinceBolton

Visualizer DaveBates

Art&DesignDirector DavisMartin

AssociateDesigner JamesonCarl

SeniorSalesManager WilsonT.,HunterD

CustomerSuccessManager JohnMathew

SalesExecutives Tim,Smith

TechnicalHead PeterHayden

TechnicalConsultant VictorCollins

ResearchAnalyst EricSmith

SEOExecutive AlenSpencer

Antonio Larranaga Supply Chain Director

Anurag jaiswal

Execu�ve Director Supply Chain Systems & Analy�cs

Bhavesh Joshi

Execu�ve Director for Manufacturing, Supply Chain and Engineering Services

Chris Lundy Director, LBS - Supply Chain Prac�ce

David Hamlet Division Director, Supply Chain

Donny Lombardi Supply Chain Director

Gaurav Goyal Director - Supply chain Design & Planning

George Thompson Director, Semiconductor Supply Chain Prac�ce

Company Name

ASSA ABLOY Opening Solu�ons assaabloy.com

Larranaga is noted for his innova�ve approaches and significant impact in his professional endeavors, inspiring many in his field.

Imran Ali Director, Supply Chain

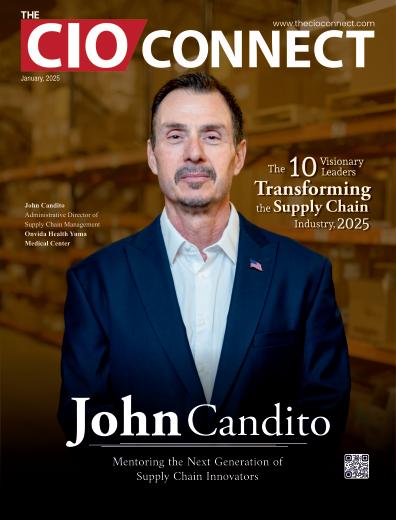

John Candito

Administra�ve Director, Supply Chain Services

UChicago Medicine uchicagomedicine.org

Jaiswal has gained recogni�on for his exper�se and dedica�on, contribu�ng to advancements in his area of specializa�on.

WonderBotz wonderbotz.com

Joshi is celebrated for his crea�ve insights and leadership, driving posi�ve change and innova�on in his projects.

Lean Focus leanfocus.com

Su�er Health su�erhealth.org

AGC Chemicals Americas Inc. agcchem.com

Coupa Supply Chain, powered by LLamaso� coupa.com Genpact genpact.com Aramark aramark.com

Lundy is acknowledged for his strategic vision and effec�ve execu�on, making a notable difference in his professional landscape.

Hamlet is recognized for his though�ul leadership and impac�ul contribu�ons, shaping the future of his industry with integrity

Lombardi is respected for his collabora�ve spirit and problem-solving abili�es, fostering teamwork and success in various ini�a�ves.

Goyal stands out for his analy�cal skills and commitment to quality, enhancing opera�onal efficiencies across mul�ple pla�orms.

Thompson is dis�nguished for his influen�al presence and ability to inspire others through mentorship and guidance in his profession.

Ali is recognized for his contribu�ons in various fields, showcasing a diverse skill set and a commitment to excellence.

Onvida Health onvidahealth.org

With a strong background in supply chain management, John plays a key role in op�mizing procurement strategies, streamlining logis�cs, and ensuring opera�onal efficiency. His exper�se supports Onvida Health's mission to deliver high-quality healthcare solu�ons with reliability and cost-effec�veness.

“ “

John’s approach focuses on collaborative relationships with internal stakeholders and external partners to enhance value-driven processes.

JohnCandito

AdministrativeDirectorof SupplyChainManagement

OnvidaHealthYumaMedicalCenter

SupplyChainManagementisessentialacrossall industriesinmanagingtheflowofgoods,services, andinformationtomeetorganizationaldemands whileoptimizingcosts.Overtheyears,thisfieldhasgrown, incorporatinginnovativetechnologieslikeartificial intelligence,automation,andSixSigmatoenhance efficiencyandresilience.Inhealthcare,theSupplyChain ensuresthatessentialmedicalsuppliesandequipmentare readilyavailabletosupportqualitypatientcare.Integrating advancedstrategiesandtechnologiesredefinestheSupply Chain’sfunctiontoachieveseamlessoperations,minimize disruptions,andprovidestrategicsupporttoorganizations' long-termgoals.

JohnCandito,theAdministrativeDirectorofSupply ChainManagement@OnvidaHealthinYuma,AZ,isa transformativeleaderknownforhisstrategicplanningand dedicationtobuildingeffectiveSupplyChainmodelsthat meetoperationalandfinancialobjectives.Hisapproach focusesoncollaborativerelationshipswithinternal stakeholdersandexternalpartnerstoenhancevalue-driven processes.Withacommitmenttoservantleadership,he activelymentorsfutureSupplyChainleadersandpromotes accountabilitywithinhisteam.Throughhisproactive guidance,Johnensuresthathisdepartmentsupports organizationalneedsandcontributesmeaningfullyto healthcareSupplyChaininnovation.

OnvidaHealthYumaMedicalCenterbenefitsnotably fromJohn’sexpertiseashedevelopsandimplements sophisticatedSupplyChainstrategiesthatalignwiththe organization’smissiontoBuildaHealthierTomorrow throughhigh-qualityhealthcare.Hisroleincludesmanaging resources,optimizinginventory,supportingcostsavings andadoptingtechnologiesthatdriveefficiencyand resiliencewithinthehospital’sSupplyChainoperations.As aleaderinhealthcareSupplyChaininnovation,Onvida HealthYumaMedicalCenterstrivestobeattheheadof modernizingSupplyChainpractices,focusingonareas suchasonshoring,AI-drivenpredictability,andcompetitive resourcemanagementtomeetgrowingindustrydemands, andachievingasustainableimpactonhealthcaredelivery

Let’s explore John’s advanced supply chain strategies: AdaptingSupplyChainAcrossIndustries

John’sjourneyinSupplyChainManagementbeganin1999 whenhejoinedaleadingAerospaceandDefense

organization.ThatorganizationpracticedSupplyChain Managementveryeffectivelyandearnedmanyawards, recognitions,andachievementsinitsSupplyChain practices.Havingthatexperienceandmodeltoleanonhas guidedJohnthroughhisSupplyChaincareerinall industriesthathehasworkedin.

Thefoundationofwhatdefinesworld-classSupplyChain Managementiswhathehaspushedtoachieveinevery organizationhehasworkedfor.Afteroveradecadeinthe Aerospaceanddefenseindustry,Johnleftandhadashort stayinthecommercialindustrialindustrybeforelandinga careerinhealthcare.Throughallofthesemoves,he believesSupplyChainisSupplyChain;it’sjusthowyou applyittodifferentindustries.Therearealotofdifferences andalotofsimilaritiesatthesametime.

Inhisrole,Johnstrategicallyplans,directs,anddevelops theSupplyChainmodeltomeetoperationalandfiscal objectivesrelatedtosupplies,services,equipment, inventorymanagement,logisticsmanagement,human resourcemanagement,newtechnologyassessments,and othersupportmanagementfunctions.

Hedevelopsandmanagesanannualbudgetandsupports balancedscorecardmeasuresbycreatingprojectsthatalign withorganizationalgoals.Heforgesandbuildsstrong, trustingrelationshipswithinternalstakeholders,clinical leaders,peers,suppliers,andcommunitypartners.His strategiesanddirectionshelpOnvidaHealthYumaMedical CenterachieveitsmissionofBuildingaHealthier Tomorrow.

John’sleadershipstyleisservantleadership,withan emphasisondrivingaccountability.Hehasanopen-door policyandisavailabletoallteammembersanytime.He believesinsettingapositiveexampleasarolemodel, providingreal-timefeedbackandknowledgesharingto teammemberstohelpguidetheirjourney,creatingand supportingtheireducationalopportunities,andprovidinga visiontomakethefollowingsuiteofleadersfortheSupply Chaindepartment.

Johnbelievesinaccountabilityandbeingaccountablefor performanceandresults.Hehaslearnedalotoverhis careerfromwatchingotherleaders,bothgoodandbad,and pickingupthosekeytendenciesandattributesthatdrive

With a commitment to servant leadership, John actively mentors future supply chain leaders and promotes accountability within his team.

success-whileavoidingonesthatdeterioratetrustand enablebadoutcomes.Hehasbeenveryfortunatetohave somegoodpeopletomodel-startingwithhisparents-and hefeelsheowesthemallrecognitionforbecomingthe leaderheistoday

LeanandSixSigmaphilosophieshavehighlyinfluenced John’sleadershipwithintheSupplyChainindustry.Hewas anearlyadopterofSixSigmainhisAerospaceandDefense days,whenanewCEO,DanBurnham,joinedthe organizationandimpresseduponallbusinessunitleadersto drivestrongSixSigmaparticipationthroughtheir organizations.

JohnhasseenthevalueofLeanandSixSigmathrough theirmethodical,process-drivenapproaches.Hebelieves thatalwayshavinganeyeforcontinuousimprovement allowsonenottomissthelittlethingsthatcanmakeabig difference.Healthcareisanindustrythatwas/islaggingin theimplementationofSixSigma,andJohndrivestodohis parttofillthatgapandcreatecompetitiveadvantagesfor theorganization.

JohnrecentlyattendedanationalSupplyChainconference inPhoenixasanindustrypanelmember,wherethis discussioncameupaspartofastrategysession.

ThechallengeintheSupplyChainisforeverysupplierto be100%ontime,withnear-perfectquality,everytime.

Whenyouconsiderthenumberofvendorsatafirst-tier levelthatanorganizationdependson,andthenfactoringin allofthelower-tieredsuppliersdowntotherawmaterial thatsupportsthefirst-tier’ssuccess,alongwithallthe resourcemanagementandconstraintissuespost-COVID, it’shardtoenvisionwhatsuccesslookslike.

Theparadigmbecomesverylargeveryquickly Tobea successfulSupplyChainleader,youmustknowthatthere willbeanotherurgentsituationemerging—whetherfroma naturaldisaster,aportstrike,manufacturerbackorders,the nextpandemic,andthelistgoesonandon.Creatingaplan toworkthroughthoseurgentissueswhentheyariseiswhat makesaSupplyChainleadervaluable.Preparednessiskey.

Specifically,Johnbelievessomeofthechallengesoverthe nextonetotwoyearswillbeunderstandingandadopting whatmakessenseintheAIworldandapplyingittoSupply Chainpracticesforbetterpredictability,forecasting,supply savings,etc.

Additionally,howorganizationswillhandlethefineline betweenglobalsourcingforthelowestcostversus reshoringoronshoringforthelowestrisk(whatwas learnedduringCOVIDwasaglaringdeficiencyinthis space)iswhathebelievesthebestorganizationswilldoto figureouthowtocreateamodelthatfindsabalance betweenthesetwostrategies.

Johnbelievesmaintainingahealthywork-lifebalanceis essentialintoday’scultureasorganizationsdemandmore fromleaders.Hefeelsit’simportanttounderstandthatit’s impossibletobehighlyeffectiveatworkifoneisnothappy outsideofwork.Johnfocusesonfamilyfirstandstays involvedinasmanyfamilyactivitiesaspossible.

Johnalsoreliesonhobbiesthathehashadformostofhis lifetokeephimgroundedandprovideasenseofreprieve whenhe’sawayfromwork.Ashardasheworks,hewants toplayequallyhard,andthatbalanceisreallyimportantto him.Timeisnotaninfinitecommodity;eachpersononly hassomuchofit.

Hebelievesit’simportantnottoletthelittlethingsinlife getinthewayandtoholdontothethingsonetrulyloves. Aleaderwhocanachievethisbalancesuccessfullywill servetheirorganizationexceptionallywellandnotlivewith regrets.

ForJohn,thekeytosuccessishiring,mentoring,and developingastrongteamofleaderswhocanmanagethe departmentandhandleanyday-to-dayeventswhilehe’s away Thatsecurityallowshimtobeawayfromwork withoutfear,worry,orconcernoveradverseoutcomes.

AccordingtoJohn,stayingattachedandinvolvedwith leadingorganizationssuchasAPICS,ISM,AHMMA,and othersallowshimtoalwayshavethelatestSupplyChain informationathisfingertips.Inthischangingworld,staying updatedwithcurrenttrends,practices,andstrategies impactingtheSupplyChainindustryisveryimportant.

Johnreliesonanetworkofclosepeers,educational institutions,andprofessionalaffiliationstomakethis possible.HeisalsoanavidreaderofSupplyChain publications,andheusesallofthesedifferentavenuesof informationtocreateandalignstrategiesthatfitwithinor complementOnvidaHealth’sspecificmodel.

“

John focuses on family first and stays involved in as many activities as possible.

“

Canditohighlightsthatcurrenttrendsshapingthefutureof SupplyChainManagementincludeartificialintelligence, onshoring,strategicpartneringwithsuppliers,findingways fortheSupplyChaintoaddvalueatthebottomline,and understandinghowthesevariablescontributetoproviding value-basedcarethroughouttheSupplyChain.

Theabilitytoworkwithvendorsandcontinuetoachievea value-basedcareapproachischallengingascosts continuallyincreaseacrosstheeconomy,laborcostsare escalating,andpayerreimbursementislagging.Someeasy winsavailableyearsagohavemovedon,andnewsavings opportunitiesaremoredifficulttoidentifyandachieve.

Atriple-aimapproach—specificallyaroundreducingper capitacosts—requiresmoreintricatestrategiesand approachesthanwerehistoricallyachievable.Thenew modelinvolvespartneringwithmanufacturers, sophisticatedcontractingstrategies,andincludingclinical teamstoshareinallaspectsofSupplyChainexecution.To achievemaximumbenefitandoutcomes,physician involvementandalignmentarecrucialinthisspace.

John’sadviceforsomeonelookingtobeginacareerin SupplyChainrightnowwouldbe:

1. Getanexcellenteducationfromaleadingglobal SupplyChaininstitution.Severalexcelinthisspace, andmorecollegesandUniversitiesareaddingSupply Chainasamajor.

2. Doaninternshipandasmuchmentoringaspossible withdifferentorganizationsthatexecutetheirSupply Chainsatalevelthatisbenchmarkedbyothers.

3. Understandtheimpactthatsupplycostscanhaveon anorganization’ssuccess.Supplycostsaregenerally thesecondlargestcostinanycompany,behindlabor

4. Understandthatthisindustryisnotforthefaintof heart.Youwillbechallengedthroughoutyourcareer, andjustwhenyouthinkyou’vefiguredoutthesecret sauce,somebodywilldropahairinit.Manytimes, theSupplyChainisathanklessindustry.Beingstrongwilled,adaptableandresilientisparamounttosuccess.

InJohn’sview,theSupplyChainhasgrownoverthelast quartercenturyfromadepartmentwherethingswere simply“tossedoverthewall”forpurchasestohappento nowbeingseenasanintegratedandstrategicpartofan organizationthatcanimpactbottom-lineperformancealong withtheoverallsuccessofanorganizationintermsof publicopinion.Therewillneverbeadullmoment,and plentyofupsideandrewardarepossible.

Overthenextfewyears,OnvidaHealthYumaMedical CenterwillexploredifferentstrategiesinwhichtheSupply Chainisnolongerjustacostcenterbutcanalsoengagein therevenue-generatingsideofthebusiness.

TheOnvidaHealthcaresystemisdevelopingsomeexciting newstrategiesintheSupplyChainspace.Whenthese strategiescometofruition,theycouldpositivelyimpact healthcareacrosstheindustry.Atalocallevel,thefocusis alwaysonrefiningandimprovingoperationalcapabilities andstrategies,controllingcosts,andprovidingtop-notch supporttoourclinicalpartners.

Inthenewyear,OnvidaHealthwillbeimplementing automation,AI,robotics,andothertechnologiesthatwill enablethesystemtoalignwithitsgoalofbeingaworldclassSupplyChainorganization.

Today,efficiencyandaccuracyareeverything,and

thesupplychainindustryisundergoingalargescaletransformation,allbroughtbytechnology. Theseinnovationsallowoperationstooptimize workflowsandtakegoodsandservicestothedoorsofthe ultimateusersdifferently.Inthisblog,weexplorehow technologyiscompletelychanginglogistics,opening multipleavenuesforbusinessestofindgrowthinthepostpandemicera.

ArtificialIntelligencewithPredictiveAnalytics

ArtificialIntelligenceisrevolutionizinglogisticsthrough intelligentdecision-making.AI-enabledpredictive analyticsgivesbusinessesthepowertoforeseedemands, optimizestocks,andefficientlyplanroutes.Thesetools provideinsightintocustomerbehaviorsothatcompanies candeliverabetterlevelofexperience.

Machinelearningalgorithmsarenowdeployedtoanalyze patternsinsupplychaindatatohelpcompaniesdiscover inefficienciesandsuggestsolutions.Thisreduceswaste andensuresresourceutilizationisoptimized,hence enhancedproductivity

BlockchainTechnologyforTransparency&Safety

Blockchaintechnologyoffersthemosttransparent solutionforlogistics.Everytransactionoractivitywithin thesupplychaincanbestoredonimmutablerecords withintheblockchain,furtherpromotingtrustamong variousstakeholderswhileminimizingactsoffraud.

Smartcontractswithintheseblockchainsystemsenhance transactionefficiencybyautomatingthetransactionprocess oncethepre-definedconditionsaremet,reducinghuman contact.Forexample,ashipmentcanbereleasedonlyupon payment,minimizingdisputesoverdeliveriesandensuring theseamlessmovementofcargo.

TheInternetofThingsisrevolutionizinglogisticswithits capabilityforreal-timemonitoringanddataacquisition. Sensorsfittedintotrucks,vessels,andstorageunitsprovide informationontheconditionandlocationofthegoods. Thus,thisensuresproperstorageconditionsforperishable goodsandtimelydeliveries.

Furthermore,itcanmonitortheremainingusefullifeand performpredictivemaintenanceonalllogisticsequipment. Thismonitoringofwearandtearallowsissuestobe resolvedbeforetheyescalateintomoresignificantproblems andleadtoabreakdown,effectivelyminimizingdowntime andenablinguninterruptedoperations.

Sustainabilityhasbecomevitalinlogistics,wherein companieshavebeenadoptinggreentechnologiestoreduce theircarbonfootprint.Someexamplesofthetransition towardssustainabilityinlogisticsareelectricvehicles, solar-poweredwarehouses,andenergy-efficientmachinery

Advancedrouteplanningtoolsthatallowminimumfueluse arebeingemployed.Byfollowingthemostefficientpaths andavoidingcongestedroads,thesetoolscontributeto savingsinbothcostsandtheenvironment.

Bigdataisheraldedasastrongassetinlogistics.By analyzingalotofdatafromdifferentsources,organizations haveagreaterchanceoffindingtrendsandmakingbetter decisions.Amongtheseareundertakingoptimalsupply chainroutes,facilitatingwarehouselayoutre-design,and enhancingaccuratedemandforecasts.

Thedatavisualizationtoolswillpresentintricate informationineasilyreadableformats,highlightingthe opportunitiesforimprovementforallstakeholdersatonce.

Includingroboticsinwarehouseenvironmentsischanging howgoodsarestoredandpicked.Fullyautomatedstorage andretrievalsystems(AS/RS)involveroboticshuttlesthat manageinventory-relatedactivitiesprecisely These systemssavetimeandminimizeerrors,helpingwarehouses ventilateattheirmostefficientstates.

Besides,cobots,orcollaborativerobots,aredeveloping alongsidehumanworkersinfunctionstohelpthemlift repetitiveworkingscenarios.Theyincreasetheir productivityandfacilitatethetransitionofhumanworkers tomorestrategicfunctions.

Technologyhasinducedatransformationalchangein logistics.Itservesthegoodwithsignificantpositive impactsbutalsoposessomechallenges.Relevant underlinedinvestmentis,however,thehighcapitalfor whichcompanieshopingtoutilizethesenewersystems needtoconsiderthemselves.

Goinghandinhandwithsuchinvestmentsistheintegration ofthesenewtechnologieswiththecompany'sexisting infrastructure,whichrequirescarefulplanning.Other aspectscategoricallyincludetheincreasingneedfortrained humanresourcestooperateandmanagesuchnewsystems.

Technologyisredefininglogisticsinunprecedentedways, enablingefficient,transparentandsustainablesupply chains.InnovationssuchasAI,Blockchain,IoT,and Roboticscreatenewprospectsforthewaygoodscannow beproduced,transported,anddelivered.

Whilechallengesmaystillprevail,themeritsofthese technologiesarelucidlylaidbare,andwhatbusinessesmay profitfromattaininginarapidlychangingworld.These changesushertheopportunityforcompaniestostrengthen servicedeliveryanddevelopanewlevelofexcellencein thelogisticsindustry

Asglobalsupplychainscontinuetoevolve,theintegration

ofenergy-efficientpracticeshasbecomecrucialindriving sustainabilityandreducingenvironmentalimpact.Inan era,whereclimatechangeandresourcedepletionarepressing concerns,businessesacrossindustriesareincreasinglyfocusingon energyefficiencyasakeydriverforbothenvironmental responsibilityandcostreduction.

This article explores various strategies for enhancing energy efficiency within supply chains, from manufacturing upgrades and transportation optimization to sustainable packaging solutions and collaborative efforts across partners.

Energy-efficientproductionandmanufacturing

Oneofthemoststraightforwardwaystoimproveenergyefficiency inmanufacturingisbyupgradingoldequipmentwithnewer,more energy-efficientmodels.Forinstance,modernmachinesareoften designedtoconsumelesselectricitywhilemaintainingoreven improvingproductionspeeds.Replacinginefficientmotors,pumps, andboilerswithmoreefficientalternativescansignificantlyreduce energyconsumption.

Leveragingautomationandprocessoptimizationtechniquescan leadtosubstantialenergysavings.Automatedsystemsthatuse sensorsandreal-timedatatocontrolproductionprocessesenable manufacturerstoeliminatewaste,reduceidletime,andimprove theoverallefficiencyofmachinery.Smartfactorysystemspowered bytheInternetofThings(IoT)canautomaticallyadjustoperations basedonenergyconsumptionpatterns,ensuringthatenergyisused onlywhennecessary.

Oneofthesimplestandmosteffectivewaystoreduceemissionsin transportationisbyoptimizingdeliveryroutes.Usingdata-driven software,companiescanplanthemostefficientpathsfortheir vehicles,consideringfactorssuchastrafficpatterns,road conditions,andweather.Byreducingtraveldistancesandavoiding congestion,businessescansavefuel,reducetraveltimes,and loweremissions.Theefficiencyofthevehiclesusedinlogistics operationsplaysasignificantroleinreducingemissions.

Byinvestinginfuel-efficienttrucks,electricvehicles(EVs), orhybridvehicles,companiescandecreasetheirrelianceon fossilfuelsandreducetheiroverallcarbon footprint.Intermodaltransportationinvolvesusingmore thanonemodeoftransporttomovegoods,suchas combiningroad,rail,andseatransport.Railandsea transportaregenerallymoreenergy-efficientthanroad freight,especiallyforlongdistances.

Forexample,usingrailforlong-haulshipmentsandtrucks forlast-miledeliverycanloweroverallfuelconsumption andemissions,whileensuringtimelydeliveries.Intermodal systemscanalsoreducecongestiononhighwaysandlower thewearandtearonroads.

Acommoninefficiencyinlogisticsistheunderutilizationof vehiclecapacity.Byconsolidatingshipmentsand optimizingloadsizes,businessescanreducethenumberof tripsrequiredtotransportgoods.Advancedlogistics softwarecanhelpcompaniestrackshipments,identify opportunitiesforconsolidation,andensurethatevery vehicleisloadedtoitsoptimalcapacity Thisreduces emissionsperunitoffreighttransportedandimproves overallresourceutilization.

Theintegrationofdigitaltechnologies,suchasreal-time tracking,predictiveanalytics,andInternetofThings(IoT) sensors,hasrevolutionizedlogisticsmanagement.These technologiesenablebusinessestomonitorthemovementof goods,trackvehicleperformance,andidentify inefficienciesinrealtime.

Oneofthemosteffectivewaystoreducetheenvironmental impactofpackagingisbyminimizingtheamountof materialused.Companiescanoptimizepackagingdesignto usefewerresourceswhilestillensuringproductprotection andcustomersatisfaction.Forexample,reducingthesizeof packagingcancutdownonthematerialsneededfor production,aswellasreduceshippingvolume,leadingto lowerfuelconsumptionandemissions.BrandslikeApple andUnileverhavealreadymadestridesinreducing packagingsizeandmaterialuse,leadingtosignificant environmentalbenefits.

Moderntechnologiesandinnovativedesignsarealso helpingcreatemoresustainablepackagingsolutions. Companiesareturningtopackagingmadefromrenewable resources,suchasalgae-basedplasticsorplantfibers, whichhaveasmallerenvironmentalfootprintthan

traditionalplastics.Additionally,“smart”packaging solutions,whichincludefeatureslikeRFID(Radio FrequencyIdentification)tagsorQRcodes,helpreducethe needforexcesspackagingmaterialwhileimproving producttrackingandshelf-lifemanagement.

Oneofthemostsignificantshiftsinsustainablepackaging isthemovetowardreusablecontainersandsystems.For example,businessescanadoptamodelwherecustomers returnpackagingforreuseinsubsequentshipments.This approach,oftenseeninindustriessuchasfoodand beverageore-commerce,reducestheneedforsingle-use packagingandhelpskeepmaterialsincirculation.

CompanieslikeLoop,whichhaspartneredwithmajor brandstoofferreusablepackagingforproducts,have pioneeredthistrend,offeringamodelthatbenefitsboth consumersandtheenvironment.

Collaborationamongsupplychainpartnerscanhavea transformativeimpactonsourcingpractices.Companies canworktogethertoensurethatrawmaterialsareethically sourcedandproducedwithminimalenvironmentalimpact. Forexample,manufacturers,suppliers,andretailerscan collaboratetoestablishsustainablesourcingpoliciesfor commoditiessuchastimber,palmoil,andmetals,ensuring thatthesematerialscomefromcertified,sustainable sources.Thiscollectiveeffortcanmitigatedeforestation, promotebiodiversityconservation,andreducecarbon emissionsassociatedwithresourceextraction.

Inconclusion,enhancingenergyefficiencyacrosssupply chainsisacriticalsteptowardachievingsustainability goalsandreducingenvironmentalimpact.Byupgrading manufacturingequipment,optimizingtransportationroutes, adoptingsustainablepackagingsolutions,andfostering collaborationamongsupplychainpartners,businessescan significantlyreducetheircarbonfootprintandresource consumption.

Theintegrationofinnovativetechnologiesandeco-friendly practicesnotonlybenefitstheplanetbutalsoenhances operationalefficiencyanddriveslong-termcostsavings.As companiescontinuetoprioritizeenergyefficiency,theywill contributetoagreenerfuturewhileensuringtheresilience andcompetitivenessoftheirsupplychains.