VICIVISION

“IN THIS INDUSTRY, REPUTATION IS EVERYTHING. THE COMPONENTS THAT YOU SUPPLY MUST BE PERFECT” “The volume of parts produced had never been so high. So, the immediate need was to increase the amount of inspections to ensure a quality product”.

T

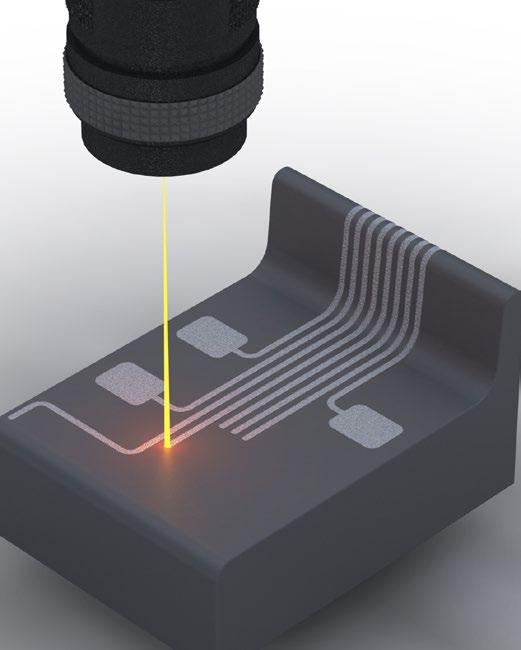

rust Precision Engineering produces precision components for the aerospace sector. In recent years it has invested considerably in quality and is now reaping the rewards of those investments: which includes a major increase in productivity. “My name is Nick Street, and I’m the owner of Trust Precision Engineering. The company was founded in 2012 to produce precision machined components, mainly for the aerospace sector. The volume of components we were producing meant we were struggling to keep up with the amount of inspections we would like to have done on a component. The immediate need was to increase the number of inspections to ensure a quality product.” To solve this conundrum, the company turned to VICIVISION UK, the official dealer of VICIVISION in the UK. TRUST Precision Engineering bought two VICIVISION Techno M304 machines which are designed to perform dimensional inspection on parts directly on the shopfloor, serving several machining centres. They can be used by more than one operator at the same time and measuring time is dramatically reduced as there’s no need to leave the shopfloor. “The return on investment will probably be 2 years for everything in this room. On a single VICIVISION alone, six months to a year, you’re going to get that return back.

radar and ends up being wrong, whereas with VICIVISION you can check everything externally, everything, so nothing gets missed.

When I bought my first machine, I saved £ 15,000. When I bought my second machine, I saved another £ 15,000. When I buy my third machine, I’ll save another £ 15,000.

Our slogan is “reputation is everything”, and in this market, reputation really is everything.

The machine keeps everything under control. Sometimes you can get so focused on a particular critical dimension or area of a component that sometimes something less critical goes under the 02 - AUTOMATION Mag - OCTOBER 2020

38

From a traceability point of view, you can save all the images every time you load a component and run an inspection, you can choose to save that image in a history file. So, in three months’ time somebody could come back to me and say they’ve potentially found an issue

with a component, we can pull up the images from that order number and literally measure the image again. It all started with a visit from one of the Vici representatives. And one year later, we bought two brand new ones to go in the new inspection room. The machines really are fantastic. It’s one less thing for me to worry about, it’s one more thing to give me confidence in what we’re doing.” https://youtu.be/H5A2Ws5G7RE www.vicivision.com