Historically, right from the time of the first Industrial Revolution that originated around two centuries ago, to the present era of Industry 4.0, technology has helped improve production and raise efficiency to unprecedented levels in industry. But even today, it is estimated that poor maintenance strategies reduce a plant’s overall productive capacity by 5 to 20 percent; the resultant unplanned downtime in turn costs manufacturers an estimated US$50 billion each year. In fact, ‘ The True Cost of Downtime’, a report released by Senseye, the leading global company for automated machine health management, estimates the direct and indirect costs of unplanned downtime to major manufacturers is up to a staggering US$1 trillion! These figures underline the importance of sound maintenance practices in industry today.

Maintenance of industrial machinery and equipment traditionally falls in three categories – reactive maintenance where assets are run to failure; preventive maintenance where the emphasis is on preventing problems before they occur; and predictive maintenance which goes a step further to predict or anticipate problems and take planned remedial action that increases plant reliability. Each of these three maintenance strategies has its advantages and disadvantages. Essentially, a company may adopt different types of maintenance services based on the value of assets as well as the seriousness of the situation should a breakdown occur. Most modern manufacturing plants have long abandoned the practice of reactive maintenance in favor of preventive maintenance and are now moving towards predictive maintenance. Since predictive maintenance monitors asset condition in real time and enables corrective actions before failures disrupt production, it is generally considered to be the most advanced and intensive type of maintenance. In other words, in the manufacturing ecosystem, predictive maintenance is now increasingly adopted as a strategy for dealing with unplanned machine downtime.

D’SILVA

Predictive maintenance increases manufacturing efficiency, saves on maintenance costs, and contributes to a healthy bottom line.

PREDICTIVE MAINTENANCE, ARTIFICIAL INTELLIGENCE AND

EFFICIENCY

There is no clear record of the origins of Predictive Maintenance (widely referred to as PdM) in industry, but it has been prevalent in some form or other for several decades now, with automation and use of sensors facilitating what is known as condition monitoring. Some accounts mention that predictive maintenance began with condition-based maintenance, and attribute it to CH Waddington, who was a biologist assigned to the UK’s Royal Air Force during World War II. It was his observation that planned maintenance actually increased breakdown in aircraft (termed Waddington Effect) that led to the concept of PdM based on condition monitoring, which dramatically increased aircraft availability. Others believe that though PdM existed in some form or other, it was only adopted widely from the 1990s by the manufacturing industry.

What exactly is condition-based monitoring on which predictive maintenance is based? Condition-based monitoring may be defined as a strategy that makes use of sensors and other tools to continuously monitor the condition of machines and assets to determine their ‘health’ and predict their condition to decide when is the right time to intervene with maintenance, without disrupting the regular production schedule. There are various types of sensors that record a wide range of data, such as sound/noise, temperature, pressure, vibrations and even conductivity, which enables an engineer to predict the failure of an asset while allowing it to be repaired or replaced in advance, before a breakdown occurs. Predictive maintenance helps maximise the life of an asset and reduce maintenance costs and equipment downtime. As a result, it finds extensive applications in manufacturing, energy and utilities, aerospace, defense, transportation and logistics, and healthcare industries worldwide. Used effectively, predictive maintenance increases manufacturing efficiency, saves on maintenance costs, and contributes to a healthy bottom line.

If one looks at the Google search result for predictive maintenance market, it shows a large number of reports with wide variations, depending on the scope and segments covered by the research agency. Some of these reports cover the entire spectrum, including utilities apart from all industry segments, which explains the variation. However, one thing is common across all these reports; the CAGR is in the range of 20-30%, which indicates a very rapid growth. For the purpose of this article, the report pertaining to the manufacturing segment makes better sense. According to a research report released by ResearchAndMarkets.com in early 2020, the global market for Predictive Maintenance for Manufacturing Industry, which was an estimated US$1.2 Bn in the year 2020, is projected to reach a revised size of US$3.9 Bn by 2026, growing at a CAGR of 21.4% over the analysis period.

This healthy growth in the PdM market is characterised by three trends:

• The intense competition in the manufacturing industry is forcing companies to exploit all avenues of increasing productivity and efficiency of their operations, and effective asset performance management is among the top priorities.

• Most companies are now in the process of digital transformation of their operations where maintenance is getting a technology led makeover with use of advanced data capturing and analytics tools that facilitates endto-end integration of PdM with the entire lifecycle of the industrial plant.

• Stringent workplace safety regulations and growing emphasis on occupational safety norms coupled growing awareness among the tech savvy workforce.

Among the leading vendors of technologies catering to PdM are global MNCs like General Electric Company, IBM Corporation, Siemens, ABB, Robert Bosch, Rockwell Automation, Schneider Electric SA, Dassault Systèmes, Software AG, Accenture plc, Cisco Systems, Hitachi,

Honeywell, Microsoft, and Oracle Corporation, not necessarily in the same order.

Speaking about the Indian market, Preshit Murudkar, Managing Director & CEO, Comau India Pvt Ltd, confirms the general growth trend. The “India Predictive Maintenance Market if considered in a holistic way is a big market and is growing at a CAGR of 25%. It is expected to reach US $4 Bn by 2026, and further with the evolution of 5G technology this will disrupt, and bring in a lot of opportunities,” he says. According to him, the market by deployment modes is divided between On-premise and Cloud, and by verticals, comprises: Government and Defense; Manufacturing; Energy and Utilities; Transportation and Logistics; Healthcare and Life Sciences; and others.

Nimish Danani, Director Consulting Services, Hitachi Application Reliability Centre, has a different set of figures, in conformity with the observation made earlier about the variations. “Going by various research and reports, the global market for predictive maintenance in the next 5 years will be about $16 Bn to $18 Bn. In the last estimate I read it is growing at about 30% CAGR. The Indian market for

predictive maintenance could inch up to $4 Bn in the next 4 to 5 years growing at about 25% CAGR,” he says.

If predictive maintenance is generally considered to be the most advanced and intensive type of maintenance, it has further reinforced this position in the age of Industrial Internet of Things (IIoT), with data analytics adding to its reliability, making it an ideal solution. While sensors were always part of predictive maintenance practices, their modern versions are highly evolved and become intelligent, and in combination with remote diagnostic tools and analytics software, make predictions even more accurate than ever before. In effect, predictive maintenance relies mainly on the data gathered by sensors and analysed to get insights that facilitate early fault detection.

With IIoT, every machine or equipment in the plant is equipped with internal sensors for constant monitoring of running status. This real-time data collection, analysis and simulation provides insights on equipment performance, based on which maintenance schedules are planned, without interrupting regular production. But how effective is data analysis in making the correct diagnoses without

missing anything of critical importance? Sensors typically collect humongous amounts of data of which almost all is of routine nature. The anomalies are hidden in a fraction of this data. So in the end it boils down to the quality of data analytics, which opens the doors for artificial intelligence (AI).

Artificial intelligence has wide applications in industry in the IIoT era thanks to its ability to make sense of the mountains of data generated by various sensors and devices. In ‘The True Cost of Downtime’ report quoted at the beginning, Senseye has demonstrated how by implementing AI-driven machine-health monitoring and predictive maintenance across large industrial organisations, it is possible to reduce levels of unplanned downtime by 50% and recoup investments in this technology in less than three months. In fact, predictive maintenance has been enriched and enhanced by the use of AI-powered algorithms which sift through the datasets gleaned from equipment history and maintenance logs. In a 2019 article published in Harvard Business Review, McKinsey partners Michael Chui, Nicolaus Henke, and Mehdi Miremadi have stated that in manufacturing, the greatest value from AI can be created by using it for predictive maintenance, thanks to its ability to process massive amounts of data, including audio and video, which means it can quickly identify anomalies to prevent breakdowns, whether that be an odd sound in an aircraft engine or a malfunction on an assembly line detected by a sensor.

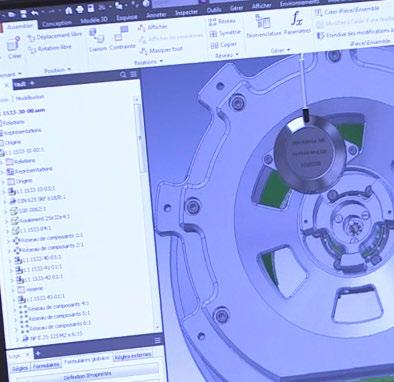

Dassault Systèmes offers its 3DEXPERIENCE® platform to manufacturers which contains a suite of collaborative digital solutions to boost workforce optimisation. The company believes manufacturers have only begun to capitalise on artificial intelligence (AI) and machine learning (ML) capabilities on the factory floor today, for driving overall equipment effectiveness (OEE), optimising processes and creating a pivotal role in predictive maintenance. “AI is required for effective predictive maintenance. With it, manufacturers can evaluate multiple inputs like usage, vibration and noise directly from the machine, compare that to historical events and forecast when a machine failure is likely to occur. It then schedules the appropriate maintenance activities at the last reasonable moment before the expected failure,” states Mike Bradford, DELMIA Strategic Business Development, Dassault Systèmes.

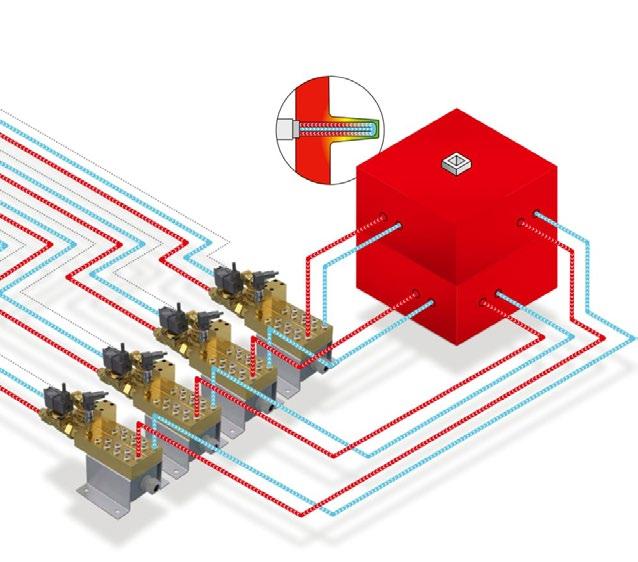

Global technology giant ABB, which uses its Ability platform for Predictive Maintenance of assets ranging from turbines to compressors and diesel driven generators to motors, is also using AI in what the company calls a hybrid approach that combines domain knowledge with machine learning algorithms. According to ABB, merely collecting data to detect anomalies is not enough because forecasting maintenance is not straight-forward. To effectively schedule maintenance, it is necessary to predict how a detected abnormal condition is likely to develop in the future. The innovative hybrid approach follows a three-pronged process:

• Condition monitoring that can provide early detection of faults

• Identification of specific failure mode(s) related to the fault detection, and

• Quantification of the extent of fault development to support maintenance planning.

Other technology companies are also riding the AI bandwagon when it comes to predictive maintenance. In January 2022, Siemens MindSphere® unveiled its first artificial intelligence application for industrial IoT called ‘AI for Everyone’, developed using the TIM InstantML technology from Tangent Works, a Belgian company. TIM, or Tangent Information Modeler, is an automatic predictive model building engine that automates the forecasting and anomaly detection process by analysing time series data and generating accurate models based on the patterns it detects. The aim of this new application is to reduce the technological barrier to powerful machine learning and AI tools. This no-code approach will allow people across manufacturing organisations to make informed decisions on future actions. “Thanks to the integration of Tangent Works’ InstantML technology, Siemens customers and partners can now better turn data into real and actionable insights and value. With the ability to use AI/ML to generate hyper-automated predictive analytics, even citizen data scientists can leverage data and achieve immediate insights, at scale. This ultimately reduces complexity and puts the power of IoT data in the hands of the user,” stated Raymond Kok, Senior Vice President of Cloud Application Solutions @ Siemens.

Schneider Electric, the global leader in the digital transformation of energy management and automation, has also demonstrated the use of AI-powered services through its EcoStruxure platform. It has documented a use case of the Nestlé Al Maha factory in Dubai of how the EcoStruxure technology evaluates data in real time from the plant’s electrical equipment and uses cloud-based predictive analytics to identify and resolve potential faults. With its open, scalable architecture, the EcoStruxure platform connects to smart devices across the electrical system and integrates with process control systems and enterprise data platforms. Data is analysed by cloud-based algorithms, and the solutions provide insights into equipment health and suggest predictive maintenance schedules, allowing for a proactive approach to asset management.

Comau, the Italian company, offers In.Grid, an innovative networking platform that combines digital and physical

worlds through sensorisation, data analysis and realtime monitoring of equipment, systems and production lines. The data collection, processing and connectivity is done at a machine level, line level or plant level, while the data analysis platform with its high-level algorithms, AI capabilities and storage features can be hosted at the plant itself, at an external data center or on a private cloud. “Our In.Grid platform is aligned with market needs from IIoT or Industry 4.0 point of view from both critical aspects. For End Product Traceability, the In.Grid MES solution is one of the flexible solutions using the latest technology of docker & microservices not only scalable but also portable, upgradable. This includes features starting from flexible User Management, Product Configuration, Flexible Connectivity with any device, Production Planning, Quality Data Traceability, Alarm Management, Cycle Time Analysis, OEE and ANDON,” says Murudkar. In its other role for Maintenance of Plant and Machinery, the In.Grid platform is easily configurable for monitoring and predicting health of the machines which are critical to avoid unplanned breakdown. “Features like Digital A/PM (similar to G-Calendar), Predictive Analysis with CBM Alarms (auto learning configurable and customisable algorithms), Machine Alarm Analysis, real time monitoring of health and alarms, make it ideal to leverage the power of Industry 4.0 in a cost-effective and highly efficient manner,” he adds.

So whether it is GE and its various predictive maintenance technology platforms for different sectors, or Rockwell Automation’s Predictive Maintenance as a Service offering that leverages FactoryTalk Analytics and apply machine learning technology, a variety of companies offer solutions in the predictive maintenance space. “From established large players to start-ups who have specific products, solutions, platforms for helping companies implement predictive maintenance solutions, thereby reducing downtime, improving yield, profitability and uptime for suppliers,” says Nimish Danani.

While established companies are all well entrenched in this space, there are the proverbial new kids on the block – the start-ups – that are now creating a niche with their boutique offerings of hardware and software solutions, or a combination of both. One such company is Infinite Uptime, which began product development in 2017 and entered the market with a solution in 2020. “As markets matured to the Industry 4.0 reality, more and more manufacturing industries realised the potential impact of predictive analytics and IIoT in their manufacturing operations. We had to quickly scale our teams to meet the global demand and maximise our reach and serviceability for our customers,” says Dr Raunak Bhinge, Founder and CEO – Infinite Uptime. The company has since added 190+ manufacturing clients across 14 industry segments across the world, as their Digital Transformation and Reliability Services partner. To date, it claims to have digitised more than 750 plants, saving 6300+ hours of downtime which has resulted in more than USD 20 Mn being saved by the businesses.

Nanoprecise Sci Corp is another start-up that specialises in the delivery of comprehensive, cloud-based solutions for the lifecycle monitoring of equipment, using IoT, AI and Data science applications. This automated predictive maintenance solution provider offers an integrated AI-based

solution that consists of a unique 6-in-1 IIoT sensor and an AI-based automated analytics platform. The wireless IIoT sensor measures Vibration, Acoustics, RPM, Temperature, Humidity and Magnetic Flux. The analytics platform utilises advanced signal processing algorithms to analyse the 6 streams of data in real time for predicting the remaining time to failure. The company was recently awarded first place in the Mobility and Automobile Innovation Lab (MAIL) programme by Maruti Suzuki India Limited (MSIL), India’s largest automobile manufacturer. The programme offers tech start-ups with digital innovations an opportunity to do a Proof-of-Concept project with Maruti Suzuki India Limited. “It can be very difficult to monitor the condition of various machines, especially when it involves cyclic-operations. With our AI-based solution, automobile manufacturers can rely on an automated system to monitor the health & performance of machines and equipment sets in near real-time. It offers the capability to detect minor changes in their operational parameters, monitor progression, and provide insights before they impact production or cause downtime,” stated Prashant Verma, Co-founder & Product Head, Nanoprecise Sci Corp.

With so much at stake, predictive maintenance, which has made rapid strides in recent years aided by emerging technologies, would be an essential component of maintenance strategies for most companies. Speaking about the most prominent emerging trends, Nimish Danani is of the view that with adoption of predictive maintenance, there is a lot of data being collected, analysed and AI applied to build models to start predicting failures and forecast more accurate maintenance updates.

“Based on our experience and exposure within the Automation industry the following features are the most sought after,” says Preshit Murudkar, listing them as:

• Data Traceability

• Predictive Analysis & Maintenance

• Remote Analysis & Maintenance

• Customised reports and charts, and

• OEE & ANDON.

Going forward, the sector will see increased investment in predictive data analytics based on AI and ML to minimise downtime and maintenance costs. While adoption of IoT is also a given, digital twins and AR/VR/XR are other emerging technologies that will feature prominently in predictive maintenance. Finally, more vendors would offer ‘Predictive Maintenance as a Service’ like Rockwell Automation, to make it easier for the user industries to benefit from a single source solution.

Mitsubishi Electric Corporation (TOKYO: 6503) is launching “Automating the World” as the global slogan for its Factory Automation Systems business from 7th November, with worldwide commercial use starting on 8th November.

The new slogan expresses Mitsubishi Electric’s goal to leverage automation for the betterment of global society by combining advanced technology, experience and know-how, and customer support as a trusted partner. “Automating the World” was developed based on the voices of numerous Mitsubishi Electric’s stakeholders from around the world, including customers in the field of industrial automation as well as company employees involved with Factory Automation Systems. For China in particular, the global slogan will be followed by a special subphrase “zizai linghuo”, which is a unique phrase created based on a similar local phrase meaning free and flexible, to support local understanding of the global slogan.

In recent years, global society has been compelled to adapt to the growing needs for work efficiency, digitalisation and decarbonisation. Under Mitsubishi Electric’s current medium-term business strategy through the fiscal year ending in March 2026, the company is growing its factory automation systems business with intelligent manufacturing solutions and other technological innovations that are enabling customers to respond to change by transforming their businesses. Mitsubishi Electric is also developing advanced automation technologies in other fields to enable global society to respond to pressing needs for change.

Going forward, Mitsubishi Electric will actively promote its “Automating the World” slogan to grow its Factory Automation Systems business and further enhance its brand value.

Automating the World - The story behind Life has become more complex and, to some degree, more confusing. Manufacturing, and from a larger perspective Society, has gone through huge challenges and resultant changes.

The most impactful have been the rapid adoption of digitalisation, the pressing need to become sustainable in all aspects, from energy consumption to pollution reduction, and the need to cope with shrinking populations in many nations. It is important to address these social issues in order to realise a sustainable global environment while striving to realise a safe, secure and comfortable society that respects all people.

Despite all these changes it is comforting to know that there are companies and partners you can rely on. Mitsubishi Electric has consistently focused on creating “Changes for the Better” for a vibrant and sustainable society through continuous technological innovation and ceaseless creativity. The company’s Factory Automation Systems team are proudly finding new ways through the application of advanced technology, sharing know-how and actively collaborating with one goal, of applying and utilising automation for the betterment of all.

This is why we want to clearly state in our global slogan, “Automating the world”, that we are not only helping a world of industries, but also a world of societies to apply automation for the greater benefit.

Mitsubishi Electric; “Automating the World” to create “Changes for the Better” for all.

https://emea.mitsubishielectric.com

Leading temporary power and temperature control company, Aggreko has announced its new One Europe strategy with a view to better supporting companies decarbonise through the energy transition, as well as addressing more immediate concerns to reduce fuel usage and costs.

Leading temporary power and temperature control company, Aggreko has announced its new One Europe strategy with a view to better supporting companies decarbonise through the energy transition, as well as addressing more immediate concerns to reduce fuel usage and costs.

At the helm of the restructure is newly appointed Nicolas Protais, Managing Director Europe, previously Managing Director of Continental Europe of nine years.

As industry strives towards a low-carbon future, Aggreko is already helping many companies to adapt effectively. Nicolas brings a wealth of expertise from previous roles which enables acute understanding of the challenges customers across Europe are facing and how best to compete.

Over the coming months, Aggreko will be continuing to help grow demand for low-carbon power and energy solutions which are already helping companies to lower fuel usage, environmental impact and reduce energy costs. New technologies such as Aggreko’s Stage V generators, hybrids and load on demand solutions have already proved successful in the UK and will continue to be invested in across Europe.

According to Aggreko, this new structure is already enabling them to help customers future-proof against forthcoming challenges via cross-geographical leaning. It is also seeing an increase in the uptake of decentralised energy solutions, where customers can generate their own, cleaner energy, with bespoke packages that can also provide more reliable power, as well as sending surplus energy back to the grid. As such, Energy as a Service (EaaS) contracts also appear to be becoming a more popular way of achieving this as it removes the barriers of high upfront capital investment.

Nicolas says: “I am excited to be leading this transformation in my new role as Managing Director for Europe, to build a low-carbon business over the coming decade. We have already come such a long way in the past few years, and our continued investment into innovations like Stage V generators, hybrids and commitment to a 100% switch to HVO are central to this.

“In order to create a ‘One Europe’ structure, I will leverage my international experience to ensure the merger of these successful two business units combine to be more than the sum of their parts. For me, partnership, communication, and collaboration are key to success, and these are qualities that are built into Aggreko. Our strength is in our people, and across Europe we have a deep pool of experience, relationships, and innovative solutions which I plan to leverage to the benefit our customers. With a shared vision and values, we are now better placed to share our technical capabilities without geographical barriers.”

www.aggreko.com

German Water Partnership e.V. is the only network in the internationally oriented German water sector and unites over 300 companies. The course for the future was set at its 18th General Assembly held in July 2022 in Berlin. Alexandra Ervenich, Corporate Account Manager Water at Mitsubishi Electric, was one of the members elected to sit on the GWP board for the next four years (2022-2026).

The topics of “Water. Climate. Change.” also dominated the network’s traditional annual conference held on 6 July 2022. Due to the reorientation of climate policy, the German water industry is increasingly dealing with the problems of climate change, sustainability, digitalisation and the resulting need for innovation.

A podium discussion and various workshop sessions gave the attendees the opportunity to network with each other as well as with representatives from the worlds of politics, business and science. Alexandra Ervenich: “Topics like reliability of supply, protection of resources and energy efficiency are currently the focus of our attention and are promoted by the GWP. In this, the latest digital technologies will make a significant contribution to climate and water protection.”

As a global player in the field of automation technology, Mitsubishi Electric has a long history of success in providing energy-efficient and sector-specific solutions for the water industry. In-house AI supports intelligent maintenance concepts, complex data analytics and process monitoring, thus making an important contribution to the achievement of climate targets.

The new board of GWP

The new board of German Water Partnership is made up of the following members:

• Dr. Michael Beckereit (Deutsche Wasser International GmbH)

• Axel Böcker (Dorsch International Consultants GmbH)

• Dipl.-Ing. (FH) Michael Drechsler (UFT Umwelt- und FluidTechnik GmbH)

• Eckard Eberle (elected in absentia, Siemens)

• Alexandra Ervenich (Mitsubishi Electric Europe B.V.)

• Prof. Dr.-Ing. Sven-Uwe Geißen (Technical University of Berlin)

• Ingo Hannemann (Hamburg Wasser)

• Georg Huber (HUBER SE)

• Michael Kersting (Hermann Sewerin GmbH)

• Dr. Michael Kuhn (Kuhn GmbH)

• Dr.-Ing. Shahrooz Mohajeri (inter 3 Institute for Resource Management)

• Dipl.-Chem.-Ing. Anja Rach (Enexio Water Technologies)

• Gunda Röstel (Gelsenwasser AG and Stadtentwässerung Dresden GmbH, chair of the board of GWP)

• Dr.-Ing. Gerd Sagawe (Dr. Weber & Partner GmbH)

• Dr.-Ing. Ursula Schließmann (Fraunhofer Institute for Interfacial Engineering and Biotechnology (IGB))

https://germanwaterpartnership.de

Innodisk has started developing strategy focusing on the AI market, and also launched the “Innodisk AI” Solution at a press conference in Taipei, Taiwan. Innodisk has amassed more than 1,000 successful cases worldwide since the business expand to AIoT in 2017. In the coming years Innodisk will expand its focus on AI development with subsidiaries, as well as its partners Intel, NVIDIA, Microsoft and ASUS IoT.

According to market research, the global AI market is anticipated to reach US$500 billion by 2023, and the demand for AI computing power is anticipated to increase by ten times before 2025. As AI gradually develops into a crucial infrastructure for growth and decision-making, it will become a major focus of future global technology development.

Innodisk is now aggressively expanding into the Edge AI market with three core strengths: absolute integration, application insight, and AI empowerment. These strengths will act as the core foundations to push Innodisk forward in the AI field.

At the press conference, Innodisk proposed a comprehensive artificial intelligence architecture, combining the data flow from cloud to edge, and integrating software and hardware technologies with heterogeneous platforms to drive industry intelligence innovation.

In recent years, Innodisk has spearheaded over 1,000 smart application projects. The company’s in-depth understanding of global industry trends and end-user application needs is its greatest advantage in facing market challenges.

Johnny Wu, Director of Innodisk’s Intelligent Peripheral Application division pointed out that “All AI development derives from the application requirements of the end user. When the application calls for it, it is necessary to collect, store and utilize high-speed and efficient data. Doing so lays out an important foundation for artificial intelligence. Ultimately, the road to further analysing and deducing huge amounts of data to achieve truly intelligent AI applications depends on the support of computing technology.”

The foundation of Innodisk’s technologies has always been data. In order to provide a comprehensive technical framework in data collection, transmission, computing, storage, and learning, the company is continuously empowering products with AI. The business has continued to introduce ground-breaking products like InnoAGE, InnoOSR, and InnoBTS.

Now, Innodisk has further formed alliances with international manufacturers such as ASUS IoT, Microsoft, Intel, and NVIDIA to expand technical collaboration, integrate various heterogeneous platforms and AI computing technologies, and create a new Innodisk AI Solution. With innovative AI architecture, integrated remote management, support from third-party software vendors (ISVs), OS operating platforms and Innodisk’s software and hardware solutions, customers are able to integrate AI solutions quickly and effectively.

Innodisk Chairman Randy Chien said “Innodisk AI not only provides more possibilities for future AI applications, but also accelerates the implementation of intelligent applications in vertical markets. We will actively create AI solutions for applications such as smart city, smart retail, industrial intelligent automation and smart medical.”

https://www.innodisk.com/index

New partnership agreement helps to move Europe closer to large-scale battery cell production. “Industry and government both agree on the need to establish battery cell production in Europe. It

essential to meet demand and establish production independence for the EU trading bloc.” Roald De Meyer, Co-Founder at Novali.

The signed memorandum of understanding between Belgium based battery company Novali and industrial automation solution supplier Mitsubishi Electric Europe B.V. demonstrates quite how soon that agreement may be realized.

Novali was set-up to finance and deliver multiple “giga factories” across Europe, with production scheduled to start in 2025. In order to meet these deadlines Novali has signed a technology partnership agreement with Mitsubishi Electric Europe.

“The relationship will encompass fast deployment of existing automation solutions for battery cell production, and then collaboration to build the value chain for the next generation of batteries manufactured in Europe.” Klaus Petersen, Director Lithium Battery Industry EMEA, Mitsubishi Electric Europe BV.

Mitsubishi Electric has long term experience in supplying automation solutions in the lithium cell manufacturing industry in Asia, and a well-established customer base of machine builders in Europe. While the value chain in Europe still needs to be built up, the partners aim at creating a network of local machine builders capable of delivering a complete cell manufacturing line at gigawatt hour (GWh) scale. The focus will be on building best in class cells while avoiding wastage within the process, something that has so far been a challenge in the sector.

“Lithium battery cell manufacturing is a relatively new field in Europe that is being built-up quickly. Any lessons already learned by our partners that we can take advantage of can help us to reach start of production (SOP) quicker. Scalingup a factory to GWh capacity is ambitious and Novali sees this as an opportunity to build up a local value chain. That is why this project is so important in our opinion as the whole European electrification initiative will profit from that.” Thomas De Clippeleer, Co-founder.

The company also believes that its mission goes beyond commercial necessities and extends to the general challenge of sustainability. The target is to achieve CO2

is

neutral manufacture of batteries. One of the key aspects is reducing consumption of energy and raw materials, which is also why a high-level of factory automation is required. The cell manufacturing process itself is challenging and Mitsubishi Electric’s automation solutions have already proven how well they can manage this task, setting high production quality standards while still prioritizing energy efficiency.

Big plans and the benefits of being agile “Novali provides a platform for scaling up manufacturing of next generation battery technology. On the one hand we partner up with technology companies that are frontrunners in their respective field, and on the other hand we work together with automotive and industrial partners like Mitsubishi Electric for developing the supply chain and bringing the batteries into mass production.

As a startup, we are agile and able to quickly set up collaborations with technology companies. This allows us to jointly offer automotive vehicle OEMs flexibility and a future-proof mix of different technologies.

We plan to manufacture four generations of battery cells. Lithium iron phosphate (LiFePO) or (LFP) cells for lowcost market segments, state-of-the-art nickel manganese cobalt (NMC) cells transitioning to high voltage cathodes and silicon anodes for mid-market segments. Solid state or lithium metal batteries we predict will enter the market at a premium.

Another important aspect is that the batteries should be available at a high volume. This requires record investments in cell manufacturing and the downstream supply chain. We are working together with global investment funds and

industrial partners setting up joint ventures with automotive companies to achieve this. Manufacturing equipment and general factory automation is a crucial element in the supply chain. Mitsubishi Electric has decades of experience supplying automation products to all the incumbent cell and equipment manufacturers in Asia. The goal of this alliance is to tap into this expertise for establishing a local ecosystem of European manufacturers.” Roald De Meyer.

Novali is a cell manufacturing company serving the mobility and energy storage markets. We offer technology companies a platform for scaling next-generation battery technology. Our mission is to contribute to the realization of the energy transition by increasing the energy and power densities and reducing the cost of batteries. We believe batteries should be manufactured CO2 neutral, relying on local supply chains and recycled materials. We also believe that industry should serve the general wellbeing of people and find it important that Novali, as a direct employer and indirectly through the employees of our suppliers and through the local communities we impact, serves this purpose.

www.novali.energy

https://emea.mitsubishielectric.com/en/

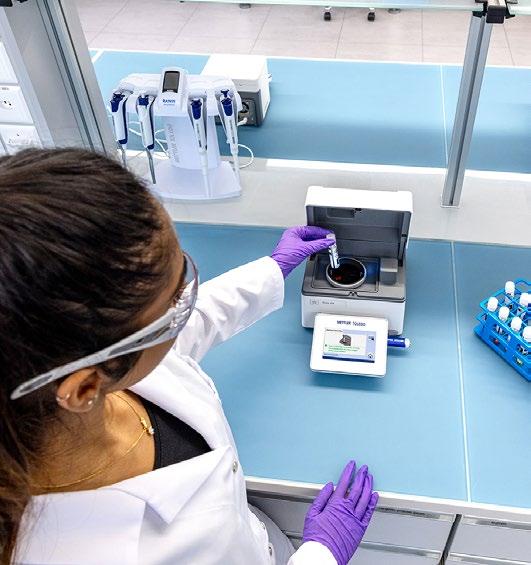

The PathDetect™ function of the compact Easy VIS spectrophotometer produced by METTLER TOLEDO recognizes which path length is measured and reduces errors.

Ease of use in a new dimension: Closing the lid of the Easy VIS spectrophotometer produced by METTLER TOLEDO automatically starts the measurement.

The new instrument analyzes liquid, translucent samples for their optical spectrum, color, and water parameters. Or any of the three. Operators speed up their processes and improve the quality of the results using Easy VIS by Mettler Toledo. They, therefore, save money, time, and space.

The instrument takes over the measuring tasks of up to three instruments: a colorimeter, a spectrophotometer, and special measuring methods for water testing, such as titration. All this power rests in one instrument about the size of a notebook. The results appear on screen in trustworthy accuracy, precision, and repeatability – within seconds. That saves money, time, and space. The instrument’s name is Easy VIS, one of the nextgeneration EasyPlus UV/VIS spectrophotometers produced by METTLER TOLEDO.

A typical place for Easy VIS is the QC lab at small manufacturers in the food and beverage industry, environmental testing labs, or any industry needing quality control and supervising their process- or wastewaters. The Easy VIS is used during multiple steps of the production process: For inspection of raw materials, quality control of semi-finished and finished products, or testing the water quality of wastewater. This streamlines the production processes considerably. Those who used to send their samples to an external laboratory profit even more, as they can now analyze most samples independently at an internal cost.

The visual user interface with workflow guidance allows you to simply scan and measure. Even untrained staff can operate Easy VIS intuitively. This increases the integrity and repeatability of the analysis and saves training time.

Easy VIS operates within a wavelength range of 330 to 1,000 nm. The light source is an easy-to-replace tungsten lamp, which any operator can replace within no time.

The partner device, Easy UV, covers the full UV/Vis spectrum with a wavelength range from 190 to 1,000 nm to cover additional applications in the UV range. Plus: The Easy UV runs with a power-saving and maintenance-free xenonflash lamp.

Analytic precision in three fields of expertise

25 standard-compliant color scales in the visible range come pre-installed and can easily be used. Some examples are ICUMSA™ for sugar color, ESBC for beer quality analysis, or OIV CIELab for wine color determination. The results reveal the quality of the product within seconds.

Water analysis shows, for example, the concentration of Aluminum, Ozone, Chlorine, or Polyphenol. This reveals whether the water is fit for human consumption or can be used in further production. Is the wastewater safe to release? With its numerous built-in water testing methods, the spectrophotometer can quickly provide the answer.

For spectrophotometry, the sample is analyzed at the wavelengths where the sample has its characteristic absorption of light. The Easy VIS measures the transmitted or absorbed light and the reading reveals the sample’s concentration or purity.

The testing procedure is very simple: One cuvette holds the blank measurement, and another is prepared with the sample. After choosing the desired analysis method, the cuvette is placed in the cuvette holder. The PathDetect™ function recognizes which path length is measured. Closing the lid automatically starts the blank measurement. (By the

way, the blank measurement is stored for seven days. So, this step can be neglected during the rest of the week unless the measurement parameters change). After determining the blank, the sample cuvette is brought into the measuring position. The measurement starts again automatically after closing the lid. Within seconds, the results show up on the screen. Now Easy VIS is free to analyze other samples or to start a different analysis method. With the EasyDirect™ software, these results may be automatically saved or exported to an external storage device or exchanged with a data management system (e.g., LIMS).

Easy VIS has the potential to replace up to three other instruments, performing color measurement, water analysis, and spectrophotometry. It does so with trusted accuracy and precision – within several steps of the production process. All this saves money, time, and space. Check with your local METTLER TOLEDO representative about how unique the price performance is!

METTLER TOLEDO’s new EasyPlus instrument line embraces the Easy VIS and Easy UV spectrophotometer. Both instruments offer equal benefits to their operators in accuracy, speed, and compactness. They differ in two aspects: wavelength range and light source. The Easy UV is of special interest to those working within the UV range from 190 to 1,000 nm. Its xenon-flash lamp is maintenancefree and requires no changing.

https://www.mt.com/gb/en/home.html

DFI, the world’s leading brand in embedded motherboards and industrial computers, was invited to participate in “AMD Datacenter Solutions Day” in September.

Based on the theme of high-performance computing (HPC). As the first in the world to launch the smallest industrial motherboard equipped with AMD products, DFI partnered with its subsidiary, AEWIN, to present their star products and share how ultra-small products can help the trend of software virtualization technologies in the forum. We hope to optimize the development of diverse services in IoT applications.

AMD invited industry giants to the event to discuss the future of high-performance computing and conduct in-depth discussions with their partners related to high-performance computing, cloud computing, and AI. DFI was a speaker in the digital learning AI session during the event. We shared our views on software-defined IoT and explained the role of ultra-small products in the application environment.

DFI stated that as cloud services continue to develop, the mainstream technology of modern data centers, containerization, has been extended to IoT edge devices and has driven the integration of edge computing workloads. Ultra-small products can create several virtual platforms and integrate applications through the software. In addition to optimizing operations, it can also reduce the cost of connecting to the cloud and improve yield and efficiency.

Due to the high-performance computing power of AMD CPUs, the DFI ultra-small products on display in the booth, GHF51 and EC90A-GH fan-less embedded systems, and the AEWIN SCB-1937C edge server, designed for intelligent applications, can reduce infrastructure requirements and optimize existing resources. They can also provide a highly flexible and scalable platform to meet different workload needs, simplifying the complexities of industrial automation.

Factory automation, in-vehicle applications, and smart healthcare are the three main focuses of DFI. Under the wave of new infrastructure projects, DFI will collaborate with IoT and automation partners to help companies overcome the challenges of virtualization, containerization, microservices, edge computing, hybrid cloud management, heterogeneous IT environments, and artificial intelligence. DFI hopes to become “the best partner for corporate intelligent OT” and will continue to innovate and develop innovative technologies with AMD for the future of highperformance computing. We will enhance software virtualization technologies through ultra-small products to meet corporate needs.

https://www.dfi.com/

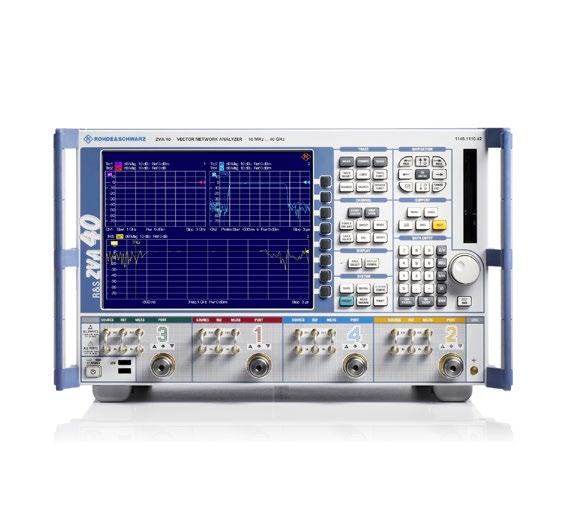

Cubtek Inc. is using network analyzers from Rohde & Schwarz in the development of 4D imaging radar for RF measurement of the E-band. Rohde & Schwarz oscilloscopes and their independently developed, application-specific integrated circuits (ASIC) provide the best measurement tools for automotive radar research and development.

Future self-driving vehicles will face complex road scenarios and 4D imaging radar sensor modules in the 77 GHz band will be indispensable. Compared with LiDAR, 4D imaging radar is less susceptible to inclement weather conditions and is more in line with safety requirements for self-driving vehicles.

4D imaging radar covers distance, speed, horizontal angle and vertical angle. Most current conventional radar systems either lack vertical angle detection or have very limited sensor capabilities for vertical angles. Relative to conventional systems, 4D imaging radar has achieved a breakthrough in horizontal and vertical angular resolution, with angular resolution of nearly 1 degree and 0.1 degree of angular accuracy.

4D imaging radar has far more antenna channels than conventional systems, which significantly enhances performance. Conventional radar systems usually have a 3-transmitter/4-receiver antenna architecture but 4D imaging radars can have a transceiver volume that is several times greater. As 4D imaging radar systems require more 77GHz millimeterwave antennas and transceiver chip integrations, their millimeterwave antenna, IC adapter design, and millimeterwave test validation will play an extremely critical role.

77GHz automotive millimeterwave radar manufacturer Cubtek Inc. partnered with NXP Semiconductors, the world’s

leading automotive radar chip manufacturer, to launch a 4D imaging radar platform at the CES last January. The NXP imaging radar chipset solution uses the flagship S32R45 radar MPU and the second generation high performance RFCMOS radar transceiver TEF82XX for 12 transmitting and 16 receiving 77GHz antenna channels that can be expanded to 192 virtual antenna arrays using MIMO technology. 4D imaging radar performance is improved by optimizing the high-resolution algorithms with angular resolution of less than 1 degree.

When developing the 4D imaging radar, Cubtek chose the R&S ZVA40 network analyzer and the R&S ZVA-Z90 millimeterwave converter from Rohde & Schwarz to make RF measurements of the E-band. The instruments provide both high performance and highlyaccurate measurement results in sensitive, high frequency environments.

Rohde & Schwarz digital oscilloscopes include the portable R&S RTH series, the mid-range R&S MXO4 and the high-end R&S RTO6 or R&S RTP series. The latter can analyze the demodulation bandwidth of FMCW signals. The company developed the ASIC itself for low noise and high performance, creating the best measurement tool for automotive radar research and development.

https://www.rohde-schwarz.com

Komatsu revealed a prototype for its first fully electric compact wheel loader showcased on its demo area at the bauma 2022 international fair in Munich.

Recently designed and built together with Moog Inc., the worldwide designer, manufacturer, and integrator of precision control components and systems, this new connected and automation-ready construction machine is battery-powered and zero-emissions and is now ready for joint testing.

Moog’s Intelligent electric system includes an electric traction motor, lift, tilt and steering electric cylinders, power electronics, system control computer, battery, and battery management system. The integrated control system connects and coordinates the actions across the machine, while the all-electric actuators and motors provide the force to the machine’s traction and loading system. The integrated nature of the system enables industry-leading system efficiency and controllability.

“To achieve our CO2 emission reduction targets from products in use of 50% by 2030 from 2010 levels, to achieve carbon neutrality by the end of 2050, we are looking for promising technologies from suppliers to accelerate our electric machine development,” said Seiichi Fuchita, Chief Technology Officer (CTO) and President of Development Division at Komatsu. “The machine built together with Moog combines the strengths of both companies and was finalized within a short period of time and we expect the joint testing will show the advantages of a full electric machine and will proof collaboration is beneficial for both sides.”

Both companies plan to jointly test the fully electric loader after bauma to prove that it can achieve a new level of efficiency, operating time, and comfort. The companies joint test will show that the machine’s operating cycle is extended, and, with innovative assist functions, that it provides a “fatigue-proof” and comfortable environment for the operator to manage the machine and his day.

The prototype’s intelligent machine electrification system is designed to be connected and automation-ready. The system has the sensing and control capabilities needed for automation while the integrated software framework comes with built-in tools to coordinate multiple axes of motion and precisely control torque, velocity, position, and force.

www.komatsu.eu

More than 80 employees in 35 different countries, ensuring a strong relationship with main local media. Mepax distinguishes itself through its extensive media knowledge and ability to select the best international online/print advertising options. PR can be translated into 35 languages.

40,000 published articles in 2020: EMEA: 48% - Asia: 31% - Americas: 21%. Most of the articles are published in the top 1000 media worldwide.

With a proven process set for more than 200 active customers, we can adapt to all specific client needs with the highest reliability. We have developed in house the most advanced PR dedicated ERP, enabling transparency and real-time full online reporting. International media management is then made easy, fast, and efficient for optimal results.

www.mepax.com info@mepax.com

EU Stage V compliant - Excellent manoeuvrability and travel performance. Visit Komatsu at bauma 2022 in hall C6 and on the outdoor demo ground FM713/1.

Komatsu Europe’s HD785-8 Rigid Dump Truck will be presented on the demo ground at bauma 2022. Designed, developed, and manufactured based on 100 years Komatsu experience and know-how, the HD7858 delivers the highest levels of safety, performance, operator comfort and productivity.

“The HD785-8 proposes excellent operator comfort, great travel performance and the well-known Komatsu reliability of the previous model” says Juuso Ahola, Product Manager at Komatsu Europe. “This machine is such a pleasure to operate that you just might want to keep the keys at the end of your shift rather than hand them over to the next operator.”

Safety & First-class operator comfort Safety is Komatsu’s number one priority. The HD785-8 is equipped with LED lights, ground level battery, starter and machine lockout disconnect switches. A newly designed stairway provides safe access to the cabin.

For improved safety, Komatsu KomVision is standard: it creates a real-time 360-degree bird’s-eye view on the cab monitor and eliminates any blind spots on the rear and sides of the machine.

Operator comfort on the HD785-8 includes a new ergonomically designed cab, with a convenient control layout and a comfortable environment for more confident work and greater productivity.

The new fabric-covered, air suspension seat is adjustable to the operator’s weight and height and includes a seat heater and a ventilator as standard.

Thanks to a low noise engine, large capacity viscous cab mountings, hydro-pneumatic suspension and independent strut type suspension on the front wheels, in-cab noise levels are kept at 72 dBA.

Radiator cleaning becomes easy thanks to the hydraulic radiator fan with reverse mode. The ground level jump start receptacle and service centre with fast fill coupler for engine, transmission, brake oil & coolant refills further facilitates easy and safe maintenance. For safety at height, technicians can attach lanyards to tie-off points (ISO 14567) well-placed around the HD785-8.

• EU Stage V emissions compliant – peace of mind.

• With front step ladder

• Komatsu Traction Control System (KTCS) – maximised productivity

• Energy saving operation – optimised efficiency.

• New, ergonomically designed operator cab – improved operator comfort

• Heated & ventilated air suspension seat – improved operator comfort

• Service centre with fuel, oil & coolant fast fill connection (Wiggins) – maximum uptime, maximum productivity, maximise profit

• KomVision surround view, with radar - for industry leading safety – Peace of Mind

• Engine secondary and emergency shut down switches –safety, peace of mind

• Full LED lighting system - safety, peace of mind

• KOMTRAX Step 5 – ultimate asset management

• Updated KOMTRAX-Plus – convenient machine follow-up & data management

• Komatsu CARE – peace of mind www.komatsu.eu

Wednesday 28th September marked the beginning of the celebrations attended by representatives from local institutions, and continued with a Family Day on Sunday 2nd October. The Lecce plant manufactures CASE machines – wheel loaders, graders, backhoe loaders and compact wheel loaders – which are distributed worldwide.

The CASE plant in Lecce, Italy, celebrates 50 years in the business. Celebrations began on Wednesday 28th September with the planting of an olive tree, a symbol of the Salento region and of the company’s roots in the area.

Local authorities attended to express their commitment to this industry that has been contributing to the economy of the area for half a century. Among them were Apulia Region President Michele Emiliano, the region’s councillor for economic development Alessandro Delli Noci and the president of the regional council Loredana Capone. Angelo Corallo, Professor at the Department of Innovation Engineering at the University of Salento - a university that has a long-standing partnership with the plant - was also in attendance.

Federico Bullo, Head of Europe for CNH Industrial Construction businesses, recalled the hub’s history, which is made up of challenges, continuity in following tradition, teamwork, skills, dedication and commitment. He thanked those who light the “engines” of the plant every day: the employees, the team. A team and an organisation that not even the global supply chain crisis has been able to challenge, considering that 2022 has been a record year in terms of production. Mr. Bullo went on to say, “CASE has always believed and believes in the development of this plant; that is why we have boosted investment in technology, facilities, training, occupational safety and ongoing innovation”.

Innovation has been carried forward by the excellence of the R&D centre which all along has been focused on reducing its carbon footprint and increasing clean energy. Concrete measures have been achieved, namely, the Lecce plant has been equipped with photovoltaic solar panels and will soon have its coating plant replaced with a powdercoating plant, with lower emissions, waterless and zero volatile compounds. Therefore, the end product quality

will improve, thanks to a longer-lasting finish that better withstands the sun’s rays.

“Together, we will continue to address the new challenges related to the 2030 Agenda, carbon footprint reduction and circular economy, by ensuring decent work, the guarantee of labor rights and the development of social dialogue. And we shall do so together because the Lecce hub is and remains key to CASE”, wraps-up Federico Bullo.

After the Institutional Day, the Family Day Celebrations continued on Sunday 2nd October, gathering the hub’s 800 employee’s families. A brief introductory speech by the plant manager Massimiliano Casaburi launched the day. He was proud to share the plaque received from CASE’s European management with all employees; a team that has always distinguished itself for its dedication and enthusiasm, as well as for the excellent results achieved, even in recent years despite the pandemic and geopolitical and energy crises.

More than 1,500 people attended the Family Day. To mark the occasion, the industrial plant was converted into a big party venue for all employees, featuring children’s games, inflatables and a raffle with prizes, in addition to live music by an exclusive band, made up exclusively of plant employees. Exceptional attractions: CASE’s construction equipmentwheel loaders, backhoe loaders, compact wheel loaders and graders - displayed on the forecourt and in the proving

ground, where they starred in operating virtuosities capable of entertaining an audience of all ages.

For the occasion, the facility and its departments were “open doors”: excellent guides - the former plant employee association showed attendees where CASE produces 4 lines of machines in 64 models and 3400 configurations.

A special day to reminisce an important anniversary, which the brand celebrated with the people who, thanks to their passion and enthusiasm, for the past fifty years have continued to come up with ideas, develop insights and manufacture products that make this plant one of CASE’s excellences worldwide.

https://www.casece.com

New Anybus® Communicator™ gateways enable fast and simple communication between industrial networks for improved operational performance.

HMS Networks now expands its second-generation Anybus Communicator range of high-performance gateways, enabling more and faster data to be transferred across networks in industrial applications. Thirteen new versions for data connectivity between EtherCAT, EtherNet/IP, Modbus TCP, PROFIBUS, and PROFINET make it simple for users to connect between different control systems, remove automation islands and maximize operational performance.

The award-winning Anybus NP40 industrial network processor ensures that the Communicators meet demanding requirements in terms of industrial performance, reliability, and security. Featuring new hardware and software, the gateways enable instant data transfer – up to 10 times faster than their predecessors. Users can also exchange significantly more data between the networks as the gateways transfer up to 1 500 bytes to and from connected PLCs.

Built using carefully selected industrial components and verified against the CE and UL industry standards, the gateways are designed to handle harsh industrial environments.

To protect users from cyberattacks, the gateways have an onboard physical security switch that prevents unauthorized configuration changes and secure boot functionality to resist attacks and infections from malware.

Fast installation and configuration procedures are guaranteed thanks to an optimized housing design, an intuitive GUI, and easy-to-understand documentation.

Installation is simplified thanks to the compact gateway design with forward-facing ports and DIN-rail mounting, which enables gateway installation close to connected devices, reducing the amount of needed wiring.

Users can configure the gateways using drag-and-drop functionality in the web-based GUI, which is accessible via a dedicated Ethernet port on the gateways. In the GUI, users can also monitor network traffic and diagnose issues before they become problems.

Hands-on assistance is also available, as a QR code in the GUI provides a step-by-step installation and configuration guide.

“We are very excited to release these Communicators, our most advanced range of gateways,” explains Fredrik Brynolf, Product Manager for Anybus gateways at HMS Networks. “The Communicators are reliable, powerful, and secure. On top of this, they offer a new level of userfriendliness thanks to the optimized design and the intuitive GUI. All this makes the Communicators excellent choices for anyone looking to connect data between industrial networks. The Communicators make it simple to connect

PLCs, remove automation islands, and maximize operational performance.”

Anybus Communicators are available off the shelf as stand-alone ready-to-install units. Users can personalize the Communicators to meet OEM and brand labeling requirements. The gateways can also be pre-configured and locked to be used as tightly integrated communication components of an automation device or a machine.

https://www.anybus.com/products/gateway-index/ anybus-communicator

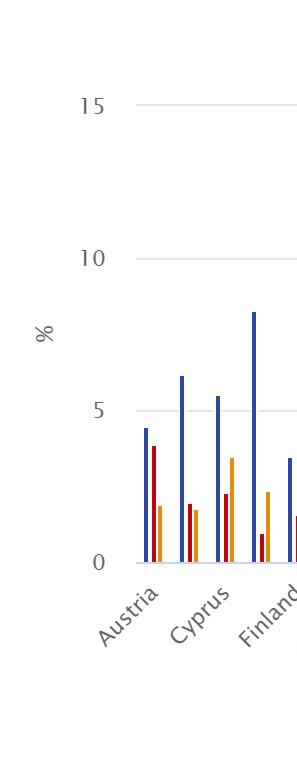

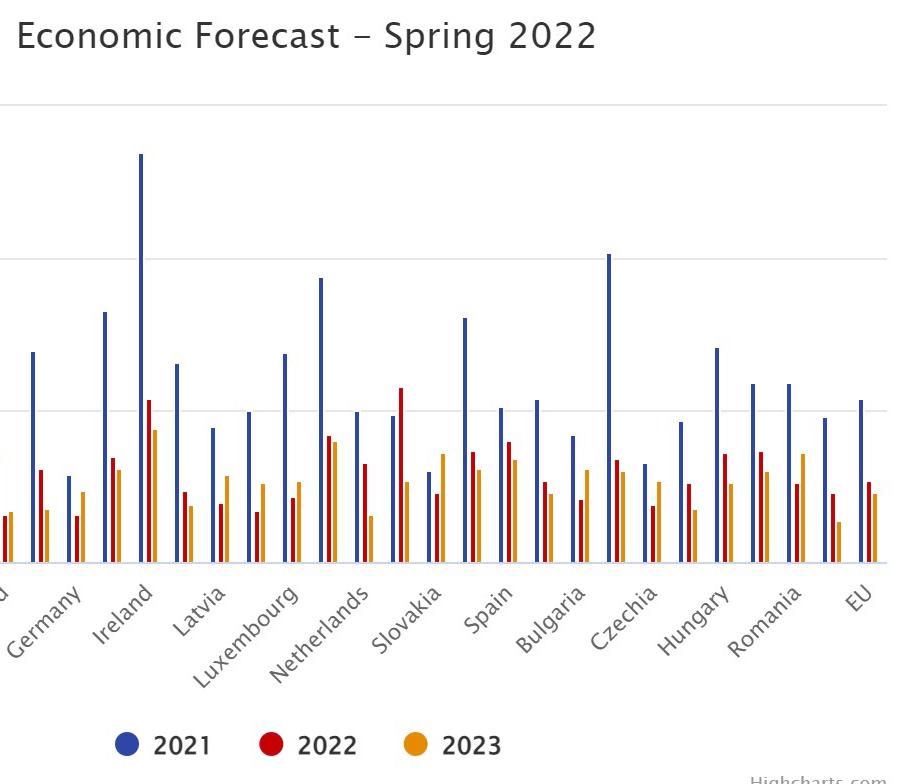

Electro Rent outlines how companies can combat the impacts of the current economic challenges and mitigate risks set out in several recent reports from prominent industry commentators. In light of current economic conditions predicted by numerous recent reports, electronic test equipment specialist Electro Rent has advice for any companies looking to mitigate this financial pressure when sourcing the equipment they need.

The argument in favour of test equipment rental is already compelling and growing in favour across the industry spectrum, but in uncertain economic times, there arises even more need to replace legacy-based purchasing strategies with a smarter way forward.

With economic headwinds driven by factors such as higher costs, inflation and geopolitical uncertainty, the EU’s recent forecast report outlines the potential impact on new investment: “Heightened uncertainty around the unfolding of the geopolitical situation and its impact on the demand outlook are set to weigh on companies’ investment decisions and delay the realisation of investment plans.”

A May 2022report by Deloitte Insights already warned that “the negative effect is particularly pronounced for companies’ operating margins, which are under pressure from a higher cost base due to rising energy and commodity prices”. In June 2022, the OECD’s Economic Outlook said that growth is set to be markedly weaker than expected in almost all economies. Many of the hardest-hit countries are in Europe, which is highly exposed to current market challenges, including the impacts of the energy crisis and inflation. All of this could impact on accessing the electronic test equipment that companies require, on time and on budget.

More and more companies are therefore turning to rental test equipment as a cost-effective yet reliable means of meeting the requirements of budget-conscious, lead-time restricted projects. Renting not only provides immediate access to the latest test equipment technologies from all major brands, but it also keeps projects on track and avoids the typical risks associated with capital expenditure, such as

a large hit to balance sheet liquidity, asset depreciation and slow return-on-investment. Renting also allows companies to easily ramp up and down in line with demand. Moreover, those renting can change their test equipment whenever necessary, providing the flexibility to support an everevolving industrial and economic landscape.

Electro Rent has extensive experience in advising customers on solutions that help them navigate different financial situations in a safe and effective way. Based on over half a century of managing test equipment investments - amid a broad spread of economic trading conditions - the company knows how to supply this equipment in a flexible manner, minimising the potential consequences of an economic downturn and keeping test schedules going without the need for capital investment.

“The key is maintaining business agility and ensuring sufficient flexibility to deal with fluctuating economic conditions,” explains George Acris, Vice President Marketing EMEA at Electro Rent. “High-end electronic test equipment is available that many are not even aware can be procured on a rental basis. For example, by using Electro Rent, customers can deploy the latest spectrum or network analyser for a high-frequency test just for the period required. No more, no less.”

Companies can achieve this ambition simply by paying as they go from their operating budget. As a point of note,

it is possible to rent equipment of this type for periods as short as one week. Moreover, the equipment is available immediately, which is a huge advantage in the current climate of long lead times, avoiding any frustrating project delays that can derail product launch dates.

“Many companies in defence and electronic goods development, as well as those in telecom installation and maintenance, for example, are already using this concept effectively and saving an average of 25% on their equipment costs while being able to deploy as needed,” says Acris. “This strategy is a proven way of keeping pace with the latest test equipment technologies, retaining total flexibility to adapt and react in line with economic uncertainty.”

Evidence is building from expert commentators that economic challenges continue to lay ahead for some time to come, so now has never been a better time for companies to look again at how they procure equipment. Electro Rent has some very effective options available to help mitigate any challenges that the economy may present moving forward.

https://www.electrorent.com/uk/services/lease-andfinance

With the FBPS 600i, only one device is needed for safe position detection. In the past, system manufacturers had to use two sensors and two different technologies for position detection. But not anymore: The new FBPS 600i safety bar code positioning system from Leuze enables position detection with a single sensor.

In intralogistics, it is important that the stacker cranes and transverse transfer cars pose no danger to the staff. The position and speed must be monitored during maintenance work or when operating with a manned car. Until now, system manufacturers had to use a redundant setup with two sensors in order to meet performance level d. This problem is now solved with the new single-sensor safety bar code positioning system FBPS 600i, which already meets the requirements of performance level e. This means that safety functions can now be easily implemented. The unit is connected to a safe connection unit, for example, a frequency inverter, via two SSI interfaces. The FBPS 600i also requires less space in the system, and the installation effort is reduced significantly.

The FBPS 600i has an impressive error reaction time of only ten milliseconds. This makes it especially suitable for position detection when quick movements are involved. Important parameters, such as the speed curves and the throughput can be optimized as a result. The sensor’s large working range of 50–170 millimeters also enables flexible integration in different types of systems.

The new safety bar code positioning system is installed on the stacker crane or transverse transfer car. A bar code tape is affixed on the opposite rack. In the development of the FBPS 600i, the Sensor People emphasized maximum reliability: With every scanning pass, the FBPS 600i reads multiple codes of the tape, from which the software determines highly precise position values.

The sensor scans the code at various locations through the diagonal path of the scanning beam and the movement of the transfer car. This prevents reading errors caused by local soiling or damage. The self-adhesive bar code tape, which was optimized for industrial application, also facilitates flawless operation: It is UV resistant, extremely resilient, and mechanically durable. In addition, the printed position values are easy to read and simplify handling.

The well-thought-out fastening concept with a quickchange system ensures simple mounting of the FBPS 600i devices. The device can be safely secured with an easy-toaccess screw on the mounting clamp. This saves time during assembly.

https://www.leuze.com/en-uk

TO THE AMERICAN STANDARD MIL-PRF-39006

Exxelia, global manufacturer of complex passive components and subsystems for harsh environments, is expanding its line of MIL-PRF-39006/22 & MIL-PRF-39006/25 tantalum capacitors, with the support of the reliability level R.

Exxelia now offers the reliability level R, in addition to level M and P for the specifications MIL-PRF-39006/22 & MIL-PRF-39006/25, equivalent to CLR79 and CLR81 series. Available in all package sizes (T1 to T4), these fully sealed products cover voltages from 6 V to 125 V, deliver capacitance values ranging from 1.7 µF to 1200 µF, and are designed to operate at temperatures ranging from -55 °C to +125 °C and withstand the harshest environmental conditions. Performance highlights over solid tantalum capacitors include higher energy density, higher ripple currents, lower ESR and lower DC leakage current.

Engineers with complex design requirements looking for a product that can be easily integrated into projects such as power supplies & converters or filtering units for the aerospace and defense industries will be pleased. MIL 39006/22 & MIL 39006/25 Level R are now available for order with a lead time of 14 weeks.

“The introduction of these new ranges builds on our decades of experience in supplying high reliability capacitors to the military market and demonstrates Exxelia’s ability to meet the most demanding specifications in terms of product development” says Jerome Tabourel, Exxelia’s vice president of sales and marketing. “We are proud to be one of the few MIL qualified tantalum capacitor manufacturers, and our flexibility and advantageous lead times will bring new supply opportunities.”

• Capacitance from 1.7 μF to 1,200 μF

• Voltage from 6 V to 125 V

• Operating temperature -55 °C to +125 °C

• Very good shock and vibration resistance (option H available)

Download the complete datasheet www.exxelia.com

Amphenol SOCAPEX’s MPO Field solution enables users to transform a standard MPO patchcord into a robust connector designed to resist the harshest environments.

The MPO patchcord is integrated into a metallic plug based on MIL-STD-38999 Series III, shell size 13 Military connector, to protect it from shocks, dust and fluids. There is no requirement for field termination.

MPO Field TV connector combines high speed and high density of well-known MPO/MTP Fiber Optic connectors using MT ferules, with high resistance of MIL-DTL-38999 Series III Military shells for various harsh environment applications such as high speed embedded network backbones for battleships, armored vehicles or airplanes and trains, datacenters in harsh environments, trackside measuring & inspection systems for trains, high resolution real time video, passenger entertainment...

MPO Field connectors feature:

High Density and Speed - Take advantage of the High Data Rates and Optical density offered through the use standard Fiber Optic MT Ferrules

High Density and Robustness

- The 12 or 24 fiber channels are integrated into 28 mm diameter 38999 metal shells, with tri thread coupling mechanism

- The solution is IP68 sealed when mated and shocks & vibration resistant

Easy to implement

- No tool or field cabling are required. The solution allows anyone to transform a standard MPO Patch cord or more complex assembly into an harsh environment connector very easily.

Check out our assembly video: https://youtu.be/WkmZGr4MrxA

“This is a great new product range to bring under the Amphenol SOCAPEX product offering in order to respond better to the needs of the market. The MPO Field TV solutions range enlarges our core offering and further defines our footprint in fiber optics applications.” comments Emmanuel Lambert, Amphenol SOCAPEX Fiber Optics Product Manager.

https://www.amphenol-socapex.com/en/products/ connectors/fiber-optics/mpo-mtp-field

We are pleased to introduce the Gas Laser with highly advanced laser technology designed to detect natural gas with the aim of enhancing safety and improving detection for fire services, and first responders.

Frequently fire personnel and first responders are called to natural gas emergencies using equipment that puts them close to potentially dangerous structures. The Gas Laser supports remote detection allowing the operator to work at a safer distance from the hazard location. When access to a property cannot be established, the Gas Laser can operate through glass, giving the user an audible and visual indication to the presence of methane. This quick scan permits fire personnel and first responders to make rapid decisions and establish control of the gas and ignition sources should a gas escape be detected.

• Quickly scan common venting points from a safe distance

• Detection distance 30 m (100 ft)

• 8 hours run-time

• Highly visible, sunshine resistant guide laser equipped for location accuracy

• Graphical interface for easy user interpretation

• Color camera with Bluetooth, WIFI, and datalogging onboard

• Certified Intrinsically Safe to Class I, Division 2, Group D, T4

Discover this new solution: our video & our website

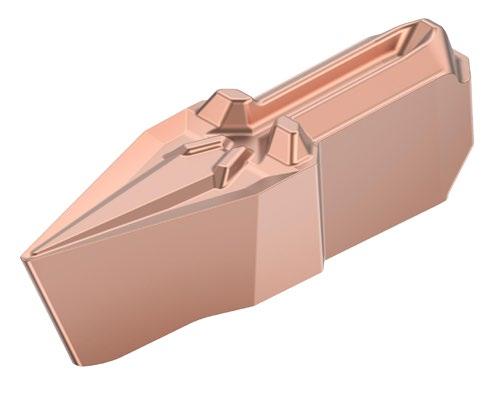

To provide manufacturers versatility and high value, Seco has launched its new X-Head quickchange replaceable milling head system. With the system, users can quickly and easily change between various solid-carbide milling geometries and types to optimize milling operations while reducing manufacturing costs and tooling inventories.

Fast and easy tool changes with the turn of a wrench Milling heads mount to a variety of available shank lengths for even greater versatility, with short and long-reach capability for a variety of overhang lengths. Head changes only require a simple turn of a wrench, eliminating the need to remove the holder from the machine to change the cutter. Users also eliminate the need to reset tool lengths thanks to a secure and reliable connection that provides exchange accuracies within 50 microns.

One tool mills it all According to Gary Meyers, Seco Product Manager Solid Milling, shops must often purchase many different endmills and holders to machine different features on a workpiece which adds higher cost to a project. “The Seco X-Head quickchange replaceable milling head system adapts to various machining needs with a range of geometries and types but without additional holders,” he said.

With 194 types of available cutting heads, users can choose between different cutters for multiple operations as well as between specific high-performance, versatile highperformance and universal type geometries. Seco also offers metric and inch products for heads and shanks.

www.secotools.com

To allow manufacturers

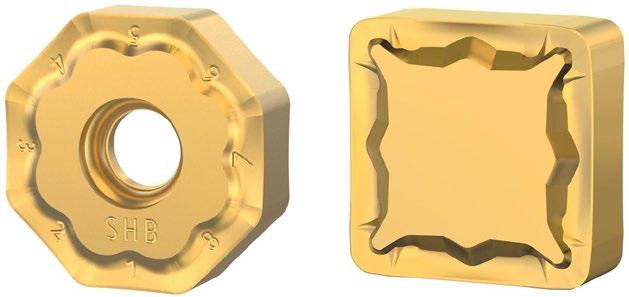

customer demand for lower part prices, the new Seco Helical SN813 milling system features double-sided helix inserts with eight cutting edges that significantly lower cost per edge to boost slotting, side milling and circular rough milling efficiency.

Built for difficult applications involving ISO P, M, K and S materials, the cutters offer application-specific subfamily designs featuring left or right-hand helixes, half- or full-effective teeth options, two front insert and many radii choices for long tool life and maximum chip evacuation. Reliable and user-friendly, the Helical SN8-13 also eliminates incorrect indexing of front and helix inserts, reducing operator error.

“The demand for price reductions is ongoing and forces shops to economize production operations wherever possible while still maintaining part quality and profit margins,” explained Benoît Patriarca, Global Product Manager Helical Milling at Seco Tools. “With the Helical SN813 system’s design combined with high performance insert geometries and grades, they can achieve all these goals with one tool.”

Perfect insert indexing Incorrectly indexed inserts can lead to machine downtime, quality issues and scrap. To eliminate the risk of mistakes, the SN8-13 milling system cutters are specifically designed to make mounting of front and helix inserts easy and foolproof, especially for inexperienced operators.

As an economical alternative to milling products for depthsof-cut from 50 mm up to 100 mm (inch range from 2” up to 3”), Seco offers the Helical SN8-13 in a range of subfamilies built with its SN13 helix inserts.

Those subfamilies include:

• R217/220.82: XO16 lead insert for standard use

• R217/220.82-H: AC15 lead insert for heavy duty applications

• R217/220.81: AC15 lead insert for low power situations

• R217/220.81-K: AC15 lead insert for weak fixturing situations

The range is designed with arbor style connections that match most standard holders as well as Seco Weldon, Weldon and Capto interfaces.

www.secotools.com/milling

to meet

With the utmost employee safety, health and wellbeing in mind, Seco Tools has initiated a far-reaching safety strategy that involves both yearly and long-term goals extending out to the year 2030. With this long-term planning and continuous improvement approach, the company will significantly lower lost time injury frequency rates as compared to results achieved through typical industry safety programs that focus solely on yearly achievements.

Typical injuries in the manufacturing environment are often those involving hands and fingers, and these injuries can happen to everyone from facilities personnel to machine operators. For its safety strategy, Seco set the long-term goals of lost time injury frequency rate (LTIFR) at 1.1 by 2022 and 0.8 by 2030. Its total recordable injury frequency rate (TRIFR) goal is 2.0 for 2022 and 1.6 or lower for 2030.

An umbrella approach to safety Seco began planning its safety program last year, taking an umbrella approach. In doing so, the company focuses on analytics and evaluates not only where key performance indicators (KPIs) such as workplace hazards, injury frequency rates and the like lag, but also where leading indicators relate to the correlation between activities and results.