Everything is ready for the grand opening of the new Seco Tools Production Unit (PU) in México, on September 29th. The new plant will house special tool manufacturing. This strategic move will allow Seco Tools to consolidate its presence in the Mexican market which extends and strengthens the configuration of its manufacturing chains worldwide.

Located in the modern 360 Industrial Park, the new PU will have privileged access to the Saltillo-Monterrey highway, with direct road communication to industrial cities in the North (Monterrey, Nuevo Laredo, Matamoros, and Reynosa) and the South (San Luis Potosí, Guanajuato, and Querétaro).

The new 2,500 square meter manufacturing facility features Seco Tools unique architecture, design, and production cell layout standards. Additionally, all Ramos Arizpe’s PU employees will have exclusive training and education spaces with multifunctional rooms for strategic, commercial, and administrative activities.

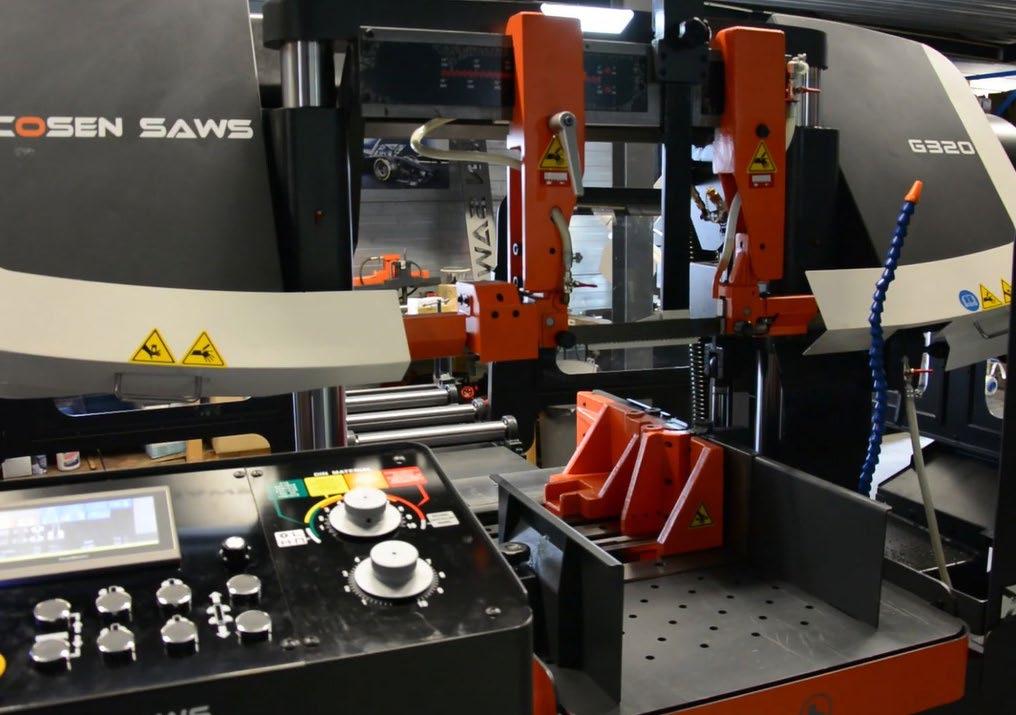

It’s been two years since the acquisition of the cutting tools division of QCT (Quimmco Technological Center), and the machinery and equipment from the previous facility will now be transferred, occupying approximately two-thirds of the PU floor. New equipment for standard tool production is expected to come soon and fill the remainder of the space.

Seco Tools has a focus on sustainability and this new location is no exception. Solar cells will be installed on the plant roof and on the top of car ports to generate up to 50% of the power needs of the PU.

“Seco is strongly committed to the environment and green technologies. It is not surprising that we are investing in solar panels in our new facility in México”, said Oksana Wade, CFO at Seco Tools. Seco Green Fund, created in 2012, supports many environmental initiatives, “which is not only about green power but also other efforts. In México, Seco Tools is not only selling new tools but also regrinding and remanufacturing carbide and PCD tools, as well as recycling carbide at the end of the tool life. Taking care of the whole tool lifecycle, the customer wins and the environment wins too”, Wade explained.

In addition to the focus on sustainability, Seco Tools philosophy is rooted in being a good corporate citizen and developing social responsibility activities to support local schools, public squares, and activities-oriented programs in the perimeter community.

This new PU is an example of Seco Tools’ commitment to the Mexican market and will be strategically positioned to better serve the growing demand for carbide and diamond tools both in México, throughout North America, and some countries in South America and Europe.

https://www.secotools.com/

With these features, steute aims to make its ES/EM 97 series universally applicable throughout the automation industry. Accordingly, it has a wide range of actuators (various fulcrum levers, roller levers, spring rods…) and dimensions to EN 50047, the prevalent standard for automation technology.

The actuator heads can be easily fastened, replaced or turned in 90o steps with four captive screws. The switching inserts can be removed after opening the screw-free cover – simplifying installation.

The new series can also be used in machine safety applications, i.e. as position switches with safety function. Paired with a suitable receiver, they achieve a safety level in line with Performance Level e to EN ISO 13849-1 and SIL 3 to EN 62061.

For the position switches with safety function, two additional actuator heads are available. In the “AZ” version, the ES 97 becomes a safety switch with a separate actuator – the classic design for position monitoring of guard doors in line with machine safety. And the ES 97 SB is suited to spacesaving hinge-mounted position monitoring of turning guard doors.

The steute business unit “Automation” is thus expanding its product range to include a – like all steute switching products – particularly flexible, robust and high-quality series of position switches which can be flexibly adapted to suit individual applications.

https://www.steute.com/

LAPP’s ÖLFLEX® HEAT 260 SC heat-resistant single-core industrial cable now carries UL AWM certification/ cRU AWM I A/B. Ideal for applications subject to extreme temperatures, the ÖLFLEX® HEAT 260 SC cable features polytetrafluoroethylene (PTFE) insulation to provide exceptional resistance to acids, alkalis, solvents, oils, other chemicals and UV exposure.

This rugged construction allows ÖLFLEX® HEAT 260 SC to resist cracks during frequent ambient temperature fluctuations while exhibiting a wide temperature range of -190°C to +260°C, with a UL/CSA rating of up to 200°C. The cable also maintains high elasticity and tensile strength, with a minimum bending radius of 10x OD and a fixed installation bending radius of 4x OD. Flame retardance ratings include:

- IEC and EN 60332-1-2

- UL Horizontal Flame Test

- CSA FT1

The silver-plated copper-stranded conductors come in 7-, 19- or 37-wire AWG sizes. In addition, ÖLFLEX® HEAT 260 SC is now available with UL AWM certification (AWM Style 11486 acc. to UL 758), with cross sections from 28 to 12 AWG.

Thanks to the series’ small diameters, ÖLFLEX® Heat 260 SC single-core cables are well-suited for space- and weightconstrained applications in mining, chemicals, refineries and metal fabrication industries as well as any environment with extreme temperature variations.

www.lappusa.com

With the new edgeAggregator, Softing offers a flexible, container-based solution for managing complex system architectures in OT/IT integration all the way to edge and cloud applications.

Data exchange plays a particularly important role in the integration of production and management levels up to edge and cloud applications. Already with a small number of servers and clients, the architecture becomes very complex. With the new edgeAggregator, Softing provides a central data integration layer that reduces complexity while addressing the large number of variables as well as managing access rights and special security requirements.

1. As an OPC UA aggregation server, it handles the aggregation of up to 100 OPC UA servers and supports up to 25 OPC UA server endpoints.

2. As an IoT cloud gateway, it handles bidirectional data transmission with cloud applications via MQTT Publisher/ Subscriber functionality.

3. As Security Supervisor, it is responsible for the central management of the security parameters of the OPC UA and MQTT connections, such as users and certificates, and acts as an “OPC UA Firewall” for protection against attacks.

As a Docker container, edgeAggregator can be easily configured and deployed as an edge solution or with central cloud platforms. The interface abstraction of edgeAggregator allows continuous adaptation and scaling of IoT solutions based on OPC UA and MQTT throughout the entire lifecycle. Users thus gain a high degree of flexibility while significantly reducing integration and configuration costs.

https://industrial.softing.com/

edgeAggregator, a flexible, container-based solution for managing complex system architectures in OT/IT integration.

edgeAggregator, a flexible, container-based solution for managing complex system architectures in OT/IT integration.

Two product releases from Softing’s smartLink family offer enhanced functionalities for Plant Asset Management and the implementation of Industry 4.0 connectivity in industrial networks.

The smartLink product family from Softing enables end customers to make efficient use of connectivity at the interface between OT and IT. The products allow simple and scalable integration of device data into plant asset management applications. The new versions of smartLink HW-DP v1.20 and smartLink SW-HT v1.20, which are now available, offer enhanced functionalities for data transfer and connectivity.

smartLink HW-DP – Integration of Industry 4.0 applications in PROFIBUS and HART systems smartLink HW-DP enables access to process, asset, and diagnostic data from PROFIBUS devices and HART devices connected to PROFIBUS remote I/Os, as well as secure export to any system inside and outside the user’s own network. The new version v1.20 now adds support for providing asset and diagnostic data from field devices via MQTT. This allows easy integration into typical IoT system architectures, such as the Namur Open Architecture (NOA) or the IoT reference architectures of large cloud platforms.

smartLink SW-HT – Data access via Emerson AMS Device Manager and other HART IP-enabled Plant Asset Management applications

smartLink SW-HT allows access to configuration and diagnostic data via Emerson’s AMS Device Manager or other HART IP-enabled Plant Asset Management applications. As the only solution available on the market, smartLink SW-HT has so far supported Schneider Electric M580 controllers and drop I/Os as well as Allen-Bradley controllers and remote I/Os. Version v1.20 now also connects Emerson AMS Device Manager to HART devices connected to R.Stahl IS1+ remote I/O. More and more modern remote IOs are using Ethernet as a connection to the controller. smartLink SWHT takes this trend into account by providing an Ethernet connection for tunneling HART commands to remote IOs. As a Docker container, smartLink SW-HT can be managed via Kubernetes-based management platforms or services of the major cloud platforms.

Both new product versions expand the possibilities for end customers to implement open, standards-based, and scalable system architectures with the smartLink product family and to integrate connectivity into IT-managed edge solutions.

https://industrial.softing.com/

Seco and its technical partners will host the company’s first hybrid (physical and virtual) Inspiration Through Innovation (ITI) event on Wednesday, September 28, 2022. The event will be focused on the aerospace manufacturing segment, with machining demonstrations, an inspiring seminar programme, and networking opportunities.

The event’s interactive sessions will be presented to a live audience and streamed live via the event website. On-site attendees will get to meet presenters in person, network with partners, and see live machining demonstrations. In addition, all recorded sessions will be available on demand after the event for every registrant.

Attendees gain valuable insights and learning from the ITI events, which demonstrate the value of collaboration in the pursuit of innovation – this time, specifically in aerospace manufacturing.

• Collaborative machining demonstrations showcased at Aero ITI 2022 will include:

• Power skiving and on-machine broaching on an Inconel jet engine compressor disk

• WAAM (wire-arc additive manufacturing) of an Inconel blisk hub and production of the additive manufactured tools used to finish the part

• Highlights from ongoing projects such as automated holemaking in stacked composites, aggressive structural machining, and a one-shot approach to aluminum A-frame machining.

• Technical partners will share inspiring live discussions and seminars on various topics and challenges facing the aerospace manufacturing segment, such as:

• Partnerships to support sustainability ambitions

• Physics of machining in superalloys

• Efficient machining in difficult materials such as CFRP and stacked composites

• Finding value in data, digitalization, traceability, and automation

“Partnerships are a journey,” says Jon Shipley, Global Business Development Manager, Aerospace at Seco Tools. “They are forged and built over time by working together to a common goal. With ITI and Innovation Hub, we work with our partners – old and new – to wrap collaborative solutions around our customers’ real challenges. We can’t wait to open the doors again and welcome you back to the Innovation Hub to meet, network, learn and grow together with us and with our partners.”

To further support aerospace manufacturers, Seco has launched a selection of technical and educational content dedicated to real-world aerospace components, such as a wing pylon and a blisk. Visitors to the Seco website will gain insights into the cutting-edge technologies, trends and individuals that are shaping the aerospace manufacturing industry through podcasts, videos and other content.

Manufacturers worldwide are encouraged to register and join live on-site, live virtually or view the event session recordings on demand after the event. For more information

and to register for Aero ITI 2022, please visit: https://event. secotools.com/aeroiti2022

ITI registrants will also have direct access to more exclusive aerospace content through secotools.com.

Seco and technical partners will host an ITI event focused on automotive manufacturing in Germany in November 2022.

Inspiration through Innovation draws on the Seco global network of partners, bringing together in-house expertise and external knowledge to explore problem-solving possibilities. During ITI events, attendees experience the results of these innovative partnerships and discover how collaboration can help them find solutions that will drive their businesses forward. This collaborative approach solves ongoing issues found in various manufacturing industry segments.

https://www.secotools.com/

How can the earth feed nine or ten billion people? “Smart farming” is an important part of the answer to this existential question: Extremely high efficiency in food production through the targeted use of the latest technology, computer-supported and – where possible – fully automatic. Seeds are individually and precisely placed; fruits carefully picked by mechanical grippers; fertilizers and plant protection products applied in small doses and in a targeted manner. These operations require a large number of small electric motors that are both robust and powerful.

Quantum computers, space tourism or hydrogen technology – the latest technological hype focuses on constantly changing topics. Curiously, the most important sector is often overlooked: agriculture. Even though it has thus far reliably fed an exponentially growing human population. The agricultural revolution, which began in the 18th century, allowed yields to increase enormously. It is based on the increasing use of high-yielding varieties, mineral fertilizers and chemical pesticides, on mechanization and large-scale artificial irrigation. These interventions into the ecology are not without unwanted side effects, however.

All well-founded population forecasts predict that the human population will grow to between nine and ten billion people by the end of this century. The earth offers the potential to supply even this large number of people with sufficient food. Agriculture faces an enormous challenge here, however. Crop cultivation and livestock farming must produce more without endangering the life-sustaining resources. Fertile soil, clean groundwater and an intact natural world are our most valuable “resources.” They must be protected at all costs.

Until now, many important work steps in crop cultivation, such as planting, fertilizing and plant protection measures have been based on land area. When spreading seed or pesticide, one calculates the quantity per acre or hectare;

the machines distribute the material with the appropriate flow rate. Instead of strengthening the plants, however, a portion of the nitrogen fertilizer, for example, reaches the groundwater, where it clearly does not belong. Tasks such as the pruning of fruit trees or the harvesting of delicate fruit and vegetable varieties require costly manual labor, while more and more enterprises suffer from a personnel shortage.

Smart farming uses modern technologies to increase the efficiency of agriculture, to use all resources more sparingly, to relieve people from monotonous work and to produce higher yields. In this context, one also speaks of precision farming, digital farming or e-farming. Using computersupported and networked processes plus machine learning and customized robot functions, focus can be placed on the individual plants instead of the field as a whole.

The more directly the measures are targeted at the plants, the more economically and efficiently these measures can be used. For example, the use of herbicides can be significantly reduced if applied to the individual plants in a more targeted manner. Fruits and vegetables could be harvested by robots in continuous passes, always at the optimum ripeness.

Lightweight, autonomous field robots also provide an opportunity to protect the ground. Today’s large agricultural machines weigh up to ten metric tons. With such weight,

every pass results in dramatic soil compaction. This greatly limits the ability of the affected layer of soil to absorb water and air, thus strongly impacting soil life; the growth and health of the crop plants in the areas near travel paths are also impacted. Smart farming can help contribute to healthier soil and increased biodiversity.

For now, many applications exist only as studies or prototypes. But smart farming is already being put to practical use, such as in precision planting. This was originally developed for research and seed breeding. These machines can plant the individual seeds at precisely defined intervals. Each plant receives enough space to grow, and the acreage is optimally utilized. At the same time, the valuable seeds are used extremely efficiently.

The most modern machines use one separation module with electric drive per row. A motor drives a slotted or toothed disk that transports the individual seeds to the outlet. Using an intelligent controller, it is possible to precisely set the optimum spacing for each type of seed; when traveling around corners, the different radii of the individual rows can be compensated for. The feeding of the seeds to the disks is likewise controlled using motorized closures.

With vegetable and flower cultivation in greenhouses, many plants are first sprouted in small pots and later replanted in larger pots or in beds. In modern horticultural enterprises,

Always perfectly ripened products through continuous automated harvesting.

Always perfectly ripened products through continuous automated harvesting.

machines perform the sorting and handling of plants and pots. Their machinery is very similar to that used in industrial production and logistics. There are conveyor belts and roller conveyors on which trays with products in various stages are transported, sorted and repotted. The grippers used here differ from those used in similar devices in other industries only in the shape of their “fingers.” Driven by micromotors, they perform the automatic handling of the individual pots and root balls.

Self-driving harvesting machines for fruits and vegetables have not yet reached series maturity for general use, but the direction of the technical development is already apparent: camera-assisted sensors detect the degree of ripeness of strawberries or peppers on the basis of color and shape and record their exact position. The on-board computer uses this data to control a robot arm, which is equipped with a type of shears and a collection device. The prototypes of this technology are full of electric motors, from the single-wheel drive and the robot arm to the cutting apparatus and the collection system for the harvested produce.

“In conventional agricultural machinery, mechanical gear transmissions and pneumatic drives are very common,” explains Kevin Moser, who, as Business Development Manager, is responsible for applications in this sector at FAULHABER. “For smaller-scale systems in smart farming, these are often too heavy, too bulky, too mechanically

complex and too energy inefficient. We therefore see an increasing number of electric micromotors in use here that supply the power for specific work steps. The drives in an agricultural environment must, however, usually meet very high requirements.”

Unlike the traditional large devices, the machines and components used in smart farming are generally more compact and lighter. This means that there is often little space available for the motors. Nevertheless, as drives of sowing disks, flaps, grippers, robot arms or shears, they must supply sufficient power to reliably perform the respective task over countless cycles. At the same time, they should operate extremely efficiently, as the autonomous units usually draw their energy from batteries with limited power reserve. It must also be possible to integrate the drive electronics in networked structures and make intelligent control possible.

“These are typical requirements placed on drive systems of the highest class; the right answers are always standard issue at FAULHABER,” says Kevin Moser. “Moreover, the drives used in agricultural environments must also be extremely robust so that they themselves function reliably and for the long term under the most demanding conditions. Large temperature fluctuations and strong mechanical loads are the norm in agriculture and horticulture. And, in spite of all of this, the costs must remain reasonable. We at

Drives used in agricultural environments must operate reliably under harsh conditions. Targeted use of fertilizers and herbicides reduces soil contamination.FAULHABER can offer multiple series of devices that manage this balancing act.”

Moser is referring to the maintenance-free brushless and especially compact flat DC-micromotors of the BXT series as well as the exceptionally robust and cost-efficient copper-graphite motors of the CXR line. The gearheads of the new GPT series are very well suited for high load transmission under harsh conditions. Extremely efficient, they are also very robust and, thus, ideal for agricultural applications. Optional incremental encoders enable highly precise positioning. Various controllers, e.g., with CANopen interface, are available for the networking of the drive systems. “Drives from FAULHABER are already being used in smart farming,” reports Kevin Moser. “They will continue to play an important role for demanding applications in this area.”

https://www.faulhaber.com

Stemming from its mission to protect the Earth and achieve sustainable corporate management DFI has conducted carbon inventories for three consecutive years.

DFI Inc., the world’s leading embedded motherboard and industrial computer brand announced that the company had received ISO 14064-1 certification for greenhouse gas inventory from an international third party this year. Stemming from its mission to protect the Earth and achieve sustainable corporate management, DFI has conducted carbon inventories for three consecutive years. DFI is responding to the Taiwan 2050 net-zero carbon policy through action and working towards energy transitions.

The harsh effects of climate change have been proven by science. Therefore, the climate has become a highly significant global issue. Net-zero emissions have become a prominent part of corporations. In response to the international net-zero trend, the National Development Council (NDC) announced “Taiwan’s Pathway to Net-Zero Emissions in 2050 and General Strategy Description” this year.

The NDC stated that the pathway to net-zero emissions in 2050 is based on the four primary directions of “Energy Transition,” “Industrial Transition,” “Lifestyle Transition,” and “Social Transition.” To respond to the net-zero emissions by 2050 goal, in addition to conducting ISO 14064-1 greenhouse gas inventory certification, DFI is also planning to implement ISO 50001 energy management certification in the future to ensure the tracking of greenhouse gas emissions. In terms of the head offices, emissions in 2021 were reduced by around 12 tons compared to the base year of 2019.

The President of DFI, Alexander Su, expressed that DFI regards sustainability as its responsibility and hopes to promote energy transitions externally. DFI aims to help companies implement energy conservation and carbon reduction to reduce corporate operations’ impact on the natural environment. Through industrial computers with high computing power and wide temperature and voltage ranges, the products can be used in solar power, wind power generation, automotive computers, and charging pylons, allowing the company to provide solutions for green energy, electric vehicles, and energy needs.

The wave of new infrastructure brought on by global production automation and the digital transformation will make smart applications a long-term, rigid demand. DFI will work with its group partners and subsidiaries to implement various energy-saving and carbon-reducing operations and improve energy efficiency. While fulfilling its social responsibilities, DFI will help companies accelerate their transformations and deployments and satisfy their foundational needs. The company will continue innovating and improving production capacity to seize new market opportunities.

www.dfi.com

Axially space-saving, economical, IP65-compliant and designed for high radial and axial forces at the output: The WPLHE combines all the advantages of the successful PLHE, the world’s first combination of the Economy and Precision gearboxes, as an right-angle variant.

Specifically, the WPLHE features both the gearing of a proven economy gearbox and a high-performance output bearing with preloaded tapered roller bearings, which are otherwise commonly used in precision gearboxes (such as the PLN and the PSN). This means that the new rightangle gearbox tolerates high radial and axial forces of up to 8,000 N at the output. For example, pulley drives with high radial loads can also be implemented in right-angle designs.

Compared to the coaxial PLHE the motor is rotated by 90° in this case, the WPLHE offers the ideal solution in confined spaces, for example in packaging and other special machines. It is the only Economy right-angle gearbox to be offered with a premounted pinion as an option. This makes it particularly suitable for space- and cost-sensitive rack-andpinion drives. There are 13 different pinions from which to choose: with choice of straight-cut or helical-cut teeth, from module 2 to 3, with numbers of teeth from 15 to 27.

Thanks to the output geometry with square output flange and long centering flange that has become established on the market, the WPLHE is easy to implement. Several different output shaft variants - smooth, keyed, splined or with premounted pinion - mean that the right-angle gearbox can be used in a wide range of applications. It is also the only Economy right-angle gearbox with IP65 protection class, making it suitable for harsh, dusty and dirty environments. Food-grade and low-temperature lubricants are also available for the lifetime lubrication commonly provided by Neugart.

The new WPLHE is now available in the three sizes 060 / 080 / 120, either as a single-stage version (in the ratio range 3 to 10) or as a two-stage version (ratios 9 to 100). Thanks to an efficient supply chain, Neugart can continue to guarantee attractive delivery times for quantities starting at 1.

https://www.neugart.com/en/

A cleanroom-classified, element-resistant high speed industrial robot.

• Racer-5 SENSITIVE ENVIRONMENTS is expressly designed for harsh settings with high risk of contamination, as found in Pharma and Cosmetics, Electronics and Food&Beverage

• It combines a ruggedized element-resistant shell with flexibility, high repeatability, and Comau-proven accuracy

• IP67 rated in all installation positions and ISO Cleanroom classification by Fraunhofer, it offers dependable protection from water, chemical agents and other contaminants

• With NSF H1 food grade lubrication and a high gloss painted surface, the newest Comau robot is safe for direct contact with any type of food

Comau introduces its new RACER-5 SENSITIVE ENVIRONMENTS (Racer-5 SE), a high-speed industrial robot designed for the special and sensitive settings that characterize the pharmaceutical, health & beauty, food & beverage and electronics industries. Featuring a protective water, heat and grease-resistant coating, the ruggedized 6-axis articulated robot fully responds to the demand for IP67 certification, high-grade ISO 5 Cleanroom classification (ISO 14644-1), protection from chemical agents and the need to reduce the risk of contamination. It also has NSF H1 food grade lubrication. Further benefits of the dedicated robot include reduced operator risk when working with potentially harmful chemicals and substances, as well as increased productivity, traceability, and quality.

Racer-5 SE addresses the specific need for speed, accuracy and repeatability within cleanrooms and other sensitive environments. The result of an intensive design process based on the study of forms and attention to detail, it has compact dimensions, 5 kg payload, an 809 mm maximum reach, and a high-gloss, ruggedized element-resistant shell.

Racer-5 SE can be used on a tabletop, inclined, or mounted on a wall or ceiling, allowing it to easily automate applications with stringent requirements such as the handling of pharmaceuticals in sterile filling rooms or the certified cleanroom assembly of microelectronics, while reducing overall operating costs. Furthermore, Racer-5 SE is well-suited for the food and beverage industry, given that its white painted surface is approved for direct contact with all types of food (Reg Eu 1935/2004, Reg Eu 10 /2011 and Reg Eu 1895 /2005) and the IP67 rating protects it from peroxide, chlorine, alcohol and other aggressive cleaning agents.

Fitted with stainless steel screws and covers, Racer-5 SE can be easily cleaned and decontaminated as often as needed, helping increase product quality and reduce the potential for human-related error or contamination. It is also one of the fastest robots of its kind. And because the electrical and air connectors and fittings are located outside the production zone, the robot enjoys greater agility while minimizing the risk of damage. All this enables Racer-5 SE to ensure higher production quality, better performance, quicker cycle times and reduced capital expenditures.

“Our new Racer-5 SE combines efficiency and technical excellence with the features and functionality required for effective application within sensitive settings,” explains Nicole Clement, Chief Marketing Officer at Comau. “We expect the adoption of Robotics in Sensitive Environments to grow significantly in the next coming years, largely

driven by increasing automation in fast-growing industries such as food & beverages, pharma, plastic & chemicals and electronics”.

Made entirely in Comau – Turin (Italy) – Racer-5 SE has a rigid construction to ensure higher precision and repeatability. It has been tested and certified for cleanroom compliance by Fraunhofer, and is available in two different 5 kg payload configurations, with a reach of 630 mm and 809 mm.

Innergie, a consumer power brand of Delta that won several international certifications and awards, today announced the launch of the C6 60 W USB-C adapter for Innergie’s flagship “One For All” Series. The latest C6 adapter takes advantage of Gallium Nitride (GaN) technology and boosts charging efficiency for consumers by up to 91.5%.

The new C6 adopts GaN instead of traditional Si-MOSFET components to optimize its electrical circuitry and to enhance power efficiency. Equipped with high-power delivery, the C6 automatically detects the output voltage for any device and provides fast charging for a wide range of 3C products. The C6 lowers operating temperature by 10 degrees Fahrenheit at 60 W full load charging—compared to Innergie’s previous 60C Pro generation of adapters.

Since working from home (WFH) is the “new normal,” seamless integration across multiple devices is a critical factor in determining energy efficiency during WFH. Innergie’s “One For All Series” adopts USB-C—the dominant connector primarily used by most smart devices—to support a power range spanning 30 W to 63 W. The series features PD 3.0 fast charging and output power customization for different devices by utilizing dynamic power allocation technology. Now users can charge laptops, mobile phones, tablets, earphones, game consoles and other devices. Innergie will continue to deploy GaN technology for new products in the “One For All Series” line—bringing efficiency, simplicity and convenience to our daily lives.

For more information about the Innergie C6: https://bit.ly/innergiec6gan

Available on Amazon for $47.99: https://amzn.to/3JYSi3e

Andantex will unveil its latest generation of high-precision planetary reducers, built around its new EVO 1 (Evolution 1) technology, during IMTS 2022 at Booth 236016.

Developed with machine tool performance in mind, EVO 1 is a new approach to driving machine tool axes. The EVO 1 mechanical gearing system approaches the performance of a linear motor at the lower price of a rack and pinion linear axis. Features include high stiffness, zero backlash and an ultra-minimal transmission error. This new design provides vibration-free motion and an optimum surface finish for the machined part.

At the show, Andantex will showcase its first range of redesigned planetary reducers featuring EVO 1 technology – the SRP, KRP, KRPX and DRP Series – which are all available in their existing sizes. The new design still features the breakthrough technologies that made this range of products a favorite for machine tool builders; small diameter integral output pinion, huge preloaded tapered roller output bearings helping to create maximum combined (radial, torsional and axial) stiffness, as well as Patented ZERO-BACKLASH DualDRIVE and TwinDRIVE solutions.

In addition to the planetary reducers, visitors can also check out many other products from Andantex’s varied lineup, including:

• Linear and rotary axis drive systems.

• Two-speed spindle drive gearboxes.

• Automatic lubrication systems.

• Merobel magnetic particle tension control systems.

www.andantex.com

Having recently opened their new state-of-the-art high-speed digital compliance test laboratory in Germany, Granite River Labs (GRL) has now further extended their scope of industry services for a growing European market. By adding the R&S ZNB20 vector network analyzer from Rohde & Schwarz to complement the previously acquired R&S RTP164 high-performance oscilloscope, the GRL test lab is able to offer an even broader range of testing services around established and future high-speed digital technologies like Automotive Ethernet or USB.

Granite River Labs (GRL), a global leader in compliance test and certification of high-speed digital designs, cables and connectors, and Rohde & Schwarz continue their partnership to build up GRL’s new European test laboratory in Karlsruhe, Germany, opened in December 2021. GRL has added the R&S ZNB20 vector network analyzer (VNA) from Rohde & Schwarz to the test equipment resources of their test lab.

With this step, the lab’s range of industry services is being extended to VNA-based measurements for verification, debugging and compliance tests of cable assemblies and connectors for Automotive Ethernet, Automotive SerDes Alliance, USB, HDMI, and many other standards. Besides that, GRL can provide customer services for accurate test fixture characterization and de-embedding in high-speed digital and RF applications. Last but not least, the R&S ZNB20 also complements the range of offered interface tests based on the R&S RTP164 high-performance oscilloscope with additional tests like return loss and mode conversion measurements as required in host/interface testing.

Rohde & Schwarz as a leading provider of test and measurement equipment offers state-of-the-art solutions for compliance test as well as an extensive tool chain for verification and debug test. Customers seeking official certification by the corresponding standards bodies can use the the same Rohde & Schwarz test solutions in-house

With the R&S ZNB20, GRL can offer VNA-based measurements at their test lab in Germany.

for R&D and pre-compliance testing, before getting their products officially verified and certified by GRL.

The R&S ZNB20 provides powerful tools for test fixture characterization and deembedding. It offers a wide range of measurement results, both in frequency and in time domain, also including transmission line impedance, signal rise time and skew as well as eye diagram and automated mask testing. In combination with the R&S ZNrun compliance automation software, it automates the complete test process from data collection, postprocessing and test report generation. The R&S RTP is based on a real-time signal processing architecture and provides a powerful tool set for verification and debug, including real-time de-embedding, real-time eye diagram, high-speed serial pattern trigger and protocol decoding, as well as an industry leading jitter and noise separation. Utilizing the R&S ScopeSuite Compliance Test framework the instrument executes automated tests for various high-speed digital interfaces with image-based workflow guidance and a comprehensive test report.

Granite River Labs as a leading test house for high-speed digital designs and interconnects offers customer services for compliance test and certification as well as debugging consultancy. Technologies, addressed at its recently opened location in Karlsruhe include Automotive Ethernet (up to 1000BASE-T1 and 2.5G/5G/10GBASE-T1) and USB 2.0 and USB 3.2, as well as HDMI, DisplayPort, MIPI, DDR and others.

Martin Stumpf, segment manager for digital design test at Rohde & Schwarz, says, “We are happy to move forward with our partnership with Granite River Labs and equip their new test lab in the heart of Europe. Pairing our expertise in test and measurement with the compliance and certification competency of Granite River Labs will help customers bring their products for current and future high-speed digital communications to market more quickly.”

Holger Kunz, President of Worldwide Services for GRL says, “Germany is the leader in innovation in the fields of automotive networking, infotainment, charging, and power management. We are pleased to be moving forward in our partnership with Rohde & Schwarz to ensure a worldclass product development ecosystem in Europe. With this relationship, GRL will be able to combine their deep technical expertise with our own extensive capabilities to support the introduction of next-generation products and solutions.”

Granite River Labs and Rohde & Schwarz have exhibited their joint competencies in high-speed digital compliance testing at the Automotive Ethernet Congress in Munich from June 1 to 2, 2022.

www.rohde-schwarz.com

Rohde & Schwarz has introduced not just one but two new maximum frequencies for the R&S SMW200A vector signal generator, bringing previously impossible high performance to digitally modulated signals up to 67 GHz and beyond. The R&S SMW200A is first to enable flat frequency response and 2 GHz modulation bandwidth above 44 GHz. In addition to all applications already supported up to 44 GHz, the 100 kHz to 56 GHz option covers all currently used 5G frequencies, plus earth-to-satellite applications. The 100 kHz to 67 GHz option also supports planned higher frequency 5G bands, the 60 GHz WiGig band, and inter-satellite links.

For the past decade the ceiling for a standalone vector signal generator capable of creating complex digitally modulated signals with high accuracy has been 44 GHz. Higher frequencies have only been possible with additional external frequency upconverters or lower accuracy, both of which have limitations. Now, with new options for maximum frequencies of 56 GHz and 67 GHz, the R&S SMW200A from Rohde & Schwarz dramatically raises the limits for generating wide bandwidth digitally modulated signals of high quality. A maximum modulation bandwidth of 2 GHz is supported, meeting the requirements of even the wider subcarrier spacings defined for 5G FR2 Release 17, and wideband satellite transmissions. The established R&S SMW200A signal qualities including excellent modulation, flat frequency response, and four

hardware-based levels of phase noise performance equally apply to the new frequency options.

Applications in the U and V bands now supported include mobile radio, Wireless LAN, and satellite communications. For mobile radio engineers developing RF components and products to support the 5G mobile radio spectrum available in the 47 GHz frequency band already allocated by the FCC to US network operators, the R&S SMW200A with 56 GHz or 67 GHz option is the ideal signal generator. 3GPP Release 17 specifying further enhancements to 5G has reached a well-defined stage, so the developers will be looking for a signal generator to cover the now extended FR2 frequency range from 52.6 GHz up to 71 GHz. The only suitable signal generator currently available is an R&S SMW200A with

a 67 GHz frequency option – supporting up to 72 GHz in overrange mode.

The new frequency options are equally interesting for high frequency WiFi and Wireless LAN, including IEEE 802.11ad, which operates in the 60 GHz unlicensed band (57-71 GHz).

For satellite communication applications, forward and reverse links operate between 37.5 GHz and 52.4 GHz; intersatellite links use frequencies up to 66 GHz with bandwidths up to 2 GHz.

In addition, for demanding applications above 44 GHz throughout the Aerospace and Defense industry, or for generating digitally modulated signals including early research on 6G components and systems, an R&S SMW200A with frequency options for 56 GHz or 67 GHz, is the highperformance single instrument signal source of choice.

The new R&S SMW200A vector signal generator frequency options are now available from Rohde & Schwarz.

www.rohde-schwarz.com

The R&S SMW200A vector signal generator now covers up to 67 GHz as a single-path instrument.

The R&S SMW200A vector signal generator now covers up to 67 GHz as a single-path instrument.

Whether you can’t have compressed air on your packaging line or want to eliminate the maintenance pains and waste issues, there is a solution. The EP4050 Linear Wipe Applicator is an all-electric Label Printer Applicator, which also means a faster return on your investment, better performance of accuracy and adhesion as well as safer for operators.

Does that sound too good to be true? It is not too good; it just works better.

This system has a fully electric applicator with a light, but robust 3D-printed pad, suitable for wipe-on applications. The applicator moves the labels to the correct position, and they get gently applied onto the labeling surface.

This applicator is perfect for applying labels on products and packages of different heights. The system can dynamically adapt the height of the applicator stroke using a smart laser sensor.

Laser sensors are typically installed before the labeling station. This communicates the product dimensions in advance and allows the applicator to position the label before the product passes. Because of this, it is also possible to label on the front edge of products and packages.

Distribution centers, e-commerce hubs and logistics facilities will benefit from this or any of the Phoenix Labeling print and apply systems, including our tamp/linear, swing arm, corner wrap, belt and pallet labeler. Printing and applying identification labels on any or every side of secondary and tertiary packaging has never been easier.

Phoenix Labeling is the world leader in the designing and manufacturing of smart electric Print & Apply labeling systems. Our machines are installed in all five continents and operate 24/7 to identify secondary and tertiary packaging in a variety of Industries.

How can you know for sure? Contact Phoenix Labeling today and let us provide you with the information you need for your application and process.

https://www.phoenixlabeling.com/labeling-systems/ ep4050-electric-pad-applicator

We are pleased to introduce the Gas Laser with highly advanced laser technology designed to detect natural gas with the aim of enhancing safety and improving detection for fire services, and first responders.

Frequently fire personnel and first responders are called to natural gas emergencies using equipment that puts them close to potentially dangerous structures. The Gas Laser supports remote detection allowing the operator to work at a safer distance from the hazard location. When access to a property cannot be established, the Gas Laser can operate through glass, giving the user an audible and visual indication to the presence of methane. This quick scan permits fire personnel and first responders to make rapid decisions and establish control of the gas and ignition sources should a gas escape be detected.

• Quickly scan common venting points from a safe distance

• Detection distance 30 m (100 ft)

• 8 hours run-time

• Highly visible, sunshine resistant guide laser equipped for location accuracy

• Graphical interface for easy user interpretation

• Color camera with Bluetooth, WIFI, and datalogging onboard

• Certified Intrinsically Safe to Class I, Division 2, Group D, T4

Discover this new solution: our video & our website

IDS NXT ocean: use multiple neural networks for multiple ROIs in one image.

Users of the all-in-one embedded vision system IDS NXT ocean now have a whole range of new features at their disposal. These include multi-ROI (“Region Of Interest”) for AI-based object detection and the possibility to use different neural networks for different ROIs in one image via Vision App. In addition, there are binning, line scan mode and performance and configuration improvements. New customers can also freely choose whether they want to use the IDS NXT lighthouse training software on AWS – as previously offered by IDS – or now also via Microsoft Azure Cloud.

With Microsoft Azure Cloud Services, IDS Imaging Development Systems now supports another hoster for the AI training software IDS NXT lighthouse in addition to AWS. The offer is aimed in particular at companies that are not allowed to work with AWS due to regulatory requirements. The scope of functions and services as well as the operation of the training software is the same with both hosters. Instead of setting up their own development environment, users can start training their own neural network right away in IDS NXT lighthouse – even without prior knowledge of Deep Learning or camera programming. This involves three essential steps: Upload sample images, label them and then

start the fully automatic training. The resulting network is optimised for use with IDS NXT industrial cameras.

Free IDS NXT lighthouse trial month for all customers How easy and convenient is the tool in reality? Interested parties can now judge for themselves. The company allows all customers to activate a free trial month and extensively test IDS NXT lighthouse. No sales contact is required to activate the full trial licence. All they have to do is register with their IDS user account at IDS NXT lighthouse (https:// ids-lighthouse.ai/login) and select the appropriate option during the process. The licence key is automatically provided.

The current software release also heralds a new, regular cycle for function updates. In future, the company will release new features approximately every three to four months, which will further improve the IDS NXT system and give customers even more scope for designing their image processing applications. The next update, also free of charge, is scheduled for April.

Learn more: www.ids-nxt.com

To date, these extremely robust and versatile emergency pull-wire and belt alignment switches have been “packaged” in a die-cast aluminium enclosure ideally suited to unfavourable ambient conditions thanks to multiple coatings (passivation, base coat, powder coat). Users can now alternatively opt for an enclosure which is made out of top-quality duroplastic and is anti-corrosive beyond all reasonable doubt. All screws and connecting elements are stainless steel.

The entire series features a high degree of flexibility. The ZS 92 S is available with a variety of pre-installed settings for the release lever and the unlocking mechanism. This means that the switch can be installed in nearly every conceivable operating position, including the rear side.

Installation dimensions are compatible with other readily available emergency pull-wire and belt alignment switches, making it easy to retrofit existing (conveyor) plants with the new switches or to exchange them later. In the ZS 92 SR belt alignment switch, the switching points for advance warning and switch off are easily adjustable in 5° steps, considerably increasing its practicality and versatility.

Users also benefit from significantly reduced release forces and paths when actuating the emergency stop function. They make the safety switch easier to operate and also mean that all the relevant international standards (e.g. regarding emergency stop devices with mechanical latching function) are reliably met.

The latest additions to the ZS 92 series with their robust plastic enclosures – whether as emergency pull-wire or belt alignment switches – are thus ideally suited to bulk conveying and handling applications.

https://www.steute.com/

Exxelia, a global manufacturer of complex passive components and subsystems for harsh environments, is expanding its CUBISIC capacitor range with a HTLP (High Temperature Low Profile) version. This CUBISIC HTLP offers, in a thin rectangular packaging, the highest energy density of capacitors in its class, combined with a high temperature resistance (-55° to +125°C).

CUBISIC HTLP, the new rectangular capacitor range that changes the game. The new range of CUBISIC HTLP by Exxelia clearly stands out! Why?

• It offers up to 60% more capacity than any other rectangular electrolytic capacitor on the market, in the same volume, while having a 5,000-hour life span.

• Covering a temperature range of -55° up to +125°C, the CUBISIC HTLP is designed to provide excellent performance in extreme temperatures, compatible with the most severe military and aerospace applications.

Engineers facing complex design requirements and looking for an easily integrated product will gain space and reliability through the use of improved materials, fully REACH compliant.

The CUBISIC HTLP withstands 20g vibrations and is lowpressure qualified, making it compatible to 92,000 feet in altitude. It is ideally suited for integration into cockpits, actuators, and power generation in commercial and military aircraft as well as radar and laser systems.

• Capacity from 140μF to 58 000μF

• Voltage from 7.5V to 350V

• Service life of 5,000 hours at 125°C

• Operating temperature -55°C to +125°C

• 20g vibrations and 92,000 feet altitude

• RoHS versions available

https://exxelia.com/en/product/detail/807/cubisic-htlp

Mitsubishi Electric Corporation has acquired 42,000 square meters of land in Owariasahi City, Aichi Prefecture, Japan to establish a new production site for the manufacture of factory automation (FA) control system products from April 2025.

Demand from the manufacturing industry for FA products is expected to show a medium to long-term growth, particularly in digital sectors such as semiconductors, electronic components, and data centers, as well as for decarbonization related areas such as lithium-ion batteries.

To meet such increasing demands, Mitsubishi Electric will invest approximately 13 billion yen (approx. 110 million USD) to establish a new production site in Owariashi City, which neighbors Nagoya where its main FA production site, Nagoya Works, is located.

The new factory will utilize several advanced technologies such as 5G communication, allowing simultaneous connection of various machines, human workers and automatic guided vehicles (AGVs) as they perform their manufacturing tasks. In parallel, high-speed, real-time data acquisition throughout the factory will provide data sets on all aspects of the production cycle for AI based analysis to realize a safe and flexible production environment.

Additionally, the factory, which will be a three-floor, earthquake-resistant building with a total floor area of 33,600 square meters, will incorporate Mitsubishi Electric’s digital manufacturing solution “e-F@ctory”. This advanced digital approach strongly impacts both the supply chain management (SCM) and engineering chain management (ECM) systems. For example, it combines information technology (IT) and operational technology (OT) with acquired know-how to achieve an integrated FA environment that reduces the total cost throughout the production process from design, manufacturing and maintenance. It also helps accelerate the improvement cycle for productivity and quality, bringing benefits which many manufacturers strive for, like shorter delivery times and higher production quality and efficiency, as well as being able to react flexibly to fluctuations in demand. Furthermore, the new factory will expand the use of automated production processes, including fully utilizing AGVs for increased efficiency in logistics, and digital twin technologies for synchronized digital and real-world production.

The factory is expected to achieve carbon neutrality by implementing a range of CO2 reduction activities that include an “e-F@ctory” based energy monitoring system, and the use of LED lighting, photovoltaic systems and biotopes.

https://us.mitsubishielectric.com/en/

Demanding die-cast components, such as structural components in the automotive sector (megacastings), place special requirements on the temperature control, in particular on the cooling of so-called hotspots. The jetPulse system from REGLOPLAS offers a reliable and economical solution for cooling hotspots in a die casting die with pinpoint accuracy and reliability.

The spot cooling of so-called hotspots in die-casting dies is an established process for improving the quality and mechanical properties of components with demanding geometries and optimising the cycle time. The trend towards ever larger components, mainly driven by so-called megacasts in the automotive sector, has further increased the need for precise spot cooling systems and has raised the requirements. The jetPulse system from REGLOPLAS offers a suitable solution for every application, configuration and die size. As a supplement to the proven temperature control units and distribution systems for pressurised water and oil from REGLOPLAS, the customer receives a complete temperature control solution for his die casting machine from a single source, including the software for monitoring the entire system and with worldwide local support and service.

The REGLOPLAS jetPulse system offers two unit sizes (30 l or 100 l). Up to six multiJet distributors with 8 channels each can be connected per unit. These reliably cool up to 64 individual hotspots with pinpoint accuracy and cycle controlled. The system is supplemented by the flow rate monitoring of each individual channel with the REGLOPLAS flowControl. The system detects problems in individual cooling channels at an early stage and thus avoids costs due to quality problems and rejects at an early stage. A Profibus interface ensures simple communication between the jetPulse system and the die casting machine.

The jetPulse 100L has a frequency-controlled, multistage, low-noise pump with a flow rate of up to 100 l/min and a system pressure of up to 30 bar. The pump is equipped with an energy-saving function and is only active while cooling is running. Using intelligent technologies, the system monitors and controls the pump pressure, temperature, flow rate and output. This ensures excellent stability and the highest

degree of safety during the cooling process. The intelligent process monitoring constantly checks the operating data and signals deviations from individually definable limit values before failures occur. Automatic core breakage and leakage monitoring is integrated in each jetPulse cooling cycle. This stops die casting machine immediately if an irregularity is detected in order to prevent possible damage to the tool. The complete system is individually controlled and parameterised in a simple and user-friendly way using the touch screen on the Siemens HMI panel, with easily understandable graphically assisted displays and representations.

The jetPulse system offers customers an extensive system with a sophisticated component architecture from a single source. The robust and compact units can be easily and quickly integrated into new or existing die casting plants and deliver more process reliability, better and more stable product quality and shorter cycle times for demanding components with hotspots at low investment costs. jetPulse from REGLOPLAS yields lower unit costs and high component quality, thus sustainably improving competitiveness.

www.regloplas.com

Robustel are glad to announce that our R1510 industrial cellular IoT gateway has been adopted by NTT DOCOMO. This milestone is major progress for Robustel on its mission to help customer’s businesses in industries across the world to solve their connectivity problems with robust, secure and scalable IoT and M2M solutions.

NTT DOCOMO, have developed a IoT service package called “DOCOMO IoT Managed Service”, it is a service bundle combining communication devices, connectivity and maintenance in a complete service offering. This service has wide reaching applications beyond the IoT industry, functioning as an alternative solution for any customer using ISDN/PSTN and 3G networks as they are scheduled to be shut down in the future.

The Robustel R1510 IoT Router is an industrial LTE router offering cost competitive connectivity with various interfaces. With thousands of units regularly being shipped worldwide, the R1510 has been certified by over 20 mobile network operators (MNOs) in Japan, the United States, Europe, Southeast Asia, etc. Therefore, the router can be quickly deployed in IoT projects not only in Japan but also globally.

The R1510 offers an industrial ruggedized housing that can be used in harsh environments with an operating temperature range from -25 to 75°C. In addition to the two Ethernet interfaces it can also support digital input/outputs (DI/DO) as well as Wi-Fi in client and access point modes.

For more information about R1510, please visit https://www.robustel.com/en/product/r1510-industrialcellular-vpn-router/

Robustel Cloud Manager Service (RCMS) Value Added Robustel Cloud Manager Service (RCMS) is a modular IoT cloud software platform compatible with all Robustel products.

RCMS is designed from the ground-up to empower Robustel customers to build their IoT Solution(s) in a manner that is scalable, cost effective and can evolve quickly with the market.

Designed to work hand-in-hand with RobustOS, RCMS unlocks the true potential of Robustel products giving customers the ultimate range of monitoring, management and control functions.

With its modular design RCMS enables new APPs to be added to the platform without interfering with core behavior, to create new functionality and allow for integration with thirdparty applications.

For more information about RCMS, please visit https://www.robustel.com/en/robustel-cloud-managerservice/

Together with our local distribution partner PALTEK Corporation (Headquarters: Kohoku-ku, Yokohama, CEO: Tadahito Takahashi, hereinafter referred to as PALTEK), we have also established a strong operational support system to match the service of NTT DOCOMO, offering local maintenance, warranty and support systems which have been a critical factor in the adoption of this solution.

https://www.paltek.co.jp www.robustel.com

Featuring three different screw technologies, AVENTICS Series SPRA rod-style electric actuators offer unmatched versatility that can better meet exacting application requirements.

Emerson today launched its new AVENTICS™ Series Servo Profile Advanced (SPRA) Electric Actuators, a line of precise and highly repeatable rod-style cylinders. While only one electric actuator screw type is typically available in the market, the SPRA actuators offer three screw technologies. These include a precision ball screw, which provides exceptional durability and accuracy for applications that need optimal quality or throughput, a cost-effective lead screw option and roller screws for precision, speed and heavy loads.

This versatile range of rod-style cylinders lets users in the automotive, food and beverage, packaging and life sciences industries configure electric actuators to meet exacting application requirements, such as improved sustainability or efficiency, rather than settle for standard approximation.

“With four sizes and multiple mounting options, the AVENTICS Series SPRA Electric Actuators are cost-effective, high-performance solutions that cover most machine automation applications,” said Linda Schwartzen, product marketing manager with Emerson’s AVENTICS actuator business. “Compliance with the ISO-15552 standard offers a wide range of accessories and our online calculation tool and configurator ensures the appropriate implementation and can meet exacting application requirements.”

Interconnected online tools allow users to instantly size and customize electric actuators, with no software installation or registration necessary. The configuration includes a direct download of CAD files, which comprises all elements of the configured solution, such as electric cylinder, accessories, mounting options and motor adapter.

https://www.emerson.com/en-us/catalog/aventics-spra

Curtiss-Wright’s Actuation Division announced that it recently completed and delivered upgrades to the Jet Blast Deflector (JBD) and Barricade Stanchion actuators used in Gerald R. Ford (CVN 78) Aircraft Launch and Recovery Equipment (ALRE) system onboard the US Navy’s Ford-class carrier constructed and supplied by HII’s Newport News Shipbuilding division.

The upgrades were part of the work to ready the carrier for deployment after its successful completion of shock trials. The upgrades provided added environmental protection as well as changes to allow for faster and simpler on-board planned maintenance.

The program required expedited refurbishment and delivery of the actuators to support the U.S. Navy’s deployment schedule for the CVN 78 carrier, the first of the new Fordclass aircraft carriers. Exlar completed the upgrades and delivery to meet the requested schedule.

Based on Exlar’s performance, HII-NNS’s Director of Supply Chain Procurement, Kelly MacDonald stated that, “The timeliness of your support and dedication to high quality standards are recognized as best in class by both Newport News tradesmen and leadership. This trust and partnership is an important piece of our commitment to our customer, the United States Navy, and plays an essential role in support of national security.”

Curtiss-Wright supplies numerous innovative and mission critical products and services in support of the U.S Navy and its ship builders for both sub-sea and surface ships. Phil Bowker, Sr. General Manager Curtiss-Wright Actuation Division, stated we are proud to continue our support of the U.S. Navy and their shipbuilders. The ability for our team to safely complete and deliver these critical upgrades, considering the on-going challenges from the COVID-19 pandemic, is a testament to our commitment, skill, and expertise. We appreciate the trust Newport News Shipbuilding places on us as a valued supplier and partner. https://www.cw-actuation.com/

Coastal Machine & Supply, an experienced US-based manufacturer of precision, custommachined parts for the oil and gas industry, has used its investment in a Keyence WM series wide-area CMM (coordinate measuring machine) to help it diversify into the aerospace market. In particular, the CMM simplifies the extensive GD&T (Geometric Dimensioning and Tolerancing) requirements associated with the machining of aerospace components.

Located in Carencro, Louisiana, the 37,200 ft2 (3,456 m2) facility of Coastal Machine is home to a wide selection of the latest CNC machining centers and lathes. Formed in 2004, the 50-employee company prides itself on the quality of its machined parts, where accuracy and precision are key to business success.

“While we’ve always served the oil and gas industry, over past two years we’ve consciously been diversifying into other markets, including aerospace and defense, largely due to the Covid-19 pandemic and how it affected the oil and gas sector,” explains Operations Manager Kody Guidry.

A traditional part of Coastal Machine’s business is the production of long downhole oil and gas parts, some of which can be up to 240 inch (6 m) long.

“Historically, we measured the overall length of these components using a tape measure or by stacking up scales,” explains Guidry. “However, for one contract we sent some parts to a premium threading shop and they were using a Keyence WM series wide-area CMM, which immediately sparked our interest.”

Coastal Machine duly contacted Keyence for a demonstration at the company’s Carencro headquarters.

“It was an easy decision to invest as we knew immediately that we could easily check our long parts to tight tolerances far more easily than with hand tools,” says Guidry. “Today, we use a macro in the WM for checking overall length, which takes the operator through the measurement process in a simple and user-friendly way.”

With its large 10 m (32.8 ft) measuring range, the Keyence WM series wide-area CMM is a far better option for large parts than a CMM arm, bridge CMM, laser tracker or hand tools, all of which suffer from restricted measurement area, the requirement for highly trained operators and difficulty in allowing single-person inspection. Maintenance costs can also be high.

The shop-floor-ready, portable WM series performs precision measurement via its triple-camera tracking system that captures near-infrared light emitted by seven probe markers. As a result, users benefit from a high-accuracy of ±28μm (±0.001 inch), even over a large area. The WM Series offers ease-of-use as the wireless probe allows for part measurement without restrictions, while the probe’s touchscreen facilitates the same operations that were previously performed on a separate computer. Low cost of ownership is another advantage as the device performs selfcalibration before measurement, so there are no costs for training, support or ongoing maintenance.

Although the checking of long components for the oil and gas sector was Coastal Machine’s original requirement for the Keyence WM, the CMM’s capability and versatility led to the company finding further uses for the device.

“It helped us to accelerate our diversification into the aerospace market as we didn’t have a CMM previously,” states Guidry. “Today, the primary use for our WM is performing GD&T measurements on aerospace parts. The system is ideal for GD&T inspection, even while the component remains in the machine tool.”

As the aerospace and defense industry grows, Coastal Machine is able to position its expertise and equipment in a way that helps to fulfill the needs of the sector and give value to clients, while simultaneously forming part of the next frontier of design and manufacturing.

“We’ve had the Keyence WM for just over a year and we work it hard,” says Guidry. “We are busier than ever and currently in a growth phase. Our processes and systems ensure we get repeat business, and investment in the latest technology is a big part of that.”

The wide-area CMM recently saved Coastal Machine the cost and time of remanufacturing parts that one customer claimed were incorrect.

“We sent some long oil industry parts to a client who checked them with scales and tried to refuse them, stating they were out of tolerance,” explains Guidry. “So we doublechecked them with our Keyence WM, which confirmed the parts as correct. The customer conceded to our superior measurement technology and passed them through.”

Component quality is a primary goal of Coastal Machine, which guarantees defect-free products. The company is certified to ISO9001 and AS9100 Rev D, registered to API Q1 and ITAR, and carries two API threading licenses.

“We have an unwavering commitment to product quality,” concludes Guidry. “However, our investment in the Keyence WM series wide – area CMM allows us to be even more accurate with our measurements, taking the company’s quality to new levels of excellence.”

www.keyence.com/CMS-coastal

168 Manufacturing, a developer of CNC machine shop automation technologies, will debut its FullShop™ Automated Coolant Management System at this year’s International Manufacturing Technology Show (IMTS). 168 Manufacturing will exhibit at Booth 431238 on the third floor of the West Building.

FullShop™ systems, which include the flagship FS120 and newer FS40 series, monitor and replenish all CNC machine sumps with optimized top-off ratios before the coolant runs low. These easy-to-install turnkey systems consist of a centralized pumping station, controller, distribution manifolds and level sensor that drops into the machine tool sump.

In addition, each machine is compatible with a coolant health app that enables users to collect, visualize and track coolant parameters from a smartphone, tablet or desktop, offering real-time visual notifications and displaying trends over time. In addition to its compatibility with FullShop™ systems, the app is available as standalone software.

IMTS, which features the latest innovations in digital and traditional manufacturing, will take place from September 12 to 17 at McCormick Place in Chicago, Illinois.

www.168mfg.com

Lanner Electronics & Hailo collaborate on one of the most cost-efficient PCIe accelerator cards on the market, with record high tera operations per second (TOPS), enabling high-end deep learning applications on edge servers.

Lanner Electronics, a global leader in the design and manufacturing of intelligent edge computing appliances, announced its first Hailo-8™AI-powered PCIe accelerator card, the Falcon H8. Lanner Electronics collaborated with leading AI (Artificial Intelligence) chipmaker Hailo to design the Falcon H8, enabling scalable and powerful intelligent video analytics applications for multiple industries operating at the edge, including intelligent transport systems (ITS), smart cities, smart retail, and Industry 4.0. The Falcon H8 is one of the most costefficient PCIe AI accelerator cards on the market, with a low power consumption and record high of up to 156 tera operations per second (TOPS) to allow high-end deep learning applications on edge servers.

Lanner’s Falcon H8modular, PCIe FHHL form factor provides a compact and easily deployable solution for engineers looking to offload CPU loading for low-latency deep learning inference. With high-density AI processors, the Falcon H8 accommodates 4, 5, or 6 Hailo-8™ AI processors, offering a modular, cost-effective Edge AI solution with high processing capabilities and power efficiency. Through a standard PCIe interface, the Falcon H8 AI Accelerator Card enables legacy devices such as NVRs, Edge AI boxes, Industrial PCs and robots to run video-intensive, missioncritical Edge AI applications such as video analytics, traffic management, access control, and beyond.

The Falcon H8 delivers unprecedented inference processing of over 15,000 Frames Per Second (FPS) for MobileNet-v2 and 8,000 FPS for ResNet-50. Its performance is up to 4x

more cost effective (TOPS/$) and 2x more power efficient (TOPS/W) compared to leading GPU-based solutions.

“Optimized for AI functionality, performance, and ease of deployment, Lanner is pleased to partner with Hailo to design a next-gen AI accelerator card that brings topperforming AI computing to the edge of industrial IoT,” said Jeans Tseng, CTO of Lanner Electronics. “Our expertise in creating high-density hardware platforms, combined with Hailo’s state-of-the-art neural chip and software framework, provides service providers and system integrators a bestin-class AI accelerator that enables running deep learning applications most efficiently with the lowest total cost of ownership.”

“The integration of Lanner’s Falcon H8 and the Hailo-8 provides unmatched AI performance at the edge. This joint solution is more powerful, scalable, and cost-effective than other solutions available on the market today,” said Orr Danon, CEO and Co-Founder of Hailo. “Our collaboration with Lanner will better power edge devices across industries, including transportation, smart cities, smart retail, industrial IoT, and more.”

Lanner Electronics and Hailo firstannounced their collaboration in 2021, launching groundbreaking AI inference solutions for real-time computer vision at the edge. Several Tier-1 customers have since adopted the companies’ groundbreaking platforms.

https://www.lannerinc.com/

With a new ultra-wideband (UWB) PHY Test Suite for the R&S CMP200 radio communication tester, Rohde & Schwarz now offers a PHY Conformance Test Tool (PCTT) to support conformance testing of the UWB PHY layer as specified by the FiRa Consortium.

Rohde & Schwarz, a leading provider of wireless device testing solutions and member of the FiRaTM Consortium, announced today that it will provide a FiRa validated ultra-wideband (UWB) PHY Conformance Test Tool (PCTT) to support the further development of an open and standardized UWB ecosystem. With expertise and experience in wireless technology verification and certification, Rohde & Schwarz is well positioned to provide a test tool to support interoperability on the UWB physical layer as specified by FiRa.

Thanks to the unique capabilities of UWB for secure fine ranging, UWB-enabled devices can accurately and securely measure the distance and direction of connected devices. These capabilities make UWB the perfect technology for use cases such as indoor navigation, social distancing, handsfree access, asset tracking, ticket validation, mobile payment, and point-and-trigger applications. The FiRa Certification Program is intended to support interoperability of UWBenabled devices on different layers. This includes physical layer conformance testing performed by FiRa Authorized Test Laboratories (ATLs). These labs use FiRa validated test tools like the test solution from Rohde & Schwarz.

Clint Chaplin, Secretary of the FiRa Consortium Board of Directors and co-chair of the Compliance and Certification Working Group says, “Delivering a seamless customer experience and device interoperability are essential for the wide success of UWB. Certification is one cornerstone to support interoperability. We are pleased that we now have a FiRa validated PHY Conformance Test Tool from Rohde & Schwarz in the FiRa Certification Program.”

As a leader in wireless device testing, Rohde & Schwarz collaborates with industry partners and organizations like the FiRa Consortium to develop UWB test solutions. These test solutions are used for R&D, certification, chipset characterization and production. The comprehensive set of UWB test capabilities of the R&S CMP200 radio communication tester controlled by the new UWB PHY Test Suite for test automation allows flexible pre-conformance testing. It also offers an option to run as a PCTT for FiRa certification.

Christoph Pointner, Senior Vice President for Mobile Radio Testers at Rohde & Schwarz, says, “We at Rohde & Schwarz, the leading supplier of wireless connectivity test solutions, are pleased to support the FiRa Consortium in its efforts to establish a strong certification framework for an open UWB ecosystem by providing a validated physical layer test tool. We look forward to continuing our work with members of the FiRa Consortium to cover upcoming UWB use cases and to strengthen the certification framework.”

For further information about the UWB test solutions from Rohde & Schwarz, go to: www.rohde-schwarz.com

With the new Light Conveyor Platform (LCP), Interroll is expanding its range of products with a platformbased material-flow solution that significantly increases the productivity of manufacturing processes. Designed as a plug-and-play modular system, the LCP allows all system integrators to implement scalable belt conveyor sections very easily in order to quickly meet customer-specific automation requirements for material flow. The high quality and availability of this solution is ensured by, among other things, the use of technical products that have already proven themselves hundreds of thousands of times with users worldwide.

Efficient material feed and discharge play a crucial role in realizing the productivity potential of manufacturing cells, assembly and packaging stations. At the same time, rapidly changing process environments in many other industries require flexible conveyor solutions that can easily adapt to new requirements.

This is what the Interroll’s new material flow solution for system integrators and plant engineers achieves. Corresponding LCP-based belt conveyors can be easily assembled from factory-preassembled and predefined modules without any engineering effort, and can be put into operation quickly and safely via an autonomous machine control system, optionally without an additional programmable logic controller (PLC). Depending on customer requirements and application, however, connection to an external PLC with user-specific programming is also possible.

Interroll’s LCP is designed to transport smaller conveyed goods, as well as boxes or polybags weighing up to 50 kilograms. The conveyors, which can also handle inclines or declines, are driven by compact and energy-efficient drum motors that have an efficiency of over 85 percent, keeping

energy consumption and energy costs very low. The fully modular system can be planned and assembled very easily and conveniently on the PC monitor using Interroll’s popular Layouter tool. This drastically reduces project lead times and the necessary effort for system integrators. In addition, the predefined module sizes in different lengths and widths create the best conditions for fast production and delivery times.