PCVUE SOLUTIONS: OPTIMIZATION AND CONTROL OF NATIONWIDE EV CHARGING STATIONS 38 35 | JANUARY 2023 EMERSON’S NEW ANALYTICS SOFTWARE AUTOMATES UTILITIES MONITORING AND REPORTING FOR CLEAN-IN-PLACE APPLICATIONS 18 MARKET OVERVIEW 3D PRINTING WHERE ARE WE AT WITH THIS INDUSTRIAL REVOLUTION? 4 FLAT PCBS TO MINIATURE IMPLANTABLE 3D-CIRCUITS 28 THE INDUSTRY MAGAZINE FOR EUROPE • MIDDLE EAST • AFRICA industryEMEA

MITSUBISHI ELECTRIC 14 EMERSON AUTOMATION SOLUTIONS 18 EMERSON AUTOMATION SOLUTIONS 20 DELTA 22 CAMILLE BAUER 34 WEARIN’ 24 KOMATSU 37 INNODISK 27 ARC INFORMATIQUE 38 HARTING 28 WATLOW 31 SECO TOOLS 32 www.industryemea.com THE INDUSTRY MAGAZINE FOR EUROPE • MIDDLE EAST • AFRICA 35 | Industry EMEA | January 2023 ADVERTISERS: MEPAX 11 MARKET OVERVIEW 4 MOXA 12 ANELLOTECH 13

Send your press releases to: editor@ipmediaonline.com To receive the Industry EMEA newsletter, please subscribe online: www.industryemea.com

Industry EMEA is the magazine published by INDUPORTALS MEDIA PUBLISHING for engineers. It presents the latest product and company news for industrial markets. Industry EMEA edits its articles with the greatest of care, however we cannot guarantee the accuracy of the information presented in them. Our teams disclaim all responsibility concerning the content of this media or how it might be used.

https://induportals-media-publishing.com

SIC MARKING 41 VERLINDE 42 DTP 43 INDUPORTALS MEDIA PUBLISHING

By K.A. Gerardino.

3D PRINTING WHERE ARE WE AT WITH THIS INDUSTRIAL REVOLUTION?

Next to industrial and digital revolutions, 3D printing is another technology changing the world. It is an ultramodern manufacturing technique that can be found almost everywhere and not just as tooling in factory settings.

While today’s 3D printing carries some impressive capabilities and is a widespread mode of production used by manufacturers across nearly every industry, it was not always like that. 3D printing has come a long way since additive manufacturing technology was introduced back in the 1980s. To understand this futuristic method, it is helpful to understand the history of 3D printing, what have come before it, and where are we at with this industrial revolution.

How it began

Additive manufacturing started in the 1980s when Chuck Hull invented a process called, stereolithography, now known as 3D printing. He discovered the method, which used UV lasers to create 3D objects layer by layer, after becoming frustrated with the long production times of prototyping. This sparked the next wave of manufacturing practices, and in 1986, he successfully patented his invention, eventually becoming the father of 3D printing. Thus, commercialized availability of additive manufacturing and 3D printing for manufacturers was born.

Endless innovation and development

Since the invention of the first 3D printing rolled into the spotlight, it has been subject to rapid and endless innovation and development. A niche technology, it has opened possibilities for start-ups to present reasonably-priced 3D printers, with major multinational corporations like HP and GE entering the 3D printing space.

3D printing technology has offered various solutions to help tackle the shortcomings that traditional manufacturing methods have for decades. The global 3D printing market is projected to grow from US$18.33 billion in 2022 to US$83.90 billion by 2029, at a CAGR of 24.3% in forecast period, 2022-2029, exhibiting a CAGR of 24% during the forecast period, reports Fortune Business Insights.

According to the market research firm, the rapidly increasing digitalization, growing adoption of advanced technologies, such as Industry 4.0, smart factories, robotics, machine learning, and others fuel the demand for online 3D printing for simulation purposes. These technologies increase the chances of broader adoption and greater utilization of this technology across industries, including aerospace, automotive, healthcare among others.

35 | Industry EMEA | January 2023 4 NEWS

MARKET OVERVIEW English version

35 | Industry EMEA | January 2023 5 NEWS

MARKET OVERVIEW

Materialise Magics 26 with CAD and mesh capabilities for 3D printing. Source: Materialise

Significant 3D printing techniques today

We have witnessed the continued evolution of 3D printing in the past year as it transitions from mostly prototyping to widespread use in manufacturing at scale. The great paces made on the technology front mean that today’s printers can provide manufacturers with parts that are faster to develop, more accurate, lower cost, and closer to the point of application. Here are some of the important techniques of 3D printing technology today:

Stereolithography (SLA): Stereolithography is an additive manufacturing process using a vat of liquid UV-curable photopolymer resin and a UV laser to build parts a layer at a time.

Digital Light Processing (DLP): Digital Light Processing displays the image of the 3D model onto the liquid polymer. The exposed liquid polymer hardens and the build plate moves down and the liquid polymer is once more exposed to light. The process is repeated until the 3D model is complete and the vat is drained of liquid, revealing the solidified model.

Selective Laser Sintering (SLS): Selective Laser Sintering is an additive manufacturing technique that uses a high-power laser (for example, a carbon dioxide laser) to fuse small particles of plastics, metal (direct metal laser sintering), ceramic or glass powders into a mass that has a desired 3-dimensional shape.

Inkjet Binder Jet: A binder jetting machine will distribute a layer of powder onto a build platform. A liquid bonding agent is applied through inkjet print heads bonding the particles together. The build platform will be lowered and the next layer of powder will be laid out on top. By repeating the process of laying out powder and bonding, the parts are built up in the powder bed.

Selective Deposition Lamination (SDL): SLD is a 3D printing process using paper. The process involves layers of adhesive coated paper (or plastics or metal laminates) that are successively glued together with a heated roller and cut to shape with a laser cutter layer by layer. A roller with the material moves each new sheet of material over the last and repeats the process until the object is completed.

Electronic Beam Melting (EBM): EBM is like laser melting, but working with an electron beam instead of a laser. The machine distributes a layer of metal powder onto a build platform, which is melted by the electron beam. The build platform is then lowered and the next layer of metal powder will be coated on top. The process of coating powder and melting where needed is repeated and the parts are built up layer by layer in the powder bed.

Fused Filament Fusion (FFF): FFF is an additive manufacturing technology, it is now the most popular 3D printing process, and in FFF a continuous filament of a thermoplastic material is used. Through a moving, heated printer extruder head, molten material is forced out of the print head’s nozzle and is deposited on the work piece layer by layer to form the desired Product.

Innovative 3D printing company to date

Every manufacturing company knows that having a vision before you have even started the process of prototyping is where the treasure lay. When great concepts are combined with technology, the possibilities can take form. Some companies have succeeded connecting the competences of 3D printing to solve the 21st century’s most perilous issues. IMARC Group released its top 3D printing companies in the world:

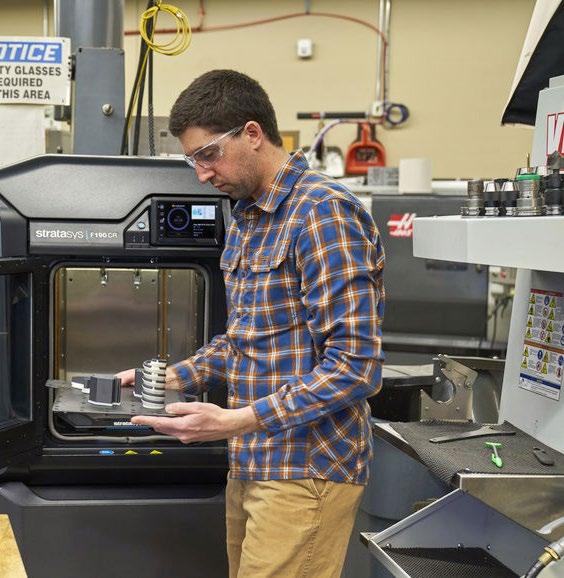

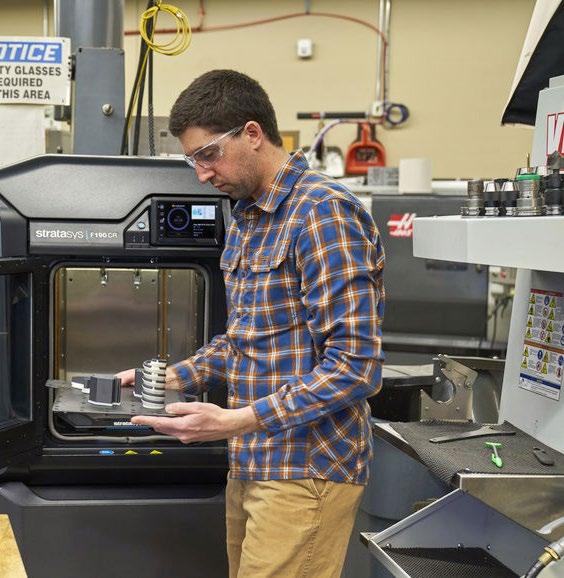

Stratasys Ltd is one of the top companies that are at the forefront of 3D printing technology. It caters to various enduse industries, including aerospace, automotive, medical start-up, as well as tech giants. It also provides decades of knowledge, consulting, training, workflow management, and end-to-end support.

3D Systems, Inc. has been leading the additive manufacturing innovation since its inception. Its portfolio includes hardware, software, and material solutions that span from plastics to metals, and is backed by industryspecific engineering expertise housed in the application innovation group. It also offers a combination of solutions, expertise, and innovation that helps users defy conventional

35 | Industry EMEA | January 2023 6 NEWS

MARKET OVERVIEW

manufacturing limitations and maximize the value of additive manufacturing.

Materialise NV has combined the largest group of software developers in the industry with one of the largest 3D printing facilities in the world to enable new users for the extraordinary potential that 3D printing offers. The company has created a range of software solutions and 3D printing services to form the backbone of the 3D printing industry.

EOS is a worldwide provider for industrial 3D printing of metals and plastics. The company brings responsible manufacturing solutions via industrial 3D printing technology to manufacturers across the globe. Today, the company’s industrial 3D printing systems make it possible to respond quickly to the demands of volatile markets and address trends like the increasing customization of end products.

ExOne has been the global leader in industrial 3D printing systems company in the United States for more than 20 years. It uses Binder Jetting technology, an additive manufacturing process, to selectively join a binding agent with industrial-grade powder particles. It also created a

Stratasys composite-ready 3D printers are designed for manufacturers to supplement traditional fabrication technologies with high-strength composite 3D printing. Source: Stratasys

custom finished product from a 3D CAD file using metal, sand, or ceramic materials.

Voxeljet AS is a global innovator and technology driver for advanced 3D printing systems and solutions in production environments. The company is equipped with state-of-theart binder jet components and seamlessly integrated into partially or fully automated production systems. It is also sustainably shifting the economic parameters and possible applications of additive manufacturing in the industry.

Hewlett Packard (HP) Enterprise Company aims to create technology that makes life better for everyone, everywhere across the globe. HP Personalization has partnered with 3D printing to make any idea, large or small, simple, or complex, a reality. Furthermore, HP MJF 3D printing technology can unlock new possibilities that complement CNC, injection moulding, as well as additive manufacturing, and powderbased technologies.

SLM Solutions Group is one of the leading providers of industrial metal 3D printing machines focused on metal additive manufacturing and multi-laser technology. They find applications across end-use industries including,

35 | Industry EMEA | January 2023 7

MARKET OVERVIEW

aerospace and defense, automotive, energy, healthcare, tooling, and research.

EnvisionTEC offers a wide variety of 3D printing systems with the ability to mass-produce polymer parts. ETEC printers deliver parts with exceptional accuracy, superior part properties, fine feature detail, and a smooth surface finish. They also provide scale and cost that are competitive with traditional manufacturing techniques like injection moulding.

CleanGreen3D is an Irish company that bought the assets and IP of the former Mcor Technologies Limited, an innovative manufacturer of the world’s most affordable, full-colour, and eco-friendly 3D printers. It makes use of ordinary business letters and A4 papers as build material. Its vision is to make 3D printing more accessible to everyone by rendering durable, stable, and tactile models.

Optomec, Inc. offers production equipment and digital solutions such as 3D printed metal, 3D printed electronics, for the digital age. It aims to reduce lifecycle costs for long-term asset management. The company also enables customers to not only print full 3D parts but also add materials onto existing 3D parts that were produced using conventional manufacturing methods.

Groupe Gorge specializes in high technology and is imbued with a strong entrepreneurial culture. It is one of the leading players in its high-tech markets and operates around the world in innovative and growth sectors such as drones, robotics, engineering, and protection systems. Moreover, the company is enabling major players to find routes to successful production processes by providing 3D printers and new premium materials.

Ultimaker is the market leader in desktop 3D printing that has built an open and easy-to-use solution of 3D printers, software, and materials. It is increasing business flexibility and continuity by 3D printing parts with software trusted by over 800,000 users. Their easy-to-use FFF desktop 3D printers can save time and money while streamlining the workflow and delivering the quality results that are expected.

Renishaw plc is a systems manufacturer and solutions provider for additive manufacturing or 3D printing. It is one of the leading manufacturers of advanced metal additive manufacturing systems and an expert provider of customer-tailored solutions. The company makes use of thin layers of materials to create complex shapes, which cannot be produced by “traditional” techniques such as casting, forging, and machining.

Beijing Tiertime Technology Corp. Ltd strives to deliver additive manufacturing solutions to a wide variety of fields, such as science, mechanical engineering, industrial design, low-volume manufacturing, and education. The company is China’s first 3D printer manufacturer that launched the nation’s entry into the additive manufacturing age with the Inspire industrial line.

35 | Industry EMEA | January 2023 8 NEWS

MARKET OVERVIEW

Various pipe fittings printed by Newport News Shipbuilding using Certified CuNi30 material on 3D Systems’ Direct Metal Printing hardware. Source: 3D Systems

XYZprinting, Inc. is one of the leading global providers of comprehensive 3D printing solutions. The company offers desktop 3D printing products and services and is venturing into the industrial additive manufacturing arena. Moreover, XYZprinting is backed by the world’s leading electronic manufacturing conglomerate, New Kinpo Group, which earns more than US$36 billion in revenues annually and has more than 8,500 engineers in research and development across four continents.

3D printing trends in 2023

With favourable balance sheets and a multitude of latest offerings, 3D printing industry is expected to accelerate adoption in manufacturing processes and make meaningful advances in 2023 and beyond.

These are a few trends that are expected to dominate this year:

Lower cost of 3D printing: One of the major trends in the 3D printing industry is the decreasing cost of 3D printing technology. As 3D printing becomes more accessible, prices are decreasing and the technology is becoming more affordable. This will make it easier for businesses and individuals to utilize 3D printing technology and will offer a new world of options.

Improved speed and quality: Speed and quality are two of the most important aspects of 3D printing. It is becoming faster and more accurate with new advancements coming in. This will enable businesses to create better products more quickly and efficiently and will lead to a greater level of customization for consumers.

Increased use of materials: In the past, 3D printing was limited to plastics and metals. However, as 3D printing technology continues to evolve, an increased use of materials, such as ceramics, polymers, and even food items are likely to happen in the future. This will open a new world of possibilities for 3D printing and will allow businesses to create products that were not previously possible.

The development of multi-material 3D printing allows to produce objects with multiple materials and properties. This technology has the potential to greatly expand the range of applications for 3D printing, including the production of functional prototypes, customized medical devices, and even consumer products.

There has also been a trend towards the development of more advanced 3D printing technologies, for instance: 4D printing and 5D printing. 4D printing involves the use of materials that are capable of changing shape or properties over time in response to external stimuli, such as heat or moisture. 5D printing, on the other hand, involves the use of multiple 3D printing techniques to create objects with complex structures and functions. These technologies have the potential to significantly expand the capabilities of 3D printing and could lead to the development of new and innovative products.

35 | Industry EMEA | January 2023 9 NEWS

MARKET OVERVIEW

Additive Minds Academy: blended learning formats

Widespread adoption: As 3D printing becomes more affordable and accessible, it is expected to be adopted by a larger portion of the population. This will open new prospects for individuals and companies to utilize 3D printing technology, as well as lead to new innovations in the industry.

A reduction in carbon emissions is to be expected, as parts now require less transportation. Parts can now also be produced more sustainably as it is easier to customise the materials and dimensions of a part, leading to waste reduction. On that note, its on-demand production capabilities will also ensure that one can only manufacture parts that they need when they need them, resulting in minimal parts wastage and excess.

Shift from process automation to workflow automation: The promise of large-scale industrial 3D printing requires us to automate not only each individual process but also the flow between them. This is what we call workflow automation.

Fred Vancrae, CEO of Materialise, explained, “We see the same requirement in a medical industry where workflow automation is needed to address the dramatic increase of customized 3D printed solutions. The good news is that the ability to meet this need is growing thanks to the creation of software platforms that allow manufacturers to define their own unique 3D printing process. Several companies including Materialise now offer these solutions to customers allowing them to automate not just the individual 3D printing processes but the entire 3D printing workflow from order intake to delivery and everything in between.”

Smart distributed manufacturing: Smart distributed manufacturing that is enabled by 3D printing when done in a strategic way can be a successful recipe, rather than an ad hoc response to problems with global supply chains, Fred Vancrae emphasized. “3D printing enables design optimizations that provide weight performance, time saving and supply chain benefits that are impossible to achieve with traditional manufacturing methods. In many cases, these benefits create cost advantages that impact the overall end-to-end manufacturing costs from design to delivery. In fact, the ability to reduce the overall manufacturing costs is cited as the most important benefit of 3D printing but that does not necessarily mean that the 3D printing process itself is cost efficient. Increasing material and energy prices have only driven up the costs even more,” he stressed.

“There are several factors that determine the cost of 3D printing parts. This comprises of the materials required, production time per part, and the type of printer. However, there are two important ways to reduce this,” Fred pointed. “The first step is by working more efficiently to increase production capacity. Software plays a major role in this by making it possible to optimize the build. We can also tune the printing process to make it more efficient and repeatable,” he indicated.

“The second step is using tools and improve quality; but quality comes at a cost. Looking at certified manufacturing in the medical or aeronautics industry for example, we see that up to 70 percent of the production cost is in quality control. 3D printing continues to transform the factory floor, as companies increasingly turn to the technology for large-scale production. But to accelerate this adoption, the industry will have to make extra efforts to reduce the cost of 3D printing,” Fred added.

Data security and data integrity: Data security is important in any form of manufacturing whether traditional or smart in both cases as addressed by Fred Vancrae in his video about the biggest 3D printing trends for 2023.

“Companies share their unique designs with contractors and suppliers and they want to know that their design data remain secure. With 3D printing, manufacturers may want to plan and scale up the production of their 3D printed parts into thousands or even millions. They need to optimize and fine-tune their unique printing process to make it efficient, reliable, and repeatable across multiple production sites. A smart production process ensures that all 3D printed components have the same quality no matter where they are produced. Creating such a process is complex and time consuming but it allows companies to leap ahead of the competition. That is why in addition to data security and data integrity, the close and secure link between the design on one hand and the production parameters on the other hand is becoming top of mind for companies that embrace digital manufacturing,” he revealed.

Conclusion

The adoption of 3D printing technology reaches new heights each year. Over the last thirty plus years, it has become an integral part of the manufacturing industry. The future is bright for 3D printing technology in 2023, as it will help companies scale up their operations into volume production and advance their overall utilization.

35 | Industry EMEA | January 2023 10

MARKET OVERVIEW

International capability

More than 80 employees in 35 different countries, ensuring a strong relationship with main local media. Mepax distinguishes itself through its extensive media knowledge and ability to select the best international online/print advertising options. PR can be translated into 35 languages.

Outstanding results

45,000 published articles in 2021: EMEA: 48% - Asia: 31% - Americas: 21%. Most of the articles are published in the top 1000 media worldwide.

Optimized process

With a proven process set for more than 200 active customers, we can adapt to all specific client needs with the highest reliability. We have developed in house the most advanced PR dedicated ERP, enabling transparency and real-time full online reporting. International media management is then made easy, fast, and efficient for optimal results.

www.mepax.com info@mepax.com

THE MOST

INNOVATIVE PR AGENCY

YOUR

OPTIMIZE

INTERNATIONAL PR AND ADVERTISING FOR THE INDUSTRIAL MARKET!

MOXA INTRODUCES EASY-TO-USE IIOT GATEWAYS THAT SIMPLIFY REMOTE DATA TRANSFER

Moxa’s newly launched AIG-100 Series includes best-in-class IIoT gateways that help achieve your IIoT targets with the lowest total cost of ownership by focusing on distributed-energyresource applications, especially in solar energy and energy storage systems.

Digital transformation and sustainability are two essential goals for businesses today. Energy companies, for example, need a reliable and efficient system to seamlessly transmit real-time data from remote edge devices to cloud applications.

Best-in-class Gateways That Bridge the Gap Between OT and IT Systems

An unavoidable challenge in IIoT systems is that most edge devices are in remote, hard-to-access, and unmanned locations. It is critical for business owners to find ways to qualify and process data collected from remote sites to transmit to cloud applications so that the information can be used to manage assets and take precise and strategic business decisions. To close the gap and accelerate convergence of operational technology (OT) with information technology (IT), Moxa AIG-100 Series IIoT gateways, with features such as built-in traffic monitoring and diagnosis, can help monitor and troubleshoot communication issues for both IT (Azure, AWS, MQTT) and OT (Modbus) protocols. The AIG100 Series IIoT gateways come with a provisioning tool and device management service for business owners to easily install and manage the gateways remotely, thereby greatly reducing downtime and increasing operational efficiency.

Go From Complex Configurations to Ready OT Data in Just a Few Clicks

To collect data for IIoT applications, it is important to have an easy-to-use and efficient solution. The AIG-100 is seamless integrated with Moxa UPort and ioLogik devices to realize plug-and-play like installation for I/O and serial expansion, eliminating complex driver installation and setup processes. Furthermore, the AIG-100 provides no-code data processing to help users easily process OT data using an intuitive UI without requiring additional programming efforts.

AIG-100 Series Highlights

• Supports data conversion/transfer from Modbus TCP/RTU to Azure, AWS, and MQTT cloud

• Built-in network traffic monitoring and diagnostic tool for easy troubleshooting

• Supports store and forward and datalogger functions to prevent data loss

• Seamless integration with Moxa ioLogik and UPort devices to easily extend I/O and serial interfaces

• Built-in data processing function to eliminate programming efforts

To learn more about Moxa’s AIG-100 Series IIoT gateways, visit the product page.

https://www.moxa.com/en/products/industrialcomputing/arm-based-computers/aig-100-series

35 | Industry EMEA | January 2023 12 MORE INFORMATION INDUSTRIAL COMMUNICATION

ANELLOTECH OFFERS DRUM-QUANTITY SAMPLES OF RECYCLED BTX MADE FROM MIXED WASTE PLASTICS VIA PLAS-TCAT® PROCESS

Anellotech is pleased to announce that it is offering drum-quantity product samples of aromatics produced from recycled mixed waste plastics. The recycled benzene, toluene and xylenes (BTX) will be available to current and potential commercial partners.

The samples are made at Anellotech’s TCat-8® facility — a fully automated, 30-meter-tall pilot plant located inside Trecora’s Silsbee, Texas facility— during ongoing studies demonstrating Anellotech’s Plas-TCat® catalytic pyrolysis technology. TCat-8 can operate 24/7 and converts a representative mixed waste plastics feedstock — including all major plastic types, with the exception of PVC, into BTX, light olefins and paraffins.

“Anellotech can offer BTX samples made directly from mixed waste plastics to potential commercial partners to encourage engagement with our program” says David Sudolsky, President and CEO of Anellotech. “Unlike thermal pyrolysis, Plas-TCat makes BTX and other chemicals in one reactor, providing true 100-percent recycled BTX (not mass balance approach) for studies and eventual future commercial use.”

Based on a proprietary catalyst and fluid bed reactorregenerator system, Plas-TCat provides a new, direct route to light olefins and aromatics from plastic waste streams — such as polyolefins, polyamides (nylon), polyethylene terephthalate (PET), polycarbonate and polystyrene — without the need for steam cracker furnaces. The resulting output of benzene, toluene and xylenes, as well as ethylene, propylene and butylene (light olefins), are suitable after separation for plastics manufacturers to produce a wide range of virgin plastics.

https://anellotech.com/

35 | Industry EMEA | January 2023 13 MORE INFORMATION WASTE AND RECYCLING

MITSUBISHI ELECTRIC EUROPE: THREE THINGS TO REMEMBER WHEN BUILDING A DATA CENTRE

The digital shift, together with the latest developments in 5G communication is stimulating a need for more cloud-based and online solutions, which in-turn is motivating huge investments in IT infrastructure such as data centres. In this article, Hiroki Nishiyama, global manager of data centre marketing at Mitsubishi Electric Corporation, explains further about the challenges facing this important rising industry.

“ The recent changes triggered by the digital shift and how we communicate, are driving huge investments in data centers. In fact the global data center market is expected to increase by around 8% over the next ten years compared to 2020,” comments Hiroki Nishiyama. “If we only focus on data center infrastructure management (DCIM), then the growth rate is even higher at 17.5%.” These figures show that data center investments will continue to grow, which means more data centers will be built globally, with more “digitally” managed operation systems being installed.

One of the questions that needs to be considered is “what is required in a data center?” Hardware like IT servers are both obvious and essential, but that is not enough to keep data centers running. There are three principal points that should be considered when building data centers: sustainability, efficiency, and redundancy.

Increasing energy efficiency for cooling IT servers

Energy efficiency is a key aspect of running a data center as they naturally consume a great amount of electricity. From powering the essential IT servers 24-7, to providing backup systems in the form of uninterrupted power supplies (UPS) and last but not least, to cooling the facility. What is often overlooked by the layperson is that IT servers produce heat. In-fact it can be a surprising amount of heat, which of course is also wasted energy, but if left unchecked, will over time contribute to a gradual degradation of the electrical components, hastening the failure of the all-important IT servers. This is why cooling is important, not only to be executed in the most energy efficient way so as not to add

35 | Industry EMEA | January 2023 14 MORE INFORMATION DATACENTER

to the waste, but also to keep an optimum environment to maintain the performance of the servers for as long as possible.

Nishiyama adds more background, “To illustrate how much heat is generated, let’s assume a server room contained 50 servers. Together they would generate around 17-18 kilowatts of heat per hour. Imagine that’s like having 15 average heaters or a small furnace running continuously. But that’s not all, there are also additional thermal effects from the UPS, routers and switches, lighting as well as exposure from any windows which may be present. So overall a lot of heat is being generated and potentially stored.” Nishiyama further notes, “Actually, on average electronics devices like servers are running at 30-40 degrees Celsius, and the common wisdom is to cool the data center to around 1825 degrees Celsius, which is a lot of continuous cooling. So, all this heat ironically needs more power consumption to generate cooling. And that means electricity bills are just getting bigger by the day, and that is why energy efficiency is one of the highest priorities.”

There are lots of imaginative ways to reduce the heat in data centers, from pioneering work to run data centers in the sea, to taking more immediate steps of turning lights off, using LEDs where necessary, reducing windows, and improving the energy efficiency of air handling and conditioning through the use of inverters on motors that drive pumps, compressors and fans. “Let’s consider an air handling system. Power consumption can be reduced by adjusting the amount of airflow by controlling the motor with a frequency inverter,” explains Nishiyama. “In fact, you often don’t need to be an inverter specialist to set the special parameters according to the application or load as many devices can automatically streamline motor control with auto-tuning features.”

More often newer cooling technologies such as cooling towers, air handling units for example have inverters fitted as standard, but if not, they can be relatively easy to retro-fit and can quickly contribute to minimizing power consumption, leading to cost efficiency and sustainability.

If cooling is so important, then another concern might come to mind: “What would happen if the device cooling system fails after some years?” Especially in the case of data centers, equipment failure might become critical for continuous operation, especially for data centers that might be serving financial transactions.

“There are inverters that support built-in preventive maintenance features, so this might be a solution,” suggests Nishiyama. If load characteristics are monitored in real-time, degrading performance could be detected at an early stage. Such preventive maintenance features enable operators to notice abnormalities such as filter clogging or effects from worn bearings, making maintenance easier to schedule in time and help reduce downtime.

Visualizing the status of the data center to streamline operations Considering the issue of maintenance, visualizing the status of the facilities can also help keep the data center running continuously and reduce the workload of maintenance engineers through clear and effective communication of the current status.

“Advanced visualization can help monitor multiple subsystems, for example electricity and lighting to air conditioning and even disaster prevention systems,” Nishiyama explains. “A flexible SCADA system can help support expanding operations through to the implementation of redundant monitoring systems as the need arises.”

Nishiyama adds, “With a SCADA system, such as GENESIS64 for example, the real-time status of the data center can be monitored through graphical displays of the data from various subsystems. Alarms can even be sent via email when something goes wrong. And in the case of an equipment fault, the SCADA monitoring system can be configured to list-up the potential causes in order of probability to make troubleshooting tasks easier.”

By further utilizing cloud services in combination with SCADA systems, larger volumes of data can be processed, potentially achieving integrated monitoring of multiple

35 | Industry EMEA | January 2023 15 MORE INFORMATION

One example to increase energy efficiency is the use of inverters for motors that drive pumps and fans in the air conditioning systems. [Source: Mitsubishi Electric Corporation, Japan]

35 | Industry EMEA | January 2023 16 MORE INFORMATION

Preventive maintenance, often supported by features on inverters, can support early notification of potential abnormalities such as equipment failure. [Source: Mitsubishi Electric Corporation, Japan]

The real-time status of the data center can be monitored through graphical displays of data from the various subsystems. [Source: Mitsubishi Electric Corporation, Japan]

SCADA systems can be used to list-up potential fault causes in order of probability to make troubleshooting tasks easierthis example is from a GENESIS64 solution. [Source: Mitsubishi Electric Corporation, Japan]

data centers. That becomes more important as the number of data centers being built around the world, from hyperscale to micro data centers, is increasing. The use of GeoSCADA systems will enable remote monitoring from a variety of terminals such as PCs, mobile devices, and smart glasses to help facilitate the monitoring and maintenance of these locations.

Reducing risks through redundant systems

One of the other priorities for data centers is to keep the facility running, no matter what happens. Redundancy is therefore a very important focus, which not only applies to the servers themselves, but also to the various operational systems such as power supplies, cooling or security systems since they are critical factors in maintaining the data center environment.

“The precise control and integration of HVAC systems to maintain the humidity, temperature and other air-quality factors that affect the data center environment, is often ‘managed’ by programmable controllers (PLCs) due to their rugged industrial specifications,” Nishiyama explains. “To reduce risks, data centers typically install redundant cooling systems where a duplicate, standby PLC may be installed in parallel to the main PLC. And in case something goes wrong with the power source or even in emergency situations like fire in the equipment room, the control will be switched instantaneously from the main PLC to the standby PLC.”

Redundant PLC systems not only make it possible to build a highly flexible air conditioning system, but can also be used to ensure the reliability of other critical equipment, such as chillers, that cannot be shut down during data center operations. “Traditionally such redundant PLCs could be very costly since they were built of many dedicated parts which in turn added to the maintenance burden due to their specialist nature. However, more recently, high reliability PLC systems, such as Mitsubishi Electric’s MELSEC iQ-R offer a hybrid solution where a single specialist redundant switching module can be added to a standard industrial PLC. This reduces the overall system cost and any impact on maintenance, but with no compromise on redundancy due to high quality and ruggedness of today’s PLC components,” adds Nishiyama.

For redundant PLC systems, it is also essential that the main and standby PLCs are separated physically, meaning a

different power source and installation location to maximize the “protection”. In such circumstances the main and standby PLCs should be linked by an optical fiber tracking cable to avoid problems from electrical noise, but also to have a reasonable distance apart and to reduce switching time between the two PLCs in case of emergencies.

“Using redundant PLCs really is a ‘goldilocks’ issue. You should be careful when planning the location of the two PLCs that they are not too far apart, but equally they should not be too close together either and definitely not placed in the same cabinet, or then it would defeat the purpose of the redundant system,” Nishiyama emphasized. “It’s important to target a high-speed system with a switching time of around 10 milliseconds or less to enable continuous control with high reliability.”

So, how do we build a reliable data center system? In this era where the demand for digital services is increasing, the pressure is also rising on providers to prevent downtimes of such services even for a short time, which makes the data centers availability a critical factor. In fact, today, if one of the big “cloud” providers has an outage, even for just 30 minutes, it makes headline news around the world.

“Since the demand for digital services is increasing and data centers are being built to meet that demand, it is important to remember it’s not just about the IT, but also how to manage your systems and make them redundant, efficient, and sustainable,” Nishiyama explains. Taking small, practical steps, leveraging known technologies such as using inverters for increased energy efficiency in cooling systems, visualizing the overall status of the data center to streamline operations, or above all, reducing risks through redundant systems are all achievable for minimum cost but with maximum returns. Nishiyama concludes, “Working with partners that have both know-how, experience and above all an eco-system of products, solutions and partners behind them is a great way to mitigate risks and manage costs in the long run.”

Learn more about how Mitsubishi Electric can empower your data center with advanced technology and solutions: https://www.mitsubishielectric.com/fa/sols/industry/ datacenter/index.html

35 | Industry EMEA | January 2023 17 MORE INFORMATION

Hiroki Nishiyama, global manager of data center marketing at Mitsubishi Electric Corporation, explains about the challenges facing the rising data center industry.

EMERSON’S NEW ANALYTICS SOFTWARE AUTOMATES UTILITIES MONITORING AND REPORTING FOR CLEAN-IN-PLACE APPLICATIONS

Technology replaces error-prone manual record keeping and monitors energy and utilities parameters, improving efficiency and productivity.

Emerson announced the release of its new Clean In Place (CIP) Utilities and Automated Reporting Analytics package delivered via PACEdge™ and Movicon™ platforms on an industrial edge control device. The software aids in digitally transforming manual and semi-automated systems by optimizing utilities consumption, benchmarking against known cycles and generating automated reports that can be used to reduce energy consumption and improve productivity in a single system or throughout a facility.

The CIP Utilities & Automated Reporting Analytics package combines Emerson’s deep application expertise and industry knowledge with advanced technology to convert process and utilities data into actionable insights for the food and beverage industries and other environments that use clean- and steam-in-place operations.

Equipped with the data and analytics provided by the software, plant managers, operators and maintenance personnel can view the information on a dashboard and share the insights with sustainability officers and other stakeholders to optimize their CIP cycles. The software package can be customized and layered into an existing system, or Emerson can provide a turn-key solution of hardware, instrumentation, valves and analytics.

Central to food and beverage production, clean-in-place systems clean and sanitize internal piping, tanks and machines between product batches to help facilities meet government regulations and guarantee product quality and safety. CIP skids that don’t have sensors and analytics software in place require manual reporting, which can be time-consuming and susceptible to errors, especially when data is transferred by hand into reports. These skids may also run at unnecessarily long preset cycles and use more time and resources than required for effective cleaning.

35 | Industry EMEA | January 2023 18 MORE INFORMATION AUTOMATION

Digitally transformed and optimized CIP processes, in comparison, only use the time, media, water, energy and labor required for effective cleaning, significantly reducing waste and increasing production time.

“Food and beverage manufacturers typically spend about 30% of utility costs on clean-in-place operations. They also lose time between changeovers and spend between 20 to 40 thousand dollars in labor costs for manual reporting,” said Amit Patel, director digital transformation for discrete and industrial at Emerson. “Emerson’s new CIP Utilities and Automated Reporting Analytics software package collects and analyzes data in real time and presents it as a report, equipping plant managers, CIP operators, maintenance personnel and sustainability officers with the actionable insights to optimize wash cycle settings, including duration and media use, for maximum efficiency and productivity.”

The CIP Utilities & Automated Reporting Analytics software package can help CIP operators better understand and forecast energy use, water consumption and resource needs. Generated reports can be used to satisfy regulation compliance, plan system maintenance, schedule downtime and order media supplies, and deeper analytics can be used to identify insights and trends that support predictive maintenance schedules and facilitate standardization of CIP processes across production facilities.

The agnostic software is compatible with any CIP equipment, which empowers manufacturers to control the digitization of their systems no matter what stage of the digital transformation journey they are in and to integrate any or all Emerson components and customize the solution for their needs.

https://www.emerson.com

35 | Industry EMEA | January 2023 19 NEWS MORE INFORMATION

The CIP Utilities & Automated Reporting Analytics allows plant managers, operators and maintenance personnel to convert process and utilities data into actionable insights for industries and environments that use clean- and steamin-place operations.

EMERSON HAS SHOWCASED INTELLIGENT INDUSTRIAL CONTROLS AND AUTOMATION TECHNOLOGIES AT SPS FAIR 2022 HELD IN NUREMBERG, GERMANY

The latest programmable automation controllers, SCADA/HMI software, smart pneumatics and industrial internet of things (IIoT) solutions and electric actuator solutions were the product highlights featured by Emerson.

This comprehensive range of powerful digital automation solutions has been designed to support flexible manufacturing requirements and to provide insights that can help optimise machinery performance and production cycles, reduce energy consumption and minimise downtime.

Sophisticated analytics, precise control

Emerson showed how its electric linear motion control solutions provided original equipment manufacturers (OEMs) and manufacturers greater flexibility and efficiency. Integrated, scalable and precise control has been provided by Emerson PACMotion™ high-speed servo motion controllers. These operate Emerson’s new AVENTICS™ Series Servo Profile Advanced (SPRA) Electric Actuators, which offer multiple screw technologies and a high level of precision and repeatability. An IIoT gateway with analytics software offers access to application performance and device condition information presented on a simple dashboard. This fully integrated solution provides assured repeatability and accuracy, helping to lower engineering time and also enable users to identify issues earlier, improving productivity and lowering total cost of ownership.

Product highlights displayed at the SPS Fair 2022

Multimedia Monitoring Solution

Emerson’s multimedia monitoring solutions can help optimise energy and utilities usage. The demonstration features a turnkey engineered solution, incorporating an edge controller with integrated analytics, pneumatic valve system and power supply. Using open protocol communications to connect to a broad range of instruments and sensors, data is aggregated and visualised to enable monitoring, analysis and trending of compressed air, gas, water, steam and energy consumptions. The multimedia monitoring solution is ideally suited for automated applications such as clean-in-place systems, which often consume over 30% of utilities. Accurate monitoring and analytics enable the user to optimise consumption and to save 30%-45% of media usage for a single clean-in-place skid. For more information, visit: Emerson.com/SustainableAutomation

AVENTICS Series SPRA Electric Rod-Style Linear Actuator

Emerson’s AVENTICS Series SPRA Electric Actuators are a new line of precise and highly repeatable rod-style cylinders. The SPRA actuators offer three screw technologies which include a precision ball screw, which provides exceptional durability

35 | Industry EMEA | January 2023 20 MORE INFORMATION AUTOMATION

and accuracy for applications that need optimal quality or throughput, a cost-effective lead screw option and roller screws for precision, speed and heavy loads. This versatile range of rod-style cylinders lets users configure electric actuators to meet exacting application requirements, such as improved sustainability or efficiency, rather than settle for standard approximation.

Emerson.com/AVENTICS

PACSystems Intelligent Edge Control Technology

Emerson’s scalable PACSystems platform provides highperformance control, analytics and visualisation in discrete, hybrid and process applications. PACSystems edge controllers can operate as either an IIoT-enabled PLC or an advanced supervisory controller for manufacturing operations. In addition, Emerson’s powerful, compact industrial computing and operator interfaces offer increased analytics and graphics capability for edge applications and reduced footprints. PACSystems edge solutions include true edge controllers, edge computing devices and compact controllers, and leverage Movicon.NExT, WebHMI, Connext OPC UA server and the PACEdge platforms in optimised software packages to provide powerful and flexible connectivity and visualization, and a cloud-enabled toolset. PACSystems makes the move to the edge easy.

www.emerson.com/PACSystems-edge

PACSystems RXi HMI: Machine Visualisation

PACSystems RXi Human-Machine Interface (HMI) is a next-generation machine visualisation solution that provides easy-to-use, smartphone-like graphical displays, but without sacrificing rugged, industrial performance. PACSystems RXi HMI is designed with projective capacitive touchscreen technology that allows users to interact with the visual display with multitouch capabilities like swipe, pinch or zoom to move to the next screen or expand a chart, enabling easy operation by a wide range of personnel with varying levels of training and experience. PACSystems RXi HMI is HTML5-ready, which allows users to collaborate from anywhere, so that the operations, management and maintenance teams can all view the same screen at the same time, no matter their location. This immediate sharing of information and access to expertise reduce maintenance costs and improve productivity. In addition, faster access to data-based operational insights helps to maximise overall equipment effectiveness (OEE).

PACSystems RSTi-EP

CPE200 Controller: Large PLC Performance — Small Form Factor

The PACSystems RSTi-EP CPE200 compact controller family delivers large programmable logic controller (PLC) capability in a small, cost-effective form factor so machine manufacturers do not have to sacrifice performance for price. It provides security-by-design, open programming and open communications built in, significantly reducing cost and complexity for OEMs and end users. A range of advanced features comes standard, such as OPC UA communication over high-speed 1-Gb Ethernet and C programming capabilities, plus the advantages of Emerson support. In addition, it includes analytics and is IIoT-ready in order to future-proof systems for new technologies or existing process equipment.

For more information, visit: https://www.emerson.com/enus/automation/control-and-safety-systems/pacsystems

Movicon.NExT: Optimising Flexibility in Automation Software

Movicon.NExT™ industrial software platform offers the most innovative and flexible software technology for Windows/Linux HMI projects, SCADA supervisory systems and efficient MES analysis solutions that are essential to Industry 4.0. Among Movicon.NExT modules, Movicon Pro.Lean™ provides performance data and analytics for evaluations of OEE and Movicon Pro.Energy™ measures and tracks consumption, while the advanced Movicon NExT.AR solves operational problems through visualisation tools that allow personnel to evaluate previously unreachable equipment. For maximum flexibility, Emerson also provides Movicon WebHMI, an HTML5-based visualisation tool that can be used as a stand-alone HMI product running on Windows or Linux operator panels, or as a Web Client for Movicon.NExT SCADA applications, as well as Connext™, an industrial protocol gateway.

For more information, visit https://www.emerson.com/enus/automation/control-and-safety-systems/movicon

35 | Industry EMEA | January 2023 21 MORE INFORMATION

www.emerson.com

DELTA HAS PRESENTED VARIOUS HARDWARE AND SOFTWARE SOLUTIONS FOR IIOT AT SPS NUREMBERG 2022

A wide range of smart, energy-efficient and highly integrated industrial automation hardware and software solutions engineered for Industrial Internet of Things (IIoT) applications were displayed at SPS Fair 2022.

The demonstration also included Delta’s new Software as a Service (SaaS) Digital Dashboard tool - DIACloud Digital Dashboard - which offers remote visualisation of cloud data for a broad range of applications; and a new IIoT function card for the PLC series to enable various IIoT applications.

IIoT Cloud-based Platform - DIACloud Digital Dashboard

Delta has launched the latest evolution of its DIACloud remote access: Digital Dashboard. This new Software as a Service (SaaS) Digital Dashboard tool offers remote visualisation of cloud data. It makes all applications and machines easily and securely accessible from the web, for increased user flexibility and convenience. Users can now create a customised interface for their applications, as well as a real-time trend graph or history data monitoring, while the Digital Dashboard also features an alarm function for real time notifications. It is ideally suited to machine builders and applications that require remote connectivity, such as pump applications that have variable frequency drives. No installation software is required, which also simplifies the whole set up.

Pump Solutions with Delta’s Fan/Pump Vector Control Drive CP2000

Delta demonstrated its Fan/Pump Vector Control Drive CP2000 in a simulated environment by showing the different operational modes that are possible through its firmware, which enables the CP2000 to control up to eight drives simultaneously. Delta also showed its latest new multi-drive solution - the redundancy water supply solution, which is suitable for applications ranging from fire water systems to domestic water systems, power generation, industrial water treatment systems, sewage treatment systems, agro culture and public facilities.

Time of Flight Camera DMV-T

New high-speed Time of Flight Camera DMV-T from Delta for machine vision utilises a built-in processor sensor, which delivers frame rates of up to 60 frames per second. The camera captures depth information by calculating phase differences between the carrier frequency of the active light emitted by the camera, and the light reflected from the object. This process enables it to acquire 3D information at very high speeds. Industries including agriculture, logistics, automatic guided vehicles and robotics can benefit from the Time of Flight Camera DMV-T, as it is well protected to make it suitable for a wide variety of challenging environments.

35 | Industry EMEA | January 2023 22 MORE INFORMATION AUTOMATION

Visitors to Delta’s stand also experienced its Barcode Scanners. In addition to reading 1D/2D barcodes, they are also capable of reading defective or damaged barcodes, helping to boost productivity and efficiency. They are already used in applications as diverse as electronics manufacturing and food packaging, as well as in logistic industry applications, ranging from communications to production tracking.

Compact Modular CODESYS Motion Controller AX-3 Series

Delta’s motion controllers AX-3 series now offers five new CPU models, which enables control of four to 64 drives, offering a broad array of connectivity interfaces from EtherCAT, Modbus TCP/RTU to Ethernet/IP and OPC UA. Delta’s latest motion controller line up increases the scalability of its motion control and PLC product portfolio, offering customers more options to meet their demands across a wide range of market segments. These range from packaging to woodworking, metalworking and material handling. Delta continues to offer the PLCs AX-324N and AX-300N, which are ideally suited to applications that don’t require motion control features.

Compact Modular Mid-range PLC AS Series with New IIoT Function Card

Delta has extended its high performance PLC AS series with the new AS-FFTP01 function card to enable various IIoT applications to extend the capability of the applications powered by Delta’s PLC AS300. The AS-FFTP01 IIoT function card is compatible with a multitude of applications. It provides

support for OPC UA, and offers increased connectivity with SCADA systems and MQTT for sharing filed data with cloud applications. Meanwhile, the FTP server function provides the ability to connect with IT related applications, such as file transfers between the PLC and a PC. Delta anticipates that the AS series will play an important role in the evolution of Industry 4.0, while improving efficiency in production and industrial environments.

“A lot of our customers are now investing in the IIoT,” said Roetger Sander, deputy director of Delta’s Industrial Automation Business Group for Europe, Middle East & Africa (EMEA) region. “Open platform communications united architecture (OPC UA) is a standard that many customers have chosen to work with. We’re excited that the new products we’re bringing to SPS is meeting the open OPC UA standard and can support a wide range of IIoT applications.”

www.delta-emea.com

35 | Industry EMEA | January 2023 23 MORE INFORMATION

WORLD FIRST: SOS CASH & VALUE’S SECURITY GUARDS REINFORCE THEIR MISSION’S SAFETY AND SECURITY BY EQUIPPING THEMSELVES WITH WEARIN’S HIGH-TECH VEST WITH ENVIRONMENTAL AND BIOMETRIC SENSORS

“Following major strategic partnerships concluded early this year, the race was on to implement them on the ground. We’re pleased that it’s in Switzerland, the country where our solution was designed, that Wearin’ is applying its unique IoT and artificial intelligence technology at the service of the connected human.”

– Jonathan Brossard, Conextivity Group CEO.

Since the beginning of October, all the agents at the security company SOS Cash & Value have been equipped with the intelligent vest from Wearin’, the startup whose Internet of Things (IoT) technology is specifically designed to reinforce the safety and efficiency of its mission-critical teams on the ground.

The high-tech vest that SOS Cash & Value’s security guards wear at all times during their mission throughout Switzerland is equipped with environmental and biometric sensors connected to the monitoring center based at the security company’s headquarters in Vernayaz (Valais). The Wearin’ dashboard integrated into the center’s warning system provides real-time information on the situation on the ground. It continuously displays the data from the sensors whose algorithms correlate biometry, movement, acceleration and positioning in the vicinity and in the armored vehicle, which is also equipped with a specific sensor. An alarm is automatically triggered when the system detects an abnormal situation such as a security guard falling over (Man Down detection), or the stress caused by an incident such as an attack on a vehicle. The alert and communication system between the agents and the monitoring center enables the SOS Cash & Value mission leaders to decide on the actions and measures to secure and intervene with the emergency services and police forces at the scene of the incident.

35 | Industry EMEA | January 2023 24 MORE INFORMATION PUBLIC SAFETY

Worn by SOS Cash & Value security guards, Wearin’s connected vest is equipped with sensors whose biometric and environmental data are transmitted in real time to the monitoring center in Vernayaz in Valais.

The Wearin’ solution comprises two scalable platforms, one physical and one digital, that communicate with each other in real time.

35 | Industry EMEA | January 2023 25

Wearin’ offers an end-to-end connectivity solution tailored to specific security and collaboration types and requirements in a series of modules defined by its customer organizations’ engagement and monitoring centers.

“This personal equipment is revolutionizing the world of private security”, explains Pierre-Yves Glassey, CEO of SOS Cash & Value. “It’s cutting-edge and provides an ingenious and reliable solution, tailored by Wearin’ to our company’s specific needs, and based on our experience and standards in security. This high-tech bulletproof vest provides a security guard with exceptional safety.”

The technology developed by Wearin’s R&D engineers in Morges (Vaud) was successfully tested on a European scale in May 2022, during first-aid drills in the event of a major disaster. It is intended for organizations whose staff is called upon to coordinate risky activities and interventions on the ground, such as police forces, firefighters and first responders, or lone workers in the logistics or construction sectors.

“Our IoT technology is unique on account of its ingenuity as well as its integrability and modularity,” specifies Alvaro Goncalves, Wearin’s Technical Director. “We implement it as a turnkey end-to-end solution, on two platforms that communicate permanently with each other: on the one hand, the physical platform of the smart vest worn in the field by the customer’s staff and, on the other hand, the digital platform that is easily integrated into the customer’s monitoring system. The digital platform collects and centralizes the data transmitted by the vests’ sensors. These data are processed by artificial intelligence and then displayed via an application on a security dashboard used by

the operators in the engagement and monitoring centers. Both platforms are modular and scalable. Our solution is designed to be adapted very easily and quickly to the customer’s own needs and technological capabilities.”

The SOS Cash & Value Security Manager notes the data security guaranteed by the solution: “This is a crucial point for the SOS Surveillance Group, to which SOS Cash & Value belongs. Our group wants to take the lead in reinforcing our agents’ security, which is the priority. Since the encryption used by Wearin’ to encode our data is of the highest industrial standard, we are protected against any criminal intent to decrypt them.”

Jonathan Brossard, CEO of Conextivity Group to which Wearin’ belongs, is pleased to implement the solution as a world first with a Swiss customer: “Three years almost to the day after the creation of our startup, and following strategic partnerships concluded early this year with leading suppliers such as Airbus with its Secure Land Communications (SLC) division, the race was on to implement the solution on the ground. We’re pleased that it’s in Switzerland, the country where our solution was designed, that Wearin’ is applying its unique IoT and artificial intelligence technology at the service of the connected human.”

https://wearin.tech/

35 | Industry EMEA | January 2023 26 MORE INFORMATION

Pierre-Yves Glassey, CEO SOS Cash & Value

Jonathan Brossard, CEO Conextivity Group (Wearin’ & Fischer Connectors).

INNODISK DDR5 RDIMM POWERS SEMICONDUCTOR AUTOMATIC OPTICAL INSPECTION

Innodisk, a global leader in industrial-grade storage and embedded peripherals is proud to announce its solution to issues faced by Automated Optical Inspection (AOI) applications relating to, and caused by the shortcomings of consumer DRAM.

With the recent launch of Innodisk AI, which provides a complete AI solution for industrial integrators, DDR5 series DRAM plays a key role for a variety of applications, including Automated Optical Inspection solutions. With the rise in demand for semiconductors, and the trend towards smaller and smaller processes, the need for automatic systems to detect semiconductor production defects has grown significantly. AOI systems are now used at every step of the semiconductor manufacturing process, and their stability is paramount to production efficiency.

Modern AOI systems face three core issues that Innodisk’s DDR5 RDIMM (registered memory) help to solve: memory bandwidth, accuracy, and high temperatures.

Memory Bandwidth

Due to the high memory bandwidth needed for training models, AOI systems often struggle when lower capacity modules are used. Innodisk’s DDR5 RDIMM solves this issue with large capacities, including 32GB and 64GB modules.

Accuracy

Due to semiconductor processes going down to the nanometer level, the resolution requirement and accuracy requirements for AOI systems has increased. Innodisk’s DDR5 RDIMM features a new dual 40-bit sub-channel

architecture, and supports rigorous side-band ECC, which can handle AOI’s high-accuracy detection demands.

High Temperatures

The high-speed and high-precision inspection that AOI systems provide generates high amounts of heat at the DRAM level, and this can cause overall system temperatures to rise sharply. Innodisk’s DDR5 RDIMM solves these heat concerns via a two-pronged strategy, involving an integration of both hardware and software. Two thermal sensors on the modules detect ambient temperatures, and two software tools: iCAP (Innodisk Cloud Administration Platform), and iSMART monitor temperatures and send warning messages.

Although memory technology is constantly being updated, Innodisk’s observation of the industry’s current situation shows that customers’ demands for new technologies vary greatly. Therefore, Innodisk not only provides the most complete industrial-grade DDR5 and DDR4 products, but also legacy products such as DDR3, DDR2, DDR and SDRAM. These memory modules will continue to be supplied with stable pricing, original IC, and the same great longevity support as all Innodisk products.

https://www.innodisk.com

35 | Industry EMEA | January 2023 27 MORE INFORMATION ELECTRONICS

FLAT PCBS TO MINIATURE IMPLANTABLE 3D-CIRCUITS

Hearing Device:

By integrating functions and the threedimensional routing of circuit tracks, the design space for the electronics of hearing aids can be optimally utilised.

The most remarkable aspect of technology is its constant development and improvement. Slimmer laptops, smaller phones, and medical devices designed to be unobtrusive and barely visible to the naked eye. Can I use 3D-Circuits to outperform the flat PCBs?.

As electronic devices continue to evolve and shrink, so do their circuits and, ultimately, their components. This development has raised the demand for component miniaturization.

3D-Circuits or also called 3D-MID (three-dimensional mechatronic integrated devices) makes this possible. It allows for more compact designs while enhancing functional density.

In this article, we take a closer look at 3D-MID technology, what it is, its many benefits, its applications and a short overview about HARTING as a full-service provider.

The Miniaturization Revolution in Electronics

Smaller devices mean less environmental impact. A laptop, for example, uses 80% less power than a desktop computer, with a peak power consumption of 60 watts compared to 175 watts for desktops. This reduction in energy use is due to miniaturization.

Miniaturization has revolutionized many sectors, from medical and healthcare to automotive as well as industrial and consumer electronics. Here are a few drivers of this movement:

Aesthetic demands

We have come to expect our devices to be visually appealing and well-designed.

Portability

We also want our devices to be lightweight and easy to carry.

Cost savings

While miniaturization can be costly initially, it allows for the use of fewer materials, which can save money in the long run.

Eco-friendly power consumption reductions

Smaller parts consume less energy which helps lower operating costs, increase battery life, and promote greener products.

Less heat dissipation

Since smaller parts use less power, electronic devices generate less heat. This means bulky heatsinks or fans can be removed, reducing weight, cost, power, and noise.

Almost every industry is moving towards functional density, meaning that hardware components need to be interconnected and made smaller and smaller.

3D-MID is a way to fulfill those requirements by reducing mass and optimizing space while allowing for those parts to offer the same or more capabilities.

35 | Industry EMEA | January 2023 28 MORE INFORMATION ELECTRONICS

Component Carrier:

The 3D-MID component carrier is an in-house HARTING development which serves as a connecting element between a printed circuit board (PCB) and electronic components (such as LEDs, ICs, photo–diodes or sensors).

What Is 3D-MID?

The term “mechatronics” was coined in 1969 by a senior engineer of the Japanese firm Yaskawa. It is a combination of the words “Mecha” (machines) and “Tronics” (electronics).

Since then, the definition has evolved. It is now used to describe the abilities to use computers, electronics, and mechanics to build more intelligent systems, such as robotic, control, and electromechanical systems.

3D-MIDstands for “Three Dimensional Moulded Interconnect Device” or “Three Dimensional Mechatronic Integrated Devices.” These are mechatronic devices that combine electronic and mechanical functionalities into a single three-dimensional component.

HARTING’s 3D-Circuits technology allows the 3D-MID parts or the injection-moulded thermoplastic part to be directly integrated with electronic circuits and components, making them more compact and functionally dense. Imagine a circuit board that is significantly smaller and composed of plastic rather than metal.

Furthermore, injection-moulded circuit boards significantly reduce the number of production processes, assembly times, individual components required, and therefore lowering the production costs.

How does 3D-MID technology work?

The flexibility of 3D-MID technology allows device designers to go where they need to. A three-dimensional component

that combines electrical and mechanical functions allows for endless possibilities.

The designers lay down their requirements along with very specific measurements. The components are then constructed through injection moulding.

Injection moulding is when materials such as plastic are heated and melted before being injected into a mould and cooled to achieve the desired shape. It is a process often used by many industries because it enables the creation of parts with complex shapes quickly for mass production.

Because injection moulding is so flexible, designers can use it to construct virtually anything with the exact specifications. Before realising a mould, different forms of simulation can be used to check if the parts fulfill the requirements and sample parts from rapid prototyping can be made.

Next comes laser activation through laser-direct structuring (LDS), a procedure created by LPKF Laser & Electronics in 1996. It is where a laser beam defines the conductive trace, etching the layout directly into the injection-moulded plastic component.

The injection-moulded plastic will have special additives, which laser beams can detect. The lasers then reveal areas where the conductor structures will eventually be placed.

In the chemical plating process, copper only lays down on the laser structured areas. This allows the engineers to create very precise electronic circuits.

35 | Industry EMEA | January 2023 29 MORE INFORMATION

Antenna in Capsule:

This is a substitution for an endoscope. You basically swallow it like a pill which makes way more comfortable than an endoscope.

3D-MID in Medical market

Mechatronics is a promising discipline that benefits multiple industries, especially medical or healthcare.

Advancements in diagnostics and treatment have been made possible because of the miniaturization of electronics due to 3D-MID breakthroughs.

Imagine this: You need to have an endoscopy. Most people find the idea and the experience of having a long, thin tube with a small camera on the top go inside them uncomfortable.

After metallization in a copper bath, conductive traces form in the areas that have been activated and will allow for metals to adhere to it.

Combining mechanical and electrical hardware makes designing and manufacturing electronic devices with complex functionality easier and less expensive. It essentially opens up a world of possibilities and possibly enormous savings for manufacturers and consumers.

What are the benefits and uses of 3D-MID technology?

- Integration of mechanical and electrical function into one component

- Better reliability and quality

- The flexibility allows for unlimited design options

- Helps reduce both size and weight

- Shortens assembly time and thus reduces manufacturing costs

3D-MID Applications

Plastics and electronics come together in practically every piece of current and future technical equipment, from medical to automotive to consumer gadgets.

3D-MID technology is often regarded as the gamechanger in several applications such as:

- Sensor devices and miniaturized electronic packaging

- LED carriers and lighting modules

- Antennas and connectivity modules

Almost all industries can benefit from 3D-Circuits in some way as many sectors have significant needs for miniaturization, such as the medical field.

But what if you were able to avoid that? Using 3D-MID, manufacturers can now design devices that are less invasive and more comfortable for patients, particularly when it comes to monitoring and examining the patient from the inside.

No longer is it necessary to insert a long endoscopic camera down the throat. You can instead consume a non-invasive capsule, similar to how you take your vitamins.

This capsule contains a little endoscopic camera that transmits 360-degree pictures of your body to your doctor, allowing them to visualize your digestive tract without the need for invasive procedures.

This is just one example of how technological advancements can make a previously uncomfortable situation more pleasant.

Mechatronics is also being used to create new types of prosthetics, such as the Luke Arm, a mind-controlled arm prosthesis that gives patients who’ve lost limbs the ability to perform everyday tasks.

3D-MID technologies are also used to design smaller medical equipment such as hearing aids, implants, and surgical and dental devices. 3D-Circuits boards can be made in any size while maintaining the same functionality and safety standards.

Conclusion

The possibilities with 3D-MID are unlimited. As this technology advances, we expect to see more organizations incorporate them for their space-saving projects, thereby reducing their assembly procedures and cutting costs.

https://3d-circuits.com/en

35 | Industry EMEA | January 2023 30 MORE INFORMATION

WATLOW® COMPLETES ACQUISITION OF EUROTHERM®

Watlow®, a designer and manufacturer of complete industrial thermal systems, is pleased to announce that it has completed its acquisition of Eurotherm® from Schneider Electric Company®, the global leader in the digital transformation of energy management and automation, on October 31, 2022. The terms of the transaction were not disclosed.

Eurotherm is a premier provider of temperature, power and process control, measurement and data management equipment, systems, software and services for global industrial markets. The company employs about 650 people worldwide, with headquarters in Worthing, U.K. and core manufacturing operations in Ledziny, Poland.

Rob Gilmore, Watlow’s CEO, said, “We are excited about Watlow and Eurotherm and all we will accomplish together. This acquisition aligns with our vision of providing innovative thermal products and technologies that help increase our customers’ competitive advantage. The combination of Watlow and Eurotherm products and technologies will create new global opportunities for our collective customers and allow us to focus our advanced thermal systems in important areas.”

Watlow will establish Eurotherm’s sites in Worthing, U.K. and Dardilly, France as Advanced Development Centers for its electronics and controls product offering and plans to invest in Eurotherm’s facility in Poland to become Watlow’s Manufacturing Center of Excellence in Europe. This additional capacity and capability also provide a path to growth in other parts of the world including the Americas and Asia.

https://www.watlow.com/

35 | Industry EMEA | January 2023 31 MORE INFORMATION CORPORATE

SECO TOOL RECONDITIONING SERVICE GROWS BY OVER 30% AND CONTINUES TO INCREASE

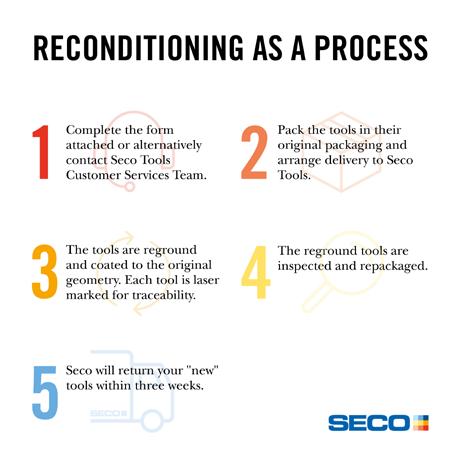

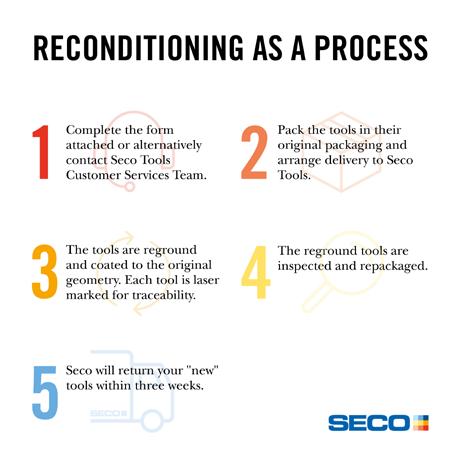

As one of the fastest growing end mill and drill areas in the Seco Tools portfolio, the company’s solid-round tool reconditioning service experienced an increase in use by over 30% in 2022.

In addition to significant cost savings for customers, a Seco reconditioned tool regains 85% to 95% of its original performance compared to tools that are reground or resharpened. Without having to readjust parameters or sacrifice performance, the reconditioned tool performance lives up to today’s advanced machining strategies, for example, in dynamic milling where only a small portion of a tool’s diameter is engaged in the cut. Manufacturers also boost their sustainability and help reduce emissions per part as well as those needed to produce new solid round tools from virgin raw materials.

Reconditioning versus regrinding

The regrinding process sharpens a tool’s cutting edges. Seco reconditioning, on the other hand, brings round tools back to a level close to their original condition in terms of properties and performance. This level of quality is guaranteed by Seco, and today’s shops demand this assurance, especially when considering process stability for automated and unmanned operations.

Benefits of the Seco process

The same process used for new tool manufacturing is applied when Seco reconditions a tool. This includes all relevant grinding steps on the same type of machine with the same programs, wheel types as well as the reapplication of coatings that were applied when the tool was produced new. Seco identifies the tool and its reconditioning program that matches all original/as-new specifications and applies all the necessary micro and geometrical properties.

Plus, Seco reconditioning can be applied to the same tool typically two or three times to significantly extend its working life. Each of these reconditioning cycles, according to Ruud Zanders, Global Reconditioning Lead at Seco Tools,

35 | Industry EMEA | January 2023 32 MORE INFORMATION MACHINE AND TOOLS

are also done at a cost level of half to one-third of the price of a new tool. “The savings,” he said, “are represented in a simple way by the equation 1+3 = 2 (one new tool cost plus three reconditions equates to the price of two new tools).”

Reconditioning contributes to a circular economy

Contributing to the circular economy’s three basic principles (waste and pollution elimination, products and materials circulation, and nature regeneration), the reconditioning program by Seco Tools helps shops maximize the lifecycle of round tools, keeps products in use longer and reduces the impact on the environment. Tools can be reused through reconditioning then finally be recycled.

www.secotools.com/reconditioning

35 | Industry EMEA | January 2023 33 MORE INFORMATION

ENERGY CRISIS AND DIGITAL SMART GRIDS – CHANGING TIMES IN THE ENERGY SECTOR

The term “smart grid” has been bandied about for years. Frequently mentioned in connection with smart meters, it has been used so many times as a buzzword without any real content to back it up, that it has become almost worn out before a global and meaningful implementation could be realized.