10 minute read

Not your typical bavarian brewery

The backdrop is taken straight from a storybook: a brewery whose walls date back to the 17th century, a beer garden with a stream happily burbling along on one side, and waitresses in dirndl dresses bearing fully loaded trays. This is precisely the picture that springs to mind when people think of Bavaria. However, all those wishing to celebrate one-dimensional clichés won’t be finding what they’re looking for at the Schneider Weisse brewery in Kelheim. It’s true that behind the ivy-clad façade beer has been brewed using traditional methods for around 140 years – however, the beers created in this way are anything but conventional.

In the Schneider Weisse beer garden, it takes just four words to give yourself away as a definite newcomer: “A wheat beer, please!” The waitresses, who serve not only the local regulars but also innumerable day-trippers and tourists every day, are used to this and answer with an indulgent smile: “Of course, but which one exactly would you like?” Looking at the menu together will bring about the “Oh I see…” effect – and will simultaneously present the dumbfounded guest with the next challenge, since the menu lists no less than ten different wheat beers to choose from. For example, the tangy-sweet Hopfenweisse, the deep-dark mahogany-coloured Aventinus-Eisbock or the Nelson Sauvin beer that has been brewed with the eponymous hop variety from New Zealand. And of course: the Schneider Original, the epitome of a Bavarian wheat beer that has been brewed to the same recipe since 1872. Thinking outside the box along traditional lines

Advertisement

But no matter how multi-facetted and distinctively original all these different beers are, they’ve got one thing in common: they do not undergo fermentation in tanks but in open vats. This ensures that the yeast gets enough oxygen, thus enabling the wide variety of aromas to be created that is typical for Schneider. In addition, after primary fermentation, most of Schneider’s products are filled into bottles or casks together with some fresh wort, where they are then left to mature into the products that send beer aficionados from Bavaria to Brazil into raptures – and regularly lead to the winner’s podium at international beer competitions.

There is probably nobody who knows better than HansPeter Drexler just what influence the combination of openvat fermentation and bottle conditioning has on a beer’s taste. The brewmaster has been working for the company for 38 years and today heads the Technology and Logistics Divisions as managing director. Many of the beer types that Schneider Weisse is currently offering were developed by him and bear his unmistakeable hallmark. But even so, the creative lateral thinker likes to experiment with new ideas and recipes: for him, sticking with a traditional process does not mean a limitation but quite the opposite – he finds it truly enriching. “I personally think our main beer type, the Original Schneider Weisse, is an ingenious beer – precisely because we owe the open fermentation process to this beer,” he explains. “Ensuring that this great process is retained has always been a matter of crucial importance to me.”

No room for error Knowing exactly what they want

This is also why he doesn’t mind the more elaborate procedures that the traditional method inevitably entails, demanding as it does perfect hygiene conditions and not forgiving even the tiniest of mistakes. In addition, there is also Schneider Weisse’s self-imposed imperative: to brew a beer of uncompromising quality in the finest of craft traditions. “Anyone buying a beer from Schneider Weisse rightfully expects a certain taste. We can afford absolutely no fluctuations here.”

So how is he able to get a wink of sleep at all? This is a question he gets asked quite often – mostly it’s his fellow brewers who want to know and ask him with a genuine tone of respect in their voice. And he replies tongue in cheek: “Well, as it is I do in fact sleep quite well at night.” That he remains so unperturbed is attributable above all to the vast fund of experience he and his team can draw upon. “You know, Schneider Weisse has been specialising in this field for a long, long time,” he says. “We know the process inside out, and have matched our system technology to suit it down to the very last detail.”

Replacing a filler that had been getting on in years

This likewise applies to the new filler (including CIP system) that Schneider Weisse commissioned in 2019 shortly before Christmas. Even though its predecessor – and the rest of the returnable-glass line – had been supplied by Krones and giving reliable service since the 1990s, Schneider Weisse approached its search for a suitable vendor with an open mind. “We had a look, of course, at several different manufacturers and while we were at it had some very constructive talks,” says Hans-Peter Drexler. “In the final analysis, though, we once again chose a Krones filler. We felt we were in very good hands here, and the price-performance ratio was also spot-on.”

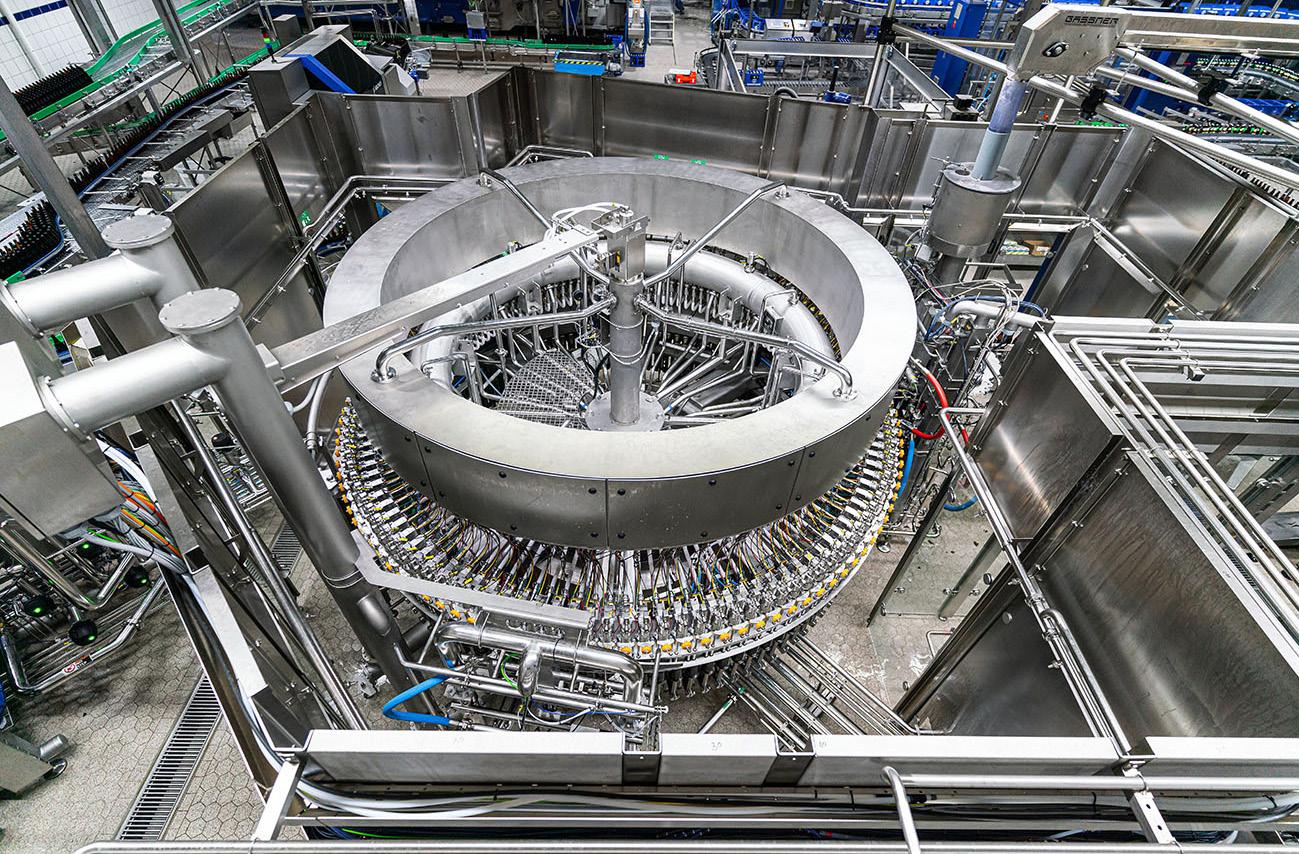

Schneider Weisse opted for a Modulfill HES, featuring 120 valves and filling up to 40,000 half-litre bottles an hour. The brewery uses sterile air as pressurising gas for those beer types that undergo in-bottle fermentation after filling – in contrast to most other breweries that use CO2, as Hans-Peter Drexler emphasises: “That’s why we wanted to have an option for switching off pre-evacuation when we’re filling our main products. It saves on compressed air, which makes quite a difference in terms of numbers.” The Modulfill HES handles the brewery’s complete beer portfolio and, depending on the season, is operated for one or one and a half shifts a day. So as to remove any living yeasts that may be left in the machine after a bottle has broken, an automatic hot-water cleaning routine is run every two hours. This requires perfect interaction between the filler and the CIP system, so as to meet the brewery’s meticulous specifications. “We don’t want to put disinfectant in the filler for an interim cleaning routine,” explains Hans-Peter Drexler. “So it was important to us that the water invariably has the same temperature, of 80 degrees Celsius, right from the first litre.”

There were likewise some customer-specific requirements to satisfy in terms of CIP system design: “Since we’re not pasteurising our products, we had some special wishes in regard to valve technology,” points out Hans-Peter Drexler. “Our specifications lay down a certain valve type for every task. Krones took that into due account and integrated into the valve rack precisely those components we’re working with here as a standard.” A lot of ingenuity was needed to fit the new machines into the hall. This was because the filler and CIP system were to be integrated into the existing line in the same space formerly occupied by two older models – and these were significantly smaller. “A whole lot of customisation work was required here, both in the planning stage and during erection as well,” says Hans-Peter Drexler. “But that was likewise solved to our satisfaction.” To accommodate the machines in the space envisaged, the Krones designers modified a number of individual features, including the housing of the filler and the position of the process components.

Digital maintenance management

The modernisation of the machine technology constituted a welcome opportunity for Schneider Weisse to take a giant step forward in regard to digitalisation as well: after long years of working with the SIPS maintenance system from Krones, the brewery has now changed over to its latest successor system, Share2Act Assistance. “The old system had been getting on in years and was quite simply no longer offering the functionalities we need,” explains Hans-Peter Drexler. “What simplified the changeover for us was that we’d already imaged all our machines in the SIPS – so we could just transfer that to Share2Act.” Werner Volkmann, who heads the Technical Service Department and works with the system every day, adds: “We use the system to cover our entire maintenance operation, of both the brewery and the bottling hall. What we’re talking about here is up to 5,000 maintenance orders.”

Everything regionally sourced

Even though it was not the reason tipping the scales in favour of Krones, the fact that the plants of Krones and Schneider Weisse are just a good half hour’s drive away from each other fits in perfectly with the “buy local” concept that the brewery has been vigorously pursuing for 25 years now. The raw materials used to make Schneider Weisse’s beers, you see, all come from the brewery’s neighbourhood. “We’ve got ideal conditions for this here. Malting barley can be grown in our region, using only very small amounts of fertiliser, and since the Hallertau is close by, we likewise have the hops grown right here in our immediate vicinity,” says a gratified Hans-Peter Drexler. So Schneider Weisse buys the majority of the grains and hops they need from local farmers. The barley even comes 100 per cent from a local farming community specifically set up for this purpose. “This enables us to choose the quality we need ourselves,” explains Hans-Peter Drexler. “What’s more, since we’re living in a densely forested region here, we operate our own wood-chip-fired heating system. And that provides us with a great deal of independence as well. We can generate all the energy we need from our own resources, from sustainable raw materials growing right on our doorstep.”

Travelling the world with eyes wide open

As small as its buying radius is, as big is conversely the brewery’s sales market. Around a quarter of the production output is exported to customers in more than 40 countries around the globe. Schneider Weisse’s international success is based not least on the inquisitive, cosmopolitan spirit of its brewmaster that’s rubbed off on the brewery, too. The craft beer movement has left a particularly deep impression on Hans-Peter Drexler. He was able to observe its birth at close quarters during several trips to the USA in the 1990s – and was thrilled. “What I brought home with me? The impactful insight that it is actually possible to approach brewing with an open mind and without any preconceived notions. An incredibly exciting experience for me,” he says, recalling those days. Back in Lower Bavaria and still in raptures, the brewmaster immediately walked the talk: he developed a beer based on a hop variety he had discovered for himself in the USA. “The hops had a heavy aroma of citrus or grapefruit,” he relates. “So I thought: that ought to go really well with wheat beer. After all, in Bavaria we used to put a slice of lemon into the wheat beer glass. And before we go fiddling around with lemons each time, we can use a hop variety for brewing that does the job for us.”

Inquisitiveness pays off And so it happened that Schneider Weisse was one of the first German breweries to bring the innovative vigour of the American craft brewers to our country – long before anyone here had actually heard of “craft beer”. “In those early days, we at home in Bavaria didn’t even know what to call a wheat beer of this kind,” says HansPeter Drexler, laughing. But this made no difference to its success. It was above all the younger consumers who were easily thrilled by the new beer creations. And when the craft beer movement picked up speed in Germany as well, Schneider Weisse had already had a foothold in this new market for some time. And what about the tradition-conscious Schneider Weisse fans? Some couldn’t resist their favourite brewery’s “experimentation bug” and went along with it, while others stayed calm and loyal to one of the traditional classics, like the Schneider Original.

Craft beer rebel or traditional brewer? Should the beer world ever split up into these two camps, that certainly won’t happen in the Schneider Weisse beer garden: there, all will sit happily around the same table, cheering each other with a freshly tapped wheat beer.