4 minute read

LIMBERLOST PLACE

Designed by the joint venture of Moriyama Teshima Architects and Acton Ostry Architects, Limberlost Place (formerly known as “The Arbour”) is a landmark project for low embodied carbon and high energy efficiency. It combines design and structural innovation with advanced prefabricated, tall-building façade systems, as well as an optimized use of decentralized mechanical systems working in consort with passive systems. The result is a building that provides the healthiest environment for both its users and for the planet.

Limberlost Place is presently under construction in Toronto’s East Bayfront neighbourhood, where it will serve as an academic building for George Brown College. The project boasts a mass timber structure, one of the first public buildings in the city to do so. It is poised to achieve the highest levels of municipal TEDI , TEUI , this occupancy world. obstructive beams. and GHGI targets (Toronto Green Standard Tier 4) well in advance of the city’s step plan to widely implement the same carbon reduction targets. Key project team members in this achievement are Fast + Epp Structural Engineers, Transsolar KlimaEngineering, and Introba (formerly Integral Group). The constructors are PCL Construction, with internal George Brown College Project Management.

The remarkable aspiration of this building is seen through the use of exposed mass timber in an educational facility, where the assembly occupancies and the teaching spaces occupy the full verticality of the ten-storey building. To the architects’ knowledge, this is a first-of-its-kind in the world use of exposed mass timber to this height for this occupancy.

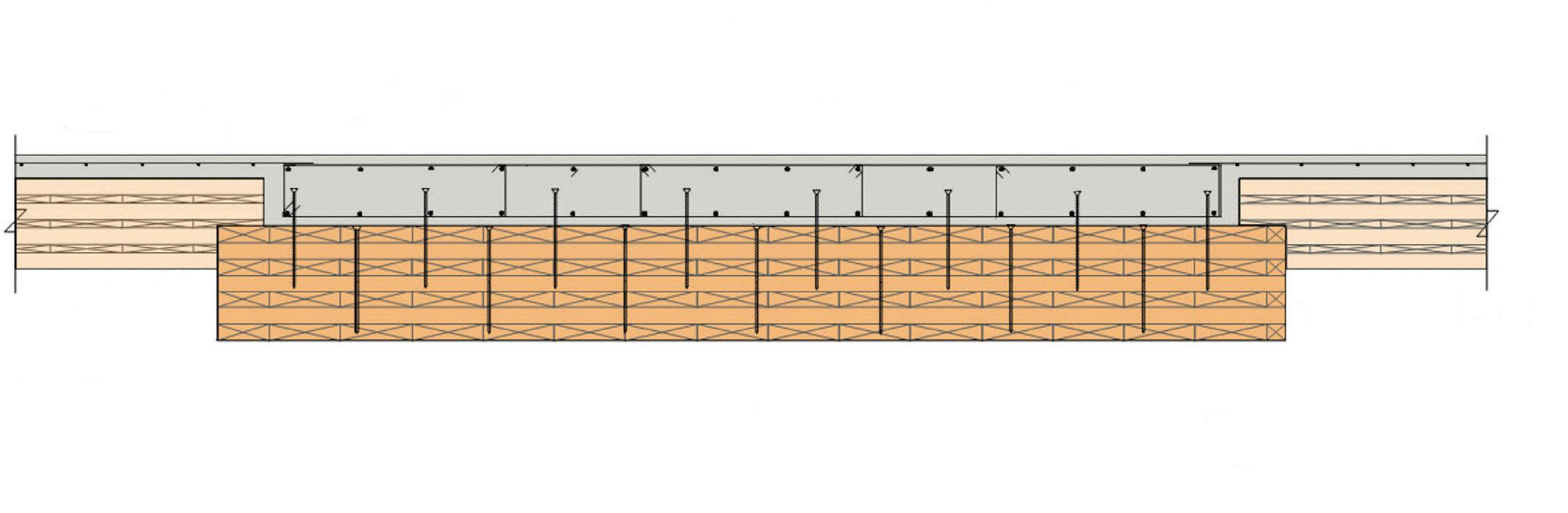

To achieve nine-metre spans within the cost and height restrictions on the site, which were requisite for column-free classrooms with good sight lines, Fast + Epp Structural Engineers created a CLT panel system that eliminated the use of beams. In this system, 7-ply CLT panels span 9.2 metres in the north-south direction, acting as slab bands on which thinner 7-ply CLT panels bear in the perpendicular direction. A concrete topping further stiffens the panels, while bespoke glulam columns support the main CLT slab bands. This mass timber solution is extremely shallow for this span, creating more head clearance, and space for the mechanical and electrical components. The connections between the CLT and concrete were the subject of testing conducted in collaboration with the University of Northern British Columbia (UNBC) and Germany’s Biberech University. This research, which is publicly accessible through the federal agency Natural Resources Canada (NRCAN) who funded the investigations, has advanced our collective understanding of timber-concrete composite systems and the connection details between the two materials. The research demonstrated that the most economical of the systems a metal bar friction-fit into the top lamination of the slab band was the preferred connector.

The next step in the process was to design a high-performance envelope. This involved an integrated design and collaborative approach, obtaining feedback from all team members. The appropriate massing and building orientation also played a key role in the envelope design, ensuring that passive design principles were prioritized. A prefabricated building envelope was determined to provide the required continuous insulation and airtight design to meet Passive House requirements, while further accelerating overall construction schedules. A fast enclosure limits weather exposure to the mass timber structure, protecting the wood from staining.

The chosen solution, a fully prefabricated modular wall system, with two-storey panels as tall as 11.7 metres in height and 4.2 metres in width, was required to undergo Underwriters Laboratories of Canada testing to meet proof of concept. The results of this testing revealed that the panels far exceeded the original design requirements, achieving a whole building air tightness of 0.4 L/sm2 @ 75Pa a performance more than twice as efficient as the target of 1.0 L/sm2 @ 75Pa.

The prefabricated envelope incorporates a natural ventilation system, through both automatically powered and manually operable windows. A rooftop weather station sends wind speed, air quality, and temperature readings to the building operating system to control the opening and closing of the windows when appropriate conditions arise. During passiveoperation mode, air travels through operable windows into classrooms, offices, and meeting rooms, then into the corridors through acoustically lined transfer grilles, finally making its way into the east and west solar chimneys. Stack effect then pulls the air through the solar chimney to 1.5 storeys above the highest occupied floor, where it is vented out the roof.

One of the unexpected revelations about the design of Limberlost Place is that the form of the building was a prime contributor to its sustainability. The striking peaked profile was derived from the inclusion of solar chimneys. The building stretches up to the north to maximize natural light to the upper floors, while minimizing heat gain from the south. The slope becomes a natural armature for solar photovoltaic panels.

The building envelope is also organized to consider the future needs of the project. Expanses of curtain wall are strategically located to take best advantage of views, and contribute to an active waterfront community. The main body of the building provides a well-insulated, sealed envelope, with just over a 40 percent window-to-wall ratio. Windows placed every three metres support the future relocation of demising walls.

The designers hope that once Limberlost Place is realized and occupied, inhabitants will be influenced by its low- and high-tech approaches to sustainability, including the visible use of renewable materials and intuitive operations of its façade.

Jury Comments :: Limberlost Place is an elegant example of mass timber hybrid construction and thoughtful systems integration to produce an exemplary project on the path to a more sustainable architecture. Together with their client, the architects have persevered through the complex regulatory, constructability and technical issues of delivering this large academic building in mass timber in a jurisdiction new to this type of construction. The team’s perseverance alone is worthy of innovation accolades, but the project is also ambitious in investigating sustainable approaches throughout the project from prefabricated façade systems to passive heating and cooling strategies.

The architects have skillfully demonstrated that the most aspirational environmental goals can be achieved in a building that is also inspiring for its beautiful and joyful spaces. Limberlost Place is what architecture should be in Canada.