55 minute read

FUTURE BUILDINGS LABORATORY

FIELD TEST

A NEW BUILDING AT CONCORDIA UNIVERSITY’S LOYOLA CAMPUS IS DESIGNED TO TEST BUILDING ENVELOPE COMPONENTS IN YEAR-ROUND, OUTDOOR CONDITIONS.

PROJECT Future Buildings Laboratory, Concordia University, Loyola Campus, Montreal, Quebec ARCHITECT Smith Vigeant architectes TEXT Shawn Moss As an architect working for Concordia University’s facilities management department, my projects include the renovation of classrooms or offices where our department, along with external professionals, are the experts. In the case of a recent project though, the architects were the learners.

Concordia University’s newest—and smallest—pavilion, designed by Smith Vigeant architectes, may look like a building. But this research facility is essentially an instrument designed to test building envelopes and efficiency under real-weather operating conditions.

The pavilion was created for the University’s Centre for Zero Energy Building Studies (CZEBS), part of the Gina Cody School of Engineering and Computer Science’s Building, Civil and Environmental Engineering department, and was informed by the CZEBS’s researchers. That group is directed by one of the world’s foremost experts in solar buildings, Dr. Andreas Athienitis; the construction project was led by Dr. Hua Ge, an expert in field-testing building envelopes. The pavilion is designed, among other things, to test building-integrated photovoltaics, motorized shading devices, hybrid renewables, urban wind energy, and smart nanogrids. It brings these technologies out of the lab, and into the field, allowing researchers and students to experiment with these technologies and serving as a demonstration of what is possible as we develop advanced concepts for carbon-neutral buildings.

PREVIOUS PAGE The Future Buildings Laboratory is currently enclosed with semi-transparent photovoltaic curtain walls and building integrated photovoltaic/ thermal collector panels. ABOVE 60 percent of the building’s walls can be removed and replaced with other assemblies; the building also is designed to test electric vehicles as a means to store extra solar or wind power.

To perform this kind of research, the house-sized pavilion incorporates large removable sections of exterior wall and roof—approximately 60 percent of its walls, including two corners, can be removed. This allows the performance and efficiency of various wall and roof assemblies to be assessed, along with their effects on occupant comfort in the corresponding enclosed spaces. Sensors embedded at various points throughout the wall composition allow data to be collected. The exterior envelope components will be changed every one or two years, depending on the research. Our research turned up only a single precedent for this unusual program—the Energy Flex House in Denmark by Henning Larsen Architects, which does not have removable walls or roof sections—and seeing it successfully realized required a number of unique details.

The facility is situated on the northern edge of Concordia’s Loyola campus, and is clad in pine to harmonize with a nearby residential neighbourhood. But its appearance will change over time—a portion of the pine-clad wall can be swapped out with any number of envelopes, from a brick cavity wall, to glazing studded with photovoltaics. Vertical steel C-channels frame the openings into which the wall test panels can be inserted, and double as a support for future shading devices. The channels are aligned with structural columns which are set back from the slab edge to allow wall thicknesses varying from 50 mm to 570 mm to be tested. Earlier in the design process, these openings were thought of as windows or doors which would slide or swing into place. Due to the need to monitor the temperature and humidity performance of the envelopes being tested, however, it was decided to treat the openings as sections of wall, accepting that membranes and caulking will have to be redone with every change in wall composition. The way the building is framed allows for such changes.

The facility faces south to optimize solar exposure, and contains four south-facing bays, each delineating a room within. This configuration can also change, with multiple rooms combining to create larger spaces. The only fixed walls on the interior enclose the mechanical and electrical rooms to the north, providing lateral bracing. Three of the bays are currently enclosed with semi-transparent photovoltaic (STPV) curtain walls developed by CZEBS researchers in collaboration with industry partners. The last bay is enclosed by spandrel panels, with building integrated photovoltaic/thermal collector (BIPV/T) panels installed on the exterior of them—an experiment that aims to recuperate the heat generated in the cavity between the spandrel and BIPV/T panels to preheat the fresh air supply.

A steel structure on the roof was built to support future photovoltaic panels, and equipped with masts that will host a weather station and wind turbine. The roof slopes at 45° on the south side to maximize solar exposure. A shallower 14° incline on the north side facilitates rooftop access, and allows for double height spaces within. Those double-height spaces are capped with a skylight, in order for researchers to test and quantify the effects of passive cooling.

Planned additions also include an electrical vehicle (EV) charging station. The building’s large access ramp is equipped with a removable handrail, allowing it to double as a pathway for a small electrical

LAMINATED WOOD COLUMN - PERMANENT STRUCTURE

SEALING STRIP

WOOD ASSEMBLY MEDIATING BETWEEN PERMANENT STRUCTURE AND ENVELOPE TEST PANELS

ENVELOPE TEST PANEL : GLAZED ASSEMBLIES WITH AND WITHOUT BIPV/T

PREFINISHED ALUMINUM OR STEEL PROFILE OVER INSULATION BRIDGING BETWEEN ASSEMBLIES

GALVANIZED STEEL C-CHANNEL ENCLOSING INTERMEDIATE STRUCTURE BETWEEN TEST PANELS DYNAMIC VAPOUR BARRIER

STEEL ANGLES TO ANCHOR ENVELOPE TEST PANELS TO STRUCTURE

INTERIOR FINISH

E D

T/O ROOF STRUCTURE

roof test panel

CDYNAMIC VAPOUR BARRIER

B A

MINERAL WOOL INSULATION ENCLOSED WITH RESILIENT BACKER RODS AND SEALANT

BATT INSULATION mast for roof equipment maintenance walkway for roof equipement operable skylight

VAPOUR PERMEABLE AIR BARRIER ON PLYWOOD T/O UPPER PANEL

SEMI-RIGID INSULATION

T/O TEST PANEL

glazed BIPV/T test panel TEST CELL #2

FURRING AND AIR SPACE

TEST CELL #1EXTERIOR CLADDING

ENVELOPE TEST PANEL : DIVERSE WALL ASSEMBLIES

GROUND LEVEL

RESILIENT BACKER RODS AND SEALANT

NEOPRENE / EPDM THERMAL BREAK TECHNICAL LEVEL

envelope test panel

PERMANENT STRUCTURE

INTERMEDIATE STRUCTURES AND ASSEMBLIES

TEST ASSEMBLIES

vehicle—so that researchers can test certain aspects of the relationship between building and automobile, such as using the EV as storage for permanent structure excess electricity generated from photovoltaics or from the wind turbine. intermediate structures and assem-One of the main challenges of the project was to persuade the generblies al contractor and builders that this was not a house, and that it had to test assemblies be built in ways that were unconventional. Smith Vigeant and our team spent close to a year in design, and conveying design intent to the builders was often an arduous process.

This experimental building was a challenge to design and build—but also a learning process in itself. We believe that our efforts will pay off, and this highly adaptable “building to test buildings” will help shape and improve our future constructed world.

Shawn Moss, LEED AP, is an architect and project manager with Concordia University’s Facilities Management department.

CLIENT CONCORDIA UNIVERSITY, GINA CODY SCHOOL OF ENGINEERING AND COMPUTER SCIENCE – DEPARTMENT OF BUILDING, CIVIL AND ENVIRONMENTAL ENGINEERING | ARCHITECT TEAM STÉPHAN VIGEANT, CECILIA CHEN, ROXANE ROUTHIER-AUDET, SALSABIL MAAROUFI, ERIC LALONDE, SABRINA CHARBONNEAU | STRUCTURAL POINCARÉ EXPERTS-CONSEILS (PAUL-HENRY BOUTROS) | MECHANICAL PAGEAU MOREL ET ASSOCIÉS (DANIEL PICARD, MARC-ANTOINE JEAN) | ELECTRICAL permanent structureintermediate structures and assembliestest assembliesPAGEAU MOREL ET ASSOCIÉS (JÉRÔME RIVARD, ABDEL KADER) | LANDSCAPE SMITH VIGEANT ARCHITECTES | INTERIORS SMITH VIGEANT ARCHITECTES | CONTRACTOR CONSTRUCTION DOVERCO | PROJECT MANAGEMENT CONCORDIA UNIVERSITY, FACILITIES MANAGEMENT | CIVIL FNX-INNOV (JADE BOSSÉ BÉLANGER) | CODE GLT+ | SIGNAGE SAIC | ACOUSTICS DAVIDSON ACOUSTIQUE & INSONORISATION | SITE SURVEY ARSENAULT LEMAY ARPENTEURS-GÉOMÈTRES & FNX-INNOV | DEMOLITION CONTRACTOR DÉMOLITON PANZINI | AREA 125 M2 | BUDGET $1.3 M | COMPLETION JUNE 2021

4

4

4

4

3 4

6

5

4

1 2

GROUND FLOOR 1 ENTRY LANDING 2 STEP 3 1:20 RAMP 4 TEST CELL 5 ELECTRICAL ROOM 6 MECHANICAL ROOM

PERENNIALS GARDEN CITY FARM

WHAT WILL IT TAKE TO DECARBONIZE BUILDING OPERATIONS?

TEXT Sheena Sharp

USING DOWNTOWN TORONTO AS A TEST BED, TORONTO 2030 DISTRICT RESEARCHERS MAP OUT THE COSTS AND LOGISTICS—FOR BUILDING OWNERS AND CITIES—FOR GETTING TO ZERO OPERATIONAL CARBON IN THE BUILDINGS SECTOR.

AED professionals are becoming increasingly adept at improving the energy performance of individual buildings. But meeting global carbon reduction targets will require much more than creating new buildings to higher standards, and retrofitting existing ones piecemeal. In provinces like Ontario, it will mean a wholesale switch away from the present carbon-intensive natural gas heating systems. While governments must decide what fuel will replace gas, architects need to understand what is coming—as it will influence the way they design in the future, and the advice that they give their clients today.

To better understand what will be needed to achieve a low-carbon future, I’ve been working with the Toronto 2030 District: a privatepublic initiative with 63 members, including building owners, operators, and investors; service providers like architects, engineers, and suppliers; and community groups like the OAA. The Toronto 2030 District is part of a North American network of 23 similar districts, linked to the non-profit organization Architecture 2030.

Using downtown Toronto as a test bed, we have taken on the challenge of exploring the wicked problem of reducing the operating emissions of buildings, which account for some 30% of global GHG emissions. The District’s physical area contains most of the building types found in Ontario: low-rise residential, high-rise residential, low-rise commercial and office towers, as well as Ontario’s Legislature, two stadia, a hockey arena, two universities, many hospitals, two city halls, hotels and restaurants. We are primarily addressing what to do about existing buildings, but we also expect the findings to influence regulation and leadership when it comes to new buildings. The Toronto 2030 District’s members are not new to greening buildings and have insight into what could work, and what will not.

Finding the Right Solution It was once believed building owners could make individual decisions that, when added together, would save the planet, but it’s become clear that this idea is not working. Progress has stalled at about 30% operational energy savings. The savings achieved so far have relatively good paybacks, like the widespread implementation of lighting retrofits. However, achieving the next 30% savings will be a lot more costly—involving moves like envelope or mechanical retrofits—and businesses going it alone will be at a competitive disadvantage.

Programs like the LEED rating system have sometimes performed better, but LEED has penetrated only about 1% of the new construction market, and affected much less of our existing building stock. Even this program has struggled to achieve deep carbon reductions because of its measuring system—based on reference buildings and proposed alternatives—rather than real-world results.

Overall, what we have been doing thus far amounts to essentially random acts of energy efficiency. We have no idea if our efforts are addressing the climate imperative. We are like mountain climbers in a fog at the bottom of a mountain: we know we are going up, but we do not know if our path leads to the summit, or to the top of a foothill. If we are taking actions to reach a target for 2030, then we should be sure the efforts are in line with what is needed to reach the 2050 targets, and will not need to be undone. Nonetheless, what has been done todate is not wasted. Our experience with LEED projects can be used to imagine what is required to take super-efficiency to scale.

It is becoming clear that what we urgently need is a political solution, rather than a consumer one. There is precedent for the work that needs to happen. In the 1950s and 60s, many governments (including Ontario’s) supported the conversion of “city gas” systems to natural gas, and continue to regulate the development and expansion of our natural gas system.

Just as happened then, the new solution will be first and foremost about fuel switching, and next about energy efficiency. In meeting our carbon reduction targets, there is no scenario where natural gas—whose primary component, methane, is a potent greenhouse gas, and which creates carbon dioxide when burnt—can continue to be used in its present form to heat buildings. There is no way to capture the resulting CO2 at the building level, and without doing so, we cannot meet the global tar-

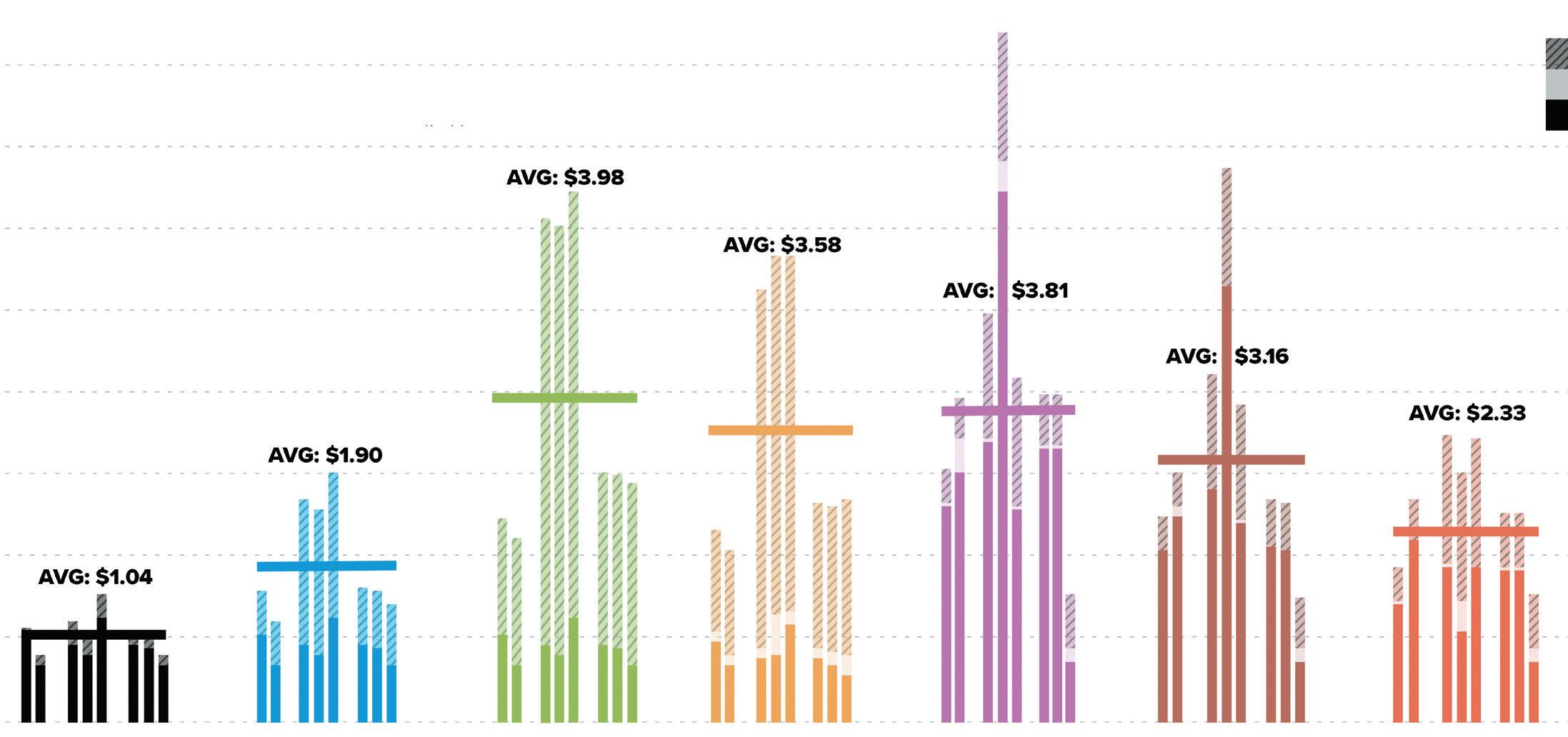

8.00$/sf/yr

7.00$/sf/yr Occupancies, left to right

Office class A, Office class B&C, Hotel, Stand-alone retail, Mall retail, Pre-2004 apt, Post-2004 condo, Single-family home

6.00$/sf/yr

5.00$/sf/yr

4.00$/sf/yr

3.00$/sf/yr

2.00$/sf/yr

1.00$/sf/yr

FUEL COST CAPITAL (ELEC.) CAPITAL (MECH.)

Natural gas baseline

Blue hydrogen

Green hydrogen

Electric resistance Air source heat pump Ground source heat pump

Hybrid (ASHP & RNG)

gets of reducing our carbon emissions to 50 percent below 1990 levels by 2030, and reaching carbon-neutrality by 2050. We need to change fuels.

A New Vision The Toronto 2030 District has already completed a utility data project that accounts for the annual energy use of all 7,216 buildings within its borders (www.toronto2030platform.ca). We are now researching the pathways to creating a decarbonized energy supply that meets the needs of buildings in the District. For this exercise, we chose a process developed by the Transition Accelerator, a Canadian non-profit whose work includes projects in Ontario, Quebec and Alberta. The process is a good fit because, like the District, it is driven by stakeholder engagement and defined goals.

To date, Toronto 2030 District has worked at understanding existing systems, co-developing an alternative vision, and analyzing some of the pathways to achieving that goal. Our group of private and public sector partners looks at the UN climate targets from the point of view of the options and costs to individual building owners: we don’t think it’s an option to say “it’s too expensive,” but rather, we have embraced the goal of showing how we can make it happen.

Notably, the project’s vision is not solely about airtightness, insulation, and efficient fans. We need to recognize the social and economic context for energy efficiency. We need to look for co-benefits—like increased value and comfort—which could pay for improvements. The District encompasses assets that are rich sources of data and ideas that can also be leveraged, like universities, research institutes, building organizations, and government agencies.

Fuel-Switching Study Our first in-depth analysis concerns fuel switching scenarios. We know for sure that we cannot achieve the UN climate targets while burning fossil-fuel-based natural gas as a primary heating source for buildings. Between now and 2050, we will need to fuel switch. Likely, we also will need to make buildings more energy-efficient to reduce costs.

To switch fuels, we will need to change the heating equipment at each building, as well as providing an energy system that can meet the shifted demand.

The fuels and technologies that are contenders for replacing natural gas are: electricity, hydrogen, and renewable natural gas. For electricity, the District looked at different heating technologies: electric resistance heaters, cold climate air source heat pumps (ASHPs), and ground source heat pumps. For the gaseous fuels, we also examined different production methodologies: blue hydrogen (created by splitting natural gas into hydrogen and captured carbon dioxide), green hydrogen (produced from water, using renewable electricity), and a hybrid of electricity and renewable natural gas (the latter captured from decomposing organic waste at farms and landfills).

Estimating the cost of the on-site building changes was very challenging. The over 7,000 buildings in the district come in a in a broad variety of shapes and sizes. Further, we wanted to work with real costs for switching out boiler, chiller and rooftop units.

To stand in for the building stock, we developed a set of 13 representative building occupancy typologies, each with typical floor plates and mechanical systems, to approximate the averages for the District’s building stock. We used public Energy Use Intensity (EUI) data for each occupancy type, and cross-checked this against actual consumption measures from our earlier data platform project. The result is a realistic, if approximate, model of how the District’s buildings are consuming energy, and the mechanical systems needed to support this.

In the analysis, we then replaced each typical mechanical system with appropriate equipment for the new fuels. We obtained current prices from an equipment supplier, and included soft costs and the cost of borrowing in our replacement estimates. Then, we translated this into square foot costs for each building type, which building owners could use to estimate their own costs and the impact on their businesses.

To estimate future utility bills, we calculated the amount of heat currently made by burning natural gas in each building type, and calculated how much electricity, hydrogen, or electricity and renewable natural gas (in a hybrid system) would be needed to generate the same amount of heat. We worked with a variety of reports and estimates to develop fuel costs that reflect the costs to generate the fuel and to build the needed energy plants, including carbon capture and storage in the cases where natural gas is the base fuel.

Adding together the capital costs and the fuel costs results in a total per-square-foot cost. This showed that blue hydrogen is the cheapest replacement for the combustion of natural gas. This is followed by a hybrid of standard air source heat pumps (accommodating heating peaks at -10°C) and renewable natural gas, then ground source heat pumps, then electric resistance heaters, then cold-climate air source heat pumps (accommodating heating peaks at -20°C), and finally, green hydrogen. The figure below shows the average cost per square foot across the eight most common building typologies.

Looking at this figure suggests that the decision is clear. But not so fast: cost is only one consideration. We also need to consider the potential for cost changes, as well as the likelihood we can make the system conversion before 2050.

To understand what a fuel-switching transition might look like from a larger perspective, the District 2030 partners and researchers devised a thought experiment, using the principles of project management to schedule the transition and gauge feasibility.

A Blue Hydrogen Strategy Blue hydrogen, the least expensive option in our initial analysis, is the name for hydrogen made with natural gas. The hydrogen and carbon in natural gas (methane) are split, the carbon is stored underground, and the hydrogen is sent by pipeline to be burned for heat at the building level.

However, there are two main issues with blue hydrogen. First, not all carbon from natural gas can be captured in the process: estimates range from 70% to 95%. We used 90% for our exercise, giving the benefit of the doubt to industry. Because of this problem, in order to be emissionsfree, we would eventually have to switch to the more expensive green hydrogen (made with water and electricity) sometime in the future.

The second issue is that though it has successful pilot projects, blue hydrogen does not exist. While we have a lot of natural gas in Canada, we don’t currently make hydrogen with carbon capture and storage at this scale.

Hydrogen is a smaller molecule than natural gas. In a hydrogenbased fuel system, parts of the natural gas infrastructure could be reused, but all of the main distribution lines, as well as some of the local distribution lines, would have to be rebuilt. In Toronto, about a third of the local distribution would have to be replaced, meaning a lot of ripped-up roads.

Our natural gas infrastructure was not installed through a process of individual owner decisions. The provincial governments installed the system neighbourhood by neighbourhood, replacing old equipment alongside new equipment. Switching to hydrogen will require a similar process.

While we know how to manufacture the required boilers and furnaces for a hydrogen-based system, and may be able to make dual-fuel equipment, we don’t currently do it. There is no supply chain, no standards, no available safety monitors, design codes or regulations.

There are also concerns about our capacity to safely store CO2, and about the social acceptability of building or rebuilding pipelines. These amount to non-trivial project risks.

To meet the UN targets, a project schedule might look something like this. We allow two years to develop policy, consensus and regulations, which would be incredibly fast. We would then need to complete the following tasks: build the generation capacity; rebuild local infrastructure as required; manufacture heating equipment; and start switching over customers. Finally, we would need to replace the blue hydrogen with green hydrogen.

Because we would have to first build the supply system, the available time to convert would be a few years, and we would have to do so at an initial pace of 950,000 building plant renovations per year, followed by a more reasonable pace of 150,000 per year.

An Electrification Strategy Electricity has a different issue than hydrogen: it has existing infrastructure, generation, codes, design standards and supply chains. But does it have the capacity to serve all of the heating needs of current natural gas customers?

When designing buildings, we do not size boilers or furnaces based on the total heat we will need in a year. Rather, we size them based on the maximum heat we will need to produce on the coldest day of the year. Similarly, when we are adding to the electricity supply system capacity, it’s the peak demand that matters, not the total load. Since electricity, unlike gas, cannot be stored, we need to size the generation system for the coldest day. The development of economical grid-scale storage is hotly pursued, and there are many pilot projects, but it is not widely deployed.

Either electric resistance technology (like baseboard heaters) or heat pump technology (a refrigerator run in reverse) can be used. Heat pumps work by taking either air or water, at some temperature, and squeezing heat out, exhausting cold water or air. Heat pumps are more efficient when the temperature difference between the incoming air/water and the desired temperature is smaller. Heat pumps are optimized for different incoming temperatures: the cold climate ones are rated to -20°C, and can handle our climate without backup heating systems.

What will happen to the peak loads if we convert to heating electrically? We based our scenario on converting all buildings to cold climate airsource heat pump technology, which although the most expensive system, gives us the lowest peak demands. In our test bed of downtown Toronto, the peak would switch from summer to winter, and increase by 100%. The electric system, as it stands right now in Ontario and most provinces, has additional peak capacity. We could start electrifying gas customers right away, and ramp up clean electricity generation at the same time.

Although electricity is sold by the kilowatt, the majority of the cost is in building the plants and distribution system. The marginal cost to produce additional clean kilowatts from existing plants is very little. It’s very likely that an all-electric system will generate additional revenue to offset upgrade costs, unlike with hydrogen.

What would a project schedule look like?

Again, we’ve assumed two years for consensus, policy and regulation. Fuel-switching in buildings could start immediately, as would building increased system capacity: we would not have to convert systems neighbourhood-by-neighbourhood like with gas. The pace of conversion up to 2032 would have to average 393,000 buildings per year, followed by 150,000 per year up to 2050. Not all of the provinces have clean electricity generation, so at some point, the coal and natural gas plants would have to be closed and replaced with clean electricity sources.

The Hybrid Gas/Electric Strategy This solution combines the benefits of the first two fuels, and takes advantage of the fact that “standard” heat pumps, which operate to about -10°C, are much less expensive than cold climate heat pumps. The idea is to electrify heating with the standard pumps, and use the existing gas system for the peaks.

Natural gas is the common name for methane extracted from the ground. Renewable natural gas (RNG) is also methane, but made from

Today Blue Hydrogen Implementation

Policy in Place

Sell only Duel Fuel Appliances Build Hydrogen CCS Plants Build Main Distribution Lines Beside Existing Lines Map Existing Local Distribution Systems Replace Local Distribution Systems as Needed

Convert 56% Customers to Hydrogen, Incl. Burners, Meters, Detection (3.33M total or 950k/yr)

Electrification Implementation

Policy in Place

More Robust Supply Chain Development Build New Generation & CCS Capacity Augment Main Distribution Lines Beside Existing Map Existing Local Distribution Systems Replace Local Distribution Systems Convert 56% of Buildings to Heat Pumps (3.33M or 393k/yr)

50% Emissions Reduction International Target

Convert the Remaining 2.66M customers at 150k/yr

Convert the Remaining 2.66M customers at 150k/yr

RNG Implementation

Policy in Place

Build Renewable Natural Gas Generation Capacity Convert 53% of Buildings to Heat Pumps maintaining RNG back-up (3.18M or 362k/yr)

Energy E ciency First

Policy in Place Convert the Remaining 2.82M customers at 156k/yr

100% Emissions Reduction International Target

Build Decarbonized Green Hydrogen Plants

Replace Gas-Fired Generation Plants

Replace Gas-Fired Generation Plants

Renovate 100% of Buildings to 60% E ciency

(5.06M or 632k/year)

Select and Build Out Clean Fuel System

Convert 100% Of Buildings to Selected Clean Fuel (5.06M or 562k/yr)

2021 2025 2032 2050

bio-based processes, such as capturing methane emissions from organic waste, landfills, and wastewater treatment. It is molecularly identical to natural gas, so infrastructure would not have to be rebuilt.

The downside of RNG is that we only have the feed stock to make about 15% of the methane that we currently use. This problem goes away if we are only using it for peaking, as peaking loads will require only about 5% of what we currently use. Furthermore, the operating costs would be high: RNG would likely cost the same as electricity. We would need to add a carbon price on top, to ensure that RNG was only used in peak periods.

The biggest project risk is that RNG would be a very flexible fuel, and the building sector will be competing with heavy industry and aviation for access to it, so operating costs could be high. Currently, natural gas use by industry is greater than its use by commercial and residential buildings. This would be a huge project risk. Another project risk is that if the conversion deadlines are not met, we would be forced to continue to use

Cost$/sf/yr

Potential for fuel cost change

Emissions

Potential for end-use cost change

Supply chain maturity

Required system expansion

Blue hydrogen

Green hydrogen

Electric resistance Air source heat pump Ground source heat pump

Hybrid (ASHP & RNG)

fossil-fuel based natural gas, and would therefore miss the UN targets. This would have the lowest building-level capital costs, and low stranded assets. After policy is in place, it could start right away.

The Efficiency First Strategy The premise of this solution is that we continue to use natural gas, but meet our targets by reducing emissions through energy efficiency measures. When we have gone as low as we can, we fuel switch at a lower level, thus reducing stranded assets in the energy system.

This strategy reduces gas use with more efficient mechanical equipment, by using controls to reduce unneeded heating, and by reducing the amount of heat lost through building envelopes. But how much efficiency is enough before you fuel switch? The City of Toronto has just released a study looking at this question. By their calculations, a 60% reduction is possible through deep energy retrofits, with energy efficiency similar to a net zero energy renovation.

Again, if this solution was proposed, we could allot two years for consensus, policy and regulations, and start renovations for gas customers immediately. In order to achieve a 60% reduction in emissions by 2032, we would need to renovate ALL gas customers in 8.5 years, or 706,000 buildings per year in Canada. Once that is done, we could change out their mechanical equipment to allow for fuel switching.

A 60% reduction in gas use cannot be achieved only with new windows and caulking. It would require significant envelope improvements. A City of Toronto report estimates the total value of renovating the building stock in Toronto to be $4.4 billion above what is currently spent on renovations. At a pace of completing all buildings in 8.5 years, this would amount to $517 million per year—for Toronto alone.

After the 60% reduction in gas use was complete, we would swap out the mechanical equipment in all of the buildings for fuel switching, at the more moderate pace of 562,000 per year.

Conclusion “The scale of the challenge is huge, but that does not make achieving the goal impossible,” writes U.S. political scientist Roger Pielke Jr. “What makes achieving the goal impossible is a failure to accurately understand the scale of the challenge and the absence of policy proposals that match that scale.”

Architects and engineers do not make the final decisions about how to spend a building owner’s money—let alone drive larger policy changes—but it is our job to offer informed choices and insights to our clients. At minimum, we should stop calculating the net present value of energy savings measures based on today’s cost of natural gas. Instead, we should offer a sensitivity analysis including the potential years of available natural gas. We should offer envelope retrofits as a more expensive, but less risky option as they will serve all the future pathways.

While compromise is beneficial in human relationships, we cannot negotiate with physics. We need to comply with the UN targets, or we will fail, with catastrophic results for humanity. We should be looking for stronger government policy that includes a carbon tax of $340 per tonne or more, a commitment to develop agreements for one or more clean fuels in no more than two years, a commitment to set performance-based building renovation targets at the net-zero or Passive House level, and a commitment to streamline compliance using existing professional licensing systems and to provide the right data to support lowenergy design.

Our conclusion? In the coming years, natural gas will cease to be used in buildings. When it comes to alternatives, there is no clear winner. Still, we have a clearer idea of the magnitude of the costs, which could be reduced with building energy efficiency measures. Whatever energy systems Canada ends up choosing, the only thing we know for sure is that to address the global climate challenge, change will need to come soon.

Sheena Sharp, FRAIC is founder and principal of Coolearth Architecture. She is a former president of the Ontario Association of Architects (OAA), and a past chair of the OAA’s Sustainable Built Environments Committee (SBEC).

The Toronto 2030 District research team for the fuel-switching study includes Co-Chair Sheena Sharp, Coolearth Architecture; Bruno Arcand, Carleton University; Peter Halsall, Purpose Building; Anton Kogan, SvN Architects & Planners; James Meadowcroft, Carleton University; Birgit Siber, retired principal, DSAI; Cara Sloat, Hammerschlag & Joffe; Geneva Starr, Purpose Building; Victor Tulceanu, BDP Quadrangle; and Svetan Veliov, Arup.

What is Renewable Natural Gas (RNG)?

Carbon dioxide and methane are collected Carbon dioxide and methane are collected Carbon dioxide and methane are collected

Waste Waste Waste Purified methane (RNG) is added to our existing system Purified methane (RNG) is added to our existing system Purified methane (RNG) is added to our existing system

Purification Purification Purification Delivered to customers Delivered to customers Delivered to customers

What makes RNG carbon neutral?

Where does RNG come from?

As waste decomposes, it releases gases into the atmosphere. As waste decomposes, it releases gases into the atmosphere. As waste decomposes, it releases gases into the atmosphere. To produce RNG, those same gases are captured (preventing them from entering the atmosphere), then purified and used in our system the same way as conventional natural gas without adding more greenhouse gases into the atmosphere. To produce RNG, those same gases are captured (preventing them from entering the atmosphere), then purified and used in our system the same way as conventional natural gas without adding more greenhouse gases into the atmosphere. To produce RNG, those same gases are captured (preventing them from entering the atmosphere), then purified and used in our system the same way as conventional natural gas without adding more greenhouse gases into the atmosphere.

Farms Farms Farms Landfills Landfills Landfills Waste water Waste water Waste water Wood waste Wood waste Wood waste Municipal organics Municipal organics Municipal organics

As our RNG supply grows, less conventional gas is used. In 2020, we added a third more RNG compared to the previous year, and we have plans to continue growing that supply. That’s energy at work. Learn how RNG can help buildings meet strict emissions guidelines at fortisbc.com/rngbuild.

Connect with us @fortisbc

THE SEVEN GRANDFATHER TEACHINGS

TEXT Vivian Manasc

IN HER BOOK OLD STORIES, NEW WAYS, ARCHITECT VIVIAN MANASC EXPLORES HOW THE SEVEN CREE GRANDFATHER TEACHINGS CAN INFORM AN ARCHITECTURAL PROCESS FOCUSED ON INCLUSION AND RESPECT—CREATING BETTER OUTCOMES FOR BOTH INDIGENOUS AND NON-INDIGENOUS COMMUNITIES.

The Seven Grandfather Teachings were first shared with Manasc by the late Elder Peter O’Chiese. Manasc was introduced to Elder O’Chiese by Diana Steinhauer, one of the building committee members for the Saddle Lake Junior Senior High School. “As I was inspired by Vivian’s vivacious capacities, so too will you be upon realizing the capacity that architecture serves in reclaiming our place and spaces,” writes Steinhauer in a foreword to the book. “This book reminds people of the stories and the processes of coming to consensus and about persevering.”

Many years ago, one of the Elders at a planning meeting asked me, “So explain to me: What is the sequence of making a building? How do you get from an idea to a building?”

I responded by drawing a typical linear timeline: We work with you to develop a concept, then we complete the schematic design, then we work with our engineering team to integrate building systems, and then we prepare construction documents, and then we get a contractor to proceed into construction.

The Elder looked at me and said, “I understand what you mean—but you have it all wrong. This process of planning and designing a building shouldn’t be illustrated in straight lines. It should be told in a circle.” He took the chalk on the blackboard and drew a circle with four parts and then with seven parts—showing that the beginning and the end of the story are connected. He offered the gift of framing the story of how we make buildings by telling the stories in a circular way. There can be four parts, or there can be seven parts, depending on how you share the teachings. Over the years, I have found that the seven Cree Grandfather Teachings have helped me to frame the story of architectural practice and the process of planning, design and construction that is at the heart of our work. These seven teachings are described in turn, and each is connected to a specific phase. This is how the circle of architecture has emerged for me.

The Seven Grandfather Teachings First, as architects, we need the Courage to explore our purpose and people’s vision. Once the vision is articulated, then we do planning, with Love for the community who will inhabit the space. Then we draw in the Wisdom of the knowledge that we have developed as designers to pull the best design strategies to the forefront. With Respect for the craft of making and building, we then develop the detailed instructions for building, and then the moment of Truth—we build and implement the vision.

Then we move in and celebrate with Humility what we have accomplished and give thanks to all those who have been part of the journey. And finally, with Honesty, we evaluate and review, and then we start all over again.

Courage Visioning together requires Courage on the part of the community. At Peguis, north of Winnipeg, at Saddle Lake and Driftpile, in Alberta, and in other communities, we set out to design new schools. Each time, we invited the community to share their vision. We asked them to imagine the

OPPOSITE The sculpture Eaglechild by Stewart Steinhauer is at the heart of Saddle Lake School, in Saddle Lake First Nation, Treaty 6 Territory. ABOVE A workshop held at Kipohtakaw (Alexander) First Nation School, at Kipohtakaw First Nation, Treaty 6 Territory.

future of learning environments. At Peguis, over two hundred people came together in a large room with magazines, markers, flip charts and scissors.

Making collages together allows community members to share their ideas, and their dreams, amongst themselves and with us, to co-create imagery that resonates for the whole community. These visions include light, warmth, bright and meaningful colours, natural materials and animal images. Years later when we go back to visit, these schools are still loved and cared for.

In the early 1990s at Saddle Lake, we learned about ways to interpret the vision. The school was eventually called Kihew Asiny, which means Eaglechild. The vision of this particular story emerged as we began to work with the community. The story of the Eaglechild is about a child who goes out for a quest to find out who he is. He ends up coming back home full circle to find out that he is who he is. We asked for the gift to interpret that story. We were taught that the story couldn’t be written or drawn literally. It had to be understood in the telling. To this day, Diana Steinhauer, who was the director of education at Saddle Lake at the time, is sharing the story of the Eaglechild and of how that story is to be understood and interpreted in the context of the community.

To understand yourself and your institutions, you have to understand your community and your relationships. By being given the gift of that story, we were able to interpret the story in the planning and design of the school, creating patterns on the floor and patterns in the building that integrated with Stewart Steinhauer’s powerful sculpture, enabling a continuous telling and retelling of that story.

Courage is needed to envision a future for the children in the school—and the creating of a school that embodies Cree teachings was the starting point at Saddle Lake.

Love Why do we create these buildings, and why do we plan them? In order to give form to the community’s vision, we interpret the connection between people, the connection between spaces, the connection between place and building, and the connection between community and building. The sense of Love is that sense of connection—of knowing how all the people in the community relate to one another and so to the building being designed.

The health authority in Edmonton decided to buy a vacant, old, red-brick schoolhouse to build a new integrated community health and primary health care centre. However, the neighbours rather liked their little brick schoolhouse and the adjacent green space, and they didn’t want any new buildings there. The health authority thought that tearing down the school could make way for a new and attractive community health centre. It seemed an impossible situation in which the health authority had made a decision, and the community seemed intractably opposed. Struggling to find a space of shared values, we drew on our tradition of inviting as many people as wanted to be there to a workshop about the future of the site.

Anxious that there would be voices and contradictory opinions that we couldn’t manage, we heaved a sigh of relief after the first design charrette. Starting with blank sheets of paper, we explored the needs and wants and fears of the neighbours. With about 125 people, we moved from anger through Love and created a shared vision that identified their fears and aspirations for this place.

A lot of people were afraid that we were going to tear down the redbrick school. So we managed to convince the health authority that it was worth considering how we could keep the brick schoolhouse. There were fears about needle exchanges and about after-hours disruption, fears of the loss of green space, and of too much surface parking, and fear by the non-Indigenous community of attracting too many Indigenous people from surrounding neighbourhoods to the new community health facility. For each of these challenges, there was an opportunity to design an integrated solution.

In the next day’s Edmonton Journal, an article reported that we were able to build the trust needed to move the project forward. And then once we had that trust, we got to work. We designed a strategy for economically integrating the red-brick schoolhouse into the health centre. Underground parking was proposed to protect trees and preserve green space. And we designed a link between the old building and the new building, complete with a circular room to serve as a gathering and prayer space for the Indigenous community. The health centre met the neighbourhood’s needs for green and heritage spaces, as well as being a very effective health clinic. Clinical spaces were placed in the new building and the office spaces and community spaces in the old building. To this day, the East Edmonton Health Centre is a well-loved and well-used member of the community.

Wisdom The Wisdom of architects and artists is often seen through their ability to draw. And with that Wisdom comes the temptation to draw before listening. It’s sometimes easier to draw, so we can see what the options might be. When that Wisdom of drawing is balanced with the Wisdom of listening to stories, we create shared images that build trust and understanding. We draw because it is a powerful way to reconcile all the contradicting requirements of a given reality. We draw together, because it is in the Wisdom of shared images that we can build an alignment around shared vision.

Drawing together can bring deep understanding. In the heart of Edmonton’s river valley is a site that many agreed concealed a historic burial ground. Located beside one of the Fort Edmonton locations, it was an area without clear boundaries, criss-crossed by roads and traffic islands. To the east, the Rossdale Power Plant loomed large, with switchyards, fences, and a gatehouse. To the south is the riverbank of the North Saskatchewan River, far below the hill. To the north, steep river roads lead to the downtown core of Edmonton, and to the west, views of the setting sun are framed by the meandering river valley.

Métis people, Europeans, Blackfoot people, Cree people and Dene people came together and appealed to the Wisdom of the City Council to honour the burial ground that was known to be at that location, just outside the walls of the historic Fort Edmonton, and build a memorial on this site.

The challenge was to create a form for this memorial. We brought together a divided group of people who each had a clear idea about the design of that burial ground. Blackfoot and Cree people felt strongly that there should be no Christian symbolism because they were reminded of the repression experienced at the hands of the churches. Descendants of fur traders and settlers argued that their Christian ancestors are buried here as well, outside of the edges of Fort Edmonton, and that a cross of some sort would be essential.

How do you have a cross and not a cross at the same time? Drawing images of crosses, broken circles and other forms, architects Shafraaz Kaba and Myron Nebozuk at Manasc Isaac arrived at a memorial that is both legible and abstract. In the landscape, we set benches in the form of the Métis symbol of infinity. The elements on the site would sit on the surface of the Earth, without foundations, as we weren’t sure where the bodies were buried. The City also rerouted the roads, creating a space where contemplation and reflection could take place.

The memorial, if you see it from certain angles, could be a cross, but if you look from another angle, it is a three-dimensional, very lighton-the-landscape sculpture. From the air, it looks like a broken circle. The Wisdom of drawing is a gift shared by many people over the years. Its Wisdom is to allow us to synthesize in a thoughtful way, the ideas, visions and plans of the community and create a single, dynamic, everchangeable image. Now designated as a burial ground, with its memorial and interpretative site, this decades-old place is still being modified, to reconcile the needs of the many stories that are told there.

Respect The fourth of the seven teachings of the Elders is about Respect. We are probably most familiar with this step as detailed design, or construction documents, or detailing. As architects, this is the phase at which we’re thinking about how things really go together, how materials go together, how sometimes abstract ideas manifest in built form and how we can illustrate those ideas and assemblies.

A reference point is the traditional teepee form. And I don’t know how many photographs I have of teepees, but from all my travels, I seem to have hundreds. I am really fascinated by how beautiful that form is against the sky, and how just so simple, functional and lovely it is. It reminds us that we do have to pay attention to the details and how it all goes together to have a coherent and refined design. Respect for the people who make things, and Respect for the knowledge that they have accumulated in that making, and Respect for the stories that are embedded in the object are also embodied in both teepees and in buildings.

Detail exists at every level, whether we’re interpreting a feather falling to the ground, or whether we’re interpreting beadwork. In the case of the O’Chiese community, the only Saulteaux community in Alberta,

ABOVE The design for the Rossdale Burial Ground Memorial in Edmonton honours the stories of different groups whose histories cross on the site.

the Elders felt very strongly that the craft and art of beadwork should be reflected in the design of the building. In that case, our team, led by Richard Isaac, incorporated colours and patterns drawn from beadwork into the design of the graphic elements inside the building.

Often the detailing is in a larger context. For example, the Centre for World Indigenous Knowledge and Research at Athabasca University was planned for the Academic and Research Centre (known as the ARC). The space had to be circular, but as we learned from Indigenous faculty, there could be nothing above that space, only the sky. So there is no second floor above that part of the building, even though the rest

of the building has three storeys. Every time we work with Indigenous leaders, whether it’s as part of the design of a larger building or as a stand-alone facility, we learn new stories, and each new story has layers and more layers of meaning.

Truth So what about building, the fifth dimension called Truth in the Elder tradition? There are endless stories about buildings. We all have them. The building is the moment of Truth for the design process. You have come to grips with the planning, the design and detailing. Does it come together? Does it make sense? Is it Truthful? It’s also the moment of Truth in that the building’s ownership grows, as there are many contractors, tradespeople and suppliers engaged in the process of making.

I want to share a story about a construction experience from a long time ago. This one is from northern Saskatchewan, in Stony Rapids, on the Athabasca River. The Athabasca Health Facility was a replacement hospital for the one that was closed in Uranium City. The new building was to serve five communities and was to be located at Stony Rapids. We flew into each of the five communities for one day. In each community, we held a large-scale design charrette, and we tried to understand how we would plan and design and build this centralized facility. This particular health facility has birthing rooms, emergency rooms, and Elder care; so it is a full-care facility, with both acute and long-term care under the same roof. At a time before email and cell phones, it was unlikely that people were in constant, instant contact with one another. Yet we heard the same thing in each community. The patient rooms should face the river. Not because you’ll be able to see the river, but rather because you would be able to hear the river. And so we designed it with all the patient rooms facing toward the river so you could hear the rapids. And in Stony Rapids, even when it’s sixty below outside, you can hear the water running—it never freezes.

So we went ahead and designed it and then began construction. Because of distance, I didn’t go out very often, and when I did go, I was largely anonymous. One day I was out on site and while I was walking around, I overheard the tradesmen during their lunch remarking, “You know, it’s really cool. You can hear the river running around here from this room. That’s amazing.” The tradesmen just got it. It wasn’t anything we told them to listen for, wasn’t anything we made them aware of; it was just there. Those are the kind of magical construction stories that let you know the planning was right, the design was right, and the detail was right. Those people, because they cared about the building, and because they understood that the river sound was important and that it was healing, did a really good job of building this building.

Another construction story is from Peguis Central School, just a couple miles north of Winnipeg. They had a masonry trades training program, and we were asked to design the building to give these masonry students work experience. At the end of the project, eight journeymen masons were ready to graduate, using the experience they gained by working on Peguis School. The purpose of the building was a lot more than just making a building; it was about making a community, about making a future for those young people.

Humility We are now at the sixth teaching—that of Humility—moving in and celebrating. When you finally finish construction and open a building, it is quite humbling. Any of you who are practitioners know that to see a building completed, to see people moving in, is surrounded by a real sense of Humility. You have been part of co-creating something that is going to be there for a very long time. It is now given over to the custody of the community. It has to be something that people not only want to celebrate, but also something that people want to take ownership of.

Amiskwaciy Academy, the Aboriginal high school in Edmonton, was originally Edmonton’s municipal air terminal building. When the Edmonton Public School Board decided to develop an Aboriginal high school, it realized that it couldn’t afford to build it from scratch. There wasn’t a school building available, so we worked with them to try to find a building in the community that was vacant, available and 80,000 square feet. There weren’t that many 80,000-square-foot buildings just sitting around vacant! But we knew about the airport terminal. It just so happened that we had done a renovation of it before it closed. It was a circular story for us as architects—to come back and re-renovate a building that we had just renovated.

We started with the key question: Why are we creating this Aboriginal school? It’s a junior–senior high school, a school where all of Edmonton’s youth have access to Cree language and culture.

It was exciting to fit it into an air terminal building because all those baggage rooms really make great shop spaces. Really robust environments make perfect schools. But turning an airport terminal into a school was a complex transformation. Again we started with imagining, dreaming and envisioning.

These Grandfather Teachings are circular. What I’ve learned is that all these stories connect, whether they are about grand openings, whether these stories are about dreaming, or about design or construction. They keep looping around, reinforcing each other. So the main entry of Amiskwaciy reflects the many different Indigenous communities that this school serves. The images are not Cree, not Dene, not Saulteaux; they are a composite set of images that reflect the visions of many of the different nations that come to this particular school.

Honesty The seventh element of the story, Honesty, which completes the circle, is the evaluation. We often speak in the world of architecture about evaluating buildings, and post-occupancy evaluations, basically reviewing how we’ve done. And it’s harder to do that than to talk about it. But we do make it our practice to come around and visit. After the Humility of opening a building, there is the Honesty of evaluating how we did. Did we really achieve what we set out to achieve? Did we miss the mark? How can we do better the next time?

An example is the Greenstone Building in Yellowknife. The Greenstone Building was the first Leadership in Energy and Environmental Design (LEED) Gold building north of sixty. We had the opportunity to integrate a lot of firsts into it. It’s a building that performs extremely well. It’s basically net-zero for water, creating enough water for its needs from rainwater. It has a green roof and a high-performance building envelope. It’s also a delightful, comfortable environment for Government of Canada employees from thirteen different departments. At the grand opening, they invited a Haida drummer. This is really unusual in a Dene community, but it spoke to the fact that Indigenous Peoples are connected across Canada and share values. This was a story the Government of Canada and the Indigenous people wanted to share.

So ultimately, what’s worth emphasizing in our shared work with Indigenous people is that it teaches us as architects about embodying the stories of our time, of our community, of the particular and of the general. The particular needs of the community are important, but so are the aspirations of the larger community. Our buildings stay around a long time, and it’s so important that the stories reflect and resonate for an equally long time.

This text is excerpted from Old Stories, New Ways: Conversations about an Architecture Inspired by Indigenous Ways of Knowing (Brush Education and Red Crow College, 2020, edited by Frits Pannekoek).

Edited by Sofie Pelsmakers and Nick Newman (RIBA Publishing, 2021) REVIEW Terri Peters

ABOVE Dorte Mandrup Arkitektur’s Ilulissat Icefjord Centre, in Greenland, is expected to be completed by the end of this year. Its steel and timber construction is based on local conditions, ensuring sustainable solutions suited to the context.

Over the last 18 months, we have all thought a lot about change: with Covid-19, wildfires and record-breaking extreme weather in many areas of the country, and global political and social upheavals. The idea of “building back better” is a positive message—and in any case, there is little chance of things going back to the status quo.

Such is the ethos of Everything Needs to Change: Architecture and the Climate Emergency, the first in the Design Studio book series from the Royal Institute of British Architects (RIBA). The well-illustrated book has an unmissable brightly coloured front cover, and is edited by Sofie Pelsmakers, professor and author of The Environmental Design Pocketbook, and Nick Newman, climate activist and director of Studio Bark.

The book features essays, interviews and case studies of new global approaches to sustainable buildings. For example, there is a profile of the UK office Mikhail Riches, an award-winning environmental architecture firm that focuses on designing projects that achieve zero-carbon targets while promoting zero-carbon lifestyles. Projects exploring ideas of resilience include the work of Indian office Samira Rathod Design Atelier, whose inspiring spaces beautifully combine passive strategies, simple forms, and local materials such as terracotta brick. Danish office Lendager Group explores building-scale reuse strategies, including in the innovative Resource Rows: a series of three-storey apartment blocks that use upcycled bricks from a nearby brewery as well as waste wood from the nearby metro construction.

The book’s overarching message is that the buildings of the future are being built right now. There is no point in architects waiting to get the perfect project, or holding out for some new technology, or for some ideal next project. We need to treat this as an emergency. We are seeing “future” climate scenarios happening all around us and need to design accordingly. In the introduction text, Pelsmakers and Newman state the obvious: we have likely about 10 years to transition into a climate-neutral society. So, yes, basically everything needs to change.

While the book focuses on professional practice, there is also the question of how well architectural education is preparing students in terms of climate change and sustainable buildings. This theme was also the focus of the recent ACSA Teachers Conference, entitled “Curriculum for Climate Agency: Design (in)Action.” The book discusses the volunteer-run network Architects Climate Action Network (ACAN), which calls for increased universal integration of environmental design, radical activism, and increased collaboration. It argues that schools must equip students with the tools to reduce carbon emissions linked with the built environment to zero by 2050. One article includes graphics of results from a number of studies: instructors scoring student understanding of sustainable design, analysis of modules offered in the current curriculum relevant to the climate emergency, and student scores of their own understanding of key terms.

The book raises some relevant questions for Canadian educators, some controversial. Should architecture students learn and be assessed on their ability to design carbon-neutral buildings? Or do educators have enough to do in just teaching the required topics to continue to meet accreditation requirements? The Architects Registration Board (ARB) in the UK recently announced that schools of architecture must start teaching sustainability and fire- and life-safety design from this fall onwards. While changing the conversation in schools and in practice is not this simple, this is a step in the right direction. It’s a solid example of the change we need to see.

Terri Peters is an Assistant Professor at Ryerson University in Toronto. Her research project launching this fall includes collecting national data about how Canadian architecture students feel about the climate change and sustainability aspects of their design educations.

Canadian Architecture: Evolving a Cultural Identity

By Leslie Jen (Figure 1 Press, 2021).

What is Canadian architecture? For author Leslie Jen, a former associate editor at Canadian Architect, there is no single satisfactory response—but exhibiting sensitivity to local contexts, creating socially minded places, responding to urban intensification, designing for health and aging, and meeting ecological challenges all play a role. This book profiles 68 recent projects that address these themes, testifying to the country’s thriving design culture.

The 33 architects represented here are a who’s who of contemporary Canadian architecture: from bigger players like KPMB Architects, Diamond Schmitt Architects, and Lemay to smaller firms such as Akb Architects, Ian MacDonald, and BattersbyHowat. The range of projects is equally wide: spanning from national landmarks like Moriyama & Teshima’s Canadian War Museum in Ottawa (completed in joint venture with GRC Architects), to small but impactful works of placemaking, such as Brook McIlroy’s trio of Indigenous Cultural Markers at indoor and outdoor locations across Humber College’s two campuses.

Each firm and project is introduced with a cogent analytical text by Jen. The book also includes superb photographs by Doublespace, Ema Peter, James Brittain, Tom Arban and Adrian Williams, among others. Key drawings make this a useful reference for both designers and students. be a social activist, a realist, a poet, a political technician, and a utopian.”

“In this theoretical development model for Venice, the city’s historical saturation of tourists is leveraged as an economic opportunity to house refugees in need,” writes principal Gregory Henriquez. “Our project’s intention is to encourage a meaningful dialogue about the relationship between citizens and cities in a global context. What does it mean to be a ‘citizen’? What is a city’s inherent accountability to an individual’s humanity? What is the role of the architect in building an inclusive city?”

GHETTO

By Henriquez Partners Architects and Wei Li (Blue Imprint, 2021).

Henriquez Partners Architects was one of several architects invited to exhibit their work in Time Space Existence, an offsite exhibition organized by the European Cultural Centre for the Venice Biennale. Instead of showing built work, they took the opportunity to propose a speculative project—a series of Habitat-like developments that would be positioned in various places in Venice, split between time-share vacation units and refugee housing.

This graphic novel presents the proposal in a compelling set of parallel narratives. “For Sale” follows a vacationing family, at first skeptical and uncomfortable staying alongside refugees at GHETTO. Gradually, they connect to their new neighbours—and even become inspired by their experiences and courage. “Sanctuary” tells the story of a refugee family arriving to GHETTO for the first time, after a harrowing sea journey. The development’s social supports—and even the sometimes awkward presence of tourists—helps them to adapt to their new lives and contend with the trauma of their displacement.

A third section of the book uses the graphics of sales brochures to present the development, complete with floor plans and a financial pro forma, inviting readers to suspend their disbelief in the radical proposal. The authors take Alberto Pérez-Gómez’s challenge to heart, which they quote in the book: “To take a leading role in contemporary issues, the architect of the 21st century must A Natural Balance: The K.C. Irving Environmental Science Centre and Harriet Irving Botanical Gardens at Acadia University

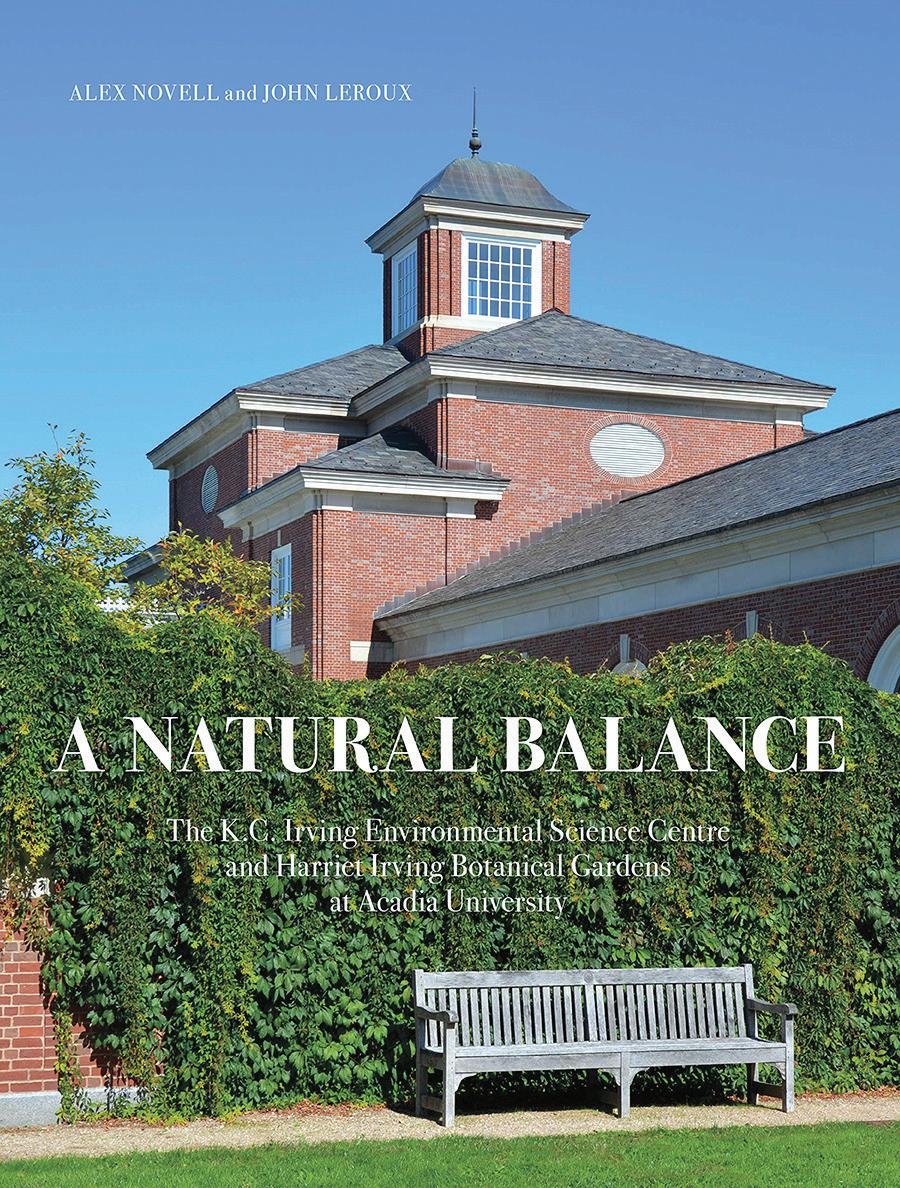

By Alex Novell and John Leroux (Acadia University, 2021).

This handsome volume documents a wellloved part of Acadia University—the publicly accessible Irving Centre and Gardens, which is celebrating its 20th anniversary in 2022. Architectural historian John Leroux’s essay on the building chronicles its design, led by American architect Robert Stern, who chose a classical style that wed the Centre to the earliest buildings on the nearly 200-year-old campus. Critic Vincent Scully deemed the resulting building to be “one of Stern’s most memorable interventions in a campus,” and Leroux believes that, following a lacklustre period for Atlantic campus architecture in the 1970s to 1990s, it was the first in a wave of excellent new institutional buildings in the Maritimes.

AURORA ARMOURY

TEXT Elsa Lam

GOW HASTINGS ARCHITECTS TRANSFORMS A CLOSED-DOORS MILITARY SHED INTO AN OPEN-ARMED VENUE FOR COMMUNITY, FOOD, AND CELEBRATION.

ABOVE A 147-year-old wooden ceiling crowns a new culinary-focused, park-adjacent community hub, created within Aurora’s former armoury building.

“Every small town has a military shed,” says architect Jim Burkitt. He’s met me at the Aurora Armoury, just north of Toronto—a recent transformation of one of those sheds, led by Gow Hastings Architects, where Burkitt is Design Director.

The Town of Aurora’s armoury building dates back to 1874, when a wood structure was constructed to support the local military unit, the Queen’s York Rangers. Infantry used the building for meetings and drills; the adjacent Town Park doubled as their parade ground. In the early 1900s, a thick concrete floor was added, allowing military equipment to be brought into the building for training cadets.

Now, the building has been converted from the country’s oldest active drill shed to the town’s newest community hub. To do this, the Town formed an unusual partnership with Niagara College’s Canadian Food and Wine Institute, which operates the building as a teaching space for aspiring chefs and community members, a catering service for park users, and a venue for weddings and other special events.

For the central event area—which hosts up to 200 guests—the architects exposed the building’s original post and beam structure. This majestic space emerged part by design, part by luck: the architects didn’t know what they would find when they removed the drywall ceiling, which had hung under the beams. “We were hoping that the existing structure was glamorous,” recalls Burkitt. When they discovered that the original wood structure was in good condition, they made the most of it. Subtle uplighting draws attention to the wood rafters, emphasizing the building’s barn-like volume. They refurbished the concrete floor, and adorned the walls with supergraphic images drawn from the Town archives, chosen to commemorate the building’s history.

Facing the park, three automatic bifold doors create a 14.6-metre-wide connection between the event area and an outdoor patio. The doors fold up into an awning—a signal to park users that the Armoury is open for business. The building also received a highly insulated wall envelope, Accoya wood cladding with vertical battens, and a zinc roof.

An addition to the south side of the building, facing the park, houses the most technical part of the program: the event kitchen, which Burkitt describes as “the high-powered engine inside the building.” The generously sized space can host workshops and chef’s table events for anywhere from two to 24 people. (For teaching to larger groups, there’s a demonstration kitchen in the main event space; both areas have built-in equipment for simulcasting the chef’s actions to overhead screens.) The architects purposefully decided to put the main kitchen on prominent display, facing the park and surrounded by glazed walls.

The most important part of the project is perhaps the symbolic transformation it enacted. In the First World War and Second World War, the Armoury was a muster point for troops—a place that mingled anticipation, bravery, and tragedy. For decades after, the Armoury’s doors seemed constantly closed. It was the building that everyone knew—yet nobody knew what it looked like inside. That fraught history remains part of the building, but now, the Armoury serves to nurture and connect residents. It’s a place for learning, for sharing food, and above all, for celebrating community.