INSIDE THIS ISSUE

WIN A FREE ONLINE COURSE LAW CHANGED TO PROTECT SUBCONTRACTORS

ENVIRONMENTALLY FRIENDLY FREEZE DRYER

HVAC&R HUB SPEAKER LINEUP ENERGY SAVING SERIES

INSIDE THIS ISSUE

WIN A FREE ONLINE COURSE LAW CHANGED TO PROTECT SUBCONTRACTORS

ENVIRONMENTALLY FRIENDLY FREEZE DRYER

HVAC&R HUB SPEAKER LINEUP ENERGY SAVING SERIES

iJW is the new range of CAREL controllers for refrigeration, aimed at refrigeration engineers operating in the distribution channel.

iJW has been designed to simplify the replacement and configuration of the controller on display cabinets, bottle coolers, plug-ins, chest freezers and in many other applications.

For accessing the complete set of advanced parameters and functions, download free Carel Applica App from App store or Google play which can connect with the iJW controller over Bluetooth.

●Wide operating voltage range tolerance from 90 to 264Vac

●Compressor safety protection against high or low power supply voltages

●Zero voltage relay switching

●In-built BMS serial card for Modbus RS485 connectivity

●Dedicated parameters for relative and absolute alarms

●Simple IO configuration via preset wizard codes for each series

PUBLISHER

IRHACE/CCCANZ/RLNZ

IRHACE: www.irhace.org.nz

CCCANZ: www.cccanz.org.nz

RLNZ: www.rlnz.org.nz

EDITOR

HVAC&R Centre admin@irhace.org.nz

MEMBERSHIP admin@irhace.org.nz admin@cccanz.org.nz

REFRIGERANT LICENSING & COURSES admin@rlnz.org.nz

ADVERTISING admin@irhace.org.nz

DESIGN

Bellacreative Ltd

HVAC&R CENTRE

PO Box 217184

Botany Junction 2164

Auckland, New Zealand

e: admin@irhace.org.nz

e: admin@cccanz.org.nz

e: admin@rlnz.org.nz

No part of this journal may be printed in other publications without prior written permission of the Managing Editor.

Disclaimer: Statements expressed in this publication do not necessarily reflect the policies or views of the associations, and members of IRHACE or CCCANZ. The IRHACE Journal publishes both local and international articles. Standards and or practices may differ from current New Zealand standards and or practices used. No responsibility is accepted by the associations and editor for the accuracy of information or for errors or omissions. The IRHACE Journal is distributed to all the IRHACE and CCCANZ financial members.

ISSN 01148257

Changes have been made to legislation to give subcontractors the confidence they will be paid the retention money they are owed should the head contractor’s business fail. The changes made provide important protections for subcontractors so they can be certain their payment is kept safe, can’t be used for any other purpose, and will be paid out should the head contractor’s business fail.

The HVAC&R Hub is coming up fast on 20-21 June 2023 at the Auckland Showgrounds and is New Zealand’s largest trade-only exhibition for people who design, construct and manage the country’s buildings and facilities. It is not too late to exhibit and the event is complimentary to attend, register online now!

RLNZ is offering to be into Win a Free A3 Refrigerant Awareness Course. Register at admin@rlnz.org.nz and entries close 31st May.

We are sad to advise the passing of two of our valued and long serving IRHACE members being Noel Holyoake and Robert McKibbin.

In this month’s issue of IRHACE Industry Journal.

• HVAC&R Hub focus on speakers

• Cuddon’s new environmentally friendly freeze dryer

• Energy Saving Series

• Privacy rights in the digital age

• Wallie Askew Entries are open

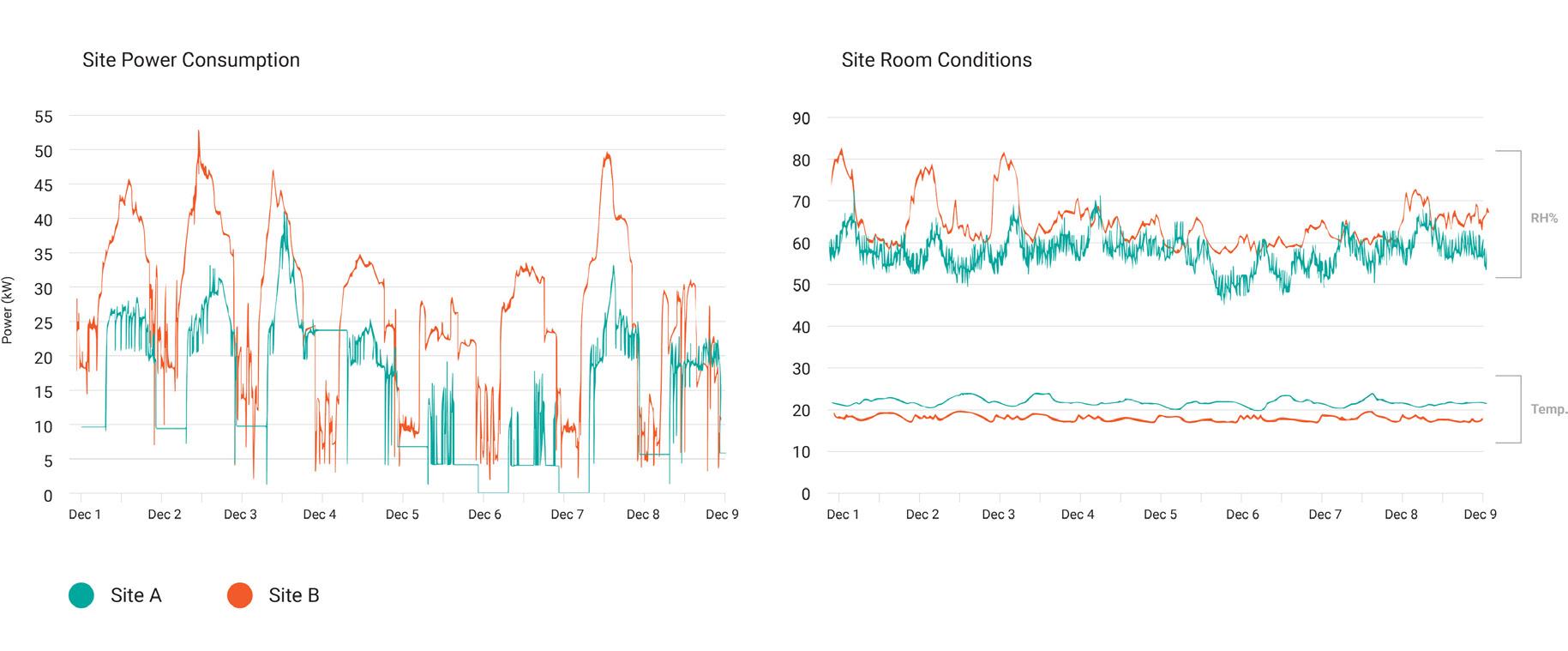

effect on room conditions?

A key challenge facing the built environment today is rising operational costs, an issue becoming more prevalent with the emerging energy crisis. The drive to optimise buildings has never been more important, finding efficiency gains through simple observations and learning from poor practice not only reduces cost but also positively impacts carbon emissions.

The findings observed from the two Australian sites presented in this study illustrate that where you set your temperature and humidity setpoints will make a considerable impact on energy consumption, and when set incorrectly can also adversely affect the comfort conditions when applied in a retail supermarket.

• Retail and Humidity control

• Data extracted from 1 Dec 2021 to 8 Dec 2021

• Package units on both sites are OPA 1400 ECO Ultra with reheat coils

• Site A serves a supermarket with a cooling temperature setpoint of 23.5°C & 55% RH setpoint

• Site B located 20 km away is also a supermarket with setpoints of 19°C & 55% RH

• Both systems are identical in capacity and both approximately equivalent in floor space

• Site B room temperature setpoint is 4.5°C lower than Site A

• Site B struggles to maintain RH% setpoint

• Site B is consuming 55% more energy than Site A

• Moisture removal rate based on air movement of 7,000 l/sec

• Site A @ 23.5°C & 55% RH = 15 g/sec or 54 l/hr

• Site B @ 19°C & 55% RH = 10.7 g/sec or 38.7 l/hr

When deciding on the most suitable room setpoints it is important to understand that the Humidity Intelligence series use the setpoint values as the fundamental part of the control strategy. The controller’s logic converts the setpoint values of temperature and humidity into the dew point value based on air properties, the program then offsets this value based on the current comfort mode which is determined by the room conditions, for example, if the room temperature is above setpoint while the room humidity is below setpoint the unit would then be running in ‘High sensible cooling’ which would conservatively offset the dewpoint value. The resulting value then defines the compressor’s target suction pressure since refrigerant properties share a direct relationship with temperature. The lower the suction pressure setpoint the more the compressor will work in order to achieve the target setpoint. This may mean the compressor runs at higher RPMs for longer durations or runs at lower RPMs for shorter durations, which all depends on the load within the space.

The intent behind this logic is to precisely match the refrigeration load based off the room setpoints, and condition the air to the minimum requirements through the day and across the seasons.

By understanding this basic design intent it will be understood that if the setpoints are aggressively set then the unit’s operation will operate more frequently and harder, this will then consequently affect power consumption with little part load gains.

Site B is not performing to set point, in fact, the unit is drawing 55% more power than Site A while not maintaining RH% setpoint. It is also observed that the comfort conditions are poor considering the store temperatures move between 17°C and 19°C during store opening hour periods.

Analysing the moisture removal rate of the equipment based on airflow, it is clear that maintaining lower temperature conditions adversely impacts power consumption and fails to achieve the desired humidity conditions.

The observations should then lead to the following question, why does site B require a lower temperature setpoint? The obvious answer to the question should be simple, there is no reason why the setpoint is low. it is a common perception that setting a lower setpoint will remove more moisture out of the air; this is not the case here.

Reheat coils are fitted to both sites and are operating throughout this period. It is observed that the reheat coils are increasing return air temperatures to maintain a higher supply temperature. This operation prevents overcooling the room which would result in regular off-cycles which would lead to poor control of humidity.

If Site B was to adopt the same temperature and humidity setpoints as Site A, they would potentially reduce daily operational energy costs by 55% from $63.00 to $28.50*, this is due to the benefits of part load operation, particularly of the inverter compressors where we see an average speed drop from 60% down to 39%. All this while maintaining a RH% closer to setpoint.

Given the considerable difference in energy consumption between the two sites over this period, compared to Site A, we see that Site B accounts for 860 kilograms more CO2 emissions each day from power generation.

Talk to us about selecting the right product for the right application. Our team of passionate and enthusiastic individuals offer advice and support on all our product lines and can recommend the best control strategy or system setup tailored to any application. You may also choose to have an expert attend site to start up the equipment, and also train your staff to ensure effective project delivery.

* Tariff @ 10 cents per kWh. ^ Attributed to energy production - Carbon Positive Australia Emissions Calculator

Changes have been made to legislation to give subcontractors the confidence they will be paid the retention money they are owed should the head contractor’s business fail, Minister for Building and Construction Megan Woods announced today.

“These changes passed in the Construction Contracts (Retention Money) Amendment Act safeguard subcontractors who are often the first to miss out in the event a construction company becomes insolvent,” Megan Woods says.

“While it is not a requirement to hold retention money, many head contractors choose to withhold part of their payment to specialist tradespeople for up to 12 months. This is one way to help ensure building work is done right first time, and acts as an insurance that the subcontractor will return if there are any defects.

“The changes made today provide important protections for subcontractors so they can be certain their payment is kept safe, can’t be used for any other purpose, and will be paid out should the head contractor’s business fail.”

Companies and directors who choose to hold retention money against subcontractors will now be required to hold retention money on trust in a separate bank account, which is unable to be mixed with other company money or assets. Information about the retention money held must be repor ted to subcontractors on a regular basis, at least once every 3 months.

Read here for full media release

CCCANZ wishes to acknowledge the huge amount of work of Grant Price and the Specialist Trade Contractors Federation.

The Office of the Privacy Commissioner marks Privacy Week each year to promote privacy awareness, inform people of their rights under the Privacy Act, and help educate agencies about their responsibilities. This year’s theme is “Privacy rights in the digital age”. Join us this year for a series of free webinars covering topics related to digital privacy like online dating, biometrics, AI and more. We’re working on beginner, intermediate, and advanced content so there’s a range of options.

Join Michael Webster, Privacy Commissioner as he launches Privacy Week 2023 by outlining his ideas and thoughts about privacy in New Zealand.

Kick of Privacy Week by hearing about the growing privacy concerns AI, and in particular generative AI.

The advancement of technology and the rise of social media have placed the spotlight on child privacy rights now more than ever before.

This webinar will cover Privacy Officer’s key focus areas, how they intersect with those of security professionals, and how security and privacy teams can work together to achieve the best shared outcomes for their organisations and the customers they serve.

Ever wonder where the privacy settings are on Facebook? How often do you mindlessly agree to cookie consent pop ups without thinking? Are you bamboozled by opt in/out questions? These deceptive tricks are known as “dark patterns”: interface design techniques that aim to trick or mislead Internet users.

Are you concerned about how artificial intelligence (AI) is changing the way we approach privacy? Join us as we dive into some of the modern AI privacy issues that may not arise in other contexts.

Following years of development, Cuddon have successfully tested a new carbon dioxide (CO2) powered Freeze Dryer that is set to have a huge impact on the industry.

In a time where we challenge ourselves to reduce our footprint, work more sustainably and consider our effects on the environment, the new Cuddon Freeze Dry CO2 machine ticks a lot of boxes.

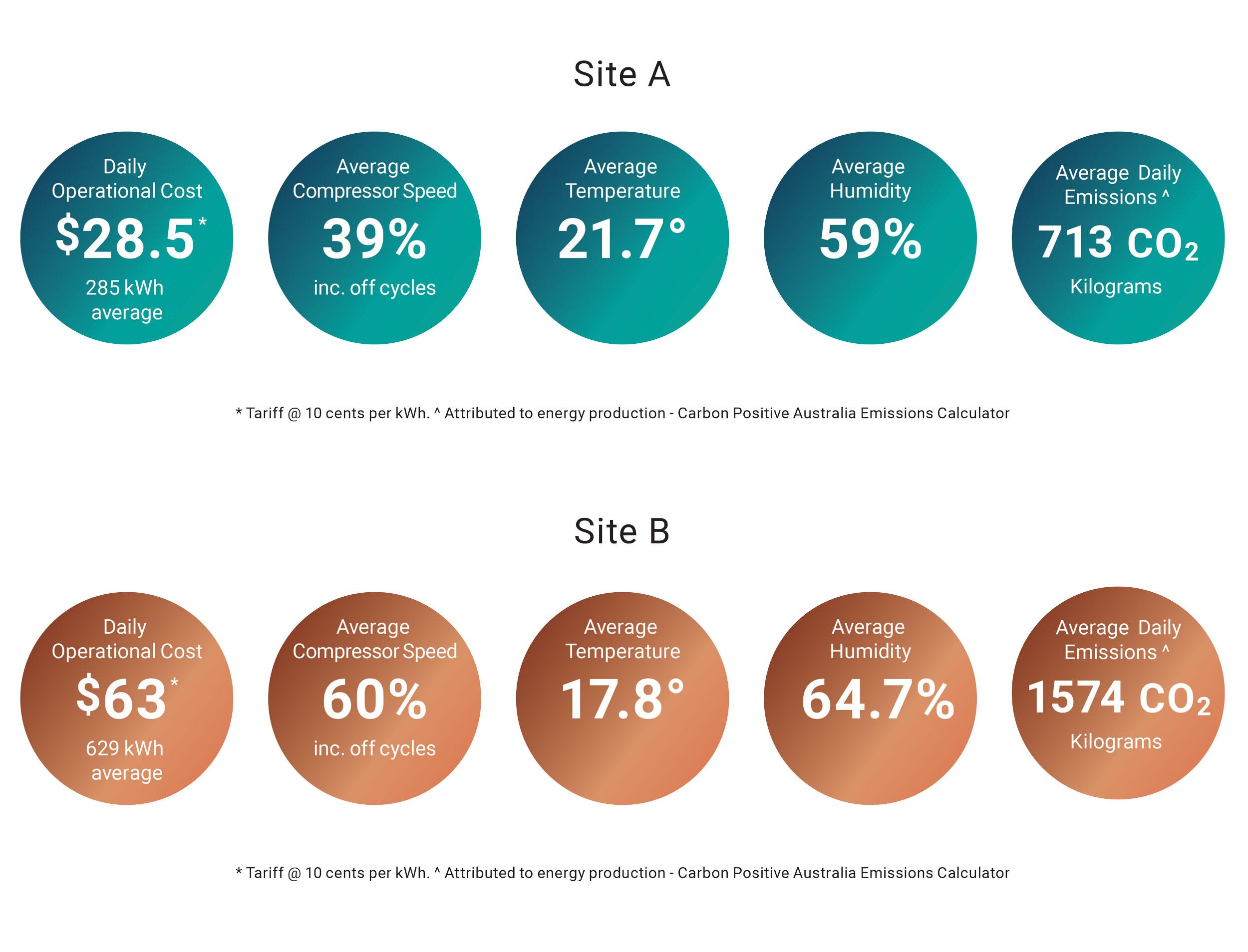

Using CO2 as the freeze dryer refrigerant to replace traditional high global warming potential refrigerants is a significant milestone, reducing the environmental impact by more than four thousand times by the use of this natural gas.

Globally the use of trans-critical CO2 as a refrigerant is becoming more common, however engineering challenges such as gas pressures of 120 bar that is 10 times higher than previous equipment required significant design work. Along with being environmentally friendly, the new Freeze Dryer design also brings other advantages such as commercially having a 30% higher product capacity, a shorter drying cycle and operational energy savings.

“We are excited to be leading the charge with the CO2 Freeze Dryer, a game changer for our customers around the world as we continue the Cuddon tradition of being at the forefront of innovation and now striving for sustainable quality engineering solutions” says Terry Duff, CEO of Cuddon Ltd.

Cuddon have been producing freeze dry systems for 60 years and have now built, shipped and installed over 450 freeze dryers globally. The team at Cuddon Freeze Dry work with businesses and organisations operating internationally in the areas of food, nutraceutical and pet food to name just a few. The development of the CO2 system comes after extensive research and development by the team at Cuddon Freeze Dry who have already received orders from overseas and within NZ.

The new CO2 Cuddon Freeze Dryer will be showcased globally this year at the European Foodex, American Pet Food Forum and the American Dairy Producers Institute.

Over the past few years the Cuddon team has grown to a staff of 95, firmly focussed on being world leaders in Freeze Drying technologies with 8 dedicated professional engineers working on overcoming engineering challenges. Recently, Cuddon delivered a Freeze Dryer to Melbourne specifically designed to restore flood damaged documents, one of a number around the world.

Now it’s in 86th year, Cuddon Engineering’s expertise continues to support a number of local industries and the Marlborough community with its fabrication, water engineering and commercial refrigeration divisions as well as their global freeze dry clients.

For further information please contact:

Terry Duff, CEO - Cuddon Ltd

Ph: +64 3 578 4299

Mobile: +64 21 323 112

terryd@cuddon.co.nz

Aquanex in-line design is revolutionising the way heat pump water heaters are applied. Through adapting an integrated whole system design ethos Temperzone solutions deliver comfort and convenience that is more cost effective, efficient and reliable.

visit www.temperzone.com

1st July - Auckland

15th July - Wellington

29th July - Christchurch

Top 2 finishers in each regional challenge battle it out in the Final Competition

Special thanks to ACSL Group, BDT, for hosting the regional challenges and to Steelfort for hosting the final competition.

SEE NEW RULES & ELIGIBILITY

Our industry came together and designed and produced a specific and unique training panel for apprentices to use in the Wallie Askew Memorial Workskills Competition.

Eurotec is proud to support the Wallie Askew Memorial Workskills Competitoin over many years, and the opportunity to create a specific and unique training panel for apprentices to fault find as part of the competition was welcomed by the Eurotec Control Panel Solutions team

Chris Farmer, Eurotec.

The idea came about during a catchup with James McLaughlan, who at the time was manager of Realcold in Petone. He had recently held a training evening in their warehouse with support from Peter Oliver, now owner of Absolute Control, on refrigeration components. He recalled having seen an electrical test panel somewhere and we discussed how it could be done and what we would ideally like on this panel.

Initially it was going to be a collaboration between Eurotec and Realcold. The people involved were Grant Holcroft, James McLaughlan, Rajesh Davuluku and Mark Patching. Eurotec supplied all the electrical components and Realcold supplied the refrigeration components and connected up the compressor, condenser and bottle cooling evaporator copper coil.

After initial meetings, the team decided to add some fault switches to train and test the apprentices’ abilities in a basic refrigeration system. During the design, additional switches were added for electrical faults along with other faults on the refrigeration cycle so that the apprentices would learn both electrical as well as refrigeration. Finger protected test points for 24Vac, 230Vac and for known resistance were added to prove that the multi meter is accurate and functioning correctly while testing. A gear plate with electrical and control gear was fitted to the back of the enclosure to make it easy for apprentices to work on it. All safety precautions were covered such as earth fault protection, finger protected test points, emergency stop and no exposed live parts.

The panel was first used in the Wallie Askew Memorial Workskills Competition Finals in Rotorua.

In 2023, the Apprentices of IRHACE have amalgamated the Eurotec Panel into the regional challenges previously it had only been used in the final competition. The Panel will move between Auckland, Wellington, Christchurch and then back to Palmerston North for the final competition. Both Eurotec and Realcold are providing staff to support the fault-finding component of the regional challenges and final competition.

Empower your staff with expert-led seminars that are completely free of charge, providing discussions on the latest industry trends and challenges. Our lineup of speakers includes:

HALL 2

21 June, 2.30 - 3.15pm

The phase-down of HFC refrigerants is resulting in increased interest in the use of low GWP refrigerants. The improper use of flammable refrigerants creates risks of fire and explosion in homes, motor vehicles, commercial buildings, and other workplaces. The intention is to highlight and discuss some current issues.

Rod DicksonHazardous Substances Technical Specialist with Worksafe

HALL 3

20 - June, 2.00 - 2:45pm

How can we collectively attract, support and retain women in our industries to address the urgent skills and labour shortage and ensure future productivity and prosperity? Aspects of this presentation will cover, Why do we need to attract women? Showcasing the amazing women in our industries and what can employers do to attract more women?

Samantha McNaughton Hanga-Aro-Rau Workforce Development Council21 June, 12:00 - 12:45pm

Join us for an informative session on the latest H1 changes, including the new acceptable solutions and verification methods. There are more climate zones, higher insulation requirements for both commercial and residential developments & crucially higher window R value requirements. We’ll be answering questions like; what are the good and the not-so-good revisions? How can we implement the changes without breaking the bank? We’ll also explore future developments in this ever-evolving field.

Peter Raimondo & James Powers Oculus Architectural Engineering LimitedFor exhibiting enquiries please contact us:

One of the roles of Refrigerant License New Zealand (RLNZ) is to ensure that there is a better understanding about Hazardous Substances and New Organisms Act 1996 (HSNO) requirements and the risks of releasing harmful refrigerants into the atmosphere.

RLNZ was part of the industry’s response to the Tamahere cool store disaster, when it was revealed that there was widespread ignorance of the regulations, and that many unqualified people were carrying out unsatisfactory work, often in direct contravention of the Compressed Gas and other regulations.

In the IRHACE Industry Journal for April, RLNZ’s article on “Why do I need a Filler’s License” has received a large number of enquiries concerning the need to have a fillers license.

On the 4 April 2016, New Zealand Parliament created the regulation “Health and Safety at Work (General Risk and Workplace Management) Regulations 2016”.

Under section 9, page 6:

Duty to provide information, supervision, training, and instruction

(1) A PCBU must ensure, so far as is reasonably practicable, that every worker who carries out work of any kind, uses plant of any kind, or deals with a substance of any kind that is capable of causing a risk in a workplace—

(a) either—

(i) has adequate knowledge and experience of similar places, and work, plant, or substances of that kind, to ensure that the worker carrying out the work, using the plant, or dealing with the substance is not likely to adversely affect the health and safety or cause harm to the worker or any other person; or

(ii) is adequately supervised by a person who has that knowledge and experience; and

(b) is adequately trained in the safe use of

(i) all plant, objects, substances, or equipment that the worker is or may be required to use or handle; and

(ii) all personal protective equipment that the worker is or may be required to wear or use.

Read here for further definitions

Health and Safety at Work (General Risk and Workplace Management) Regulations 2016 (LI 2016/13) (as at 01 December 2020) – New Zealand Legislation

New Zealand Parliament created the Health and Safety at Work (Hazardous Substances) Regulations 2017 on 26th June 2017.

As a means of a control measure that is a method of work, process, or procedure designed to minimise risk when dealing with Hazardous substances.

Under Section 15 – 15.64 – 15.66, pages 347-348.

(1) A PCBU with management or control of a workplace must ensure that no person at the workplace charges a gas container unless —

(a) the person is an approved filler; or

(b) the person —

(i) is undertaking a course of instruction or other training to become an approved filler; and

(ii) is supervised at all times by an approved filler while charging the container.

(3) A PCBU who contravenes this regulation commits an offence and is liable on conviction,

(a) for an individual, to a fine not exceeding $6,000:

(b) for any other person, to a fine not exceeding $30,000.

(1) A person must not carry out a duty of an approved filler under this subpart unless the person holds an approved filler certificate that is issued by a compliance certifier who is authorised to certify the competence of approved fillers.

(2) An individual who contravenes this regulation commits an offence and is liable on conviction to a fine not exceeding $2,000.

(3) The certificate may specify its end date (no later than 5 years after issue).

Periodic tests

Schedule 22 of the Health and Safety at Work (Hazardous Substances) Regulations 2017 states: All other cylinders including refrigeration cylinders have a maximum test period of 5 years. These intervals relate to periods beyond which a person must not charge a cylinder unless that cylinder has been inspected and tested.

(1) A PCBU with management and control of a workplace must ensure that no person charges a cylinder at the workplace unless the cylinder has passed the tests referred to in subclause (2), or the inspections and tests referred to in regulation 15.3(1)(b)

(3) A PCBU who contravenes this regulation commits an offence and is liable on conviction, (a) for an individual, to a fine not exceeding $6,000: (b) for any other person, to a fine not exceeding $30,000.

Read here for further definitions

Health and Safety at Work (Hazardous Substances) Regulations 2017 (LI 2017/131) (as at 05 January 2022) Contents – New Zealand Legislation

Worksafe receives a large amount of information about harm, or the risk of harm. This comes in a number of different ways, for example: notifications, complaints or repor ts of concern, our own intelligence, or an inspection.

This harm, or the risk of harm, can be the result of a single event, a pattern or a series of events, a precursor event or a near miss. Because of the large amount of information we receive, we are deliberate in choosing when we will, and won’t, investigate. Even if it’s a matter within our remit, we won’t necessarily investigate. We start by applying “When we intervene” and this helps us decide if the matter is something we could investigate.

Further information

More information can be found on the Worksafe website under “Guide to Gas cylinders”

Read here for further definitions

WKS-4-Hazardous-substances-guide-to-gas-cylinders.pdf (worksafe.govt.nz)

Companies in Africa have called for a halt to the introduction of flammable refrigerants and equipment until its technicians are appropriately trained.

In an open letter, U-3ARC, the refrigeration and air conditioning group representing companies in all 54 African countries, has declared that without training the introduction of flammable refrigerants and technologies in Africa is inappropriate.

“This preliminary training must be accompanied by a vast awareness campaign among end users of these technologies which can cause disasters for humans, in terms of fires, even if they are beneficial for the environment,” it says.

U-3ARC argues that the risks are “enormous” and that it has already received repor ts of accidents.

“The protection of the environment only makes sense if the human being, who is at its center benefits from it. We find it imperative that this human being is safe from explosions due to flammable gases.

“This is an opportunity for us to firmly express Africa’s refusal to serve as a “guinea pig” for a technology, so far only tested here, in the absence of training sessions, without delay and supported by these same designers and other OEMs.”

The announcement comes as the world begins phasing down HFCs under the Montreal Protocol, a move which will require the transition to flammable refrigerants. Further, the latest European F-gas revision proposals which would begin banning non-flammable HFCs in new equipment from as early as 2026, would also ban European manufacturers from exporting non-flammable HFC equipment at the same time.

Source: Cooling Post 4 April 2023, https://www.coolingpost.com/world-news/no-flammable-refrigerants-without-training/

We welcome our new members to both IRHACE and CCCANZ.

Whether you are an experienced HVAC&R professional, training in the industry or a supporter of our industry we have a membership for you. Membership is the life blood of our existence. The greater the representation of our industry we can gain, the stronger our Institutes will be.

Bruce Blackman

Seth Tutty

Theresa Wiener

Fishing from the vessel Seafarer II a 50ft ex-cray fishing boat off the Seaview Marina for a 6-hour deep sea fish was held on 14 April 2023. Targeting inshore areas for tarakihi, blue cod, kingfish, snapper and other species. Fishing around Wellington’s south coast areas or the Mana coasts depending on best weather options and we had a great day and thanks to Cook Strait Fishing Charters and to Craig Levien for organising.

Wednesday 17th May

5.30pm - 8.30pm

Finger Food & Cash Bar

The Cashmere Club, 50 Colombo St, Christchurch

DOOR PRIZES

TRADE TABLES SPEAKERS

PRESENTED BY

admin@irhace.org.nz

Opportunity to you to be involved and show your products or services by having a trade table at $300

Included are presentations from Chris Arvidson, Silver Fern Farms speaking on the applicable standards in a refrigeration system –comparing old v new engine rooms. Followed by a celebration of Life Member Brian Walker’s contributions and efforts over the last 40 years.

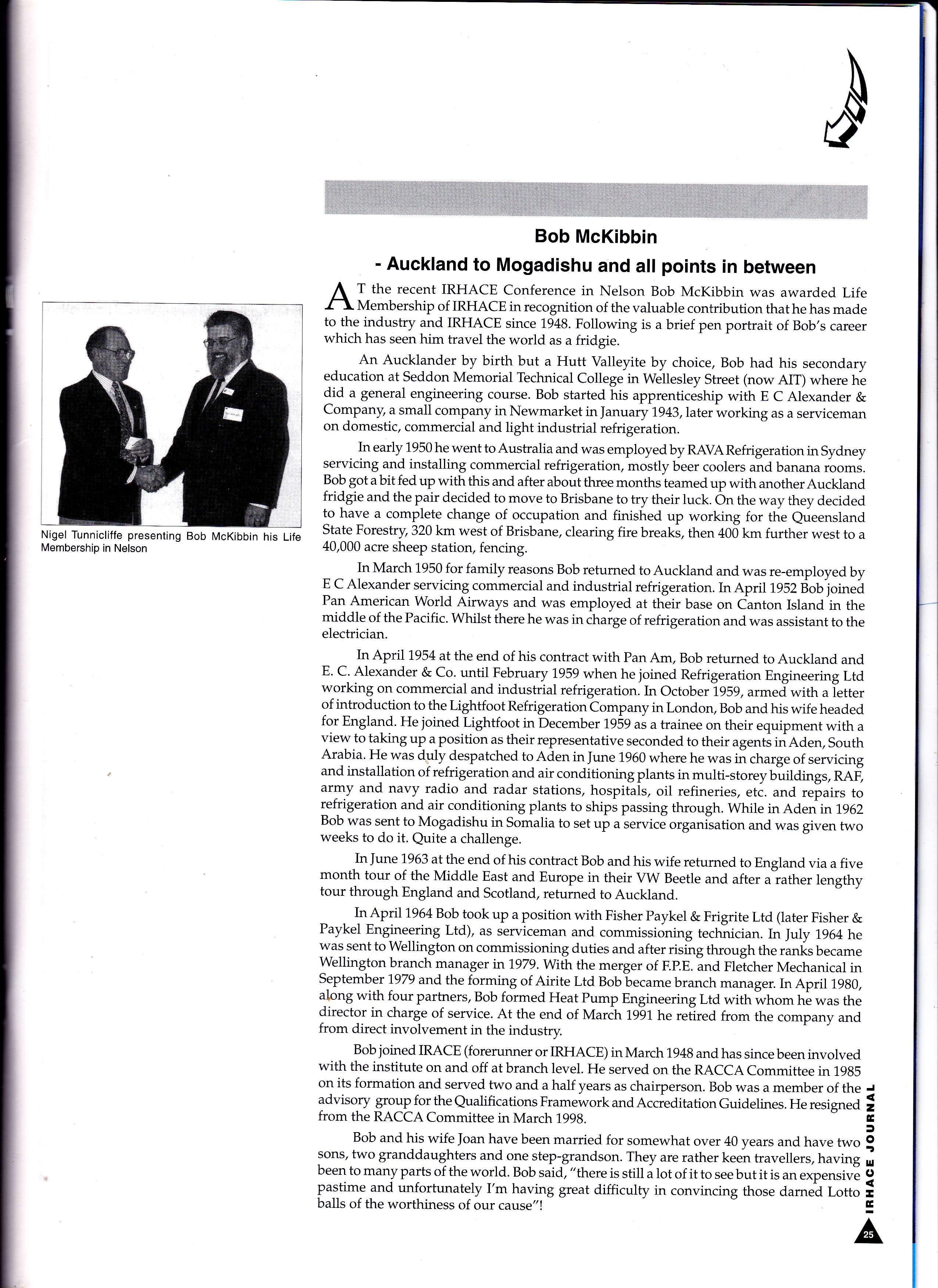

It is with great sadness that I advise that Bob McKibbin passed away on 11 April 2023, after a short illness in his sleep. Bob was a life member of IRHACE a committee member at national and Wellington branch level for many years and an avid proponent of IRHACE and the HVAC industry. Personally, I liked and respected Bob very much and he was great help to me as a mentor in my younger days.

RIP Bob my old mate.

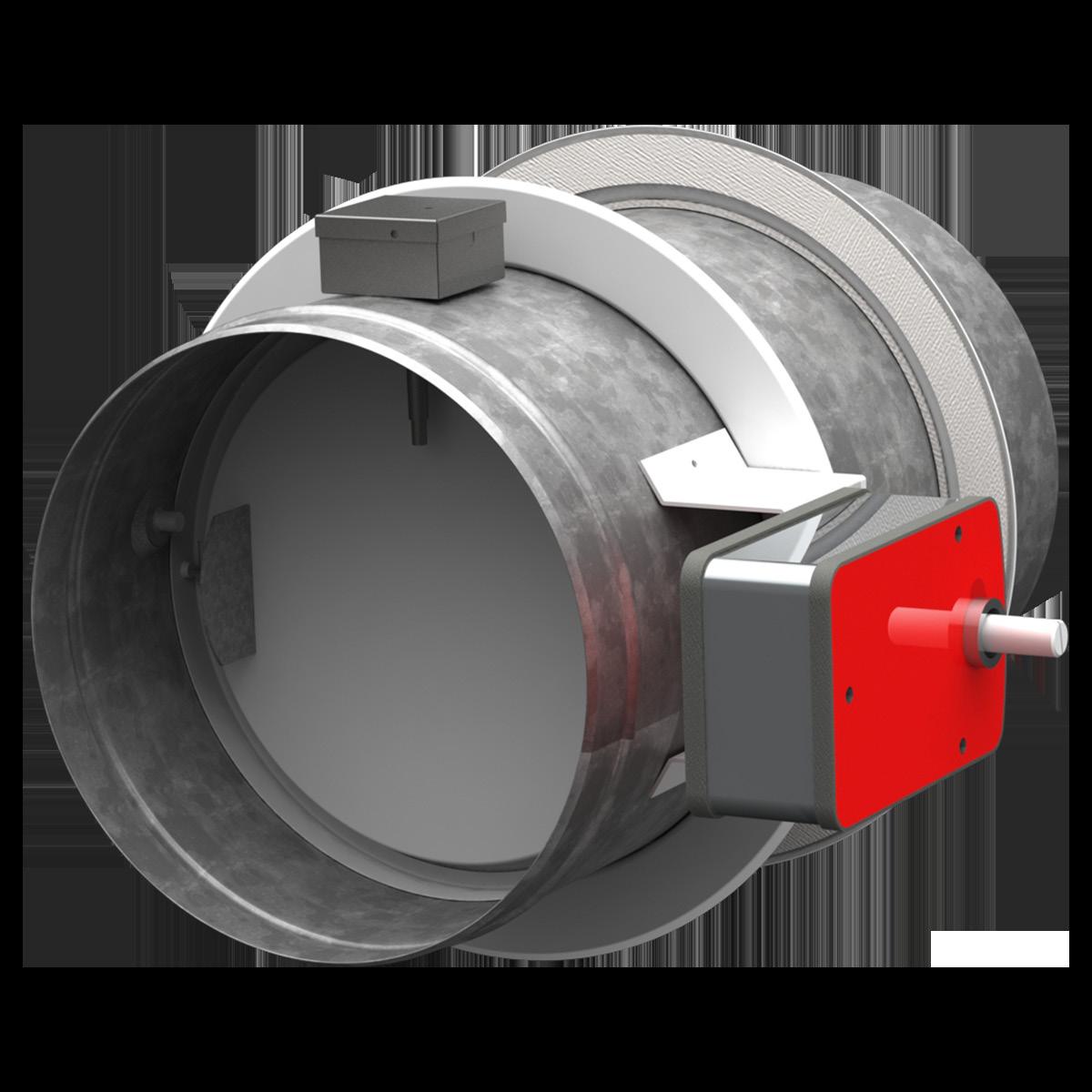

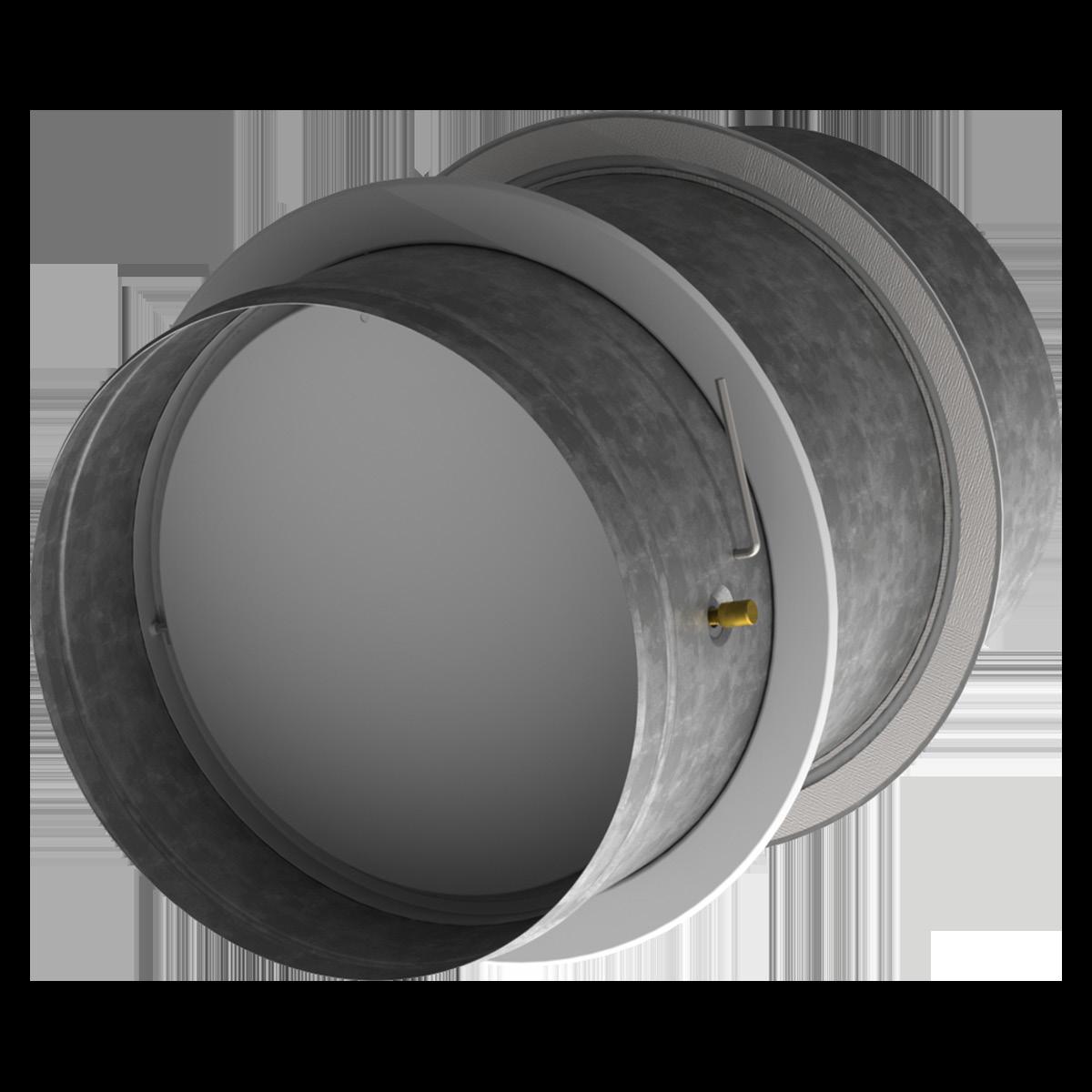

Pete Hutson, F.IRHACENoel Holyoake founded Holyoake Industries in 1953, which is the largest manufacturer of air distribution equipment in the Asia-Pacific region. Price Industries and Holyoake Air Management Solutions formed Holyoake by Price in March 2021.

A proud Rotarian, Noel established Trees for Survival Project which has planted almost two million trees since its inception.

Noel was induced into the Business Hall of Fame in 2016 in the area of Heating, Ventilation and Air Conditioning, http://www.businesshalloffame.co.nz/past-laureates/holyoake-noel/

IRHACE is proud to have had Noel Holyoake as a member since 1956 and he became a Fellow of the Institute in 2011. Noel passed away peacefully on 4th March 2023 at home and our condolences to the family and his wife Betty.

Attain your CPD points with IRHACE by attending Technical Education

RANGE FROM 1 TO 2 POINTS

• Designing with Ventilation Louvres – 1 point

• Expansion work recovery - 1 point

• Air Quality ventilation and Covid 19 - 1 point

• The application of reinforcement for vapour compression cycle control - 1 point

• Flammable refrigerants in an airconditioning application - 1 point

• Commercial Kitchen Exhaust Systems - 1 point

*To earn CPD points you must be an IRHACE member