International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 12 | Dec 2024 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 12 | Dec 2024 www.irjet.net p-ISSN: 2395-0072

Abhilash M1 , Bharath Kumar A2 , Bhuvan Gowda V3, Chiranjivi Pavan B L4, Kiran Kumar M K5

1Assistant Professor, Department of Mechanical Engineering, MIT Mysore, Karnataka, India 2 3 4 5 Student, Department of Mechanical Engineering, MIT Mysore, Karnataka, India ***

Abstract - This paper presents the development and evaluation of an eco-friendly paint formulation utilizing cow dung as a primary raw material. A novel machine was designed and fabricated to efficiently process cow dung, transforming it into a suitable pigment for paint production. The paint formulation incorporates key additives such as calciumcarbonate, titanium dioxide, xanthumgum, a binder, and sodium benzoate to enhance its properties. The performance of the developed paint was assessed in terms of its color, opacity, adhesion, and durability. The results demonstrate the feasibility of producing high-quality, ecofriendly paints from a readily available and sustainable resource like cow dung, offering a promising alternative to conventionalpetroleum-basedpaints.Thisprojectcontributes to sustainable practices in the paint industry by utilizing a waste product and reducing environmental impact.

Key Words: Eco-friendly paint, pigment development, sustainable resource

The global paint and coatings industry faces increasing pressure to minimize its environmental impact. Conventionalpaintformulationsrelyheavilyonpetroleumderived raw materials, contributing to greenhouse gas emissionsandresourcedepletion.Furthermore,thedisposal of synthetic paints poses significant environmental challenges. To address these concerns, there is a growing interest in developing eco-friendly alternatives utilizing renewableandsustainableresources.

Cowdung,anabundantagriculturalbyproduct,presentsa potential sourceofnatural pigments for paintproduction. Previousstudieshaveexploredtheuseofanimalwastein various applications, including biofuels and fertilizers. However,theutilizationofcowdungasapigmentforhighqualitypaintformulationsremainsrelativelyunexplored.

Thisstudyinvestigatesthefeasibilityofdevelopinganecofriendlypaintusingcowdungasaprimarypigmentsource. Anovelprocessingtechniquewasemployedtoextractand prepare pigments from cow dung, followed by the formulationofapaintusingthesepigmentsinconjunction withsuitableadditives.Theperformanceofthedeveloped paint was evaluated in terms of key parameters such as color,opacity,adhesion,anddurability.Thisresearchaims

to contribute to the development of sustainable and environmentallybenignpaintalternativeswhilepromoting thevalorizationofagriculturalwaste.

1. Utilization of Agricultural Waste in Eco-Friendly Products:

Saha and Gupta (2018), in their study "Sustainable ApplicationsofAgriculturalWaste," exploredthepotentialof converting agricultural by products like cow dung into valuable materials. They highlighted its adhesive and antimicrobialproperties,makingitsuitableforeco-friendly products,includingconstructionmaterialsandcoatings.

2. Development of Eco-Friendly Paints

Kumar et al. (2019), in their work "Formulations for Biodegradable Paints," discussedtheuseofnaturalbinders, pigments, and additives in the formulation of eco-friendly paints.Theirresearchestablishedthatbiodegradablepaints could achieve performance benchmarks comparable to conventionalcoatingswhilereducingtoxicemissions.

3. Properties of Cow Dung as a Raw Material

Sharma andMehta (2020), in their research "Thermal and AntimicrobialPropertiesofCowDung," examinedthechemical compositionofcowdung.Theyfoundthatitshighcellulose and antimicrobial content enhance its suitability as a raw material for various applications, including eco-friendly coatings.

Theliteraturesurveyunderscoresthepotentialofcowdung as a sustainable raw material for producing eco-friendly paintsduetoitsnaturalbinding,antimicrobial,andthermal properties.Whilepriorresearchhasexploredbiodegradable coatingsandwaste-to-resourceconversion,gapsremainin optimizingformulations,standardizingprocesses,andscaling production. Our project aims to address these gaps by developing and evaluating a high-performance cow dungbased paint, focusing on durability, antimicrobial effectiveness,andmarketfeasibility,therebycontributingto sustainablepracticesandcommercialviability.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 12 | Dec 2024 www.irjet.net p-ISSN: 2395-0072

The conventional paint industry faces significant environmental challenges due to the widespread use of syntheticmaterials,petroleum-basedchemicals,andvolatile organiccompounds(VOCs),whichcontributetoairpollution andareharmfultohumanhealth.

Despitethegrowingawarenessoftheseenvironmentaland health issues, the transition to eco- friendly alternatives remainsslow.Theavailabilityofcost-effective,sustainable paints is limited, particularly in rural and low-income regions. There is a need for innovative solutions that are bothenvironmentallysustainableandeconomicallyviable forsmall-scaleproduction.

Theobjectiveoftheprojectis,

1. Todevelopasustainableandnon-toxicpaintusing cow dung as the main raw material, focusing on creatinganenvironmentallyfriendlyalternativeto conventionalpaints.

2. To evaluate the performance and environmental impactofthecowdung-basedpaintincomparison toconventionalpaints,assessingparameterssuch asdurability,coverage,andcost-effectiveness.

The methodology for developing eco-friendly paint using cow dung as a sustainable raw material is structured to ensure an efficient, scientific, and practical approach to achievingtheprojectobjectives.

Sl. No Steps Involved

1. CollectionofCowDung

2. PreparationofCowDung

3. FormulationofPaint

4. OptimizationofPaintmixture

5. TestingandEvaluation

6. CostAnalysis

7. DocumentationandReporting

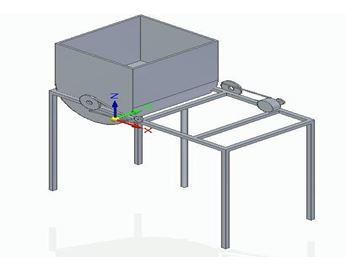

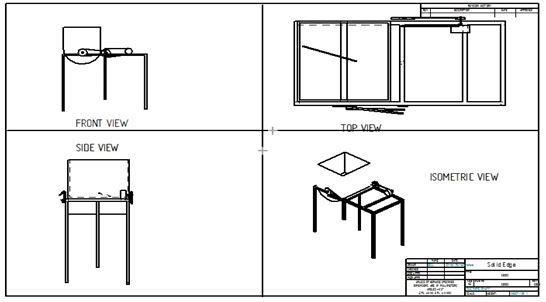

5.1 DESIGN

The3Dmodel,developedusingCATIAV5providesavirtual representationofthemachine,enablingdetailedanalysisof itscomponents,functionality,andpotentialforoptimization. This virtual prototyping approach facilitates the design process, minimizes potential errors in the physical

construction, and allows for cost-effective modifications beforephysicalfabrication.

5.2 ADDITIVES AND BINDERS

Thefollowingadditiveswereincludedaftertheextractionof cowdungpigment,

Calcium Carbonate: Acts as a filler material to improve opacity, reduce cost, and enhance the smoothnessofthepaintfilm.

Titanium Dioxide: Provides excellent whiteness and opacity, enhancing the paint's coverage and hidingpower.

Xanthum Gum: Anaturalthickenerthatimproves the viscosity and flow properties of the paint, ensuringsmoothandevenapplication.

Binder: A polymeric substance that binds the pigmentsandadditivestogether,formingacohesive anddurablepaintfilm.

Sodium Benzoate: A preservative that inhibits microbial growth, preventing the paint from spoilingduringstorage.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 12 | Dec 2024 www.irjet.net p-ISSN: 2395-0072

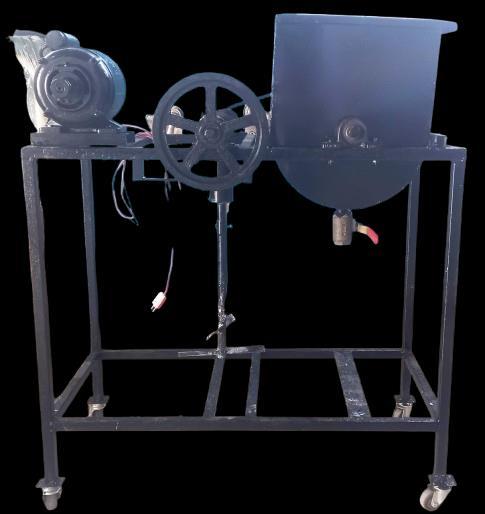

Thecowdungprocessingmachinewasfabricatedbasedon the3Dmodelusingmildsteel. Theframewasweldedusing electric ARC welding. The rotating drum was fabricated usingsheetmetalrollingandwelding.Allcomponentswere thoroughlycleanedandinspectedbeforeassembly.

The paint formulation consisted of the following components:

Cow Dung: 300g

Pigments:

o CalciumCarbonate(CaCO3):150g

o TitaniumDioxide(TiO2):50g

Binder: 100 g (e.g., natural latex or plant-based polymer)

Thickeners: XanthumGum:10g

Preservatives: SodiumBenzoate:5g

Water: 385g

6.1 Paint Preparation Process

1. Cow Dung Preparation: Fresh cow dung was collectedandmixedwithwatertoformauniform paste. This mixture was allowed to sit for 24-48 hourstofacilitatethebreakdownoforganicmatter bynaturalenzymes.

2. Filtration: The cow dung mixture was filtered throughafine-meshsieveorcheeseclothtoremove solidparticles.

3. Pigment Mixing: Calciumcarbonateandtitanium dioxideweremixedwithasmallamountofwaterto createauniformpigmentpaste.

4. Pigment Incorporation: The pigment paste was gradually added to the filtered cow dung mixture whilestirringcontinuously.

5. Additive Incorporation: Thebinder,xanthangum, and sodium benzoate were added to the mixture andstirredthoroughly.

6. Final Mixing and Filtration: The mixture was stirred for approximately 30 minutes to ensure uniform distribution of all components. Subsequently, the paint mixture was filtered throughafine-meshsieveorfilterpapertoremove anyremainingimpurities.

7. Filling: Thefilteredpaintwasfilledintocontainers, leavingadequatespaceforexpansion.

The paint formulation process was successfully implemented, resulting in the production of a visually appealingandhomogenouspaintmixture.Figure4depicts the final paint mixture after the completion of the formulationprocess.Followingformulation,thepaintwas appliedtoasheetmetalsubstrate,asshowninFigure5.This applicationstepallowedforapreliminaryassessmentofthe paint's coverage, adhesion, and overall appearance on a practicalsurface.

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 12 | Dec 2024 www.irjet.net p-ISSN: 2395-0072

7.1 Paint Characteristics

Thedevelopedcowdungpaintexhibitedseveraldesirable characteristics:

Physical Properties:

Thepaintpossessedanatural,earthycolorranging fromlightbrowntodarkgray.

It exhibited a thick, creamy texture due to the incorporationofcowdungandnaturalbinders.

Theviscosityofthepaintwasfoundtobesuitable forbrushorrollerapplication.

Chemical Properties:

ThepHofthepaintwasdeterminedtobeneutralto slightlyalkaline,rangingfrom7to9.

Thepaintexhibitedamoderatemoisturecontent.

Notably, the paint demonstrated low levels of Volatile Organic Compounds (VOCs), making it a healthier option compared to many conventional paints.

Performance Properties:

The paint exhibited good adhesion to various substrates,includingwood,drywall.

The paint exhibited moderate water resistance, making it suitable for both interior and exterior applications.

Importantly, the paint demonstrated good breathability,reducingtheriskofmoisturebuildup andpotentialmoldgrowth.

Environmental Properties:

Thedevelopedpaintisconsideredeco-friendlydue to its formulation using natural and non-toxic ingredients.

Theuseofcowdung,areadilyavailableagricultural waste product, promotes the utilization of renewableresources.

The paint is biodegradable, minimizing its environmentalimpactattheendofitslifecycle.

This project successfully demonstrated the feasibility of producingeco-friendlypaintutilizingcowdungasaprimary rawmaterial.Bydevelopinganovelprocessingmachineand formulating a paint with key additives, we successfully produced a paint with promising initial performance characteristics. This approach not only promotes the utilizationofareadilyavailableandsustainableresourcebut alsoreducesrelianceonpetroleum-basedmaterials,offering a more environmentally friendly and potentially costeffectivealternativetoconventionalpaints.Furtherresearch anddevelopmentarenecessarytooptimizetheformulation, assesslong-termperformance,andexplorethepotentialfor large-scaleproduction.

[1].Saha,A.,&Gupta,R.(2018).SustainableApplicationsof AgriculturalWaste.JournalofEnvironmentalSustainability, 12(3),45-56.

[2].Kumar,P.,Sharma,M.,&Das,S.(2019).Formulationsfor Biodegradable Paints. International Journal of Green Chemistry,15(2),112-125.

[3].Sharma, K., & Mehta, V. (2020). Thermal and Antimicrobial Properties of Cow Dung. Materials Science Advances,8(4),78-85.

[4].Patel,R.,&Reddy,S.(2021).CircularEconomyPractices in Construction Materials. Construction and Building SustainabilityJournal,23(1),89-101.