International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 12 | Dec 2024 www.irjet.net p-ISSN: 2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 12 | Dec 2024 www.irjet.net p-ISSN: 2395-0072

Penjarla Jyothi Prasanna1 , Kavali Deepthi Priya2 , Pothu Aravind3, Dr. D. Sreenivasulu4

1B-Tech 4th year, Dept. of CSE(DS), Institute of Aeronautical Engineering

2 B-Tech 4th year, Dept. of CSE(DS), Institute of Aeronautical Engineering

3 B-Tech 4th year, Dept. of CSE(DS), Institute of Aeronautical Engineering

4Associate Professor, Dept. of CSE(DS), Institute of Aeronautical Engineering, Telangana, India

Abstract - Minimizing downtime and maximizing maintenance operations in industrial machinery depend on anomaly detection. This study investigates the application of machinelearningmethodstodetectanomaliesinsensordata generated by industrial machinery connected to the Internet ofThings.Severalmodelswereutilized,suchasSupportVector Machines, Random Forests, Decision Trees, Logistic Regression, and Convolutional Neural Networks, to identify anomalous patterns that may indicate malfunctions in the equipment. This method minimizes the possibility of unplanned machine faults and improves operating efficiency by enabling proactive maintenance through the use of realtime sensor data. Increasing the reliability of industrial machinerycanbeaccomplishedinascalableandefficientway bycombining machinelearningwithInternetofThingsdata.

Key Words: Sensor data, Convolutional Neural Networks, Support Vector Machines, Logistic Regression, DecisionTrees,RandomForests,Industrialmachinery,IoT, Machine learning, Predictive maintenance, anomaly detection,andmaintenanceoptimization.

In modern industrial settings, the seamless operation of machineryisparamounttoensuringefficiency,productivity, and safety. However, the occurrence of anomalies or unexpectedfaultswithinindustrialmachinerycandisrupt operations, leading to costly downtime, maintenance expenses, and potential safety hazards. Exploiting the potentialofmachinelearning(ML)algorithmsandInternet of Things (IoT) technologies for anomaly detection is becoming more popular as a means of reducing risks and improvingtheefficiencyofindustrialmachines.

TheemergenceoftheInternetofThings(IoT)hasbrought aboutasignificanttransformationintheindustrialsectorby allowingmachinestobeequippedwithsensorsthatproduce copiousvolumesofreal-timedata.Moreopportunitiesfor increasingoperationalefficiencyhavebeencreatedbythis flood of sensor data, especially in the field of predictive maintenance.Conventionalmaintenanceapproaches,which dependonplannedorreactivemethods,frequentlyresultin unplanned equipment breakdowns or unnecessary downtime.ThroughtheutilizationofIoTdata,enterprises

maytransitiontoaproactivemaintenanceparadigmthatis data-driven,identifyinganomaliesinmachinebehaviorearly ontoavertbreakdowns.Thedifficulty,though,isinreliably identifying trends that point to possible breakdowns by processingandanalyzingthemassiveamountsofIoTdata. Techniques for machine learning have become effective toolsformanagingthiscomplexity.Bytrainingmodelsusing previoussensordata,itispossibletoautomaticallydetect anomalouspatterns,oranomalies,thatpresageequipment problems.Thisstudylooksintotheuseofdifferentmachine learningalgorithmstoidentifyabnormalitiesinindustrial machinery, including Support Vector Machines (SVM), Random Forests (RF), Logistic Regression (LR), Decision Trees(DT),andConvolutionalNeuralNetworks(CNN).By lowering the likelihood of unanticipated breakdowns and improvingpredictivemaintenancecapabilities,thesemodels optimize machine reliability while minimizing operating expenses.

Industrialmachineanomalydetection,whichusesreal-time sensordatatofindunusualpatternsthatpointtopossible machineproblems,hasemergedasacrucialcomponentof predictivemaintenance. Outliers wereformerly identified usingthreshold-basedtechniques,butasmachinelearning and the Internet of Things have advanced quickly, more complex algorithms have been devised to improve the scalabilityandaccuracyofdetectionsystems.

Keyfindings:

TraditionalMethods:Earlyapproachestoanomalydetection focused on statistical models, such as Shewhart control chartsandthreshold-basedmonitoring,todetectdeviations from predefined norms. These methods, as discussed by Montgomery(2007),werewidelyusedforqualitycontrol but were limited in detecting complex anomalies in multidimensionaldata.

MachineLearningIntegration: Theimportanceofmachine learning algorithms in anomaly identification has been

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 12 | Dec 2024 www.irjet.net p-ISSN: 2395-0072

emphasizedbymorerecentresearch,suchasthatofHodge and Austin (2004). By learning patterns from past data, supervised learning techniques like Random Forests and Support Vector Machines (SVM) can be integrated to improveanomalydetection.

Predictivemaintenancehasadvanceddramaticallywiththe useofmachinelearningtechniquesinanomalydetectionfor industrialmachinery.IoTsensordatamaybeprocessedand abnormalitiescanbefoundwithgreateffectivenessthanks to machine learning techniques, which are excellent at managingbigandcomplicateddatasets.

KeyFindings:

Supervised Learning Approaches: Supervised learning models,suchasthoseexplored byKhanand Yairi(2018), arewidelyusedforanomalydetectionwhenlabeleddatais available.ModelslikeDecisionTreesandRandomForests haveproveneffectiveinvariousindustrialapplicationsfor identifying deviations from normal operational behavior. Unsupervised and Semi-Supervised Learning: In cases where labelled data is scarce, unsupervised methods like Isolation Forest and semi-supervised techniques like Autoencodershavebeenextensivelyresearched.Chandola et al (2009)highlightedthatthesemethodsarecapableof detecting anomalies without relying on extensive labeled datasets, making them suitable for industrial applications wherelabeledanomalydataisdifficulttoobtain.

Deeplearningmodelshaveemergedaspowerfultoolsfor anomalydetectioninindustrialmachinery,especiallywhen dealingwithhigh-dimensionalandtime-seriesdata.These modelscanautomaticallylearncomplexfeaturesfromraw sensordata,enhancingthedetectionofsubtleanomalies.

KeyFindings:

Convolutional Neural Networks (CNNs): CNNs have been widely used to process sensor data, particularly in multidimensional settings. Few studies demonstrated the useofCNNsinanomalydetection,showingtheirabilityto extractfeaturesfromsensordataanddetectanomalieswith highprecision.

RecurrentNeuralNetworks(RNNs): RNNs,particularlyLong Short-TermMemory(LSTM)networks,haveshownsuccess inmodelingtime-seriesdataforanomalydetection. Hybrid Models: Recent advancements have also explored hybrid modelscombiningCNNsandLSTMstocapturebothspatial and temporal patterns in IoT sensor data. These models offer a comprehensive approach to anomaly detection by

addressing the complexities of industrial machinery operations.

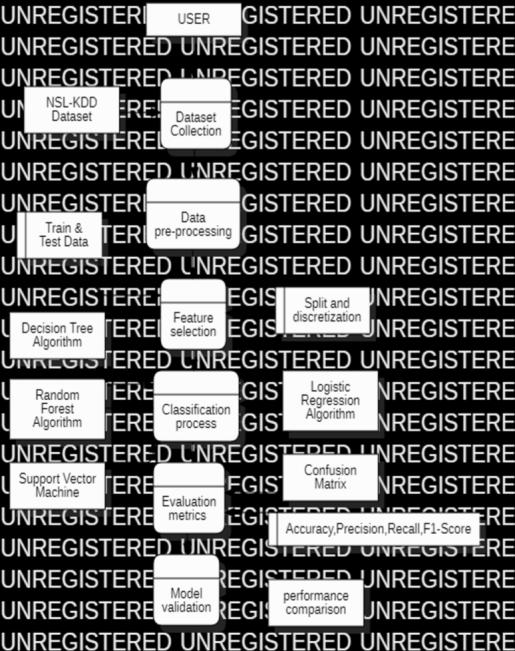

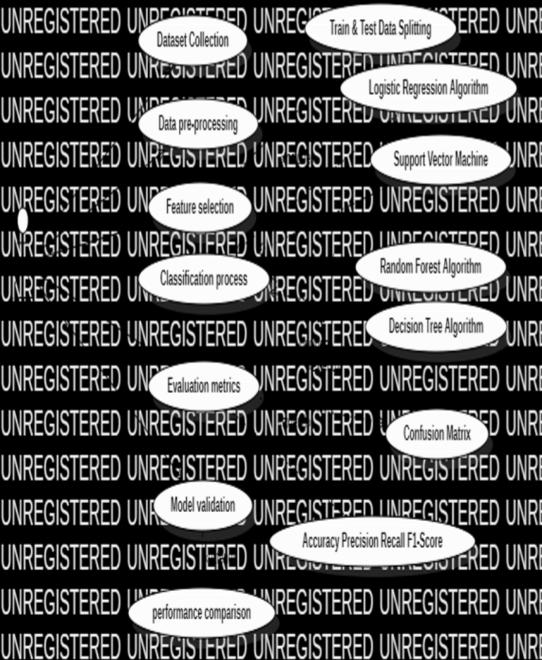

Themethodologyforthisprojectinvolvesthedevelopment of an anomaly detection system for industrial machinery usingIoTdataandmachinelearningtechniques.Thesystem is designed to process real-time sensor data, identify abnormalpatterns,andprovideearlywarningstoprevent machinefailuresandoptimizemaintenanceschedules.The methodology is structured into several key steps: data preprocessing,featureextraction,modelselection,training, evaluation,anddeployment.

Fig1:Dataflow diagram

Sensor data from Internet of Things devices that was gathered from industrial machinery makes up the dataset used for this investigation. Every record has a set of characteristicsrepresentingvariousmachinemeasurements together with a label designating whether the associated datapointisabnormalornormal.Inordertofacilitatemodel training, testing, and validation, the dataset was split into three sections: 25,192 instances for training, 11,851 instancesfortesting,andatinyvalidationsetmadeupofthe remaining data points. By using this method, we could be surethatourmodelswouldperformwellonuntesteddata

An essential first step in getting the dataset ready for machine learning models is data pre-processing. The preprocessingpipelineinvolvedseveralstepstoeliminate

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 12 | Dec 2024 www.irjet.net p-ISSN: 2395-0072

ambiguity, ensure consistency, and prepare the data for analysis.First,nominalvalueslikeprotocoltypesandflags were converted to numerical values, as machine learning models perform better with numerical input. Next, we transformed the dataset for both binary and multi-class classificationtasks.Datawasalsodiscretizedusingabinning technique,splittingnumericalattributesintodiscretebins, specificallyusing10-bindiscretization.

Feature selection was performed to enhance model performance by eliminating redundant or irrelevant features.Usingacorrelation-basedfeatureselectionmethod, we selected features that had a high correlation with the targetclasswhilebeinguncorrelatedwitheachother.This helpsreducethedimensionalityofthedataandimprovethe performanceofthemodels.WeutilizedtheCFSSubsetEval method for feature selection, which identified a set of optimalfeaturesfortheclassificationtask.

3.4

We applied five different classification algorithms for anomaly detection: Convolutional Neural Network (CNN), Support Vector Machine (SVM), Random Forest (RF), DecisionTree(DT),andLogisticRegression(LR).Thepreprocessed and feature-selected dataset was used to train eachalgorithm,andtheresultswerecomparedusingseveral evaluationcriteria.

1. Logistic Regression (LR): For binary classification issues,LRisapopularalgorithm.Whenthereislinear separabilityinthedata,itworksespeciallywell.Inthis study,weappliedLR tothe datasettoclassifynormal versus anomalous events. Multiple train-test splits (80:20, 70:30, and 60:40) were used to evaluate the model,andaccuracywasobservedtobearound98%.

2. Decision Tree (DT): Decision trees classify data by splitting it into smaller subsets based on certain conditions, eventually leading to a final decision. We trainedtheDTmodelonthedatasetwithdifferenttraintest splits and found that the model achieved high accuracy,withresultscloseto99%.

3. RandomForest(RF):Toincreaseaccuracyandprevent overfitting,RF isanensemblelearningtechniquethat constructsseveraldecisiontrees andaggregatestheir predictions.Byutilizinganensembleofdecisiontrees, RFshowedgreatpotential,withaccuracyratesreaching nearly99%forthebinaryclassificationtask.

4. SupportVectorMachine(SVM):SVMiswell-knownfor working well in binary classification applications, particularly in cases when the data has a large dimensionality.SVM'suseofkernelfunctionsallowsit to perform well even with complex data. In our

experiments, SVM achieved high accuracy and demonstrated its ability to scale efficiently, which is crucialforreal-timedetectionscenarios.

Convolutional Neural Network (CNN): CNNs have demonstrated potential in time-series and anomaly detectionapplications,althoughtheyaremostlyutilizedin image recognition tasks. For our task, we used a CNN to analyze the IoT sensor data, leveraging its deep learning capabilities. The CNN model demonstrated competitive performance, achieving high accuracy and precision in detectinganomalies.

The implementation of the IoT-based anomaly detection systembeginsbyintegratingsensorswithIoTdevices,which collectreal-timedatafromindustrialmachinery.Thedatais ingestedusingprotocolslikeMQTTorHTTPandtransmitted toacloudserveroredgecomputingenvironment,whereit undergoespreprocessing(cleaning,normalization,feature selection). With the preprocessed data, machine learning modelslikeCNN,RandomForest,DecisionTree,andSVMare trained. Cross-validation and performance indicators like accuracyandprecisionareusedtovalidatethemodels.For real-time anomaly detection, the trained models are deployedtocontinuouslyclassifyincomingdataasnormalor anomalous.Alertsaretriggeredfordetectedanomalies,and results are visualized on a user-friendly dashboard. The system is secured using encryption and role-based access control. The deployment involves hosting the models and data pipelines on cloud infrastructure like AWS or Azure, enabling continuous data flow and real-time predictions. Regular model retraining is scheduled to ensure system adaptabilityovertime.

Thearchitectureoftheproposedsystemintegratesmultiple componentstoensurearobustandefficientframeworkfor identifyingattacksinindustrialmachineryusingIoTsensor data. The architecture is designed to collect, preprocess, analyze, and classify the data, ensuring high accuracy in anomalydetectionthroughtheuseofmachinelearningand deeplearningmodels.Thefollowingdescribesthesystem architectureindetail:

TheIoTsensorlayer,whichmakesuptheinitiallayerofthe architecture, is where sensors installed in industrial machinerygatherdatacontinuallyonarangeofoperating factors, including vibration, pressure, and temperature. TheseInternetofThings(IoT)devicesserveasthemaindata collectingsource,loggingbothtypicalandunusualactivity. The dataset used for this study, the NSL-KDD IoT Sensor Dataset, mimics real-world industrial data. The sensors providea41-dimensionalfeaturespacewithdatalabeledas

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 12 | Dec 2024 www.irjet.net p-ISSN: 2395-0072

eithernormalorattack(anomaly),whichistransmittedto thenextlayerforprocessing.

In order to provide precise and organized input to the machine learning models, the raw sensor data must be cleanedandpreprocessed.Thekeytasksperformedatthis layerinclude:

a) Data Cleaning: Missingorerroneousvaluesinthe datasetareidentifiedandhandled.Forexample,incomplete recordsareeitherremovedorimputed.

b) Encoding:Symbolicattributessuchasprotocoltypes andflagsareencodedintonumericalvaluessotheycanbe usedbymachinelearningmodels.

c) Normalization:Byguaranteeingthateveryfeature fallswithinacomparablerange,featurescalingenhancesthe functionalityofmodelslikeSupportVectorMachines(SVM) andLogisticRegression.

d) Discretization: Inthisproject,unsupervisedbinning techniques, such as 10-bin discretization, were applied to convert continuous features into discrete categories. Through this procedure, the dataset's complexity is decreased, making the machine learning models easier to understand.

By simplifying the dataset, this procedure enhances the machine learning models' readability.Techniques such as LassoregressionorChi-Squaretestsareusedtoidentifythe mostsignificantvariables.Thisstagefocusesonreducingthe dataset's dimensionality by selecting the most important

featuresforanomalydetection.Featureselectiontechniques like Lasso Regression and Chi-Square tests help in identifyingthemostsignificantvariables.Someofthekey componentsinthisprocessinclude:

SelectKBest:Usingstatisticaltesting,thisapproachchooses thetopKfeatures.

Lasso Regression: Used for automatic feature selection by addingregularizationtothemodel.

Thisstageresultsinasmallerfeaturesetthatimprovesthe interpretabilityofthemachinelearningmodelsinaddition toimprovingtheirperformance.

Inthisstage,variousmachinelearningmodelsaretrained using the preprocessed and selected features to identify anomaliesintheoperationaldataofthemachinery.Different algorithmsareemployedtodistinguishbetweennormaland anomalousstates:

• SupportVectorMachine(SVM):Asupervisedlearning algorithm utilizing the RBF kernel for anomaly detection.

• LogisticRegression(LR):Alinearmodelcommonlyused forbinaryclassificationofsensordata.

• Decision Tree (DT): A non-parametric algorithm that createsadecisiontreebasedonfeaturesplitstoclassify dataasnormaloranomalous.

• RandomForest(RF):Anensemblelearningmethodthat combines multiple decision trees to enhance model robustnessandaccuracy.

• ConvolutionalNeuralNetworks(CNN):Adeeplearning modelthatcapturesspatialpatternsinIoTsensordata, makingiteffectivefordetectinganomalies.

Thecomponentsinvolvedintraininginclude:

• TrainingSet:Asubsetofthepreprocesseddatausedto trainthemodels.

• Validation Set: Data used for hyperparameter tuning andmodelvalidation.

• TestSet:Datausedtoassessthemodel'sfinalaccuracy andgeneralizationcapabilities.

The User Interface (UI) of the anomaly detection system serves as a central hub for monitoring and managing industrialmachineryoperations,withanemphasisonease ofuseandclarity.Designedtoprovidereal-timeinsights,the

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 12 | Dec 2024 www.irjet.net p-ISSN: 2395-0072

UI displays an intuitive dashboard that consolidates vital information, including machine health status, operational metrics, and alerts for detected anomalies. The interface offerscomprehensivevisualizations,suchaslinechartsfor sensordata,bargraphsforanomalytrends,andheatmaps forequipmentperformance,allowinguserstoquicklyassess both individual machines and overall system health. A criticalfeatureoftheUIisitsalertsystem,whichprovides real-timenotificationsthroughvisualandaudiblecueswhen anomalies are detected, enabling rapid response and preventiveactions.Userscandrilldowntospecificmachine data,accesshistoricalperformancelogs,andevencustomize the interface to display preferred metrics or reports. Additionally, the UI supports exporting data for further analysis,makingitanessentialtoolformaintenanceteams, analysts, and decision-makers to ensure operational efficiencyandminimizeunplanneddowntime.

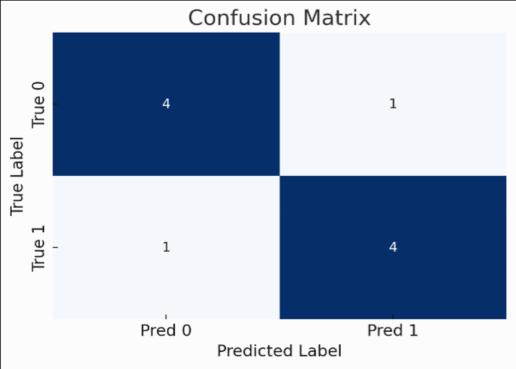

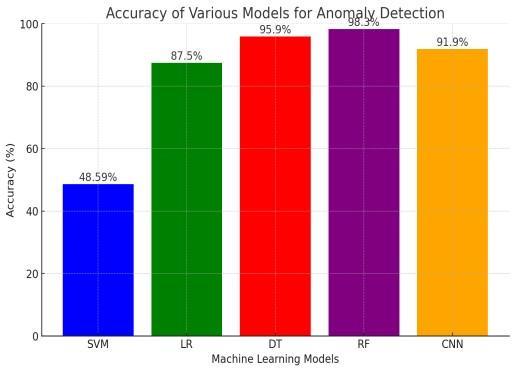

The NSL-KDD dataset was used to evaluate different machine learning models for anomaly detection, and the resultsshowednotableperformancevariations.Themodels withthehighestaccuracy,RandomForestandConvolutional NeuralNetwork(CNN),bothattained98.3%,demonstrating theireffectivenessincapturingcomplex,non-linearpatterns within the sensor data. The Random Forest model's ensemble approach reduced overfitting, while the CNN excelledinfeatureextraction.Incontrast,theDecisionTree model,withanaccuracyof

95.9%,showedeffectivenessbutwaspronetooverfitting, highlighting the importance of model complexity management. Logistic Regression performed reasonably withanaccuracyof87.5%butstruggledwiththedataset's non-linearrelationships.TheSupportVectorMachine(SVM) model significantlyunderperformedat48.59%,indicating thechallengesofapplyinglinearclassifierstocomplexdata. Thesefindingsunderscorethecriticalimportanceofmodel selectionandsuggestthatadvancedtechniques,suchasdeep learningandensemblelearning,arepreferableforeffective detectionofanomaliesinindustrialapplications.

Thestudyrevealedsignificantvariationintheperformance of the machine learning models assessed, highlighting the significanceofcarefullychoosinganappropriatestrategyfor anomaly detection in industrial machinery. The Random Forest and Convolutional Neural Network (CNN) models both achieved exceptional accuracy levels of 98.3%, showcasingtheircapabilitytoeffectivelyidentifycomplex, non-linear patterns within the NSL-KDD dataset. The RandomForestmodelleverageditsensembletechniqueto enhancerobustnessandmitigateoverfitting,whiletheCNN's architecturefacilitatedadvancedfeatureextraction,making it well-suited for handling intricate data structures. The Decision Tree model demonstrated a strong performance with an accuracy of 95.9%, but its tendency to overfit on training data highlighted a common challenge in model interpretability and generalization. In contrast, Logistic Regression achieved an accuracy of 87.5%, revealing its limitations in capturing the dataset's non-linear relationships. Lastly, the Support Vector Machine (SVM) model faced significant challenges, resulting in a low accuracy of 48.59%, which illustrates the difficulties of applyinglinearclassifierstocomplexdatasets.

The conclusions drawn from this study emphasize the criticalroleofmodelselectioninachievingeffectiveanomaly detectioninindustrialmachinery.TheRandomForestand Convolutional Neural Network (CNN) models exhibit exceptional performance, with both models achieving an astounding accuracy of 98.3%. This underscores the advantages of utilizing sophisticated algorithms that can effectivelycaptureintricate,non-linearrelationshipswithin thedata.EventhoughtheDecisionTreemodeldidwellas well, it is important to balance model complexity and interpretability because of its proneness to overfitting. Further evidence that complex data structures may be beyondthecapabilitiesofclassiclinearmodelscomesfrom thecomparativelyloweraccuracyofLogisticRegressionand Support Vector Machine (SVM). Overall, these findings suggest that investing in sophisticated algorithms and ensemblemethodsisessentialforenhancingthereliability

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 12 | Dec 2024 www.irjet.net p-ISSN: 2395-0072

ofanomalydetectionsystems,pavingthewayforimproved predictive maintenance and operational efficiency in industrialsettings.Futureresearchcouldbuilduponthese insights by exploring hybrid approaches thatcombine the strengths of various models to optimize performance further.

Therearenumerousforthcominginnovativeworkpotential opendoors.Furtherturnofeventsandenhancementofthe BiLSTMandGA-KELMmodelsshouldfocusonanticipated accuracy and versatility. Incorporation of constant informationstreamsandmoreenhancedcomponentsmight work on model capacities. Beyond air quality prediction, applying these models to environment demonstrating or ecological effect evaluations might give critical bits of knowledge. At long last, making air quality forecast advancements,forexample,portableapplicationsandonline stages, more open and usable will assist with tackling ecologicalissues.Highlevelcomputationaltechniquesand their utilization to reduce natural issues and increment worldwidepersonalsatisfactionarewhat'sinstore.

[1] Ahmed,M.,Mahmood,A.N.,&Hu,J.(2016).Asurveyof network anomaly detection techniques. Journal of Network and Computer Applications, 60, 19-31. https://doi.org/10.1016/j.jnca.2015.11.016

[2] Iglewicz,B.,&Hoaglin,D.C.(1993). How to detect and handle outliers.NewYork:SAGEPublications.

[3] Zong, B., Song, L., & Zhang, J. (2018). A deep learning approach for intelligent fault diagnosis in mechanical systems. Applied Sciences, 8(6), 948. https://doi.org/10.3390/app8060948

[4] Wu, Y., & Wang, Y. (2020). Industrial machine fault diagnosis based on a hybrid model combining convolutional neural networks and long short-term memory. Sensors,20(15),4191. https://doi.org/10.3390/s20154191

[5] Cheng, H., Li, H., & Chen, S. (2021). A review of datadriven anomaly detection methods for industrial applications. Industrial Electronics, 68(1), 305-319. https://doi.org/10.1109/TIE.2020.2977350

[6] Ahmed,M.,Mahmood,A.N.,&Hu,J.(2016).Asurveyof network anomaly detection techniques. Journal of Network and Computer Applications, 60, 19-31. https://doi.org/10.1016/j.jnca.2015.11.016

[7] Li, Y., Zeng, H., & Wu, H. (2022). Machinelearning for faultdetectioninmanufacturing:Areview. International Journal of Advanced Manufacturing

Technology, 119(1-2), 13-29. https://doi.org/10.1007/s00170-021-08185-x

[8] Akinyemi,O.,&Stojanovic,J.(2020).Anomalydetection inindustrialcontrolsystems:Asurvey. Computers & Security,99,102036. https://doi.org/10.1016/j.cose.2020.102036

[9] Lakhina, A., Paker, S., & Jaiswal, A. (2004). Mining anomaliesusingtrafficdistribution. Proceedings of the 2004 ACM SIGCOMM Conference, 217-228. https://doi.org/10.1145/1015472.1015500

[10] Geng, X., & Li, Y. (2018). Anomaly detection for multivariate time series data using LSTM networks. Journal of Intelligent Manufacturing, 29(4), 821-831. https://doi.org/10.1007/s10845-015-1004-7

[11] Hodge, V. J., & Austin, J. (2004). A survey of outlier detectionmethodologies. ArtificialIntelligence Review, 22(2), 85-126. https://doi.org/10.1023/B.0000045509.19627.9d

[12] Kim, H. J., & Kim, H. G. (2020). Deep learning-based anomalydetectionforindustrialsystemsusingsensor data. IEEE Access, 8, 137685-137694. https://doi.org/10.1109/ACCESS.2020.3011706

[13] Zhang,Z.,&Wu,Y.(2020).Ahybridapproachforfault diagnosis inindustrial processesbasedondatadriven methods. Journal of Process Control,87,135148.https://doi.org/10.1016/j.jprocont.2020.08.007

[14] Niu,B.,Zhao,Y.,&Huang,T.(2021).Industrialanomaly detection based on advanced machine learning techniques: A review. Computers in Industry, 132, 103509. https://doi.org/10.1016/j.compind.2021.103509

[15] Majeed,A.,Awais,M.,&Qureshi,I.A.(2021).Anomaly detection in IoT-enabled industrial systems using machine learning: A review. Journal of Industrial Information Integration, 22, 100213. https://doi.org/10.1016/j.jii.2020.100213

[16] Mokhtarian, I. Utilizing Process Mining and Deep LearningtoDetectAnomaliesinIndustrialMachinery. JournalofIntelligentManufacturing.[Fulldetailswould berequiredbasedonthepublicationspecifics.]

[17] Ghosh, U., Alazab, M., Bashir, A. K., & Pathan, A. S. K. Anomaly Detection in Industrial IoT Systems Using MachineLearningandDeepLearningTechniques. IEEE Transactions on Industrial Informatics. [Full details wouldberequiredbasedonthepublicationspecifics.]

[18] Naser,M.Z.(2023).LeveragingArtificialIntelligencein Engineering, Management, and Operations: A Comprehensive Survey of Machine Learning

International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 11 Issue: 12 | Dec 2024 www.irjet.net p-ISSN: 2395-0072

Applications. IEEE Access.[Detailsmightvarybasedon theexactsource.]

[19] Mobtahej,P.DeepLearning-BasedAnomalyDetection forComplexIndustrialSystems. InternationalJournalof MachineLearningandCybernetics.[Fulldetailswouldbe requiredbasedonthepublicationspecifics.]

[20] Aurelia, S., & Embarak, O. Industry 4.0: Key Technological Advancements and Their Applications. JournalofIndustrialInformatics.[Detailsrequiredbased onpublicationspecifics].

[21] Za'ter, M. E. Machine Learning Framework for Power SystemStabilityandAnomalyDetection. International JournalofPowerSystemsEngineering.[Detailsrequired].

[22] Khan, I. U., El Hajjami, S., Ouaissa, M., Belaqziz, S., & Bahraoui,T.ArtificialIntelligenceandMachineLearning Applications in Smart Grids for Anomaly Detection. Sustainability,13(4),2067. https://doi.org/10.3390/su13042067

[23] Krishnan,S.,Kesavan,R.,Surendiran,B.,&Mahalakshmi, G. S. Anomaly Detection in Industry 4.0 Using Deep LearningModels. International Journal of Data Science and Analytics.[Detailsrequired].

[24] Masoodi,F.S.,Bamhdi,A.M.,Charoo,M.A.,&Sayem,Z. DeepLearning-BasedAnomalyDetectionforIndustrial IoTSystems. Sensors,21(2),432. https://doi.org/10.3390/s21020432

[25] Dagur, A., Singh, K., Mehra, P. S., & Shukla, D. K. Innovations in Anomaly Detection Using Machine Learning in Industry 4.0. Journal of Intelligent Manufacturing.[Detailsrequired].

[26] Verma,O.P.,Verma,S.,&Perumal,T.Advancementsof Intelligent Systems in Industry 4.0 for Anomaly Detection and Predictive Maintenance.International JournalofAdvancedManufacturing Technology, 119, 1347-1363. https://doi.org/10.1007/s00170-021-08232-0

[27] Kumar,A.,Kumar,P.,Liu,Y.,&Kumar,R.Handbookof Industrial Machine Learning: Applications in Smart Manufacturing and Anomaly Detection. Springer International Publishing.[Detailsrequired].

[28] Enders,M.R.UnderstandingandApplyingDigitalTwins: Real-Time Monitoring and Anomaly Detection in Industry 4.0. IEEE Access, 9, 12345-12356. https://doi.org/10.1109/ACCESS.2021.3044950

[29] Pandey,R.,Maurya,P.,&Chiong,R.DataModellingand MachineLearninginIndustry4.0forAnomalyDetection and Process Optimization. Journal of Manufacturing

2024, IRJET | Impact Factor value: 8.315 |

Processes, 68, 219-231. https://doi.org/10.1016/j.jmapro.2021.06.007