EDITRICE ZEUS - Vial Ballerini 66, 20831 - SEREGNO (MB) - Tel. +39 0362 244182 -0362 244186 - www.editricezeus.com Tariffa R.O.C.: Poste Italiane spa - Spedizione in abbonamento postale - D.L. 353/2003 (conv. in L. 27/02/2004 n.46) art. 1, comma 1, DCB Milano TAXE PERCUE (tassa riscossa) Uff. Milano CMP/2 Roserio - ISSN 1827-4102

beverage & packaging

COP FP 2/13.indd 1

PATENT PENDING

speciale IFFA

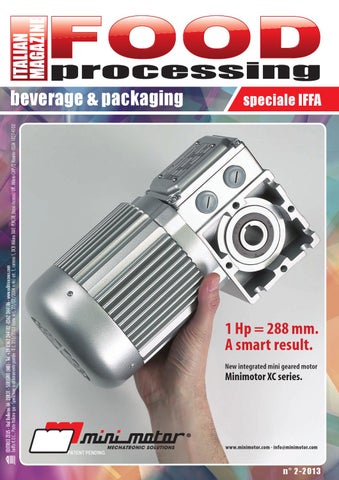

1 Hp = 288 mm. A smart result.

New integrated mini geared motor

Minimotor XC series.

www.minimotor.com - info@minimotor.com

n째 2-2013

22/03/13 09.55

Veripack. Progetti su misura.

Termoformatrice PROGRESS

salumi

mozzarella e formaggi freschi

pasta fresca

carni fresche

panini farciti e tramezzini

pizza e prodotti da forno

gastronom. e ristor. collettiva

frutta e verdura

dolciario

conserve e sottoli

Gli impianti Veripack (100% Made in Italy), sono la soluzione ideale per confezionare i prodotti alimentari. Semplici, resistenti ed affidabili rispondono alle esigenze di qualunque produttore, anche il più esigente e assicurano un’assoluta igiene e sanificabilità.

Frankfurt am Main 4 – 9. 5. 2013

The No.1 for the meat industry Come and visit us at our stand at IFFA! Hall 11.0, Stand A25

info@veripack.it - www.veripack.it

ADV_progettisumisura.indd 2

15/04/13 14.20

chiaravalli FP.indd 3

05/03/13 10.01

Cooling solutions r

®

BestCoP TECHNOLOGY

natural gases

energy saving system

R290 propane - R1270 propylene

ZANOTTI S.p.A. Via M.L.King 30, Pegognaga (MN) - Italy • Tel. +39 0376 5551 • Fax +39 0376 536554 • info@zanotti.com doppia.indd 2

22/04/13 11.29

ns resPeCting the environMent

s

MultiCoMPressor raCk

ene

NH3 ammonia - CO2 carbon dioxide

www.zanotti.com doppia.indd 3

22/04/13 11.29

SUMMARY

01-56

SPECIAL IFFA

57-64

DAIRY INDUSTRY

ZANOTTI 2-3-54/56 ZANOTTI, 50 years of activity

65-77

NEWS

78-87

PACKAGING

PIETRIBIASI 61-62 Equipment for the dairy industry and for soft drinks, juices and beverages

88-107

PRESERVING INDUSTRY

EXHIBITIONS

65-66 Steel Belts Are Top of the Milk for Tetra Pak

www.editricezeus.com

We’ll exhibit at... INTERNATIONAL PRESS STAND SOMMARIO FP 2-13.indd 2

Check us at...

108-128

BELT TECHNOLOGIES EUROPE

23/04/13 16.03

GSP 82-83 GSP Packaging Equipment: focus on GSP 45 EVO

editorial management and registered office: Via Ballerini, 66 20831 SEREGNO (MB) - ITALY Tel. +39 0362 244182 +39 0362 244186 web site: www.editricezeus.com e-mail: redazione@editricezeus.com portal: www.itfoodonline.com e-mail: marketing@itfoodonline.com skypeTM: editricezeus

Machineries, plants and equipment for food and beverage industry year XXV - issue n.2 - April 2013 managing editor Enrico Maffizzoni

SGORBATI 96-97 Peeling and cutting machines for all kinds of products

e ditorial manager S.V. Maffizzoni editorial production Sonia Bennati account dep. manager Elena Costanzo project and layout design ZEUS Agency

AGROPRODMASH 119 18th International exhibition for machinery, equipment and ingredients for the food processing industry

graphic and paging ZEUS Agency translation Nexo Translations printing Faenza Industrie Grafiche Italian Magazine Food Processing Europe: single issue: Euro 25 Annual (six issues): Euro 120 Outside Europe: single issue: US$ 30 Annual (six issues): US$ 170 Subscription payment can be made in the name of Editrice Zeus sas, by bank money transfer or cheque. Italian Magazine Food Processing An outline of the suppliers of machines, plants, products and equipment for the food industry. Published: Bi-monthly Registration: Court of Milan no. 676 of 20-09-1989 Shipment by air mail art.2 comma 20/b law 662/96 - Milan Panorama dei fornitori di macchine, impianti, prodotti e attrezzature per l’industria alimentare Periodicità: bimestrale. Autorizzazione del tribunale di Milano, n°676 del 20-09-1989 Spedizione in a. p. 45% art. 2 comma 20/b legge 662/96 Filiale di Milano The reproduction of the articles and/or pictures published by this magazine is reserved (the manuscripts and/or photos sent to the Publisher will not be returned). The Editor declines all responsibilities for any mistake of photocomposition contained in the published papers of any magazine by EDITRICE ZEUS.

SOMMARIO FP 2-13.indd 3

23/04/13 16.03

Special

QUADRANT LAUNCHES BROADEST RANGE OF EU 10/2011 COMPLIANT STOCK SHAPES FOR FOOD INDUSTRY

Q

uadrant Engineering Plastic Products (EPP) has updated its range of Food Grade Plastics in line with the new European Union Regulation (EU) 10/2011. The move makes Quadrant EPP the first and only engineering plastics’ manufacturer to offer such a broad and fully-tested range of thermoplastic stock shapes complying with the regulation. The portfolio of certified materials, covering PE through to PEEK, gives food producers the assurance of fulfilling the highest safety and quality levels for their food and beverage production systems. New Regulation (EU) 10/2011 is a further development of Directive 2002/72/EC for plastics materials in contact with food, and specifies much stricter test conditions for migration. Within the EU, compliance is required for all food contact materials. All Quadrant EPP Food Grade semifinished stock shapes and customized finished parts are processed and handled according to the new regulation and to the consistent quality control guidelines of Good Manufacturing Practice (GMP). Quadrant EPP accompanies each delivery with complete documentation, from choice of raw material to finished parts. This allows

full traceability and also supports customers in reducing their own in-house product testing time and costs. Customers receive a Declaration of compliance with the order (DCO) according to EN 10204-2.1 that ensures the uninterrupted traceability of the plastic product from the stock shape back to the raw material used by batch. Each production step is tested and documented by Quadrant EPP. Quadrant is also ahead of the market in introducing a Declaration of Compliance (DoC) for every delivery – a documentation requirement valid as of 2016 – that includes the complete test conditions together with the migration values of the materials. Tests to determine the migration values of Quadrant EPP’s food contact polymer materials were conducted on the thermoplastic stock shapes by independent external laboratory Intertek. These tests were performed according to regulation (EU) 10/2011. The portfolio of over 30 products was tested per Overall Migration Limit (OML) and Specific Migration Limit (SML) to measure the material inertness and provide a toxicological evaluation of individual substances. By including the pre-tested results with the DoC, customers can more easily calculate migration values for

Quadrant Food Grade semi-finished stock shapes with Food Grade and traceability labels.

QUADRANT FP.indd 3

Quadrant Food Grade semi-finished stock shapes with Food Grade and traceability labels. their individual applications – a further step in supporting their overall cost-efficiency. As part of its complete Food Grade Program, customers can benefit from Quadrant’s international partner network to select the right material for their application. The material selection and application advice considers the food type in contact with the plastic parts, and temperature and food contact time. “Quadrant is constantly developing innovative production and application solutions to help customers improve their production performance,” comments Ulf Barth, Market Segment Manager Food Processing Industry, Quadrant EPP Europe. “The Quadrant Food Grade Program offers the food market the widest selection of engineering plastic stock shapes and design possibilities. Materials certified to the highest safety level, migration calculation support, and application selection recommendations, assist our customers in reaching the best possible cost-performance ratio for their individual system.”

10/04/13 10.29

Special

QUADRANT STELLT BREITESTES SPEKTRUM VON EU 10/2011 KONFORMEN HALBZEUGEN FÜR DIE LEBENSMITTELINDUSTRIE VOR

Q

uadrant Engineering Plastic Products (EPP) hat seine Palette von „Food Grade“Kunststoffen in Übereinstimmung mit der neuen Verordnung (EU) 10/2011 der Europäischen Union aktualisiert und erweitert. Damit ist Quadrant der erste und einzige Hersteller von technischen Kunststoffen, der bereits eine derart breite Palette von vollumfänglich getesteten und zertifizierten thermoplastischen Halbzeugen anbieten kann. Das Portfolio deckt zertifizierte Materialien von PE bis PEEK ab. Es ermöglicht Nahrungsmittelherstellern, das höchste Sicherheits- und Qualitätsniveau für ihre Lebensmittel- und Getränke-Produktionssysteme einzuhalten. Die neue Verordnung (EU) 10/2011 ist eine Wei-

Quadrant Food Grade -Halbzeuge mit Food Grade- und NachverfolgbarkeitsEtikett

Quadrant Food Grade -Halbzeuge mit Food Grade- und NachverfolgbarkeitsEtikett

QUADRANT FP.indd 4

terentwicklung der Richtlinie 2002/72/ EG für Kunststoffe im Kontakt mit Lebensmitteln und legt sehr viel strengere Prüfbedingungen für die Migration dar. Innerhalb der EU ist deren Einhaltung für alle Materialien mit Lebensmittelkontakt gefordert. Alle Quadrant Food Grade-Halbzeuge und maßgeschneiderte Fertigteile werden nach der neuen Verordnung verarbeitet, und der konsequenten Qualitätskontrolle gemäß den Richtlinien der „Gute Herstellungspraxis” (Good Manufacturing Practice - GMP) behandelt. Quadrant begleitet jede Lieferung mit kompletter Dokumentation, von der Wahl der Rohstoffe bis zum fertigen Bauteil. Dies ermöglicht eine vollständige Rückverfolgbarkeit und unterstützt Kunden bei der Reduzierung ihres eigenen Zeit- und Kostenaufwandes für hausinterne Produkttests. Kunden erhalten ein Werksbescheinigung (Declaration of Compliance with the Order - DCO) nach EN 10204-2.1, die für lückenlose Rückverfolgbarkeit der Kunststoff-Produkte sorgt, vom Halbzeug bis zurück zur verwendeten Rohstoff-Charge. Jeder Produktionsschritt wird getestet und von Quadrant dokumentiert. Quadrant ist auch führend am Markt bei der Einführung einer Konformitätserklärung (Declaration of Compliance = DoC) für jede Lieferung - eine Dokumentationspflicht gültig ab 2016 -, die die kompletten Prüfbedingungen zusammen mit den Migrationswerten der Materialien enthält. Tests zur Bestimmung der Migrationswerte von Quadrant’s Kunststoffen für den Kontakt mit Lebensmitteln wurden an den thermoplastischen Halbzeugen vom unabhängigen externen Labor Intertek

durchgeführt. Diese Tests entsprechen den Richtlinien der Verordnung (EU) 10/2011. Das Portfolio von über 30 Produkten wurde pro „Overall Migration Limit“ (OML) und „Specific Migration Limit“ (SML) getestet, um die Trägheit des Materials zu messen und eine toxikologische Bewertung der einzelnen Substanzen zu beurteilen. Durch die Einbeziehung der vorgeprüften Ergebnisse gemäß DoC können Kunden Migrationswerte für ihre individuellen Anwendungen leichter kalkulieren. Quadrant unterstützt seine Kunden bei Bedarf bei der Berechnung der Migrationswerte. Als Teil des kompletten Food Grade-Programms können die Kunden vom internationalen Quadrant Partner-Netzwerk profitieren, um das richtige Material für ihre Anwendung zu wählen. Die Auswahl der Materialien bei der Anwendungsberatung berücksichtigt Lebensmittel-Typ in Kontakt mit den Kunststoffteilen, Temperatur und die Kontaktzeit (von Nahrungsmittel und Kunststoffteil). “Quadrant entwickelt ständig innovative Produktions- und Anwendungslösungen, die dem Kunden wiederum bei der Verbesserung ihrer Produktionsleistung helfen”, kommentiert Ulf Barth, Markt-Segment-Manager Lebensmittelindustrie, Quadrant EPP Europe. “Das Quadrant Food Grade-Programm bietet dem Lebensmittelmarkt die breiteste Auswahl von technischen KunststoffHalbzeugen und Gestaltungsmöglichkeiten. Konforme Materialien auf höchstem Sicherheitsniveau, Unterstützung bei der Migrations-Berechnung und Empfehlungen bei der Auswahl der Anwendung unterstützen unsere Kunden bei der Erreichung des bestmöglichen Preis-Leistungs-Verhältnisses für ihre individuellen Systeme.”

10/04/13 10.29

Special

FOAMED APET

Sustainability is demonstrated in practice at BUERGO.FOL

B

UERGO.FOL, the renowned manufacturer of flexible films, rigid films, reclosable films, skin films, and shrink films for the food industry and for numerous technical applications, is increasingly focusing on sustainable packaging systems. The film manufacturer therefore not only pledges to realize real and verifiable protection of the environment, but also translates this concept into action. Saving resources and recycling while maintaining its renowned product quality are the goals declared by the company headquartered in Siegenburg, Germany, in the lower Bavarian district of Kelheim.

1. Are the current bioplastics really sustainable? Everyone uses the term „sustainable“ today, but due the extremely widespread use of this term, especially in the packaging industry, very few people actually know what is meant by this term. Wikipedia says the following: „Sustainability is the capacity to endure. For humans, sustainability is the long-term maintenance of responsibility, which has environmental, economic, and social dimensions, and encompasses the concept of stewardship, the responsible management of resource use. In ecology, sustainability describes how biological systems remain diverse and productive over time, a necessary precondition for human well-being. Longlived and healthy wetlands and forests are examples of sustainable biological systems.“ [1]. All too quickly now - under the guise of „sustainability“ – companies are bridging the gap to the use of renewable raw materials in the production of films, the manufacture of biologically degradable films, and to the natural cycle by subsequent composting of the films or packaging. It is a very

BUERGOFOL FP 2/13.indd 3

good and well-rounded concept that will surely forge its own path in the future. However, in the year 2013 this concept will not yet become complete because when you take a critical look behind the green curtain, you will see numerous corners and edges. For example, the raw material polylactic acid (PLA) is a renewable resource, but it is unfortunately manufactured today in the USA based on genetically modified corn. It is unthinkable to use this PLA in films and packaging in many European countries, and especially in Switzerland. The exact same criticism applies to the heavily advertised compostability of packaging made using biomaterials, which can even be certified according to DIN EN 13432 [2]. Only a few packages and bags land in (industrial) compost – just like before, they continue to be fed to incinerators [3]. Experts in the field of biopolymers also expressly recommend their incineration [4]. Furthermore, there is not any method available for recycling biomaterials. In contrast: If large amounts of PLA were to be sent to the recycling plant, then the raw materials would contaminate the waste stream and make other recycled plastics unmar-

ketable. Based on a report from the experts at Euwid, the Petcore organization views the recycling of PET bottles to be at risk. Even a small market share of PLA could lead to a serious disruption of the infrastructure for recycling PET bottles in Europe.“ [5]. Another setback in relation to the use of biopolymers for packaging arose at the beginning of 2013: Until the end of the year 2012 biodegradable packagings made from renewable raw materials were exempted from the DSD fees. This “promotion” ends from the beginning of the year 2013 [6]. As the European Bioplastics has announced in June 2012, further amendments of the German Biowaste Ordinance lead to restrictions, that not all “biopackaging” may be disposed of in the brown bin [7]. The entire system of biopolymers based on renewable materials is evidently still in its infancy. There are only a few suppliers, and they often have a monopoly in the market. Even in terms of the properties of the materials, films made of biopolymers cannot measure up yet to established products manufactured on a petrochemical basis because in many cases they are still too

15/04/13 12.45

Special

brittle, sensitive to water, temperaturesensitive (below 60°C for PLA based biopolymers), poor-sealing (for cellulose-based), difficult to process, and do not function as a barrier. BUERGO.FOL Managing Director Gregor Schleicher does not see the end of the possibilities for biopolymers by a long shot yet. Without the support of petroleum-based polymers, it is impossible to achieve the properties in films and packaging that customers are accustomed to. In addition, Schleicher also expressed moral considerations regarding the manufacturing of plastics using food intended for humans and livestock. In summary, it can be said that this still does not justify the high price for films made of biomaterials. Very few consumers are willing to pay for them because they are not convinced yet of the advantages of packaging made of biomaterials and are even confused and insecure about their use due to the continuous flood of new organic logos and controversial public discussions. It may take many years before bioplastics, praised as

being renewable and sustainable, and the products produced using them become a serious alternative to petroleum-based plastics. BUERGO.FOL is monitoring these developments very closely, but only after the concept of renewable resources is sensible and consistent in all aspects will consumers be willing to accept them.

2. Real Sustainability In the meantime, BUERGO.FOL is following and realizing a different path to more sustainable products. As a pioneer in Germany, the company has been offering foamed APET films in thicknesses ranging from 300 to 800 μ under the new brand name „BUERGO.PET expanded“ for some time now. These films are produced on the ultramodern facilities available at the site in Ingolstadt, Germany. The weight of the foamed film is approximately 30% lower in comparison to that of conventional APET films. This results in significant material savings, and therefore to a more sustainable use of natural resources. BUERGO.PET expanded has

THE FOLLOWING IMAGES SHOW SOME EXAMPLES

Black bottom section of a package made of BUERGO.PET expanded (left) with a magnified view of the foam structure (right)

BUERGO.PET expanded is very suitable as package for meat and sausages. In combination with barrier films, an excellent barrier effect is obtained

BUERGOFOL FP 2/13.indd 4

a very high mechanical strength and is perfectly suited for use as a deep draw film on all common thermoforming and packaging machines, even on older models. This means processors of the film and packagers using the film can still use their existing machines without having to retrofit them, and they can even continue working with their standard machine settings. The thermal formability is also much better in comparison to non-foamed films as well. For example, extremely deep recesses can be formed without requiring the use of a stamp. The structures applied to the thermoforming mold are formed precisely and with detailed contours on the foamed film. Furthermore, the foamed APET film can be cut perfectly – sharp edges and sharp corners are a thing of the past now. At the same time, wear on the cutting knifes is minimized. The foaming effect also provides other advantages in addition to the advantage of a reduction in weight: due to the insulating effect, the keeping quality of the packaged product improves as well. Visually, the foam structure is very appealing and attractive, and the film and packaging feel soft and smooth in your hand while still providing a good grip. This provides an additional incentive to the consumers at the point of sale to purchase the product. In addition, BUERGO.PET expanded is also available in various colours, and the film can be printed with excellent results, which means it is possible to realize new and individual packaging ideas as eye-catchers on the shelves and ideal product presentations. The innovative foam films based on polyester are therefore superbly suited for the manufacture of trays, tablets, pans, plates, dishes, and cups for the food area as well as for the non-food area. Their use for packaging foods such as meats and sausages, cheese, snack items, fish and seafood, poultry, baked goods and ready-made meals on the one hand, and for consumer and industrial goods such as hygiene products, household goods, office sup-

15/04/13 12.45

Special

plies, electronics on the other hand, must be particularly emphasized. The combination of stackability and slippage resistance in the packaging is guaranteed.

Composite Films Just like before, the new foamed APET films can also be bonded to a laminate with barrier films from the BUERGO. FOL company in an additional refinement step. The bond is strong and permanent. Delamination does not occur in top films or in bottom films. By selecting suitable laminating films, it is possible to vary the barrier properties for oxygen, carbon dioxide, and water vapour as well the opening characteristics of the packaging. The spectrum ranges from tight sealed packaging to packaging that is especially easy to open, i.e. easy to peel. As a whole, this allows the realization of customized packaging, and the film specialists from Bavaria are ready to meet the demands and requirements of manufacturers, retailers, and consumers.

4. Savings Sustainable development will be part of the future of the packaging market. In times of heavy pricing pressure, the economical use of resources will become more important than ever. The following table shows the potential savings in packaging by comparing the foamed APET film BUERGO.PET expanded with the non-foamed BUERGO. PET film. The table shows how much packaging material weight can be saved when using the foamed film. In addition to the cost savings in material and the lower transportation costs Typical bottom film

resulting from the lower packaging weight, it is also necessary to consider the not-so-insignificant savings in DSD (dual refuse system) fees for the „Green Point“ system. Particularly noteworthy in this context is the fact that the foamed APET sheet BUERGO.PET expanded is mainly produced with recycled materials. This results in a very low value for the carbon footprint (kg of CO2 eq. / kg polymer) in a Life Cycle Assessment (LCA) and a considerable saving of energy.

5. Summary and Outlook The new, verifiably sustainable concept from BUERGO.FOL, who has already realized the production and sales of foamed APET films in the BUERGO. PET expanded product class, also offers a whole range of advantages on the product side: • Excellent processing characteristics on existing machines • Appealing look and feel • Outstanding mechanical properties In comparison to other plastics, Gregor Schleicher, Managing Director of the BUERGO.FOL GmbH, stated the fol-

Material

Not foamed Foamed APET-Film BUERGO.PET BUERGO.PET expanded APET/PE APET/PE

Thickness

300 µ/50 µ

300 µ/50 µ

Weight in g/m2

466,2

350,0

Weight 100.000 m2 in kg

46.620

35.000

Weight savings in kg

-

11.620

Weight savings %

-

24,92 %

BUERGOFOL FP 2/13.indd 6

lowing: „In comparison to polypropylene PP, the foamed APET film stands out due to is significantly better processing properties, higher plant effectiveness, and lower energy consumption. Compared to polystyrene PS, BUERGO. PET expanded has significantly better mechanical properties with comparable recyclability.“ One of the reasons why the marketing of foamed APET film is now being advanced is the fact that weight savings of up to 30% are possible in packaging and that the packaging material show a very good LCA-value. This responsible handling of resources is environmentally friendly since it reduces the overall energy consumption and CO2 emissions. This and other sustainable concepts will be more intensely pursued in the future at BUERGO. FOL because this company is aware of responsibility for the environment and for the living conditions of future generations.

About BUERGO.FOL BUERGO.FOL produces flexible films, rigid films, reclosable films, skin films, and shrink films for the food industry and a number of technical applications at three locations in southern Germany using an ultra-modern machine park, and employs almost 300 people.

About the Author Dr. Kurt Stark studied chemistry at the University of Bayreuth with emphasis on polymer and colloid chemistry. In 1999, he began his professional carrier at Wacker Polymer Systems in Burghausen. As a laboratory head, he

15/04/13 12.45

We

have the solution The best of rigid and flexible films! Ottimi film rigidi e flessibili! We offer a diverse and advanced product catalogue comprising shrinkwrap films, skin films and reclosable films for the food industry, medical products, pet food, the chemical industry as well as special customized applications. With more than 40 years of experience, BUERGO.FOL provides unique know-how in the development of modern packaging solutions.

OUR PRODUCTS TUBULAR POUCHES BUERGO.FLEX FLOW / TOP

POUCHES BUERGO.BAG

TOP AND BOTTOM FILMS BUERGO.FLEX TOP / BOTTOM

LAMINATES / RECLOSABLE BUERGO.FLEX SPECIAL

RIGID FILMS / FOAMED RIGID FILMS BUERGO.PET / BUERGO.PET EXPANDED

SKIN FILMS BUERGO.SKIN

SHRINK FILMS BUERGO.SHRINK

SPECIALISED FILMS BFCR

PREMIUM PRINTS ON FILM BUERGO.PRINT

FILM EXTRUSION 路 PRINTING 路 LAMINATING 路 CONVERTING

www.buergofol.de contact@buergofol.de 路 Tel. +49 (0) 94 44/97 91-110

Anz Buergofol A4 Italy.indd 1

16.04.13 13:48

Special

was responsible for the development new polymer products, the optimization of existing products, and supporting production. From March 2005 to September 2011, Dr. Stark worked at Huhtamaki in Forchheim, a manufacturer and processor of polymer films. In his function as head of the Research & Development Department for the technical film and packaging film market segments, Dr. Stark worked on renewable and biologically degradable films, primarily on those based on PLA. He developed completely new blowing and casting PLA film systems for custom solutions. Since October 2011, Dr. Kurt Stark has assumed a position at the BUERGO. FOL GmbH in Siegenburg as a head of product development for techni-

Sources:

Dr. Kurt Stark Director Business Development BUERGO.FOL GmbH cal films and as the Business Development Director. In this function, he will also promote the development of new packaging solutions and technical films for the next generation at BUERGO.FOL.

[1] http://en.wikipedia.org/wiki/Sustainability [2] http://www.dincertco.de/de/produkte_ aus_kompostierbaren_werkstoffen.html [3] Jacqueline Brzinzky: „Mogelpackung Biotüte“, www.geo.de, Article from 17th of June 2011 [4] Hans-Josef Endres, Andrea Siebert-Raths, „Technische Biopolymere“, Carl Hanser Verlag Munich, 2009, p. 256 [5] Gunnar Sohn, Biokunststoffe erschweren Abfallentsorgung, 30.04.2008, „Bezeichnung „biologisch abbaubar“ kein ökologisches Qualitätssiegel“; Quelle: pressetext.deutschland http://www.innovations-report.de/html/berichte/studien/bericht-109058.html [6] Bioplastics Newsflash from 09/18/2012, published by European Bioplastics [7] Infoflyer published by European Bioplastics, June 2012: „Die deutsche Bioabfallverordnung“

BUERGO.FOL

B

UERGO.FOL GmbH from Siegenburg in Bavaria is a company of around 300 employees specializing in the manufacture and converting of rigid and flexible films. We offer a diverse and advanced product catalogue comprising shrink-wrap films, skin films and reclosable films for the food industry, medical products, pet food, the chemical industry, as well as special customized applications. With more than 40 years of experience, BUERGO.FOL provides unique know-how in the development of modern packaging solutions. Our wealth of experience combined with the constant drive to advance the current state of technology has made BUERGO.FOL market leader in the field of high-tech technical films and special-purpose films with content customers in many different branches of business and industry. At BUERGO.FOL we provide a full inhouse service in the development and manufacture of highly customised packaging solutions ranging from the production of advanced rigid films and flexible films to customized printing of

BUERGOFOL FP 2/13.indd 8

the films. We pride ourselves in only providing products of outstanding quality to our customers. Over the last 40 years our unique combination of using only highest quality raw materials, cutting-edge research and state-of the art production facilities has made us a trusted brand as a supplier of barrier films to many branches of industry especially the pharmaceuticals, food, non-food and converting industries. This longstanding business relationship has given us the expertise to help our customers meet their specific needs e.g. production under the very high hygiene standards compliant with HACCP and BRC/IoP. However, we believe that there is more to quality than producing outstanding products: True quality means taking

seriously our responsibility to our customers as well as to the environment and the societies we live in. At BUERGO.FOL we rise to every challenge and always strive to offer innovative, efficient and effective solutions to our customers. In order to achieve this, we draw on our 40 years of experience as a highly successful system provider of standard films, heavy-duty high-barrier applications for MAP, vacuum packaging and flow packs. Furthermore, we invest in the future by constantly improving existent films and developing new film recipes designed to meet specific customer requirements. contact@buergofol.de · Tel. +49 (0) 94 44/97 91-110

15/04/13 12.45

Contacts:

www.fracchiolla.it

Z.I. 70010 Adelfia (BA) ITALY T. +39 080 459 69 44 F. +39 080 459 68 10 info@fracchiolla.it

Our customers, our best advertising.

Wine

Beer

Winegar

Industrie Fracchiolla S.p.A. progetta, costruisce ed installa serbatoi in acciaio inox di qualsiasi capacità, con realizzazioni in azienda e sul posto (dissolutori, cristalizzatori, miscelatori, fermentatori per birra). Leader a livello internazionale nel settore enologico, chimico-farmaceutico ed alimentare. Industrie Fracchiolla S.p.A. nel 2012 ha raddoppiato il fatturato rispetto agli anni precedenti lavorando su due turni per tutta la durata dell’anno, non ha mai subito crisi, nè è mai ricorsa a cassa integrazione. Il perseguimento di una logica produttiva votata alla realizzazione di un prodotto di prima qualità con puntualità nell’evasione delle commesse supportata dall’assistenza tecnica costante senza incremento dei prezzi ha consentito di centrare l’ambizioso obbiettivo. Industrie Fracchiolla S.p.A. wich designs, manufactures and installs stainless steel tanks of any capacity, with Factory and Onsite realizations (dissolvers, cristalizzatori, mixers, beer fermenters), is a leader in the international wine , food and beverage, chemical and pharmaceutical industry. Industrie Fracchiolla S.p.A. has doubled its turnover in 2012 compared to previous years working on two day-shifts during whole year, has never suffered the international crisis, nor has never resorted to redundancy found. The pursuit of a production logic devoted to the creation of a quality product delivered on time, supported by technical assistance without constant increase in prices, has allowed the ambitious goal.

Food

Paints

Perfume

Tradizionale

Tecnologico

Traditional

Technological

Special

SUSTAINABLE FOOD

The food industry focuses on clean energy. Two excellent examples promoted by Energy Resources: Cbm Fileni and Vis Industrie Alimentari

T

argeting international development trends, Energy Resources’ mission desires to translate the vision into a much more solid approach by designing technologies, systems and products that really mean zero impact for each human activity, from producing energy from renewable and inexhaustible sources to the use of energy to supply buildings and sustainable mobility systems. With more than 110 megawatts of total power installed in plants exploiting renewable energies, Energy Resources is one of the leaders in the Italian renewable energy market. In six years the company has reached a turnover of more than ₏ 350 million. To date more than 600 among the most important Italian companies have chosen ER to create photovoltaic and geothermal plants, Green Buildings and for renovating the energy systems as well as integrated systems for sustainable mobility. Energy Resources is also a green energy producer with 8.5 megawatts of owned photovoltaic plants which open the Italian energy market to foreign investors. Food is converting to renewables. A host of companies in the industry are renovating the energy systems in their facilities. There are two aims: restore old plants, often featuring asbestos roofs which require reclamation, and cut heating and electricity consumption thus reducing costs for the companies. Renewable energy is the answer to

ENERGY RESURCE FP 2/13.indd 3

these pressing needs. Vis Industrie Alimentari and Cbm Fileni are two good examples created by Energy Resources in Italy. With Ministerial Decree of 19 February 2007, Italian companies and private individuals were given the chance to make a real contribution to protecting the environment, by installing solar panels on roofs and on the ground. There are not only financial savings involved. Many people and companies jumped at the chance, also considering that photovoltaic panels insulate roofs better, with no risk to their waterproofing. Renewable energy is an excellent investment in terms of communication and green marketing: today’s consumers are more and more

26/02/13 15.20

Special

interested in a company’s impact on the environment in addition to the sustainability of its production chain. This value directly reflects on the end product, increasing the perception of quality and authenticity. «Every plant installed for our customers – explains the chairman of Energy Resources, Enrico Cappanera - is like a tailor-made suit, designed and created on the basis of the real needs and potential of the structures we work on. We are talking about efficient, effective and safe investments».

C.B.M. FILENI This well-known chicken farm conceived two separate projects for energy development at the chicken houses and warehouses located in San Marcello (An), by installing a 200kw photovoltaic system with the Net metering formula (90% guaranteed coverage of the company’s electricity require-

ment), supported by another 1Mw system to complete the transfer of energy produced to the network. The panels almost cover the entire surface of the roofs. The opportunity was seized to replace the now obsolete roof with 8-centimetre “sandwich” insulation panels that provide significant thermal/acoustic insulation as well as an additional overall energy saving of more than 10%. Almost two years from commissioning the panels, the production of “green” energy has exceeded 1,542,888.608 kWh, equalling 819,274.04 kg of CO2 not released into the atmosphere, and 336,261.90 litres of petrol not used: the equivalent of 106,000 new trees.

VIS INDUSTRIE ALIMENTARI In 2011 this leading company specialised in the production and wholesale of frozen food decided to transform the roof of the facility in Noale (VE)

into a true solar-power electricity production plant while reclaiming the old asbestos covering. Energy Resources proposed the most competitive bid in technical and financial terms. This allowed Vis Industrie Alimentari to benefit from the incentives to the production of green energy in addition to a further bonus for reclaiming the asbestos. The 292.5 kWp photovoltaic system guaranteed a new source of revenue by producing considerable savings by slashing electricity consumption. Almost two years from commissioning the panels, the production of “green” energy has reached 400,000 kWh, equalling 200,000 kg of CO2 not released into the atmosphere, and a saving of around € 90,000 per annum. Thanks asbestos reclamation, the incentive recognised to VIS was among the highest obtainable from the GSE (Energy Services Manager).

SUSTAINABLE FOOD

Die Lebensmittelindustrie setzt auf saubere Energie. Zwei exzellente Beispiele aus dem Hause Energy Resources: Cbm Fileni und Vis Industrie Alimentari

B

ereits auf die Dynamiken der internationalen Entwicklung ausgelegt, möchte die Mission von Energy Resources die Vision in einen sehr viel konkreteren Ansatz übersetzen, und dabei Technologien, Systeme und Produkte entwickeln, die in der Lage sind, eine wirkliche Null-Auswirkung für jede menschliche Tätigkeit zu erzielen, von der Stromerzeugung aus erneuerbaren und unerschöpflichen Quellen, bis hin zur Nutzung desselben für die Energieversorgung von Gebäuden und nachhaltigen Mobilitätssystemen. Mit über 100 Megawatt installierter Gesamtleistung in Anlagen zur Nutzung erneuerbarer Energien ist

ENERGY RESURCE FP 2/13.indd 4

Energy Resources einer der TopLeader auf dem italienischen Markt der erneuerbaren Energien. In sechs Jahren hat das Unternehmen einen Umsatz von über 350 Millionen Euro erwirtschaftet. Bis heute haben sich über 600 der bedeutendsten Unternehmen des Made in Italy zur Verwirklichung von photovoltaischen und geothermischen Anlagen, Green Building und energetischen Requalifizierungen, nebst integrierten Systemen für die nachhaltige Mobilität, für ER entschieden. Energy Resources ist auch Erzeuger von grünem Strom durch 8,5 Megawatt eigene Photovoltaikanlagen, die den italienischen Strommarkt für ausländische Investoren öffnen.

26/02/13 15.20

Special

Die Lebensmittelindustrie sattelt auf erneuerbare Energien um. Zahlreiche Unternehmen der Branche setzen auf die energetische Requalifizierung ihrer Strukturen. Dabei wird ein zweifaches Ziel verfolgt: Die Sanierung der alten Werke, die sich oftmals noch durch Asbestabdeckungen auszeichnen, die saniert werden müssen und die drastische Reduzierung des Heizungs- und Stromverbrauchs zur Senkung der Betriebskosten. Die Antwort auf diese dringenden Bedürfnisse kann nur von den erneuerbaren Energien kommen. Es gibt zwei virtuose Beispiele, die Energy Resources in Italien verwirklicht hat: Vis Industrie Alimentari und Cbm Fileni. Durch das Ministerialdekret vom 19. Februar 2007 hat sich die Möglichkeit für die italienischen Unternehmen, aber auch für Privatpersonen eröffnet, durch die Installation von Photovoltaikpaneelen sowohl auf Dächern, als auch auf dem Boden, einen aktiven Beitrag für den Umweltschutz zu leisten. Mit Blick auf die Einsparung, und zwar nicht nur aus wirtschaftlicher Sicht. Und sehr viele haben die Gelegenheit beim Schopf gepackt, auch in Anbetracht der Tatsache, dass die Photovoltaik für eine bessere Isolierung des Daches sorgt, ohne Gefahren für die Abdichtungseigenschaften der Dachböden. Die erneuerbaren Energien stellen im Übrigen eine ausgezeichnete Investition in Bezug auf Kommunikation und Green Marketing dar: Der moderne Verbraucher wird immer aufmerksamer und achtet neben der Nachhaltigkeit der Produktkette auch auf die Umweltauswirkungen des Unternehmens, einen Wert, der sich direkt im Endprodukt widerspiegelt, und die Wahrnehmung von Qualität und Ursprünglichkeit steigert. «Jede für unsere Kunden installierte Anlage - erklärt der Präsident von Energy Resources, Enrico Cappanera - ist wie ein Maßanzug, geplant und gebaut auf Grundlage der tatsächlichen Bedürfnisse und Potenziale der Strukturen, für die wir

ENERGY RESURCE FP 2/13.indd 5

arbeiten. Wir sprechen hier von effizienten, effektiven und sicheren Investitionen».

Erdöl überschritten: Das entspricht 106 Tausend neuen Bäumen.

C.B.M. FILENI

Das bedeutende, auf die Herstellung und den Großhandel von Tiefkühlwaren spezialisierte Unternehmen hat 2011 beschlossen, das Dach des Werks in Noale (VE) in ein wahres Kraftwerk für die Erzeugung von Solarenergie zu verwandeln, und dabei gleichzeitig die alten Asbestabdeckungen zu sanieren. Energy Resources hat das sowohl technisch als auch wirtschaftlich gesehen wettbewerbsfähigste Angebot abgegeben und der Vis Industrie Alimentari dadurch ermöglicht, nicht nur auf die Fördermittel für die Erzeugung von „grüner“ Energie, sondern auch auf eine weitere Prämie für die Asbestsanierung zuzugreifen. Die 292,5 kWp Photovoltaikanlage stellt eine neue Einnahmequelle dar, da sie für deutliche Einsparungen durch die starke Senkung des Stromverbrauchs sorgt. In fast zwei Jahren nach Inbetriebnahme der Paneele, hat die Produktion von „grüner“ Energie 400.000 kWh, entsprechend über 200.000 kg nicht in die Atmosphäre abgegebenem CO2, sowie eine wirtschaftliche Einsparung von etwa 90.000 Euro pro Jahr erreicht. Dank der Asbestsanierung zählt die der VIS zuerkannte Förderprämie mit zu den höchsten, die man von der Energieagentur GSE bekommen kann.

Das bekannte landwirtschaftliche Unternehmen, das im Bereich der Verwaltung von Geflügelzuchten tätig ist, hat zwei separate Projekte der energetischen Requalifizierung von Ställen und Werkshallen in San Marcello (AN) entwickelt, und eine 200 kW Photovoltaikanlage mit der Formel des Stromtauschs vor Ort installiert (Garantie für eine 90%ige Abdeckung des Bedarfs des Unternehmens an elektrischer Energie), neben einer weiteren 1 mW Anlage, deren erzeugte Energie vollständig ins Stromnetz eingespeist wird. Die Paneele decken nahezu die gesamte Fläche der Dächer ab. Man nutzte die Gelegenheit, die nunmehr veralteten Abdeckungen durch 8 cm dicke „Sandwich“-Isolierpaneele zu ersetzen, die sowohl für eine ausgezeichnete Wärme-/Schalldämmung sorgen, als auch eine weitere Energieeinsparung von insgesamt mehr als 10% ermöglichen. In fast zwei Jahren nach Inbetriebnahme der Paneele, hat die Produktion von „grüner“ Energie den Wert von 1.542.888,608 kWh, entsprechend über 819.274,04 kg nicht in die Atmosphäre abgegebenem CO2, sowie 336.261,90 Liter nicht verbrauchtem

VIS INDUSTRIE ALIMENTARI

26/02/13 15.20

idealplast A4.indd 1

17/04/13 09.55

Special

LABELING SYSTEMS FOR MEAT INDUSTRY

F

ood products packaging in thermoformed trays, has been for a long time an established condition in the food market particularly for meat and derived products packaging. To face the enquiry of labeling, identification and traceability, LABELPACK has developed a wide range of labeling systems, able to apply one or more labels onto the package and managing online printing for variable data and barcodes. The labeling systems of MODULAR series represent the solution to top level, designed and manufactured on an “open frame” structure in stainless steel, on which various labeling modules of LABELX series can be integrated for application onto the top and bottom of the product trays. This system is equipped with an electronic control unit positioned in a hanging framework where is housed the PLC and the operator interface Touch Screen, the operation speed are all electronically synchronized and all the adjustments are equipped with numerical indicators to facilitate the exchange format and the consequent repositioning to the previous position. MODULAR sy-

labelpack IFFA.indd 3

stems can integrate different conveyor modules, studied according to the characteristics, size, weight and shape of the container to be labeled, this conveyors are integrated in “balcony” position that allows easy cleaning of the floor area under the machine, avoiding that any liquid drop could reach the parts of the machine which result difficult to be cleaned and sanitizing. The labels application units LABELX which are available for label width 140 -250 mm and can integrate all the thermal transfer industrial print engine, available on the international market,

with a 4 “and 6” printing width made by DATAMAX, ZEBRA, SATO, AVERY, CAB, CARL VALENTIN. The print engine module allows to manage online printing of variable data, bar codes and other information necessary for the traceability of food products. For the entry level application, are available the labeling systems of the COMPACT series, made in stainless steel structures too, they integrate the labeling units of the LABELX JR series, that allow to have reliable solutions with a very competitive price. Very often we are asked also to be able to integrate our labeling modules onto existing packaging machines and new plants, both for end users and OEM manufacturer to which we provide all our technical support and our experience, gained in more than twenty years of activity in this field, and suggesting the best solution among the various models of the LABELX series and the print and apply solutions of the PandA series available in over 30 models and complete of many accessories that allow an easy integration onto all the packaging machines such as: flow-pack, heat sealing machines, thermo forming, vertical bagging, bundling machines, cartoning and case packers.

25/02/13 15.27

Special

MACHINES AND TECHNOLOGIES FOR IFFA 2013 All the news about meat processing and packaging CUTTER TYPE TITANE 120V Exhibitor

DADAUX S.A.S.

Product description › Entirely stainless steel 18-10 › Blade motor power 30Kw ( 40CV) › Variable speed 1000 to 3600 turn/minute › Variable reverse mixing speed of 150 to 300 turn/min › Bowl motor 1.5 – 2CV › Manual cover › Capacity 120 Litters › Digital thermometer › Bowl in moulded stainless steel ( thickness 2 to 3 cm) › Equipped of 6 knives, exchangeable head › Complies with E.C. standards › Made in France

806 SERIES GRINDER Exhibitor

Weiler® | Provisur Technologies

Product description Weiler® is an established leader with best of breed equipment for meat and poultry processors. The company’s reputation for highly productive, durable and reliable equipment is complemented by the following benefits. Weiler® systems provide: › Excellent paybacks times › Lower maintenance costs › Longer wearing parts › Superior quality and performance › Respected customer service

FP 2/13 SPECIALE IFFA.indd 3

22/04/13 15.03

Special

AEW DELFORD POLYLINE WITH NEW POLYSLICER 1000 Exhibitor

Marel hf

Product description Maximise line speed and throughputs The new compact Polyslicer 1000 provides small to medium producers and packers with the ultimate in flexibility and efficiency – at an affordable price. With a large, 3 log slicing capacity, quick, assisted loading, simple to adjust slicing head and a choice of orbital or involute blade for high output, the slicer handles a wide variety of product. Integration of the new compact VBS Vertical Buffer to buffer sliced product groups and re-introduce them into the flow during slicer reload provides a cost effective way of maximising line speed. VBS provides a more consistent flow of product to robots or operators downstream, thereby increasing line performance by up to 25%. The well proven IPL Robot loads portions or groups of meat into trays or thermoformers. It can be integrated with virtually any other machine in a production system, e.g. slicers, saws, thermoformers and tray sealers, and can be adapted and tailored precisely to a client’s needs.

AFOGRILL Exhibitor

Afogrill

Product description Multiple products can be processed with the Afogrill, both bulk and convenience products. The Afogrill combines two methods of heat transfer when grilling or colouring meat products, namely infrared irradiation complemented by classic convective heat. Both methods of heat transfer can be turned on and adjusted separately generating the following advantages: › Short grilling times (between 15” and 60” depending on the product and the desired result) › Minimum weight loss (sometimes less than half compared to conventional systems) › Low energy consumption (approx. consumption of €5.- per hour for grilling 250kg of hamburgers) › Starting up and getting the oven ready for production takes only a few minutes › Multiple products: By setting four parameters (capacity IR, t°, conveyor belt velocity and height) one single installation is capable of grilling a whole range of different products. › The Afogrill combines a high capacity with a small footprint (one third of the length of conventional systems) › The simple removal of the conveyor belt guarantees quick and efficient cleaning. › The use of the Afogrill results in a beautiful, handmade appearance of your product (BBQ effect) › Sensory tests carried out by an accredited research institute (UGent Sensolab) confirm the excellent results achieved as regards appearance and taste

ARP 125 PATTY FORMER Exhibitor

RISCO S.p.A.

Product description The ARP 125 system produces hand-made style circular-shaped products. The Risco filler makes the portion, a guillotine separates these portions which are subsequently conveyed by a transport belt and gently crushed by a roller system which creates the effect of manual production. The thickness of the product is adjustable, the final product is then conveyed by a transport belt to the packaging machine. The system may include, as an option, the automatic positioning paper underneath the product.

FP 2/13 SPECIALE IFFA.indd 4

22/04/13 15.03

Special

AUTOMATIC CLIPPING MACHINE MOD. CLXP 240 Exhibitor

Inox Meccanica s.r.l.

Product description The main feature of this new clipping machine is its flexibility. This machine equipped with the right accessories can portion thanks clipping the following product: › Roast in elastic net and edible film; › vacuum product to be cooked in tubular thermo-retractile material, “cooking” system; › vacuum product to be cooked in tubular thermo-retractile material “strip-off” system; › salami in collagen or cellulose casing with the possibility of adding on the stuffing pipe a device that allows to use casing elastic netting at the same time › product in synthetic tubolar, of big dimensions such as mortadella and similar product. The clipping machine has to be connected to a vacuum filler which carries out the portioning operation. In the case the vacuum filler is not equipped with a portioning system, our machine is able to carry out the portioning either thanks to a timing-system or by controlling the length of the product. The finished product is discharged from the machine by a special conveyor belt. The exceptional advantages these new models have introduced are: › strong flexibility : it is possible to process a multitude of products, by only changing the stuffing tube, from Ø50 up to Ø240mm, a fast and easy operation › Stuffing hornes available in these sizes: Ø36, Ø48 and Ø60 standard, Ø60 and Ø90 with aspiration system to stuff big products with an high vacuum level. It is possible to stuff products to be cooked minced or cubed, ham, mortadella and similar products. › Stuffing hornes with the DV 3 cutting system, an innovative and patented system, which, in order to stuff whole muscle pieces, makes a perfect cut of the portion to the end of the stuffing tube, guaranteeing a perfect separation of the product and a production velocity highly superior to other systems available on the market Also these stuffing tubes, with an aspiration system in order to pack under vacuum, are available in the measures of Ø60, Ø90 and 110 mm.

459 CASEPACKER – SIDELOADER Exhibitor

FOCKE & Co. - General Packaging

Product description The multi-purpose case packer from FOCKE & CO – General Packaging The models of range 459 stand for versatility and can be used for a variety of products and case types. Food, hygiene products, confectionery or tobacco products can be reliably packed in cases. The machines are designed for non-stop applications in multi-shift operations. All of the modules can be easily and swiftly converted to a new format (product orientation, case size) without using any tools. The application of the case packer from FOCKE & CO provides: › Trouble-free alignment of blanks › Protective handling of products › Maximum packaging stability › Secure sealing and gluing › Suitable for automatic palletizing with FOCKE palletizer 542 › Stable packaging as protection from external influencing factors › Time-saving case handling – easy and swift filling of shelves › Optimum product presentation at the POS › Good accessibility

FP 2/13 SPECIALE IFFA.indd 5

22/04/13 15.03

Special

834 EP SERIE Exhibitor

Deko Holland - Verbas B.V.

Product description Fully-automatic slicing and stacking - ideal for volume production › Easy operation › Large quantities, high speeds › From paper-thin slices to 5 mm thick › Stacked and tiled arrangement possible With a DEKO machine from the 834 EP series, the slice thickness as well as the slicing speed and the manner of stacking can all be adjusted. The machine begins its work with just the press of a button. The cutting wheel of this impressive machine glides through large volumes of meat and cheese with a smooth, steady motion. The result? Perfect slices and virtually no waste. Easy to clean The machines from the 834 EP-serie can be (dis)assembled without any equipment. Because of this it is easy to clean the several components. This makes it simple to come up to standards regarding to hygiene. Models The 834 EP serie contains of the following four models: › 834 SPBS Shaver Slicer without stacking mechanism › 834 EPB Stakcer fully automatic system: stacked and tilled arrangement › 834 EPC Stacker slicer with a conveyor belt › 834 EPBK fully automatic slicer for cheese DEKO slicers, for ease of use, hygiene and a professional appearance All DEKO machines comply with EU health and safety regulations and various ISO standards. Each machine is also provided with the CE Marking. Parts that come into contact with meat and cheese are made of stainless steel. This results in a long service life and low maintenance and service costs. The stainless steel last slice device, combined with the automatic stacking mechanism, minimizes the amount of waste drastically. The machines have an integrated sharpener. Just a single hand movement is required to switch from slicing to sharpening.

BANDALL SEMI-AUTOMATIC BANDING AND BUNDLING EQUIPMENT Exhibitor

Technoclip ZAO, Meatline Ltd.

Product description High capacity, user friendly, low maintenance Bandall equipment automatically places a paper or plastic band, printed in up to full colour, around virtually anything! The unique in-feed system ensures a fast and reliable processing of the banding material. The advantages are numerous: a high production capacity; user friendly operation; very low and clean maintenance. Also, a clean banding process is guaranteed by virtue of the UCS (Ultra Clean Sealing) system installed in all Bandall models. The Bandall is designed to work with very fine banding, considerably reducing material requirements, saving in costs and reducing waste. Variety in arch dimensions and material widths The Bandall is available with very wide ranging arch sizes to accommodate all sizes of products and groups/stacks of products. It is possible to add a thermo-transfer printer to print directly into the band, for example, a bar code, series number, date, etc. Our sales advisors will be pleased to offer you information and advice.

FP 2/13 SPECIALE IFFA.indd 6

22/04/13 15.03

Special

AUTOMATIC TYING MACHINE BINDER XP Exhibitor

Inox Meccanica s.r.l.

Product description Automatic machine for tying in continuous, available in two distinct versions: model “S” for tying salumis already stuffed into casing such as coppa, pancetta, and the model “R” for product in one or more pieces rolled togheater or overlapped like roast and so on. This machine can use for tying various type of elastic and traditional twine: Here are the main technical characteristics of the machine: › This machine can tie products with a minimum diameter from 60 mm. up 200 mm. approx, there are no restriction regarding the length. The cycle phases are as follows: › The operator places the product to be tied onto the loading conveyor belt of the machine. › Once the product arrives in the tying area, the machine automatically initiates the cycle, respecting the distance between one tie and the other one, according to the model, which have been set on the control panel. › Once finished the tying, through the output conveyor belt, the tied product is discharged. › This machine is equipped with a special system that allows to adjust twine stretching. › With the control panel board it’s possible to choose according to the model, the distance of beginning and finish of the tying on the product, the pace of the continous tying on model “S”, or the distance between one tie and the other and the number of twine runs for the model “R”. › The electro-pneumatic installation with low voltage components is controlled by a PLC connected to a touch screen control panel, on which the various cycles according to the product type can be chosen. › The entire structure is made of stainless steel AISI 304 and materials suitable to be used with foodstuff. › The above described machine has been constructed in compliance with the European machines directive about safety, noise and hygiene

BAGS FOR MEAT Exhibitor

Hevel Vacuum B.V.

Product description The main reasons for vacuum packing meat is that it prevents fast dehydration and discolouring, and prolongs the tenability of the product. More and more professionals also use vacuum packing for the process of ripening. If a lower quality bag is used, the product will quickly loose its colour and taste, and therefore its quality. In the market it is a trend to use cheaper and cheaper vacuum bags. After a while it shows that the quality and taste demands of the customer can not be reached anymore. The problem with using cheaper vacuum bags is that the quality of the packed product will go down as well. Many do not realise that using a brand vacuum bag will give good results, without the need for extra investments or changes in the packaging. Because of the very high lucidity of HEVEL Super Export vacuum bags, the perfect presentation for your meat is created. The bags are non-powdered, and together with the high barrier, they slow down the dehydration of the product, and assure a longer tenability, and better taste and colour. After opening, when the oxygen reaches the meat again, the nice red colour will be retained. The small amount of “drip” makes it also possible to save a lot of money with HEVEL vacuum bags. Meat is mainly vacuum packed.

FP 2/13 SPECIALE IFFA.indd 7

22/04/13 15.03

Special

BANDING OPPORTUNITIES - “BRANDING BY BANDING” Exhibitor

Bandall International BV

Product description Bandall banding is a new, unique and innovative way to package and label your products. We offer banding equipment with printed paper or film banding materials: all designs and finishes to your specifications. From simple hand fed semiautomatic models up to fully automatic, integrated in-line total banding solutions - we offer full professional advice from idea conception to finished product. Automatic banding with Bandall offers many benefits, such as: › New and flexible marketing possibilities with lots of printing area - Branding by Banding › Maximum visibility of your product where desired › Banding together of 2 or more products, for example for promotional packaging › Tamper evidence - no undetected opening of products › Reductions and savings in banding materials › Reductions and savings in labour › Reduced waste - a benefit to you and to the environment as a whole › 100% biodegradable printed banding material also available › Shelf Ready Packaging - major reductions in costs and wastage easily achievable At the show we shall demonstrate examples of banding equipment and have many banded products and banding materials to help inspire. And please don’t forget – Bandall banding is GREEN too! Please come along to find out in how many ways Bandall banding can reduce the burden on the environment and at the same time improve brand identity and offer great savings.

ARCTICJET Exhibitor

Schröter Technologie GmbH & Co. KG

Product description Intensive chilling and rinsing systems from Schröter are the ideal addition to your production flow for quick cooling and direct packing of your goods. Different cooling media such as ice water, cold air and brine are at your disposal for the handling of meat products.

CFS COOKSTAR Exhibitor

CFS B.V.

Product description New generation CFS CookStar: Re-defining yield performance and cooking productivity The new generation CFS CookStar spiral oven offers up to 3% higher yield, better quality and up to 15% shorter cooking times than its predecessor. The original was introduced in 1992 and became the benchmark in double spiral cooking. The new generation CFS CookStar Turbo multi-zone roaster adds impingement technology to increase the number and flexibility of applications, speed up cooking and create a crispy product with an extra 0.5 to 1% higher yield. Applications include steamed, coated, marinated and enhanced browned products, roasted bone-in and boneless products and formed products. The machine is available for ‘live’ demonstrations at the CFS Technology Center in the Netherlands.

FP 2/13 SPECIALE IFFA.indd 8

22/04/13 15.03

Special

CFS POWERGRIND Exhibitor

CFS B.V.

Product description CFS PowerGrind: High capacity grinding of fresh and frozen meat With a history of producing some of the industry’s most respected grinders – Wolfking, Krämer+Grebe and Simo joined the company in the nineties – a totally new CFS grinder is a notable event. Premiered on the stand, the CFS PowerGrind 280 is a very high-capacity grinder suitable for both fresh meat and frozen meat blocks without a tool change. Based on the twin-worm concept pioneered by the CFS AutoGrind, it produces fewer fines when grinding blocks than a single worm machine, leading to a higher cooking yield. The new grinder has an enlarged hopper volume and infeed area, meaning up to10 blocks per charge can be loaded without bridging. The machine is also designed for hygiene, and includes a hinged lining and complete separation of product and drive zones.

DEEP FRYER Exhibitor

M. Serra S.A.

Product description Machine to fry, cook, blanch, braise, mix, and homogenise various types of food products. Description: › Machine with rounded and bowl-shaped inner basin with horizontal wands. › Can be tipped and it is supported on two columns forming a solid structure on adjustable footings. › Basin, lining and bench completely made of stainless steel. › Thermally insulated to ensure a very high performance. › All mechanical and hydraulic parts located on one side of the machine. › Electrical panel built into the interior of the structural columns with control devices properly protected. › Easy to clean and to maint. Heating types: Gas oil with a double jacket, indirect steam, or thermal fluid Capacity and dimensions: Fryers are made starting from 200 liters.

BEEF FEET DE-HAIRING CENTRIFUGE MACHINE MODEL D-45/CE Exhibitor

Ollari e Conti International S.r.l.

Product description These machines are suitable for peeling cattle, pig and sheep feet and heads, piglets. The centrifuges are made entirely of AISI304 stainless steel and are equipped with a pneumatic opening system for internal cleaning. They are supplied insulated, with an air-operated product out feed door and an electric control panel with a stainless steel cabinet and low tension 24 V push-buttons.

FP 2/13 SPECIALE IFFA.indd 9

22/04/13 15.03

Special

CFS CUTMASTER Exhibitor

CFS B.V.

Product description CFS CutMaster: Better control means more consistent results CFS is no newcomer to bowl cutters. Krämer+Grebe (part of CFS since 1989) launched the world’s first propeller cutter with a single-sided knife arm in 1945, and the first the vacuum bowl cutter in 1956. The latest generation CFS CutMaster is still evolving, with achievements like the world’s fastest cutting knives (162 m/s) and the revolutionary TopCut knife system. The cutter on the stand features upgraded control capabilities that help processors attain more consistent quality results. Examples include the latest release CutControl software with a touch-screen operator panel, and renewed CutView software for documentation, analysis and reporting. The story continues with the CookBook, a unique way of sharing CFS expertise to produce products in the most safe and reliable way.

DIAFRAGMA Exhibitor

De Jong Engineering Elburg B.V.

Product description Producing a variety of products With our diafragma units we can produce a wide variety of products such as: meatballs, potato balls, noodle portions and various products. One total portion of the stuffer is divided by the pressure dividing system into multiple exact equal portions Benefits: › Wide variety of products. › Easy shaping on the display. › High accuracy in portion weight. › Increasing efficiency by up to 20 percent. › Very high quality. › No damage of product structure. › Product profile stored in program Features: Accuracy and flexibility are the most important characteristics of the system. A number of years ago De Jong Engineering Elburg B.V. introduced its digital pressure dividing system DVS. By means of the DVS-system one flow of product from the vacuum stuffer is divided into several exact equal flows. Every flow has a diafragma for the production of round or oval balls. With the servo-drive it is possible to change the profile of the portion at a certain diafragma opening. The system has a lot of advantages. The most important advantage is: Whatever weight of product you put in, it will all end up as finished product. Moreover there is no water used only for low weight portions. The advantage of this is a clean and dry production. And last but not least is the consistent shape and exact weight repeatedly being produced. Capacity: 0 – 150 cycles / minute Number of heads: 1-15 in 1 to 3 rows Max. diameter balls: 50mm (70mm). Applications Production process in the fastfood or convenience industry: › meatballs › potato balls › ice-cream portions › vegetable products › pastry balls/products

FP 2/13 SPECIALE IFFA.indd 10

22/04/13 15.03

Special

CONTINUOUS CONVEYOR PASTEURIZING AND COOLING VIA WATER, STEAM AND AIR Exhibitor

Sinteco Impianti S.r.l

Product description Continuous pasteurization is obtained through specific mechanical systems and different thermal fluids, below is a list of the most reliable methods used: › Overlapped multi-line core water pasteurizers and coolers “Coretex” used for processing frankfurter sausages with a capacity of up to 10.000 Kg/h including dripping phase. › Continuous surface water pasteurizers/coolers “Suretex” used for processing hams and cooked products with a capacity of up to 2500 p/h including dripping phase. › Spiral air pasteurizers and coolers “Spiroaertex” used for processing packaged and unpackaged food products.

DOUBLE D’S REVOBAND CHAR GRILLING, SEARING AND BAR MARKING UNITS Exhibitor

JBT FoodTech

Product description Double D’s Revoband Char Grilling, Searing and Bar Marking Units are designed to enhance a wide range of finished products, both in taste and appearance. The units can be custom-built to be stand-alone or to integrate with JBT’s range of continuous cookers and ovens. The units offer food processors a whole host of new options for added value products.

CONTINUOUS CONVEYOR COOKING AND STERILE COOLING VIA WATER, STEAM AND AIR Exhibitor

Sinteco Impianti S.r.l

Product description Continuous cooking is implemented by choosing an optimized range of reliable solutions guaranteeing high quality and hygiene standards at reduced investment costs: › Conveyor or tank water cookers “Thermotex Free Cooking and Rack Cooking” used to process packaged and unpackaged food products. › Direct steam conveyor cookers “Nastrosteamex” for fresh pasta. › Multi-layered conveyor cooler “Nastrotex” or spiral cooler “Spirotex” with sterile air in a controlled atmosphere.

COMBO KNIFE Exhibitor

Combicut

Product description Designed primarily to stop overworking the product and give you a better finished product the Combo knife will also save you money with lower running costs.

FP 2/13 SPECIALE IFFA.indd 11

22/04/13 15.03

Special

NEW FOOD SLICERS AVN140 MULTISLICES AND AVM250 FOR BACON

T

he company B.S. srl manufactures and offers the market the new food slicers AVN140 multislices and AVM250 for bacon, designed and built to deposit the sliced product (cheese, ham, cooked ham, speck and other cured meats, cooked meat, vegetables, fish) with a thickness ranging from 0.5 mm to 15 mm. AVN140, the smallest of the series, has an area of cutting of 125mm x 125mm suitable for cutting small calibers such as those used for sandwiches or rolls. Although very compact and easy to handle, the machine achieves very high cutting speeds always ensuring a perfect storage, with the multislices mode too. The loading of the product, in various lengths, is performed continuously and in succession in the cluster. The sliced product is deposited directly on toast, bread, cakes, pizzas, trays that will be moving continuously or rhythmic pace. The machine is also equipped with an innovative system that allows a rapid and complete sanitation, without using any tools. AVM250, mainly suitable for pizza, mortadella and product of large size, reaches sizes up to 250mm x 600mm. The standard AVM250 was renewed for cutting slices of bacon with an output of 160 cuts per minute on 2 rows. Each cut slice will be subsequently divided into two parts, then to obtain a total of 640 pieces perfectly aligned on the conveyor belt. To ensure high precision of the thickness of the slice, the two shear zones will be managed independently by a proper engine and from the operator panel you can adjust diffe-

BS FP 2/13.indd 3

rent heights. On the same line can be connected to each other more slicers, this allows to align the mechanism of the two machines and thus have product rows perfectly in series. The loading of the product takes place continuously and in succession in the cluster. On all BS slicers, while maintaining the same characteristics, it is also possible to install a ribbon to achieve the “portions� with amounts of slices to be chosen that can be stacked or staggered by a programma-

ble distance. The ribbon becomes very useful if you want to deposit more slices on a sandwich, or to prepare the trays with a specific amount of product. All operations can be programmed and stored in order to be able to draw in the shortest possible time data related to a processing previously executed. Finally, the machines are presented ductile thanks to the wheels of which are equipped that allow adaptability to different lines in a short time.

15/04/13 13.10

Special

FOOD CONTAMINATION RAISES HALAL CONCERN

Consumers should be aware of halal norms to avert contamination, mis-selling

B

ack to back local as well as international cases of contamination of halal food have brought into focus the need for general consumers to be aware of halal rules and regulations. Last week, in a startling revelation, UK’s Food Standards Agency was informed by the ministry of justice that a number of meat pies and pastries supplied to prisons in England and Wales were labelled and served as halal but contained traces of pork DNA. The scandal came days after a UK super market found its frozen beef burgers supplied by an Irish meat processor to contain horse meat and pig DNA. Closer home, some residents were shocked to find that restaurants in five-star hotels used same kitchen equipment on halal and pork products. Last month, in the US, a global fast food chain and one of its franchise owners agreed to pay US$700,000 to members of the Muslim community to settle allegations a Detroit-area restaurant falsely advertised its food as being prepared according to Islamic dietary law. “Such instances of food contamination and mis-selling are worrying, and at the same time unacceptable, to any Muslim irrespective of

HALAL FP 2/13.indd 3

the country or region. Such incidents would have offended and distressed a large number of Muslims across the world. Several times such instances are reported even when there are clear regulations for food establishments to abide by while handling and selling pork products,” said Mr. Saif Mohammed Al Midfa, Director-General of Expo Centre Sharjah. Mr. Midfa pointed out that the public should be aware of proper halal rules and regulations while buying food items, stressing role of the Halal Middle East trade fair and congress in educating the Muslim community on how to ensure that what they are consuming is genuinely halal. Halal Middle East will be held at Expo Center Sharjah from December 16 - 18, 2013, that includes Halal Expo and along with Halal Congress Middle East. “Consumers need to be aware the halal norms governing the system for preparing and serving food products... for

example, in case of meat how animals are slaughtered, labelled, stored, refrigerated, cooked and served,” said Mr. Midfa. “Not just consumers, but retailers, suppliers and restaurants too need to be aware that people have a right to know what food they are eating and it is their duty to describe their products correctly. They should adhere to halal norms prescribed by respective authorities and should not mess up products or cut corners by padding out food with cheaper meats to boost profit,” added Mr. Midfa. Besides stressing the need for being aware of halal procedures, it also underscores the requirement of common halal standards for food as well as other products and services, reflecting the importance of a show like the Halal Middle East. Moreover, global attention is now on the UAE, as the Emirates Authority for Standardization and Metrology (ESMA) is working on unified standards for halal food and cosmetics, which, once approved by the OIC, will be introduced in all Islamic countries in the near future.

15/02/13 10.28

Senza titolo-1 1

25/03/13 11.04

Special

TAKING YOU FORWARD

GEA Food Solutions zeigt auf der IFFA neue Entwicklungen bei Fleischverarbeitungs- und Verpackungsmaschinen, mit denen fleischverarbeitende Unternehmen ihre Leistung steigern können. Hygienische Konstruktion und anwendungs-spezifische Lösungen sind das zentrale Thema dieses Messeauftritts, bei dem sechs Produkte ihre Premiere feiern und viele Verbesserungen bekannter Maschinen vorgestellt werden.

GEA auf zwei Ständen auf der IFFA Wertschöpfung hat viele Gesichter, angefangen bei flexiblen Universalmaschinen bis hin zu leistungsoptimierten Lösungen, die exakt auf spezielle Anwendungen abgestimmt sind. GEA Food Solutions präsentiert anlässlich der IFFA 2013 seine neuesten Entwicklungen bei Maschinen zum Zubereiten, Marinieren, Weiterverarbeiten, Slicen und Verpacken von Fleischund Wurstwaren. Die neuen Maschinen und kontinuierlichen Verbesserungsprozesse unterstreichen das in dem Slogan ‘Taking you Forward’ formulierte Kundenversprechen. Das Unternehmen ist auf zwei Ständen vertreten: In Halle 8 (Stand D06) präsentiert sich GEA auf einem eigenen 700 m² großen Stand und in Halle 11.1 (Stand D70) stellt das Unternehmen auf dem Robotic-PackLine-Stand eine komplette automatisierte Verpackungslinie vor.

GEA FP 2/13.indd 3

Innovative Slicer-Technologie Als eine der großen Produktpremieren auf der IFFA wird ein neuer Slicer vorgestellt, bei dem viele Pluspunkte der innovativen Technologie und der hygienischen Konstruktion der Hochleistungsmaschine GEA GigaSlicer auf eine Maschine des mittleren Leistungsegments übertragen wurden. Der GEA DualSlicer hat zwei separate Greifer, so dass er zwei Stangen unabhängig voneinander mit minimalem Übergewicht (Giveaway) schneiden kann. Wie sein großer Bruder ist er sehr leicht zu reinigen und bietet für einen Slicer dieses Formats Hygiene auf einem neuen Niveau. Zu sehen ist der DualSlicer auf dem RoboticPack-Line-Stand als Teil einer arbeitenden Komplettlinie mit dem GEAWägesystem Check3000, zwei neuen automatisierten Beladesystemen von GEA, dem GEA PowerPakRT Thermoformer und dem GEA PowerGuide Linienvereiniger. Auch der GEA GigaSlicer wird kontinu-

ierlich weiterentwickelt und hat nun einen noch größeren Schneidquerschnitt (640 mm), so dass sechs Stangen mit 105 mm Durchmesser geschnitten werden können - womit er aktuell die leistungsstärkste Maschine auf dem Markt ist. Dieser Slicer steht auf dem GEA-Stand an prominenter Stelle in Kombination mit einem GEA OptiScan Röntgenscanner, der das Portionsgewicht im laufenden Betrieb kontinuierlich optimiert.

Weiterer Fortschritt bei horizontalen und vertikalen Verpackungsmaschinen Auf dem GEA-Hauptstand feiert eine komplett neue GEA PowerPak TiefziehVerpackungsmaschine ihre Premiere und läutet den Einstieg des Unternehmens in das Segment der anwendungsspezifischen Verpackungslösungen mit optimierter Leistung ein. Mit der vertikalen Schlauchbeutelmaschine GEA SmartPacker CX400 mit kontinuierlichem Folientransportsy-

23/04/13 12.14

Special

stem stellt GEA seine Vielseitigkeit in puncto Verpackungslösungen unter Beweis. Die bei Supermärkten beliebten QuatroSeal-Beutel und Doypack-Standbodenbeutel können samt und sonders nach nur geringen Modifikationen auf dieser Maschine befüllt werden. Auf diese Weise hat der Anwender eine große Auswahl an attraktiven und preisgünstigen Flachbodenbeutelvarianten, die in den Verkaufsregalen und Displays nicht zu übersehen sind. Und bei Bedarf können mit der gleichen vertikalen Schlauchbeutelmaschine auch standardmäßige Schlauchbeutelverpackungen befüllt werden.

setzt neue Maßstäbe bei Präzision und Hygiene und zeichnet sich durch kompromisslose Flexibilität aus.

Ausgelegt für Hygiene und Produktivität Für den Bereich der Produktvorbereitung werden auf dem Stand eine Weiterentwicklung des Wolfs GEA PowerGrind 280 und der Kutter GEA CutMaster V500 gezeigt. Diese Maschinen zählen in ihrer jeweiligen Klasse zu den Hochleistungsmaschinen und wurden kontinuierlich weiter perfektioniert und aufgerüstet. Diese hygienischen, produktiven und äußerst robusten Maschinen haben innerhalb der Branche neue Maßstäbe gesetzt.