Watching adrenaline-pumping fleet racing at break-neck speeds with 50-foot foiling cats is a world-class spectacle beyond comparison, a whole new level of high-performance sport. But the philosophy behind SailGP is a global race of a different kind, and coming second is not an option.

"What sealed the sponsorship deal for us was SailGP's sustainability vision. They have put environmental and social sustainability at the heart of everything they do, and that's perfectly in line with our vision for ITM and the local communities we work with," says Darrin Hughes, CEO of ITM.

"SailGP has developed the event intending to be the most sustainable sport in the world. And the kiwi team is right up there pushing the same initiatives with their charity partner, Live Ocean Foundation."

Burling and Tuke established Live Ocean because they were concerned for the health of the ocean and the life in it. Through their sport, they champion action for the ocean, taking the message of ocean health and restoration to the world.

SailGP fans will be familiar with the charityprominently displayed on the wing of the New Zealand team’s F50, Amokura as the team’s official ‘Race for the Future’ partner.

▷ The SailGP series is a global sailing event with a focus on sustainability.

▷ The championship consists of multiple events featuring teams of skilled sailors competing on highspeed foiling catamarans.

▷ The first event in New Zealand is in Christchurch on March 18 and 19 this year. There is an Auckland event in 2024.

The Kiwis compete for prize money to support the foundation’s work through SailGP’s worldfirst Impact League. The award-winning initiative sees teams compete not only on the water, but off the water too - scored against positive social and environmental actions.

An integral part of SailGP is that each crew includes male and female athletes - with women racing in the role of ‘Strategist’ or helm assist.

For more information on the teams and current leaderboard, go to www.sailgp.com

The attitude:

While competition among the teams is intense, one attitude unites them: their commitment to raising awareness about global issues.

The boats:

SailGP’s F50 catamarans are built for speed, regularly reaching speeds of over 80km/h. With nine teams made up of the best sailors in the world, all on the same course at once, the competition is fierce.

Best of all, being one-design boats, the F50s are identical, everyone's racing on a level playing field. Winning comes down to skill, talent and teamwork, and who can harness the power of nature best on the day.

The contest:

The global championship visits world-class venues around the world - including, for the first time this year, Christchurch (18-19 March 2023) with the inaugural Auckland stop scheduled for March 2024.

Right from the start, the overriding objective of SailGP was to build an international sporting series that is ultimately 100% sustainable in terms of environmental considerations. In recognition of this, the SailGP competition was declared the winner of the prestigious BBC Green Sports Awards in 2022.

What's it like racing on a supercharged 50-foot hypercat? Here's how New Zealand SailGP Team strategist Liv Mackay describes it:

"It's the type of sailing that once you put your helmet on, you have to be switched on every time. Your adrenaline is pumping for as long as you're racing. Things can go wrong quickly, and the level of trust you need in those around you has to be high. And that's what really bonds you as a team.

"The speeds you're travelling at are phenomenal, and the g-forces are so strong – there are times when you're trying to sprint across the boat, and you're not actually moving anywhere. Other times, you're collecting bruises being slammed from one hull to the other.

Each event comprises a series of two-day fleet races, culminating in the final showdown where the three top teams match up in one thrilling do-or-die race to determine the event champion.

The event in Christchurch will be critical for all the teams as it is the last regatta in the series before the grand final in San Francisco in May 2023.

The crews:

There are nine teams in the global SailGP series, crewed by some of the most successful sailors in the world, including Olympic medallists, America's Cup legends and world sailing championship winners.

"On the first reach, I look around, and everyone's sending it, pushing the boat to the edge of its limits, and you think, this can't be real.

"It's an experience that's hard to describe in words. It's like stepping into a whole different world; high-paced, exhilarating. I can't get enough of it."

#CW003GZ01

• Powered by a single 40V XGT, 18V LXT battery, 12V car adaptor or AC power (batteries not included)

• Can cool between 10°C and -18°C and warm to 60°C

• IPX4 water resistance and enclosed battery compartment

$769

#DML814

• Powered by 18V LXT batteries (not included)

• Foldable compact design for easy transport and storage

• Up to 10 hours runtime (on low) with a 5.0Ah battery

• 3 independently pivoting spotlights

• Telescopic head height from 1,250mm to 2,240mm

$499

18V

Reciprocating Saw (tool-only)

#DJR189Z

• One-handed compact and lightweight design

• 22mm stroke with a cutting capacity of 255mm in wood

• 3,100spm no load speed

• XPT technology to protect against dust and moisture

$239

18V

Drill Driver / Impact Driver Kit

#DLX2411T

• DHP486 Brushless Cordless Hammer Drill Driver

• DTD171 Brushless Cordless Impact Driver

• Includes: 2 x 5.0Ah batteries (BL1850B), Rapid Charger (DC18RC), Carry case

$799

#ML005GX

• Powered by 40Vmax XGT or 18V LXT batteries (not included)

• Up to 15 hours runtime (on low) with a 40V 4.0Ah battery

• IP65 rated for protection against dust and moisture

• 3 stage LED brightness switch

$359

10,000 Lumen LED Worklight

#ML009GX

• Powered by 40Vmax XGT or 18V LXT batteries (not included)

• Up to 14 hours runtime (on low) with a 40V 4.0Ah battery

• IP65 rated for protection against dust and moisture

• 3 stage LED brightness switch

$559

BONUS: Buy any 2x combination of ML009GX & ML005GX and get a free tripod (GM00002073) via redemption

#DTM52ZX3

• Tool-less accessory changes with lever locking system

• Variable speed dial 10,000 - 20,000 OPM no load speed

• 12 angle settings of accessories at every 30° from 0° to 360°

• Small barrel grip for comfortable handling

$349

#DLX6111TX1

• DHP486 Cordless Brushless Hammer Drill

• DTD171 Cordless Brushless Impact Driver

• DGA504 Cordless Brushless Angle Grinder

• DHS660 Cordless Brushless Circular Saw

• DJR187 Cordless Brushless Reciprocating Saw

• DML815 LED Torch, 160 Lumens

• Includes: 2 x 5.0Ah batteries (BL1850), charger (DC18RC), tool bag

$1589

BONUS: LED Worklight #ML003G via redemption

Made from sustainable New Zealand Radiata. Southern Pine’s range of clear, timber cladding is strong, stable and well suited to New Zealand’s coastal environment.

MBIE has introduced a way for modular component manufacturers to be certified and registered to design and manufacture modular building components that comply with the Building Code.

Off-site construction, also known as prefabricated or modular construction, is rising in New Zealand as sustainability, efficiency and productivity increases are sought in the design and construction industry. Prefabricated panels, 3-D pods and even whole buildings are now being manufactured off-site in a factory, then transported and installed on-site.

While off-site construction is a complementary system to traditional construction, there are some key differences where and when LBPs are involved in the manufacturing and installation processes, particularly under the new voluntary modular component certification scheme recently introduced by the Ministry of Business, Innovation and Employment (MBIE).

The scheme, called BuiltReady, will allow modular component manufacturers to be certified and registered to design and/or manufacture modular building components deemed to comply with the Building Code. In most cases, the scheme will allow

▷ MBIE has introduced the BuiltReady scheme for off-site construction certification.

▷ BuiltReady certifies the design, manufacture, transportation, and installation of modular building components as compliant with the Building Code.

▷ Certification bodies will certify manufacturers, who must be approved and registered with MBIE to use the scheme.

▷ BuiltReady enables faster, more consistent building consent approaches for the manufacture of modular components, with the aim of improving productivity, reducing costs and contributing to better environmental outcomes.

for reduced inspections and faster, more consistent building consent applications, helping to reduce costs and on-site building time.

Under the BuiltReady scheme, the entire prefabricated construction process from design (where applicable), manufacture, assembly, transportation, and onsite installation of modular components will be assessed and certified. Figure 1 on the previous page shows the process flow diagram for the BuiltReady framework.

Scheme certification bodies, both accredited by the accreditation body and registered with MBIE, will be responsible for certifying manufacturers. Similarly, manufacturers must be approved by a certification body and registered with MBIE before using the scheme’s compliance pathways.

A certification body will evaluate a manufacturer’s policies, procedures and systems to ensure that the design and/or manufacture of modular components are done competently and reliably to a standard that complies with the Building Code.

These systems include an appropriate quality plan and quality management system, documented design and/or manufacturing processes, employee and contractor systems, including competency and training requirements, and complaints and disputes processes. Ongoing monitoring of a manufacturer will include regular third-party audits and installation inspections.

A registered manufacturer may issue manufacturer’s certificates for the modular components it produces that fall within its scope of certification. Building consent authorities (BCAs) must accept a certificate from a manufacturer certified to design and manufacture as evidence that the specified modular component complies with the Building Code.

BCAs will only inspect work that is not covered by a manufacturer’s certificate. Examples of such work are foundations and site works or other parts of the building not covered by a manufacturer’s certificate.

A manufacturer can apply for BuiltReady certification in one of two ways:

▶ Design and manufacture – manufacture modular building components to a Building Code compliant design that the manufacturer has developed or adapted themselves

▶ Manufacture only – manufacture modular building components to a Building Codecompliant design.

Three types of modular components that can be certified are defined by the Building (Modular Component Manufacturer Scheme) Regulations 2022:

▶ Prefabricated frames and panels include open frames, trusses, enclosed frames, or panels. Examples include floor, wall and ceiling panels or cassettes, frame and truss, panelised building systems, and structural insulated panels (SIPs). They may also include mechanical, electrical, or other systems.

▶ Prefabricated volumetric structures. These are three-dimensional products comprising one or more prefabricated frame or panel products. Examples include laundry and bathroom pods and types of modular units. They may also include mechanical, electrical, or other systems.

▶ Prefabricated whole buildings - the entire building is manufactured off-site.

Manufacturer’s certificates deemed to comply

A registered manufacturer can issue a manufacturer’s certificate to accompany a building consent application and a second certificate to accompany a Code compliance application.

For manufacturers certified to design and manufacture, the manufacturer’s certificate will cover both the design and manufacture of the modular component in the building consent.

For manufacturers certified to manufacture only, the modular component will be deemed to comply, but the building design still needs to be approved by the responsible BCA. Any building work not covered by a manufacturer’s certificate must still be approved by the BCA as per standard practice.

A manufacturer’s certificate issued for a Code compliance certificate is a statement that the modular component has been designed (if applicable), manufactured, transported, stored and installed according to the specifications provided in the initial manufacturer’s certificate, including any approved variations. Given that most offsite construction projects require traditional on-site works and installation, LBPs may encounter more ‘hybrid’ builds in the future and opportunities to learn how to install and integrate modular components.

For traditional construction, any LBP who carries out restricted building work must provide a certificate of design work or a record of building work. However, the Building (Definition of Restricted Building Work) Order 2011 has been amended. It does not apply to building or design work carried out by a registered manufacturer designing or manufacturing a modular component off site.

All relevant records of LBP work by a registered manufacturer will be part of the manufacturer’s own quality management systems, ensuring a record of building work for that building.

A record of building work is still required for site works such as foundations/subfloor framing and any work that falls outside what is specified in a manufacturer’s certificate.

A certificate of design work will be required if a manufacturer is certified to only manufacture modular components.

BuiltReady will be open for applications from manufacturers from mid-2023, and a register of certified manufacturers will be available at www.building.govt.nz.

The BuiltReady pages at www.building.govt.nz contain detailed information about the scheme, including scheme rules and guidance material.

by Amanda Macauley Senior Advisor Design and Implementation, MBIE

by Amanda Macauley Senior Advisor Design and Implementation, MBIE

1. Is a modular component accompanied by a manufacturer’s certificate deemed to comply with the Building Code?

a) Yes – as long as the specified modular component falls within the registered manufacturer’s scope of certification

b) No – a BCA still needs to assess the compliance of the specified modular component

2. Where might an LBP potentially be involved with the BuiltReady scheme?

a) Designing modular components for a registered manufacturer

b) Installation of deemed to comply modular components

c) Site works, including foundations, connections, and any non-modular work

d) All of the above

3. Does a registered manufacturer certified to design and manufacture modular components in the BuiltReady scheme need to supply a Record of Building Work and a Certificate of Design Work for the modular components it manufactures off-site?

a) No – as the building or design work carried out designing or manufacturing a modular component is not considered restricted building work.

b) Yes – the manufacturer will need to supply records of work for the restricted building work undertaken by an LBP off site.

Answers: 1.a 2.d 3.a

This article is from Codewords Issue 110

portal lbp.govt.nz and update your Skills Maintenance activities.

Log-in to the

PACKOUT™ Cabinet

M18 FUEL™ Blower (tool-only)

#M18FBL-0

• Power to clear from 4.6m to clear leaves, jobsite debris, and clippings in a single pass

• Full throttle in under 1 second

• Variable speed trigger

$389

M18™ Fuel Tracksaw (tool-only)

#M18FPS55-0

• 165mm blade size

• 2,500 - 5,600 RPM

• Wrench storage for quick and easy blade changes with onboard tool

EXCL GST

M18 FUEL™ 21” Self-Propelled Lawn Mower (tool-only)

#M18F2LM210

• 533mm steel deck

• POWERSTATE™ brushless motor

• Up to 60 mins runtime with 2 x 12.0Ah batteries*

• Front and side LED lights for 180° visibility in low light scenarios

EXCL GST

M18™ REDLITHIUM™-ION HIGH OUTPUT™

Dual Bay Starter Pack #M18HOSPD802B • 2 x M18™ REDLITHIUM™-ION HIGH OUTPUT™ 8.0Ah batteries • M18™ Dual Bay Simultaneous Rapid Charger $859 EXCL GST

M18 FUEL™ 305mm Dual Bevel Sliding

Compound Mitre Saw with ONE-KEY™

#M18FMS305-0 (tool-only)

• POWERSTATE™ brushless motor

• ONE-KEY™ tool tracking and security

• Adjustable stainless steel detent plate

• A 12.0Ah HIGH OUTPUT™ battery pack delivers up to 330 cuts per charge

$1659

With landfill costs going through the roof and significant building material inflation in recent years, astute builders are starting to review how they approach rebuilds and major renovation projects.

The traditional approach of demolishing existing structures and carting the waste to the dump doesn’t stack up like it used to. In many cases, deconstruction is a much better option whereby valuable materials and fittings can be salvaged to be re-used, re-purposed or on-sold.

While there is no doubt that deconstruction is a better option environmentally, there has always been debate about the economic benefits, with demolition generally considered the cheapest option. But that’s changing.

In 2020, Kāinga Ora carried out a public housing deconstruction project at a Mount Albert development in Auckland known as Martin Leone.

As part of a pilot programme, 8 of the 10 existing houses were removed using deconstruction, and two homes were lifted offsite for resale—the project resulted in an 85% diversion from landfill.

Crucially, the analysis showed the cost and duration of the deconstruction were similar to conventional demolition.

As the land value in established residential areas increases, it often makes sense to demolish the existing house on the site and build a new one, or where regulations allow, build two or more homes.

Nowadays, a better choice is to relocate the house or deconstruct it to recover valuable components that cannot easily be sourced. Some examples include native timber framing, joists, trusses, weatherboards, flooring, multi-paned windows, doors, architectural mouldings, unique plumbing and electrical fixtures.

With kitchen or bathroom renovations, the same principle applies. Cabinetry, appliances, plumbing and light fittings can all be re-used. Before you start a project, talk to your customer about the benefits of deconstruction and make a plan together.

There will be charity groups within your community that will be happy to help. Another option is your local recycling centre; most centres have shops that sell usable household items and building materials.

Other options include Trade Me, Facebook Marketplace, or exchanging materials through sites such as Freecycle (nz.freecycle.org), Waste Exchange (nothrow.co.nz) or by using the Civilshare app (civilshare.co.nz).

To find out more about managing your construction waste, visit the construction waste section at makethemostofwaste.co.nz

The building industry is working to reduce its carbon emissions by using sustainably sourced and reclaimed materials, including locally sourced and recycled or repurposed materials. Reclaimed timbers are a good choice as they release carbon more slowly into the atmosphere and can be repurposed for many years, reducing the need for landfill or burn-off disposal.

The NZ building environment presently accounts for approximately 20% of New Zealand’s total carbon emissions. This statistic needs to dramatically improve, and can be achieved with an environmentally conscious consumer mindset. This requires a change in thinking as regards material selection and performance, and starts with the predominant factor of environmental stewardship and increased focus on using sustainably sourced and reclaimed materials.

This growing demand for sustainably sourced materials both in New Zealand and globally creates a first step of seeing carbon reduction as a critical principle early in the design stage.

Consumers are consciously choosing to use more planet-healthy materials, even though some increased costs may be associated with this decision.

▷ The building industry is using reclaimed materials to reduce carbon emissions.

▷ Consumers are choosing environmentally friendly materials, despite potential increased costs.

▷ Reclaimed timbers release carbon more slowly and can be repurposed for many years, reducing the need for disposal.

Organisations like the NZ Green Building Council, Sustainable Business Network and the Living Future Institute provide resources and knowledge to help architects, builders, and individuals reduce carbon in the NZ building environment.

Progress is being made with better material selection and the reduction of emissions in resource extraction, manufacturing and transportation. There is also a growing global demand for transparency in supply chains and builds, with an expectation that ecosystems are preserved and that more significant conservation efforts are made using ecologically and sustainably sourced materials.

The first step can be as simple as sourcing locally, thus reducing shipping and transportation carbon emissions and avoiding overseas manufacturing processes, which may have little or no regulations protecting the environment.

A second step is the use of recycled and repurposed materials. Recycled hardwood timbers show a slower release of carbon into our atmosphere, which is particularly relevant to reducing global warming.

Avoiding landfills and burn-offs by re-purposing timbers and other materials for another 30-50+ years can significantly reduce carbon. These aspects of environmental consciousness are becoming increasingly relevant as environmental awareness continues to rise.

Interlink has a core commitment to repurpose rustic timbers. It is the national supplier to ITM, providing its customers with easier access to reclaimed timbers, helping minimize environmental impact.

Reclaimed timbers also provide a pleasing aesthetic compared to manmade alternatives, and in addition, many have a colourful history that makes an interesting story.

Reclaimed timbers provide architectural scale and can be used for applications like beams, trusses, mantels, and lintels, as well as simple elements such as internal and external cladding, landscape features, pergolas, retaining walls, and steps, to name but a few..

Rustic timbers provide a sense of uniqueness that is eye-catching and evokes comment. No two pieces are ever the same, and all have a unique backstory and future.

Help reduce our national and global output of CO² by using sustainable and reclaimed materials. Carbon reduction is no longer exclusively for the eco-savvy consumer. It is now a concern at the forefront of decision-making for all individuals, organisations and industries, helping to create change for the better.

The H1 insulation changes may seem a little daunting, but with the new Comfortech® range of Pink® Superbatts® we’ve got your H1 insulation needs sorted.

From locally tested products for standard builds, to a project-specific modelling service for more complex designs. We have the advice and support to help you navigate the new H1 insulation code changes.

And with our nationwide network of BCITO qualified PinkFit® installers, you can be confident we’ve got your H1 insulation needs covered from technical support through to solutions through to installation.

To find out more about how we can help with H1 and installation visit our H1 Hub at comfortech.co.nz

BlondeLine® is an economical wall lining ply that has an attractive face on both sides. It is great for lining your garage or industrial structure. bbi BlondeLine® has been brace calculated using the P21 method by Scion Research New Zealand. It also comes in a prefinished version known as BlondeLine® Plus, this has three coats of a matt UV polyurethane on both sides.

Key features

- Plywood is hard wearing and takes knocks well

- P21 Brace tested

- Both sides are finished to the same standard

- Comes in both raw and a pre-finished version

- Economical

- No stopping or sanding required

For more details or to download the bbi® PlyBrace™ Technical Document, go to www.bbi.net.nz

Endless possibilities.

0800 224 759 / sales@bbi.net.nz www.bbi.net.nz

BlondeLine® Birch

Poplar Core

2400 x 1200 x 9, 12 & 18mm

BlondeLine® Plus Matt UV Coated Birch

Poplar Core

2400 x 1200 x 9 & 12mm

2700 x 1200 x 9 & 12mm

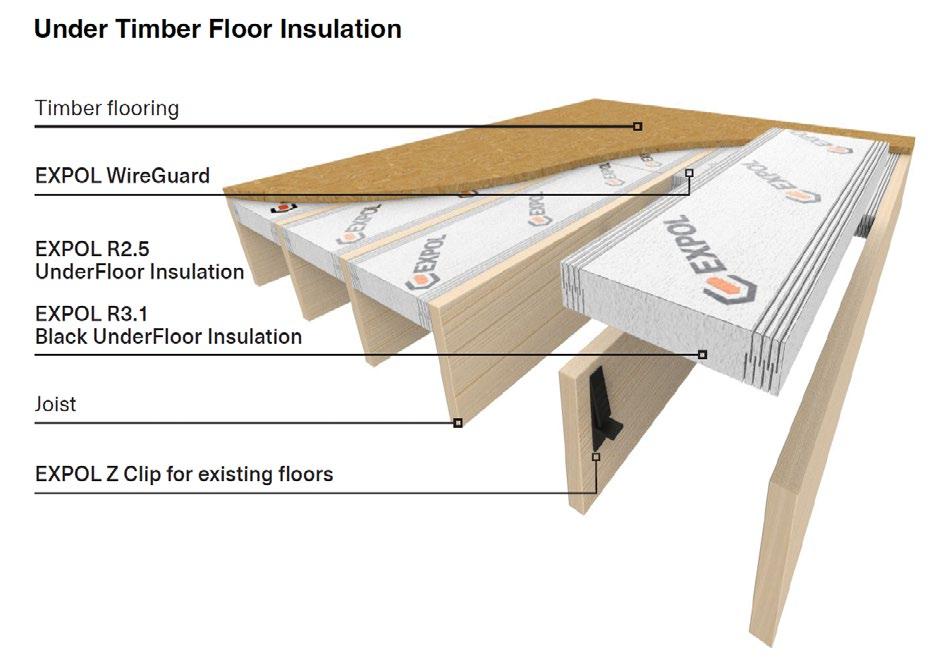

With substantial changes to the Building Code coming into force in 2023, EXPOL's research and development team has been working hard to ensure the building industry will have access to compliant insulation solutions from day one.

EXPOL's Technical Sales Manager, Wayne Watson, explains that the business was eager to introduce a comprehensive range of solutions before next May.

"We've invested significantly to ensure EXPOL has specific solutions catering to every part of New Zealand. Each product has been developed and tested to perform to the new Code requirements," he says.

With specifiers looking for solutions that meet the 2023 Code's Clause H1 requirements, EXPOL has launched a new range of engineered floor and slab insulation products.

"Meeting the energy efficiency provisions of the updated Code will be a key focus for specifiers and trade in 2023. Our new range provides guaranteed performance for floors and slab insulation, giving peace of mind that the build will comply," says Wayne.

Wayne adds that one of EXPOL's strengths is the lengths it goes to deliver on its promise of guaranteed performance.

"For example, instead of a single product development team, we have experienced technical experts based in both the North and South Islands. That means the people developing our range know first-hand what it's like to live and work in the climates they're designing for," he says.

In addition to its updated range, EXPOL has also launched an online calculator that simplifies the process of specifying floor and slab insulation. "The online calculator, available on the EXPOL website, is a game changer for specifiers and builders," says Wayne.

"After entering the required R-value, add your slab area and perimeter and the area-to-perimeter ratio, and then you can submit the details to our technical team. "We'll provide a solution with an R-value that will suit your region," he says.

Are you interested in learning more about the EXPOL Concrete Slab Insulation Calculator? Visit expol.co.nz/ floor-slab-insulation-calculator or scan the QR Code

EXPOL has invested hundreds of thousands of dollars in developing new production facilities that enable the company to recycle polystyrene waste into new products.

"As a manufacturer, we're keenly aware of reducing our impact on the planet. That's why we've taken the major step of adding a recycling plant to each of our seven factories," says Wayne.

"Along with our in-house recycling capability, we've made sustainability a core focus of our product development efforts. As a result, many EXPOL products are now made of either partially or fully recycled polystyrene," he says.

Proudly Kiwi-owned and operated, EXPOL is a family business with a 40-year consistent performance history. Strong relationships with ITM stores, nationwide manufacturing facilities and a fleet of delivery vehicles mean that EXPOL is wellplaced to ensure a continuous supply.

"We know that certainty means everything to our customers, so we work hard to maintain production levels that meet market demand – even during challenging periods like the lockdowns of 2020 and 2021," says Wayne.

Interested in learning more about EXPOL's New Generation floor and slab insulation solutions? Visit expol.co.nz/download/expol-floor-and-slab-insulationsummary or scan the QR Code

Investing in a home improvement project like building a fence or deck is no small decision.

Made from New Zealand radiata pine, our premium grade products can help you deliver the best outcome for your clients.

Find us in your local ITM store.

“We use Genia’s palings on the homes we build.

Attention to detail is essential to us; the dressed finish and consistent grade emphasise the premium quality of our houses.”

- Karl Bryson, Japac Homes Palmerston North

- Karl Bryson, Japac Homes Palmerston North

Genia’s 90mm x 19mm palings are an excellent substitute for rough sawn palings. Dressed (D4) with pencil round edges and sized consistently, they are easier to install and make stain or paint application a breeze.

Scan to view our range of product and available sizes.

Our kiln-dried dressed balusters and balustrade range are perfect for enclosing outdoor areas, such as decks and pools, and provide a modern alternative fencing option.

#7073 – 500ml

• A permanent repair or filler

• Can be used on a variety of surfaces

• Ideal to repair gaps, cracks, holes, dents or replacing rotten or missing wood sections

• Smooth and easily applied

• Will not rot and is waterproof

ADOS Multipurpose Spray Adhesive

#8017 – 575ml

• A spray glue that bonds most materials

• Formulated to give a fast tack-off, low-soak spray and dries clear

• Remains repositionable for 1-2 minutes

• Once positioned, the adhesive will bond within 10-20 minutes. Full cure will take 24 hours.

$15

#446247 – White, 447530 - Grey, 447531

- Black, 447527 - Bronze, 447528 - Ivory

• 300ml cartridge

• High performance joint sealant with excellent weather ability and UV resistance

• Very durable and highly flexible

• Paintable any time after curing

• BRANZ Appraised

• Primerless adhesion to most substrates

$18

GST

#7074 – 1 Litre

• A permanent repair or filler

• Can be used on a variety of surfaces

• Ideal to repair gaps, cracks, holes, dents or replacing rotten or missing wood sections

• Smooth and easily applied

• Will not rot and is waterproof

Evapo-Rust Spray Gel

#1753336 - 500g

• Clings to surfaces to effectively remove rust on all types of mild steel and iron, without the need to soak

• Safe on chrome, copper, brass, aluminium, vinyl and most plastics.

$19

#442764

• 300ml cartridge

• Transparent adhesive and sealant

• Bonds and seals most construction material substrates

• Internal and external use

• Transparent glass-like clarity

• MS Technology

• Good initial grab

$19

The Marshall Weatherization System provides a complete weatherproof construction envelope, delivered by a single supplier.

The full Marshall Weatherization System consists of: [1] Tekton Wall Underlay, [2]

BRANZ appraised, complete technical specification to simplify the design process, backed by a 50-year durability warranty.

Specifically developed for the New Zealand built environment, to stand tough against our unique weather conditions and meet all local code requirements.

Business coach Daniel Fitzpatrick from Next Level Tradie looks at how to use Key Performance Indicators (KPIs) to stay in control.

There's never been a more critical time to use KPIs. Because doing business is hard right now. Material and wage costs are increasing, and construction costs for new homes have risen by 9.6% over the last 12 months, according to RNZ.

Disruption of schedules, jobs being shifted around all the time, a downturn in the market in areas, a shortage of good staff, your existing team having more time off, and expecting more leniency.

All these things add pressure to your profits, cash flow, and day-to-day running of the business.

KPIs allow you to keep a firm handle on all essential aspects of your business. Without having to be involved in every detail.

The truth is, tracking your performance numbers and your progress is the only way to make sure all your hard work will be worth it.

▷ Key Performance Indicators (KPIs) can help to improve staff performance and accountability

▷ Involving staff in the development of their own performance goals can be effective

▷ It is important to keep KPIs simple in order to effectively track progress and improve business performance

#1: Use KPIs to make difficult conversations with staff easier

Ever had a team member who wasn't performing, had a bad attitude, or was making too many mistakes? It's easy for these issues to get kicked down the road. But the longer it goes on, the worse it gets.

The best thing about KPIs is that it's not personal It's just about what the business needs to succeed. When standards are set, everyone knows what's expected. And it's clear if they are meeting the mark - or not.

A drainlayer I have been working with recently had a lot of issues in his team of seven. Jobs were taking too long, and gear was being forgotten, and there was a lack of accountability when things went wrong.

He'd tried motivating them before without success, so he was sceptical about KPIs. But he brought it up at the next team meeting and gave each guy the responsibility of creating their own KPIs (with some guidance).

KPIs ranged from the apprentice turning up on time to the foremen committing to finishing jobs on schedule. Results were starting to happen. Then one day, he overheard his guys comparing their targets and how they would achieve them. That was when he knew it was working.

Remember to only measure your staff on stuff they have influence over!

For example, I once worked with a building company that needed more jobs. The sales rep was not getting the results. It was awkward, there were lots of excuses, and the owners were almost resigned to accepting poor performance even though it was hurting their business.

We worked together on putting KPIs in place. Suddenly it was much easier to have those sales conversations. Combined with the proper support, the focus shifted to meeting targets. Tracking how many new enquiries each week, how many quotes were completed, and followed up.

Conversion rates increased from 22% to 35%, which everyone was happy about - including the rep who was on commission.

How to get your team to perform at their best? It's one of the hardest things about being in business. Unfortunately, if you don't provide the proper structure and direction, even your star players won't be able to deliver.

Does your team know if they are winning or losing each week? Is their definition of success the same as yours? Developing KPIs with your team will get everyone on the same page.

The trick is: KPIs only work if your team owns them.

To get buy-in, it's most effective to get your staff to come up with their own performance goals.

#3: Don't overcomplicate your KPIs - only use the ones you really need

I'm a fan of Xero and job-tracking software. I'll tell you what, though, all of those complicated reports aren't going to help you much.

KPIs are most effective when they are kept simple. In each part of your business, you should only focus on a few key things.

For example, if you want to improve cashflow, the main KPI to watch is how much cash you have in the bank after all bills are paid.

The numbers you're tracking must be identifiable. So you can use them to make smarter decisions. If not, what's the point?

When I work with tradies to improve their profits, I put all their most important KPIs into one dashboard. Then it only takes around 20-30 minutes a month to see how we're tracking. It gives

them laser focus on where to concentrate to get the best results.

This dashboard is a quick check. All the numbers are in one place. The last thing you need is to be hunting out info all the time!

One company I've been working with for the last eight months has gone from significant losses to now making $10k-$20k every single month. This success is mainly down to using the dashboard, and consistency is key.

#4: Never base your KPIs on what others are doing

A word of caution: Don't look at what others are doing and think you should be doing the same. And definitely don't measure success by how big your team is compared to theirs. Take it from me: A bigger team does not automatically mean a bigger profit.

KPIs will vary depending on what stage you are at in your business. When deciding your sales target, this will depend on where your break-even point is, your gross margins, and how much money you want to make for the year. It's individual to you and always will be.

If you're a builder, you won't be getting the same margins as an electrician. If you complete highend work, your margins should also be higher than others in the same industry. It's important to get crystal clear on where your margin should be specifically for your business.

Wouldn't you rather base your pricing and margins on concrete numbers that are right for you and your overheads? So you know that you're making money on every job and know exactly where you're winning and losing?

By now, you'll have realised that not having solid KPIs costs you more than you thought. Lost margins, lost profitability, lost focus.

Knowing precisely what you are aiming for will help you avoid mistakes (or at least see things in time to make adjustments when needed).

You can avoid pricing incorrectly (usually, this happens if you don't know where your target margin should be) and avoid leaking profits by tracking jobs well throughout.

You can avoid booking too many jobs (if you haven't worked out exactly how much work is optimal for your team). This also means no burning out your team (and reputation) with too much work and crazy deadlines.

You can constantly avoid not having money in the bank when you need it and sleepless nights with cashflow worries because you haven't created a cash buffer or know what that should be.

These mistakes all cost you time, stress, and money.

Running a business without tracking your performance is like being the captain of a ship in the dark of night during a storm and trying to avoid the rocks - without a lighthouse to guide the way.

It's time we had a chat.

Book here: www.nextleveltradie.co.nz/nextstep

by Daniel Fitzpatrick Business Coach

1200mm Level

#ST196-2-1200

• 2 x hand grips

•

#ST19579

•

$25

•

2000mm Level

#ST96-2-2000

Electrostatic powder coating

Shock-absorbing removable end caps with anti-slip stoppers

Rectangular aluminium profile with reinforcing ribs

$199

03 768 0441

☐ Hamptons ITM Waltham 03 374 3333

☐ Hillside ITM Hornby 03 349 9739

☐ Kaiapoi ITM 03 327 8829

☐ Kaikoura ITM 03 319 5447

☐ McMullan ITM Hokitika 03 755 8519

☐ McVicar ITM Harewood 0800 191 674

☐ ProBuild ITM Rolleston 0800 445 520

☐ Rangiora ITM 03 313 4862

☐ Timaru ITM 03 688 8074

☐ Waimate ITM 03 689 7427

OTAGO/SOUTHLAND

☐ Dunedin ITM 03 262 1008

☐ E H Ball ITM Invercargill 03 218 3787

☐ Fraser Hardware ITM Balclutha 03 418 0170

☐ Gore ITM 03 208 0649

☐ Mosgiel ITM 03 489 8885