Project Management

What does it take to build the future?

What does it take to build the future?

The Port of Long Beach is innovating by testing and deploying the latest technology –new digital infrastructure to improve cargo tracking and electric yard equipment and trucks as we head to zero-emissions operations.

transmountain.com

sary icon should be used next to the ogo whenever possible

The preferred minimum size is 1.25” wide for th horizontal format. However, if necessary, the ab minimum size is 0.85” wide.

Berth one of Westridge Marine Terminal’s (WMT) updated state-of-the-art facilities will be commissioned imminently. Our new facility will ensure efficient and safe vessel turnaround while also expanding loading capacity to meet global oil demand.

CELEBRATING

Since 1953

YEARS STRONG

The upgraded terminal will include a new three-berth dock complex with fenders treated to inhibit marine growth, new vessel approach systems for safer docking and a Trelleborg dynamic mooring system to ensure vessels are moored safely in all marine conditions. Each berth contains two loading arms and a third arm that is part of WMT’s improved vapour management technology. The new dock layout and orientation allow loaded ships to depart efficiently, while our weather monitoring system continuously measures wave height, visibility and wind conditions.

For more information, visit transmountain.com/westridge-marine-terminal.

CELEBRATING

YEARS STRONG Since

2.50” wide

CELEBRATING

36 LEADERSHIP

New

38 PORT LEADERSHIP

Port of Brookings Harbor's new Port Manager a familiar face

40 CLIMATE CHANGE

Climate resiliency — a megachallenge for ports

By Gordon Feller

July 2023

Volume 4/Issue 2

Publisher

Association of Pacific Ports

Executive Director & Editor

Jane McIvor

Contributors

Molly Bold Eric Bradley

Derek Chow Mario Cordero

Kirk DeJesus Gordon Feller

Darcey Hormann Captain Jamie Marshall

Ian Marr

Shao-Liang Chen, First Vice President/Treasurer, Taiwan International Ports Corporation, Ltd., Taiwan

Kim B. Puzey, Second Vice President, Port of Umatilla, OR USA

Conchita Taitano, Port Authority of Guam, Guam USA

Kimberlyn King-Hinds, Past President, Commonwealth Ports Authority, CNMI

Shu-Hui Cheng, Taiwan International Ports Corporation, Ltd., Taiwan

Sean Clark, Port of Columbia County, OR USA

Lorianna Kastrop, Port of Redwood City, California USA

Thomas Maddison, Republic of the Marshalls Islands

Port Authority, Marshall Islands

Steve Ribuffo, Port of Alaska, AK USA

Sara Young / Kevin Ware, Port of Skagit, Washington USA

Falenaoti Loi-On Fruean, American Samoa Department of Port Administration

Zoran Knezevic, Port Alberni Port Authority, British Columbia Canada

Ian Marr, Port of Nanaimo, British Columbia Canada

Jane McIvor (jane@pacificports.org)

Philippe Critot (philippe@pacificports.org)

The APP has been committed to building partnerships, facilitating dialogue, and encouraging best practices for port governance and management throughout the Pacific since it was established in 1913 as the Pacific Coast Association of Port Authorities.

Throughout our 100+-year history, our objectives have remained consistent. With a focus on collaboration, the APP strives to encourage and facilitate best practices and professional development through conferences, workshops annd strong communications.

Jane McIvor

Konrad Mech Baron Mendiola

John Nedwidek Gary Nelson

Matt Wartian Travis Webster

Advertising

Phone: 323-578-2452

Philippe Critot (philippe@pacificports.org)

Editorial & Association business

Phone: 604-893-8800

Jane McIvor (jane@pacificports.org)

Contents copyrighted 2023

Association of Pacific Ports 300 - 1275 West 6th Avenue, Vancouver, British Columbia Canada V6H 1A6

Phone: 604-893-8800 / E-mail: jane@pacificports.org

The opinions expressed by contributing writers are not necessarily those of the Publisher. No part of this magazine may be reproduced in any form without written permission of the publisher.

EDITOR’S NOTE: Due to the international nature of our membership, spelling within each article remains consistent to the country of origin.

During a recent discussion with APP members, the issue of why they belonged to the Association was raised. The answers were ones we’ve heard before: To learn; to network and build relationships; to provide leadership within the port community; and even to market and promote the capabilities of their own port. All very relevant reasons. There was one comment, however, that stuck out. It was Lorianna Kastrop, Commissioner with the Port of Redwood City, who said: “You just don’t know what you don’t know.” A simple enough statement but it really resonated with the group because it so

aptly and succinctly defines a key element of the APP and the initiatives we undertake.

As we quickly approach the APP’s 109th Annual Conference — August 13 to 16, 2023, hosted by the Port of Long Beach — this is the message I would like members (and non-members) to take away.

Regardless of the size of your port — whether your facility is large or small, includes container or bulk terminals, recreational boating or commercial fishing vessels, or upland businesses, I guarantee you will learn something that you can take back and apply to your own port’s practices.

Looking at the agenda for the upcoming Conference in Long Beach, there is a good balance of presentations from small and large ports hailing from locations around the Pacific Ocean and covering issues that are of importance to all — environmental sustainability, security, digitization, and resiliency planning to name just a few. We have also created numerous opportunities to network with old friends and build new relationships as well as shine a spotlight on our Host Port, the Port of Long Beach, an impressive organization to say the least. I look forward to seeing you soon!

— Jane McIvorThe Port of Skagit will receive $8-million in grant funding from the Washington State Broadband Office to build broadband infrastructure in the under-served rural area near Bow.

The WSBO grant was announced this week, supporting the ongoing rural broadband infrastructure deployment work led by SkagitNet, an entity jointly operated by the Port of Skagit and Skagit PUD.

“The Port has heard from many citizens who need affordable, reliable internet service, so we are working diligently to identify and secure the funding to get fiber optic infrastructure built in those communities,” stated Port Commission President Steve Omdal. “ The trick is finding the right grant opportunity to match with an eligible project area, and we were able to do that in the outlying area around Bow.”

Approximately 630 homes and businesses near Bow and the surrounding area will be served by this project. The total cost of the project is $8.95-million.

The required 10% match is being funded by Skagit County with approximately $895,000 in ARPA funds. Skagit County

committed to providing the match funds required for the project in order to connect another rural area of our community with affordable access to high-speed internet.

“Skagit County’s Board of County Commissioners recognize the importance of connecting our rural communities to fiber optics and appreciate the partnership with the Port of Skagit,” said Board of County Commissioners Chairperson, Ron Wesen. “Broadband is an essential service required for business, education, and public safety. The County is excited to provide the matching funds needed for the Bow project.”

This grant is part of $121-million in grants awarded to communities statewide by the Washington State Broadband Office through the federal Coronavirus Capital Project Fund. Construction for this Bow-area project is anticipated to begin by the end of 2024.

This funding is in addition to funding already secured for projects that will serve Sauk-Suiattle and Fir Island areas. There is still great need for digital access in rural communities throughout Skagit County and the Port continues to identify solutions to meet those needs.

The Board of Port Commissioners has voted to increase annual funding for the Port of San Diego’s Maritime Industrial Impact Fund (MIIF). This fund has supported numerous efforts in communities adjacent to the Port’s maritime industry and terminals, such as youth programs, bicycle infrastructure, air quality improvements, noise reduction efforts, and more.

Established by the Board in 2010, the MIIF was originally funded with $500,000. In 2017, the Board updated the policy to commit one-half of one percent (.5%) of the Port’s annual gross maritime industrial revenue to the program. At its meeting on Tuesday, June 13, the Board voted to increase the annual funding to two percent of the Port’s annual gross maritime industrial revenue. At that rate, it’s estimated that more than $4.8 million will be directed into the MIIF over the next six fiscal years.

“The Maritime Industrial Impact Fund is part of the Port’s overall strategy to support our communities,” said Chairman Rafael Castellanos, Port of San Diego Board of Port Commissioners. “We’ve invested tens of millions of dollars into electrification, we’re improving and building new parks, we reach more than a half a million kids each year through our various environmental education programs, and more. Now, we’re more than doubling our annual funding into the MIIF so we can do even more to improve our neighbors’ quality of life.”

Since 2017, the Port has directed more than $1.7 million from the MIIF to reduce and mitigate maritime-related impacts for those in Barrio Logan and West National City. Examples of MIIF-funded projects and programs to date include the installation of air filters at Perkins K-8 School in Barrio Logan; air filters for residents living adjacent to the industrial bayfront; support for the Monarch School Garden and Nutrition Program; the Port’s Barrio Logan Nighttime Noise Study; and more.

Impacts covered under MIIF include diminished air quality; visual impacts; excessive noise; heavy movement of vehicles or equipment through adjacent residential or commercial areas; or disproportionate degradation or use of public infrastructure, such as roads, streets, or sidewalks. Port member cities and public entities may propose projects for MIIF consideration.

The MIIF is one of many of the Port’s environmental justice initiatives to reduce maritime and industrial impacts in the Portside Communities. To date, the Port has spent more than $63 million on electrification and emissions reduction technologies, including shore power, an all-electric dual mobile harbor crane system, Port fleet electrification, a vessel air emissions capture and control system, clean trucks corridor deployment, and more. These and many other projects and initiatives are identified in the Port’s Maritime Clean Air Strategy.

The Port of Columbia County is pleased to announce Guy Glenn Jr. began on May 30, 2023, as the port’s new Executive Finance Manager. Glenn is taking over for Bob Gadotti, who will retire at the end of July after serving in the position since December 2016.

The Executive Finance Manager plays a critical role at the port, managing all aspects of municipal finance, budget, audit, and compliance with federal and state laws and statutes.

“I want to thank Bob for all he has done over the years to improve the port’s budget process and finance policies. On behalf of the Commissioners and staff, we wish him the best in his retirement and want him to know that his contributions to the port won’t be forgotten,” said Sean Clark, port Executive Director.

Glenn joins the port from Ecological Land Services, where he was the General Manager. He previously spent ten years at the Port of Ilwaco, Washington, first as Finance Director and then nine years as Port Manager. During his tenure at the Port

of Ilwaco, Glenn led and lobbied for the successful allocation of $19.66 million in federal funding for channel maintenance from 2014-2021 along with state and local grant awards totaling approximately $7.56 million over the same period.

“We’re excited to have Guy on board,” said Clark. “He brings a wealth of port experience and financial expertise, and we look forward to his involvement as the Port of Columbia County continues to grow.”

Glenn is a past board member of the Pacific Northwest Waterways Association and Marina Committee Chair for the Washington Public Ports Association. He completed his bachelor’s degree and MBA prerequisites at Colorado State University.

On the night of May 24, Super Typhoon Mawar passed directly over Guam. The strongest typhoon to hit the area in over two decades, Mawar brought sustained winds upwards of 150 miles per hour, intense periods of rainfall and wave heights over 40 feet. The Typhoon had a significant impact on the Port of Guam — Piers F3, F4, F5 and F6 were left with varying degrees of damage; portions of the fender system were damaged or broken off; flooding occurred at the container yard and empty containers as well as Port vehicles were damaaged. Extensive damage was also done to the Hågat and Hagåtña Marinas.

By the morning of May 28, U.S. Coast Guard Captain Nicholas Simmons, Captain of the Port, and Port General Manager Rory J. Respicio, had issued the all-clear from both the waterway perspective and the dockside. Working with partners from the U.S. Coast Guard, the Federal Emergency Management Agency, Matson and many others, Respicio and his team are to be congratulated for their tireless efforts in returning the Port to working condition in record speed.

“The Port received substantial damage to our facilities and our Port Strong Family has been working to get the Port up and running,” Respicio said. “With the leadership of Governor Lou Leon Guerrero and Lt. Governor Joshua Tenorio, along with our Board, we have been working diligently with our industry partners for the last 48 hours and the Port is ready.”

Indeed, the Port Team welcomed Matson's Maunawili on May 28, followed by a vessel from APL and two additional Matson vessels over the next few days.

While the dedication and efforts of the Port of Guam team to restore the Port to working condition — something that was critical to the well-being of the Island's 170,000 residents — were nothing short of stellar, the Port's updates and communications throughout the recovery can serve as a lesson in best practices for all. Throughout the month of June and into July, the Port was posting updates (sometimes more than one) on a daily basis. The information provided was clearly written, succinct, and useful.

The Port of Guam is to be congratulated on a well-executed strategy that not only proved their resiliency in the face of a crisis, but demonstrated a key part of that strategy was keeping stakeholders up to date.

Trans Mountain Corporation has released its 2022 Environmental, Social and Governance (ESG) report, highlightingtheir continued dedication to managing ESG matters responsibly and being transparent about the organization’s progress on ESG topics relevant to our business.

Highlights from the report include Trans Mountain’s progress on 18 ESG commitments and notable achievements including:

• Contributing to Indigenous reconciliation through our ongoing efforts to build lasting and respectful relationships and improving economic opportunities for Indigenous communities.

• More than 3,100 Indigenous workers have been employed on the Expansion Project as of December 31, 2022.

• Approximately 25 per cent of contracts on the Expansion Project have been awarded to Indigenous businesses and partnerships, totaling upwards of $4.8 billion.

• Trans Mountain developed and delivered an Indigenous cultural awareness training module to all employees and contractors in 2022.

• Conducting our operations in a responsible manner that is respectful of the environment and minimizes our impact to water, land and air.

• As part of the Expansion Project, Trans Mountain’s teams conducted more than 18,700 person days of environmental inspection, completed more than 6,400 person days of Indigenous Monitoring, and more than 40,000 person days of technical field studies and monitoring were completed by third-party consultants.

• Trans Mountain has one of the largest archaeological programs in Canada. To protect heritage resources, since 2016 the company has invested more than $40 million in archaeological studies and conducted more than 79,000 shovel tests.

• Remaining steadfast in our focus on safety by protecting the health and safety of Trans Mountain’s employees, contractors, and the public.

• More than 12,500 focused inspections were conducted on the Expansion Project.

• Trans Mountain mentored 36 new hires through the company’s “Green Hand” new and young worker program and expanded the Safety Recognition Program corporate-wide with more than 400 rewards distributed to employees and contractors in 2022. The company is governed by a skilled Board of Directors and driven by a strong leadership team conducting the business ethically and responsibly with transparency and attention to a long-term vision of growth.

Trans Mountain published its greenhouse gas (GHG) emissions reduction plan in late 2022. The company supports the Government of Canada’s ambition to be net zero by 2050 and has set targets to reduce and/or offset Scope 1 and Scope 2 emissions along with a milestone target to reduce absolute GHG emissions by 100,000 tonnes of CO₂e by 2030 (compared to the first full year of operations of the expanded system).

The report was prepared to align with requirements of the Sustainability Accounting Standards Board (SASB) and the Task Force on Climate-related Financial Disclosures (TCFD) and shares our contributions towards the United Nations Sustainable Development Goals (SDGs).

Trans Mountain plays a key role in safely connecting energy sources with people in Canada and around the world. As a responsible company, Trans Mountain strives to balance the economic, social, and environmental impacts of its activities, while serving this important function.

TGS and Kongsberg Gruppen have announced a strategic collaboration to jointly develop integrated data and digital solutions for the offshore wind industry. The aim of the partnership is more efficient use of data and digitalisation to drive faster scaling of offshore wind.

According to forecasts, the offshore wind installed base worldwide is expected to more than quadruple between 2023 and 2030. To support and enable this growth, TGS and KONGSBERG have signed a Memorandum of Understanding agreeing to collaborate on developing solutions that meet offshore wind client needs and jointly engage leading offshore wind developers.

The offshore wind industry holds potential for exponential growth and is widely viewed as being crucial for increasing the production and share of renewable energy needed to reduce emissions in line with global goals set for 2030 and 2050. To enable the scaling speed required to achieve this ambition, the process of prospecting, site assessment, and field development needs to be more efficient. Responding to this need, TGS and KONGSBERG aim to combine high-quality data with digital solutions that are accessible, modular, scalable, and support an open ecosystem.

TGS and KONGSBERG are among the leaders in their respective domains related to offshore wind, with TGS specialising in energy data acquisition, asset management, high-power computing and data analytics. At the same time, KONGSBERG excels in sensors, marine robotics, automation, industrial digital twins and collaboration tools.

“We are delighted to announce this strategic cooperation which will leverage

our joint expertise to deliver high quality data and digital solutions for the offshore wind industry. Together, TGS and KONGSBERG are uniquely positioned to provide reduced development and installation costs, shorter cycle times, and better operational performance for the entire offshore wind project life cycle from site assessment to operations. This partnership signifies another landmark in our ongoing commitment to providing the offshore wind industry with the most advanced energy data and intelligence solutions to improve efficiencies and optimise decision-making,” says Kristian Johansen, CEO at TGS.

“We have a shared ambition with TGS that far more effective use of data and digitalisation will be key to drive and sustain faster scaling of offshore wind. We believe that combining high quality energy data with our marketleading solutions for energy industries digitalisation will assist developers to collaborate better and be more productive. Moreover, “digital by design” field development will underpin a broader application ecosystem and successively unlock additional value propositions to developers,” underlines Håøy.

Since 2021, TGS has actively diversified its energy data and insights into

renewable energy and carbon storage via strategic partnerships, organic initiatives, and acquisitions. TGS’ offshore wind solutions include market intelligence from 4C Offshore, wind and metocean measurements, analytics platforms, subsurface data for site assessment, and data management. TGS has a client base of over 450 companies focusing on offshore wind.

KONGSBERG has been part of the offshore renewables industry since its inception, mainly through ship design and marine systems of Kongsberg Maritime, and subsea data acquisition Template last updated: February 2023 sensors and solutions by Kongsberg Discovery. In 2022, KONGSBERG established Kongsberg Renewables Technologies to accelerate organic and inorganic growth further. Recently, Kongsberg Digital acquired a majority ownership in FutureOn, which offers a cloud-based platform for offshore energy field development (FieldTwin), delivering collaborative working environments with access to distributed data, best-in-class industry software and geospatially accurate data visualization. KONGSBERG has current revenues from offshore wind exceeding 200 mEUR annually.

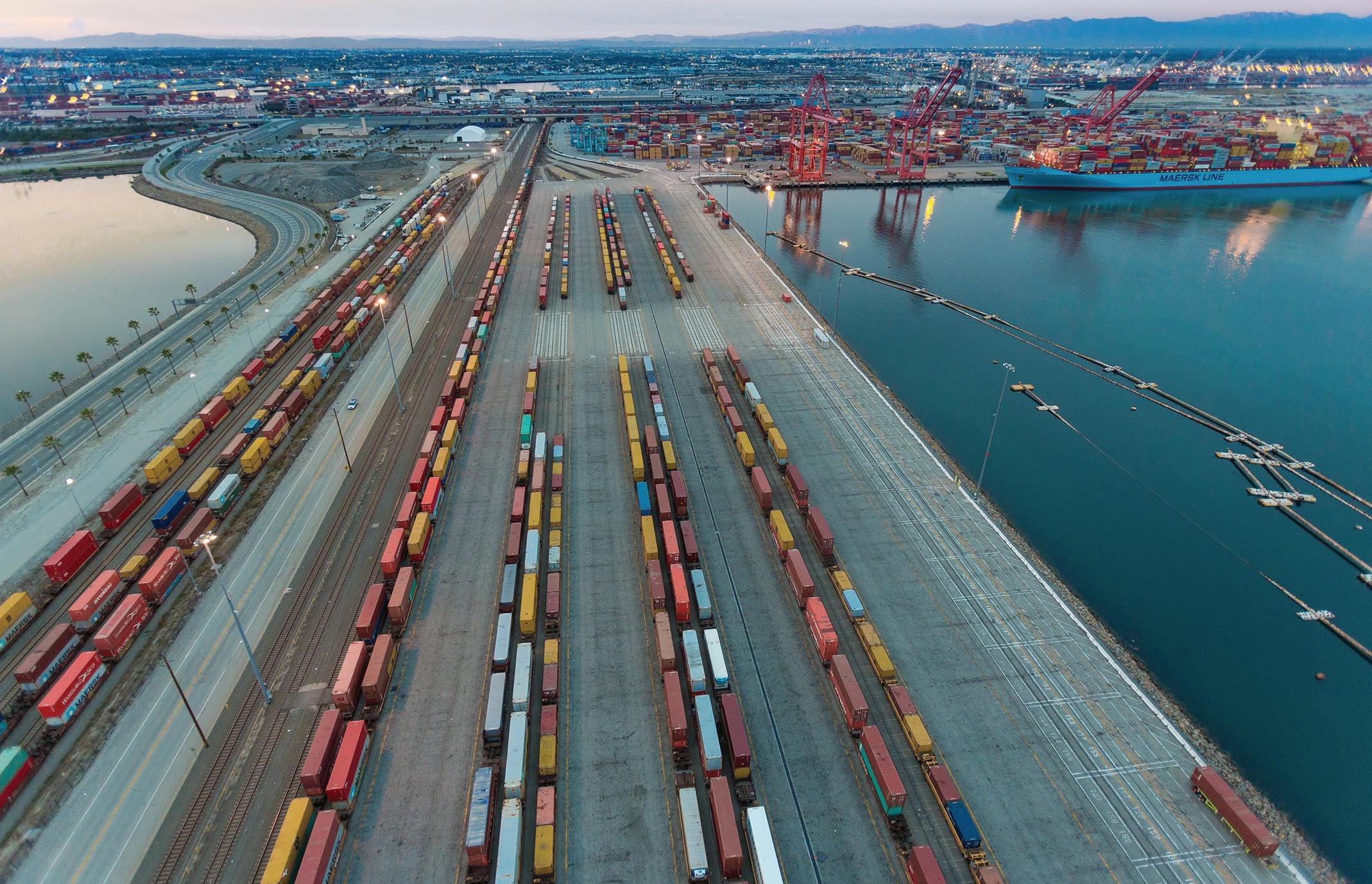

California State Transportation Agency officials Thursday announced a $383.35 million grant for the Port of Long Beach to complete a series of construction and clean-air technology projects aimed at accelerating the transformation to zero-emissions operations and enhancing the reliability and efficiency of cargo movement.

As part of the state’s Port and Freight Infrastructure Program, nearly $225 million will fund a variety of zeroemissions cargo-moving equipment and supportive infrastructure projects across the Port of Long Beach, and include “top handlers” and other manually operated cargo-handling equipment, as well as tugboats and locomotives. The sum is the single largest grant the Port has ever received to support the zero-emissions goals of the 2017 Clean Air Action Plan Update.

Additionally, $158.4 million of the state grant will go toward the planned Pier B On-Dock Rail Support Facility, which will shift more cargo from trucks to on-dock rail, where containers are taken to and from marine terminals by trains. The $1.57 billion facility will be built in phases, with construction scheduled to begin in 2024 and be completed in 2032.

As part of its Clean Air Action Plan, or CAAP, the Port of Long Beach has set a goal of zero-emissions terminal operations by 2030, and zero-emissions trucking by 2035. The Port has a long track record of air quality improvement projects that have dramatically lowered emissions since 2005.

Officials hailed Thursday’s grant announcement as a major step forward in the effort to continue improving the port’s sustainability — especially when it comes to air quality — and to build

rail facilities needed to speed cargo to its destination.

“Thank you Gov. Gavin Newsom for delivering a golden opportunity to increase cargo capacity, improve operational efficiency and put the Port of Long Beach one step closer to reaching its environmental goals,” said Long Beach Mayor Rex Richardson. “The state’s investment will ensure continued growth and resiliency for this vital gateway for trans-Pacific trade.”

“This game-changing grant will make a tremendous difference in our efforts to bring more business and jobs to the harbor, enhance the efficiency of cargo movement and accelerate the Port’s ongoing transformation to zeroemission operations,” said Port of Long Beach CEO Mario Cordero. “I would like to thank Gov. Gavin Newsom and the state Legislature for having the foresight to invest in California’s seaports and to secure our spot as an economic engine for the state and the nation.”

“Thank you to the California State Transportation Agency for funding projects to enhance cargo efficiency at the Port of Long Beach and make the air healthier for our surrounding

communities,” said Long Beach Harbor Commission President Sharon L. Weissman. “These critical projects will make the Port stronger, more competitive and a better neighbor well into the future.”

“The Port of Long Beach has been and will continue to be at the forefront of zero-emissions goods movement,” said Assemblyman Josh Lowenthal, whose district includes the Port of Long Beach. “Today’s announcement is a testament to their ongoing progress and will help the Port continue to be an industry leader in efficiency and environmental responsibility.”

The 2022-2023 state budget sets aside $2.3 billion for supply chain resilience, including one-time funding totaling $1.2 billion for the Port and Freight Infrastructure Program to support goods movement networks affected by the pandemic-induced cargo surge that resulted in unprecedented congestion at California’s seaports.

The program’s goal is to improve the capacity, safety, efficiency and resilience of goods movement through California’s seaports, while also enhancing air quality and growing the state’s economic competitiveness.

Mario Cordero, Chief Executive Officer, Port of Long Beach, has had a unique career path – from practicing law and teaching political science, to serving on the Long Beach Harbor Commission, the Federal Maritime Commission, the L.A. County Economic Resiliency Task Force, and the Board of the Federal Reserve Bank of San Francisco. The broad perspective gained from the diversity of his background has allowed Cordero to lead the Port of Long Beach in a way that balances public responsibilities and surrounding community considerations with the need for ensuring an efficient, fluid, and sustainable supply chain. APP Members who will be attending the APP’s 109th Annual Conference this year — August 13 to 16, 2023 in Long Beach — will benefit from the insights provided by Mr. Cordero as they tour POLB operations both from land and water.

PP: Before we look at the Port and its operations, let’s talk about the strengths you bring to this leadership role.

The broad perspective gained from the diversity of his background has allowed Cordero to lead the Port of Long Beach in a way that balances public responsibilities ... with ... an efficient, fluid, and sustainable supply chain.

MC: Ironically, one of my strengths is not really industry related. Keeping in mind that, for the most part, ports in the U.S. are public authorities, my experience serving for eight years as a commissioner while practicing law full time; and then serving on the Federal Maritime Commission in Washington, provides a perspective that considers public responsibilities. I’m well versed when it comes to the industry dynamic and the movement of containerized trade given my background, but I think my perspective creates some diversity in terms of commitment to both the public sector as well as the local community.

PP: Tell me what it was like to serve on the Harbor Commission and how that prepared you for your current position.

MC: I was appointed by Long Beach’s Mayor at the time, Beverly O’Neill, in 2003. It was a critical period regarding environmental advocacy that had been previously missing from the port’s planning and strategy. Mayor O’Neill was looking for diversity of thought with the ability to consider the community and environmental sustainability. With that in mind, I knew what my mandate was: As a commissioner, I helped lead the Port to the cuttingedge policy that was passed in January 2005, the Green Port Policy. It was the environmental policy that was heard around the world. It clearly articulated the importance of environmental sustainability and moved the Port into a leadership position in this regard.

PP: Indeed, that policy was reflected in the Port’s overall branding but a few

years ago, you changed the branding from “The Green Port” to “The Port of Choice”. How did that change the Port’s strategic planning as well as day-to-day operations?

MC: It didn’t change our prioritization of environmental sustainability. In fact, environmental sustainability has been elevated with the whole national discussion focused on ESG (environmental, social, and governance). In my view, this needs to be a big part of any organization’s portfolio — public or private.

As for our branding, the point we wanted to make with the change is that the port authority not only leads in sustainable development and environmental initiatives but also in customer

service. It’s not just the environmental initiatives that are important but also the business component. Hence, we believe that the type of elevated customer service we provide for cargo owners makes us the Port of Choice. It’s about moving the needle on the environment but also ensuring awareness of our efficiencies in cargo movement.

PP: I’ll provide a quick snapshot of port infrastructure and operations here but would then like to ask what you feel are the unique characteristics of POLB that set it apart from other ports. Readers looking for a more holistic view of POLB statistics will find a wealth of information at www.polb.com

POLB covers almost 12 square miles with 31 miles of waterfront and over one

billion square feet of warehouse space. It has six container terminals moving over nine million TEUs per year, 80 berths and 72 gantry cranes, and boasts 2,000 yearly vessel calls. And it also has five liquid bulk terminals moving over 200 billion barrels of petroleum liquid bulk per year. It is the busiest loaded export container port in the U.S. with over $200 billion in trade and generates over 51,000 jobs in Long Beach, 575,000 jobs in Southern California, and 2.6 million jobs throughout the U.S. Top imports are furniture, machinery and parts, electronics and plastics for containerized cargo, and petroleum bulk for non-containerized cargo. Top exports are wastepaper, agriproducts and plastics for containerized

cargo, and petroleum products for noncontainerized cargo.

So, what sets POLB apart from other ports, both nationally and internationally?

MC: The one area that distinguishes us is our environmental initiatives. In this year and years prior, the metric of cargo volume has not been the most important metric. While it’s certainly significant, our efforts on

the environmental front are equally important to us, especially given our goal of zero emissions by 2030 for terminal operations.

PP: I know that California ports are subject to many state regulations that other ports on the West Coast (including Canada) don’t face. First, are the regulations achievable? And second, how does that impact on California’s competitiveness?

MC: There’s some irony in the fact that, while we are absolutely committed to environmental leadership and recognized for it around the world, we’re also the target of state regulations that are aggressive in my opinion. We don’t just talk about environmental sustainability, we have the metrics and accomplishments to prove our commitment, so it’s difficult to understand why there would be a desire to hamstring California ports with regulations that risk reducing competitiveness.

If I had a crystal ball and was able to see what we looked like in 2030, from an environmental perspective, we’re going to be pretty solid with zero emissions while other ports (both nationally and internationally) will still be trying to figure it out. We’ll have the competitive advantage at that point.

PP: You’ve been publishing statistics on air emissions for several years now and, while the trend has been moving downward, I noticed that there was an increase in 2021. To what do you attribute that?

MC: The data from 2021 is an anomaly given what we experienced during the pandemic and the unprecedented cargo surges. We were backed up by as many as 100 vessels waiting to get into Long Beach or Los Angeles. I believe the next air quality report — now that the congestion has eased — will be greatly improved.

One initiative that we recently undertook was the signing of a Memorandum of Understanding with Los Angeles and Singapore for the establishment of a green shipping corridor. It outlines a commitment to share technologies and best practices that will encourage a transition to net zero emissions in the decades to come.

PP: Would this include a transition to vessels using LNG? Are there plans to develop infrastructure for LNG bunkering?

We don’t just talk about environmental sustainability, we have the metrics and accomplishments to prove our commitment...The recently signed MOU between the Ports of Singapore, Long Beach, and Los Angeles demonstrates a commitment to further best practices toward a zero-emission future. Photo courtesy Port of Long Beach

MC: We don’t plan to have an LNG bunkering facility at this point. The push to zero emissions is going to be a long road for international vessels and carriers. We need to acknowledge that the transition is taking place. LNG is a big component of reducing emissions as compared to bunker fuel, but it’s viewed as a transitional fuel. Going forward, in the coming years we will see exciting emerging fuel options.

PP: Let’s spend some time on current port operations. What performance numbers are you seeing for containerized cargo now that we’re past the worst of the pandemic? Further, are you able to identify trends in terms of the types of cargo being moved?

MC: There has been a drop in container movements, but this is across the board in the U.S. and other countries. If you compare numbers to 2019, i.e., before the pandemic, we’re back to normal. This is going to be a tough

year for us because we’re going to have numbers reflecting a double-digit loss of volume, but we recognize this is compared to unprecedented volume in 2021 and 2022. When you look at the end number for 2022 for POLB, we were down 2.7 percent from 2021 so that’s not much. We’re getting back to some sense of normality.

Regarding types of cargo, even before the pandemic, we were having conversations about how we diversify our portfolio — not just focus on containerized trade or even the containerized cargo component but look to growth in areas of liquid bulk and dry bulk. Not many people realize that California is the number one agri-state in the nation. We have a tremendous

opportunity to accelerate exports, especially from the grain/agriculture community.

We’re also looking at ways to assist in the move toward 100 percent renewable energy. One solution we’re considering is the Pier Wind proposal, a floating offshore wind facility to support the manufacture and assembly of offshore wind turbines. We recently received a study that outlines the steps required to accomplish this and we’re having discussions with stakeholders including the State of California. The goal would be to produce five gigawatts of wind power by 2030 and 25 GW by 2045. At this point, it’s just a concept but if all goes well, we’d start construction by 2027.

The priority should be how do we move 20 million TEUs ... without congestion and bottlenecks, and part of the solution is to expand hours of operations.

So far, people have been really embracing it. We’ve had a lot of accolades for the concept.

PP: You were recently interviewed by the Journal of Commerce where you noted that there will likely be another event that disrupts global trade and you advocated for resiliency plans. What sort of strategy does that look like for POLB?

MC: History will tell you there will always be some event that will impact the supply chain, but I think we can mitigate the negative impacts of these types of events, like the pandemic, if we continue to transform how we operate. This is the reason that I haven’t stepped back from the vision of 24/7 operations. The priority should

be how do we move 20 million TEUs (Long Beach and Los Angeles volumes combined) without congestion and bottlenecks, and part of the solution is to expand hours of operations. We’re not reinventing the wheel here — there are ports around the world that do this when handling that type of volume — but we do need to transform from the status quo so that we’re in a better position to move the cargo better. But to be clear, it takes a collaborative effort in the supply chain — not just the ports or terminals.

PP: I understand that there has been significant investment into creating more fluidity and building greater access to ports, for example, with rail.

MC: That’s right. We’ve spent $4 billion over the last two years and another $2.2 billion expected in the next 10 years with a lot of that funding being earmarked for rail projects. Our goal is to elevate the percentile of containers that commute by rail as opposed to truck given the challenges of the metropolitan area of greater Los Angeles. The projects are designed to elevate our on-dock performance. The recent announcement by BNSF to develop the Barstow International Gateway further affirms our investment in rail.

PP: I imagine that creating efficiencies through digitization has been a key part of your plan. Dr. Noel Hacegaba

(Deputy Executive Director and Chief Operating Officer) gave a presentation at one of our previous conferences about the Supply Chain Information Highway being developed by POLB.

MC: Yes, having an integrated system approach like the Information Highway is critical. We already have buy-in with seven other ports to collaborate on this initiative. Data sharing is part of the solution in moving forward with efficiency, visibility, and transparency. We believe the Information Highway will allow people, no matter what platform or technology is being used, to integrate it into this system so that data can be easily accessed. We see this as the most practical approach, recognizing that every sector has its own platform or portal whether it’s trucking, rail, carrier, or terminal. To us, this is what the future looks like. We are on schedule to move from concept to reality.

PP: For the future, are you able to forecast growth in the longer term for POLB?

We believe the Information Highway will allow people, no matter what platform or technology is being used, to integrate it into this system so that data can be easily accessed.

Also, are there any emerging trends we’ll see become more important for ports?

MC: I don’t perceive growth in the double digits that we saw over the last couple of years. We’ve been using a baseline of activity between 2016 and 2019, the year before the pandemic. We predict soft growth, but that needs to be considered in the proper context. As it stands right now, there is no other gateway that moves even half the number of containers being seen in the San Pedro Bay complex. The challenge for us is how to move that much volume without congestion and bottlenecks.

I believe our current planning answers that question and ties into an emerging trend for ports — the inland port concept. A good example of how that’s playing out is the announcement last year from BNSF Railway

to develop the Barstow International Gateway, a 4,500-acre integrated rail facility that will consist of a rail yard, intermodal facility, and warehouses for transloading freight from international containers to domestic containers. The facility will allow the direct transfer of containers from ships at the Ports of Los Angeles and Long Beach to trains for transport through the Alameda Corridor onto the BNSF mainline up to Barstow. Westbound freight will similarly be processed at the facility to bring trains more efficiently to the ports and other California terminals.

PP: Mario, thank you very much for such great insights.

For more information about the Port of Long Beach, visit: www.polb.com

From infrastructure renewal and supply chain integration to sustainability mandates and stakeholder relationship-building, the port and marine industries have a lot going on these days. Captain Jamie Marshall and Darcey Hormann are at the heart of the action, helping sector players take on ambitious new projects through their work at Colliers Project Leaders, a Canadian firm with more than 30 years’ experience planning and executing complex, large-scale infrastructure initiatives.

Pacific Ports: If you had to sum up the state of today’s port and marine industries in a word, what would it be?

Captain Jamie Marshall (National Sector Lead, Ports & Marine): For me, the word is definitely ‘transformative’. Organizations are trying to plan their way forward while dealing with

changing economic conditions, climate impacts, industry consolidation and technological advancements. They need to build more capacity, which requires close partnerships with Indigenous communities and a variety of stakeholders. Everywhere you look, there’s change going on.

Darcey Hormann (Director, Infrastructure – Western Canada): I agree and would add ‘complex’. We’re seeing big projects with dozens of participants that can take years — sometimes a decade or more — to get to the finish line. And we are here for our clients to see them through. Often, it’s

not just a single project: industry members are engaging in whole programs of change. We’re involved in a mandate for flood protection and enabling infrastructure works in Ontario, which includes 21 sub-projects under that banner. As these and other projects evolve, we’re noticing a shift toward industry greening. This adds another layer of complexity as we move away from fossil fuels and seek more sustainable solutions.

PP: What makes the sector so complex?

DH: There are so many dimensions to it, for one thing. From stakeholder and Indigenous engagement to

“We’re seeing big projects with dozens of participants that can take years to get to the finish line. And often it’s not just a single project...”

overseas shipping and logistics, commuter ferries, recreational boating, offshore infrastructure, power generation and so much more. Each element is very different. The challenges and requirements vary from project to project, but each is truly unique.

CJM: None of it exists in isolation, either. Ports are tightly integrated with road and rail systems, for instance. If you want to increase capacity at the port, you need truck and train infrastructure to keep up. Pilotage is another example. You can bring ships in from sea, but you need pilots to get them to harbour. The systems have to work together, so projects need a very broad, big-picture view. And that picture needs to extend beyond project logistics. You need to consider the natural environment you’re working in, engage the right Indigenous communities, and be prepared to make operational changes to protect species at risk.

PP: Is there a key to managing all those moving parts?

DH: The first thing is to understand the ecosystem and its interdependencies, and to define strategic outcomes. Which industries or professions are affected by a given project? Which government bodies, at which levels, should be involved — or may be potential funders? What does the community look like, and how do you give people a voice in the process? We use tools including stakeholder and engagement sessions to identify risks that the program or owner team may not otherwise be aware of and then use tools like risk registers and workshops to map out dependencies and develop mitigation or risk transfer strategies.

CJM: It’s about knowing who your neighbours are and building relationships with them even before you have a project to discuss. That’s especially critical when you’re working with Indigenous communities. It takes time

to establish a foundation of trust. You can’t just walk in and say, “We want to build this, let’s collaborate.”

PP: Are there other groups that should be included more often?

CJM: It’s important for environmental organizations to be included. Places like Denmark and Singapore offer proven examples of how regulations can drive enabling legislation and promote growth and development in the economic sector. We’re moving that way in Canada. It’s continually improving.

PP: What types of projects are you seeing most today?

DH: Ports are expanding their physical footprints to increase capacity, whether that’s to handle more ship-to-shore traffic or for rail gantry systems, container storage and the like. We’ve actually just started working on a new container terminal project in Eastern Canada. There’s also a lot of focus on optimizing operations to process more cargo faster. And companies are investing in digitalization — integrating the supply chain from end to end with automation, GPS tracking, and Internet of Things sensors. It’s all paperless and connected.

CJM: Environmental safety and sustainability are big drivers as well. Those were the key components of a series of wharf and harbour projects across Canada’s East Coast. We provided comprehensive project management services to more than 30 projects including dredging, wharf reconstruction, sheet pile installation, environmental clean-up management and more — laying the foundation for future investment planning and growth.

PP: How does environmental sustainability factor into some of the other projects you’re overseeing?

CJM: It’s motivating a lot of innovation. The challenge is to be as futureproof as possible. When I was in the ferry industry, we switched from diesel to liquid natural gas as a stepping stone to a lower carbon future. Today hydrogen and electric power are commercially feasible. But even with batteries, there are questions: How long will lithium supplies last? Where will the supply of energy come from? Whatever gets adopted today has to be viable long term.

DH: Commercial and economic goals go hand-in-hand with environmental sustainability. When you’re more efficient and cost-effective, you can scale up more easily to meet demand, with less impact on the marine environment and other habitats. Climate resiliency is more of a common driver. We’re seeing an increase in extreme weather events. As a result, there are more frequent conditions where port operations are impacted, which in turn makes infrastructure resiliency more critical.

PP: Given the scope of today’s projects, where do organizations need the most support?

DH: Stakeholder relations is an area where more support is needed: building relationships, getting partners aligned and establishing common ground. Also, project planning to clearly understand the stated and implied needs of all project participants for all project elements, including the selection of the project delivery model. These projects often have to be phased in over years, with

“Ports are expanding their physical footprints to increase capacity. There’s also a lot of focus on optimizing operations to process more cargo faster.”

realistic milestones and coordination of everything from engineering and permitting to procurement and construction.

PP: Are you feeling positive about what’s ahead for the port and marine industries?

CJM: Absolutely. There’s a lot of energy and urgency behind what’s happening in the sector today. Governments are making capital investments because they know how important it is to have efficient, competitive port, marine and rail systems. The will is there to get Canada’s natural resources into the global economy — by air, land, or sea — so we can

support industry greening and create a more sustainable future.

DH: And there are new priorities emerging, too, like Arctic shipping, which is going to be huge in the decades to come. It’s already happening in Canada. For example, we’ve provided project management and technical expertise for the early stages of a port works project in Northern Canada.

CJM: The port and marine industries have been around for a long time, but this really does feel like the dawn of a new era.

Captain Jamie Marshall is the National Sector Lead for Ports & Marine, at Colliers Project Leaders.

He has more than 40 years’ experience in the marine sector, including nearly a decade in the Canadian navy, and as a captain and executive leader at BC Ferries. He has served on several boards of directors, including the Canadian Ferry Association, Pacific Pilotage Authority, and the Association of BC Marine Industries.

Darcey Hormann is the Infrastructure Director for Western Canada at Colliers Project Leaders. With 16 years’ experience in the transportation-sector supporting operations and heavy construction including Class 1 rail, he has a deep understanding of client perspectives and what organizations need to plan and carry out large-scale infrastructure projects.

For more information on Colliers Project Leaders and its services for the port and marine sector, visit colliersprojectleaders.com or email info@colliersprojectleaders.com.

“Port operators know ports, shippers know shipping. They need a partner who understands the bigger context and how it all fits together, and who can be their representative as the project rolls along.”

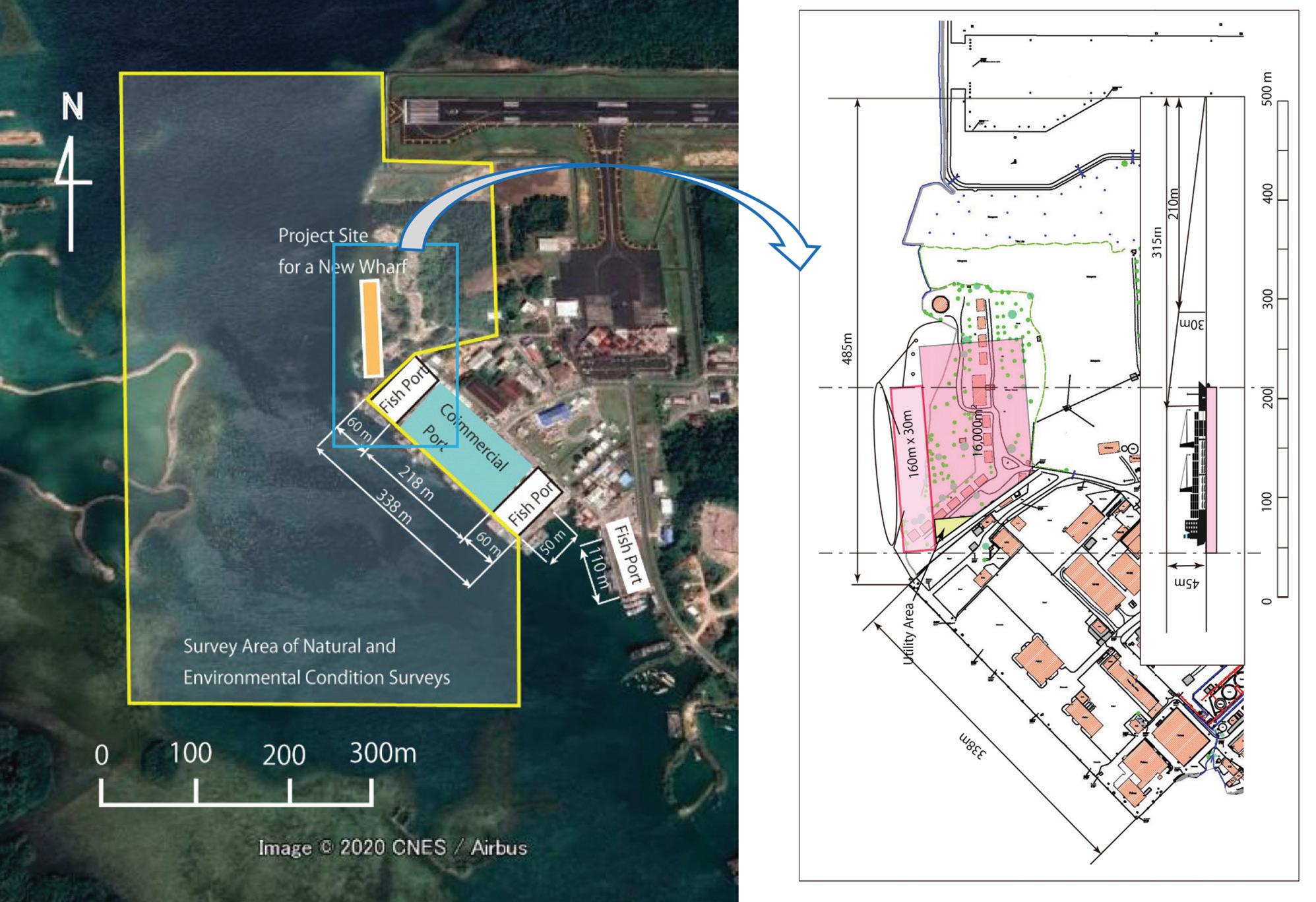

The Federated States of Micronesia (FSM) consists of four major islands (Yap, Chuuk, Pohnpei, Kosrae) located over 2,700 km east and west and surrounding islets of these major islands. With this geographical configuration in the Pacific region, FSM is one of the countries having the largest Exclusive Economic Zones (EEZ). The tuna fisheries in this area have been recording the largest catch in the world (80,000 to 250,000 tons of annual catch).

Located on the northernmost of Pohnpei Island, Pohnpei Port plays extremely important roles not only as a commercial port, but also as a base port for tuna fishing vessels. The 320m long main quay of the port is the mooring facilities not only for international

cargo vessels and interisland passengercargo ships but also purse seine fishing vessels. During high tuna fishing seasons, purse seine fishing vessels congest the port and sometimes hinder the safe maneuvering of large cargo vessels in the basin and increase the risk of accidents, because both ends of the 320m-long main wharf was used for mooring fishing vessels. Under this circumstance, the Pohnpei Port Authority and the Japan International Cooperation Agency has been working for developing an expansion plan of the port with an aim to alleviate congestion and to provide more space for promotion of fish processing and product logistics.

In 2019, the first survey was carried out to examine the feasibility for

the expansion and a conceptual plan for the construction of a new quay for commercial vessels to the north of the existing deepwater wharf, aiming at the separation of the commercial vessels from fish port.

The second survey for the basic design of the new quay could have started in July 2020, but it was suspended for two and half years because of the closure of the Micronesian border as a countermeasure against the COVID 19 pandemic, The survey resumed in March 2023. Field surveys have been carried out not only for engineering purposes but also for the baseline data collection of environmental conditions. The survey is scheduled to propose a concrete project plan by May 2024.

Interferry is heading Down Under for Interferry2023, the 47th Annual Interferry Conference in Hobart, Tasmania, Australia from November 4 – 8, 2023. Hosted by ferry operator and President’s Sponsor Spirit of Tasmania, this conference marks Interferry’s return to Australia for the first time since 2002. The Interferry conference is renowned for attracting top-level decision makers from a wide array of international companies including ferry owners and operators; shipbuilders; designers and engineers; equipment suppliers and manufacturers; and many other related fields.

Interferry2023 will be held at the Hobart Convention and Exhibition Centre (HCEC). Located within The Hotel Grand Chancellor Hobart — the conference hotel — the HCEC is the largest purpose-built conference and events facility in Tasmania and promises to be a fantastic venue. The conference will offer many networking opportunities, and sponsors and exhibitors will enjoy a flexible and open exhibition area in which to display their products and services. Networking opportunities and events include the Welcome Reception at the Henry Jones Art Hotel and Atrium; the Networking Reception at AURA; and the Farewell Dinner at Wrest Point. The Technical Tour of Incat’s shipyard sponsored by Incat and Wärtsilä will be a must-attend event. Incat’s founder Robert Clifford — along with Kim and Craig Clifford — will welcome and guide you during this fitting conference finale.

The conference theme, “The Leading Edge — Elevating the Customer Experience and Sustainability” promises to deliver another set of topical sessions. Customer Experience presentations will demonstrate innovative

ways to improve the passenger experience that can simultaneously improve operators’ efficiency, revenues and ultimately their bottom lines. Sustainability presentations will demonstrate how the ferry industry can reduce its environmental footprint on a total lifecycle basis, along with ways to handle the various types of vessel discharge; new ship construction

methods; and maintenance practices ranging from on-the-run to refits and dry-docking.

For complete conference information, check out InterferryConference. com. Follow Interferry on LinkedIn and @InterferryOrg on Twitter and subscribe to the mailing list via the website.

The Interferry conference is renowned for attracting toplevel decision makers from a wide array of international companies...Ferry operator Spirit of Tasmania is the host sponsor of Interferry's Conference in Hobart, Tasmania.

HOBART, TASMANIA • NOVEMBER 4-8, 2023 • JOIN US!

Interferry2023 will be held at the Hobart Convention and Exhibition Centre (HCEC). Located within the conference hotel – the Hotel Grand Chancellor Hobart – the HCEC is the largest purpose-built conference and events facility in Tasmania and will be a fantastic venue. Our event will feature topical speakers and sessions; many outstanding networking opportunities; an excellent Technical Tour; and sponsors and exhibitors will enjoy an open exhibition area in which to display their products and services. Check the conference website often and follow our social media accounts for news and updates.

“On behalf of Spirit of Tasmania, I look forward to welcoming you to Hobart, Tasmania in November 2023 for the 47th Annual Interferry Conference.”

Bernard Dwyer – CEO/MD, Spirit of Tasmania

Bernard Dwyer – CEO/MD, Spirit of Tasmania

OUR SPONSORS, SUPPORTERS AND PARTNERS

With funding in place — thanks to the efforts of Congressman Derek Kilmer, Representative for Washington’s 6th Congressional District — the Port of Grays Harbor announced the start of the Westport Marina Modernization Plan earlier this year. “Westport Marina plays an important role in the community in terms of job creation and revenue,” said General Manager Molly Bold. “The strength of this maritime core can’t be overstated.” Bold, of course, is referring to the commercial, charter and recreational fishing activities that use Westport Marina as a hub to catch and process an estimated 132 million pounds of Dungeness crab, albacore tuna, salmon and groundfish. For the Port of Grays Harbor,

While many areas of the marina are still in good shape, gradual degradation, and the increasing size of fishing vessels, have taken a toll.

the announcement of funding reflects years of preparation and planning — and years of work to follow…

While Westport has a rich history dating back centuries as the home to the Chehalis Tribal peoples, it was in the 1940s that that the Marina began to take shape as a commercial and sport fishing mecca. When the Port of Grays Harbor was officially established as a public port in 1911, the responsibility of guiding development fell to the Harbor Commission who recognized

its future potential. Throughout the latter half of the 20th century, successive improvements to docks and berthing spaces attracted additional fishery-related enterprises that now define the town’s economy.

“The marina that we see today was completed in the early 1980s and it has been 40 years since the last major ‘visible’ improvement to the floating docks,” said Bold, adding that the Port has been continually investing in “unseen” improvements such as the replacement of tank lines, water outfall capacity, electrical upgrades,

banklines, and dredging. While many areas of the marina are still in good shape, gradual degradation, and the increasing size of fishing vessels, have taken a toll.

Building off a major planning process that was undertaken between 2009 and 2011, the Port embarked on a demand study update with BST Associates that provided a good understanding of the demands for both the Port’s resident fleet as well as the transient fleet sailing the West Coast. “It allowed us to determine the focus of our priorities, both for slips and upland usage,” said Bold. “Once the study was complete, we went through a conceptual planning phase which resulted in the current Modernization Plan developed by Moffat & Nichol.”

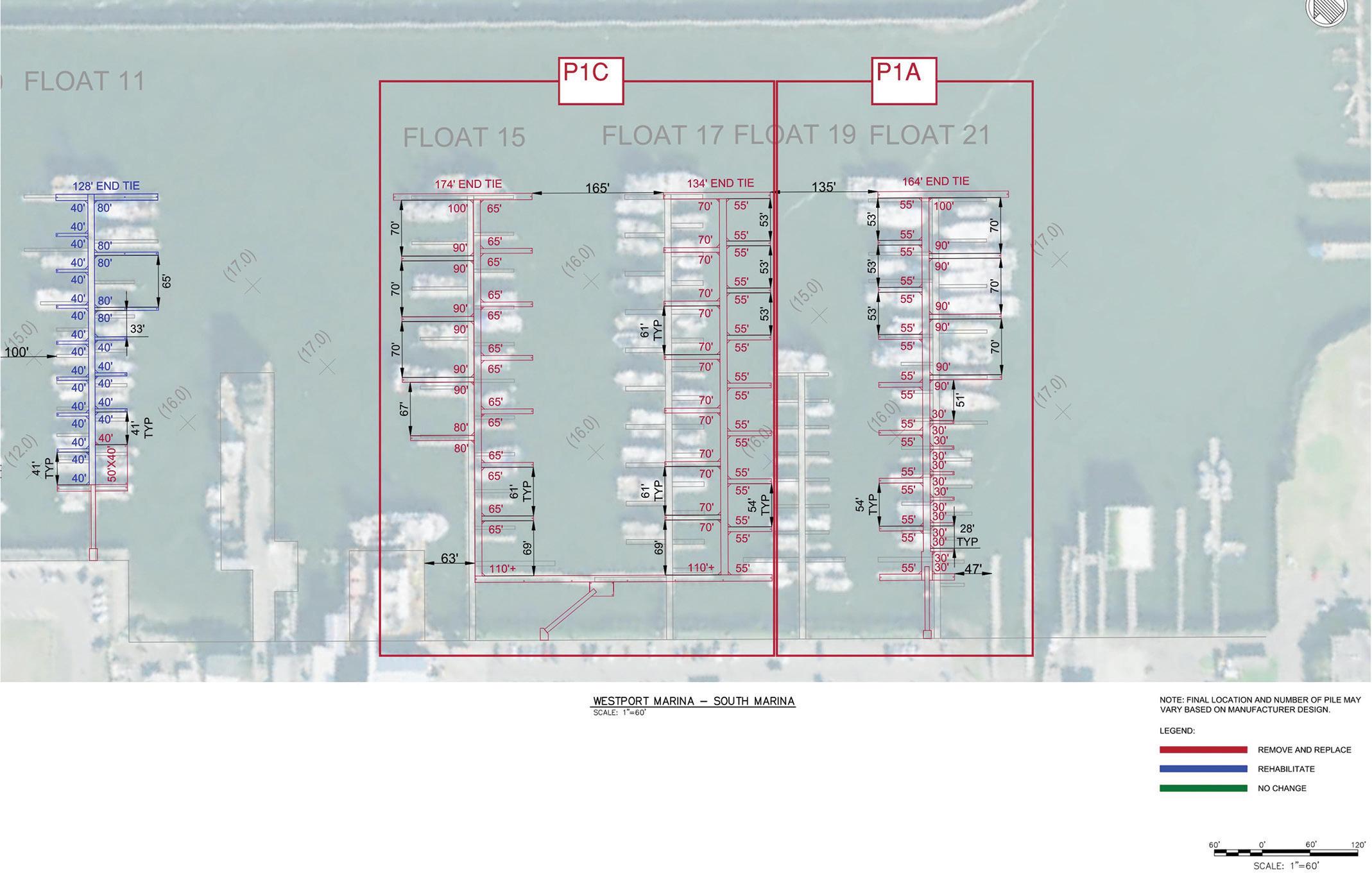

The Port worked with Moffat & Nichol to define goals and targets for the marina modernization, develop and evaluate conceptual approaches and layouts, and define the final phased modernization strategy and associated planning level costs. Three main marina areas were identified: South Marina, Mid Marina, and North Marina, with strategic one-tofive year, five-to-13-year, and 12+-year projects classified into three categories — Removal and Replacement, Rehabilitation, and No Change.

The Plan identified the South Marina as the highest priority area. “The docks in the South Marina, as well as Dock 11 (just outside of the South Marina) have reached the end of their useful service life,” said Bold. “Slip widths are inadequate for the commercial fleet that we’re now seeing come into the Harbor. The Marina was originally built for 40-foot trollers and just last week, we had 12 vessels arrive from the South Pacific that ranged in size from 80 to 105 feet.” Bold added that, while they were able to accommodate them,

an 80-foot boat berthed at a 60-foot finger “stuck out like a sore thumb”.

The first phase of the Modernization Plan (Phase 1A) calls for the removal and replacement of Floats 19 and 21 inclusive of guide piles, utilities, gangways, and abutments, and replacing with one dock tree, approximately located in the Float 21 footprint. Access will be from a new abutment structure and gangway. Apart from a small number of 30-foot fingers retained for recreational boat launch users, 11 new finger piers will range from 55 to 100 feet, with a 150-foot+ end tie. These new features will directly address the need for environmentally friendly and sustainable infrastructure, including light-penetrating docks and the use of lighter weight material where appropriate.

Armed with the approval of the Port of Grays Harbor Commissioners that was given in December 2022, and $750,000 from Community Project Funding Grant secured by Congressman Kilmer, Executive Director Gary Nelson and his team got down to work.

The road ahead

“We’re starting with Docks 15, 17, 21, and 11,” said Bold, adding that the full cost of work for just the South Marina is estimated at upwards of $20 million. “As a port, we’re bound by our financial capacity, so we’d love to embark on a $20 million project in one fell swoop, but we don’t have the funds or the ability to displace half of our fleet for an extended period. Working in phases, we have flexibility to address different parts of the project as funding presents itself.”

The Port will start the project by procuring the preliminary design. “The funding from Kilmer’s Office covers 60 percent of the preliminary design work and the Port will contribute matching funds to complete the

work,” Bold said. The Port was recently awarded $1M from the Washington State Recreation Conservation Office. “The funds will provide a new abutment, 80-foot gangway and 14 slips for recreational users given that the moorage is right next to the boat launch. It is a great first step in a long journey.”

Bold anticipates the preliminary design work to be completed by February 2024 and, depending on the permitting process, to start construction by the 2025 work window. While

“The commercial fishing industry that is dependent on our infrastructure employs over 2,700 people in a town of only 2,500. That really says something about the value we bring to the community and region...

the city’s limitations on water capacity. “The city is aware of this and have been advocating for an increase in step with the Port and other development efforts in the community.”

there is no estimate yet for the completion of construction, Bold did note that preliminary work on Floats 15 and 17 will start before construction on Float 19 and 21 gets underway.

In terms of service interruption, Bold pointed to the major dredging project that the Port of Grays Harbor did in 2019/2020. “It was like a test run,” she said. “Every boat had to move at one point and it took a massive amount of communications between our office and boaters to keep our contractors moving along in a timely fashion. It gave us a taste of what it would be like but because we’re taking this phased

approach, we’re only having one dock that will be impacted.”

Currently, there are no immediate plans for the upland area where five seafood processing operations serve the fleets. “The seafood processors are healthy in terms of business and infrastructure, and we continue to partner with them on infrastructure upgrades — whether it’s dock related or, more importantly, process-water related,” said Nelson. “I’m sure we’ll see more upgrades related to water outfall, but we rebuilt the outfall about 10 years ago and there’s still capacity.” Nelson noted that the bigger challenge may be

In terms of revenue, the Westport Marina piece of the greater portfolio for the Port of Grays Harbor might be small but both Bold and Nelson recognized the importance of operations to the surrounding community. “The Port plays an important role within the town of Westport,” said Nelson. “The commercial fishing industry that is dependent on our infrastructure employs over 2,700 people in a town of only 2,500. That really says something about the value we bring to the community and region, and we are proud to work with Westport to ensure rewarding opportunities.” Docks 15,

Marking the 90th anniversary of the Port of Stockton, Pacific Ports Magazine reflects on the journey that led from a stop along the San Joaquin River during the California Gold Rush to a crucial link in the international supply chain. “As we reflect on the past 90 years, it is important to note the vision, resilience, and collaborative spirit of the countless individuals who have contributed to the Port of Stockton’s success,” said current Port Director Kirk DeJesus. “From the dedicated employees and partners, to the valued customers and supportive community, this is a time to reflect on the Port’s achievements and to look forward to the promising years ahead.”

Today, the Port of Stockton plays a significant role in the economic

development of not only the Central Valley of California but of the United States. Indeed, tracing the development of the Port of Stockton is like tracking the history of the nation from the mid-19th century, through the highs and lows of the 20th century, to the thriving hub we see today.

The origins of the Port of Stockton can be traced as far back as the California Gold Rush of 1849. As gold prospectors flocked to the region, the demand for transportation and trade increased exponentially. The need for a reliable port on the San Joaquin

River, which flows through Stockton, became apparent. In 1849, Captain Charles M. Weber, a German immigrant, recognized this opportunity and established a ferry service across the river. This venture laid the foundation for future maritime activities in the area.

Recognizing the potential for growth, the citizens of Stockton lobbied for federal support to develop a full-fledged seaport. While early efforts were interrupted with the beginning of World War I, subsequent efforts paid off when the United States Congress

Today, the Port of Stockton plays a significant role in the economic development of not only the Central Valley of California but of the United States.

approved the Rivers and Harbors Act in 1890, providing funding for the construction of a deep-water channel to facilitate navigation and trade. The dredging of the San Joaquin River began, making way for larger vessels to access the port.

By the early 20th century, the Port of Stockton had become a crucial

center for shipping agricultural products, especially wheat and barley, which were key commodities in the region. The introduction of the Stockton Ship Canal in 1933 further enhanced the port's capabilities by providing a direct connection to the Sacramento-San Joaquin Delta, opening up additional transportation routes.

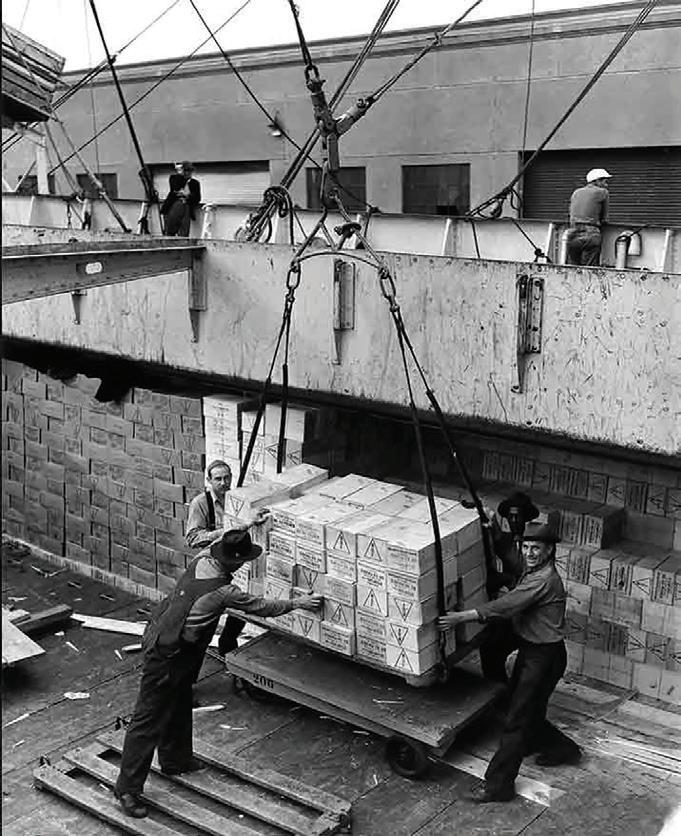

On February 2, 1933, the Port District officially opened with the arrival of the Daisy Grey carrying lumber from Oregon. Throughout the 19030s, the Port built up its infrastructure to include three wharves, three warehouses and the first grain terminal.

During World War II, the Port of Stockton played a vital role in supporting the war effort. The port was utilized for the shipment of military supplies, equipment, and personnel. It also served as a base for the construction and repair of naval vessels. The war years brought substantial growth and development to the port, solidifying its importance in the region.

Following the war, the Port of Stockton underwent significant modernization and expansion. New facilities were constructed, including warehouses, grain silos, and berths equipped with modern loading and unloading equipment. These upgrades enabled the port to handle a wider range of agricultural commodities and increased its capacity to meet growing trade demands.

The 1960s saw a shift in the port's focus towards containerization, reflecting trends in the global shipping industry. The port invested in container cranes and facilities and improved the ship channel to allow for the berthing of large Panamaxclass ships and the efficient handling of containerized cargo. This strategic

move positioned the Port of Stockton to capitalize on the emerging container shipping market, contributing to its continued growth.

In the late 20th century, the Port of Stockton expanded its operations beyond agriculture and container shipping. It diversified its cargo base to include bulk cargo such as cement, petroleum products, and steel.

Environmental stewardship and sustainability have become significant priorities for the Port of Stockton in recent decades. The implementation of initiatives, such as moving toward zero-emission cargo-handling equipment, have earned the port recognition for its commitment to sustainability.

Today, the Port of Stockton continues to thrive. It handles a wide range of commodities, including logs, steel products, heavy project lifts, fertilizer, cement, and dry and liquid bulk cargo as well as rice, coal and

sugar, its top exports in the late 2010s. The port's strategic location, welldeveloped infrastructure, and efficient operations make it a preferred choice for businesses involved in international trade, especially noting its designation as a Foreign Trade Zone.

Looking ahead, the Port of Stockton is always looking to further expand and enhance its capabilities. Plans include the recently announced Rail Rehabilitation and Upgrade Project that will see the replacement and upgrade of approximately 13,400 feet of existing rail. Almost $10 million in funding for the project was made available through MARAD’s Port Infrastructure Development Program. Initiatives like this will not only solidify the port's position as a key economic engine in the region but also contribute to the continued growth and prosperity of Stockton and its surrounding communities.

During the APP’s Winter Conference in Honolulu, Hawaii in February this past year, Board Chair Donna Hais gave an intriguing update that warranted further investigation. With only a few minutes to provide the update, Hais highlighted such initiatives as a new auto import customer for the BC Vehicle Processing Centre, a new passenger-only ferry, plans for the continued expansion of the DP World Container Terminal, and new tenants that could result in new partnerships for the Port. President and CEO Ian Marr provided additional details in a follow up interview.

Starting with the announcement of a new market entrant auto producer, Nanaimo Port Authority, and partner Western Stevedoring, welcomed VinFast, an electric automobile manufacturer based in Hai Phong, Vietnam, that has been recently certified to sell electric vehicles in Canada. “The first shipment of VinFasts cars to Canada arrived in mid-May with 781 VF 8 SUV models as part of an initial shipment of close to 1,900 vehicles,” said Marr, adding that the cars are being processed in Nanaimo before being short sea shipped to Vancouver, and then to dealerships across Canada. Vinfast represents one of three auto shipments to Nanaimo following the Pandemic and the Port anticipates continued demand for the British Columbia Vehicle Processing facility given the current market conditions.

Marr also said that the Port was looking into adding extra capacity this year now that vehicle purchases were returning to pre-pandemic levels. He expects capacity to jump from the current 1,800 vehicles to over 3,000.

Next on the list of new initiatives is the passenger-only ferry service

announced in 2022 and set to start operations by August 2023. Vancouver Island Ferry Company (VIFC) and its operating company, Hullo, has ordered two 354-passenger catamarans, both of which are on their way to the company’s base in Nanaimo and will operate out of the Port’s Passenger Facility at 100 Port Drive. While the Passenger Facility has seen limited cruise ship activity in the past, Marr noted that the Fast Ferry opportunity supports an increased and diversified use of the first-class facility. “The passenger-only service will improve transportation modes to and from Vancouver Island, building exciting economic potential for increased for tourism, commuter options, and improved access to Vancouver’s broad range of health services.” Marr added that, having hired new staff to further develop the cruise

business as the value of promoting tourism in Nanaimo and throughout central Vancouver Island, is another key priority.

The Port and VIFC are adding 400 parking stalls as well as EV charging stations to accommodate travelers. Sailing between Downtown Nanaimo and Downtown Vancouver (docking at the Vancouver Harbour Flight Centre at Burrard Landing), the voyage is expected to take 70 minutes with up to seven round trips per day, every day. VIFC teamed up with Snuneymuxw First Nation to name the vessels “spuhéls” (pronounced spah – els) and “sthuqi ” (pronounced sta – key). Fare prices were announced in early June and range from $39.99 to $59.99 for a one-way trip depending on a passenger’s choice of service level with the higher prices receiving priority

The Duke Point Phase 4 Feasibility study will focus on the Pacific Gateway supply chain needs and the expansion of Duke Point’s container handling capacity...

off-boarding, high-speed WiFi and complimentary snack and beverage. Another area of the Port of Nanaimo’s operations that is poised to see growth is the expansion of Duke Point Terminal. Operated by DP World through a 50-year lease, the terminal’s berth face will be lengthened from 182 metres to 325 metres and the paved storage area will double from approximately 15 to 30 acres. New features will also include improved utilities, expansion of the existing quay crane rail system, a new truck gate, warehouse, administration, and maintenance building, and an upgraded fendering system for large deep-sea vessel mooring. Estimated at a cost of $105 million, funding is coming from a variety of sources, including DP World (Canada), the federal National Trade Corridors Fund, the B.C. Economic Recovery Plan, and, of course, the Port itself. Once completed, Marr expects the terminal will have an annual capacity of 300,000 TEUs.

In more news focused on Vancouver Island’s supply chain, Marr reported additional funding had been received from the National Trade Corridors Fund to study further expansion of Nanaimo’s container-handling capacity. “With the growing needs of Vancouver Island’s population and the broader gateway’s fragility with respect to capacity and the impacts of unplanned events, the role that the Port of Nanaimo can play in facilitating the movement of goods is not fully realized,” he said. The Duke Point Phase 4 Feasibility study will focus on the Pacific Gateway supply chain needs and the expansion of Duke Point’s container handling capacity, the development of land near the Port to support warehousing, distribution, and manufacturing, and the assessment of potential improvements to the transportation of cargo by sea over short distances between Vancouver Island and the Lower Mainland. Marr

Recognizing that growth and expansion of key facilities must be done in line with environmental sustainability, the Port of Nanaimo engaged Dillon Consulting to provide a climate risk assessment document.

expects to issue an RFP for the study by the end of July 2023.

As reported by Hais during the APP Winter Conference, the Port of Nanaimo welcomed GRT Nanaimo to Duke Point. GRT reclaims waste soil for reuse in construction. “It’s a big boost for the Island,” said Marr. “Material that would have otherwise ended up in landfills is now being turned into clean clay and gravel.”

Previously operating from a barge, the Nanaimo location is GRT’s first permanent facility. Contaminated soils are washed, sorted, and reused for industries such as construction.

Another company new to the Nanaimo region is Shift Environmental Technologies which uses ocean technologies to support planning, economic development, and sustainability goals specific to coastal First Nation communities in British Columbia. Made up of a team of engineers, operational specialists, and technologists,

Shift specializes in surface, sub-surface, and aerial methods of coastal monitoring and surveillance to assist in marine and land-use planning. Marr noted that there may be potential to integrate Shift’s technology into their own marine domain awareness system.

Recognizing that growth and expansion of key facilities must be done in line with environmental sustainability, the Port of Nanaimo engaged Dillon Consulting to provide a climate risk assessment document. “The report provided recommendations on the best ways to proceed with infrastructure development,” Marr said. “Combined with City and Regional District studies, we have a very good understanding of the exposures and risks over the next 50 years.”

Given the opportunities for growth and the methodical and strategic approach the Port is taking, Nanaimo is a destination to watch in the coming years.

With an impressive track record of continually being at the leading edge of technological advances, Kongsberg Mesotech is not only celebrating its 50th anniversary this year but is doing so with a new leader in place and a renewed position within the Kongsberg group of business streams. “In January 2023, Kongsberg established a new business area — Sensors & Robotics — to address the growth of advanced underwater sensor technology and solutions within underwater acoustics, sonars, marine and vessel robotics, and positioning systems,” said Martin Fjell, President of the newly formed division that is now identified as Kongsberg Discovery. “Mesotech’s technology has played a key role in contributing to this sector’s growth and now, with Kongsberg Discovery, Mesotech products will play an even larger, integrated role.”

Selected to head up this new business area, Mr. Fjell brings a wealth of experience to the role, including his work on integrating Rolls-Royce into Kongsberg when that company was acquired in 2019. Prior to becoming President for Kongsberg Discovery, Fjell was Vice President, Group Business Development for the Kongsberg Group, and then Executive Vice President, Global Customer Support in Kongsberg Maritime. In addition to being President for Discovery, he is also Executive Vice President for Kongsberg. Before joining Kongsberg in 2013, he gained experience as CFO and Business Development for Umoe Maritime, a Norwegian shipbuilding company; was a partner in Fondsfinans; and an Analyst at Morgan Stanley.

Kongsberg Mesotech is not only celebrating its 50th anniversary this year but is doing so with a new leader in place and a renewed position within the Kongsberg group of business streams.

Having been acquired through Kongsberg Simrad in 1996, Mesotech was originally formed in 1973 to design and manufacture underwater acoustic products, including multibeam imaging, profiling, and diver detection sonars as well as altimeters.

In 1982, they developed the Mesotech 971 Scanning Sonar — a high resolution sonar that was quickly accepted by military and offshore oilfield market users, becoming the standard for all remotely operated vehicle operations.

“The success of Mesotech has been built on the people of the company. Their commitment to innovation and