www.jcjoel.com SYSTEMS

FLYING

POWERED

Contents Stagehand 17206 Pilewind 04 Stagehand Pilewind 08 Pulleys 12

17206 J&C Joel’s EN 17206:2020 UC1 & UC2 Compliant Pilewind Winch

STAGEHAND PILEWIND WINCH

At a Glance

The Stagehand 17206 Pilewind Winch brings additional safety at a cost effective price for theatre lifting applications. It comes fully EN 17206:2020 compliant for UC1 and UC2 and is CE marked. We offer a range of WLL capacities and can vary the number of lines to suit your needs. The standard sizes are shown in the table below. Custom options are available upon request.

Standard Features

• MGM Motor with self-sustaining gearbox

• Two Precima Brakes with manual release

• Load-cell head pulley

• Overload and underload protection

• Two limit switches for end & ultimate travel

• Redundant rope keeps on the drum

• Floor, wall or ceiling mountable

• EN 17206:2020 Compliant for UC1 & UC2

• CE Marked

Optional Features

• Soft start/stop & variable speed

• Absolute Encoder

• Slack line detection

• Motor overheat detection

• Brake release sensors

Local Control Interface

Local Control Features

Every Stagehand 17206 comes with a control box local to each unit, which includes a series of features that ensure EN 17206:2020 compliancy.

The local controller uses a series of toggle switches to set the winch for local control and remote control. A set of LED lights indicate the current status of the hoist, for example whether the system is overloaded or if a limit switch is triggered.

• Local / remote control selection toggle

• Power status indication

• Limit struck indication

• Limit switch bypass for testing

• Overload / Underload detection

• Power source failure indication

• Local e-stop for individual winch

• Local isolator on control box

Page 05

UP LIM BYPASS CONTROL POWER TEST UP LIM BYPASS DO LIM BYPASS ABS LIM LOCAL UP DOWN DO LIM ABS LIM OVERLOAD UNDERLOAD

System Control Schematic

System Control Overview

The Stagehand 17206 is compatible with numerous control systems and J&C Joel can advise on the most suitable for your needs. Full schematics are available on request.

An entry level, cost effective control schematic is shown to the left. This includes a power distribution MCC and a wall mounted controller. The Controller comes supplied with a key for security and an E-stop. The key features are;

• Entry level control which is EN17206:2020 compliant

• Wall mounted control panel

• Winch selection on the control panel

• Key to lock the panel when not in use

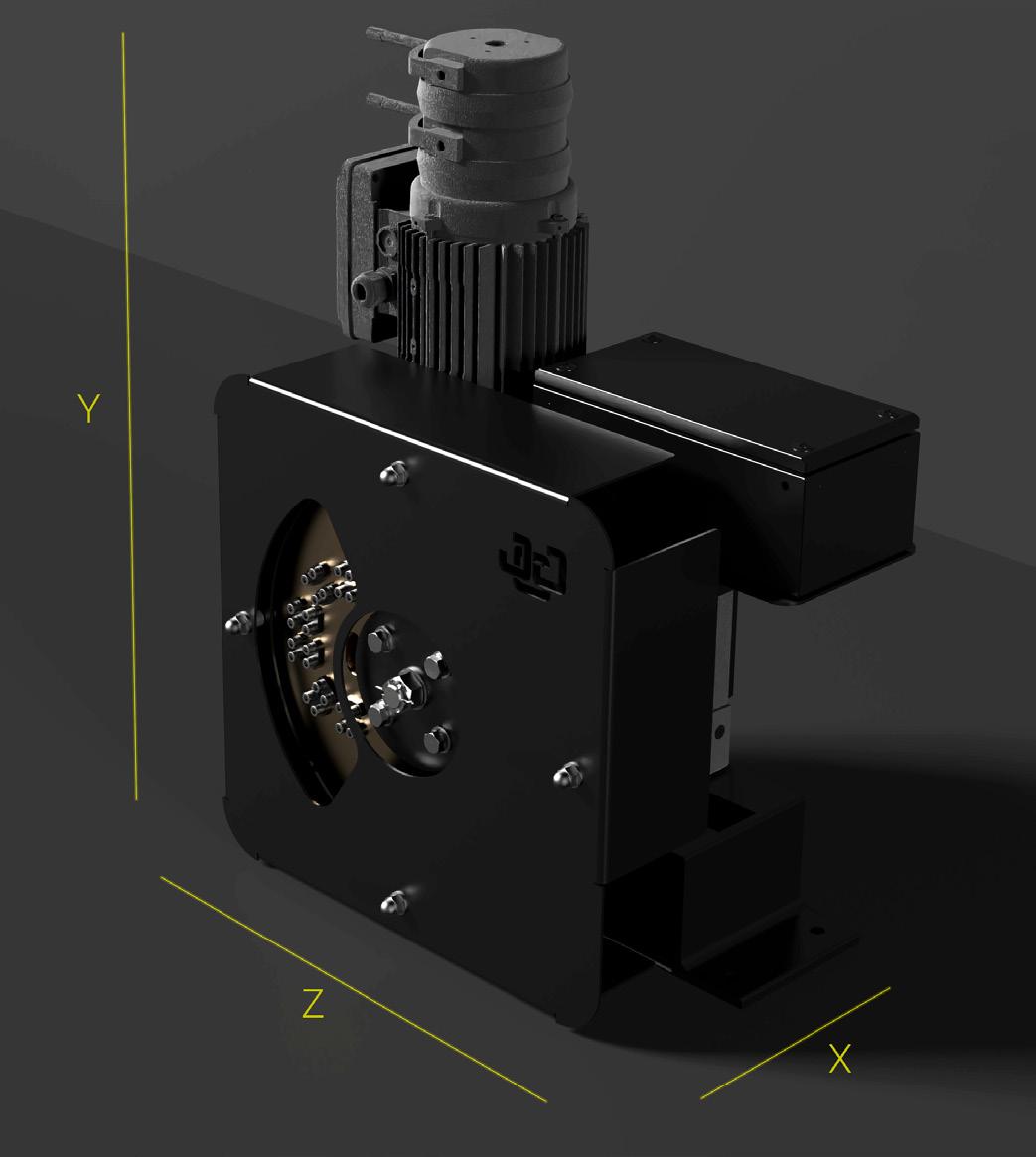

Stagehand 17206 Variants

Centre to Centre Spacing

Set centres with hoists adjacent - See table spacing A Set centres with hoists offset - See table spacing B

Page 06

Pilewind Pilewind MCC 4 core 1.0mm YY cable 4 core 1.5mm YY cable 2 core 1.0mm YY Cable E-Stop E-Stop Key operated Wall Panel Control 380V 50Hz 5 core 2.5mm YY Cable 380V 50Hz

Pilewind

Winch ID WLL (kg) No. Lines Speed (m/s) Travel (m) Rope Ø (mm) Self Weight Power (kw) Dim. X (mm) Dim. Y (mm) Dim. Z (mm) Spacing A (mm) Spacing B (mm) JCJ-PW+300-3 300 3 0.1-0.2 14 5 123 1.1 763 537 467 488 244 JCJ-PW+300-4 300 4 0.1-0.2 14 5 129 1.1 763 537 467 488 244 JCJ-PW+300-5 300 5 0.1-0.2 14 5 136 1.1 763 537 467 488 244 JCJ-PW+300-6 300 6 0.1-0.2 14 5 143 1.1 763 537 467 488 244 JCJ-PW+500-3 500 3 0.1-0.2 12 6 159 1.85 802 601 685 706 353 JCJ-PW+500-4 500 4 0.1-0.2 12 6 166 1.85 802 601 685 706 353 JCJ-PW+500-5 500 5 0.1-0.2 12 6 173 1.85 802 601 685 706 353 JCJ-PW+500-6 500 6 0.1-0.2 12 6 180 1.85 802 601 685 706 353 JCJ-PW+700-3 700 3 0.1-0.2 12 6 194 2.2 888 641 515 536 268 JCJ-PW+700-4 700 4 0.1-0.2 12 6 200 2.2 888 641 515 536 268 JCJ-PW+700-5 700 5 0.1-0.2 12 6 207 2.2 888 641 515 536 268 JCJ-PW+700-6 700 6 0.1-0.2 12 6 214 2.2 888 641 515 536 268 JCJ-PW+1000-3 1000 3 0.04-0.08 12 6 206 1.5 998 706 506 526 263 JCJ-PW+1000-4 1000 4 0.04-0.08 12 6 212 1.5 998 706 506 526 263 JCJ-PW+1000-5 1000 5 0.04-0.08 12 6 219 1.5 998 706 506 526 263 JCJ-PW+1000-6 1000 6 0.04-0.08 12 6 226 1.5 998 706 506 526 263 JCJ-PW+300-3-T 250 3 0.1-0.2 22 5 128 1.1 763 537 467 488 244 JCJ-PW+300-4-T 250 4 0.1-0.2 22 5 134 1.1 763 537 467 488 244 JCJ-PW+300-5-T 250 5 0.1-0.2 22 5 141 1.1 763 537 467 488 244 JCJ-PW+300-6-T 250 6 0.1-0.2 22 5 148 1.1 763 537 467 488 244 JCJ-PW+500-3-T 450 3 0.1-0.2 18 6 164 1.85 802 601 685 706 353 JCJ-PW+500-4-T 450 4 0.1-0.2 18 6 171 1.85 802 601 685 706 353 JCJ-PW+500-5-T 450 5 0.1-0.2 18 6 178 1.85 802 601 685 706 353 JCJ-PW+500-6-T 450 6 0.1-0.2 18 6 185 1.85 802 601 685 706 353 JCJ-PW+700-3-T 650 3 0.1-0.2 18 6 199 2.2 888 641 515 536 268 JCJ-PW+700-4-T 650 4 0.1-0.2 18 6 205 2.2 888 641 515 536 268 JCJ-PW+700-5-T 650 5 0.1-0.2 18 6 212 2.2 888 641 515 536 268 JCJ-PW+700-6-T 650 6 0.1-0.2 18 6 219 2.2 888 641 515 536 268 JCJ-PW+1000-3-T 900 3 0.04-0.08 18 6 211 1.5 998 706 506 526 263 JCJ-PW+1000-4-T 900 4 0.04-0.08 18 6 217 1.5 998 706 506 526 263 JCJ-PW+1000-5-T 900 5 0.04-0.08 18 6 224 1.5 998 706 506 526 263 JCJ-PW+1000-6-T 900 6 0.04-0.08 18 6 231 1.5 998 706 506 526 263

Page 07

STAGEHAND PILEWIND WINCH

At a Glance

The Stagehand Pilewind Winch is J&C Joel’s entry level winch for theatre lifting applications. We offer a range of ELL capacities and can vary the number of lines to suit your needs. The standard sizes are shown in the table below. Custom options are available upon request.

Standard Features

• MGM Motor with self-sustaining gearbox

• Single or double Precima Brakes

• Two limit switches for end & ultimate travel

• Redundant rope keeps on the drum

• Local control - up, down, e-stop

• Floor, wall or ceiling mountable

• CE Marked

Optional Features

• Load-cell head pulley

• Overload and underload protection

Standard Pilewind - Girts Control

• Soft start/stop & variable speed

• Absolute Encoder

• Slack line detection

• Motor overheat detection

• Brake release sensors

System Control Schematic

Local Control Overview

Every Stagehand Pilewind Winch comes with a control box local to each unit. This includes an up, down and local e-stop.

System Control Overview

The Stagehand is compatible with numerous control systems and J&C Joel can advise on the most suitable for your needs. Full schematics are available on request. An entry level, cost effective control schematic is shown to the left. This includes a power distribution MCC and a wall mounted controller. The Controller comes supplied with a key for security and an E-stop.

It is also possible to offer the Stagehand equipped with a cost effective soft start and stop add-on which uses a variable frequency drive.

Page 09

Pilewind MCC 4 core 1.0mm YY cable 2 core 1.0mm YY Cable 4 core 1.5mm YY cable E-Stop E-Stop Key operated Wall Panel Control Pilewind Pilewind 380V 50Hz 5 core 2.5mm YY Cable 380V 50Hz

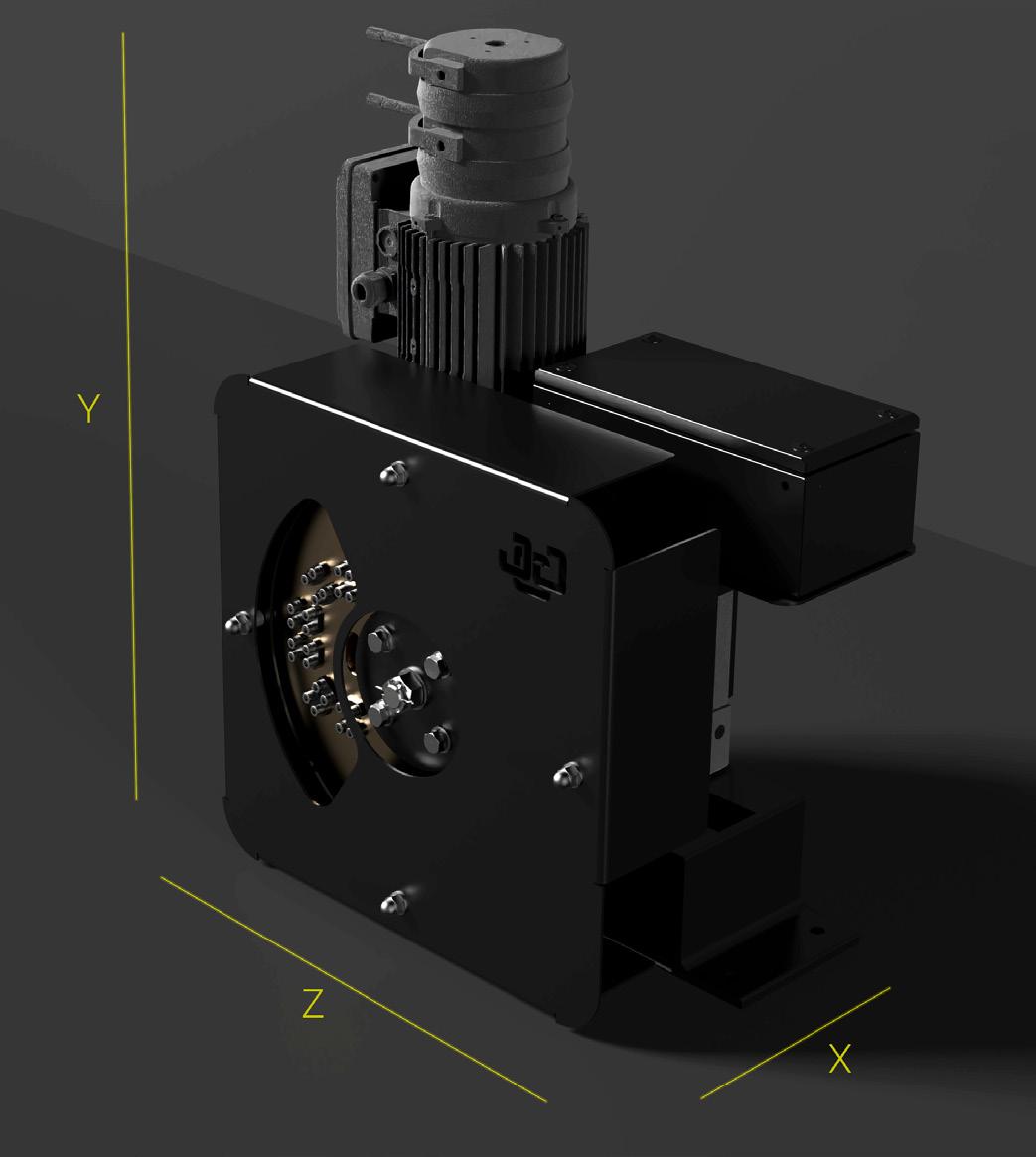

Stagehand Variants

Please note, the “-F” range requires use of the soft start and stop add-on.

Centre to Centre Spacing

Set centres with hoists adjacent - See table spacing A

centres with hoists offset - See table spacing

Page 10 Winch ID ELL (kg) No. Lines Speed (m/s) Travel (m) Rope Ø (mm) Self Weight Power (kw) Dim. X (mm) Dim. Y (mm) Dim. Z (mm) Spacing A (mm) Spacing B (mm) JCJ-PW-250-3 250 3 0.15 - 0.30 14 5 145 1.1 348 760 600 368 184 JCJ-PW-250-4 250 4 0.15 - 0.30 14 5 154 1.1 360 760 600 380 190 JCJ-PW-250-5 250 5 0.15 - 0.30 14 5 161 1.1 373 760 600 393 196 JCJ-PW-250-6 250 6 0.15 - 0.30 14 5 168 1.1 385 760 600 405 202 JCJ-PW-500-3 500 3 0.15 - 0.30 12 6 172 2.2 376 845 600 396 198 JCJ-PW-500-4 500 4 0.15 - 0.30 12 6 179 2.2 389 845 600 409 205 JCJ-PW-500-5 500 5 0.15 - 0.30 12 6 186 2.2 402 845 600 422 211 JCJ-PW-500-6 500 6 0.15 - 0.30 12 6 193 2.2 414 845 600 434 217 JCJ-PW-1000-3 1000 3 0.04 - 0.07 12 6 199 1.5 404 725 868 424 212 JCJ-PW-1000-4 1000 4 0.04 - 0.07 12 6 206 1.5 417 725 868 437 218 JCJ-PW-1000-5 1000 5 0.04 - 0.07 12 6 215 1.5 429 725 868 449 225 JCJ-PW-1000-6 1000 6 0.04 - 0.07 12 6 222 1.5 442 725 868 462 231 JCJ-PW-1000-3-F 1000 3 0.15 - 0.30 12 6 199 1.5 404 725 868 424 212 JCJ-PW-1000-4-F 1000 4 0.15 - 0.30 12 6 206 1.5 417 725 868 437 218 JCJ-PW-1000-5-F 1000 5 0.15 - 0.30 12 6 215 1.5 429 725 868 449 225 JCJ-PW-1000-6-F 1000 6 0.15 - 0.30 12 6 222 1.5 442 725 868 462 231 JCJ-PW-250-3-T 200 3 0.15 - 0.30 22 5 145 1.1 348 760 600 368 184 JCJ-PW-250-4-T 200 4 0.15 - 0.30 22 5 154 1.1 360 760 600 380 190 JCJ-PW-250-5-T 200 5 0.15 - 0.30 22 5 161 1.1 373 760 600 393 196 JCJ-PW-250-6-T 200 6 0.15 - 0.30 22 5 168 1.1 385 760 600 405 202 JCJ-PW-500-3-T 450 3 0.15 - 0.30 18 6 172 2.2 376 845 600 396 198 JCJ-PW-500-4-T 450 4 0.15 - 0.30 18 6 179 2.2 389 845 600 409 205 JCJ-PW-500-5-T 450 5 0.15 - 0.30 18 6 186 2.2 402 845 600 422 211 JCJ-PW-500-6-T 450 6 0.15 - 0.30 18 6 193 2.2 414 845 600 434 217 JCJ-PW-1000-3-T 900 3 0.04 - 0.07 18 6 199 1.5 404 725 868 424 212 JCJ-PW-1000-4-T 900 4 0.04 - 0.07 18 6 206 1.5 417 725 868 437 218 JCJ-PW-1000-5-T 900 5 0.04 - 0.07 18 6 215 1.5 429 725 868 449 225 JCJ-PW-1000-6-T 900 6 0.04 - 0.07 18 6 222 1.5 442 725 868 462 231

B

Set

Page 11

PULLEYS

At a Glance

J&C Joel offer a range of pulleys designed for use with flying systems. We offer various WLL capacities and lines per pulley. Standard sizes are shown below. Custom options are available upon request.

Features

• Suitable for manual or motorised systems

• Dual ball bearings to assure smooth operation

• Pulleys manufactured from black polyamide

• Steel side plate and frame

• WLL of upto 1000kg available on request

• Standard and custom mounting brackets available

• CE Marked

Mounting & Girder Dogs

We have a range of solutions to clamp each pulley block onto an I beam. Our standard fixes to beams with a flange width between 41 - 207mm and a flange thickness of 10mm, with a safe working load of 250kg. Custom brackets are available on request.

Pulley Variants

Page 13

Pulley ID WLL (kg) Pulley Ø (mm) Rope Ø (mm) No. Lines Dim. X (mm) Dim. Y (mm) Dim. Z (mm) Dim. A (mm) Self Weight (kg) Plate Thickness JCJ-PU-100-1 125 100 4 1 36 142 150 80 1.60 4 JCJ-PU-100-2 125 100 4 2 36 142 150 80 1.60 4 JCJ-PU-100-3 125 100 4 3 45 142 150 80 1.70 4 JCJ-PU-100-4 125 100 4 4 53 142 150 80 1.85 4 JCJ-PU-100-5 125 100 4 5 62 142 150 80 1.95 4 JCJ-PU-100-6 125 100 4 6 70 142 150 80 2.15 4 JCJ-PU-150-1 250 150 6 1 36 167 200 80 2.40 4 JCJ-PU-150-2 250 150 6 2 42 167 200 80 2.55 4 JCJ-PU-150-3 250 150 6 3 54 167 200 80 2.85 4 JCJ-PU-150-4 250 150 6 4 66 167 200 80 3.40 4 JCJ-PU-150-5 250 150 6 5 78 167 200 80 3.80 4 JCJ-PU-150-6 250 150 6 6 90 167 200 80 4.10 4 JCJ-PU-150-1-500 500 150 6 1 40 172 205 80 3.95 6 JCJ-PU-150-2-500 500 150 6 2 46 172 205 80 3.95 6 JCJ-PU-150-3-500 500 150 6 3 58 172 205 80 4.00 6 JCJ-PU-150-4-500 500 150 6 4 70 172 205 80 4.40 6 JCJ-PU-150-5-500 500 150 6 5 82 172 205 80 4.90 6 JCJ-PU-150-6-500 500 150 6 6 94 172 205 80 5.45 6

United Kingdom (HQ) Corporation Mill, Corporation Street, Sowerby Bridge, Halifax, HX6 2QQ Tel: +44 (0)1422 833835 Email: sales@jcjoel.com www.jcjoel.com