Mark Thornhill, Co-founder of Statii, explains how he took the experience of running engineering factories for over 25 years and created one of the industry’s highest-rated MRP systems.

Throughout my career, I’ve used almost every type of system to help run my businesses. It doesn’t seem long since I was flipping through the yellow pages! But it wasn’t until I created a sub-contract engineering business that I realised there wasn’t anything ‘off-the-shelf’ appropriate for a small manufacturing business. Especially one that needed a great deal of flexibility due to the bespoke nature of sub-contract manufacturing.

When we started in 2012, you had two options, purchase an on-site software package that cost a fortune to implement and service with your own hardware and crowbar its functionality to work with your processes. Or open your wallet and start the process of developing your own.

So, co-founder Mark Kemp and I opened our wallets and got work on creating software bespoke for us, and as Cloud solutions were increasing in popularity then, we decided to seek out cloud developers.

After many long days and a sore head from all the butting of heads to make it in our vision, not the developers, we finally launched. It wasn’t long before local customers and suppliers started taking a look and asking if they could have a copy.

Typically, small manufacturing businesses have the same challenges and objections that prevent them from implementing an MRP system. So we decided to start selling Statii, concentrating on making it as userfriendly and accessible as possible to small manufacturers like ourselves.

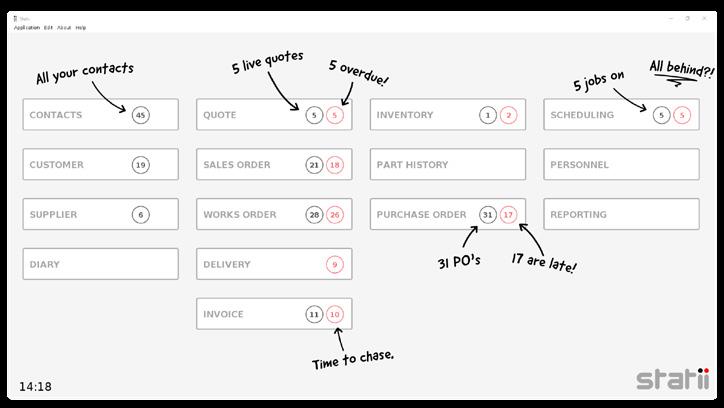

I wouldn’t describe Statii as bare bones, but it certainly doesn’t contain an arsenal of nice-to-look-at but useless features clogging up the system. I found many software larger than needed, confusing users and making training more complicated and longer. The more features something has, the longer it takes to implement and train, wasting time and money small businesses don’t have spare.

The days of rooms filled with filing cabinets stuffed with paper aren’t behind us, but they should be. Statii ties every document raised against a customer or supplier automatically to their profile. This means you never have to search for a document or ask someone where the information you need is. Acquiring ISO accreditations is essential to many manufacturing businesses, and the traceability Statii provides automatically makes getting and keeping these almost effortless. If that’s not a good enough reason to go digital, consider the financial and environmental cost printing has.

For a small business with a handful of estimators at most, the quoting process can often be the brick wall between them and achieving that next level of growth. It takes time, and there’s no promise of winning the job. So, we wanted to speed up the process, increase conversion rates and make the hard work done at the quoting stage count for something. We’ve done this by:

• Integrating the quoting system with supplier details, inventory parts and more to create a rapid drop-down selection.

• Allowing old quotes to be requoted and edited.

• Providing visibility on job histories to see how long processes previously took.

• Automating the creation of sales orders, purchase orders, works orders and schedules using the information used to build the quote when the job goes live.

• Collecting and reporting on lost reasons allowing you to prioritise your quotes.

The best estimators can’t ensure profit, even with Statiis ability to set default profit margins and markups. It all comes down to what happens on the shop floor, which is why we created the shop floor data collection (SFDC). Laptops or tablets, the device doesn’t need to be fancy. They just need to be big enough that your staff can read the instructions and see the drawings attached to the works orders.

Whilst this is the feature that gets the most staff resistance, it’ll be worth it as you can:

• Send works orders and drawings digitally

• Get staff to timestamp their hours to jobs

• Use historic time-taken figures to improve future quote accuracy

• View live profit figures on a job as time is associated with it

• Identify areas of the business that are making and losing profit

It was always our mission to create a virtual production manager of sorts. With all the effort we put into the quoting process, we knew getting work through the door was only a fraction of the battle. Helping businesses get jobs out the door is when our experience would really help design the system.

We focused on automation and the fundamental belief that everything should be traceable and organised without additional effort. For example, when you convert a quote, a sales order is automatically generated, which raises and attaches all the relevant documents you need to complete the job. Works orders and a production schedule are created considering the current workload. Statii even checks stock levels and alerts you if you’re short on materials. If you have a preferred supplier, it’ll even raise and send the purchase order for you.

Manufacturing businesses literally and figuratively have many moving parts, many of which cannot be automated. This is why it is so important to automate what you can, to help guide a job through a factory with the least amount of friction possible.

In one of our latest case studies, we asked Gareth Baker, the founder of Leeds Plastic Engineering, how he would describe Statii, to which he responded:

train remotely to save on hardware and travel costs for installation and training. Eliminating the significant investments required that deterred small manufacturing businesses for years. As an affordable monthly subscription, Statii has helped hundreds of companies access software. I’m glad that has been reflected in our independent reviews on Capterra with a 4.6/5 value for money score.

Software is only as good as its support. Ultimately, the knowledge of the support team will decide whether the implementation goes smoothly and if your business will grow with the software. We try to keep up with technology so our customers have the best experience, but we take a more traditional approach towards support. We provide telephone support, who can screen-share to resolve issues almost instantly, with no directions to bots, FAQs or ticket systems.

Almost everything is a subscription these days, and whilst many software providers have caught up, we have stood with the same principle for over a decade. As cloud software, we don’t need to visit the site and can

We’re told our years of experience in manufacturing shows in our software, but where it comes into play is in our support and understanding of our customer’s processes. Ranked 4.9 out of 5 for customer service is almost perfect and reminds us, whilst we’re a software company, humans and relationships still lead the manufacturing industry.

www.statii.co.uk

“The software you use to run your company.”

ENGINEERING PDATE

Finally, MRP made and supported by manufacturers See

At the forefront of digital marketing, Engineering Update strives to bring the latest in industrial engineering in a format that provides the best usability and ease of use for its readers.

Publication Director

Kane Weller

01843 580 460 Kane@engineering-update.co.uk

Managing Director

Jodie Little

jodie@jetdigitalmedia.co.uk 01843 595818

Editorial Assistant

Laura Sharpe

01843 448 443

laura@engineering-update.co.uk

Publishing House

Jet Digital Media Ltd, Suite 1 & 2 Spratling Court Offices, Spratling Street, Manston, Kent CT12 5AN

As we end 2022, let’s take a moment to look back at how the Engineering sector has thrived this year!

The automation sector has increased over the recent years as businesses navigate the uncertainties and challenging economic landscapes resulting from the global pandemic.

Over the past few years, technological advances have meant that automation is now a viable solution to businesses of all sizes in terms of boosting productivity in a market that’s ever short of talents.

With robotics, people will have more time to do higher-value tasks, although it will also mean the loss of more menial jobs. It’s not that robots will replace these jobs. However, skilled engineers familiar with using these machines will replace those who are not, making the future brighter for engineers.

As more and more women are making advances in electronics engineering, now is the perfect time for female engineers to further their engineering careers. With the high demand for engineering professions companies looking to hire women engineers should consider using the services of electronic recruitment firms that specialise in electronic recruitment.

We hope you enjoy the issue!

Kane Weller - Publications Directorwww.engineering-update.co.uk

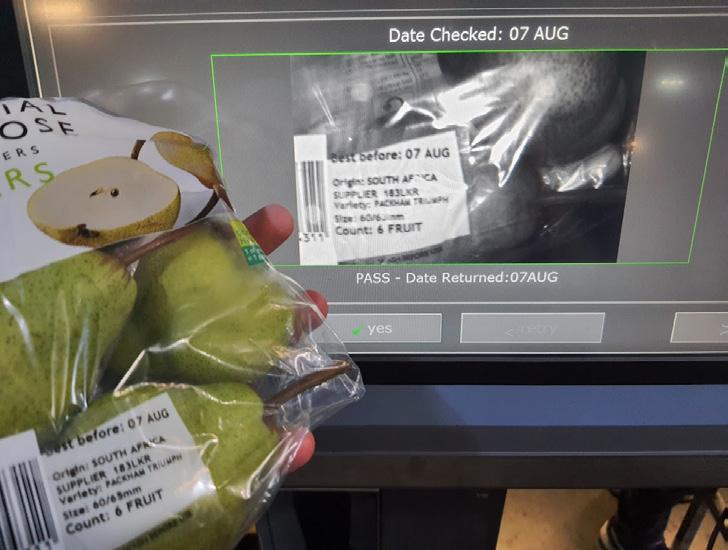

Previously manual human checks of product labels, date code and country of origin were undertaken, but these methods are susceptible to human error, especially in a high-complexity business like Worldwide Fruit. Their complex operations handle thousands of different product, grower, and packaging combinations. For one category like apples, there are many varieties of apples from different countries with different packaging and promotion requirements from each retailer.

For a production run, Worldwide Fruit must ensure the right product (apple), is in the right packaging with the right date code and country of origin. Any mistake in the process could result in a product recall and a fine from retailers. To address these challenges Worldwide Fruit turned to automation.

After a review of suppliers, Worldwide Fruit chose to work with OAL because of recommendations and previous experience implementing the OAL system. Furthermore, they wanted to work with a business that could integrate with their existing ERP system, which OAL could demonstrate.

The priority was implementing an “online” label and verification system across its packaging lines to accelerate its digital transformation. Online meaning, every product is verified as opposed to “offline” where a sample is verified.

Fran McNally, Quality Manager at Worldwide Fruit described the project: “The team at OAL are easy to work with, working together we have implemented a robust automated label and date code verification system. By introducing cutting edge artificial intelligence technology

we’ve futureproofed our packaging lines, enabling further automation. Crucially we’ve been able to customise the system to meet our unique requirements. The 247 support is quick, friendly, and efficient!”

The OAL solution has a number of elements to automate the process. A digital master product database was created containing all critical SKU information. OAL Line Terminals were installed on every line for operators to start and finish jobs and conduct quality checks related to the job. This includes online cameras to scan and verify packaging to ensure the right packaging is applied to the product. Each online printer was connected to the OAL system. The OAL system controls the printer and tells it the date code to print based on the date code rules in the master product database.The offline print room printers were also under the control of the OAL system to ensure offline printed labels were also correct.

Finally, the site chose to add an extra layer of assurance with APRIL Eye date code verification. APRIL Eye gives the OAL system the functionality to read back and verify printed date codes in an image. This ensures the right date code is applied, it’s legible and in the right location.

At Worldwide Fruit, as part of start-up, interval and end-of-run checks the operator takes a picture of a finished pack with the OAL line terminal hand scanner. The system checks it’s correct and legible against the current job.

Finally, every check, scan and data point is recorded providing a complete digital audit trail to ensure BRC and retailer code of practice compliance.

OAL is proud to announce its latest project with Worldwide Fruit to stop packaging errors with artificial intelligence and automation. Worldwide Fruit has scaled and improved its quality control processes, resulting in happier customers and reduced operational risk. Automation has helped find and prevent “hard-to-spot errors” whilst reducing the time it takes to complete quality control checks. They have also removed substantial paperwork from the business helping meet and surpass sustainability goals.

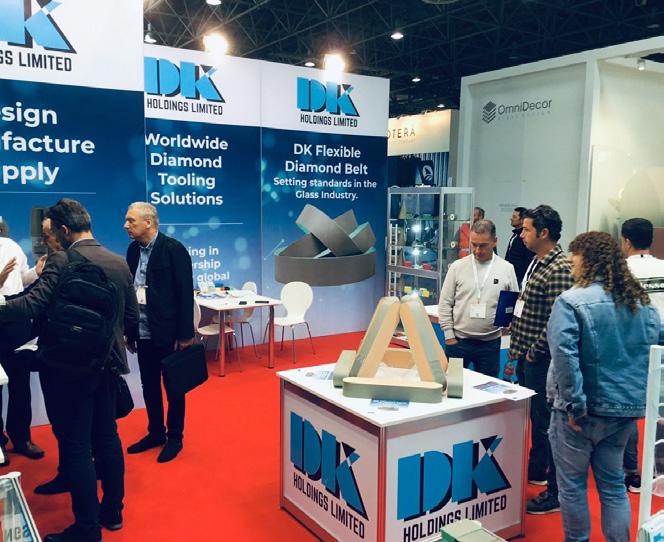

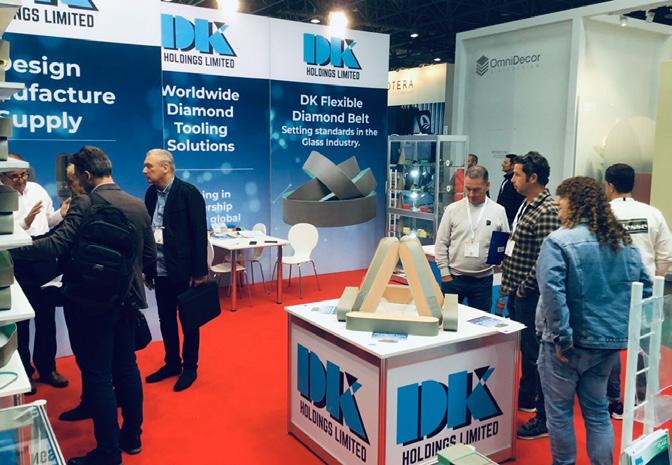

The company attended two major trade shows this year, JEC WORLD in Paris which brings together professionals in the Composite industry, and glasstec in Duesseldorf which serves the hugely innovative Glass industry. “Nothing beats being able to have face-to-face conversations with customers and understanding their unique production requirements. We are lucky to have a great team of technical engineers who work in partnership with our global customer base from inception to the

supply of a Diamond Tooling solution tailored to their needs”, John continues.

DK Holdings has furthermore continued to invest in both, personnel and machinery in 2022, which has enabled the company to now expand its portfolio by offering the design, manufacture, and supply of precision engineered components and a subcontract manufacturing service. “Offering our subcontract capabilities of one-off specials and smaller batch component manufacturing alongside larger production runs enables us to continue to support our customers and establish long-term partnerships”, John tells us.

A major “green” milestone was achieved in November 2022, when the company was awarded the Gold Membership of The Green Organisation, one of the world’s leading environment groups. “We are incredibly proud of this achievement”, John tells us. “Supporting this fantastic non-profit group means that we are actively adopting measures that will continue to improve our quest to be greener for future generations. We continuously strive to reduce our carbon footprint through a variety of initiatives so keep following us on our social media channels, there is lots more to come in 2023” , John concludes.

A � ick so� are o er ie

Good introd c on to MRP

T picall a larger gro p

In-depth so� are alkthro gh Q&A session a�er ards

T picall a smaller gro p

Whether o are considering man fact ring so� are for the first me or looking to replace an e is ng s stem, e ha e created t o online e ents to help o gain a be er nderstanding of hat MRP can do for o r b siness, in terms of efficiencies, cost sa ings and traceabilit .

The INFO E change gi es o a taster in min tes, allo ing o to see the insight so� are and MRP in ac on. The -ho r E al a on Workshop gi es o a deeper look ith a Q&A session at the end, allo ing o to make a decision and mo e for ard. Yo ill also recei e a free cop of o r book ‘How to implement a manufacturing system’ j st for a ending.

Alterna el , register to get access to o r online Demo Mo ies, broken do n b job role, hich e plain hat insight ill do for each department in o r b siness.

Book to a end at insight.com

Free book on implemen ng MRP hen o a end.

The topic of “explosion safety” is omnipresent for plant operators and OEM´s when it comes to handling or transporting combustible dusts. Despite the widespread assumption that an increased risk of explosion only exists for gases, enormous forces can also be released by explosive dust- / air mixtures.

To help minimise the risk of explosions when handing combustible dusts, it is important to understand the requirements for an explosion and the respective dust safety characteristics, which are described below. The following picture shows the fire triangle and the explosion pentagon which must be taken into account.

The following conditions must exist for an explosion to occur within a production facility or machine:

Operators of spray dryers must combat a particular type of ignition source – namely smouldering nests that can lead to spon taneous combustion if the material under goes excessive caking. Caking occurs due to sub-optimal drying of the material and its initially high moisture content. The caked material is then insulated against the surrounding air by a build-up of moist material. The high temperatures ensure that the caked material is continuously heated until a biological reaction takes place involving protein, carbohydrate and water – known as the Maillard reaction. The Maillard reaction generates additional heat that cannot be dissipated due to the insulating layer of caked material. This process continues to accelerate until spontaneous combustion finally occurs.

Caking of this kind can build up both on the nozzles and the inner wall of the spray dryers. If the nozzle malfunctions, droplets may fall down into the fluid bed and cause further clumping. If a smouldering nest is able to form, this can ignite the explosive atmosphere inside the dryer or the down stream machinery.

How can such conditions, which are frequently encountered in practice, be prevented?

accuracy. At the same time, the realtime fingerprint analysis eliminates the cross-sensitivity to other gases in the measurement spectrum that is common in commercial gas analysers.

To ensure a reliable measurement of the operating status, samples are sucked in from all of the dryer's relevant supply and exhaust air ducts under very high vacuum. REMBE calculates the delta CO value on the basis of the absolute values meas ured at the individual measuring points. This value is the mathematical difference between the CO content of the extract air and the CO content of the supply air. Thus, only events that actually occur in the respective process are detected. External factors that may disturb the process can thus be ignored.

A proprietary evaluation algorithm (RFA REMBE Flow Algorithm) enables the measured supply and exhaust air values to be compared in real time. As a result, the REMBE CO.Pilot is the first system on the market that makes it possible to adjust the individual alarm limits and gas run times for the individual measuring points in the dryer's various air throughputs with out any delays. The ratios of the different supply air channels and the flexible oper ating hours are balanced via the software and calculated accordingly in the PLC.

Thus, if an increased carbon monoxide concentration is detected due to spontaneous combustion during the process, countermeasures can be initiated immediately.

If any one of the aforementioned prereq uisites is eliminated, explosion prevention has intrinsically been practised. However, if this is not possible at all times and in all operating states, explosion hazards will still be present. In this case, it is necessary to divide any potentially explosive atmos pheres into zones and systematically apply safety measures.

Drying processes in particular are used in many industries to produce material, for easier storage, more efficient transport and a longer shelf life. However, the com bination of moisture extraction and high temperatures creates an increased risk of both, fires and explosions.

If fires and/or explosions occur in drying plants, which are usually very large, the situation is not only extremely dangerous for the machines and the business, but especially for the employees on site.

Everything starts with the human factor, i.e. properly trained personnel for the respective processes. Optimal process control is also required to avoid caking. But without precise and reliable information/ measurements, this is virtually impossible, even for specialists. Nowadays, humidity and one of the by-products of spontane ous combustion at early stages – carbon monoxide (CO) – are used as indicators to ensure a smooth and thus safe pro cess. However, the fact that combined measurement systems cannot clearly distinguish between these two indicators is problematic and can result in inaccurate measurements.

The REMBE CO.Pilot makes exactly this symbiosis possible!

Via a permanent comparison of recorded data with a database of stored reference gases that serve as "fingerprints" of the selected gases, it is possible to perform a one-time check in real time and thus permanently verify the measurement

This special sampling process eliminates the need for costly and error-prone gas treatment, thus ensuring that the CO.Pilot is less susceptible to faults and requires less maintenance. Furthermore, this measurement method can make recurring calibrations unnecessary. Due to the precise meas urement technology and the reproducible results, false alarms and downtimes can also be avoided. And in combination with moisture meas urements, the entire drying process can be optimally con trolled, significantly increasing the energy efficiency of the system.

The signing ceremony took place on November 1st, in Hanoi, Vietnam, within the framework of Vietnam-Denmark Business Summit Forum 2022, organised by the Embassy of Denmark in Vietnam, Vietnamese Government Office and the Vietnamese Ministry of Foreign Affair in Denmark.

Through this alliance their first Smart factory and transform the traditional jewelry manufacturing process with digital technologies like Robotic Process Automation, Artificial Intelligence, and more. The new manufacturing plant is set to be completed by the end of 2023 in Hoa Lac Hi-tech Park, Vietnam's first and largest hi-tech industrial zone.

The newly established partnership also transforms Julie Sandlau's operations and work processes, from human resources, operational management, to accounting and so on. FPT Software's automation and robotic processing solutions help ease the usual back-office procedures, reduce workload and workforce, thereby promoting and accompanying Julie Sandlau's towards sustainable development. The strategic step also allows Julie Sandlau's to expand its operations to a strategic market like Vietnam and target potential customers here.

FPT Corporation Chairman Dr Truong Gia Binh said. “In the past five decades, Vietnam and Denmark have established a strong relationship, with many deals among companies of both countries. With this partnership with Julie Sandlau, FPT believes that we can help reinforce the tight relationship between both nations.”

“As Vietnam’s leading IT solutions provider, FPT is confident to help Julie Sandlau with their digital transformation process and expansion goals”, Chairman Binh added.

“Vietnam always has a special place in our hearts since we started our business in 2006 here in Hanoi, so we are very excited to continue our Vietnam journey investing and developing further into digitalization, AI, blockchain technology and robotics.”, said Julie Sandlau’s CEO Soren Roed Pedersen.

“For years we have been first movers with our strong focus on ESG and we are now ready to start our digital transformation together with FPT and thus further proving the great collaboration between Vietnam and Denmark. We find the core values and vision of FPT and Julie Sandlau are a great match as we aim to transform a jewelry industry from traditional manufacturing methods to a modern digital hub. We have obviously great ambitions for our partnership with FPT as our long term strategy for Vietnam will develop into much more than just manufacturing.”, he further added.

On nurturing and developing human resources, FPT Software will transfer expertise and provide comprehensive training to Julie Sandlau's employees in Vietnam, with a deep dive into Artificial Intelligence applications. This practice will turn Julie Sandlau the world's first jewelry manufacturer to involve emerging technology in its production process, supporting its goal of becoming a digital transformation hero in premium accessories production by 2025.

The strategic partnership allows the two companies' employees to exchange knowledge and experiences, with Julie Sandlau offering fresh graduates from FPT University and FPT Corporation's staffs internship and employment opportunities. The program aims to improve educational quality and develop a guaranteed career path for future industrial engineers for FPT

https://www.fpt-software.com/

First system with built-in cybersecurity to prevent costly downtimes New All-in-One platform station facilitates soldering & desoldering

Leading distributor of electronic and technical components, Distrelec, is bringing to the market Weller Tools’ new smart soldering platform WXsmart. Weller Tools, a leader in hand soldering solutions, is part of the Apex Tool Group, one of the largest manufacturers of professional hand and power tools in the world.

Available today from Distrelec, the WXsmart platform consists of a 2-channel soldering station and a hot air module with an air and vacuum requirements. This All-in-One station acts as ‘the brain’ of the workbench by consolidating all soldering applications into one station. A calibration unit as well as a soldering tip holder truly make this platform a complete soldering solution.

Designed to meet today’s top manufacturing trends including Industrie 4.0, miniaturisation and sustainability, the WXsmart platform facilitates control operations, delivers soldering quality and enables data collection for greater traceability, audit & report purposes. It is the first system of its type with built-in cybersecurity to prevent costly downtimes.

The All-in-One WXsmart hand soldering platform is the most connected, smartest and secured hand soldering solution in the world. Managing the complete soldering process, from tip to station, will never have been easier nor more productive.

WXsmart is available from Distrelec immediately. For more info visit www.distrelec.biz.

•

2-channel Soldering Station

• Desoldering

• Hot Air Module

• Soldering Tip Holder

• Traceability from tip to station

Flow measurement plays a fundamental role in upstream, midstream, and downstream segments of the Oil and Gas industry. Applications such as highpressure additive injection, require highly accurate and chemically resistant flow metering sensors.

For the successful transportation and refining of crude oils, a whole raft of additives are required. These vary from simple surfactants through to complex blended scale and corrosion inhibitors. The chemical additives are injected in small quantities at high pressure and are critical to the whole refining process. Consequently, careful monitoring of their addition to any process is essential.

Petrochemical additive injection fluids vary in both viscosity and density, and any flowmeter installed into a plant should be able to cope with a wide range of physical and chemical properties. Unlike other types of flowmeter, measurement accuracy of Oval Gear flow meters improves as the liquid viscosity increases, from a nominal 1% of reading to around 0.1% of reading at higher viscosities.

Titan’s Oval Gear range of flowmeters include ATEX compliant IP67/NEMA 4 protection models, designs that can be pressure tested in-house up to 1200 bar, and devices that offer intrinsically safe options to be used in potentially explosive atmospheres. These oval gear meters offer excellent chemical resistance whilst maintaining high performance and 0.1% repeatability. Titan’s proprietary oval gear design ensures these flow meters give reliable, high performance in high pressure applications.

Titan’s standard Oval Gear models used in additive injection are manufactured with options in materials compatible with the presence of strongly acidic or basic chemicals, such as 316 stainless steel, aluminium, and non-metallic PEEK, with pressure ratings from 10 bar to 950 bar (for custom-designed models). Benefiting from a compact, rugged design, Titan’s Oval Gear flowmeters are proven to operate reliably even at high pressures and at temperatures up to 150°C, providing long-term performance with minimal maintenance.

Adapting designs to meet specific high-pressure requirements and aid chemical compatibility, the use of non-magnetic materials and exotic metals, such as Hastelloy and

Titanium, are examples of our growing bespoke flow meter capability. Titan has partnered with OEM customers to provide optimised flow metering solutions for oil, petrochemical and green energy applications. These have included bespoke oval gear flow meters for marine fuel flow measurement, monitoring the volume of grease being supplied into a wind turbine main bearing mechanism, high pressure intrinsically safe units for offshore oil drilling additive injection, and for biodiesel plants converting bio waste into sustainable biofuels

For further information on Titan’s full range of Oval Gear flowmeters visit https://flowmeters.co.uk/ or to discuss your specific OEM application, contact Titan Enterprises on +44 (0)1935 812790 or sales@flowmeters.co.uk

MPW Precision reached a six-month traceability goal in just four weeks, earning the ISO 9001 without a single non-conformance.

About MPW Precision

MPW Precision was founded in December 2020 by father and son entrepreneurs Maurice and Paul Watson, who between them have over 60 years of combined experience in precision manufacturing. The company specialises in producing high-precision quality engineered components for use in larger fabrications and power generation.

With years of previous experience leading a manufacturing company, Paul knew that complex manufacturing needs a capable MRP system for efficient and well-organised operation.

Since all of MPW Precision’s clients require ISO 9001 and other quality assurance certifications, an important functionality that Paul required was end-to-end traceability. Being located over three manufacturing sites and two home offices, it was also important that the software be web-based and able to run on off-the-shelf PCs and tablets. A final determining factor was affordability.

After trialling several MRP systems, Paul demoed MRPeasy and felt it ticked all the boxes and seemed easy not just in name but also for day-to-day use and crucially – to implement.

Having prior experience with implementing manufacturing software, Paul decided to go at it himself. “I had a target to install MRPeasy and become ISO 9001 approved within 6 months,” he says. Using the wealth of resources on MRPeasy’s website he got the system up and running in just about 4 weeks.

“After 6 months of using MRPeasy, SGS (an industry-leading certification company) came in to undertake the certification audit and we passed without a single non-conformance. On the report, SGS also commented on how good MRPeasy was with traceability”, Paul explained.

Since MPW Precision opted for a day-one implementation, there were no metrics on how MRPeasy affected efficiency after going live. However, comparing with the MRP solution that Paul and Maurice had previously used, Priority Software, they can now do things like taking an order and getting it to the shopfloor in around 25% of the time. “There was approval and other stages involved and we had 40 employees instead of 8 but all-in-all, it’s around 70% more efficient.” says Watson.

Today, MPW Precision uses MRPeasy for pretty much everything, except for some ISO-specific QC processes, and benefits from having business-critical information all in one place and accessible from the shop floor, office, or any internet-enabled external location. The owners have also been praised by their customers for the speed at which the system makes documentation available to them. Meanwhile, the seamless QuickBooks integration ensures the accounts are well taken care of.

MRPeasy is a cloud-based ERP/MRP system for small manufacturers and distributors. For more information and a free trial, visit www.mrpeasy.com

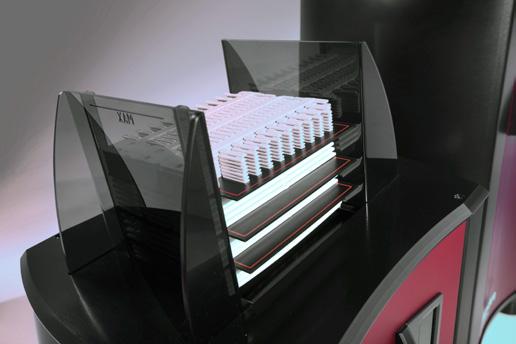

Low initial cost and low machine running cost with the benefit of high output and long machine life span - that’s the promise from MurrSystems and the LM-3 Laser Marking System. The ideal labelling system for companies with a medium to high volume of labelling work without any compromise to the quality and durability of the labelling produced.

MurrSystems undoubtedly has the credentials to be at the forefront of laser labelling technology. Founded in 1963 as Murrplastik GmbH, the company launched its first labelling system (ACS) in 1986, making them a pioneer in early labelling technology. Today, under the new name of MurrSystems, the company is a global specialist in industrial labelling technology and this is evidenced by the design, development and launch of the powerful LM-3 Laser Marking System.

Tim Bradbury, UK Sales and Technical Manager, discusses the benefits of the LM-3 Laser Marking System from MurrSystems.

Laser inscription by colour changes (carbonisation) in the material.

Aa a complete system of hardware, software and accessories the LM-3 laser printing system provides a cost-effective solution for quality, speed and profitability.

UK MurrSystems Sales and Technical Manager Tim Bradbury explains “As the LM-3 is a laser printer there is no need for additional consumables such as printer cartridges, ink, thermal transfer ribbons or even toners. The whole inscription process is done by laser, inside the unit. Making it the premium choice of automated and cost-efficient laser labelling systems on the market today.”

The LM-3 is the ideal solution for organisations with a variety of label and marking requirements – including marking of wires, cables, components, control panels or signaling equipment. “The majority of our customers in the UK are Panel Builders, System Integrators, Machine Tool Manufacturers, Special Purpose and Equipment Manufacturers and our technology has evolved with the increasing requirement for abrasion-proof quality labelling on a wide variety of base materials for numerous environments and applications. We have longstanding customers in the UK who initially purchased a plotter system and then, at the end of the machine’s life span, switched over to the more flexible and more automated laser system. Finding it a much more efficient and flexible solution for their diversifying labelling requirements.”

With a dedicated UK Sales and Technical Team devoted to helping customers get the very best out of their MurrSystems hardware, it’s clear to see why Murrsystems are the number one choice for a flexible cost-effective solution for the inhouse production of industrial labels.

As technology has developed, laser marking has become faster, more accurate and thus more popular. Subsequently, this technology is now the preferred method for permanent marking of metal and plastic labels in a diverse range of industry sectors. The growing use of laser marking systems and divergence into new sectors is a development that Tim has personal experience. “I’m very confident that laser marking technology will continue to get more precise and more cost effective in the future. The LM-3 is at the forefront of this technology and offers a complete laser marking solutions for companies and organisations looking for a faster, more accurate process of producing inhouse labels now.” And as for the future, Tim is very clear “There continues to be demand for laser marking systems

LM-3 Laser Marking System - A complete system for the economic production of metal and plastic ID labels.

that enable organiastions to produce industrial cable ID labels inhouse and the LM-3 is the perfect low cost, high output solution for these applications, Our customer base grows year on year as our technology continues to evolve and offer the best solution on the market.”

The Global Data Centre Power market is expected to reach $13 billion by 2028, a market growth of 7.7% CAGR. The increasing data generation and need to improve data centre performance is boosting the need for data centre upgrades and renovations. Murrsystems have seen the demand for their marking systems expand into this market. Tim explains, “It makes perfect sense for organisations working in critical power distribution and data centre power distribution to realise the benefits offered by laser systems such as the LM-3. Each data centre contains a vast amount of computing equipment, servers and other components including network, telecommunications and storage systems that all need labelling or marking. The LM-3 is so flexible and automated that it can label onto polycarbonate, polypropylene, adonized aluminum, stainless steel or laser foils. Producing durable labels that are UV, acid, oil, chemical resistant. The LM-3 is able to function under extreme environmental influences and mechanical stress, making it the ideal laser labelling system for these facilities”

The collaboration of hardware, software and accessories provides real added value. The high degree of automation allows users to focus on their primary business objectives and save resources.

Automated batch processing and marking software integration enable high output. The magazine filling aid mp-LM B enables a smooth and time-optimized labeling process due to parallel preparation of the magazine loading. The mp-LM carrier plates are used to flexibly hold various murrSystems labeling materials.

Labelling material can be stacked directly in the labeling magazine. However, separator plates can also be inserted into the magazine. These allow mixed loading in one batch – various materials in different thicknesses, shapes and colours for different applications can be labelled. With the help of the mpLM single-line adapter plates, part used label frames can continue to be used. The Universal Marking software used with the mp-LM 3 can also operate other labeling technologies or devices: deviceindependent and process-optimized, time- and costsaving, as well as intuitive and interactive.

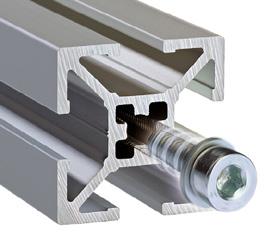

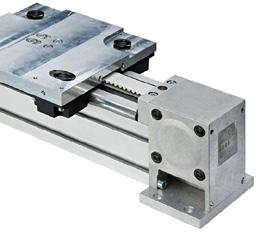

The Meltio Engine Integration can turn a CNC machine tool into a hybrid manufacturing system with no inherent size constraints. The Meltio Engine is the ideal CNC complement for producing near-net shape parts, repairing existing ones or adding new features to existing stock. Metal parts can be printed in full density to any size allowed by the system to which it is integrated, providing a high degree of capability and flexibility.

The University of Central Lancashire acquired the first Meltio integrated into a HAAS machine and are currently completing initial testing phases and starting to develop applications internally and for local businesses.

Wire-Laser Metal Deposition is a Directed Energy Deposition (DED) process that functions by precisely stacking weld beads on top of one another when introduced into the laser generated melt pool. The combination of Meltio and Haas technology solutions lead to a machine which is capable of traditional machining coupled with an additive manufacturing process using direct energy deposition technology. DED offers a cost-effective method of manufacturing and repairing components. Hybrid manufacturing combines the advantages of each additive and subtractive process in a single machine, offering value and complexity benefits that wouldn’t be accessible through just one process.

CNC machining is suitable for the application of the prototype industry and the prototype production in your early product development. This is also the most mainstream production process.

Production cost needs to be taken in all the aspects from the technology to the material. Including all this aspect it has the lowest production cost of the market.

Lowest production cost, lowest price of acquisition and high performance are converted in the best Return on Investment of the market

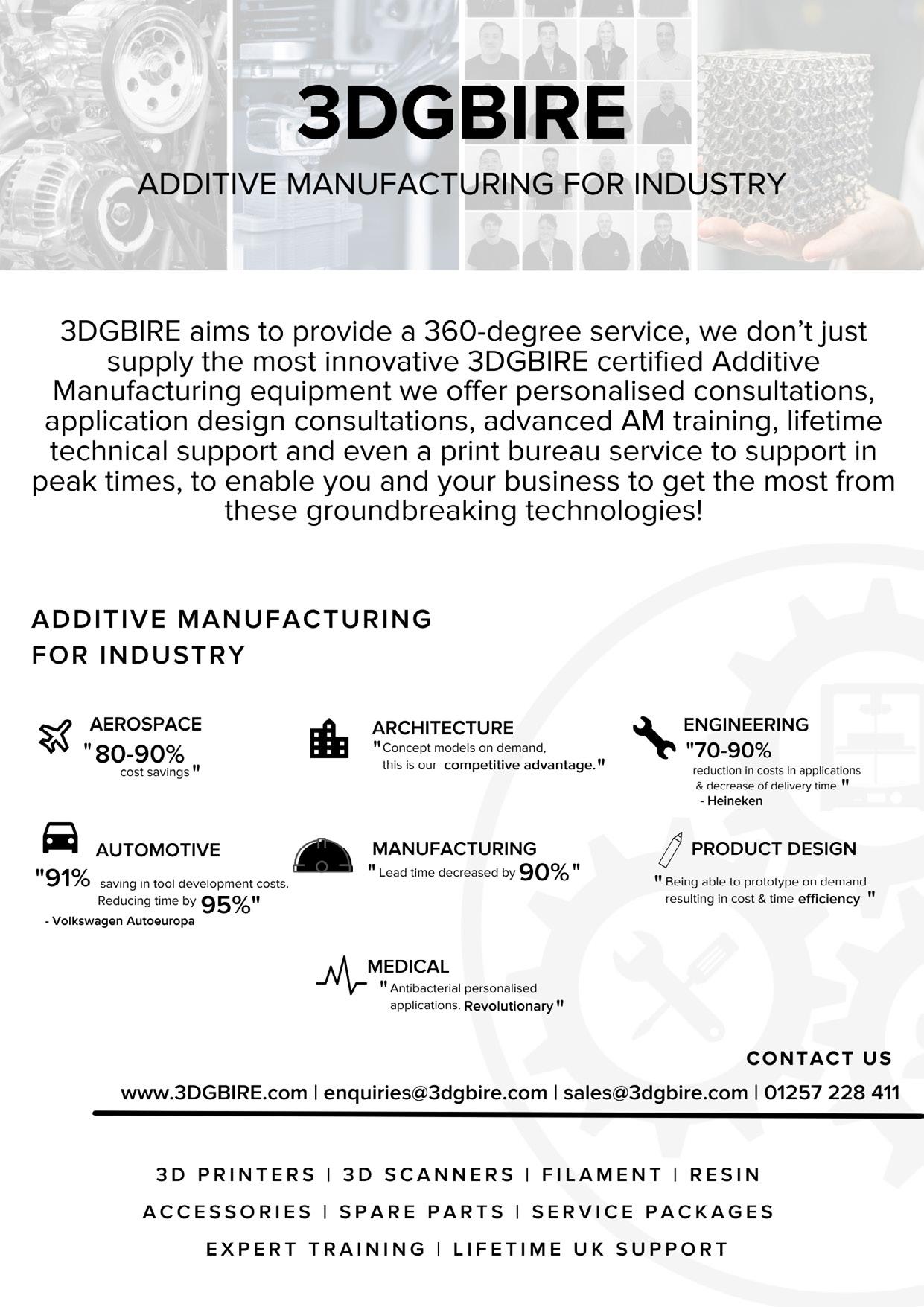

3DGBIRE aims to provide a 360 degree service and offer consultations for businesses to ensure they make the right investment, we support with application design consultations, advanced AM training, lifetime technical support and a print bureau service to enable you to get the most of these groundbreaking technologies.

Website: www.3dgbire.com

Book a consultation: https://bit.ly/consultation3DGBIRE

Telephone: 01257 228411

As engineering managers come under pressure to meet demanding schedules, often with fewer skilled hands and tighter budgets, the benefits of professional tool storage and management become stronger than ever.

Snap-on Industrial’s Level 5™ automated total asset management system brings order to any workplace, enabling engineers and technicians to know exactly where to find every tool they need, when they need it, saving time and easing stress.

How useful would it be if all valuable tools could be tracked from one central point? Snap-on’s Level 5™ system makes that possible. It provides complete reports on everything

managers or supervisors need to keep an eye on.

And then there’s FOD. The threat of foreign object damage is a real and present danger in many engineering workplaces. Using Snap-on Level 5™ minimises the risk of human error, as automated tool control constantly tracks every tool and detects which tools have been removed or returned, ensuring greater protection against FOD.

Engineered to track individual tools by user, without bar codes, scanners, RFID tags or other add-ons, the system works at the speed its users demand. Other systems require additional steps to scan or log activity. The Snapon system does this automatically so users save time and don’t have to depend on other steps to ensure accurate results.

Snap-on’s Level 5™ ATC boxes are network ready, using either Ethernet or wireless connection. That enables users to review activity at all Level 5 boxes in their location from one central computer, avoiding the time consuming need to inspect each box.

Major benefits of the system include:

• No individual tool scanning required;

• No RFID tags to install or replace;

• No limitations on tool size: from ¼” screwdriver bit upwards;

• Intuitive interface, with an easy to use touchscreen

• Audible voice announcement of tool removal and replacement

• Automatic locking for maximum security

• Errors announced and displayed to indicate incorrect tool position or advise when a drawer is not closed.

Says Richard Packham, Director UK & Europe for Snap-on Industrial: “Snapon’s automated system takes asset management to an entirely new level. The ability to monitor several boxes from one central computer offers a huge advantage to engineering managers.”

For technical details visit: www.snaponlevel5.com call (01536) 413904 or e-mail: ukindustrialmarketing@snapon.com

Wolf Safety have introduced a powerful new range of ATEX certified LED installed lighting, designed for permanent use in potentially explosive atmospheres.

The world’s leading manufacturer of portable and temporary ATEX and IECEx certified hazardous area safety lighting, Wolf have been keeping people safe for more than 110 years.

The company’s designers and production engineers have now brought their vast knowledge and expertise to bear on a new range of highly effective LED installed lighting, which is safe to use in Zones 1 and 21 hazardous areas.

The range includes:

• Linear luminaires featuring the new, revolutionary Directional Linear Optics (DLO) or standard Forward Facing Array LED configurations (with battery back-up emergency versions also available);

• Floodlights with a market leading maximum light output of up to 25,932 lumens;

• Bulkhead lighting, also featuring DLO (with battery back-up emergency versions also available);

• High bay lighting.

DLO directs light exactly where it’s needed and is ideal for use in specific, close-up workspaces, reducing glare to avoid people being ‘blinded’ by the emitted light, while its excellent colour definition facilitates safety critical hazardous area tasks.

Forward Facing Array (FFA) technology can be preferable for safely illuminating large hazardous areas which need wide, even and bright light coverage, where lights are mounted away from people or at heights where glare and intensity can’t have an adverse effect on the working environment.

Says Miles Jackson, Wolf Safety’s Sales and Marketing Director:

“We know that users of Wolf products trust us to keep them safe, especially when they need to work in highly volatile atmospheres and other hazardous workplaces.

“All the values people expect from Wolf - and are seen in our portable and temporary lighting ranges - can now be found in this new installed lighting range, which we are proud to introduce.”

For detailed technical information visit: www.wolfsafety.com

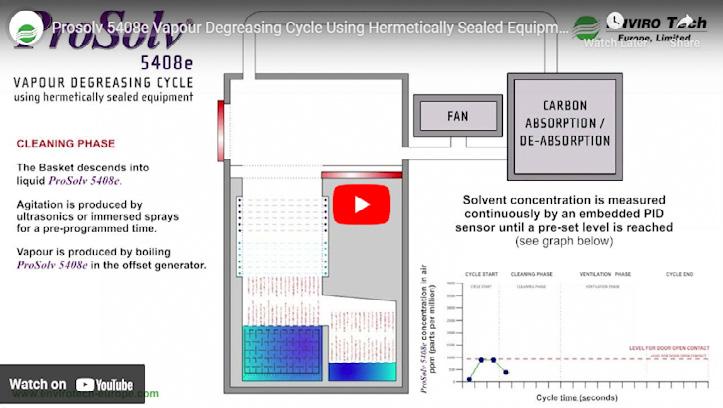

ProSolv®5408e is a high-performance solvent cleaner used for sustainable and future proof vapour degreasing. Soft on the environment and safe for users, it offers improved cleaning at lower costs. Low boiling point, economical with energy with low solvent losses and faster production.

Vapour degreasing, with or with-out ultrasonics, is the oldest, simplest and most effective solvent degreasing and metal cleaning process used today. It has, until recently, been subject to little change since it was first invented in the early part of the last century. In the UK, Europe, United States and other advanced industrialized economies increasingly stringent legislation to control emissions of VOCs, Solvents with a high Global Warming Potential (GWP), or a high Ozone Depletion Potential (ODP), and those compounds associated with human health con cerns has led to Envirotech Europe manufacturing new formulations for precision cleaning solvents with low or near zero potential.

Halogenated hydrocarbons are the solvents of choice for vapour degreas ing and cleaning. The process is essentially simple. A tank with a sump to contain the solvent, heaters at the base and condensation coils around the top section to control the height of the vapour is all that is needed. When heated in the sump halogen ated solvents produce, in most cases, a saturated vapour between 3 and 4 times heavier than air at a temperature greater than the ambient temperature of the parts to be cleaned.

This allows the solvent vapour to con dense on the surface of the parts. The condensate dissolves the contaminants such as oil, greases, flux, and soils returning the used solvent into the sump of the machine for recycling into vapour which continuously condenses onto the parts until they have achieved vapour temperature when, with no fur ther condensation, the process is com plete. Parts removed from the cleaning machines are very clean, warm and dry.

The most common halogenated sol vents, in use for commercial purposes, are non-flammable so present no risk in this process. Perchloroethylene, used mainly for dry cleaning, methyl ene chloride previously used widely in paint strippers, 1,1,1- trichloroethane and trichloroethylene used for vapour degreasing were the original materials used based on chlorine chemistry. However continuing concern about the environmental impact and danger to operators by exposure to chlo rine-based solvents, especially trichlo roethylene, has led to a continuing search for safer alternatives, such as ProSolv®5408e, a trans-1,2-Dichloro ethylene based solvent mixture that is non-flammable.

usage, low footprint on the factory floor, safety for the operator, and high production rates with low solvent usage or environmental impact.

With the new generation of sealed cleaning machines the future of vapour degreasing as the process of choice is assured.

Please visit our website for information about other uses and applications for ProSolv®5408e

For more advice, please telephone us on +44 (0) 20 8281 6370 or use our website contact form

All products are supplied and sup ported by EnviroTech Europe Ltd. Manufactured in the United Kingdom and available on short delivery times through our dedicated team of distrib utors worldwide.

Video animation of Solvac hermetically sealed equipment by kind permission of CC Hydrosonics Ltd.

ProSolv®5408e 23kg can.

The ProSolv®5408e vapour degreasing process gives the highest levels of eco nomical cleaning with minimum energy

Supplied and supported by www.envirotech-europe.com

The new compact conductivity sensors LDL100 and LDL200 from ifm impress with their fast and precise media differentiation. This helps you to control CIP processes efficiently and to increase the availability of your system. The new LDLs are also simple to commission: They are ready for use out-of-the-box and transmit the conductivity and temperature of the medium via a single M12 connection - digitally and loss-free thanks to IO-Link. As there is no additional evaluation unit required, you also save system costs. So easy, so good. ifm – close to you!

Rittal is expanding its smart cooling unit solutions by adding the new Blue e+ S range. Our latest generation of cooling units with their lower output categories of 300, 500, and 1,000 W have been designed for efficiency, ensuring a smaller footprint and lower costs –just like their “bigger brothers.” So it’s a win-win both for users and for our future.

Solutions that reduce our carbon footprint during production are in high demand. But at the same time, these solutions need to be intelligent and communication-enabled so that they can be easily integrated into digitalised manufacturing environments. Seven years ago, Rittal responded to this demand with its Blue e+ range of cooling solutions and launched extremely efficient enclosure cooling units, which provided on average energy savings of 75 percent. Now we have a new generation – the next generation – but still developed with that same design DNA. These new cooling units with their lower cooling outputs of 300, 500, and 1,000 watts called “Blue e+ S” add to the Blue e+ family and bring with them additional smart capabilities. And furthermore, this new generation offers innovative energy-saving features for the production process.

What’s behind this energy-saving and therefore cost reduction is the technology used, combining a heat pipe with inverter-controlled components. The heat pipe works without a compressor, expansion valve, or other regulating elements and so does not need any electrical energy except to operate the fan. Depending on the thermal energy generated in the enclosure and the current ambient temperature, cooling can be performed with the heat pipe alone. The additional compressor cooling only operates if a large amount of heat has to be dissipated from the enclosure or if the ambient temperature is very high. And what’s more – when it does operate, it is far more energyefficient than conventional units. This is because the compressor and fans possess an inverter-controlled drive, which automatically adjusts their speeds depending on the requirements. As a result, the temperature within the enclosure remains constant, and the energy efficiency is significantly higher than with other more conventional cooling units.

Alongside energy efficiency, another feature also reduces the carbon footprint: The new Blue e+ S series uses a refrigerant with a GWP (Global Warming Potential) that is 56 percent lower than those used in comparable cooling units. Furthermore, instead of the R-134a previously used, the cooling circuit in the new generation of units now runs with R-513A refrigerant.

With their additional smart functions, the new cooling units also help in the digitisation process. With a fully integrated IoT interface as standard, the cooling units can be intelligently monitored in digitalised environments and easily connected to Rittal’s new Smart Service Portal. This optimises the service processes and increases efficiency through predictive maintenance. As a result, fewer unplanned downtimes occur which all helps to manage the high cost of production, especially with Industry 4.0 processes.

These cooling units in the lower output classes have also undergone a facelift. Their most striking feature is an integrated coloured LED light strip. This means that warning messages can be immediately seen, even from far away. A display on the front of the enclosure provides additional up-to-date information. Moreover, the cooling units are equipped with the familiar NFC interface, which enables them to communicate with mobile devices that have the Rittal Scan & Service app installed.

For further information on the entire Rittal range visit www.rittal.co.uk or check out our linkedin page @rittal-ltd-uk

Linear motors are ideal for fast and accurate motion in a machine.

Linmot, the leading manufacturer of cylindrical linear motors, has made them even more suitable for demanding food and pharmaceutical applications. For these environments, any mechanism needs to have a high protection class and be easy to clean and require little maintenance.

The motors have been developed to be fully sealed and are made in High grade Stainless Steel. The cylindrical design allows the motor to be completely smooth and does not require seals. There are no food or particle traps and they can be fully washed down.

This is a big advantage over screw, belt actuators or pneumatic cylinders.

The motors are available in Linear modules with protection class IP64S and stainless steel linear modules with protection class IP69 consisting of a linear guide and an integrated LinMot linear motor.

Motor series in stainless steel (EN 1.4404/ AISI 316L) for wash down applications. The motors are characterised by their hygienic design and the high motor protection class IP69 according to DIN EN 60529. Perfectly suited for «inplace» cleaning processes like CIP and SIP.

LinMot linear motors have been used in the food industry for years. They score here with industry-

specific advantages, such as simple integration, flexible programmability, dynamics and hygienic design. The motors can be connected to common control platforms in synchronous operati on or simple point-to-point motion. The advantages of servo technology enable the gentle and dynamic processing of food. With the help of stored motion profiles, frequent product changes can be achieved simply by pressing a button. LinMot linear motors are available in stainless steel with a high protection class, meaning they can be cleaned under high pressure and with caustic cleaning solutions.

Users wishing to combine the advantages of dosing based on flow measurement with those of piston dosing in a rotary filling machine now have clean design LinMot motor options. Using LinMot stainless steel motors, the stroke movement of the filling needles can be mechanically decoupled from the movement of the carousel. Even highly dynamic needle raising applications are possible.

Unlike mechanical lifting curves, electrical direct drives do not exert any destructive forces on the bearing shafts. www.quin.co.uk/linmot

With several years of enforced online events behind us, the packaging industry’s live show calendar finally returned this year – and is in better shape than ever.

Following a packed 2022, with events like Packaging Innovations and The Print Show leading the reunion as the first UK meeting points for the global print and packaging sector, it’s fair to say the industry is realising how vital live events are. No home office could ever truly replace the bustle of a meeting on a packed show floor, surrounded by cutting-edge technology and industry leaders with the crackle of creativity in the air.

At a time when the print sector is continually innovating to play its part in improving sustainability, the return of live shows – an environment that lends itself to breaking down barriers and improving collaboration – is particularly welcome. After several years of focusing on steadying supply chains, the print industry can now focus on using innovations to find efficiencies and add value to its products.

After several years of presenting through webcams, exhibitors are once again able to show their A-game live on the event floor. This is more useful for both exhibitors and attendees, who are able to thumb through reading materials, explore the tactile feel of samples, and compare colour cards live and in person.

Bringing in this packed calendar is February’s Packaging Innovations & Empack, Featuring Contract Pack &

Fulfilment show. Held 15 & 16 February at the Birmingham NEC, the triple-tier event covers every aspect of the packaging journey and includes a dedicated Label & Print Zone – one of four zones on the show floor.

The event is set to attract over 6,000 attendees from some of the world’s most prominent brands, where they forge new relationships or rekindle old ones by collaborating with one of the over 300 exhibitors at the NEC. As the show has returned to its traditional February dates, it once again acts as first-quarter inspiration for the print sector – and the wider packaging industry - on a scale that simply isn’t possible in an online event.

If 2022 is any indication, live events like Packaging Innovations are set to generate increased enthusiasm from attendees and exhibitors going forward. 2023’s bumper line up shows that show organisers are more than rising to the occasion.

Packaging Innovations & Empack, Featuring Contract Pack & Fulfilment is an early statement of intent that lays down a marker for the rest of 2023 to follow. Live shows aren’t just back, they’re bigger and better than ever!

For more information please visit: www.packagingbirmingham.com

Testament that digital is the future, Fortress Technology triumphed at the recent PPMA Group Industry Awards 2022, winning the top prize for Halo Digital Testing in the most Innovative Processing System category.

Topping off another successful PPMA show, judges commended the company’s Halo Digital Testing solution for “solving a problem applicable to all food manufacturers doing metal detection testing, making it simpler for staff with no production disruption.”

Celebrating the best in British manufacturing, earning such high acclaim in the Most Innovative Processing System category showcases the appetite for digital tools among industry leaders to improve efficiency and increase audit transparency. Highly regarded in processing, packaging, manufacturing and robotics circles, Fortress fought off strong competition from automation counterparts to win this revered trophy.

Commercial Manager Jodie Curry exclaims that it’s a sign of the times how much ‘digital’ tools are changing

and improving the way tasks are performed. Particularly in fast paced food processing environments. She expands: “The adoption of automated technology features that deliver standardisation, less complexity and ease of access, all help food processors to be more efficient and productive. Our Halo Digital Testing is a brilliant example of how our company goes about creating technology tools that give corporations better control over compliance data, optimising food safety and providing fully traceable and auditable reporting documentation.”

Unique to Fortress and developed in-house in collaboration with the largest snack factory in the United States, Halo Digital Testing was originally engineered to overcome the major limitations of performing manual checks on vertical snack inspection lines.

With over 100+ Vertex metal detectors operating around the clock, 24/7, side-by-side, this global snack manufacturer, and subsequently several more, reported significant challenges resourcing manual checks to adhere to international food safety reporting standards. In particular the access challenges, high waste and health and safety risks incurred when testing metal detectors located below walkways on high freefalling product lines.

Answering their calls for a productive automated testing solution, Halo Digital Testing – a separate kit of electronics from the metal detector search head – was engineered. Mimicking the signal disturbance without physically passing a test sample through the product, food operatives and QC staff can activate tests remotely or from ground level via the HMI. Not only is this safer for staff, it saves snack, ingredient, cereal, meat and dairy processors and packing plants significant time, money and other

operational costs, with an ROI of less than 12 months.

Honouring the cream of the manufacturing crop, the annual PPMA Group 2022 awards recognised just five companies for their technological innovation, packaging prowess, vision and robotics machinery and customer

service. “Winning this respected award was a great way to celebrate another highly successful PPMA show. Having our product, time and money saving engineering efforts endorsed by our industry counterparts proves that innovation is alive and kicking in UK food manufacturing,” adds Managing Director Phil Brown.

No other technology in the food inspection market can test all sizes and metal types so reliably, precisely and at such a fast speedA team effort: The Banbury-based team celebrate winning most Innovative Processing System for Halo Digital Testing

There is a variety of award categories and EngineeringUK is proud to be sponsoring the Small-Medium Enterprise (SME) of the Year award, to recognise and reward a SME which has made a commitment to creating a more diverse and inclusive engineering industry.

Do you know any SMEs committed to creating a diverse and inclusive industry?

Engineering is made up of many organisations, both big and small, working with young people to grow the workforce and inspire tomorrow’s engineers. It is important to not only celebrate the larger engineering organisations that are committed to widening participation and creating a diverse industry, but we also need to recognise the smaller organisations that are working towards this goal.

EngineeringUK is proud to be supporting the award that celebrates the work of SMEs. Susi Farnworth, Head of Internal Equality, Diversity and Inclusion (EDI) at EngineeringUK, commented: “It is important to reward and recognise the breadth of talent in the engineering sector, celebrate diversity and acknowledge the companies, programmes and individuals that are working towards creating an inclusive and representative workforce. We are proud to be supporting the Engineering Talent Awards which will recognise brilliant engineers and engineering organisations in this space.”

Dr Mark McBride-Wright, awards founder and EqualEngineers Managing Director, said: “The awards aim to raise the profile of the engineering and technology professions across the UK and highlight diversity in engineering on a national platform...

“Through showcasing role models and inspiring people, we can celebrate the diversity of organisations and engineers…We will shine a light on the individuals and organisations working to promote and diversify in the engineering and technology sector while acknowledging milestones in business, media, politics and grassroots activism.”

Previous winners have included engineering apprentice of the year at Dyson, engineer of the year at Transport for London and FJD Consulting as SME of the year, for their work in increasing the diversity and inclusion in engineering. Last year’s ETAs honoured Costain Group’s disability and wellbeing network with the Overall Excellence in Engineering Award. They were recognised for their work to support people with Down's Syndrome and autism into work and presenting to Crossrail and HS2 on neurodiversity, while also embedding inclusive design engineering standards into their processes and training.

Award categories for the 2023 Engineering Talent Awards

• Engineering Apprentice of the Year

• Engineering Graduate of the Year

• Engineering Student of the Year

• Engineer of the Year

• Engineering Returner of the Year

• Engineering Society of the Year

• Inclusion Programme of the Year

• Employee Network of the Year

• Innovation of the Year

• Small-Medium Enterprise of the Year, supported by EngineeringUK

• Large Employer of the Year

The closing date for nominations is Friday 17 February 2023 at 5pm and the winners will be announced at the awards ceremony on 14 September 2023. Find out more on the Engineering Talent Awards website

Through recognising good practice and achievements from both individuals and organisations driving forward good work in diversity and inclusion, the 2023 Engineering Talent Awards (ETAs) set out to celebrate the diverse population among the industry.

Gripple, the manufacturer of wire joiners and tensioners for agriculture and suspension solutions for construction, is celebrating five wins at the prestigious TMMX Awards (The Manufacturer MX Awards), in partnership with the Institution of Mechanical Engineers.

The company beat off strong competition from manufacturers across the UK to win the following awards: Manufacturer of the year, Young Manufacturer of the Year, International Trade, Operational Excellence and Leadership and Strategy, after being shortlisted in 10 out of 11 categories.

Judges crowned Gripple ‘Manufacturer of the Year 2022’ due to its “growing, innovative, people-led, customer aware and focused business.”

The Young Manufacturer of the Year 2022 category was won by Natasha Lyth, Sustainability Manager at Gripple. Natasha joined Gripple in 2018 and now spearheads the company’s Net Zero strategy. The judging panel said “Natasha is fully committed to manufacturing, evidenced by her development plan. She sees her future in the sector.” Another panel member praised Natasha for the “continuous improvements she implements at Gripple.”

Gripple won the award for International Trade for the company’s commitment to expanding its international business. Judges commented on Gripple’s entry as “great, conveying a sense of strategy, illustrating innovation and strong market adaptation.”

The Operational Excellence award recognised Gripple’s effective use of lean methodologies and techniques to drive improvements across its operations. Gripple was praised by judges for its

Gordon Macrae, Special Projects Manager at Gripple, explains: “This was a fantastic night for Gripple and for manufacturing in South Yorkshire! The TMMX Awards are the most prestigious manufacturing awards in the country, so it is a real honour for us to win five categories. The entry process and judging criteria are, quite rightly, rigorous and the judges really do put you to the test when they visit, but we are so pleased with the feedback we received and will use this to continually improve our operations. Well done team Gripple!”

He adds: “The TMMX awards are an opportunity to showcase the passion for excellence we have across our business which is driven by Gripple being an employee-owned business.”

The winners were announced at The Manufacturer MX Awards ceremony and gala dinner which took place on Thursday 17th November at the Exhibition Centre in Liverpool, hosted by comedian Rory Bremner. The evening was held at the end of Digital Manufacturing Week and attended by 900 people from the manufacturing industry.

For more details, visit www.gripple.com

“Toyota-style thinking, which is testimony to how the company is actively achieving operational excellence through adopting a lean approach to manufacturing.”

Mr Minoru Ito, European Sales Office, Gronauer Straße 1, 61194 Niddatal, Germany 0049 (0)6034 930970 europe.office@tandd.de www.tandd.com

European Corporate Office, Hambridge Lane, Newbury, Berkshire, RG14 5TU 01635 279621 www.cwst.co.uk eurosales@cwst.com

Phoenix Mecano Ltd

26 Faraday Road, Aylesbury, Buckinghamshire, HP19 8RY +44 (0)1296 611660 www.phoenix-mecano.co.uk

Monitran

Monitran Ltd, Monitor House, 33 Hazlemere Road, Penn, HP10 8AD, UK

T: +44 (0)1494 816569

E: info@monitran.com www.monitran.com

ODU-UK LTD.

Unit 3A, Whitworth Court, Manor Park, Runcorn WA7 1WA. Tel.: (0044)-330 002 0640, sales@odu-uk.co.uk www.odu-uk.co.uk

Trifast House, Bellbrook Park, Uckfield, East Sussex, TN22 1QW

Free phone: 08454 811 800 E-mail: sales@trfastenings.com www.trfastenings.com

Blackfast Chemicals Ltd

Unit 5 Russell House , Molesey Road, Walton-onThames, Surrey, KT12 3PE 0207 339 7370, sales@blackfast.com www.blackfast.com

Ecopac (UK) Power Ltd

Unit 4, Ridgeway, Crendon Industrial Area, Long Crendon, Bucks, HP18 9BF Tel: +44 1844204420 www.ecopacpower.co.uk

Foremost Electronics Ltd

14 Bluegate Business Park Great Bardfield, Essex CM7 4PZ

TEL: +44 (0) 1371 811171 FAX: +44 (0) 1371 810933 WEB: www.4most.co.uk

3, Abloy House, Hatters Ln, Watford WD18 8AJ www.hrs-heatexchangers.com Email: info@uk.hrs-he.com Tel: +44 (0)1923 232 335

Seepex UK Ltd. 3 Armtech Row Houndstone Business Park Yeovil, Somerset, BA22 8RW

T +44 1935 472376 sales.uk@seepex.com www.seepex.com

Mecmesin Ltd

Newton House, Spring Copse Business Park, Slinfold, West Sussex, RH13 0SZ w: www.mecmesin.com t: +44 (0) 1403 799979 e: info@mecmesin.com

BÜLTE GmbH

Rotech Machines Limited

1 Brownfields Court Welwyn Garden City Hertfordshire, AL7 1AJ www.rotechmachines.com

Wood Automated Systems UK (ATG – Systems)

Tenter Road, Moulton Park Industrial Estate Northampton, NN3 6AX +44 (0)7827 327231

Tim.Bednall@woodplc.com www.the-atg.com

Kunststofferzeugnisse

Carl-Sonnenschein-Straße 22 D-59348 Lüdinghausen – Germany

Phone: (+49) 02591 / 91 94 – 0 info@bulte.de www.bulte.com

Lascar Electronics Ltd UK

Module House Whiteparish, Wiltshire SP5 2SJ +44 (0)1794 884 567 sales@lascar.co.uk www.lascarelectronics.com