Hop[e] Brewing

Year 4.2 - Final Year Project

Location: Swindon, UK

Sector: F&B / Research

Year: 2023 / 2024

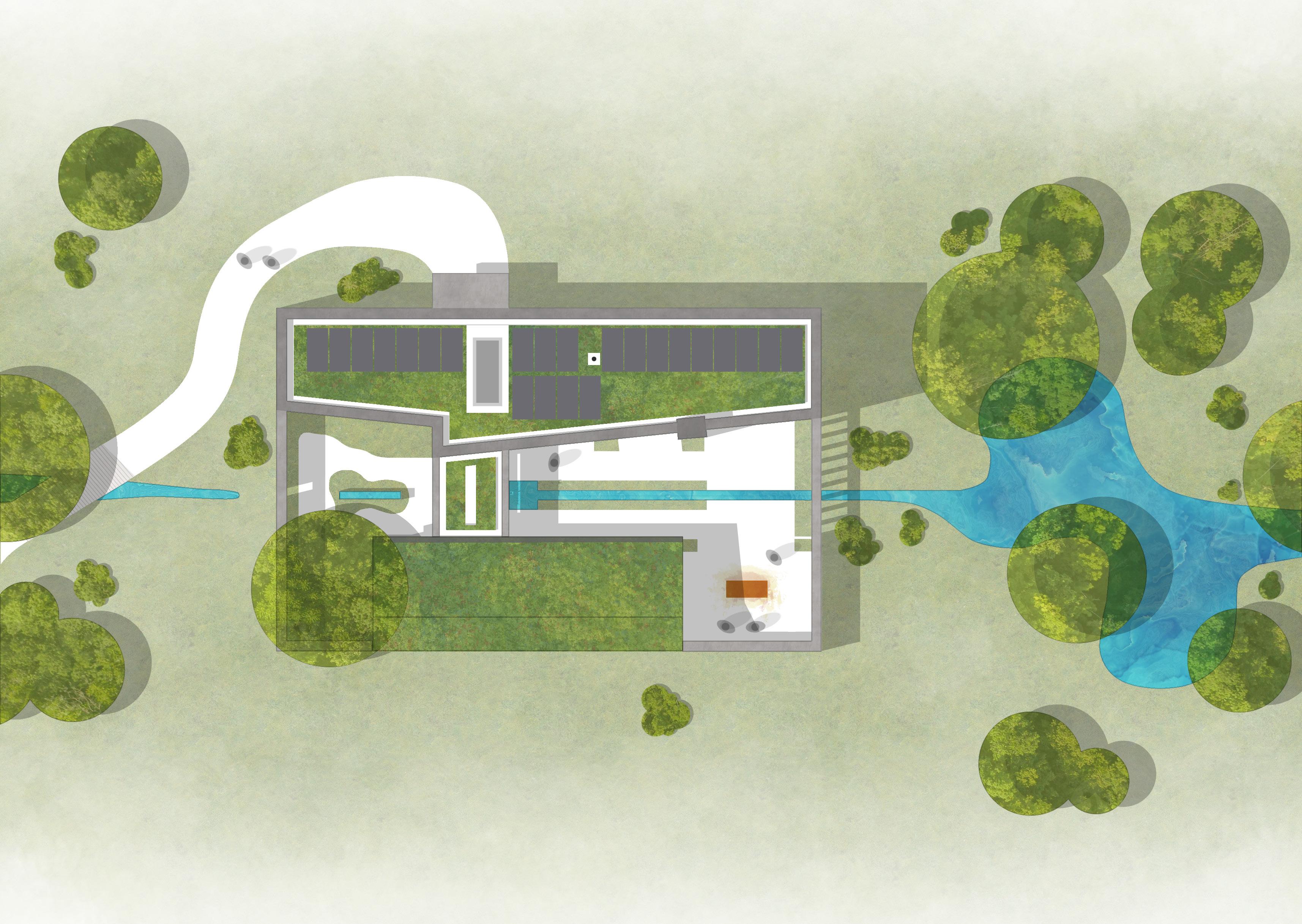

The culminating design project of my undergraduate degree is a cyclical brewery; merging the historic and traditional process of brewing with cutting edge science to create a process where ingredients are cultivated in-house and waste products are recycled into biogas. The proposal reimagines the vacant Old Town Hall & Corn Exchange in Swindon as a test bed for this new method of brewing; a manifesto project to develop and expose this technology for adoption by larger brewing manufacturers. Taking references from the existing Listed structure and arranged as an inflection of served and service zones, the proposal offers opportunities for the public to observe and understand the roles the various spaces and processes play in the continued operation of the building.

With the demolition of an existing neighbouring building a necessity for the proposal, the project takes a unique approach to repurposing these otherwise waste materials. Instead, they are viewed as a kit of parts, with their integration into the scheme creating a visible dialogue of reuse.

The full design report for this project can be viewed by scanning the QR code above, or by clicking here

p. 7

Pre-TreatmentChemicalsIn C0 2 fromfermentation Hops Barley BREWEDPRODUCTS OUT Yeast Treated&filtered wastewater recirculated‘Excess’wasteheatnot distributedintobrewingtanks toUFHsystem mashUnreactedgrain recirculated KITCHEN Grainmash composted WASTEIN 01 02 03 04 05 06 07 08 SpentGrains 09 10 11 12 13 13 13 14 14 15 16 17 18

In 2020, global annual beer production was estimated at 1.82 billion hL (1hL=100L). Of all waste produced during this process, wet BSG (Brewers Spent Grain) accounts for 85% - equating to an annual production of 39 million tons worldwide. For every 100 litres of beer produced, 20kg of spent grains are created as a waste product.These currently have little opportunity for further use outside of feedstocks or compost, with around 20% sent to landfill. For every ton of BSG sent to landfill, 513kg CO2 is released.

In 2022, the UK produced 37.5 million hL of beer, ranked 4th in the EU. Using the ratios discussed previously, it can be estimated that the approximate annual UK production of brewers spent grains is 750,000 tons. Anaerobic digestion processes can turn these grains into hydrogen; a clean fuel which can be turned into electricity using a fuel cell. The only waste emission is water; the ‘left over’ BSG can be used for compost. A circular model is critical to generate maximum potential from this otherwise waste product - the UK produces enough spent grains to generate enough clean energy to satisfy the annual power demand of 1.1 million homes.

Lauter Tun

Brewing Kettle

Whirlpool Tank

Fermentation Tank

Serving Tanks, Canning & Kegs

Pre-treatment Tank

Separator Tanks

Granular Biomass Reactor

Anaerobic Digester

Exhaust Gas Flue

Hydrogen Storage Tanks

Hydrogen Fuel Cells

Water Filtration System

Solar PV Battery Storage

1 Ton BSG Waste Power OR 513kg CO2 3900 kWh

Beer movement Linework Key: Water movement Plant movement Waste movement Chemical movement 01 Process Key: 02 03 04 05 06 07 08 09 10 11 12 13 14 15 16 17 18 19 20 21 22 23 RWH Tank UV Treatment Water Storage Tank Vertical Hop Farm External Growing Areas

Macerator

Composting

Grain Mill

POWER POWER 19 19 21 20 22 23

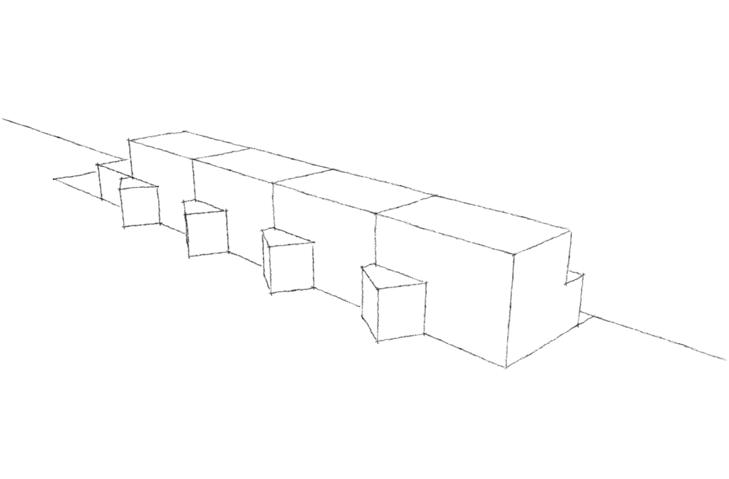

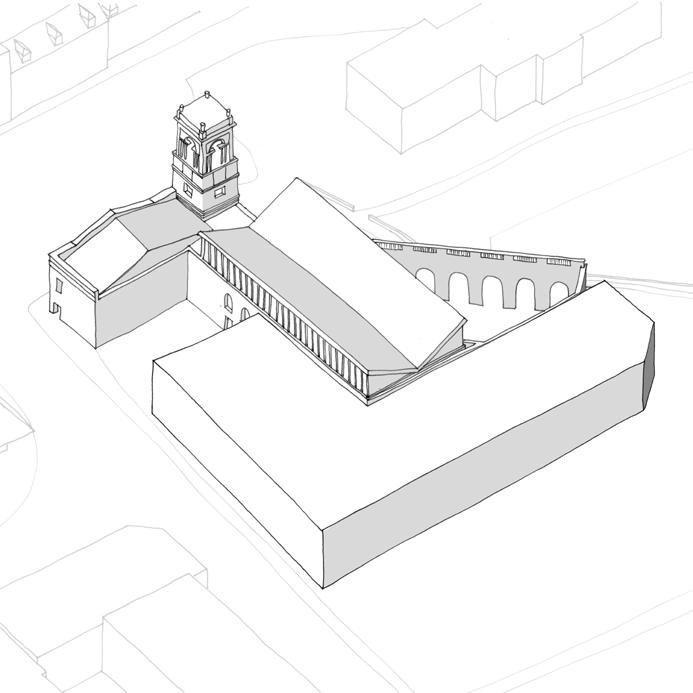

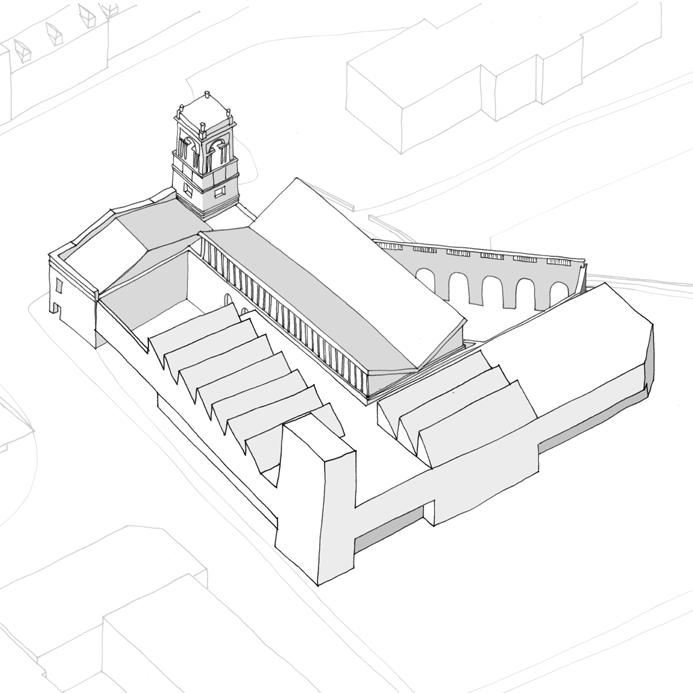

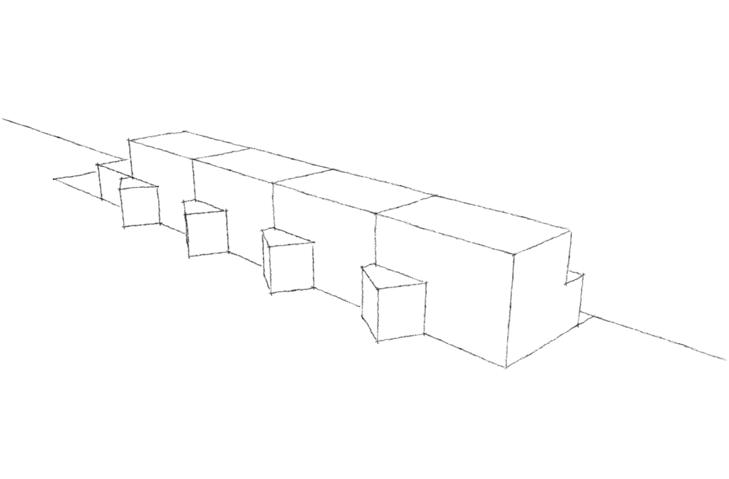

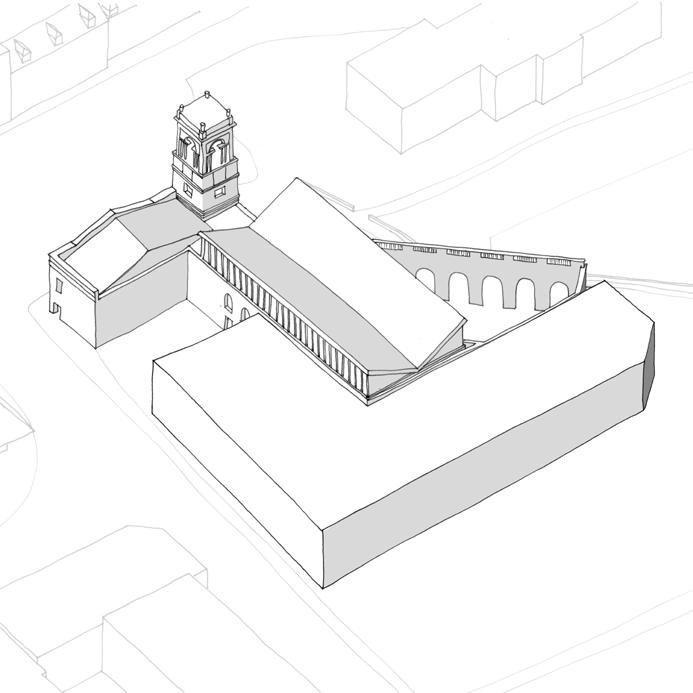

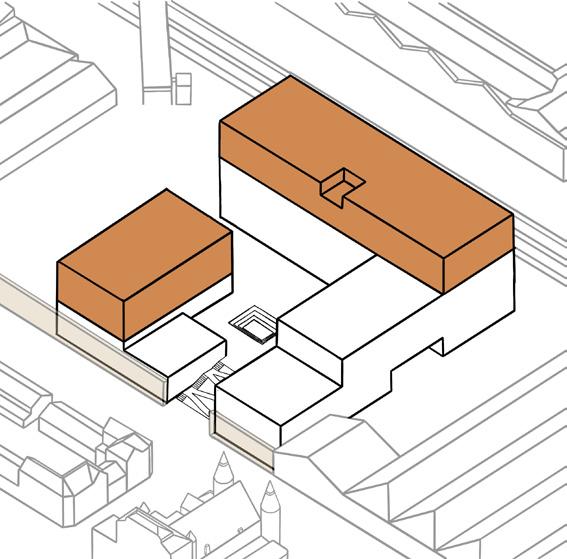

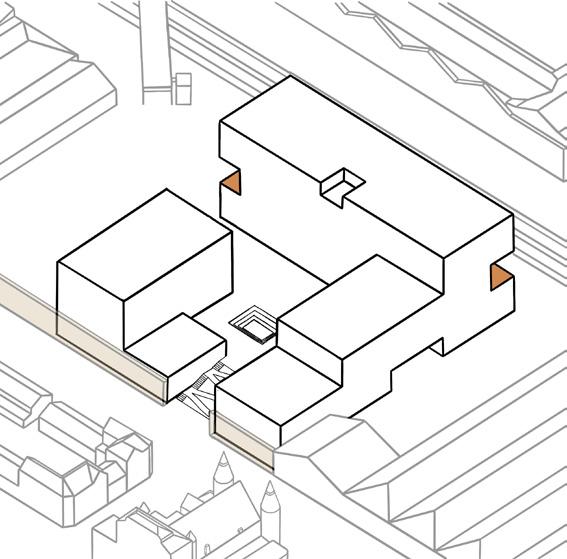

The existing 1970’s office block (‘The Forum’) is demolished. Materials salvaged and retained to be reused within the new proposal.

New trussed butterfly roof structure and mezzanine inserted into existing Corn Exchange. Continuous clerestory added to East and West elevations between the underside of the new roof, and top of existing wall.

New massing proposed to South and West of existing building, with the extent of massing to the South informed by historic plot boundaries. Massing stopped short of the existing Town Hall to form a courtyard and allow the existing building to breathe.

p. 10

[Demolish]

[Insert]

[Envelop]

[Align] [Inflect]

The elevation to the West is skewed to align with adjacent road edge, maximising the active frontage and meshing the building with the public realm.

New tower added to South West corner to anchor the new massing, acting as an inflection of the existing bell tower to the North. The new West facade at first floor level is extruded to abut the existing Town Hall building, providing enclosure to the new courtyard.

[Emphasise]

Sections of the Ground Floor are recessed to add vertical emphasis to the new elevations and further reinforce the solidity of the new tower. Sawtooth roof planes are added over key spaces (the brewing hall and labs) to provide North light and break up the flat roof plane.

p. 11

My proposal aims to re-inhabit the existing vacant Old Town Hall and Corn Exchange, known locally as the Locarno. The building has a rich history - built in 1852 and currently Grade II listed. It was gutted by two fires in 2002 and 2004 which left the building as a vacant shell; long since abandoned with no plans for its redevelopment.

Being a highly active, public building, the project aims to enliven the area surrounding the Old Town Hall and so breathe life into this fractured area of Swindon. The building can be seen as a nexus; stitching together the myriad of architectural languages, urban grains and masterplanning typologies which clash within the wider context of Old Town. It also creates a building which the community can rally around, and from which they can draw new civic pride.

My proposal sees an adjacent 1970’s office block demolished; the structure used as a ‘catalogue of parts’ which both informs the design of, and is used in, the new building. Through the development of the project, a language of reuse has emerged, with materials used in their raw and unapologetic state as taken from the demolished building. New interventions are designed in a lighter, sympathetic language, sparking a dialogue between new and old.

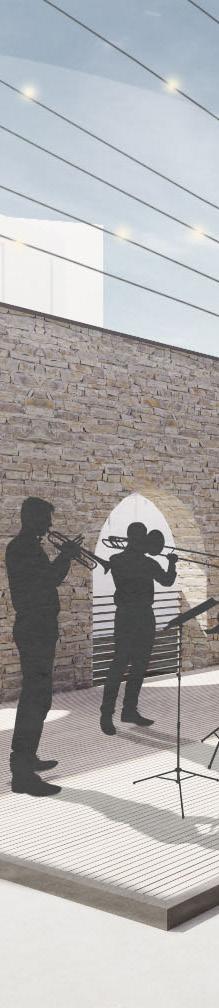

Visual from Taproom

Visual from Taproom

The proposal is planned around an inflection of public and manufacturing zones, reflecting the historic and new elements of the scheme. Interfaces at the boundaries provide opportunities for the public to observe and understand the roles the various spaces play in the continued operation of the building.

The building is a permeable entity, able to be entered and explored from several angles. This naturally draws the users into the heart of the proposal; the taproom. From here, each distinct aspect of the building is visible, and the served/service boundaries typical to food & drinking establishments are blurred.

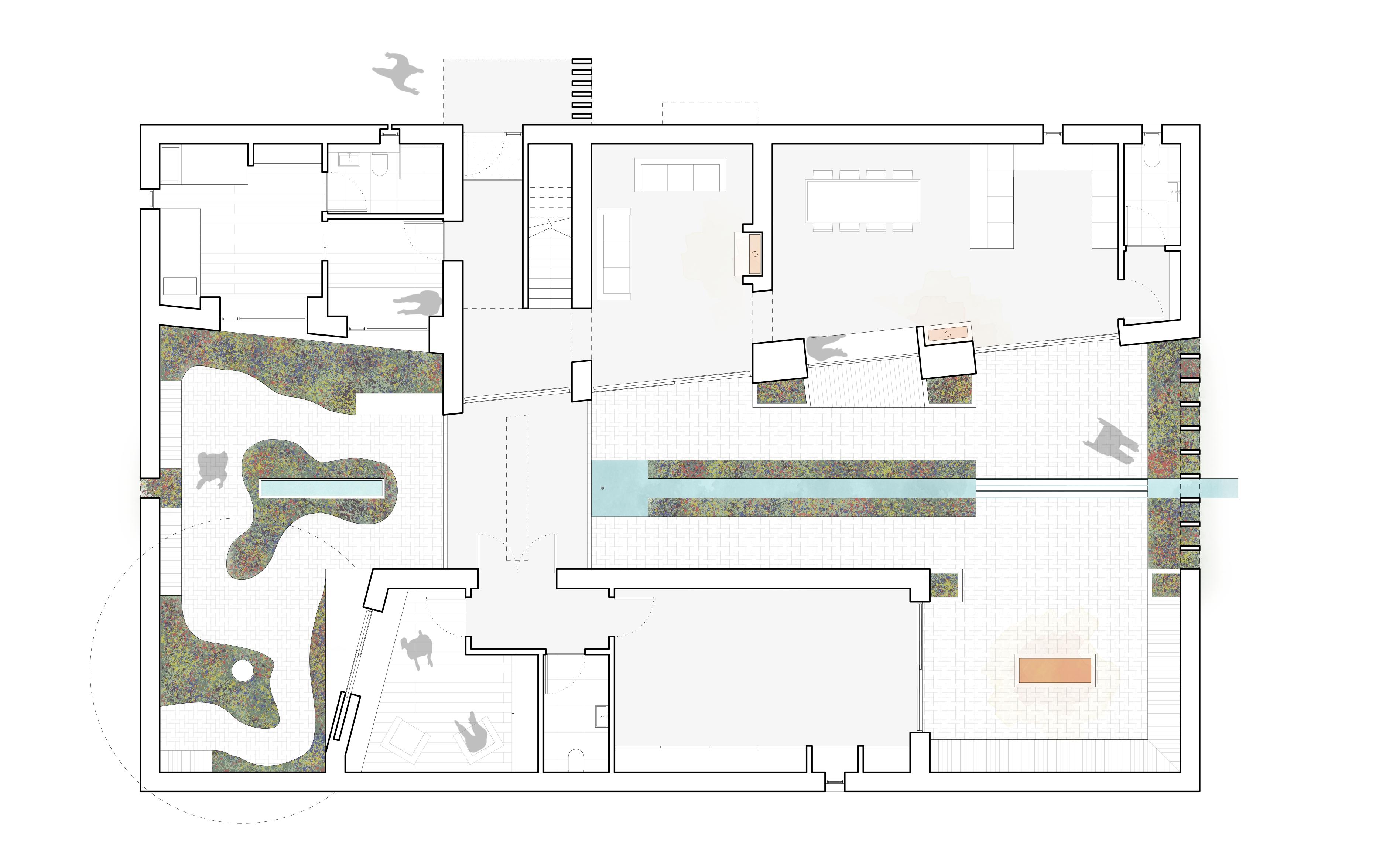

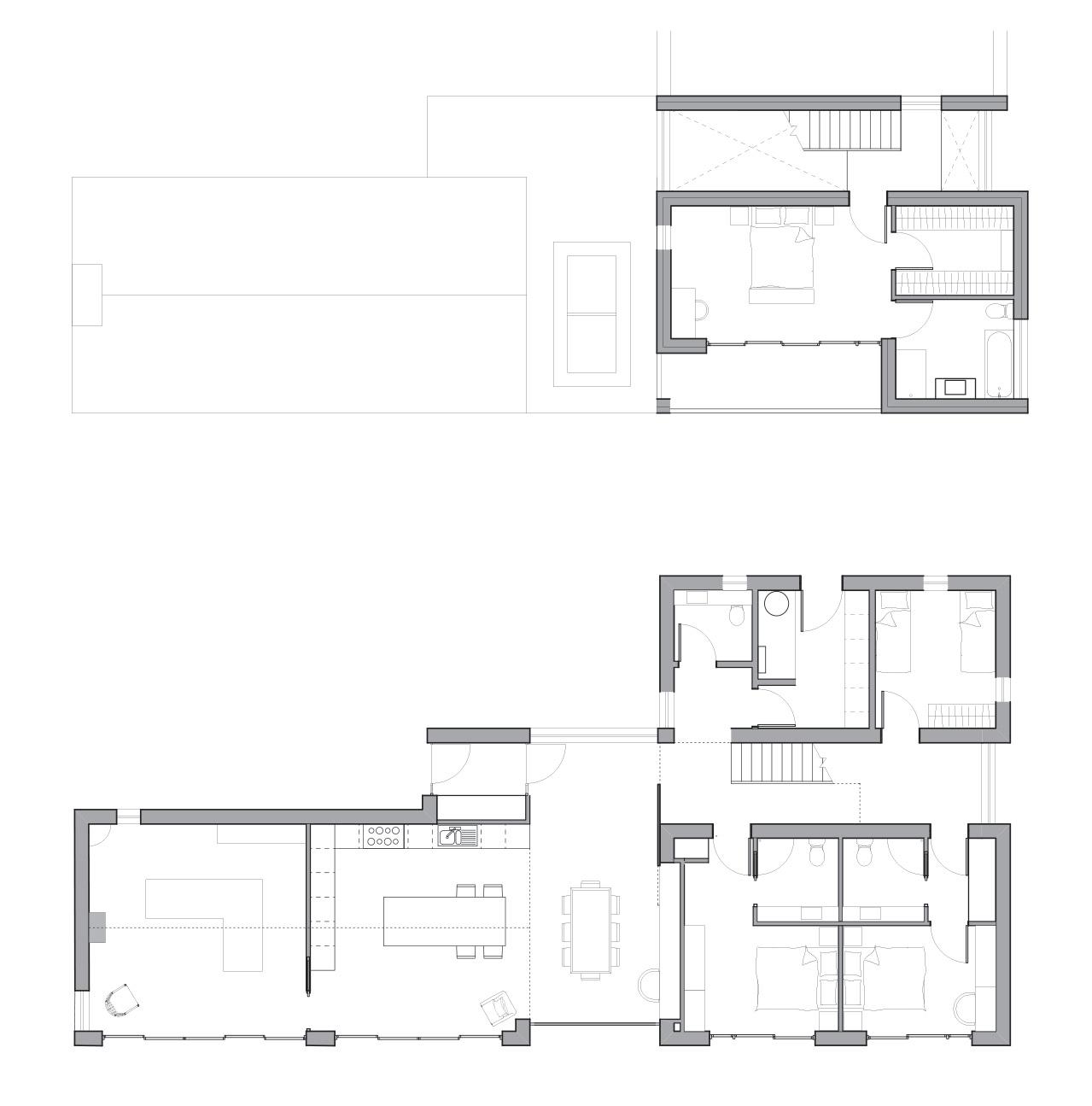

p. 15 Ground Floor Plan

01 01 02 02 03 03 04 04 05 05 08 08 08 07 07 06 06 09 09 12 10 10 11 11 12 13 13 14 14 15 15 16 16 Taproom & Bar Exhibition Space Entrance Tower Prep Kitchen Beer Garden Shop Hydroponics Growing Hall Observation Space Brewing Hall Packaging & Storage Workshop Bio-hydrogen Generation Bio-hydrogen Storage Goods Lift Seminar Room Changing Places W.C

p. 16 VENTED AT TOP AND BOTTOM? C B A D E Tectonic Section 20m 10 20m 15

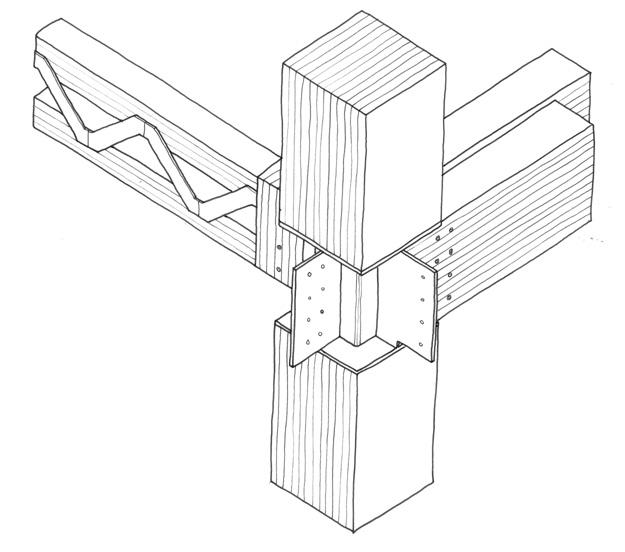

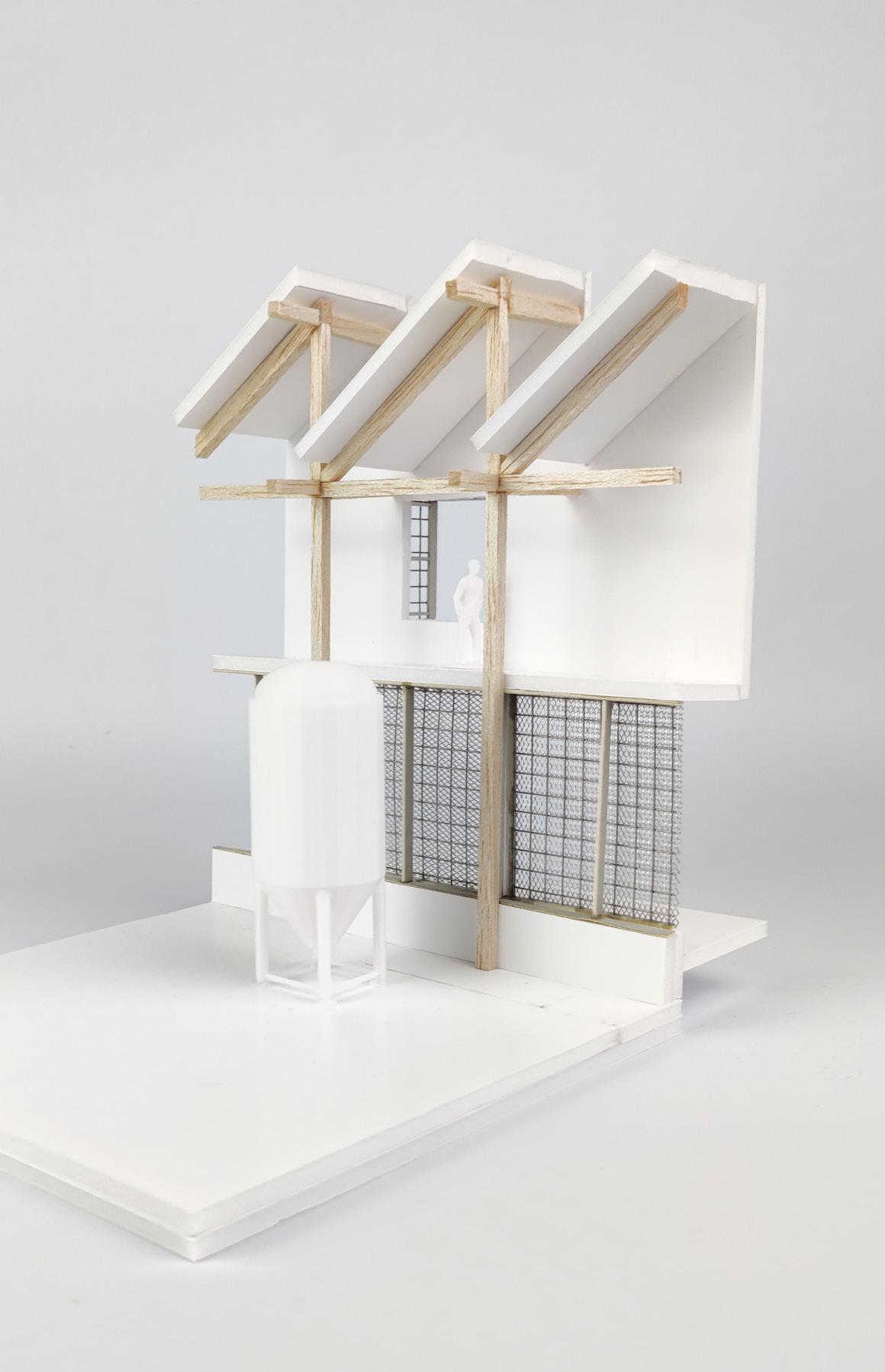

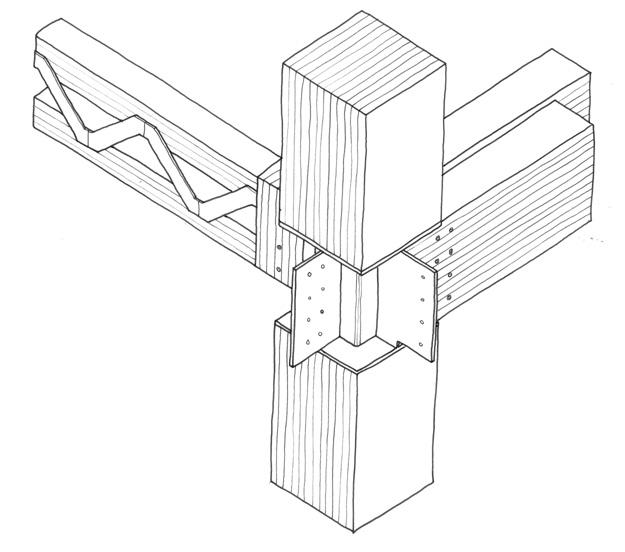

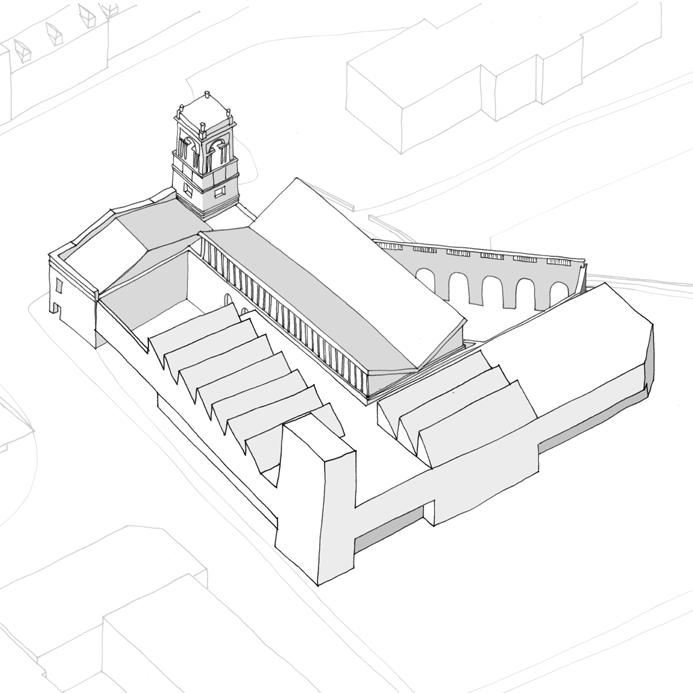

The scheme proposes a clear tectonic strategy to clearly differentiate historic, reclaimed and proposed elements. New structure is typically lightweight timber, contrasting with the heavier masonry of the existing building. This creates a strong narrative of levels of permanence - the new lightweight structure easily removable at the end of its life, whereas heavier elements (including those reclaimed) are tied to the site either in their historic form or reimagined for a new lease of life.

The proposal endeavours not to purely reuse materials in their original forms, but to reimagine how they may be reused or repurposed into forms not originally intended. This both extends the life of materials which would otherwise be left as waste, and opens a crucial dialogue on how new projects elsewhere in Swindon, the UK or across the world can inventively reuse old or reclaimed materials.

Within the existing Corn Exchange which houses the proposed taproom, the main intervention takes the form of a glulam butterfly truss, a lightweight structure which supports the roof above whilst allowing for generous clerestory above the existing walls. These elements come together to create a language of insertion, with the existing stone walls acting as a container for the new structure.

The primary benefit of a truss of this type is that all forces are contained within the members, with no external forces applied on the existing building apart from at the base of the columns. In turn, this ensures there will be no long term damage to the existing walls; the frame can hypothetically be removed at the end of the building’s life and leave no imprint on the existing structure.

p. 17

Butterfly Roof Development Model (1:200)

Visual in Brewing Hall

Visual in Brewing Hall

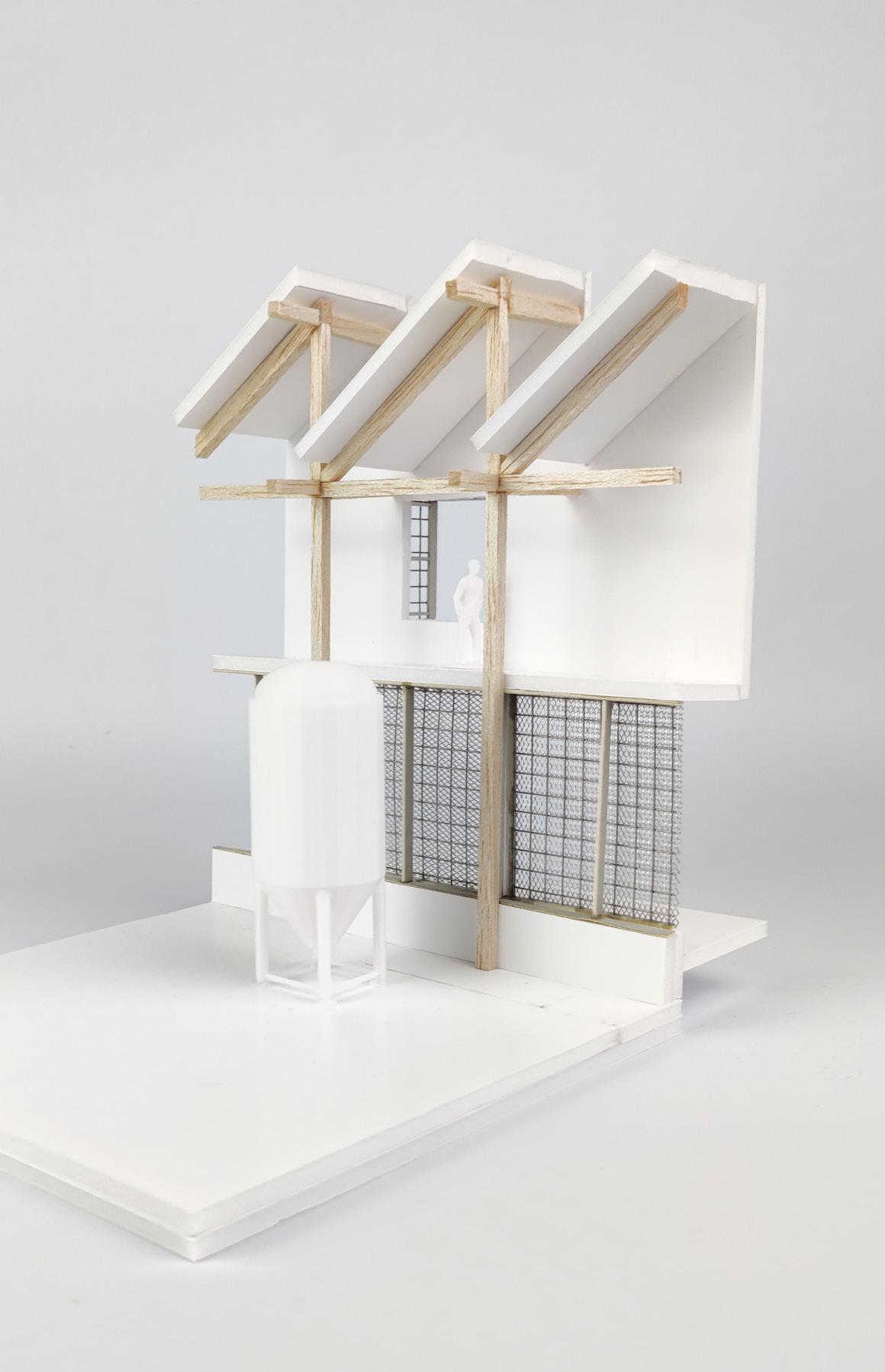

p. 19 1:50 Tectonic Model

Sitting adjacent to the taproom and facing onto the busy public realm to the West of the site sits the Brewing Hall. The tectonic language of this space is about ‘connections’ - opening the space up to both the taproom and public realm to engage the public with the activity occurring within. In line with the overall concept, it can also be viewed as an inflection of the tectonic of the taproom; a heavy brick ‘lid’ sitting over a lightweight base, as opposed to a lightweight roof sitting over heavy masonry walls.

As a result of this, the materiality of the ground and first floors are vastly different; the ground level much more permeable, and the first floor more solid. Continual glazing runs the length of the ground floor, exposing the glulam structure and brewing vessels behind. Galvanised mesh panels provide varying degrees of privacy, and an ever changing play of light and dark within the space. On the contrary, the masonry panels read much heavier; hung from the glulam structure with deep openings punched into the facade.

Line of soldier coursed brick to top of wall, bedded in lime mortar 1m x 1m reclaimed brick panel cut from facade of existing demolished building, bedded on 25mm thick concrete backing panel

p. 21 Bay Elevation

A

Sawtooth Roof Gable Detail (A)

Glulam structure (300x500mm)

CLT roof deck

Reclaimed standing seam roof

1 2 3 4 5 6 1 1 2 3 4 5 6

PPC aluminium pressing

Year 4.1 - TED Integrated Design Project

Location: Swindon, UK

Sector: Education

Year: 2023

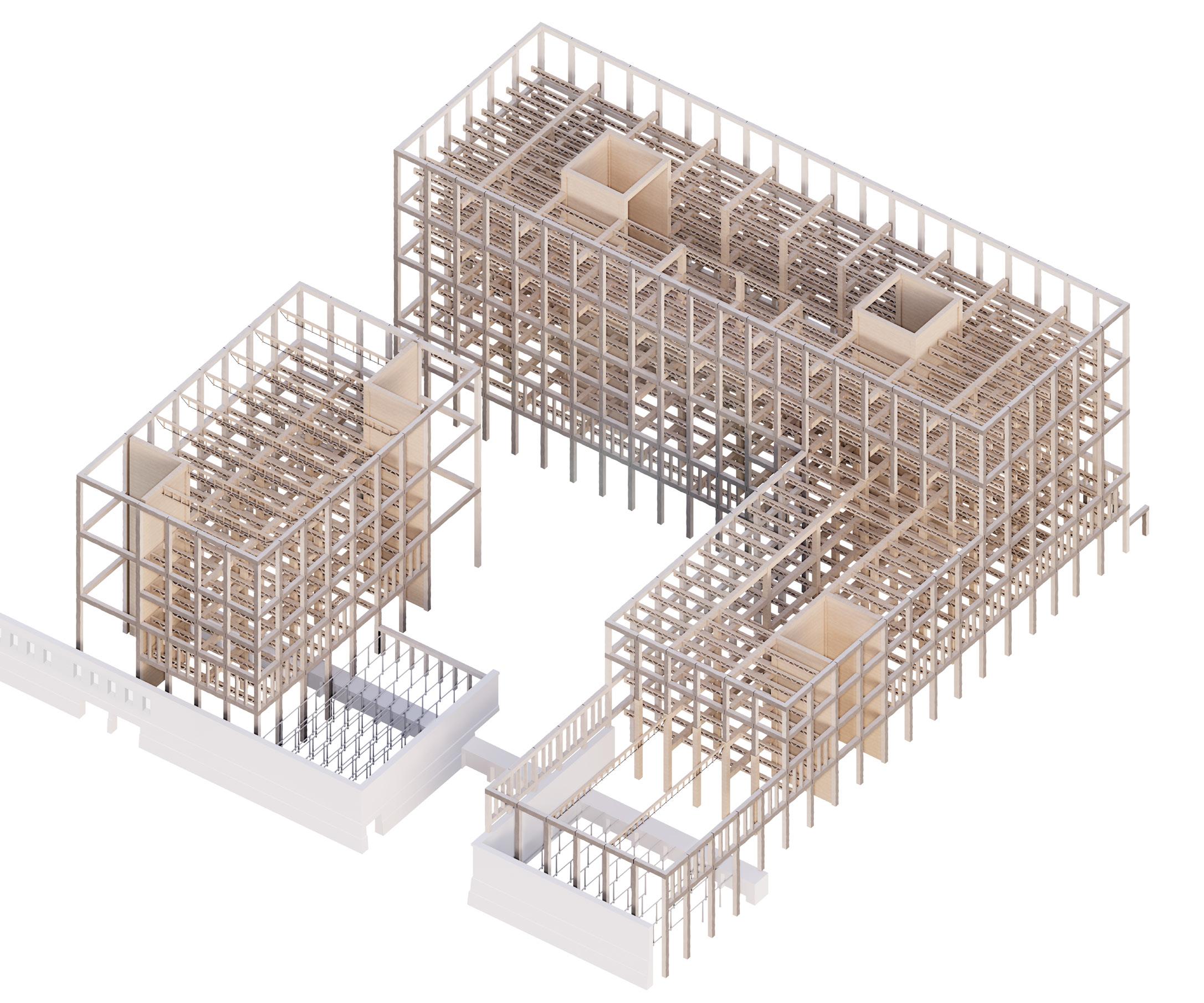

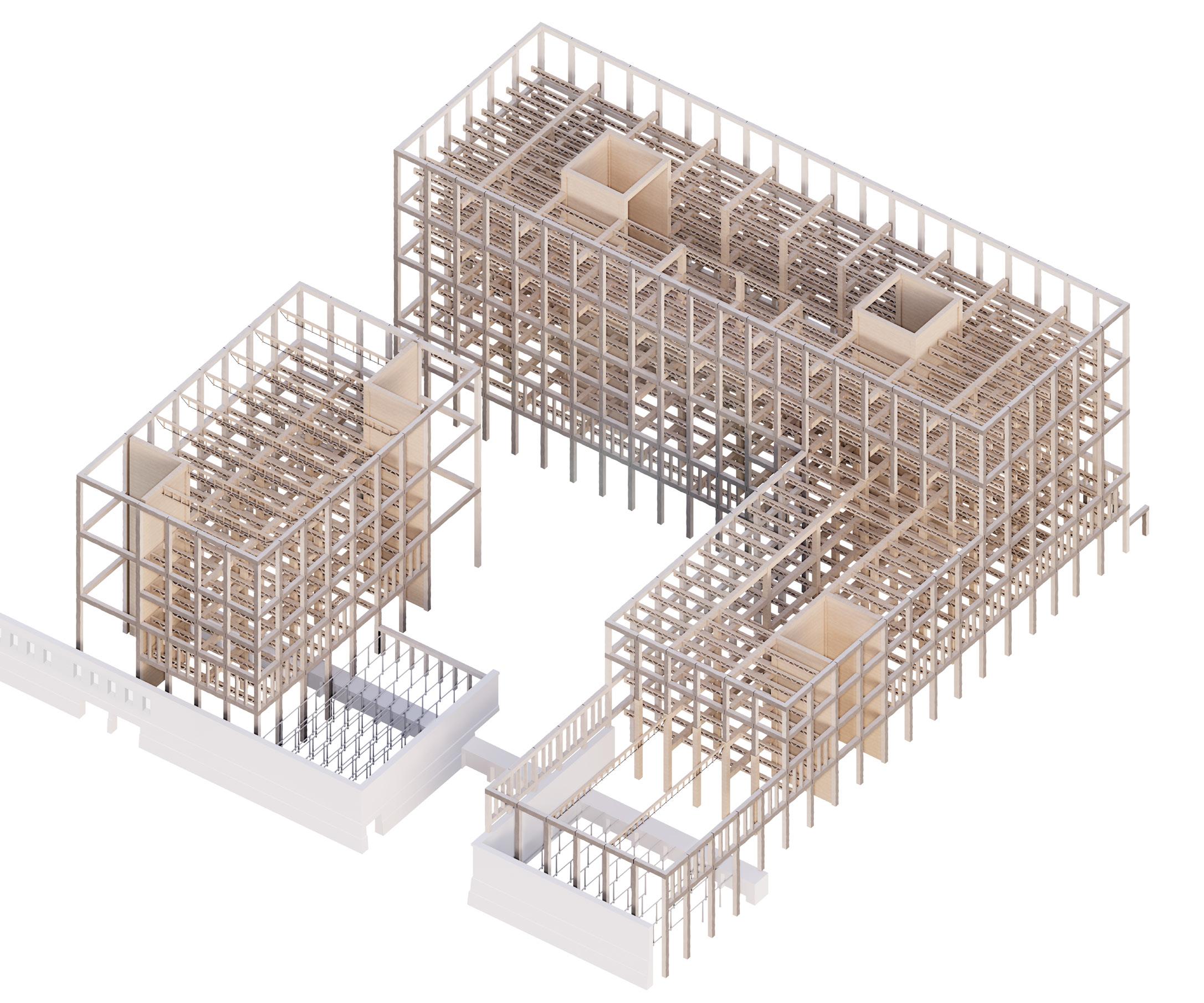

Our group project in fourth year, the TED Happold Integrated Design Project, placed us in a group with Civil Engineering students and set a complex design brief for a proposal at a much larger scale than any of our previous projects. This year’s brief called for a new HE institute in the town of Swindon, set on a vacant site adjacent to the railway, specialising in two key subjects chosen by the group.

Our group chose to focus on the subjects of Biomedical Engineering and Materials Science; proposing that our Institute works closely with a nearby UoB & UoO research hub called iCAST. Our scheme was developed with the idea of ‘transfers of knowledge’; facilitating spaces of all scales to enable shared learning between all stakeholders of the building - from students and researchers, to staff and public.

p. 23

Connexus

Our brief for our group project was complex; to design a new HE institute in the town of ‘New Swindon’ combined with an industry innovation hub, which together will act as the public face of a regional university. The building was required to facilitate two specialist subjects of our choosing - these were Materials Science and Medical Engineering. The project was required to include a detailed schedule of accommodation, which is summarised below.

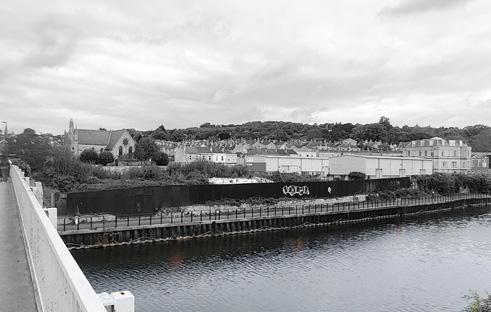

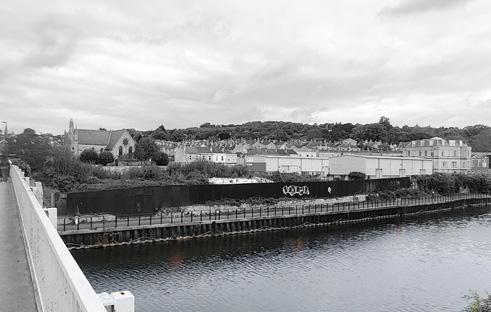

Through industry collaboration, the proposal aims to pull new FE students into STEAM fields. The site, Bristol Street Car Park, sits within the now designated Swindon Railway Conservation Area and is in the local vicinity of several significant buildings including the Mechanics’ Institute, Historic England archives and the National Trust ‘Heelis’ building.

Library 24x Classrooms Specialist Subjects

Workshop

124x Bedrooms

Public Connection Dining Hall Auditorium

(By Others)

Figure Ground Image from Group Project

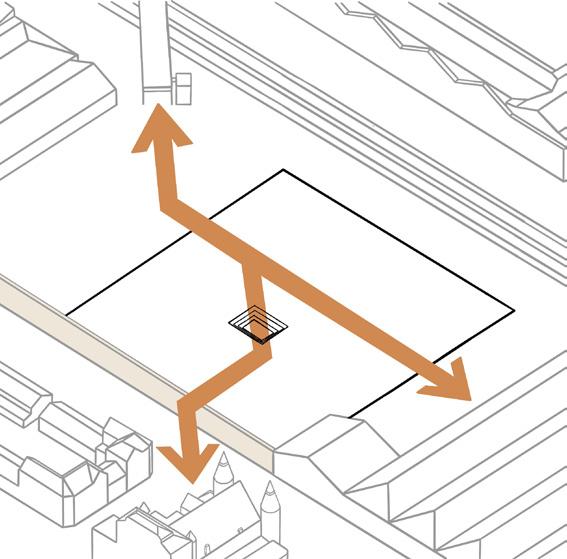

Establishing two key connections through the site. The first is the Mechanics’ Institute to the new bridge adjacent to our site. The second is iCAST to the new public realm.

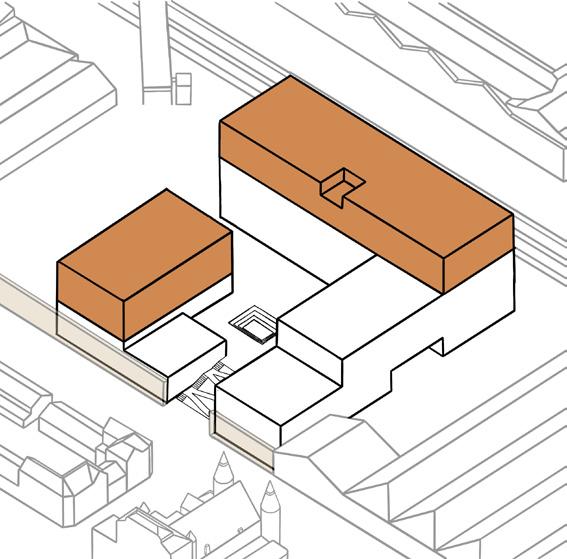

We introduce the two subject faculties which meet at the corner creating an informal ‘meld’ used for knowledge transfer. The massing is stepped back away from the existing wall.

Using the key axes, we established a route through the site. We connected our ‘heart’, an amphitheatre used for knowledge transfer as well as acting as a rain garden, a key part of the scheme.

Student accommodation lies on the top floors of the north building, providing a strong facade to the railway. The student library occupies the next floors of the smaller tower.

Our massing has been arranged around the route through the site, creating a central courtyard surrounded by two L-shaped buildings.

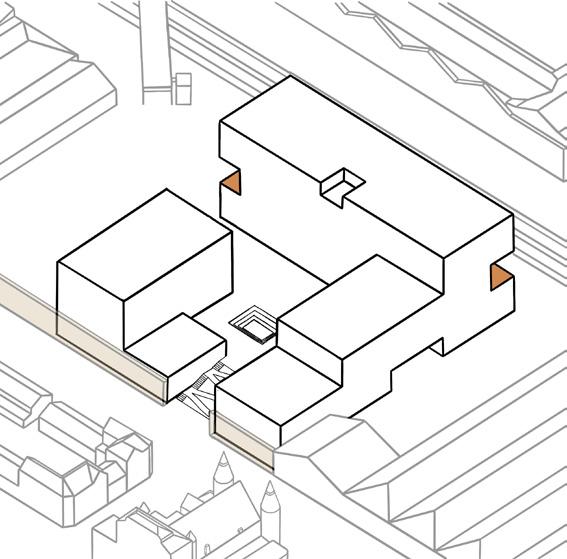

In response to the railway, we have cut out sections of the massing to create depth and interest to onlookers from the trains.

We have a public lower ground level within the existing structure of the site. All public functions are arranged along the main route across the site with auditorium and food hall at either end.

At the top of the smaller tower, we have placed an industry workshop. This is to be used as our Innovation Hub where collaboration is the focus of all activities and knowledge transfer between research and industry is fundamental.

p. 25 Images from Group Project (By Others)

2.

3.

4.

8.

1. KEY AXES

THE ROUTE & HEART

THE MASSING

LOWER GROUND & PUBLIC 5. THE FACULTIES & ‘MELD’ 6. STUDENT LIFE

7.

THE RAILWAY FACADE

THE INNOVATION HUB

N

Our proposal re-imagined a locally available, vernacular material – stone – as a structural exoskeleton, with the building acting as a manifesto for this emerging method of construction. Stone provides many benefits as a material, but is currently ignored in the wider construction sector. Drawing on existing precedents such as 15 Clerkenwell Close (designed by Amin Taha + GROUPWORK, and Webb Yates Engineers), this choice demanded a collaborative approach where structural, architectural and environmental requirements were of equal importance. Our unique structural system, alongside a considered architectural design and rigorous environmental strategies, created a carbon negative building with the capacity to last for generations.

Site Plan

Bristol Street

Bristol - London Railway Line

p. 27 Section A-A Section A-A 0 5 10 15 20 25 1:200 @ A3 Section A-A Key Plan

Auditorium

Library Innovation Hub

Exhibition Space

Visualisation from ‘Innovation Hub’

Visualisation from ‘Innovation Hub’

Stone exoskeleton beams (500x600mm)

Galvanised steel connection ‘T’ with integrated thermal break positioned within insulation line

Glulam trimmer beam between trusses (200x300mm)

Powder coated aluminium fascia to parapet

Proprietary insulated structural angle (IsoChemie ‘Winframer’) allowing for glazing frame to be positioned within insulation line, so eliminating cold bridging from interface

Multiwall polycarbonate glazing (by Lamilux) with thermally broken frame - U value 0.9 W/ m2K

Horizontal louvres fixed to exoskeleton beams (to suit South East facing facade orientation)

Timber acoustic panels fixed to ceiling (with acoustic insulation between and above timber fins) to suit required reverberation time of less than 1 second

Screed layer over CLT floor (providing vibration dampening, acoustic and thermal mass

Insulated timber cassette panel with rainscreen panels over

p. 29 Innovation Hub Tectonic Section

Detail A (Facade to Roof)

Detail B (Facade to Floor)

Detail A

Detail B

1 2 3 4 6 7 8 9 10 5 1 2 3 4 6 8 7 7 5 1 2 5 6 9 8

The specialist teaching spaces are arranged within distinct faculties with labs on the lower floor and workshops above. Each faculty has a double height atrium and a dedicated stair between the two floors. This creates a sense of identity to each faculty and prevents a ‘copy/paste’ approach. Informal and flexible study spaces are provided between defined teaching spaces to facilitate discussions and “transfers of knowledge” between students, researchers and staff.

Labs and workshops were designed to respect the hierarchy of the grid established by the exoskeleton, with the same linear language continued inside to ensure a cohesive whole.

p. 30

Floor Plan Extract Visualisation of Faculty Study Space LIFTS Going 167 Rise Flexible Study Space (Atrium) Biomaterials Lab Biomechanics Lab Computer Lab WCs Changing Rooms Student Work Store Prototyping Workshop 1 2 3 4 5 6 7 8 1 2 2 3 4 5

Second

Section Through Biomedical Engineering Faculty

Triple glazed rooflight with thermally broken frame

U value 0.9 W/m2K

Rooflights fixed on angled firrings to allow for drainage

Fins framed with softwood battens, voids infilled with acoustic insulation batts

15mm plywood facing to fins (by ‘Purebond’ or similar, containing zero formaldehyde or VOC’s) with routed slots

Recessed shadowgap at joints with integrated LED lighting

p. 31

Rooflight Fin Detail (C)

Glulam posijoist

1 2 8 6 4 Second Floor Third Floor 1 2 3 4 5 6 1 2 3 4 5 6 Detail C

As part of our schedule of accommodation, we were required to include 124 student bedrooms. We designed these with a focus on socialising, providing opportunities for interaction at every level of ‘division’ within the accommodation blocks. To do this, we turned to the concept of streets; at the larger level, providing internal and external shared streets which facilitated socialising between flats. Internally, bridges linked flats across a three storey atrium, creating a community within the student accommodation.

At the smaller scale, we challenged the concept of a corridorseeing this more as a street with flats organised around paired doorways. This creates more intimate connections between individual rooms and their ‘neighbour’, referencing the elevations of Brunels’ GWR Workers Cottages adjacent to the site.

p. 32

Fourth Floor (Student Accommodation) Plan Extract

Visualisation of Internal Student ‘Street’

p. 33

Axonometric of Student Room Cluster

p. 34

Structural Axonometric

Detail A

Detail C

Detail B

N.B: Flooring systems not shown for clarity

Details drawn by myself, designed in collaboration with group engineers

p. 35

Detail A: Exoskeleton to Primary Beams & Floor Slab

Detail B: Exoskeleton to Secondary Beams

Detail C: Internal Structural Node Connection

Wall Cassette Panels Curtain Walling Rainscreen Cladding Steel Connections Stone Exoskeleton Sheathing Insulation

Exploded Facade Assembly Sketch

Playtime

Year 3.2

Location: Oxford, UK

Sector: Community / Performing Arts

Year: 2022 / 2023

Our main design project of third year revolved around designing a new community theatre within the historic city centre of Oxford. My chosen site was an existing but underutilised building to the north of Bonn Square, which was to be demolished following a hypothetical fire. Sitting at the West end of Oxford’s historic high street and adjacent to the Westgate shopping centre, the proposal evolved from a simple theatre into a multifaceted offering which gave back to the public realm and reactivated the square it faced.

p. 37

Our proposals were required to be designed in response to the needs of a minority / under-represented group, who would utilise the theatre in either a performer or audience role. My proposal focussed on the homeless population of Oxford, with my chosen site (Bonn Square), being the rough sleeping hub of the City Centre.

My scheme incorporated a small hostel which could be used by rough sleepers, and included a communal kitchen, washing, laundry and sleeping facilities. The theatre would act as an extension of an existing local charity - Crisis Skylight - who provide employment and support for homeless and struggling people through the medium of theatre.

According to the 2019 Index of Multiple Deprivation, 10 of Oxford's 83 neighbourhood areas ('Super Output Areas') are among the 20% most deprived areas in England.

The number of rough sleepers in Oxford has increased by 400% since 2012.

In Oxford the average house price of £513,754 is around 17 times the UK average yearly household income of £29,600.

Index of Deprivation (Per Ward) Over Figure Ground

Proposed Site

Oxford City Council

Homeless Oxfordshire

The skyline along Oxford High Street, and indeed throughout Oxford itself, is dominated by spires. Each is used as a wayfinding device, helping users navigate through the city. In the case of the High Street, the towers draw people along its length by providing a dominant feature in the backdrop of each snapshot of the street.

On arrival at Bonn Square, my chosen site, there is a break in this rhythm. Previously, St Peter le Bailey church filled this gap, with the church tower sitting harmoniously with Carfax tower (to the East). But following the demolition of the church in the 1870’s, there has been no new tower on this site. This proposal aims to rectify this, with a new tower element of similar scale to Carfax, which reintegrates the site into the wider context of Oxford.

p. 39

Annotated aerial view of Oxford High Street, highlighting the network of spires along its length. Bonn Square is also highlighted in red

Concept model showing the two towers of the proposed scheme in relation to the surrounding buildings

Along with an auditorium and associated supporting spaces, our proposals were required to provide a ‘Gift to the City’. For my scheme, this took the form of a flexible auditorium, capable of being arranged to suit a multitude of uses. This provided a secondary benefit of the auditorium acting as an extension of the adjacent public square.

p. 40 2 4 5 6 7 Ground Floor Plan N

Ground Floor Plan 01 05 01 02 03 04 05 06 07 08 Entrance Lobby & Reception Cafe Sunken Performance Space Reception Circulation Core Communal Hostel Kitchen Auditorium Laundry Facilities 02 06 03 07 04 08

lectures,

Transverse Stage Thrust Stage

POOR THEATRE... Jerry Grotowski

POOR THEATRE... Jerry Grotowski

Audience near to performers

Audience near to performers

A transverse stage layout which creates an intimate proximity between the performer and the audience. The stage is open to the square, allowing the public to be ‘invited’ into the auditorium. This stage layout facilitates ‘poor theatre’ styles of performances - a term coined by Jerry Grotowski which involves minimal props and a focus on characters and immersion.

More 'traditional' theatre, but still less of a focus on props and sets and more on experimental type theatre. Smaller

More 'traditional' theatre, but still less of a focus on props and sets and more on experimental type theatre. Smaller

Covered Market Space

POOR THEATRE... Jerry Grotowski

POOR THEATRE... Jerry Grotowski

Audience near to performers

Audience near to performers

End on for other activities - lectures, seminars, talks etc.

Visiting Exhibitions or Events

End on for other activities - lectures, seminars, talks etc.

audience size so much more intimate

audience size so much more intimate

A thrust stage with seating on three sides. The stage is closed off from the square and provides an intimate relationship between the performer and the audience. This setup can facilitate both traditional and experimental types of theatre.

The size of the auditorium provides ample room for pop up markets, or similar events. The scope of these events can be expanded to take over the entirety of Bonn Square, breathing new life into the public space.

Alternatively, the space could be utilised for visiting art exhibitions or events, with the public easily able to interact with any exhibits once the space is opened to the square.

p. 41

p. 42 First Floor Plan 2 4 5 6 7 8 9 13 14 15 16 N First Floor Plan 01 01 05 Auditorium Hostel Bedrooms Circulation Core Wash Facilities Dressing & Green Rooms Locker Room Costume Store 02 02 06 03 03 03 03 04 05 07 05 06 06 07 04

p. 43 Section B-B 1:100 @ A3 0 2.5 5m B B

Long Section (A-A)

100mm reclaimed brickwork in Flemish bond

200mm wood fibre insulation batts

140mm ‘Porotherm’ thin joint blockwork

12mm wet plaster finish

Typical Ground Floor Buildup (B):

100mm reclaimed brick floor finish

75mm screed with UFHS to offices etc.

150mm rigid insulation

50mm proprietary waterproof membrane and spacer (Type C)

150mm reinforced concrete slab

Proprietary Type A waterproofing membrane

25mm sand blinding

150mm compacted hardcore NTS

Typical Roof Buildup (C):

Zinc standing seam roof

18mm plywood carrier board

50mm ventilated void

Proprietary breather membrane

75mm wood fibre insulation batts

18mm plywood

75mm wood fibre insulation batts

350mm x 150mm Glulam structural truss

Proprietary vapour control layer

100mm acoustic insulation batts

25mm open boarded timber cladding

p. 44 M 0 1 2 3 4 5 M Tectonic Section

Key Plan

Typical Wall Buildup (A):

Rehearsal Space

Dressing Rooms Corridor

Auditorium

Entrance Lobby

Sunken Black Box Theatre Space

W.C’s

p. 45

Final Proposed Bay Elevation

Proposed Elevation Studies

Existing Street Elevation

p. 46

East

East

1:100 @ A3 0 2.5 5m

Proposed

Elevation

Elevation

p. 47

Visualisation of Auditorium

River Avon 1 1 2 2 3 4 5 6 6 10 7 8 9 2 3 4 5 6 7 8 9 10 Cycle Path Windsor Bridge St Johns Church Samaritan’s Centre Allotments Greenhouse Covered Market Pedestrianised Zone Cookery School Image from Group Project (By Others)

Biophillia

Year 3.1

Location: Bath, UK

Sector: Community / Public Space

Year: 2022 / 2023

Biophillia is a term that defines our innate affinity to connect with the natural world. As a result of urbanisation, we have lost our connection with nature, and more recently, with our neighbours and wider communities.

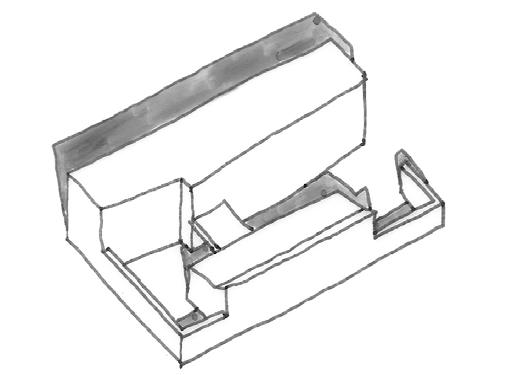

This three week group project in third year challenged us to redevelop a dilapidated brownfield site in the western quarter of Bath. Our proposal revolves around the core narrative of regeneration; regenerating the site and the community in tandem. Clear connections are developed to the neighbouring Church and Samaritans centre, providing new facilities for those in need.

p. 49

RECLAIM

The existing brownfield site is reclaimed in preparation for remediation.

CONVERT

After the initial remediation phase, the existing warehouses are converted and associated hard landscaping works completed.

ASSESS

At the end of the anticipated design life of the existing warehouses, the site will be assessed to determine how the later stages of development should be carried out.

REDEVELOP

If a more suitable use for the site is identified at the end of the design life of the current proposals, the site can be redeveloped to facilitate another use.

REMEDIATE

An extended programme of bio- and phyto-remediation breaks down and removes contaminants from the soil, through targeted planting schemes.

CULTIVATE

After the full remediation programme is completed, planting pivots to crops to be used in both the cookery school and wider community.

MAINTAIN

If proposals are shown to have a positive impact to the local community, and no other uses are identified for the site, then further maintenance and upgrades can be provided to extend the design life of the scheme.

p. 50

2022

DECISION

2029

2042 2024

2034

The intention of the proposal is to work closely with the adjacent Church and Samaritans charities to provide additional facilities for use by people in need.

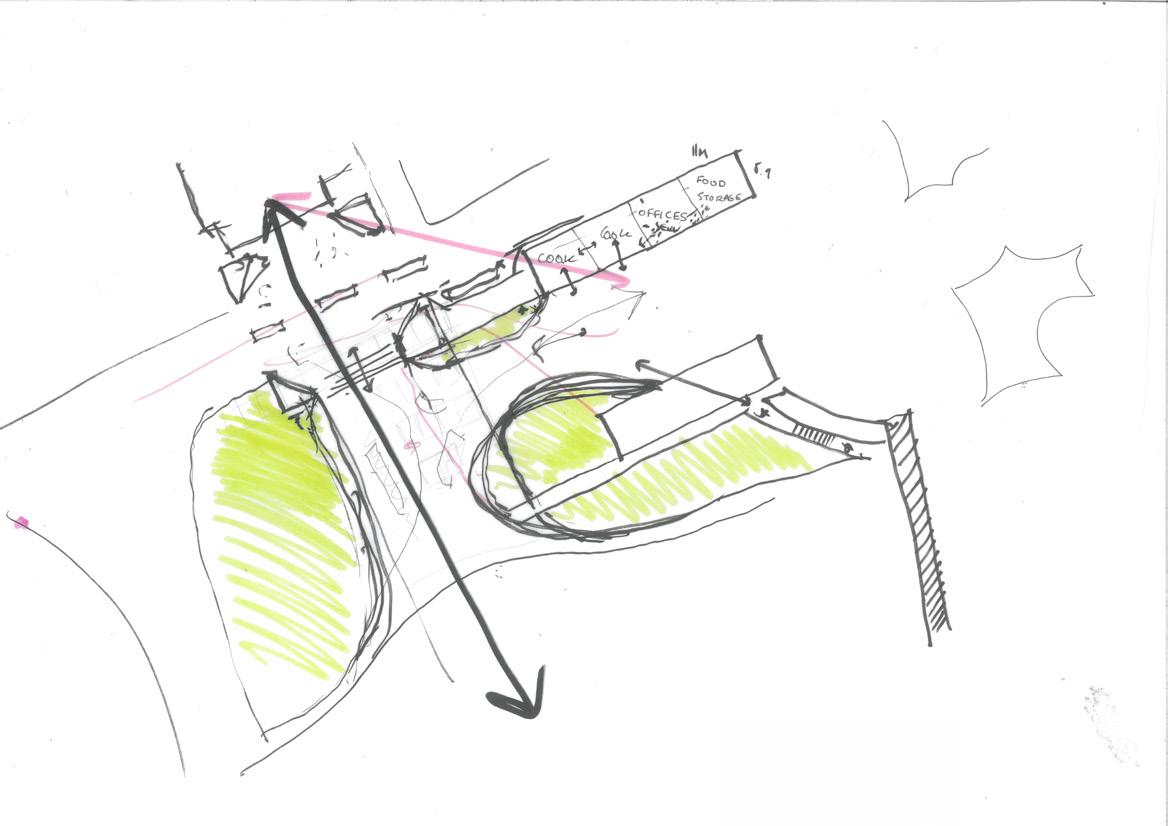

The masterplan for the site was developed through creating a strong axis between the important elements on the site; namely the Church (to the North), warehouse buildings (t0 the East), and river (to the South). Pedestrianising a section of road outside the Church facilitates a more direct connection to our site; creating an informal square which can be used for events and gatherings.

The site contained two existing portal framed warehouses, which will be converted into a cookery school and greenhouse to supplement the proposed allotments. These three elements will come into use after the remediation measures are completed.

In tandem with this, a lightweight timber canopy will be created between the two warehouse buildings, providing a flexible multi-purpose space for food events, performances, markets or simply as a covered seating area.

p. 51

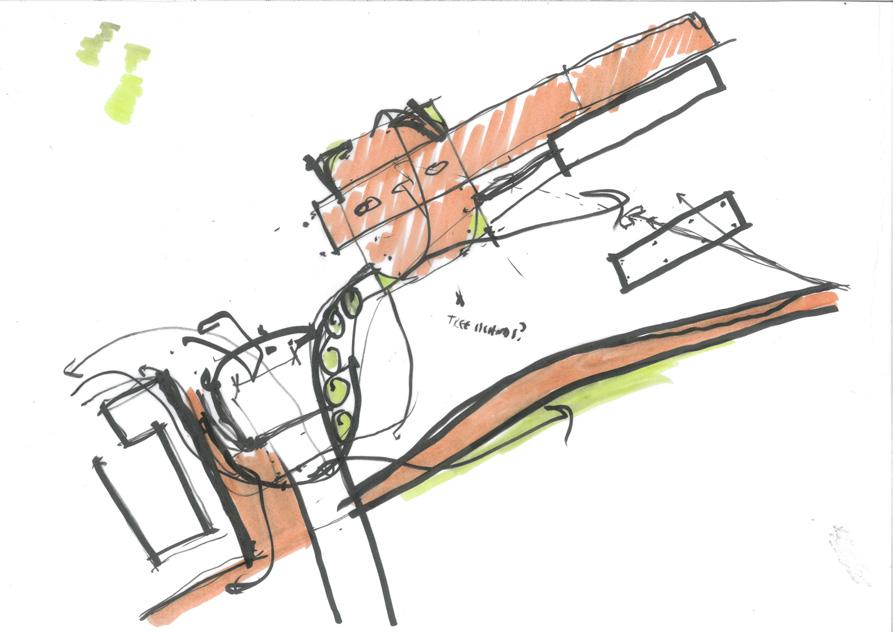

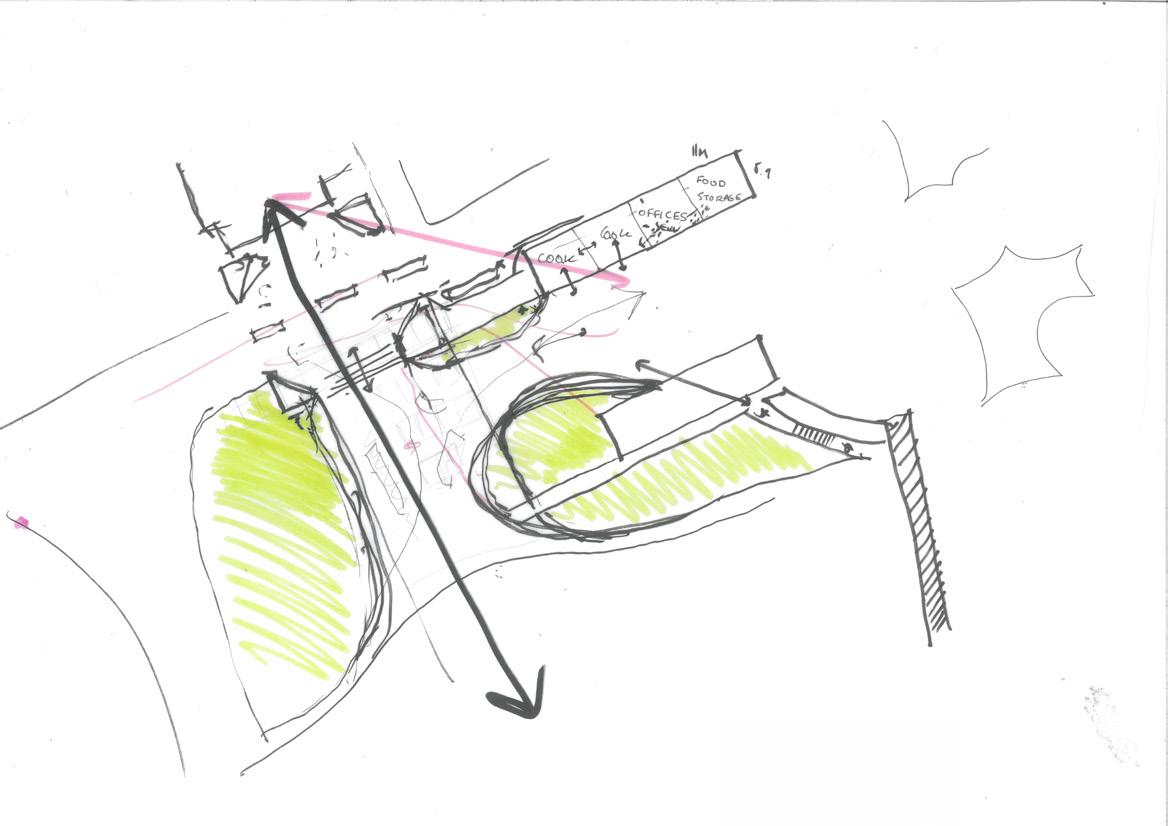

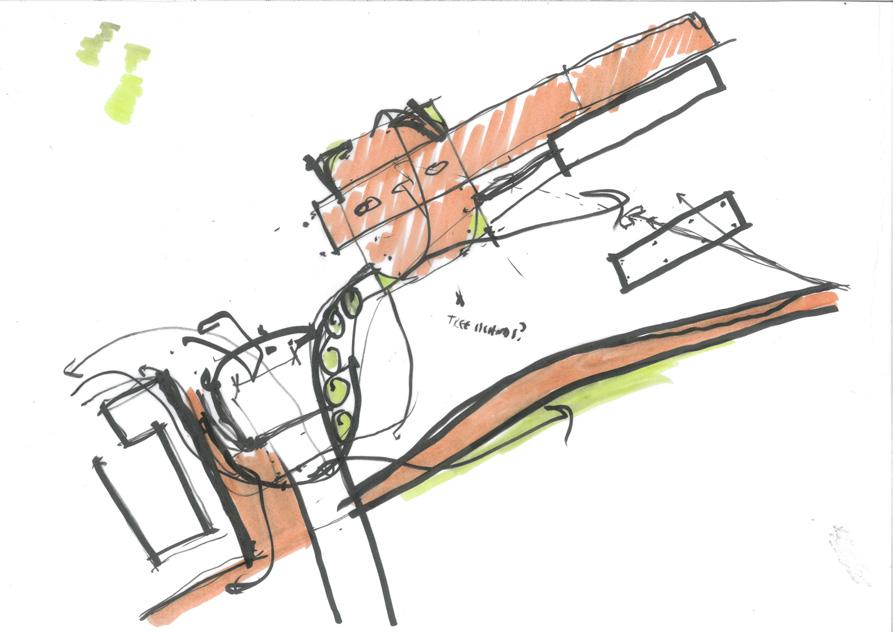

Masterplan Development Sketch

Design Development Sketches

By making plants & wildlife a dominant force within the public realm, the lines between natural and urban are blurred; nature becomes part of the spatial experience for those moving through the urban environment. Both the allotment spaces and reed bed will change throughout the seasons, as will the types and abundance of wildlife - making for an ever changing space which will bring benefits to the wider community for years to come.

Visualisation from River Avon

Medical Centre

Year 2.2

Location: Bristol, UK

Sector: Healthcare

Year: 2021 / 2022

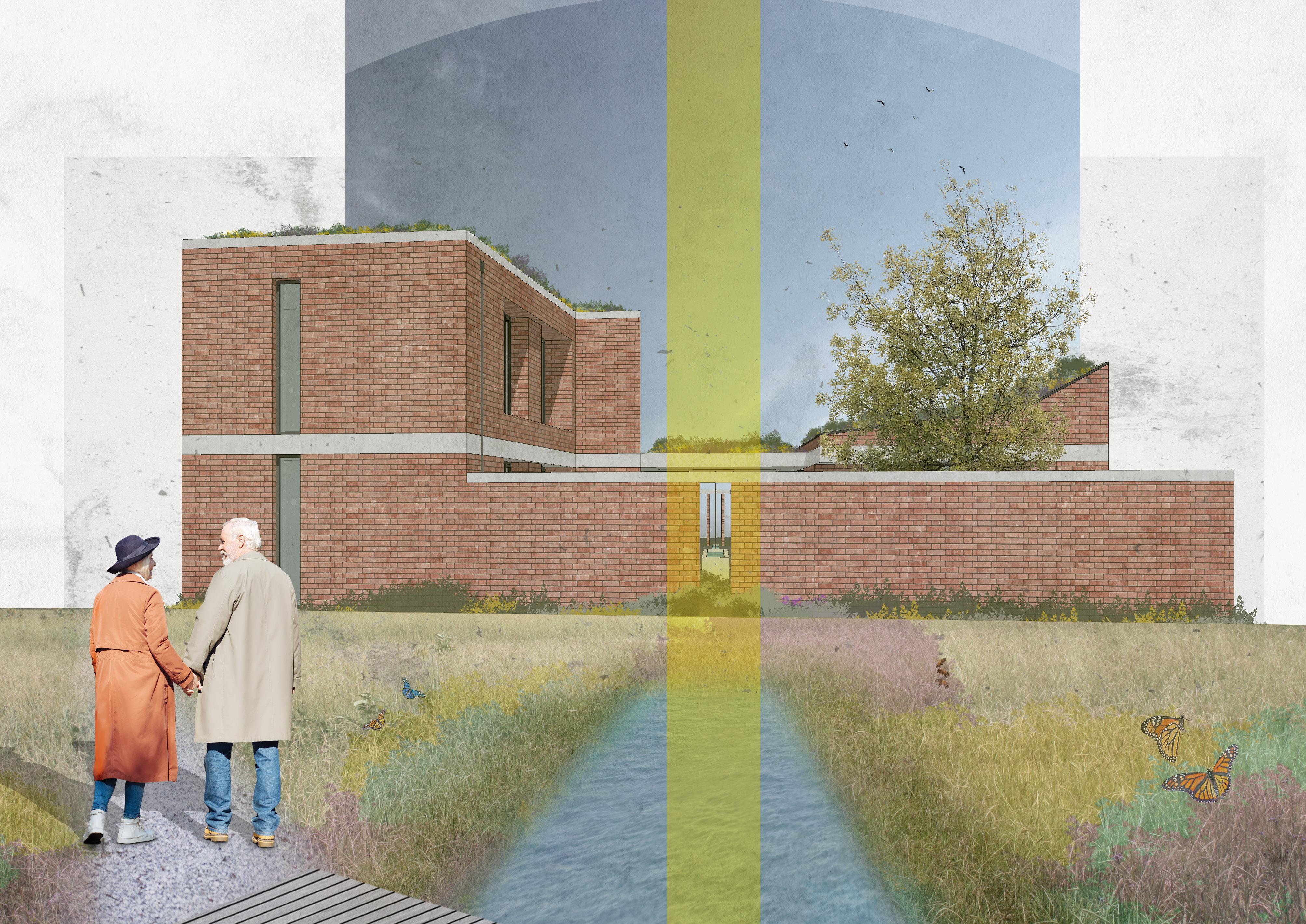

My main second year project focused on providing a new medical centre set within Castle Park, Bristol. The building was set within a complex site context, including a Listed church tower (St Mary le Port) which sits adjacent to the Northern facade. The site was previously occupied by the vacant Bristol Law Courts, so this redevelopment provided the opportunity to enhance the public realm at the same time.

The scheme aims to create a place of calm and healing within the busy city context, through defined boundaries between public and private. At its core, the proposed building is one which wishes to heal the users as much as the doctors and nurses who work within it.

p. 55

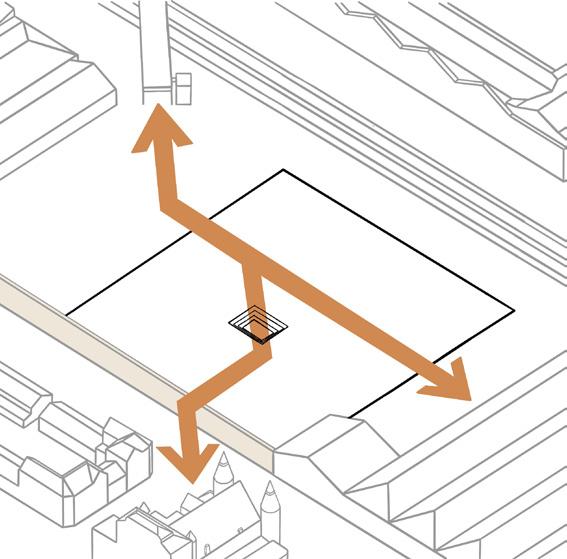

The initial move was to insert a solid element along the Northern boundary of the plan area to separate the adjacent public space from the private spaces within the medical centre. This element was cranked to run perpendicular to the desire line of public movement running between the church tower and the nearby bridge.

The L shaped plan sets up two strong axes which run the length of the mass, with horizontal circulation occurring along these axes and both views/permeability and vertical circulation provided at the ends.

The two entry points into the building are positioned at the intersection of the two axes (principal entry on the upper storey, and a secondary entrance on the lower storey).

A partially sunken mass is inserted to the South of the courtyard, bounded by the new wall. The single visible storey on the courtyard side reduces the building’s impact on this space.

The mass also creates three distinct courtyard spaces each with different characters; the West space focused on movement, the North stiller and focused on the church, and the South much more private and calming.

The plan allows for a clean distinction of spaces over both floors; with served spaces (consulting rooms etc.) pushed to the front of the plan to benefit from the connection to the private courtyard and the staff and BoH spaces placed at the rear of the plan.

The waiting room is located at the West end of the plan to benefit from the Southern views down river and the adjacency to the entrance.

To divide the consulting spaces thick masonry fins are inserted perpendicular to the main axis; these provide a feeling of enclosure and separation and improve patient privacy.

03.

05.

01. L Shaped Wall Inserted to Provide Privacy

Axes and Entry

Served and Service Spaces

06.

Perpendicular Fins

04.

Courtyards

PUBLIC PRIVATE SERVED SERVICE High Street

02.Sunken Mass Inserted to South

The proposed building aims to sit subserviently to the existing church tower, ensuring the spire remains dominant in the surrounding context. To create a calm internal space in a public dominated realm, the building takes the form of an L shaped plan which provide separation from the existing public plazas. One of the legs of the L is oriented off angle to face directly South – the building’s edge framing the view of the river.

The proposal is spread across two storeys, with the lower floor embedded into the topography of the site. In response to my site analysis and the need for increasing tiers of privacy throughout the spaces, the plan developed into a linear spatial arrangement – with the levels of privacy increasing as the users move through the building.

Refer to next project for details of Housing Scheme.

p. 58 9 5 4 2 7 8 7 6 5 4 3 2 1 9 1:150 @ A3 Lower Ground Floor Plan 01 07 13 Entrance Lobby Practice Manager’s Office Treatment Room Store Interview Room Consulting / Nurses Room Examination Room Plant Room Reception Medical Waste Storage Waiting Area Cleaners Cupboard Medical Records Store Pharmacy W.C Pharmacy Store Staff Common Room / Kitchenette Complimentary Services Space 02 08 14 03 09 15 04 10 16 05 11 17 06 12 18 03 05 05 05 05 14 09 18 13 14 17 17 17 17 16 16 16 16

p. 59 24 23 22 21 20 19 1011121314151617 9 8 7 6 5 4 3 2 1 24 23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 7 5 4 2 18 1:150 @ A3 Upper Ground Floor Plan 01 07 13 Entrance Lobby Practice Manager’s Office Treatment Room Store Interview Room Consulting / Nurses Room Examination Room Plant Room Reception Medical Waste Storage Waiting Area Cleaners Cupboard Medical Records Store Pharmacy W.C Pharmacy Store Staff Common Room / Kitchenette Complimentary Services Space 02 08 14 03 09 15 04 10 16 05 11 17 06 12 18 01 07 13 14 02 08 03 09 15 15 04 10 05 05 05 05 11 06 12 12 12

Detail Section Calculating Depth of Shading Devices

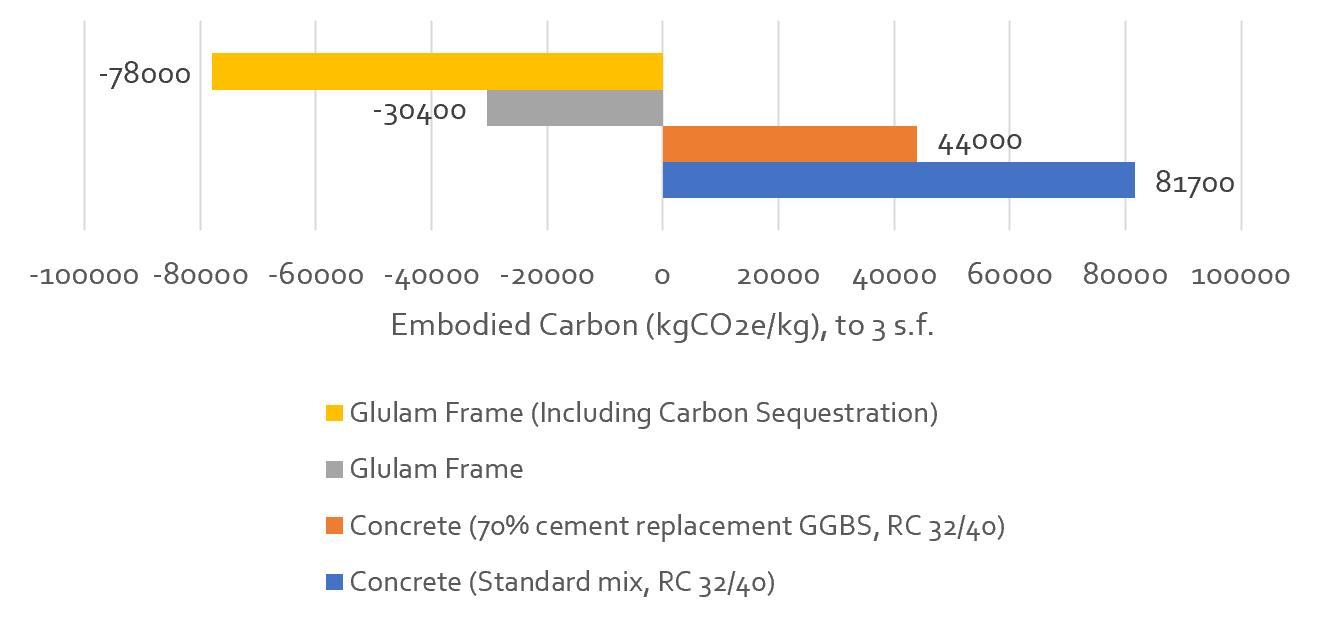

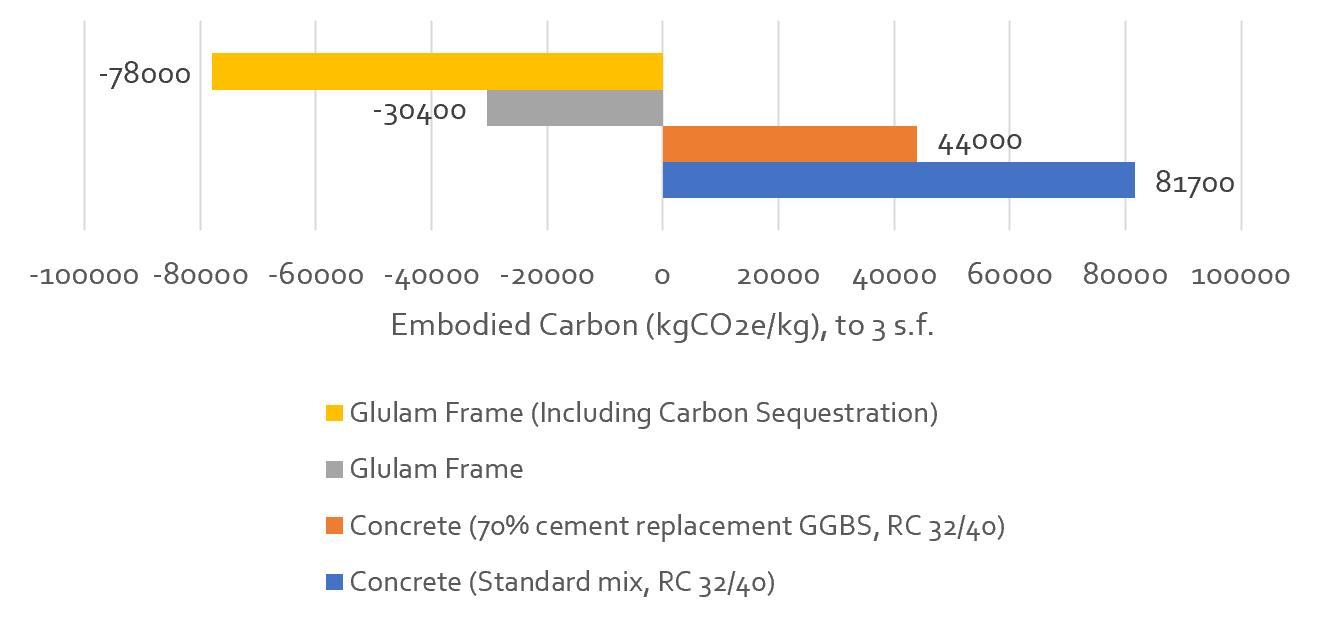

Embodied Carbon Calculation of Structural Elements

Graph Highlighting Space Heating Requirements Against Passive Internal Gains

Ventilation and Daylighting Strategy Section

p. 60

PrEvailing wind from South & South wESt

y max = 62o 21 / 06 y max = 16o 21 / 12 750mm 1415mm 75% of window shaded natural vEntilation daylighting mEchanical vEntilation

no Sky linE (to ridgE of houSing adjacEnt)

p. 61 Upper Ground Floor +4.000 Lower Ground Floor +0.000 A - Flat Roof Construction 40mm drainage board Geotextile membrane 100mm min. soil substrate with native vegetation (planting not shown) B - External Wall Construction 75mm x 25mm vertical cedar cladding fixed with zinc coated s/s lost head nails left untreated. Replace with projecting 50mm x 75mm vertical cedar board every 5 no. boards as per detail elevation Detail Section A-A 1:25 @ A1 Detail Elevation 1:25 @ A1 A3 A1 A2 A4 A5 A6 A7 A8 A9 A10 A11 A12 A13 D1 D2 D4 D3 D5 D6 D7 E2 E1 E3 E4 E5 E6 E7 E8 E9 E10 C1 C3 C4 C5 C6 C7 C8 C11 C2 C9 C12 C13 C14 C10 0 1 2m 0 1 2m B1 B2 B3 B4 B5 B6 B7 B8 B9 B13 B14 B10 B11 B12 F5 F1 F2 F6 F3 F4 F7 F8 F9 F10 F4 F11 F12 Insulation batts - acoustic or wood fibre Rigid PIR flat roofing insulation (providing suitable adhesion for single ply membrane) Closed cell XPS rigid insulation (waterproof, suitable for use below DPC) Membrane Key: Single ply membrane Breather membrane Vapour control layer DPM's, DPC's and cavity trays G9 G10 G1 G2 G3 G6 G12 G5 G11 G7 G8 G4 A1 A2 A3 B1 H6 H4 H1 H2 H3 H7 H5 H8 H9 H10 D6 Seperation membrane Note: Downpipes concealed within stone walls to either side of each bay Upper Ground Floor +4.000 Lower Ground Floor +0.000 A - Flat Roof Construction 40mm drainage board Geotextile membrane 100mm min. soil substrate with native vegetation (planting not shown) B - External Wall Construction 75mm x 25mm vertical cedar cladding fixed with zinc coated s/s lost head nails left untreated. Replace with projecting 50mm x 75mm vertical cedar board every 5 no. boards as per detail elevation Detail Section A-A 1:25 @ A1 Detail Elevation 1:25 @ A1 A3 A1 A2 A4 A5 A6 A7 A8 A9 A10 A11 A12 A13 D1 D2 D4 D3 D5 D6 D7 E2 E1 E3 E4 E5 E6 E7 E8 E9 E10 C1 C3 C4 C5 C6 C7 C8 C11 C2 C9 C12 C13 C14 C10 0 1 2m 0 1 2m B1 B2 B3 B4 B5 B6 B7 B8 B9 B13 B14 B10 B11 B12 F5 F1 F2 F6 F3 F4 F7 F8 F9 F10 F4 F11 F12 Insulation batts acoustic or wood fibre Rigid PIR flat roofing insulation (providing suitable adhesion for single ply membrane) Closed cell XPS rigid insulation (waterproof, suitable for use below DPC) Membrane Key: Single ply membrane Breather membrane Vapour control layer DPM's, DPC's and cavity trays G9 G10 G1 G2 G3 G6 G12 G5 G11 G7 G8 G4 A1 A2 A3 B1 H6 H4 H1 H2 H3 H7 H5 H8 H9 H10 D6 Seperation membrane Note: Downpipes concealed within stone walls to either side of each bay

Construction Section & Elevation (Drawn Originally at 1:20 @ A1)

Detailed

p. 62

Visualisation from Church Courtyard

p. 63

Visualisation of South Facade

City Centre Housing

Year 2.1

Location: Bristol, UK

Sector: Residential

Year: 2021 / 2022

This short group project in Second Year challenged us to design a small housing development set within Castle Park, Bristol. Context was key to this project, with the proposals needing to respond sensitively to the adjacent historic buildings, as well as sit comfortably next to a busy public park.

The proposal made use of the existing connection with the site to the River Avon by creating two short runs of 4 houses built into the existing river wall, separated by a sunken courtyard. This courtyard was in turn serviced by two cafés located on the ends of each run of housing. The intention was to create a public offer which was ‘given back’ in exchange for the housing, so better integrating the scheme into the very public context.

p. 65

01. Single Mass Interacting with River

Public path pushed behind to provide privacy & views to dwellings.

Creating public space between the two masses and reconnecting the park behind to the river. This also provides a place to pause along the path - something which is currently not provided.

Terraces split to set up strong facade rhythm, responding to opposing buildings.

Balcony recessed into main floor, angled to face direct South and accentuating the view down river.

Internal arrangement organised around a central core, which divides the spaces into a South facing living/sleeping zone and a service zone to the North.

Lower storey built into existing wall allowing views from the park over to opposite roofs and the rising city beyond.

Single storey mass peeled back from main facade line to highlight entrance; low wall continues to form ‘buffer’ space between public and private.

p. 66

02. Mass Pulled Apart

03. Mass Sunk into Wall

06. Entrance

04. Terraces Split into Three

07. Spaces Organised around Central Core

Massing from Approach (NW)

Massing Along River (SSW)

05. Forming a Balcony

p. 67

Visualisation of Sunken Courtyard

p. 68

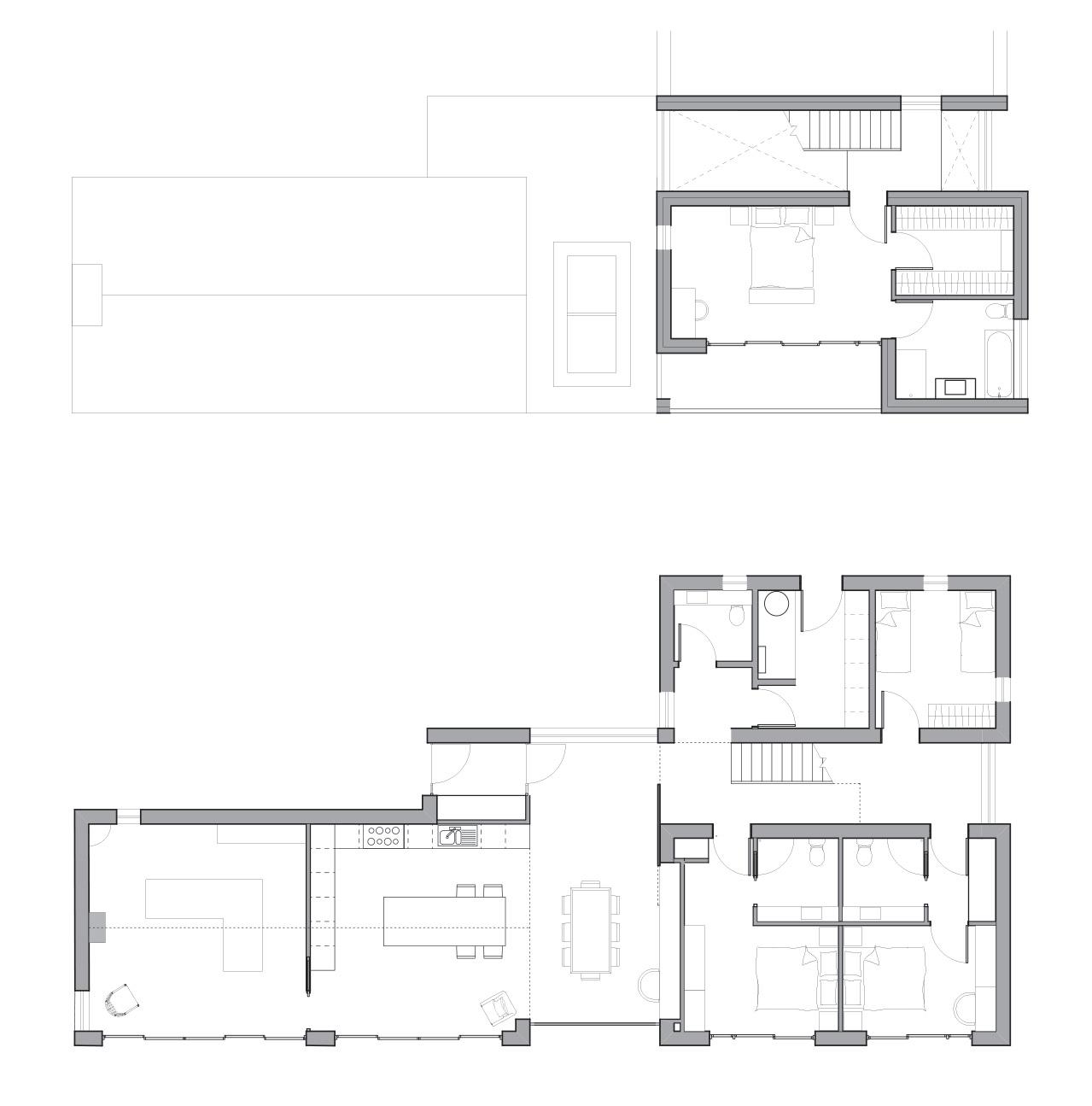

Floor Plan 0 5 10 M N Ground Floor Plan Lower Ground Floor Plan Detailed

First

Plans on Adjacent Page

Leadengate Fields

New Private Dwelling (PMA)

Location: North Devon, UK

Sector: Residential

Year: 2022

Status: Under Construction

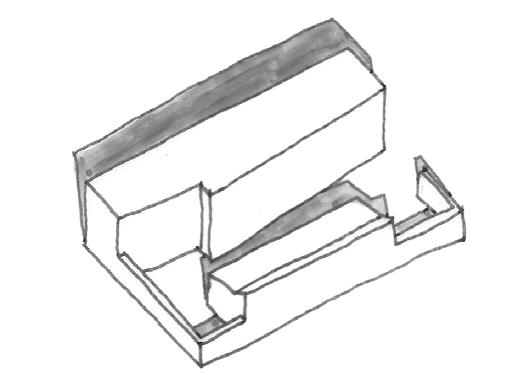

This project was undertaken during my professional placement in the first half of 2022.The client asked us to replace an existing dilapidated prefabricated holiday cottage with a new contemporary dwelling, located within the popular seaside town of Croyde, in North Devon.

The site was incredibly small for the size of building the client was looking to build. The proposal was developed around the idea of two linear pitched roof masses containing the living and sleeping spaces, linked by a small circulation ‘core’. This strategy helped to reduce the impact of the building on the neighbouring dwellings whilst maximising the available space on site.

I was involved in this project from Stages 0 - 4 (I left PMA during the Tendering period). I produced all drawings for this project, including the full tender pack and written specification, and liaised directly with the client & design team throughout.

p. 85

p. 86 PROJECT TITLE DRAWN BY DATE DRAWING NO 8 Leadengate Fields Proposed Ground Floor Plan 1:100 @ A3 JG April 2022 21105_P_03 THE OLD SAIL LOFT PAIGES LANE BARNSTAPLE EX31 1EF T: 01271 377776 Mr P Forbes CLIENT SCALE DRAWING TITLE Replacement Dwelling LOCATION Croyde EX33 1PB Note: This drawing is protected under copyright and whole or in part without the Architects' consent Peregrine Mears Architects Ltd accept no responsibility appointed to provide full architect's services under Engagement Any discrepencies must be reported commences Drawing Status: Do not scale from this drawing Planning NOTES: GIA reduced and soft landscaping LPA and GPC comments A 28/06/2022 RL RL rwp rwp rwp rwp rwp rwp RL RL Existing fence forming site boundary Proposed storage shed (approx 1.5m x 2m TBC by client) clad in timber to match new dwelling Existing bank forming boundary to adjacent plot with new planting to enhance screening between properties P R I V A T E R O A D 2 no parking spaces (increase over existing allocation of 1 no parking space) External timber deck to North West corner of plot Living / Kitchen / Dining Space Utility Entrance Hall Built in bench seat to entrance hall with coat storage etc adjacent Full height glazing with sliding doors providing access to timber deck Bedroom 2 Exposed timber rafters to vaulted ceiling Bathroom Ensuite Master Bedroom Vaulted ceilings to both bedrooms External shower adjacent to entrance External Deck Entrance Outline of previous dwelling (now demolished) shown red dashed 2550mm 2750mm 3300mm 1300mm 1225mm 4000mm Sliding doors providing access from master bedroom onto external deck Strip rooflight over hallway A A 2825mm 7105mm Fireplace on feature plinth against gable wall FFL +23.400 B B 3300mm Electric car charging port adjacent to entrance door Open frontage and grass verge to Leadengate Fields maintained as existing arrangement in accordance with Sections 7.5 & 7.7 of the Leadengate Design Guide New planting proposed adjacent to proposed building to soften edge 0 1 2 3 4 5 10m Proposed Ground Floor Plan 1:100 @ A3 Sunpath Diagram Summer Solstice (21/06) 13:20 21:35 16:10 Winter Solstice (21/12) shown GIA Comparison: Existing: 51.8m2 GIA Proposed: 72m2 GIA (<72.5m2 limit) This increase in GIA is compliant with the recommendations of the Leadengate Design Guide Section 7.11b 7.11b (i): Floor area of existing + 40% = 51.8 x 1.4 = 72.5m2 GIA 7.11b (ii): Floor area of existing + 40% of curtilage (excluding offroad parking - 1 no space existing) = 51.8 + (124*0.4) = 101.4m2 GIA Ground Floor Plan (Originally 1:100 @ A3)

p. 87 External Visualisation

p. 88 PROJECT TITLE Mr P Forbes CLIENT Replacement Note: This drawing is whole or in part without Peregrine Mears Architects appointed to provide Engagement Any discrepencies commences Drawing Status: Do not scale from this Technical NOTES: Drawings A 30/06/2022 Roof B 07/07/2022 Wall amended General C 29/07/2022 Detail D 11/08/2022 01 GA Section A-A 1:20 @ A1 RG01 Kitchen / Living / Dining RG02 Hall RG07 Bedroom 2 O A B C D 2400mm 2490mm 195mm 255mm 2815mm 2708mm 2325mm 2940mm 150mm Min 150mm Min 4135mm 2940mm 4130mm 440mm 430mm 1660mm 1720mm L10/25 Schuco AWS70 aluminium double glazed units Timber lintels to S.E design details and specification R10/11 100mm PPC aluminium half round gutters concealed behind cladding Q10/30 Linear slot drain to base of full height glazing installed in weak mix concrete haunching to manufacturers details connecting to proposed below ground drainage system Foundations to S.E design details and specification Built in bench seat to hallway lined with 45x18mm PAR Western Red Cedar to match feature wall opposite Refer to PMA drawing 21105_T_30.02 for details 20.01 RT02 20.01 FT01 20.01 RT01 20.01 WT02 20.01 WT03 20.01 WT01A 20.01 RT02 20.01 FT01 V90/312 GB Sol Solar Slates to West facing roof pitches installled in accordance with manufacturers details and specification FFL: + 23.400 AOD TOS: + 23.155 AOD 23.01 02 01 23.01 02 25.03 03 25.03 21.02 01 03 21.01 04 23.01 23.01 02 23.02 04 23.02 02 T.O .B: + 23.380 AOD T.O .B: + 23.605 AOD L10/45 Double glazed rooflight on insulated kerb installed as manufacturers design and specification V90/312 - GB Sol Solar Slates to West facing roof pitches installled in accordance with manufacturers details and specification 4230mm 1875mm 3615mm TOS + 26.040 AOD TOS + 27.070 AOD TOS + 27.070 AOD General Notes: All drawings to be read Specialists/Consultants appropriate All sizes of structural steelwork joists/rafters Engineer's design details reported to the Architect Dimensions are given otherwise Dimensions surfaces in doubt etc are to be checked S H CO Mains wired Mains wired Carbon Monoxide Smoke and heat alarms EN 14604 Alarms to Ceiling mounted smoke and between heat detectors All alarms to be wired standby power supply capacitor to BS 5839-6 Escape Window B1 Diagram IC Surface water IC Foul drainage Back inlet gully BIG Linear slot Drawing Key: Recirculating specification Drawing Series Series 10: GA Series 11: GA Series 12: GA Series 20: Construction Point of connection investigated The site is within an Protection Damp Proof Visqueen 'R400' radon approved All to be specifications and written Radon: Series 14: Building Series 21: Floor Series 22: Wall Series 23: Roof Series 25: Glazing Series 30: Finishes Series 31: Sanitaryware Series 40: Electrical Eastern Boundary Details TBC SVP rwp rwp rwp rwp RG03 Utility RL Over RL Over RG04 Bedroom RL Over RG05 Ensuite RG06 Bathroom WG02 EDG02 WG04 WG05 D04 ASHP Loft Hatch Over RL Over RG07 Bedroom RG01 RG02 Hall A GA Construction Section (Originally 1:20 @ A1)

Slab Edge Detail (Originally 1:5 @ A1)

Eaves Detail (Originally 1:5 @ A1)

Eaves Detail (Originally 1:5 @ A1) Flat Roof Verge Detail (Originally 1:5 @ A1)

p. 89 PROJECT TITLE 8 Leadengate Fields Slab Edge Details (Sheet 1 of 2) Mr P Forbes CLIENT DRAWING TITLE Replacement Dwelling LOCATION Croyde EX33 1PB Note: This drawing is protected under copyright and may not be reproduced in whole or in part without the Architects' consent Peregrine Mears Architects Ltd accept no responsibility for works on site unless appointed to provide full architect's services under the RIBA Conditions of Engagement Any discrepencies must be reported to the Architects before work commences Drawing Status: Do not scale from this drawing Technical Design NOTES: Notes amended TOB spot height added Membrane sealing details added Drawings amended to coordinate with S.E design A 12/08/2022 JG General Notes: All drawings to be read in conjunction with all other PMA and Specialists/Consultants Drawings Details Schedules and Specfications as appropriate All sizes of structural members noted on the drawings are indicative only all steelwork joists/rafters lintels slabs masonry etc are to be to Structural Engineer's design details and specification Any discrepancies or clashes are to be reported to the Architect as soon as possible Dimensions are given to structural components/openings unless noted otherwise Dimensions coloured blue are reference dimensions taken to finished surfaces If in doubt ask All fabrication dimensions for windows doors steelwork etc are to be checked and confirmed on site prior to fabrication S H CO Mains wired smoke alarm detector Mains wired heat alarm detector Carbon Monoxide alarm detector Smoke and heat alarms to be linked and mains operated to conform with BS EN 14604 Alarms to be positioned to BS 5839-6:2004 Ceiling mounted smoke detectors to be positioned 300mm away from walls and between heat detectors to be between 25mm 150mm below the ceiling All alarms to be wired on an independant circuit and they should both have a standby power supply such as battery (rechargeable or non-rechargeable) or capacitor to BS 5839-6 Escape Window openings in accordance with Approved Document B1 Diagram .10 IC Surface water inspection chamber IC Foul drainage inspection chamber Back inlet gully BIG Linear slot drains to thresholds Drawing Key: Recirculating cooker hood above AGA to client specification ventilation rate min 13l/s Drawing Series Key: Series 10: GA Plans Series 11: GA Sections Series 12: GA Elevations Series 20: Construction Buildups Point of connection to the existing SWW combined sewer to be investigated and confirmed on site prior to works starting The site is within an area of elevated radon potential and so requires Basic Radon Protection Damp Proof Courses and Membranes are to be radon resistant Visqueen 'R400' radon membrane and Visqueen 'Zedex CPT' DPC or equivalent approved All to be installed in strict accordance with manufacturers details specifications and written instructions and the recommendations of BR211 Radon: Series 14: Building Strategy Drawings Series 21: Floor and Slab Edge Details Series 22: Wall Plan Details Series 23: Roof Details Series 25: Glazing & Internal Door Schedules and Details Series 30: Finishes Drawings Series 31: Sanitaryware & Bathroom Drawings Series 40: Electrical Plans 50mm 440mm Min 50mm 50mm 300mm 150mm 440mm Min 01 Typical Slab Edge Detail 1:5 @ A1 02 Slab Edge Adjacent to External Deck 1:5 @ A1 WT01 21105_T_20.01 FT01 21105_T_20 .01 14mm underfloor heating to specialists detailed design and specification Nom 20mm floor finishes in accordance with PMA Finishes Schedule (drawing no 21105_T_30.01) Proprietary 25mm underfloor heating expansion strip to UFHS suppliers specification P20/20 Timber skirting board all fixing holes filled and sanded smooth to hide P10/61 Vapour control layer lapped and sealed to DPM with proprietary airtightness tape to ensure continuity of airtightness layer Overlap of VCL to DPM to be minimum 150mm wide J40/35 Radon resistant DPM laid over blockwork upstand and fixed behind XPS insulation to outer face of blockwork P10/46 75mm XPS insulation fixed to outer face of blockwork H21/20 End of breather membrane laid over and sealed to vertical DPC Timber frame to .E design details and specification J40/70 Black coloured protection board over XPS insulation Breather membrane sealed to DPC against blockwork using proprietary adhesive in accordance with membrane manufacturers recommendations Client specified gravel finish laid in retention mesh as per PMA Drawing 21105_T_10.03 Where gravel is replaced by paving leave 100mm gravel margin to perimeter of paving (measured from face of XPS board) F10/37 140mm low lambda blockwork to minimise thermal bridge compressive strength to .E specification 140mm below ground blockwork to S.E design and specification Concrete foundations to .E design details and specification FFL +23.400 T.O .S +23.155 T.O .F +22.705 FT01 21105_T_20 .01 14mm underfloor heating to specialists detailed design and specification Nom 20mm floor finishes in accordance with PMA Finishes Schedule (drawing no 21105_T_30.01) Proprietary 25mm underfloor heating expansion strip to UFHS suppliers specification P20/20 Timber skirting board all fixing holes filled and sanded smooth to hide P10/61 Vapour control layer lapped and sealed to DPM with proprietary airtightness tape to ensure continuity of airtightness layer Overlap of VCL to DPM to be minimum 150mm wide J40/35 Radon resistant DPM laid over blockwork upstand and fixed behind XPS insulation to outer face of blockwork P10/46 75mm XPS insulation fixed to outer face of blockwork H21/20 End of breather membrane laid over and sealed to vertical DPC Timber frame to S.E design details and specification J40/70 Black coloured protection board over XPS insulation Q55/380 Composite non slip external decking boards installed as manufacturers recommendations 140mm below ground blockwork to .E design and specification Concrete foundations to S.E design details and specification FFL +23.400 T.O .S +23.155 T.O +22.705 F10/37 140mm low lambda blockwork to minimise thermal bridge compressive strength to S.E specification Q55/380 Adjustable decking pedestals installed as manufacturers details over geotextile membrane and hardcore Q55/380 Proprietary decking joists at max 600mm centres as manufacturers details and instructions Q25/64 Geotextile membrane laid over 150mm compacted hardcore Reduced Level Below Deck +23.100 Q25/64 Geotextile membrane laid over 150mm compacted hardcore TOB +23.605 Ex FFL +23.400 Ex FFL +23.400 01 10.02 Eq Eq Eq Eq 01 10.02 H21/21 Proprietary insect mesh installed at all openings in rainscreen in accordance with manufacturers recommendations TOB +23.605 H21/21 Proprietary insect mesh installed at all openings in rainscreen in accordance with manufacturers recommendations GL GL 21.01 03 GL TOB +23.605 WT01A 21105_T_20.01 K11/54 12mm calcium silicate board fixed over insulation to provide 30 minute fire resistance adajcent to boundary H21/20 fire resistant breather membrane fixed over CS board in accordance with manufacturers details and instructions H21/21 Proprietary insect mesh installed at all openings in rainscreen in accordance with manufacturers recommendations 38x75mm tanalised s/w stud fixed at base of insulation zone to provide additional support for edge of CS board DETAIL VARIANT WITHIN FIRE RESISTING CONSTRUCTION F30/48 Radon resistant DPC laid over soleplate To be laid down both sides of block and sealed to breather membrane and DPM as shown in accordance with manufacturers details and instructions DPM taped and sealed to DPC in accordance with manufacturers details to ensure radon-proof connection DPM taped and sealed to DPC in accordance with manufacturers details to ensure radon-proof connection F30/48 Radon resistant DPC laid over soleplate To be laid down both sides of block and sealed to breather membrane and DPM as shown in accordance with manufacturers details and instructions Breather membrane sealed to DPC against blockwork using proprietary adhesive in accordance with membrane manufacturers recommendations 125mm 140mm 85mm 230mm 230mm 01 Eaves Detail 1:5 @ A1 02 Ridge Detail 1:5 @ A1 230mm 03 Verge Detail 1:5 @ A1 WT01 21105_T_20.01 21105_T_20RT02 .01 Wall Plate +26.090 Eaves +26.360 G20/7 Underside of exposed rafters to .E design and specification P10/61 Vapour control layers lapped and sealed with proprietary airtightness tape to ensure continuity of airtightness layer Overlaps to be minimum 150mm wide Battens supporting cladding stopped short to allow for concealed gutter Top of rigid sheathing insulation to be tapered to prevent water ponding R10/10 100mm dia PPC aluminium half round gutter fixed with standard brackets back to plywood laid to falls of 1:300 towards outlet Gutter to be marine grade powder coated to match glazing RAL TBC Breather membrane dressed into gutter S/W tilting fillet Natural slate roof tiles as RT02 installed and fixed in accordance with BS 5534:2014 Breather membrane within roof construction lapped and sealed to wall membrane in accordance with manufacturers details and instructions Minimum lap width to be 150mm P10/63 Seal strips of VCL with proprietary self healing butyl tape to ensure continuity of airtightness layer VCL strips to be installed prior to fixing plywood sheathing and left loose until primary roof and wall VCL's are installed WT01 21105_T_20.01 RT02 21105_T_20 .01 Timber frame & wall plate to S.E design details and specification P10/61 - Vapour control layers lapped and sealed with proprietary airtightness tape to ensure continuity of airtightness layer Overlaps to be minimum 150mm wide Breather membrane within roof construction lapped and sealed to wall membrane in accordance with manufacturers details and instructions Minimum lap width to be 150mm ALIGN H72/33 Proprietary PPC aluminium profile to edge of slates marine grade powder coated RAL 7016 to coordinate with slate colour fixed back to roofing battens Natural slate roof tiles as RT02 installed and fixed in accordance with BS 5534:2014 G20/7 underside of exposed timber rafters to S.E design details and specification Top of timber cladding to be aligned with and conceal verge pressing as shown G20/7 - Timber bearing plate fixed to top of steel Timber to match exposed rafters H62/3 Natural slate roof tiles as RT02 installed and fixed in accordance with BS 5534:2014 P10/60 Vapour control layer laid over tops of rafters prior to fixing insulation Rafters birdsmouthed over exposed ridge beam and fixed with proprietary fixing plates to S.E design details and specification H74/32 Folded zinc ridge detail to specialists detailed design fixed with 50mm wide zinc tacks at 500mm centres Length of ridge pieces should not exceed 1m to prevent pull-out G20/7 Underside of exposed rafters to .E design and specification Rafters to be birdsmouthed over exposed ridge beam above H62/47 Over fascia ventilator installed in accordance with manufacturers details and instructions V90/312 GB Sol solar slates to West facing roof pitches as shown on PMA Drawing 21105_T_10.02 installed in accordance with manufacturers details and instructions Top of cladding battens cut at angle to match roof pitch to prevent water ponding Ends of battens to be sealed with preservative treatment to cladding manufacturers recommendations Timber frame and wall plate to S.E design details and specification H21/21 Proprietary insect mesh installed at all openings in rainscreen in accordance with manufacturers recommendations GL GL 245mm 04 Eaves Detail Within Fire Resisting Construction 1:5 @ A1 K11/54 12mm calcium silicate board fixed over insulation to provide 30 minute fire resistance adajcent to boundary H21/20 fire resistant breather membrane fixed over CS board in accordance with manufacturers details and instructions H21/21 Proprietary insect mesh installed at all openings in rainscreen in accordance with manufacturers recommendations 38x75mm tanalised s/w stud fixed at head of insulation zone to provide support for edge of CS board Notes Generally as Detail 01 Adjacent Additional 38x75mm tanalised s/w stud fixed in front of head of timber frame to support top section of CS board 21.01 04 DETAIL VARIANT WITHIN FIRE RESISTING CONSTRUCTION Refer to PMA Drawing 21105_T_14.01 for Extents H21/21 Proprietary insect mesh installed at all openings in rainscreen in accordance with manufacturers recommendations 21.01 05 DETAIL VARIANT WITHIN FIRE RESISTING CONSTRUCTION 25mm timber noggins to support outer counterbatten if required Maintain void beneath batten to ensure drainage ventilation is not compromised Outline of steel beam to Western eaves shown greyed Structure to S.E design details and specification Exposed steel ridge beam to .E design details and specification Beam to recieve white intumescent paint finishes as PMA Specification Clause M60/21 Any fixings from bearing plate above to be painted white to match beam Sample section of steel to be painted on site with finish confirmed with Architect and Client prior to full application 01 Flat Roof Verge Detail 1:5 @ A1 60mm 200mm 200mm 35mm 420mm 300mm 515mm Refer to PMA GA Drawings 15mm 85mm 02 Rooflight Kerb 1:5 @ A1 WT01 21105_T_20.01 J42/10 Single ply membrane installed in accordance with manufacturers details and instructions Membrane to be coloured RAL 7016 RT01 21105_T_20 .01 .O Joist +26.010 Timber joists to S.E design details and specification P10/63 VCL within wall construction to be carried up and fixed over firrings as shown Apply length of proprietary self healing butyl tape over VCL then fix plywood decking over to create airtight seal 300mm wide drainage gully formed in insulation as shown to falls of 1:300 towards outlet refer to PMA Drawing 21105_T_10.02 for details Single ply membrane to be lapped and sealed to aluminium pressing with min 40mm hot air weld in accordance with manufactuers details and instructions Breather membrane to be fixed below pressing as shown H72/38 Two part marine grade PPC aluminium pressing to specialists detailed design and specification in accordance with the dimensions shown All measurements to be confirmed on site prior to manufacture Pressings to be fixed back to s/w battens behind using colour matched c/s fixings concealed within shadow gaps Pressings to be powder coated to match glazing; RAL TBC 100 50mm s/w studwork forming upstand to edge of flat roof Doubled up joists to edge of flat roof to support timber upstand to .E design details and specification H21/20 Breather membranes lapped and sealed together to form weatherproof join minimum lap width to be 150mm End of aluminium pressing to be fixed to s/w battens within wall construction with fixing concealed by timber cladding 35mm 25mm 10mm 10mm Shadow Gap Fixing Detail 1:2 @ A1 R10/26 Proprietary flat roof spigot fitted into drainage gully connecting to PPC aluminium downpipe below as shown Spigot to be installed in accordance with manufacturers details and instructions with single ply membrane dressed into and sealed to spigot .O Joist +26.010 Edge of rooflight profile to be clear of upstand distance TBC with rooflight manufacturer S/W timber firrings cut to falls Single ply membrane to be laid over and sealed to top of upstand Termination bars and fixings to restrain edge of membrane manufacturers details and recommendations L10/45 Frameless double glazed flat glass rooflight installed in accordance with manufacturers details and instructions detail TBC with manufacturer Rooflight set at 5 degree pitch with solar control cleaning glass Frame to be marine grade powder coated RAL 7016 Refer to PMA Drawing 21105_T_25.01 for additonal information Joist Setting Out Position (as shown on PMA Drawing 21105_T_10.04 Suspended ceiling as Roof Type RT01 (refer to PMA drawing 21105_T_20.01 for details) RT0221105_T_20 GL GL GL GL

© Lawrence Liddy

The Ark

New Private Dwelling (PMA)

Location: North Devon, UK

Sector: Residential

Year: 2018 - 2020

Status: Completed

‘The Ark’ is a bespoke dwelling in Ashford, North Devon, situated to the edge of the village with panoramic views over the Taw Estuary and beyond. The form takes inspiration from a traditional Devon Longhouse, with the building oriented along the line of the topography, facing South.

I was involved between RIBA Stages 3 & 6 on this project, working alongside the Project Architect to develop Planning and Tender Packages. I was directly involved in the construction process after the Project Architect left the Practice, dealing with the clients and contractor, resolving site queries and participating in bi-weekly site meetings.

Regional Finalist: LABC Building Excellence Awards 2020 (Best Individual New Home)

p. 92

First Floor Plan Ground Floor Plan

© Lawrence Liddy

© Lawrence Liddy

Galvanised 203x203x46 UC as S.E design and specification Webs to be fully filled with rigid insulation 15mm

8mm galvanised steel plate welded to underside of beam to support stone wall, as SE design and specification

25x38mm s/w battens shot fired to steel plate above, providing fixing for flashing

PPC aluminium flashing, RAL 7016

PPC aluminium flashing, RAL 7016 Fixed back to battens with C/S screws with heads coloured to match flashing

38x50mm s/w battens to cill fixed back to chipboard floor deck Void between battens to be filled with mineral wool

EPDM sealed to VCL

Window Head & Cill Details (Originally 1:5 @ A1)

Flexible bitumen sheet cavity tray, contractor selected item

Weep holes provided in blockwork to drain cavity, spacing as manufacturers guidance

PPC aluminium flashing, RAL 7016 Drip edge to be provided at end of flashing Fixed back to plywood rip above Top edge of flashing to be laid underneath end of cavity tray

EPDM taped and sealed to underside of steel plate

Isochemie ‘ISO-BLOCO 600’ expanding sealing tape to gap between window frame and flashing to be installed in accordance with manufacturers instructions

Schuco AWS 70.HI openable aluminium window, RAL 7016 Fixed back to structure with window straps and base block as Schuco standard details

EPDM lapped and sealed to single ply membrane

PPC aluminium cill/flashing with profile matching side/head flashings RAL colour TBC Cill to be angled to allow for water runoff Timber fillet to aid drainage

Kingspan Thermabate, or similar approved insulated cavity closer, sized to suit 140mm cavity Shorter flange (nearest to internal blockwork skin) to be removed as Kingspan guidance

Slab Edge Detail (Originally 1:5 @ A1)

p. 93 Reveal Details - Windows 2 1217 Drawing Title Project Title Long Lane Ashford for: Mr and Mrs Clapp Details amended A 12/6/18 CE Structure to head of beam amended in detail 06 B 15/6/18 CE Amendments to wall build up on detail's 05 & 06 C 04/09/18 LMJ Feature wall ammended Details 05/06 updated to suit Lintel to Detail 06 updated to suit new S.E design D 18/09/18 JG Details updated to suit new glazing system E 22/01/19 JG Detail 02 and 04 updated to suit contractors comments F 06/02/19 JG -For all Lighting Information see Amos Lighting Drawings - All drawings to be read in conjunction with supporting information provided by PMA, including Construction Notes, Specifications, and Schedules as relevant 05. PLAN DETAIL IN PPC

have

match flashing window EPDM to provide airtight seal 25x38mm timber battens forming boxing around window frame, providing fixings for aluminium pressing Voids in boxing to be filled with mineral wool slabs between away (or closed external in directly grey) angle to

aluminium pressing, RAL 7016 Screw fixings to

C/S heads PPC'ed to

208mm 172mm 218mm 45mm 235mm 30mm 88mm 190mm 253mm 45mm

150mm +36 AFFL

AFFL

+1995

Client selected 30mm paving slabs with permeable joints laid on 50mm sharp sand bed Multitrack NW8 geotextile membrane 90mm Kingspan Styrozone N300R XPS closed cell insulation below DPC level Plasterboard with 110mm service zone behind to allow for recessed blind enclosure DPM to be continued down outer face of blockwork Concrete strip foundations as S.E specification Below ground blockwork to have a minimum compressive strength of 7N/mm2 as S.E specification min 150mm Bottom of cavity to be filled with lean mix concrete Weep holes formed in stonework to allow for water egress Distribution to manufacturers guidance SureCav 50 Novia Black U resistant breather membrane 50mm Kingspan Kooltherm K112 Framing Board Breather membrane lapped and fully bonded to cavity tray in strict accordance with manufacturers details and written instructions with minimum overlap of 150mm Novia 1000 VCL VCL lapped and fully bonded to DPM in strict accordance with manufacturers details and written instructions with minimum overlap of 150mm 140x50mm timber sole plate fixed to blockwork below Visqueen Zedex Bitumen DPC under cavity tray Flexible bitumen sheet cavity tray, contractor specified item 69x18mm hardwood skirting board painted white 500 gauge seperation layercontractor specified item 1200 gauge DPM contractor specified item 14mm UFHS pipes fitted in NuHeat “ClipTrack” or similar approved UFHS to be designed and installed by specialist subcontractor 120mm Kingspan Kooltherm K103 rigid insulation board 150mm in-situ cast reinforced concrete slab RC28/35 with 1 layer A193 mesh to bottom of slab to S.E specification 110mm Ancon Statifix-Thor Helical Timber Tie Ancon Statifix RT2 cavity wall tie with insulation clip 198mm 600mm 450mm Insulite medium density blockwork compressive strength 7.3N/mm2

p. 94 CE Feature 1:20 @ A1 14.02.2018 Scale Drawn By Date Drawing Title Project Title Change steel A 04/09/18 Spider replaced B 17/09/18 Staircase specialist's C 08/10/18 Foundation D 14/01/19 Drawing redesign E 10/04/19 SERIES KEY: Series 10 GA Series 11: GA Series 12 GA Series 14 Building Series 21 Floor Series 22 Wall Series 23 Roof Series 24 External Series 25 Door/Window Details Series 30 Feature Series 33: Fireplace Series 34 Internal Series 35 Feature Series 36: Joinery Series 40 Electrical/Lighting -For all Structural Sizes/Connections Consultants -For all Lighting Lighting Drawings - All drawings supporting information including Construction Specifications STAIR SECTION 1:20 STAIR ELEVATION 1:20 1000mm 17.5mm toughened glass balustrade fixed back to staircase with stainless steel point fixings Glass to be pre-drilled with fixing holes during fabrication All to specialists design Top of oak handrail to landing to be set 1000mm above flooring line, position of fixing hole for handrail support by specialist subcontractor Point fixing supporting handrail to align with point fixings supporting glass below Pitch line of stairs Staircase handrail omitted for clarity Fixing height as specialists design Dotted line marks line of glass balustrade behind cut plane forms section of staircase guarding Refer to specialists drawings for details Foundations and below ground blockwork as S.E design and details Floor buildup as F004 Refer to PMA drawing 1217_T_21.01 for details Stair bolted to top of blockwork Fixing to subcontractors design STAIR BASE DETAIL 1:10 SHS stringer bolted to Steel I-Beam Fixing to specialist sub contractor design Timber flooring returned to edge of landing depth to match finalised stair tread thickness 10mm pre-formed aluminium channel between timber lip and plasterboard to form shadowgap STAIR HEAD DETAIL 1:10 Plasterboard returned to fascia 1000mm 17.5mm toughened glass balustrade fixed back to staircase with stainless steel point fixings Glass to be pre-drilled with fixing holes during fabrication All to specialists design Top of oak handrail to landing to be set 1000mm above flooring line position of fixing hole for handrail support by specialist subcontractor Point fixing supporting handrail to align with point fixings supporting glass below Pitch line of stairs Staircase handrail omitted for clarity Fixing height as specialists design Dotted line marks line of glass balustrade behind cut plane forms section of staircase guarding Refer to specialists drawings for details Foundations and below ground blockwork as S.E design and buildup as F004 Refer to drawing 1217_T_21.01 for bolted to top of blockwork subcontractors design floor to be fitted and cut stair stringers STAIR BASE DETAIL 1:10 laid over top of blockwork SHS stringer bolted to Steel I-Beam Fixing to specialist sub contractor design Timber flooring returned to edge of landing depth to match finalised stair tread thickness 10mm pre-formed aluminium channel between timber lip and plasterboard to form shadowgap STAIR HEAD DETAIL 1:10 Plasterboard returned to fascia 15mm engineered oak flooring TBC Stair Head Detail (Originally 1:10 @ A1) Stair Elevation (Originally 1:10 @ A1)

© Lawrence Liddy

p. 95

N.B: Visualisation produced prior to Value Engineering works

Riverside Community Centre

New Library, Council Offices and Community Hall (PMA)

Location: Bovey Tracey, UK

Sector: Public

Year: 2016 - 2022

Status: Completed

The project proposed a new Community Centre within Bovey Tracey; collating the town library, tourist information centre, and the Town Clerk’s offices into a single building. The design took inspiration from the industrial background of Bovey Tracey, and proposed an offset sawtooth roof form over a large multi-purpose hall, with the ancillary spaces encasing the sides and rear.

This project passed through several stages of Value Engineering before reaching site, to bring the scheme back within the Client’s budget. This resulted in numerous changes visible in the drawings and photos shown on the following pages.

I was involved on this project between RIBA Stages 3 & 5, working with the Project Architect to develop various drawing packages and assist in Contract Administration on site.

Winner: RICS UK Awards 2022 - Best Public Sector Project, South West Region

Project featured in the Architect’s Journal

p. 97