2024 See for Yourself

May

Who went from 0 to 13% fast? YOU did.

All soybean farmers, including you, created biodiesel, which supports 13% of the price per bushel of soybeans. How? By pooling your resources through your soy checkoff. Learn how your soy checkoff is bringing tangible returns back to you and your operation at iasoybeans.com

Moving Soy Forward.

Moving You Forward.

©2022 United Soybean Board [61978 7/22]

YOU )

(

President

Suzanne Shirbroun, Farmersburg | D3

President-Elect

Brent Swart, Spencer | D1

Secretary

Tom Adam, Harper | D9

Treasurer

Jeff Frank, Lake View | D4

At-Large Director

Brent Renner, Klemme | D2

Board of Directors

Paul Kassel, Spencer | D1

April Hemmes, Hampton | D2

Sam Showalter, Hampton | D2

Rick Juchems, Plainfield | D3

Marty Danzer, Carroll | D4

Corey Goodhue, Carlisle | D5

Dave Struthers, Collins | D5

Robb Ewoldt, Davenport | D6

Dave Walton, Wilton | D6

Scot Bailey, Anita | D7

Lee Brooke, Clarinda | D7

Warren Bachman, Osceola | D8

Randy Miller, Lacona | D8

Pat Swanson, Ottumwa | D9

Tim Bardole, Rippey | At-Large

Aimee Bissell, Bedford | At-Large

Sharon Chism, Huxley | At-Large

American Soybean Association

Board of Directors

Tom Adam, Harper

Steph Essick, Dickens

Morey Hill, Madrid

Randy Miller, Lacona

Pat Swanson, Ottumwa

Dave Walton, Wilton

United Soybean Board of Directors

Tim Bardole, Rippey

Robb Ewoldt, Davenport

April Hemmes, Hampton

Brent Renner, Klemme

Staff Credits

Bethany Baratta | Editor

Aaron Putze, APR | CO of Brand Mgmt and Engagement

Susan Langman | Creative Design Coordinator

Joclyn Bushman | Multimedia Specialist

Jeff Hutton | Senior Writer

Kriss Nelson | Staff Writer

Joseph Hopper | Communications Specialist

Brock Johnston | Public Relations Manager

4

Plan or Wander

The Iowa Soybean Association’s (ISA) new strategic plan provides direction for the association.

8 Soy Sales

Explore how the Mexican market relies on U.S. soy.

18 Checkoff Clarity

Farmers traveling to South America saw firsthand the power of their soybean checkoff investment.

30 Scout to Find Out

Iowa’s mild winter and its potential impact on pests.

On the cover:

In this ‘See for Yourself’ themed issue, explore the markets through various travel experiences, dive into the data from recent fungicide trials and see how on-farm trials can help determine the effectiveness of products on your acres.

The U.S. Department of Agriculture has announced a soybean checkoff request for referendum (RFR).

Eligible U.S. soybean farmers may request a referendum beginning May 6, 2024, and ending May 31, 2024, in county Farm Service Agency offices.

To be eligible to participate in the Request for Referendum, producers must certify that they or the producer entity they are authorized to represent paid an assessment at any time between January 1, 2022, and December 31, 2023.

The RFR occurs every five years, and the official notice is available online in the Federal Register (federalregister.gov).

IOWA SOYBEAN REVIEW® | 3

Soybean

is

monthly by:

Soybean

SW Prairie

iasoybeans.com

For advertising information contact Bethany Baratta at (515) 334-1020 or bbaratta@iasoybeans.com

Iowa

Review

published

Iowa

Association 1255

Trail Parkway, Ankeny, Iowa 50023 (515) 251-8640 |

E-mail: bbaratta@iasoybeans.com

Comments and

should be sent to

address. Advertising

Executive Committee

statewide news articles

the above

space reservations must be made two months preceding publication. In consideration of the acceptance of the advertisement, the agency and the advertiser must, in respect of the contents of the advertisement, indemnify and save the publisher harmless against any expense arising from claims or actions against the publisher because of the publication of the content of the advertisement.

May 2024 | Vol. 37, No. 8

NAaron Putze, APR ISA Chief Officer of Brand Management & Engagement aputze@iasoybeans.com Plan or Wander

NAaron Putze, APR ISA Chief Officer of Brand Management & Engagement aputze@iasoybeans.com Plan or Wander

ew York Yankees Hall of Fame catcher Yogi Berra once proclaimed, “If you don’t know where you are going, you might wind up someplace else.”

His unique perspective on the importance of planning was evident during my family’s 3,000-mile spring break journey to Scottsdale, Arizona.

While I do OK with travel prep, my wife Crystal takes it to a whole other level. Our get-away to the Valley of the Sun went off like clockwork because of her meticulous planning. Every mile was carefully plotted ensuring we overnighted in comfort, never ran low on fuel, sampled a variety of restaurants, and enjoyed unique experiences (like “Standing on a corner in Winslow, Arizona”).

Without determining a destination and the necessary steps to get there, we’d likely be somewhere in Canada or stranded alongside I-40 near Gallup, New Mexico, begging for fuel.

For associations, the stakes are even higher when failing to plan. Members rightly expect leadership to keep its eye on the ball, invest resources wisely, operate efficiently and effectively, be responsive to their input, and get results.

The Iowa Soybean Association (ISA) board approved a new strategic plan in March. It was a privilege to help lead the process that began nearly a year ago with a thorough

review of our previous plan written in 2019. Senior ISA staff met with farmer directors to assess changes in the global soy value chain and what the future might hold on a host of issues impacting global and domestic supply and demand for soy. We obtained farmer input about the opportunities and threats facing agriculture and ISA’s strengths and weaknesses via focus groups, telephone interviews and online surveys.

When farmers headed to the fields for harvest last September, drafting the new strategic plan began. Updates were provided to directors throughout the winter, culminating with the plan’s approval when the ISA board met during Commodity Classic in Houston.

ISA’s new strategic plan…

• Emphasizes market development for all things soy (including whole beans, biofuels and soybean meal) and independent, farmer-led production research to improve farmer profitability through increased production and adoption of regenerative ag practices;

• Prioritizes greater engagement of farmers in ISA programming and using ISA policy as a catalyst for regulatory reform, market access and maintaining access to critical crop protection tools;

• Elevates the importance of ISA operations (the engine that drives all of the association’s functions), including improved data and software management, culture, diversity of experience and thought; and

• Embraces on a very personal level the needs of the individual farmer — from their physical and mental well-being to supporting the smooth and successful succession of farms enabling the next generation of soybean farmers to take their place behind the wheel.

You’ll be hearing (and reading) much more about ISA’s new strategic plan, including a deeper dive in next month’s Iowa Soybean Review. It will also be referenced frequently over the coming years and, while not set in stone, will provide firm direction to help soybean farmers successfully navigate whatever the future might hold.

Buckle up, as it promises to be quite a journey.

4 | MAY 2024 | IASOYBEANS.COM

Get started today! Sign up for a free estimate at theoutcomesfund.com! ENROLLMENT FOR 2024 NOW OPEN! This material is based upon work supported by the U.S. Department of Agriculture, under agreement number NR233A750004G002. Any opinions, findings, conclusions, or recommendations expressed in this publication are those of the author(s) and do not necessarily reflect the views of the U.S. Department of Agriculture. In addition, any reference to specific brands or types of products or services does not constitute or imply an endorsement by the U.S. Department of Agriculture for those products or services. Eli Lynn, ISA member and participating SWOF Farmer, and SWOF’s Rosemary Galdamez Earn More for Your Acres! Financial and Agronomic Support for New and Expanding Conservation Ag Practices REDUCED TILLAGE | COVER CROPS | EXT. CROP ROTATIONS | AND MORE

WISHH leverages partnerships for U.S. Soy to help meet the protein needs of 8 billion consumers

wishh.org

Time for Bingo

Editor’s

Note

by Bethany Baratta bbaratta@iasoybeans.com

“ Bingo!” our son, Luca, yelled, beating his chest like Tarzan after shuttering O61 during an Easter round of bingo. Up until this point, he had been listening intently to his great grandmother, replying to every letter and number called: “not that one” and a sigh for the missed spaces, and a “yes!” for those letter-number sequences that matched his card. Like any good bingo player, he petitioned which combinations would make him a winner. He looked over at my card, then his dad’s, trying to judge who would win first.

Playing bingo on Easter and Thanksgiving has been a tradition in my husband’s family for decades. I don’t know when it started, but I remember the first time I won. It was the first Thanksgiving I spent with his family. Adding me to the group meant one less chance for other family members to win one of five prize bags. In fact, when I won bingo that year, there was a ‘who invited her?!’ voiced among the players (maybe my husband?). My future mother-in-law quickly hushed the naysayer; she was one

of the few who cheered as I collected my prize money. One year, since adding me to the family made five, my mother-in-law got us shirts that, when we stood together, spelled out bingo (or BIG NO when my husband, father-in-law, and brother-in-law sourly coordinated our t-shirt photo opp). That ‘B’ shirt still hangs in my closet.

These past few years, the farming bingo card has been wild. Who knew you could have drought and ‘one of my best yields ever’ in the same card? (I bet our seed companies did!). Despite this, Iowa farmers managed to turn it into an opportunity, harvesting 573 million bushels last year.

As you dip in and out of your fields this season, I hope you get to check off some of those winning spaces on your bingo card. I hope you shutter the FREE space when you need a win for the day, and I hope those glorious shots of sunshine and rain pull you closer to a winning round. Like Luca, I hope you get to beat your chest like Tarzan once you complete a successful year, and you collect your bingo winnings in the form of bushels collected and sold. In case you’re wondering, Luca’s winning bingo card was B5, I29, FREE, G51 and 061; his great grandma verified his card, and he collected his winnings.

Take care,

P.S. I’m on a never-ending mission to learn more about the farmers who make up this great state, and I’d love to hear from you directly. Drop me a line at bbaratta@iasoybeans.com or call me at 515-334-1020.

Route 2

Rural

IOWA SOYBEAN REVIEW® | 7

Increasing U.S. soy sales tied to branding success of Mexican beef company

STORY AND PHOTOS

BY AARON PUTZE, APR

8 | MAY 2024 | IASOYBEANS.COM

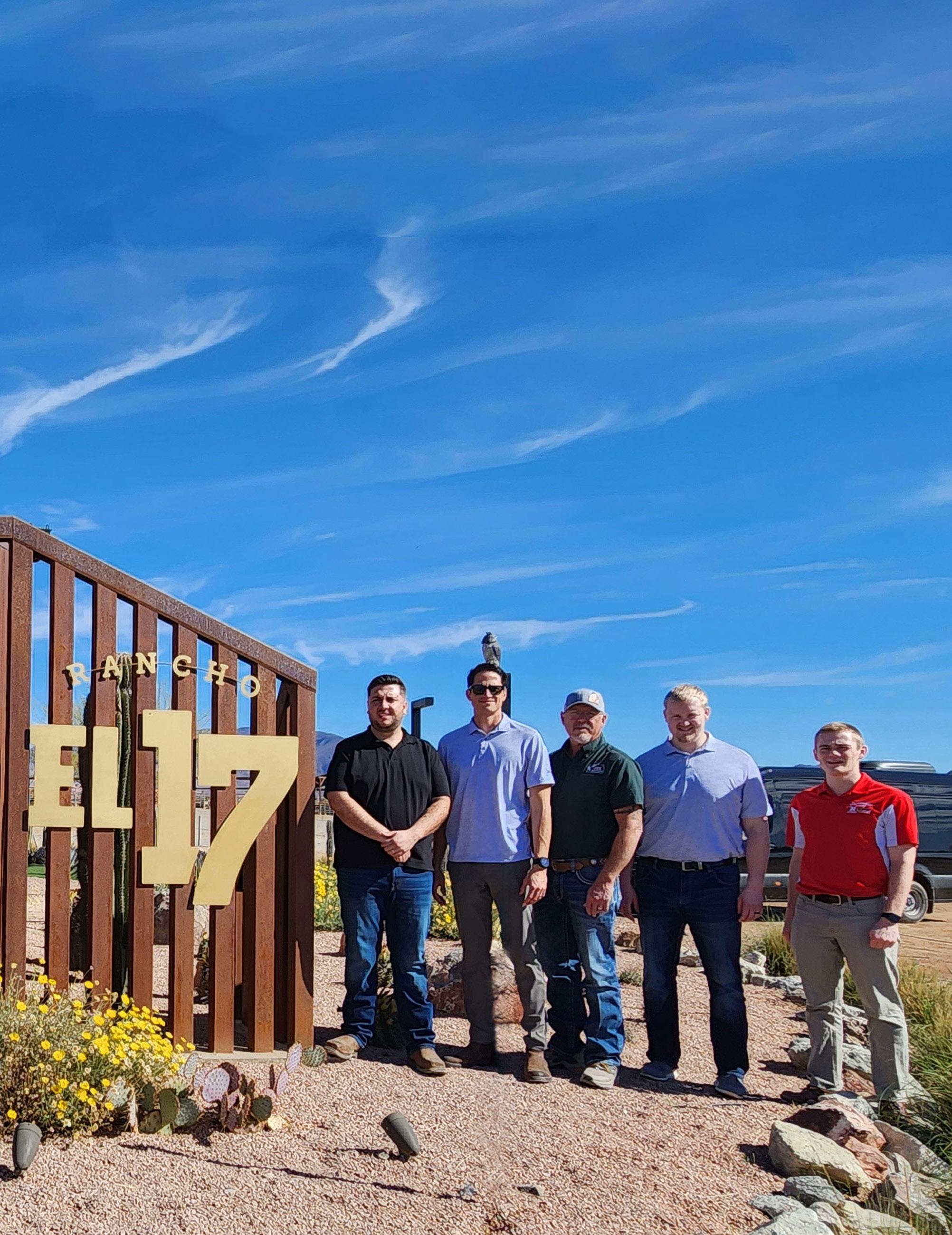

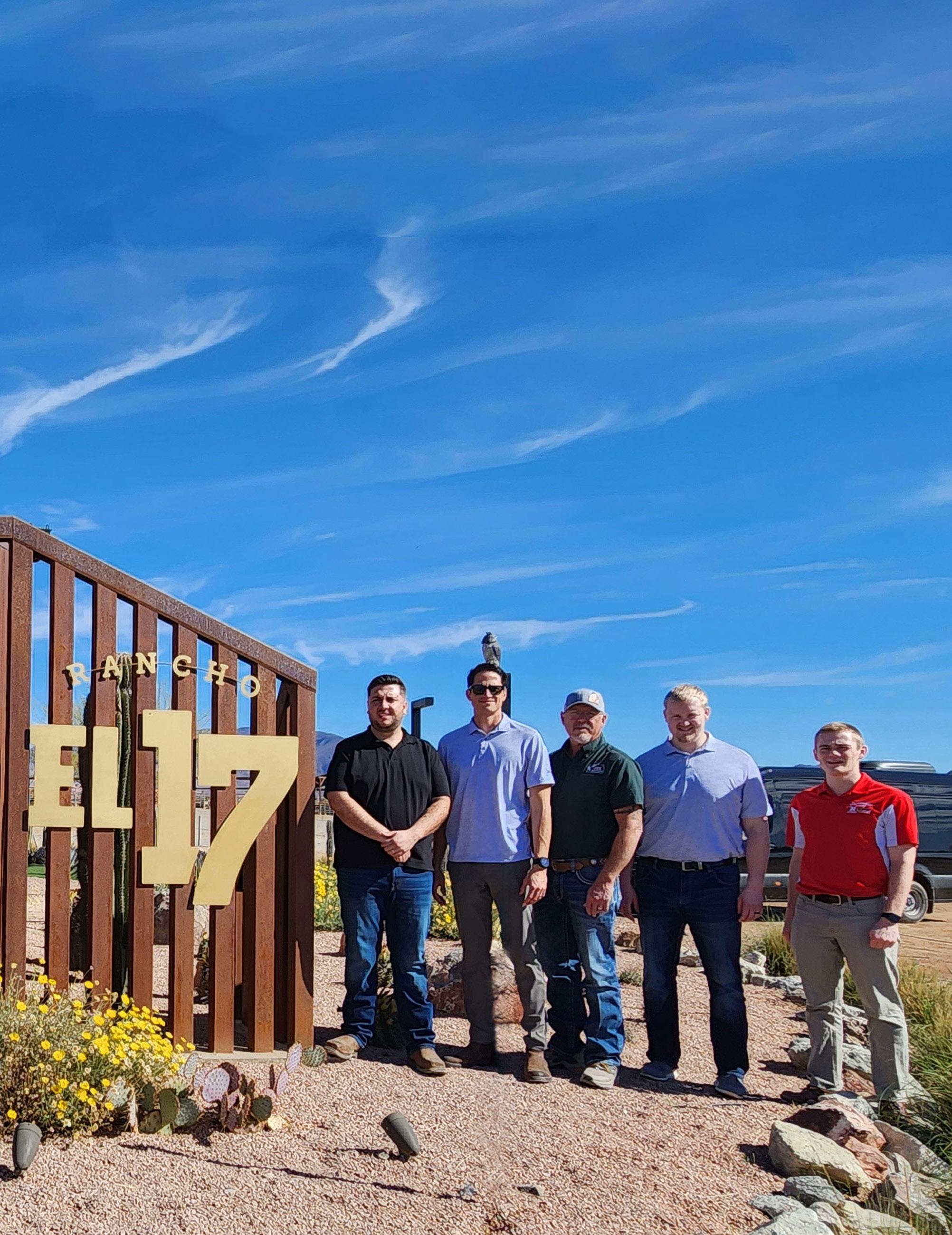

Soybean leaders from the U.S. Midwest make a stop at El 17. Located near Hermosilla in northwest Mexico, the company specializes in the production and retail of high-quality beef. When priced competitively, the company uses soy in place of dried distillers grain in feed rations at its 19,000-head feedlot.

Abrand has long been used by cattle farmers and ranchers to identify an animal’s original ownership and discourage theft.

Effective branding also differentiates one product from another in the retail marketplace, and the ability of a Mexican beef producer to do it successfully will benefit Iowa and Midwest soybean farmers.

For El 17, a 33-year-old company based in northwest Mexico specializing in the production of high-quality beef, the power of its brand is increasing sales of its premium steaks. It will also be the catalyst for the company’s aggressive expansion of Taste, its retail marketplace featuring cut-to-order butcher shops, ready-to-cook meals, and a variety of popular convenient store offerings.

“People believe in our brand,” says Roberto Loustaunau, the company’s second-generation owner. “Our goal is to keep the brand top of mind as the best quality beef in Mexico.”

The success of El 17 directly impacts the bottom line of U.S. soybean farmers, including those who

visited the company’s feedlot and retail stores during a market development trip to Mexico Feb. 18-23. The meetings were arranged by AGP.

Iowa soybean farmers like Warren Bachman pay attention to Mexico as it is America’s second-largest single export market for soy with sales of nearly $4.76 billion. Bachman, an Iowa Soybean Association (ISA) District 8 director, joined fellow soybean farmers and association staff from Missouri, Kansas and Nebraska in the trade mission.

The goal of their time in Mexico: to increase soybean sales south of the border and build upon the 88% market share U.S. farmers have of the country’s 14.2 million metric tons of annual soy imports.

“It’s important to visit your trading partners so you can see firsthand what’s happening with their economy and what they think of your product,” says Bachman, who farms near Osceola and is serving his eighth year on the ISA board. “You got to invest in your customer if you want them to invest in you.”

Continued on pg 10.

IOWA SOYBEAN REVIEW® | 9

It’s important to visit your trading partners so you can see firsthand what’s happening with their economy and what they think of your product.

Warren Bachman, ISA district 8 director

Adding numbers

That includes major meat producers like El 17. The company’s feedlot, located on the outskirts of Hermosillo (pop. 850,000), sits on 1,000 hectares (roughly 2,500 acres). About one-fourth of it is penned, with a capacity of 19,000 head. The number on feed varies with the economics of cattle production and consumer demand for beef. After declining to just 40% of capacity in 2022, El 17 has returned to 15,000 head on feed.

The goal, says Loustaunau, is to return to producing 19,000 head within a year or two, increasing to 25,000 head within 3-5 years. The growth will meet increasing domestic and international demand for its premium beef cuts and hamburger.

Iowa farmers marketing soybeans through AGP keep close tabs on feedlots like El 17 because its success means more demand for U.S. soy.

Amino Plus, a bypass protein feed formulated and milled by AGP, is a desired feedstock for dairy and cattle. When priced competitively, it becomes an attractive option to dried distillers grain.

Andrew Metzger, senior merchandiser for Omaha-based AGP, makes frequent visits to the country to promote sales of the processor’s soybean meal. That includes Amino Plus, a product high in lysine and amino acids that make it an especially helpful feed ingredient for boosting milk output in dairy herds.

AGP’s work with Mexico began almost 20 years ago. The farmer-owned cooperative continues to network aggressively with feed suppliers and livestock producers to boost demand in Mexico while establishing market share in Panama, Japan, Slovakia, Belgium and Saudi Arabia.

“There’s great potential to increase market share of Amino Plus due to its performance and as it becomes more competitively priced,” Metzger says.

The value of U.S. soybean exports to Mexico has a 10-year average value of $2.09 billion with a growth rate of 53%, according to the U.S. Department of Agriculture. Soybean meal mainly comes from domestic crushers and imports. The core share of soybean oil also goes to domestic crushers, with imports primarily coming from the U.S.

Mexico’s current soy import dynamics reflect developments in the crush industry as key players expand capacities and leverage soybean imports. The U.S. Soybean Export Council says soy and soy products are in high demand in the country of 136 million. The legume accounts for almost two-thirds of Mexico’s total volume of oilseeds processed.

Expansion plans

With Cat front-end loaders continuously moving feedstocks for mixing, Cesar Valencia speaks above the din as he shares the company’s commitment to producing quality beef using quality feed.

As general manager, Valencia oversees the feedlot’s daily operations-from feeding to the overall care of the cattle. Feed ingredient staples include grain, alfalfa, wheat straw, minerals, fats, vitamins and soy. Five formulas of feed are milled on the farm and fed based on the growth rate and dietary needs of the cattle.

U.S. soy is known by El 17 and other livestock producers in the area for its quality. As domestic U.S. crush intensifies to boost oil output, soybean meal and its co-products will become more competitively priced in the global marketplace. And that may be just the price signal that bumps demand in places like Hermosilla and for customers like El 17.

The feedlot’s 50 employees monitor the health of the animals and formulate and mix feed rations to match the maturity and weight of the animals. The continuous attention is warranted

10 | MAY 2024 | IASOYBEANS.COM

Middle: Premium beef at the retail counter (right) begins with high-quality feed developed and fed by El l7.

as temperatures can spike to 120 degrees June through mid-September. As a result, the breakfast bell rings at 5 a.m. instead of 7, taking advantage of the cooler morning air.

Antibiotics are used in disease prevention but not in feeding. Heifers and steers arrive at the feedlot weighing around 600 pounds, doubling their weight before heading to market.

More than 150 tons of feed are mixed and fed daily at El 17. The feedlot contracts with a third party to remove the manure, which is sold as fertilizer to fruit producers in California.

Loustaunau, who holds a degree in business management, says El 17 provides complete traceability from the feedlot to the client, the latter of which includes upscale steak and seafood restaurants located throughout the country. It also sells to Mexico’s largest supermarkets including Wal-Mart and Soliano and area butchers. Some product is exported to Japan and the U.S.

Consumers rule

But El 17 increasingly prefers selling direct to consumers as more people seek to know the origins and production methods of the food they enjoy. In addition to traceability, the company is known for producing beef of exceptional color, marbling and flavor.

El 17’s retail market expansion seeks to make the most of these brand attributes while boosting its bottom line. Founded nearly 10 years ago, El 17 now operates 25 Taste Boutique de Carnes stores (premium meat products sold locally). Last year’s expansion included six new stores in Mexico City. The company’s goal, says Loustaunau, is to grow by 6-8 new stores annually, with 100 in operation by 2034.

The company’s decision to target Mexico City for expansion was based on online sales growth during the Covid pandemic. Those interactions provided key insights about El 17’s customers and their preferences.

“People know about the brand in Mexico City as half of our online sales (during the pandemic) came from that city,” Loustaunau says.

“We capture the brand value with our stores. They know the brand, the quality and that it’s produced in Mexico. They are confident and like the product. No one else is doing this in Mexico.”

The challenge now, he says, is to fully convert the company’s staff and culture to match its full embrace of retail.

“We’re no longer just raising beef but managing stores to grow sales and our bottom line,” says Loustaunau. “It takes a different kind of team to advance in that market, but we are in a good spot to grow. The time is now.”

Contact Aaron Putze at aputze@iasoybeans.com.

IOWA SOYBEAN REVIEW® | 11

Top: Cattle pose at El 17’s feedlot. With demand growing for its high-quality beef, company officials are planning to expand its feedlot from 19,000 to 25,000 head.

Bottom: ISA Director Warren Bachman and El 17’s secondgeneration owner Roberto Loustaunau talk cattle following a tour of the company’s feedlot. “Our goal is to keep the brand top of mind as the best quality beef in Mexico,” says Loustaunau.

MAINTAINING OUR REPUTATION TO DELIVER

Whether shipping by river, road or rail, the soy checkoff is committed to ensuring America’s infrastructure is a significant advantage for U.S. soybean farmers. We’re looking inside the bean, beyond the bushel and around the world to keep preference for U.S. soy strong. And it’s helping make a valuable impact for soybean farmers like you.

See more ways the soy checkoff is maximizing profit opportunities for soybean farmers at unitedsoybean.org

unitedsoybean.org Brought to you by the soy checkoff. © 2018 United Soybean Board. Our Soy Checkoff and the Our Soy Checkoff mark are trademarks of United Soybean Board. All other trademarks are property of their respective owners.

( YOU )

Who’s the No. 1 protein source in chicken feed? YOU are. That’s right. You’re winning.

All soybean farmers, including you, are really big in poultry and livestock feed. How? By pooling your resources through your soy checkoff. Learn how your soy checkoff is bringing tangible returns back to you and your operation at unitedsoybean.org/hopper

Moving Soy Forward.

Moving You Forward.

©2021 United Soybean Board [61133-1 7/21] IA

EXPLORING MEXICO’S

As a trading partner, Mexico brings soy to shrimp, benefiting Midwest farmers.

STORY AND PHOTOS BY AARON PUTZE, APR

Much of central and northern Mexico remain in severe drought, evident by this dry river bed located

14 | MAY 2024 | IASOYBEANS.COM

outside Hermosillo, a city of nearly 850,000.

EXPLORING MARKET

The landscape looks more like Mars than the world’s second largest consumer of U.S. soybeans. Dust-coated vegetation, dry riverbeds, large swaths of lifeless land and dancing heat waves simmer from pavement. Little moves, and what does moves as little as possible.

From inside an unmarked Sprinter van washed daily yet still showing signs of wear, a dozen representatives of the U.S. soy industry traverse the rugged northwest countryside of Mexico in search of buyers and users of Midwestsourced soybeans.

With global soybean supplies ample and cash prices in places like Hubbard, Montezuma, Algona and Fairbank trending lower, finding markets takes effort — and being oblivious to motion sickness.

Among those bouncing from place to place south of the U.S. border is Warren Bachman. The farmer from Osceola has harvested north of 60 soybean crops and is committed to helping find markets for a growing supply of the popular and versatile commodity.

The Iowa Soybean Association (ISA) board member pays close attention to the countryside zooming by. He’s an expert on knowing nearly every make and model of harvesting equipment, even those scattered throughout Mexico’s parched and sparsely populated rural communities stretching from Hermosilla to Culiacan (a distance of about 428 miles).

Continued on pg 16.

IOWA SOYBEAN REVIEW® | 15

Top Right: Soybean leaders from Iowa, Nebraska, Kansas and Missouri at a shrimp hatchery operated by Mexcio-based Vimifos. About one-third of the breeding stock’s feed ration is soy, much it sourced from U.S. Midwest farms.

For many years, Warren traversed the southern U.S. gobbling up wheat acres as part of custom threshing operations. Today, he seeks to harvest new marketing opportunities for fellow Iowa soybean farmers.

“It’s dry, even in places where agriculture is king,” he muses while scanning the pale brown fields where what little green appears is sustained through irrigation. Joining Warren on the market development journey through western Mexico are directors and staff representing the Kansas, Nebraska, and Missouri soybean associations. The group is led by representatives of Omaha-based Ag Processing, Inc., a farmerowned cooperative specializing in the aggregation, processing and shipping of whole soybeans and soybean meal.

Drought intensifies

Even with extensive and labor-intensive irrigation covering almost every possible hectare to which one can stretch a hose or dig a ditch, locals forecast below-normal white corn, tomato, pepper and food bean harvests. These are staples of agricultural productivity near the country’s western coast stretching along the Gulf of California. On a good year, 10 inches of rain fall. The skies have failed to yield that amount over the past 18 months…and counting. The cloudless skies have led to intensive water rationing in many locations, including Mexico City (pop. 22 million), the world’s fourth largest city.

After a nearly four-hour ride, the stark, white buildings of Lavaras El Dorado shrimp larvae lab and hatchery break the visual silence.

It’s operated by Vimifos, a diversified agricultural food and feed producer with locations scattered across Mexico and the globe.

The 30-year-old facility and its team of 160 aqua farming scientists and employees know how to coax shrimp to mate.

Large tanks supplied with water direct from the sea are the ideal home for stock that breeds six times in three months.

Vladimir Morales, who serves as supply chain director for Vimifos, estimates the facility’s breeding stock produce 60-80 million larvae daily. Invisible to the naked eye when spawned, the larvae mature upon taking up residence in 20, 18,500-gallon tanks nestled in a building adjacent to the hatchery.

Soy appetite

Feed rations for breeding shrimp are comprised of 30-35% soy, much of it sourced from the Midwest U.S. That equates to about 20 metric tons of soy in the 50 metric tons of feed needed to nourish and sustain the breeding stock’s ravenous appetite.

The facility’s proximity to ample supplies of salt water is logistically savvy. From June-December, the shrimp’s breeding stock live and procreate in the warm waters just off the shore. During the remainder of the year, cooler water temperatures send the production indoors where conditions are made suitable for the astonishing ability to reproduce.

The region west of Obregon where Lavaras El Dorado is located is known for its prolific shrimp production. Nearly 300,000 metric tons of shrimp are produced annually. Roughly 10% of that volume is supplied by the Lavaras El Dorado hatchery.

Shrimp production flourishes with quality feed. Vimifos takes matters into its own hands by producing and bagging feed at its state-of-the-art milling plant in Obregon. The company says protein levels provided by meal supplied by AGP measure 46-plus percent, often as much as 2 points clear of the soybeans sourced from South America.

16 | MAY 2024 | IASOYBEANS.COM

Top left: Shrimp pulled from the hatchery tanks at the Lavaras El Dorado shrimp farm near Obregon, Mexico.

Bottom right: Warren Bachman, ISA farmer director from Osceola, chats with Vladimir Morales, who serves as supply chain director for Vimifos, at the company’s shrimp hatchery located on the shores of the Sea of Cortez.

Vimifos constructed its first feed mill in Mexico shortly after its founding by livestock farmers in 1977. Three years later, it built its first phosphate plant followed in 1992 by perfecting the pelletizing of feed for swine. Soon after, it joined with ADM as a strategic partner and developed into new markets including the shrimp feed market.

Over the next 18 years, Vimifos established its own financial entity providing loans and credit to customers and suppliers, built a feed plant in Guadalajara capable of producing 70,000 metric ton of feed (its largest in Mexico), launched a line of dry pet food and extruded shrimp feed and opened a swine feed production plant in Navojo.

Market share dominance

A network of dealers propels Vimifos’ feed production and consumption growth. Its more than 500 customers include Pilgrims, Purina, Cargill, Mars, Nestle and El 17, a Mexico-based company specializing in the production and direct-to-consumer sale of high-quality beef. Vimifos is also the largest producer of shrimp feed, capturing around 21% of the country’s market share, while accounting for 33% of the Mexico’s tilapia feed market.

U.S. soybean farmers keep a close eye on Mexico in part because of Vimifos. The company’s global feed production in 2022 totaled 1,187.7 million metric tons (mmt). Only China and the U.S produce more feed than Mexico. For Vimifos, that feed nourishes growing numbers of broilers, layers, swine, cattle, dairy, shrimp and fish. Soy, a major ingredient in each application, is also found in the company’s production of 1.4 metric tons of pet food.

“We’ve got to be in this market, as both a product and farmer producer,” says Bachman.

The numbers illustrate Bachman’s point. Per-capita meat consumption in Mexico is increasing. The average resident now consumes 77 lbs. of chicken vs. 61 lbs. less than 15 years ago. Egg consumption during the same period has increased by three to 52 lbs while pork consumption has increased by almost 20% — from 37 lbs to 45 lbs.

While consumer preference is trending toward lower-cost protein options like poultry, egg and pork, seafood and beef consumption are holding their own. Consumption of both is expected to rebound once Mexico’s economy shakes off sticky high inflation (nearly 8%). Pet food production is also expected to increase, as will the amount of soy needed to feed the demand.

Solid prospects

“The general public seems to be better off than one might expect,” says Bachman, “as do the prospects for selling more soy to Vimifos and other Mexico-based feed, fish and livestock producers.”

His first market development visit to the country of 136 million certainly won’t be the last for the association that Bachman helps lead.

“There’s potential here but we’re going to have to work at it because the competition will,” he adds while bumping along the winding roads to the next stop on the journey — an agri-expo farm show in Culiacan.

“The Iowa soybean farmer is best served if we focus on the feed suppliers and have them sell to their customers,” says Bachman. “We’re growing more soybeans than the market currently needs, so finding new users, whether in Mexico or anywhere in the world, should be priority number one.”

Contact Aaron Putze at aputze@iasoybeans.com.

IOWA SOYBEAN REVIEW® | 17

LARGEST SINGLE EXPORT MARKET CONSUMED U.S. SOY (2023) MILLION METRIC TONS POPULATION STRATEGIC TRADING PARTNER FOR U.S. SOYBEAN FARMERS OF DOMESTIC SOYBEAN MEAL, DECREASING IMPORT DEMAND EXPANSION OF DOMESTIC CRUSHING CAPACITY IS DRIVING A LARGE INCREASE U.S. SOY MARKET SHARE IN MEXICO

MEXICO Source: USSEC

SOY STATS ABOUT

ISA members travel to South America to see the power of U.S. soybeans.

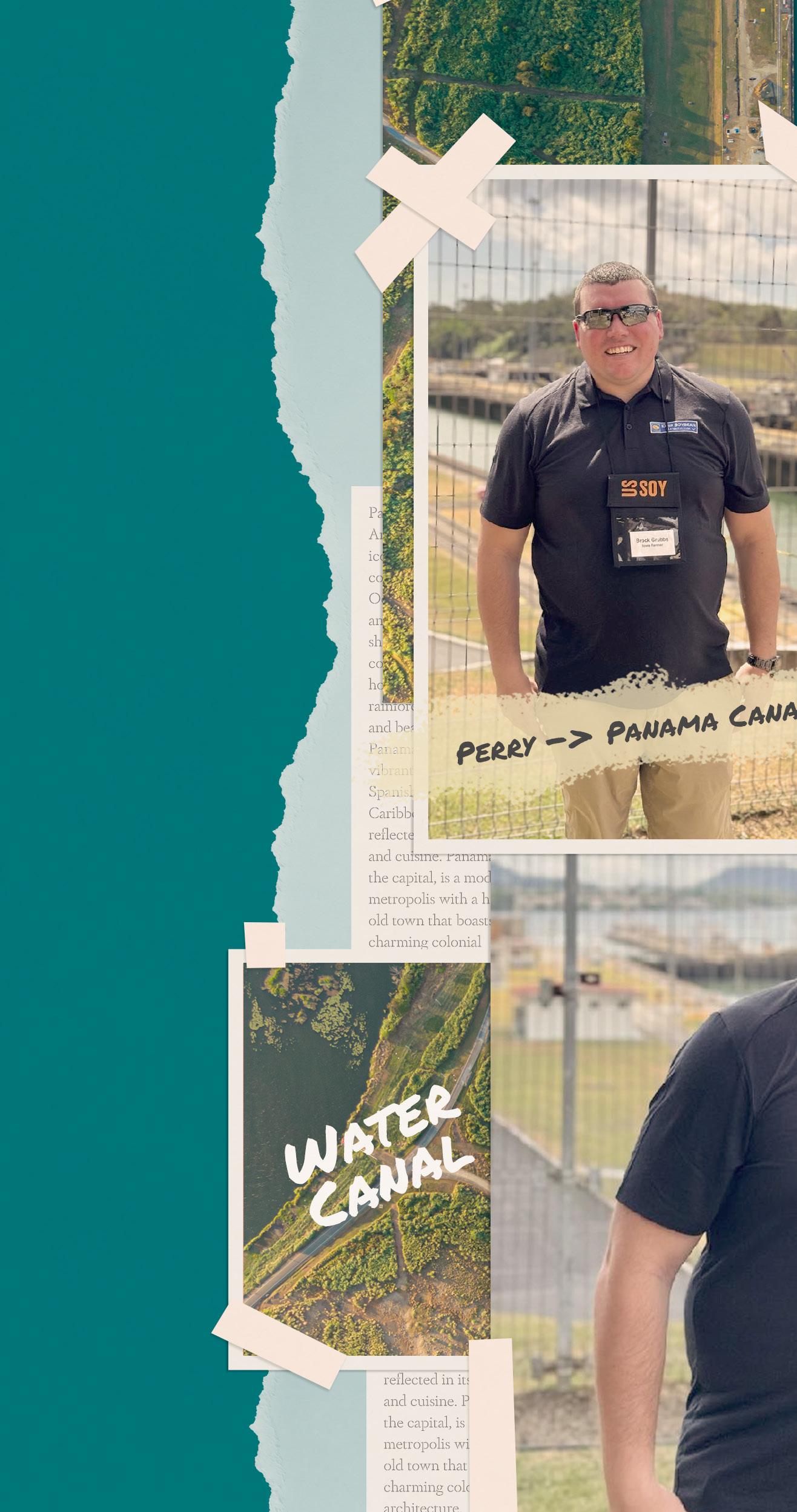

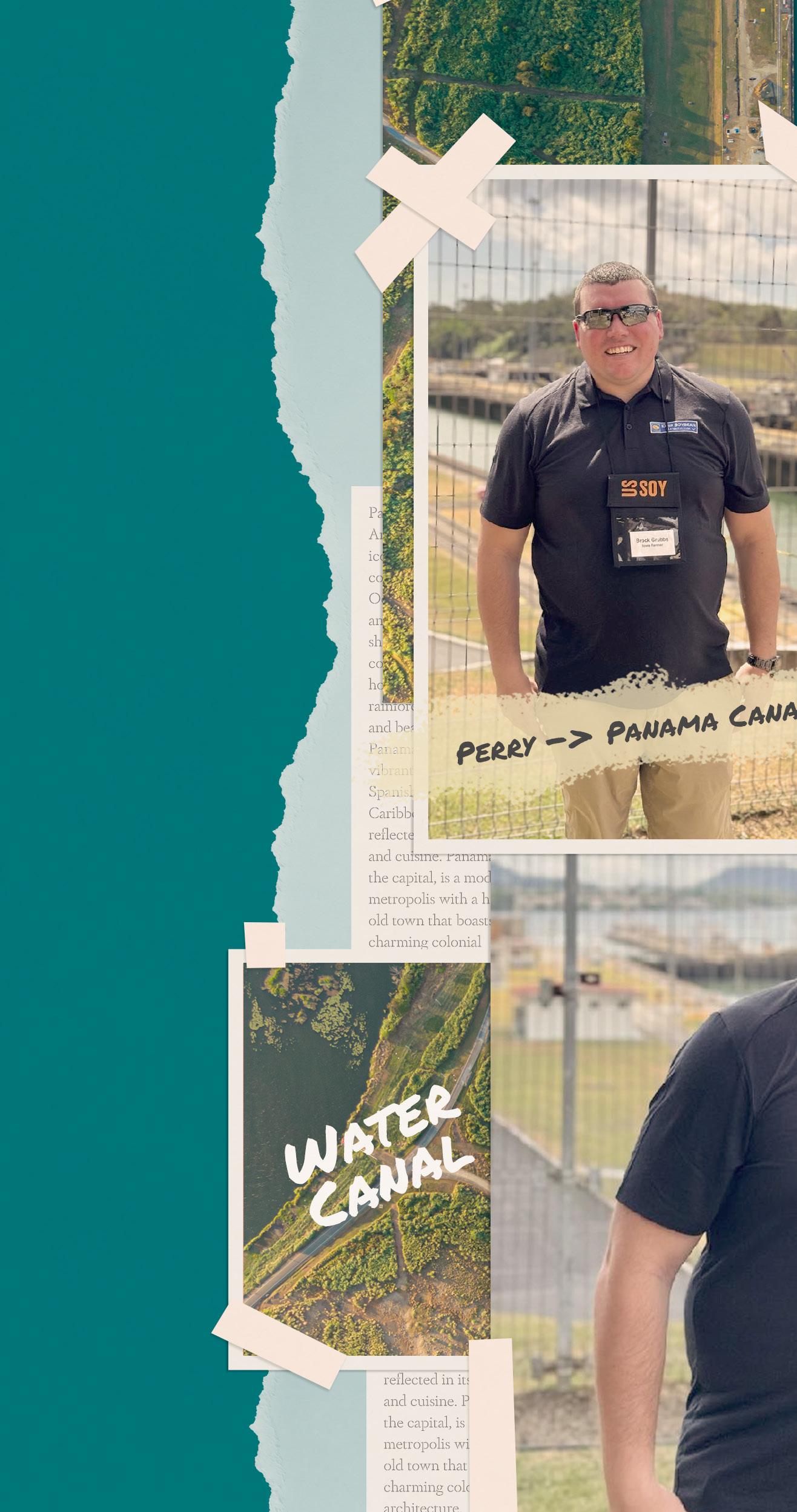

Seeing is indeed believing and if you ask April Hemmes and Brock Grubbs, they know the positive impact the soybean checkoff has made around the globe.

Hemmes, the Iowa Soybean Association (ISA) District 2 director from Franklin County, and Grubbs, an ISA farmer-member from Perry, recently traveled to Panama and Colombia as part of the United Soybean Board’s (USB) “See For Yourself” tour.

USB selected Grubbs and Hemmes, who also serves as a USB director, and nearly 20 others to travel to Central and South America to see and evaluate the work of the checkoff — from the use of U.S. soy domestically to its export to customers around the world. The group met with customers, discussed aquaculture and learned about the soybean industry’s contribution to animal ag and how checkoff investments are opening up the world to U.S. producers.

As part of their journey, the duo from Iowa shared some of their thoughts. Here are a few dispatches from their trek:

PANAMA

Hemmes:

Our first night in Panama City we had a great presentation by Soybean Transportation Coalition Executive Director Mike Steenhoek about the Panama Canal. This was my first trip to both Panama and Colombia, so I was excited to learn about our checkoff investments there. Everyone said, “Oh they aren’t taking anything through the canal, it’s too dry!” Not true. They have cut the trips in half and the most valuable (meaning those who will pay the most) have priority. Unfortunately, that is not soybean mass bulk ships. We were lucky to see a ship go through the new canal. After seeing both the Atlantic and Pacific sides of the canal we also had a presentation by the Port Authority. It is always interesting what you learn. The engineering and innovation they produced in the late 1800s is amazing.

Grubbs:

We went to a few local supermarkets and checked out products they were selling that had a U.S. Soy stamp on them such as soybean oil and frozen meats. The supermarkets were neat for a variety of reasons, but one of the things I found most interesting was not only the size but also what was being sold. From the exterior, they looked like any average U.S. grocery store; but then when we walked inside, we could quickly see they were much larger. One of the stores had three stories, and besides groceries, there was clothing, furniture, electronics, tools and household appliances. It truly was a one-stop shop. Later that afternoon, we departed Panama City and flew to Bogota, Colombia. Continued on pg 20.

18 | MAY 2024 | IASOYBEANS.COM

IOWA SOYBEAN REVIEW® | 19

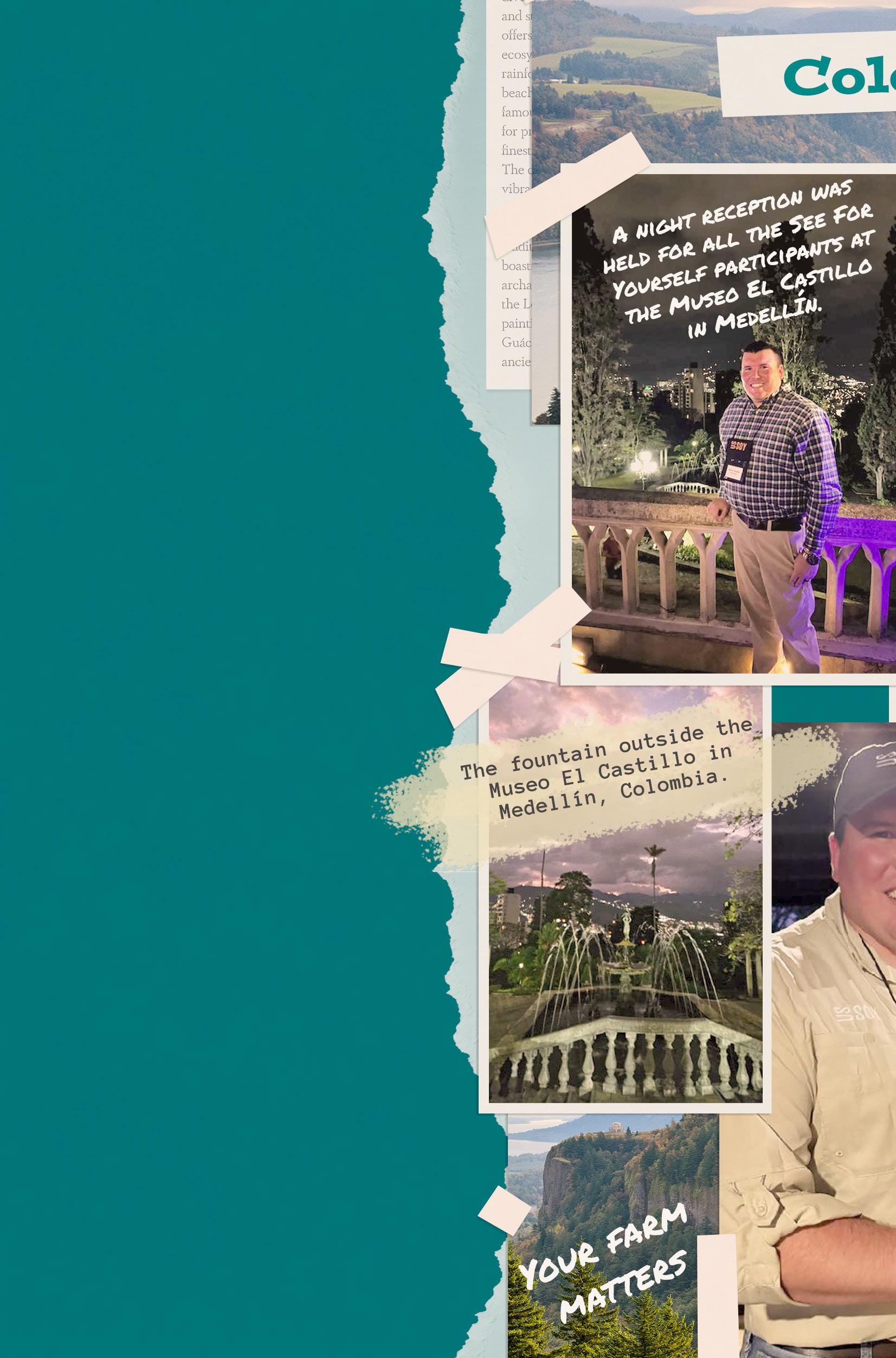

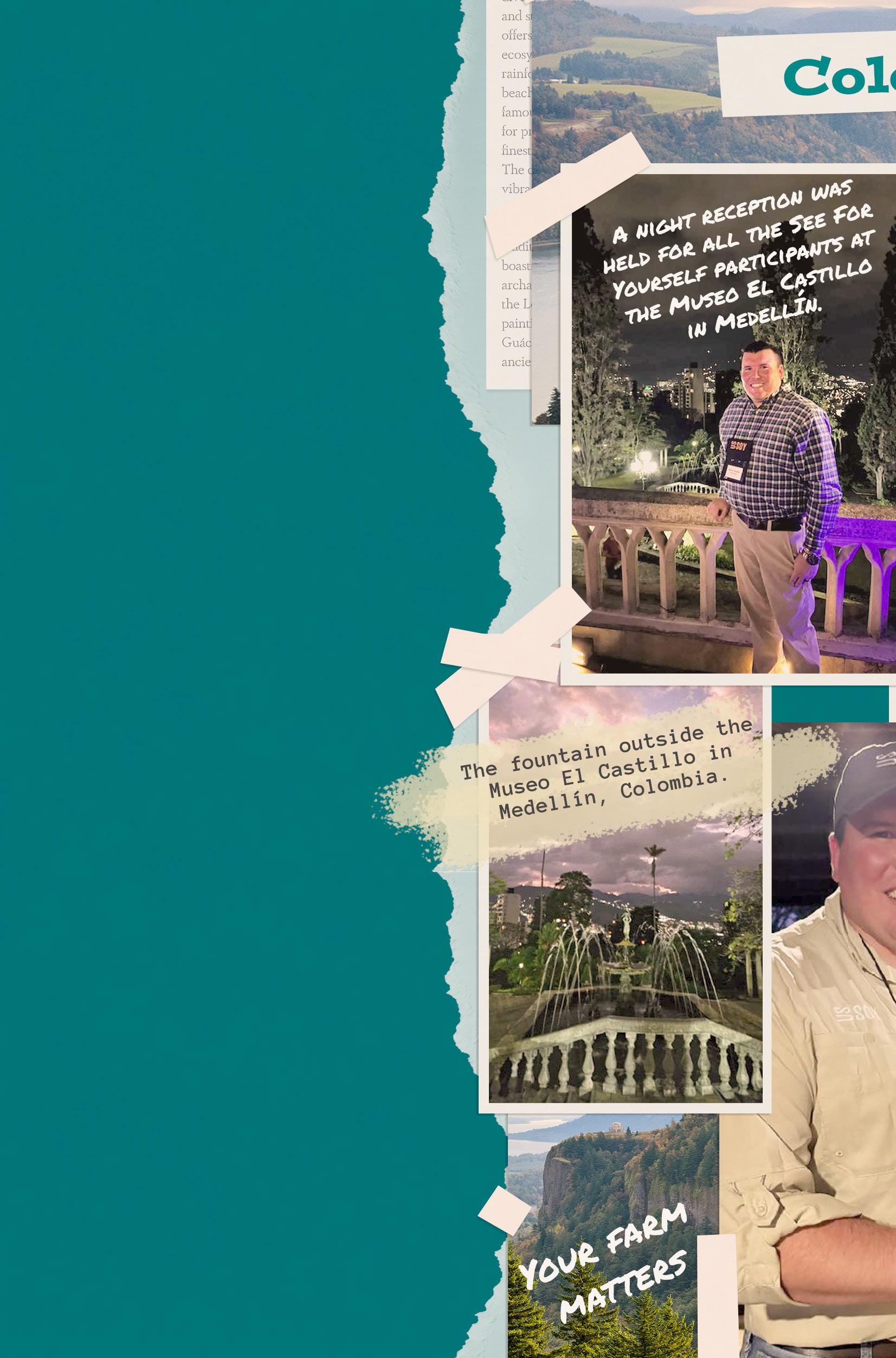

COLOMBIA

Hemmes:

We headed off to Colombia. What a beautiful scenic country. So many hills, everywhere. How do they get around? Tunnels! We had a great welcome dinner and learned about the Colombian market. They love our U.S. value-added goods, meaning pork and poultry. There was a ban on poultry allegedly because of avian influenza, but many agree it (the ban) was a political move on Colombia’s part. But they do love U.S. pork and beef and we have many promotions there with the U.S. Meat Export Federation (USMEF) and the USA Poultry and Egg Export Council (USAPEEC). It was good for me, as USB’s demand team chair, to see what they did there with our checkoff investments. Lots of signage and displays. They have also partnered with chefs, and they are using American meats in their restaurants. We were treated to many meals featuring U.S. products.

Grubbs:

After arriving in Bogota, we were up early again the next morning to fly to Neiva, Colombia, to visit an aquaculture farm. I had always heard of people trying aquaculture, and knew it was done but had never seen it firsthand. The name of the farm was Piscola Los Camimos, and they grew tilapia fish in what are called “raceways.” The food they feed the fish is 30% U.S. soybean meal. That afternoon we were able to visit the processing plant for the fish. It is largely a hands-on process as the fish go from being delivered alive to being boxed, packaged and shipped.

Hemmes:

We went there to see an In-Pond Raceway System (IPRS) for Red Tilapia. This is a system that ISA helped to fund first in China. The practice is now all over the world.

(According to the Soy Aquaculture Alliance, IPRS circulates water like a river to distribute oxygen, manage temperature and control bacteria. Instead of combating algae and other organisms, the system mirrors a natural ecosystem to manage phytoplankton growth to assimilate biomass. And rather than leaving the stock vulnerable to the elements and prey, their confined net-covered raceway leads to improved survival rates.)

Grubbs:

We started off the next day with a trip to a local market. This was a bit of a culture shock for me because I wasn’t sure what I was about to see. The local market was a huge building with individual “stores” that sold a variety of things, but most of what was being sold were fruits, vegetables and meats. One thing that stood out for me was an employee carrying a pig carcass over his shoulder through the market to be butchered. I had to chuckle when I thought about what would have been done if that would have happened in the United States. Once we were done looking around the inside of the market, we walked around the flower market outside. There were thousands of locally-grown flowers being sold. A dozen roses could be bought for just more than $1. The same roses in the States were going to be sold for closer to $100 a week later for Valentine’s Day. Supply and demand as they say. Later that day, we departed for Medellín for the final portion of our trip.

20 | MAY 2024 | IASOYBEANS.COM

Hemmes:

In Medellín, we toured Groupo Bios, a large company that processes U.S. soybeans. I asked why they didn’t import from Brazil when they border the country? Well, they can get a shipment in a few days from the United States and the part of the country where they border Brazil is all rainforest. So, they would have to ship it out anyway.

Grubbs:

This day left the biggest impact on me as we visited a Groupo Bios feed mill. Groupo Bios is a huge producer of meat, poultry and eggs. How big are they? They currently have 830 million broiler chickens, 51 million chicken layers, 280,000 sows and 29 million head of cattle. The plant we visited used about 1,000 metric tons of soybean meal a day to produce feed for these different animals around their region. U.S Soy is the key cog that drives the plant. I’ll never forget my visit with Julio, who is second in command of this plant. I asked him about various aspects of the mill. We talked about efficiency and logistics and then I asked him about their employees. He explained to me that because of U.S. soy, they can run their plant more efficiently, and that allows them to pay their employees around $600 a month compared to the average workplace in the region where the average pay is about $300 a month. He then almost started to tear up when he said, “You guys really don’t know how much your soybeans mean to not only our facility but to this country.” This statement moved me in more ways than I can explain and something I will remember for the rest of my life.

Hemmes:

We visited many grocery stores that were running USMEF promotions. The highlight of our last day was meeting Álvero Uribe Vélez, the former president of Colombia, who was also instrumental in creating the U.S.-Colombia free trade agreement. He was amazing to listen to and his stories were fascinating. He was the first to take on the drug cartels in the country and escaped multiple assassination attempts. He spoke to us during breakfast, then we went to his house for supper; he later showed us his horses. His guards said it was the most relaxed they had seen him in years. When we asked why he took on the drug lords, he said to love your country means sometimes you have to do difficult things.

Grubbs:

The next day we all flew home. While there were so many memories, stories and friends made on this trip, the main thing that I am going to remember from this “See For Yourself” trip is that I matter. Grubbs Land & Cattle, a century farm in Perry, Iowa, matters. Your farm, wherever it may be in Iowa, matters. There are people all over the world counting on U.S. soy every day for more reasons than we will ever know. This trip proved that our checkoff dollars really matter and there are people all over the world who are counting on us.

Information compiled by Jeff

Hutton

IOWA SOYBEAN REVIEW® | 21

Protecting Crop Yields and Profitability: Understanding Fungicide Efficacy

TSuzanne Fey ISA analyst sfey@iasoybeans.com

TSuzanne Fey ISA analyst sfey@iasoybeans.com

he agricultural landscape is laden with challenges.

Fluctuating weather, including temperature and humidity variations, can significantly impact the proliferation of fungal pathogens. Because of this, the role of fungicides becomes increasingly critical and serves as the frontline defense against unpredictable environmental conditions that can promote fungal growth.

The Iowa Soybean Association (ISA) is actively exploring a range of fungicides to understand their effect on final yields and return on investment. Frogeye leaf spot, among other fungi, are significant threats to soybean yield in Iowa. Caused by the fungus Cercospora sojina, it targets leaves, creating lesions that lead to defoliation, impacting plant growth and yield. Frogeye is promoted through warm and humid conditions, providing an ideal environment for its proliferation. By evaluating different fungicide groups (3, 5, 7 and 11), ISA aims to inform farmers about which tools are effective for managing fungal diseases in Iowa fields.

Exploring options

Recognizing the diverse range of fungal threats, ISA has conducted extensive research to evaluate various fungicides’ efficacy. However, in 2023, Iowa experienced a notably

Alex Litvin ISA research agronomy lead alitvin@iasoybeans.com

dry season (Fig. 1), which led to minimal fungal pressures across soybean fields.

Scouting reports indicated low disease pressures, with sparse scout reports of frogeye, making it challenging to quantify fungicide efficacy accurately. Several fungicides were evaluated that year, including Lucento (group 3+7), Miravis Neo (group 3+7+11), and Veltyma (group 3+11), with minimal impact observed on crop performance (Fig. 1).

Overall, in 2023, there was no statistical difference between soybean crops treated with a fungicide (average yield of 62 bushels per acre) versus untreated (average yield of 63 bushels per acre).

However, this has not always been the case, and previous years, characterized by more favorable moisture conditions, provided a more conducive environment for evaluating fungicide efficacy.

In 2020, fungicides such as Delaro (group 3+11), Miravis Neo and Veltyma showcased promising results in enhancing soybean yields under moderate mold pressures. However, whether this pressure was due to Frogeye or another fungal pathogen is not understood. These three fungicide products resulted in similar average yield gains of approximately 1.9 bushels per acre.

22 | MAY 2024 | IASOYBEANS.COM

Yield Response vs June-September Rainfall Difference from 25-year Average Yield Difference Treatment to Control (bu/ac) 10 35 5 15 25 -5 -15 0 -5 5 -10 -35 -25 Rainfall Difference Trial Year vs 25 year Average (in)

Fig. 1: Comparative fungicide yield response in 2020 and 2023 against the trial year difference from the 25-year rainfall average for each site.

GUTHRIE SAC IDA MONONA HARRISON SHELBY POTTAWATTAMIE CASS ADAMS MONTGOMERY MILLS PAGE FREMONT CRAWFORD CARROLL AUDUBON BUENA VISTA POCAHONTAS HUMBOLDT WRIGHT HANCOCK FRANKLIN GRUNDY

Key takeaways and observations

While fungicides play a crucial role in mitigating pathogen damage, their efficacy is influenced by environmental conditions and the specific fungal pressures present.

In examining the differing response to fungicide application in 2023 versus that of 2020, a key element is the amount and timing of rainfall.

Fungicide-treated soybeans in 2020 had higher yields than untreated when the rainfall was higher than its 25-year average in Iowa (Fig. 1). In short, conditions must exist for the disease pressure to see the effect of fungicide protection in the field. Without the environmental conditions for pressure, the application of fungicides appears to impart no additional benefits.

Applying fungicides under minimal to no disease pressure does not typically damage plants. Junqueira et al. (2021) reported that no measurable effects were observed when healthy soybeans were treated with group 3 and 7 fungicides on the plants’ normal growth and development. However, in the field, there is a rich ecosystem of other life,

Fig. 2: Map of fungicide trial locations 2020 and 2023 annotated with corresponding June through September rainfall.

and it is believed that over-application of fungicides could harm beneficial fungi and insects, resulting in increased pest pressure.

Also, the cost of chemicals and the application can result in a negative return on investment if seasonal moisture is insufficient.

Proper application, including adherence to recommended dosages and rotation strategies, minimizes resistance development and optimizes economic returns.

Looking ahead

In the pursuit of safeguarding crop yields, the journey toward understanding and harnessing the potential of fungicides is an ongoing endeavor, shaping the future resilience of agricultural systems against fungal threats.

As field conditions evolve, ongoing research is imperative to refining fungicide strategies. ISA remains committed to exploring new avenues for managing fungal pathogens effectively. Farmers are encouraged to engage with their local ISA research agronomists and participate in fungicide trials to contribute to this vital area of agricultural research.

Citations: Junqueira, V.B., Müller, C., Rodrigues, A.A., Amaral, T.S., Batista, P.F., Silva, A.A. and Costa, A.C., 2021. Do fungicides affect the physiology, reproductive development and productivity of healthy soybean plants? Pesticide Biochemistry and Physiology, 172, p.104754.

HAVE A TRIAL OR A PROJECT YOU’RE INTERESTED IN?

We can potentially explore it as a topic in a future issue. Better yet, we’ll connect you with your local expert so you can implement a trial on your farm.

515-251-8640

JMCCLURE@IASOYBEANS.COM

SCAN THE QR CODE

7.1 6.7 14.7 9.7 20.4 21 18.6 19 21.1 12.9 22.8 22.9 12.4 8.9 10.5 16.5 2020 2023 June-Sept precip (in) TRIAL LOCATIONS 14.4 8.2 9.2 7.5 CERRO GORDO LYON OSCEOLA O’BRIEN DICKINSON EMMET KOSSUTH WINNEBAGO SIOUX PLYMOUTH

WORTH CLAY PALO ALTO CHEROKEE FLOYD

HARDIN MITCHELL CHICKASAW BREMER BLACK HAWK BENTON TAMA HOWARD FAYETTE BUCHANAN LINN WINNESHIEK CLAYTON DELAWARE

IOWA POWESHIEK

KEOKUK MAHASKA

WAPELLO

DAVIS

WOODBURY

BUTLER ADAIR

JONES

JOHNSON

WASHINGTON

MONROE JEFFERSON

APPANOOSE VAN BUREN HENRY LEE CEDAR MUSCATINE LOUISA DES MOINES DUBUQUE JACKSON CLINTON SCOTT ALLAMAKEE WEBSTER HAMILTON CALHOUN BOONE STORY MARSHALL DALLAS POLK JASPER MADISON WARREN MARION

UNION CLARKE LUCAS RINGGOLD DECATUR WAYNE GREENE TAYLOR

IOWA SOYBEAN REVIEW® | 23

A NEW WAY TO BUY FROM LANDUS

The Landus Portal has a new feature that allows you to purchase your spring inputs 100% online through the GROWERS App.

Fueling and Feeding Our Nation

For every 50 bushels of soybeans harvested, 550 pounds of soybean oil for clean fuels and 2,200 pounds of protein for food are generated*.

*Food and Fuel: Modeling Food System Wide Impacts of Increase in Demand for Soybean Oil, Purdue University.

The benefits keep growing.

cleanfuels.org Materials supported by United Soybean Board, soybean farmers and their checkoffs.

WE WORK FOR THE FUTURE OF AGRICULTURE AND THOSE WHO WANT TO BE A PART OF IT.

If you have a plan to farm or ranch, we have a plan to help.

The future of agriculture is our future, too. That’s why we’re working with nearly 9,000 young and beginning producers — providing special financing and guidance, plus scholarships, youth programs and more. If agriculture is where you want to be, start with the lender uniquely built for you.

Learn more at 800-884-FARM. Agriculture Works Here.® youngandbeginning.com

Russell F. / customer since 2019

Are the Future of Farming?

Decide for yourself through an on-farm trial.

BY KRISS NELSON

The use of agricultural biologicals is growing — and fast. The agricultural biological market size is anticipated to reach $27.9 billion by 2028, up from $14.6 billion in 2023, according to MarketsandMarkets, a competitive intelligence and market research firm.

Although biologicals are nothing new to the agricultural industry, there are still many unknowns. The Iowa Soybean Association’s (ISA) Research Center for Farming Innovation (RCFI) is working to bring on-farm trial results to farmers, but there is a lot of work to be done.

ISA Farmer Member Brent Bierbaum has been working for five years to find a space on his farm near Griswold for biologicals.

“I like the concept, but I am not totally sold on the outcome yet,” says Bierbaum. “That is why I am still experimenting with different products, methods and placements.”

Defining biologicals

The ag-retail industry has grouped biologicals into three categories: biofertilizers, biostimulants and biopesticides.

ISA Research Agronomist Drew Clemmensen says RCFI has put a focus on researching biofertilizers, which are products that help with nutrient usage and effectiveness.

“Biologicals will never 100% replace commercial fertilizers,” says Clemmensen. “But, I think there is an opportunity for biologicals to fit in conjunction with lowering nitrogen and phosphorus inputs.”

Biologicals are available in many forms, such as in-furrow applications, seed treatments and foliar sprays.

Iowa Soybean Association Farmer Member Brent Bierbaum on his farm near Griswold.

26 | MAY 2024 | IASOYBEANS.COM

On-farm trials

RCFI began researching biologicals through on-farm trials nearly eight years ago as ISA farmer members became increasingly interested in them.

Research is centered around nutrient uptake, specifically phosphorus and nitrogen. Could biologicals help reduce the assumed over-application of these commercial fertilizers?

“Introducing these biologicals is supposed to help plant roots absorb those nutrients better. However, across all our trials, taking into account the management variables that come into play with those trials, we have not seen anything that stands out as to having any kind of significance to a yield advantage,” says Clemmensen, noting there are a lot of unknowns and research to be done.

One key to finding positive results with using biologicals could be a good management system already in place.

“These (biologicals) are not key nutrient products that we are using to grow our crops,” Clemmensen says. “If those core nutrients aren’t there, don’t expect these products to bail you out or show you any kind of return.”

For example, if a biofertilizer is not showing a positive return on investment, it could mean that field already has ample nutrients available to the plant. Farmers might see some advantages to using biologicals in tougher environments that struggle to make nutrients available to the plant, Clemmensen notes.

“This may be an area where those products are going to be effective or at least offer a return on your investment,” Clemmensen says.

Bierbaum has been experimenting with an in-furrow product with the hopes of increasing the nitrogen uptake of the corn plant. He has also used foliar and soil applications of a biological on both soybeans and corn.

While he has seen some good returns using biologicals, results have not been consistent.

“It’s been a mixed bag. Some years, we see good responses, but not every year,” says Bierbaum. “I would like to be able to reduce our applications of phosphorous and nitrogen — as the products claim — but we’re not there yet. I am not saying it doesn’t (provide these benefits). I am saying it has been up and down for us.”

Do biologicals have a place on your farm?

With thousands of biological products available, how does one choose where to start?

“There are a lot of products out there, and you have to sort through what is relevant and what is snake oil,” says Bierbaum, adding he relies on university and ISA research. “ISA can replicate more than I can on my farm; I can only do so much.”

Begin sorting through products by setting a goal.

“Are you trying to decompose residue? Are you trying to reduce your reliance on commercial fertilizers? Are you trying to build organic matter in your soil? Start with a goal and then explore those products that touch those components,” says Clemmensen. “Then consider the application. Are you set up to apply these products? What already fits into your system that you can easily add them to?”

Once you have chosen a product, try a replicated strip trial on your farm. ISA agronomists can help fine-tune the creation of a trial and assist with the analysis to give a farmer the best answer possible.

“Create your own strips. It is the best way to get an honest evaluation,” Clemmensen says. “If you are planning on doing the whole field, it might mean leaving strips untreated in a couple of different places in the field. If you are skeptical about the product, only have two or three strips using the product.”

Also, try adjusting nutrient rates and use multiple rates in the field. Look at those fields that have lower yield potential and in fields where nitrogen or phosphorus fertilizers are applied at various rates to understand if these products add value and when these products respond to provide a return on investment, Clemmensen advises.

“If you put a product out there in a strip and the only variable you have is that product, adjusting nutrient rates could help you determine in the end if the product worked or did not work,” says Clemmensen.

Clemmensen feels biologicals are here to stay; it is just finding a way for them to fit into your system. One hypothesis he has is that macronutrients and micronutrients must be well established in your soil for the biologicals to do their job.

“I think long term, there is a fit for biologicals on our farms,” says Clemmensen. “But I don’t think we fully understand how they work and what their capabilities are yet.”

Contact Kriss Nelson at knelson@iasoybeans.com

“ There is a fit for biologicals on our farms. But I don’t think we fully understand how they work and what their capabilities are yet.”

Drew Clemmensen, ISA research agronomist

IOWA SOYBEAN REVIEW® | 27

your cooperative soybean processor www.agp.com Funded by the soybean checkoff. Celebrating 60 years of service to Iowa soybean farmers. Learn more at iasoybeans.com. Farmer Membership Form You can complete the form below and text a photo of it to Paige: 712-379-9901 or visit iasoybeans.com/join, and use promo code ISR Confirm or activate my no-cost farmer membership: YES By opting in to an ISA farmer membership, you are certifying that you market a minimum of 250 bushels of soybeans annually. County Name Farm Name Address Phone Zip Code Email-required City home cell ACTIVATE OR CONFIRM your Farmer Membership today!

YOU WE’LLwork the work the CSIF IS A NON-PROFIT ORGANIZATION FUNDED BY THE IOWA BEEF INDUSTRY COUNCIL, IOWA CATTLEMEN’S ASSOCIATION, IOWA CORN GROWERS ASSOCIATION, IOWA FARM BUREAU, IOWA PORK PRODUCERS ASSOCIATION, IOWA POULTRY ASSOCIATION, IOWA SOYBEAN ASSOCIATION, IOWA TURKEY FEDERATION + MIDWEST DAIRY. SUPPORTFARMERS.com 800.932.2436 YOU DON’T NEED TO KNOW ALL THE RULES, YOU JUST NEED TO KNOW US. YOUR FARM. YOUR FAMILY. OUR FOCUS.

What implications could the warm winter bring for the 2024 growing season?

BY KRISS NELSON

With the warmer weather we experienced over the winter and spring, farmers are being encouraged to go straight from planting to scouting as there could be increased pest pressure.

“I would advise getting out into the fields early this season looking for weeds, insects or diseases,” says Shane Beck, Iowa Soybean Association (ISA) research agronomist. “Farmers will need to have an active role in scouting this year.”

Insects incoming

Early-season insects, including bean leaf beetles, spider mites, alfalfa weevil and a host of migratory insects, including black cutworms and true armyworms, could be making an earlier-than-normal appearance.

“The warmer winter could mean there is a higher chance of surviving insects that could have a better start this year,” says Erin Hodgson, Iowa State University (ISU) professor and Extension entomologist. “It is hard to predict; I can only imagine it was a good winter for insects.”

Although the anticipation of earlierthan-usual insect pressure is a cause for concern, it could have actually been to the detriment of pests, Hodgson says.

“If some pests became active in February and March, they resumed development because it was nice, but there were no crops for them to eat and they might starve,” says Hodgson.

Insects may choose to feed on earlyseason weeds and other types of vegetation.

“Weeds are greening up earlier this spring, and some insects feed on them, making it a bridge food source,” says Hodgson.

The wide temperature swings earlier this spring may have also had a negative effect on early emerging insects.

“When the weather gets above 50 degrees some insects begin waking up from diapause, and that takes energy. If the temperature drops, they stop development. If this warm-cold cycle repeats a few times, it can use up all their energy reserves,” says Hodgson. “Sometimes insects run out of fuel (starve) and die before the crops emerge.”

Timing will be key, Hodgson says. As crops begin to emerge, so can insects.

“Scouting early seedling crops is going to be crucial this year,” says Hodgson. This spring is not typical due to the prolonged drought and unusually warm winter.”

Although most farmers use an insecticidal seed treatment, that might not be enough — especially if the seed has been in the ground for a longer period of time.

“Scouting can help you decide if a rescue treatment is going to be needed to protect defoliation caused by insects,” says Hodgson.

Disease detection

How warmer conditions affect diseases has yet to be determined.

Daren Mueller, ISU professor and Extension plant pathologist says some pathogens could be established earlier than normal.

“This could give some of the foliar diseases more of a season to cause damage,” says Mueller.

Spring rains could make diseases such as frogeye leaf spot and Cercospora leaf blight more problematic. Warmer soils could also increase the intensity of other diseases, including Phytophthora root and stem rot.

Seed treatments and a variety of resistance could help battle these earlyseason diseases.

30 | MAY 2024 | IASOYBEANS.COM

Shane Beck

Iowa Soybean Association, research agronomist

Erin Hodgson Iowa State University, Professor and extension entomologist

Meaghan Anderson Iowa State University, extension agronomist

Daren Mueller Iowa State University, Professor and extension plant pathologist

“Be on the lookout and scout early, especially during the early part of the season,” says Mueller. “Pay attention to the chatter on social media or from local companies and fellow farmers about what they are seeing in their fields.”

Weeds awaken

The early warmth gave weeds a jump start this spring. Winter annual weeds and some early summer annual species began emerging in March which was problematic in some burndown scenarios.

“It is possible weeds may get ahead of the crop during the growing season without careful monitoring for weed emergence from early herbicide applications,” says Meaghan Anderson, ISU Extension agronomist. “We don’t know exactly what the season will bring, but timely monitoring will help us keep ahead of the potential problems.”

If conditions remain dry, that could have a negative effect on residual herbicides.

“Rainfall will play a big factor in how effective our residuals will be,” says Beck. “If we do not get timely rains, it could mean farmers may have to rely on a second pass of a post-emergence herbicide.”

Contact Kriss Nelson at knelson@iasoybeans.com

Oval-shaped

Dark yellow with black markings

Migrate to available host plants to mate Injury will impact plant growth and development

Transmission of bean pod mottle virus

Secondary infection of fungi

Twospotted spider mites

Cream or green color

Feeding starts at the bottom of the plant and moves to the top as the plant’s health deteriorates

Injury symptoms: small yellow dots or stipples on lower leaves

Prolonged feeding will cause leaf to die

TRIALS

ISA’s Research Center for Farming Innovation (RCFI) relies on farmer feedback to help develop trials that will best benefit a farmer’s return on investment and the soybean industry.

No matter the response, all data is shared.

Trials for 2024 include work with the Iowa Nitrogen Initiative, soybean seeding rates, SCN seed treatments, improved cropping systems, herbicide trials, iron chlorosis deficiency, and the effects of long-term cover crops on the management of soy and corn, specifically weed populations.

RCFI is currently recruiting farmers to participate in a soybean fungicide project and trials that start this fall involving manure, nitrogen and cover crops.

To inquire about trial opportunities, contact Shane Beck at sbeck@iasoybeans.com or call (563) 920-1103.

Alfalfa weevil

Have blunt “snout,” thick golden hairs and a dark, narrow stripe down the back

Larvae feeding creates pinholes in leaves

Maturing larvae go down the plant and feed between leaf veins, resulting in skeletonization

Injury reduces yield and quality

Black cutworms

Adults have dark brown forewings and a light band at the end of each wing

Larvae are caterpillars with grey skin and a dark brown head

Have pairs of dark wart-like bumps along the side of the body

Larvae create holes in corn leaves and cuts plants at or below the soil surface

True armyworms

Attracted to fields that have living ground cover

Female moths lay eggs on green plants

Larvae feed on plants until the plant is completely consumed or killed

Larvae then move to corn

Western and northern corn rootworms

Western adult has yellow body and three black stripes

Northern adult has light green body

Injury symptoms: stunted, chlorotic, wilted or signs of nutrient deficiencies because of root feeding

Injury causes yield losses occuring at the end of the season

Source: Integrated Pest Management

IOWA SOYBEAN REVIEW® | 31

WISHH leverages partnerships for U.S. Soy to help meet the protein needs of 8 billion consumers

wishh.org

NAaron Putze, APR ISA Chief Officer of Brand Management & Engagement aputze@iasoybeans.com Plan or Wander

NAaron Putze, APR ISA Chief Officer of Brand Management & Engagement aputze@iasoybeans.com Plan or Wander

TSuzanne Fey ISA analyst sfey@iasoybeans.com

TSuzanne Fey ISA analyst sfey@iasoybeans.com