THE SUBSEA EXPERTS

Norwegian company IK Subsea, a specialist in delivering bespoke engineering solutions

Norwegian company IK Subsea, a specialist in delivering bespoke engineering solutions

Norwegian company IK Subsea, a specialist in delivering bespoke engineering solutions to solve the biggest challenges in the subsea industry, is expanding its global footing. “We have used the lessons learned on the Norwegian Continental Shelf to drive an innovative approach that helps our customers wherever they may be – in the Gulf of Mexico, Asia, the Middle East, South America or the North Sea,” says Adrian Gamman, VP and leader for IK Subsea.

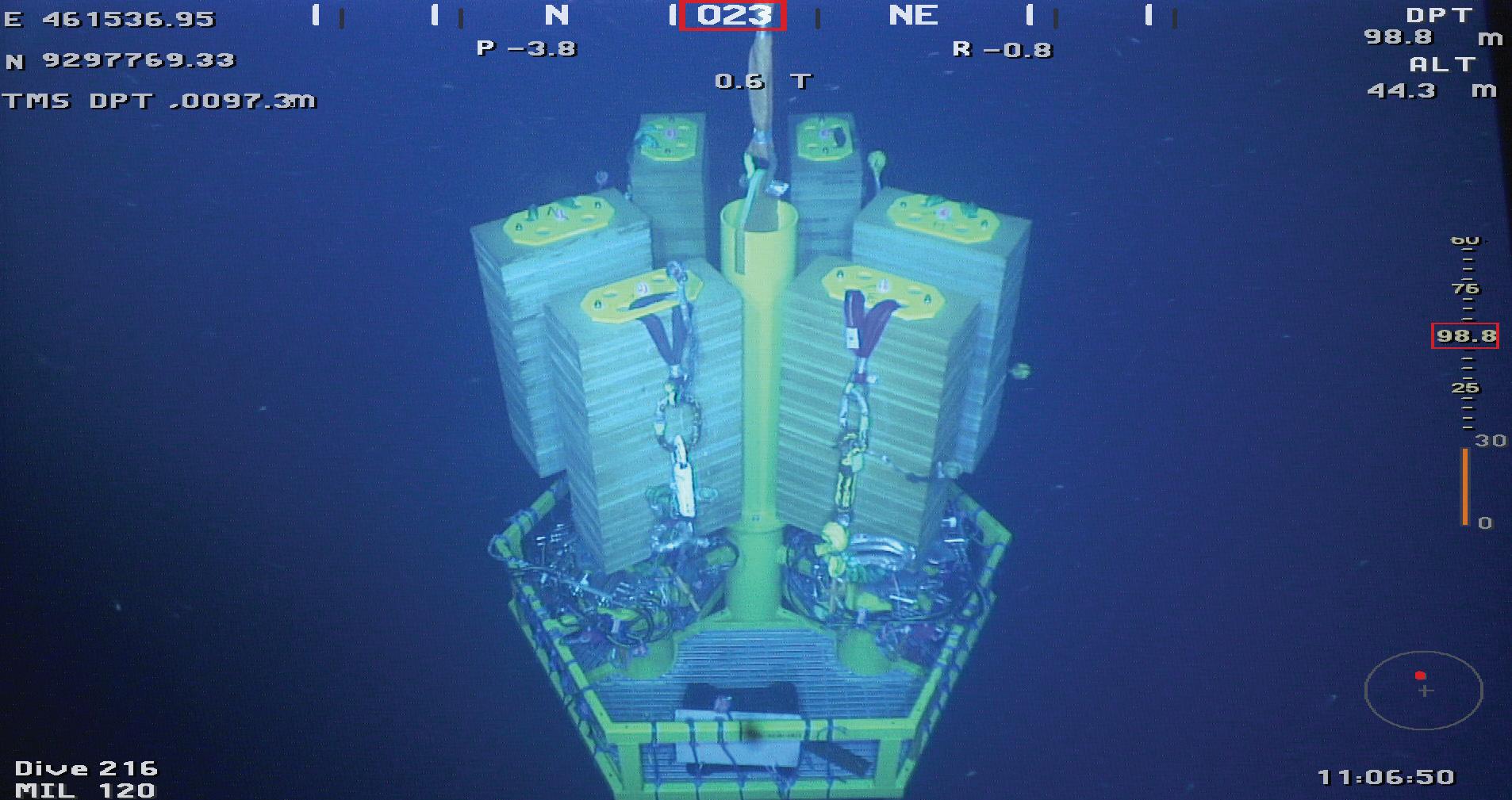

IK Subsea is a wholly owned subsidiary of the IK Group, based in south-western Norway, which specialises in the design and manufacture of subsea tools used in the harshest environments worldwide. The company has a strong track record of helping customers with their challenges in all water depths – sometimes deeper than 2,000 metres, maintaining pipelines and subsea infrastructure, repairing leaks and correcting structural problems – all critical elements for performing safe and environmentally friendly operations.

In an industry where excellence and innovation intersect, Namtvedt Sealmaker Service stands at the forefront, heralding a new era of leak repair solutions for oil and gas operators facing the challenges of subsea and downhole leaks. As specialists in advanced sealant technologies, we provide bespoke solutions that ensure the integrity and efficiency of complex subsea infrastructure s . Our partnership with IK Subsea is more than a collaboration; it is a union of visions dedicated to setting unprecedented standards in subsea operations. “This partnership exemplifies our shared commitm ent to excellence, sustainability, and the relentless pursuit of perfection,” states Peter B. Namtvedt, CEO of Namtvedt Sealmaker Services AS.

At the core of the success is our proprietary sealant technology, a beacon of innovation that has guided Sealmaker through 32 years of industry leadership. “Our technology’s 90 95% success rate is not just a statistic; it represents our unwavering dedication to our clients’ operational continuity and financial efficiency,” Namtvedt remarks. Designed for versatility, our sealants address the most challenging downhole and subsea leaks, proving Sealmaker as the definitive solution for operators globally.

Namtvedt Sealmaker was recognized with the Outstanding Achievement Award by Shell Philippines Exploration for our expertise and operational success. This award followed our initial project with the IK Group in November 2015, involving complex subsea operations aboard the SkandiHawk marine vessel. The project demonstrated our i nnovative capabilities and our proficiency in managing challenging conditions effectively. The breadth of our capabilities extends beyond mere product

excellence. “We’ve developed specialized techniques to repair a wide spectrum of leaks, showcasing our engineered solutions’ ability to withstand extreme conditions,” says Ken Phillips, Partner & COO. The sealant’s performance is unmatched, capable of enduring pressures over 15,000 psi and temperatures above 260 degrees Celsius, ensuring reliability across all operational environments.

Sustainability forms the bedrock of our philosophy. “The sealant is completely environmentally friendly and 100% Plonor, which makes it 100% safe to use and protect all sea life after being applied and during the application”, continues Ken. Our commitment to non pollution and environmental stewardship is unwavering, as we continue to innovate in alignment with our sustainabi lity ethos.

Reflecting on Sealmaker’s 32 year legacy, Namtvedt shares, “Our journey is defined by a continuous pursuit of excellence and a deep understanding of subsea complexities. This experience is our guiding light, propelling us towards innovative solutions for tomorrow’s challenges.” Our partnership with IK Subsea marks a pivotal moment in our journey, setting new industry benchmarks for leak repair success and environmental responsibility.

Looking ahead, Namtvedt Sealmaker’s vision is clear. “We aim to lead the industry in delivering solutions that not only ensure operational integrity but also protect the marine environment,” Namtvedt asserts. Join us as we advance toward a future where subsea and downhole leaks are addressed with unparalleled expertise and success rate.. “Together, we’re not just solving today’s challenges; we’re setting the standards for the future of subsea operations,” concludes Namtvedt.

Prolonging the lifetime of subsea assets has a substantial impact on sustainability, and the market is not only vast but also expected to remain in place for many years to come. This is evident in the company’s recent developments and plans for the future. Since 2021, IK Subsea has been experiencing continuous growth, with revenues tripling from 2020 to 2023 and expected to

reach a 100% increase in 2024. A record number of orders are already in place.

We had the pleasure of speaking to Adrian Gamman, Vice President IK Subsea, about recent developments, the company’s technological capabilities, and its plans for the future. Adrian joined IK Group in 2015 as a project manager. After overseeing some of the company’s most significant and challenging projects, he became Subsea Manager in 2020 and was subsequently promoted to Vice President of IK Subsea.

Congratulations on your recent entry into the Asian market! What were the key factors that led IK to make this move, and what are your expectations for the region?

Post-COVID, we started increasing our global reach, and the Asian market has been something we have been looking at for a long time. When an opportunity came along last year, we saw that the time was right.

But perhaps we should add a little background colour to the importance of energy security globally and the key drivers around offshore markets, and subsea in particular. Recent geopolitical events have sharpened the focus of every global political and business leader on the critical importance of a secure,

Until alternative energy sources become abundant and reliable globally, hydrocarbons will realistically play a critical role in the energy mix for at least the next decade or longer. Hence, oil and gas continue to play an important role in energy supply. In the offshore segment, platforms and subsea production and transportation (pipelines) are critical elements of extracting and transporting hydrocarbons to process plants and end users.

IK Subsea supplies technology to keep this subsea infrastructure functioning efficiently and cleanly. Our blend of brilliant engineering and our delivery times have been seen in the Asian market as a very attractive proposition.

Adrian, IK has seen impressive year-on-year growth recently. Can you elaborate on the main drivers of this growth?

Perhaps more impressive than the steep increase in revenues is that around 70% of our revenues are from customers outside of Norway. A key element in our growth has been increased sales to the Middle East and, most recently, China, as energy players prioritise environmental oversight and are becoming highly focused on robust solutions. While clients may have highly developed technologies in some areas, these countries buy the best available subsea technology and are very international in their procurement strategies.

Over the last few years, we have also become more customer-centric. Our entire ethos

is built around engineered solutions that help our customers repair their complex infrastructure in situ. IK Subsea technologies mitigate and repair structural problems and, where necessary, instantly repair subsea leaks. At IK Subsea, we have utilised our unique engineering skills and understanding of customer needs to manufacture highly competitive custom designs and standard products. As large orders increase from new markets, maintaining our reputation for on-time delivery on a budget will be key.

What strategies are you implementing to sustain this trajectory?

We will strive to leverage our engineering centre in Poland as well as our team in Aberdeen, as we rely on seamless integration between Norway, Poland and the UK to drive our successes. We will also continue to hire the right talent at the right time; we feel that our strengths are in our flat organisational structure, our open and diverse culture, and our robust training and staff development plans.

Lastly, we are convinced that pursuing sustainable growth is essential. We have integrated sustainability plans into our key strategies and see a real competitive advantage for companies that walk the talk.

IK Subsea believes that as part of a brown industrial segment, we need an independently verifiable approach to sustainability, including our carbon footprint. Additionally, our technologies lower our customers’ emissions. It’s about a social licence to operate but also about being first and best to ensure our continued growth.

IK is known for its commitment to sustainable

manufacturing. How does this commitment manifest itself in your production processes, and what are the biggest challenges you face in upholding these standards?

By definition, our technologies help our customers lower their carbon impact by mitigating or stopping leaks. We focus on equipment lifetime extension and help decommission, ensuring that equipment is brought up from the subsea environment and disposed of safely. So, our business ID in itself is based on sustainability. But we want to do more as well. And that’s what we are working on.

We are already working hard with employ -

ees in a structured approach to reducing our footprint, whether that means travel, logistics, efficiency, or quality initiatives. We have also entered a sustainability partnership with ClimateAdvisor, which has introduced us to a non-profit group called TerraVera. TerraVera’s mission is to represent real sustainability by modelling the world as it is and verifying data. We aim to understand our current impact, identify efficient improvement measures, and document our sustainable advantage.

As the first pilot, our sister company, Izomax, is mapping out the AOGV tool value chain and measuring emissions. IK Subsea is leveraging

that understanding and data set, and now, together with TerraVera, we will begin modelling some of our key Subsea technologies. Our next step involves documenting avoided emissions (scope 4) and setting a benchmark for the industry. So, addressing a complex question and providing an answer can only be achieved through intricate and accurate measurements of today’s processes, followed by modelling alternatives that lead us to lower carbon footprint solutions.

Collaboration seems to be a core value at IK, as evidenced by your focus on sustainable partnerships throughout the value chain. Can you share some examples of successful partnerships that.

As mentioned earlier, IK Subsea has been operating since 1987, so we have forged long-lasting partnerships with key suppliers and established new relationships. This has been a huge success factor for us, specifically considering that over 70% of our revenue is generated in export markets.

Beyond the major Asian project, IK has been involved in numerous projects across Africa and Europe. How does IK approach its project selection process, and which criteria are the most important when considering new opportunities?

First of all, any new opportunity needs to match our expertise. Our organic growth has been aligned with our technology development. This brings a natural alignment with geographies with offshore activity and infrastructure. We already have a track record of sales and installation/support to most corners of the globe, and with that comes an understanding of the cost of doing business.

We select our projects by analysing technology fit, capacity, and lead times and understanding customer requirements. It goes without saying that profitability is a critical element; we can spend hundreds of hours of engineering time before an order is awarded, so we do not have the luxury of constant failure when we bid for work. Also, compliance with export (or import) regulations is vital.

The subsea pipeline and infrastructure industry is constantly evolving. What are the most significant technological advancements you see on the horizon, and how is IK preparing to adapt and stay ahead of the curve?

Three words come to mind—cost, innovation, and sustainability. We compete with companies from Scandinavia, Europe, Asia, and the US, to name just a few areas. That in itself keeps us on our toes. Norway has a reputation, somewhat deservedly, as a high-cost country, which means IK Subsea needs to manage costs and resources. We have seen that engineering expertise and technology innovation can lower expenses and overcome cost differentials.

A great mix of experience helps us understand the fundamentals required to operate in ultra-harsh environments while utilising advances in technology and materials science to innovate and improve. This will continue to provide us with a competitive advantage. Lastly, our partners, suppliers and others will choose to work with companies that take sustainability seriously.

Looking towards the future, what are IK’s main goals and aspirations for the next 5 to 10 years?

The next decade will be a defining one for IK-Subsea. We’re committed to driving innovation, expanding our global reach, and championing sustainability while prioritising our customers and workforce.

The market is there, and we have the competence, innovation, and products to really grow. We want to be a company with revenue of around one billion NOK by 2030, which basically means tripling in size from what we are today. This is a steep growth curve, but it is realistic. How do we want to achieve it? By delivering outstanding standardised products and developing cutting-edge, innovative, and customer-centric solutions. We firmly believe this combination will fuel our growth.

We plan to continue attracting and investing in talent and expand globally with strategic partnerships, enhancing our reach into key markets. We also strive to minimise our environmental footprint for a greener future. By staying true to our values and embracing change, we’re confident in achieving these goals and shaping a brighter future for IK Subsea, our customers, and the industries we serve.

Given your extensive experience in the subsea pipeline and infrastructure industry, what advice would you give aspiring entrepreneurs or businesses looking to enter this market?

That’s a difficult question. This is a maturing, high-tech market in a highly challenging environment. Think of the temperatures and pressures at 2,000 m of water depth. Only highly specialised components survive and function under these conditions. Having said that, market researchers estimate that the global subsea market is worth between $15 and $20 billion, so there is always room for new entrants. A profound understanding of the market is key, as is a laser focus on the niche.

Addressing local markets is challenging. Building networks, visiting customers, and putting together detailed proposals all take time and investment when it comes to international markets. The subsea market is vast, but you must be a specialist to identify your niche and leverage your expertise. You must have the right product or solution for the customer and keep delivering it to secure sustainable growth.