2024

PORTFOLIO Justin Hanlon |

In 2021, I was serving as a Tactical Coordinator in the Royal Canadian Air Force. A role uniting adventure and service.

Now, a new challenge in robotics and construction. How might we make the places we inhabit more accessible, more meaningful, more sustainable, more beautiful?

I intend to find out using the modern tools of parametric design, 3D printing, and artificial intelligence.

CASA FAMI 2 TEIXIT 8 KIBAHA 16 PRINT - SCAN - CUT 22 PREDICTIVE DEFORMATION 28 OBJECT OF MY AFFECTION 32 ROBOMOSAIC 36 ABBREVIATED CV 39 SELECTED WORKS

A Family Oriented Home CASA FAMI

Project type:

Advisors:

Team:

Contribution:

Tools and Skills:

Competition entry: Initiative 99 (First Place, Student Catagory). IAAC, 3DPA Phase 2, 2023

Edouard Cabay, Nestor Beguin

Joseph Naguib, Vesela Tabakova

Wall Design, Performance maps, narrative

Parametric Design

Rhino/Grasshopper

Written communication and storytelling

2

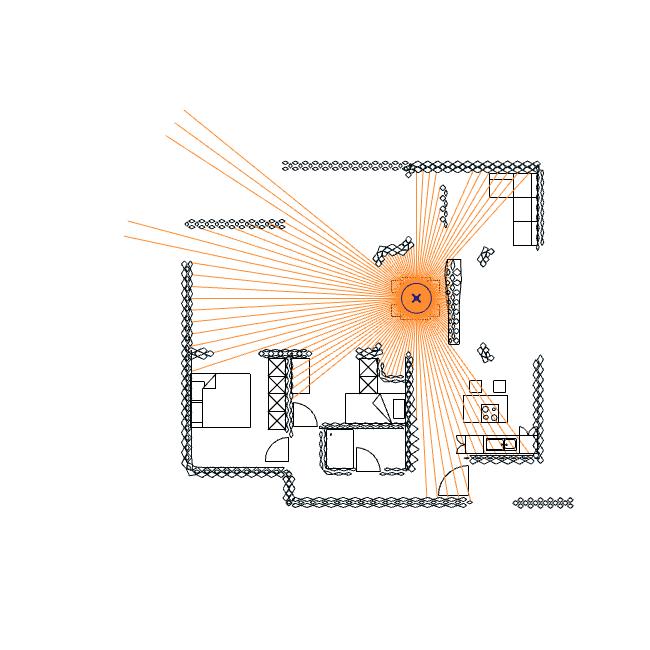

Casa Fami is a house designed for single-parent families in Austin, Texas. It is built around inner courtyards, which provide natural light, peaceful views, and safe play areas for children. Through historically-inspired, passive, climate-regulating techniques, it optimizes comfort and keeps utility bills low. Sophisticated walls are selectively encoded with privacy, airflow, and illumination oriented features. It is a home that - enabled by 3D printing - aims to put comfort, beauty, and even luxury within financial reach of as many families as possible.

Casa Fami is introverted in nature, providing internal views through courtyards such that every home is a personal oasis, even in a busy, built up environment. Sheltered and comforted, yet not closed off from the outer world. Different regions of the home have varying degrees of openness to the external environment, leaving the choice of interaction open to the inhabitants.

3

Views of the courtyards are available from any part of the home. First, it facilitates the supervision of children playing in the sheltered spaces. Second, serene glimpses of natural space are always in view, while the house is flooded with natural light. Wall-to-ceiling courtyard windows frame peaceful views for quotidien enjoyment.

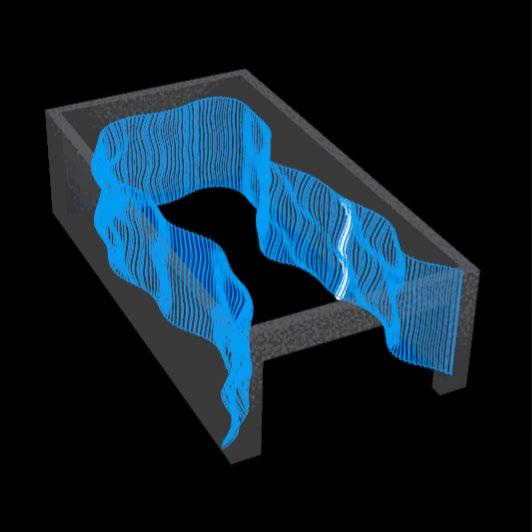

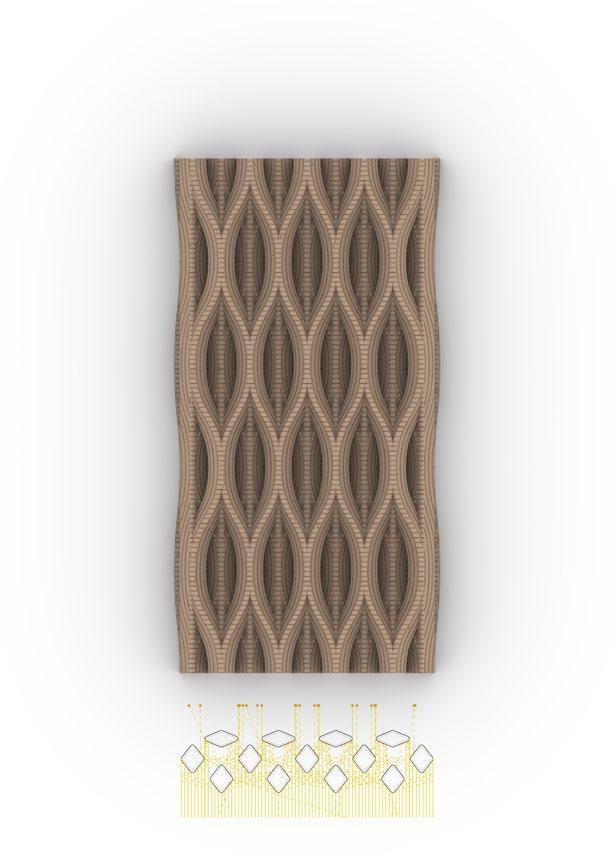

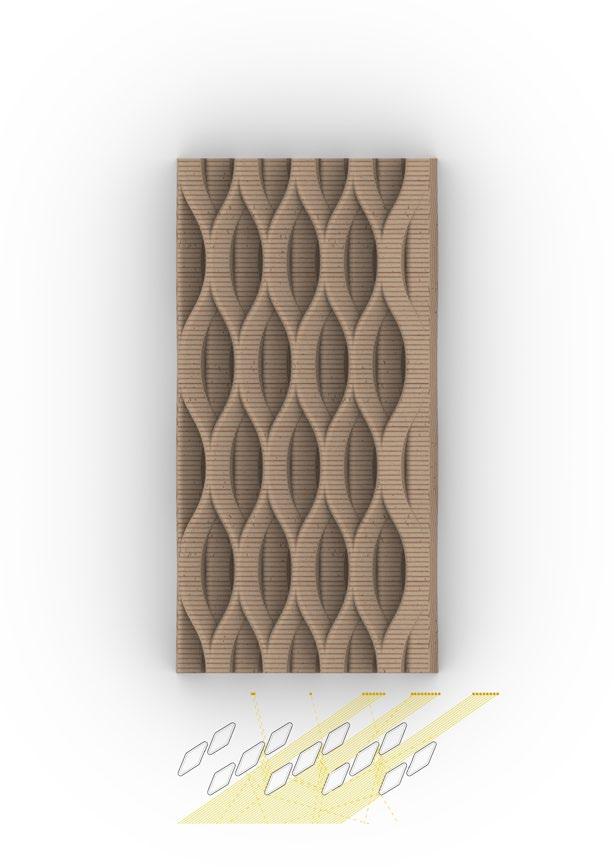

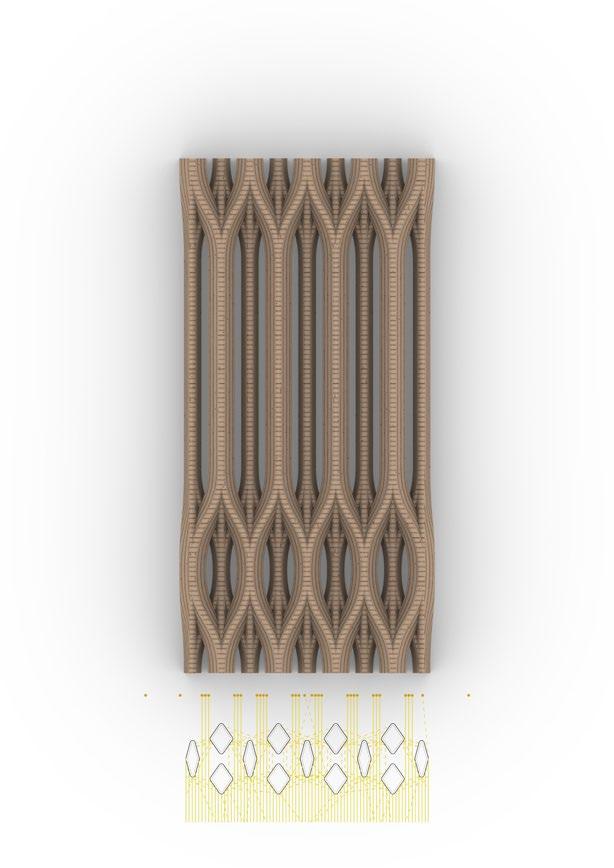

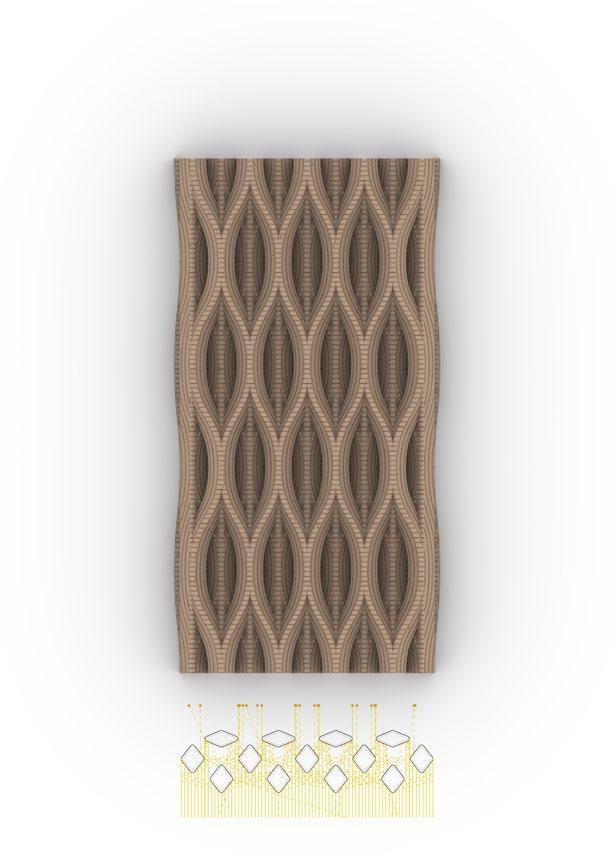

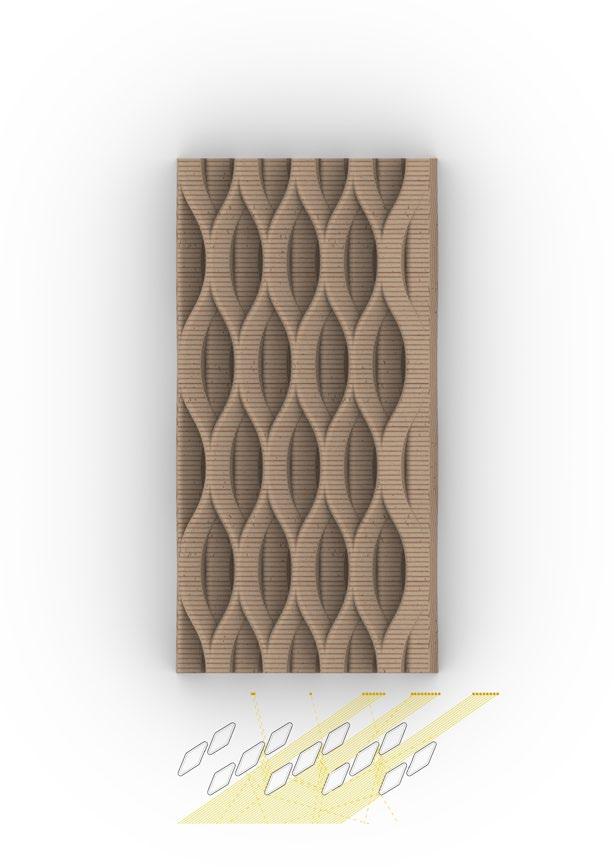

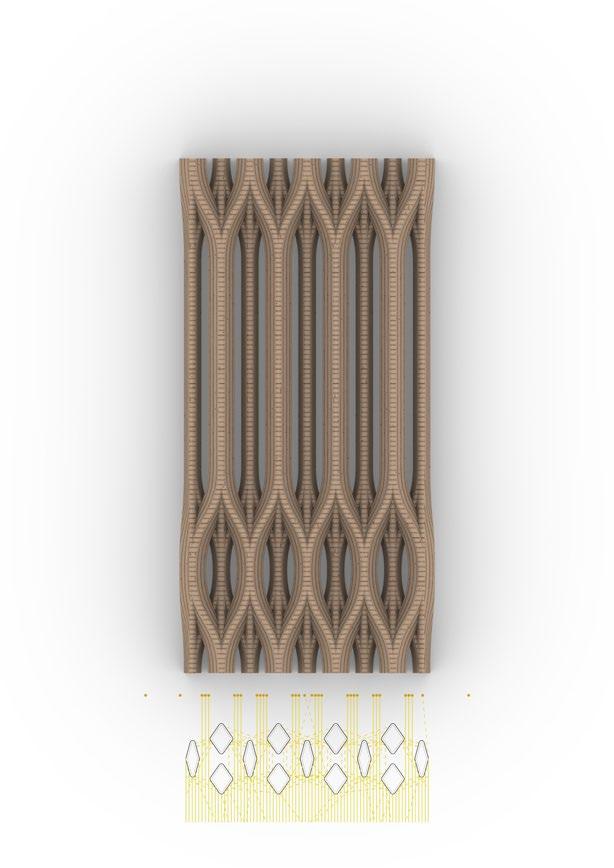

Inner patterns within the wall can be adjusted to various purposes. Precise openings permit selective ventilation. Closed cavities can be used for insulation, and utilities can be routed through as needed. Using a parametric pattern, mass can be increased to provide load bearing performance or to provide sound insulation between spaces.

4

Computational design shapes the walls. Selectively porous, they serve multiple purposes: allowing light, ensuring privacy, and channeling airflow. Their unique composition and structure enable them to cool humid air and maintain a comfortable indoor climate.

5

3D printing allows for an array of wall typologies that respond to the different climatic, visual, and practical requirements of the floorplan. The walls can be porous in certain areas to conduct airflow, while being closed and insulated in others to retain heat. For light permeability, openings in the walls can be precisely oriented; direct views, selective glimpses, diffuse light that tempers the sun’s harshest rays are all possible. Surfaces can vary from flat to richly textured within the same wall, allowing for the placement of furniture or wall hangings as desired. These parameters can be functional; but also provides a sense of organic sophistication to the space.

6

TEIXIT

A project exploring light and lightness in earthen architecture

Project type:

Advisors:

Team:

Contribution:

Tools and Skills:

IAAC, 3DPA Phase III, 2024

Oriol Carrasco, Edouard Cabay, Alex Dubor, Secil Afsar, Nestor Beguin

3DPA 23/24

Project coordination team, structural geometric research (tall windows), print supervision, print path and GCode generation, material preparation and research, timber fabrication

Leadership and team coordination

Large-scale 3D printing

Paremetric modeling

Research and performance analysis

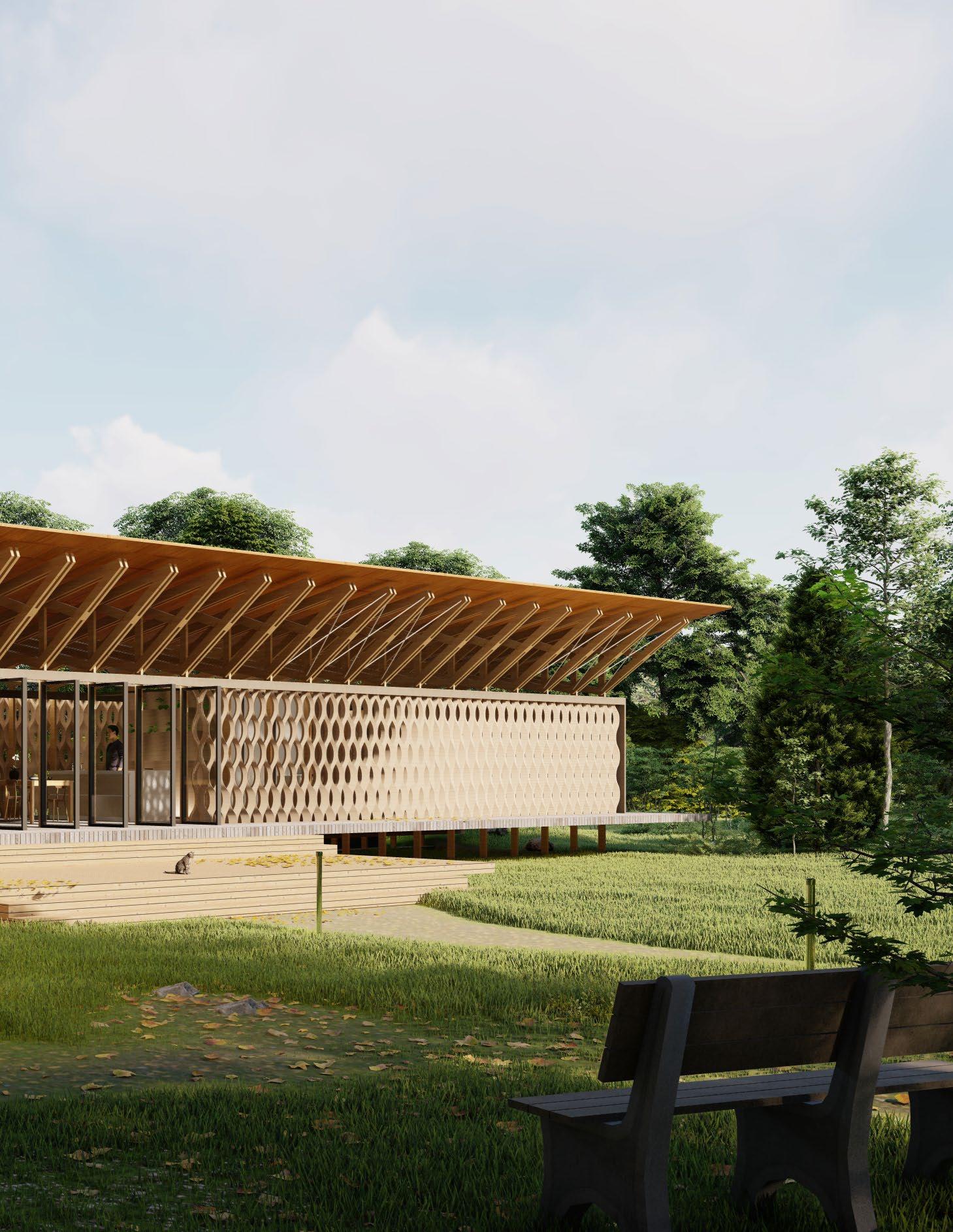

8

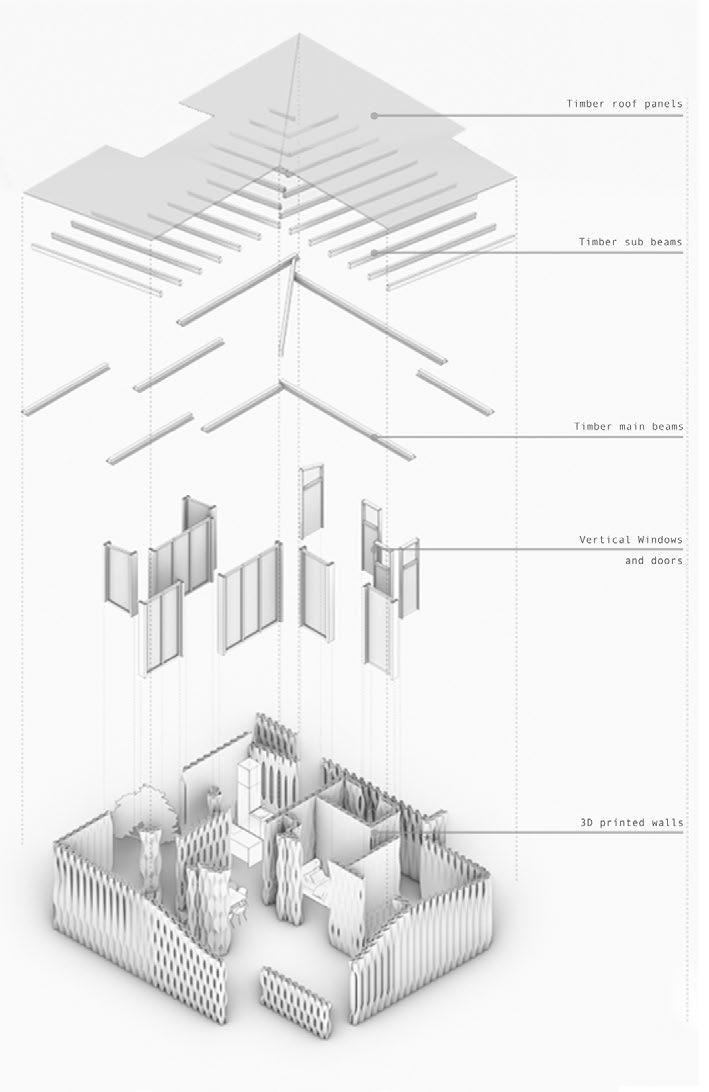

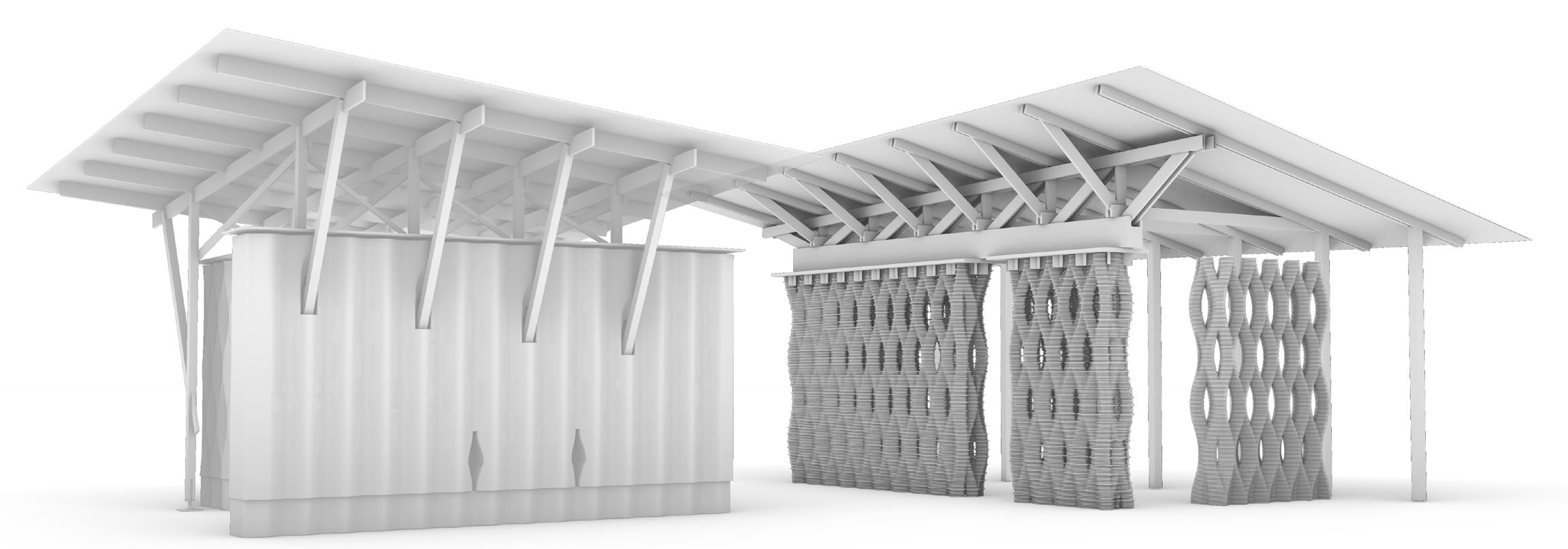

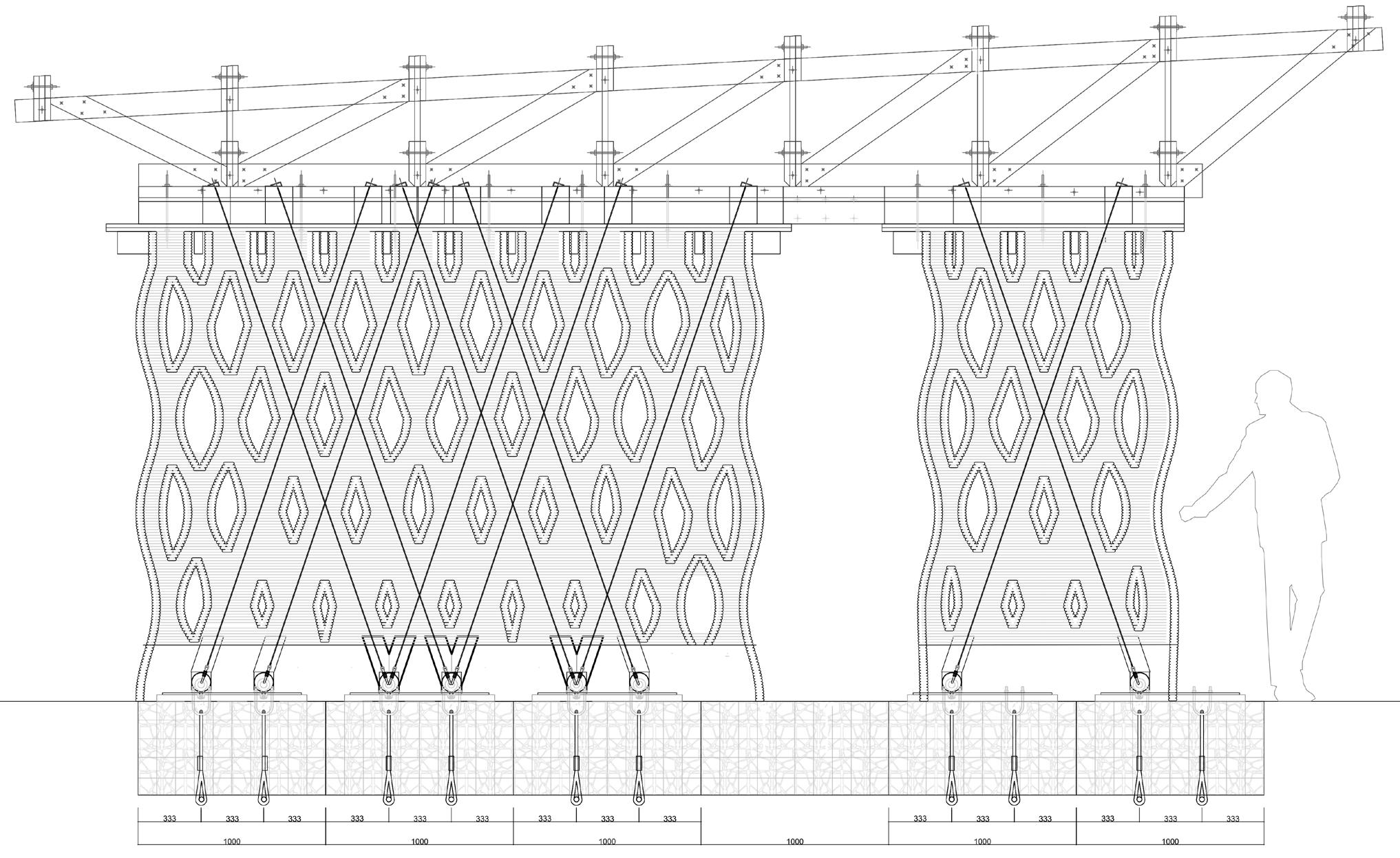

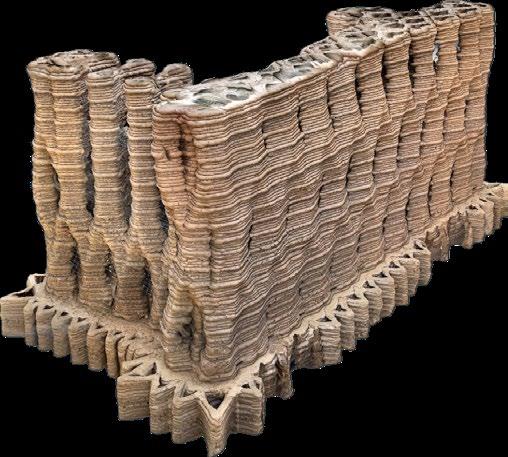

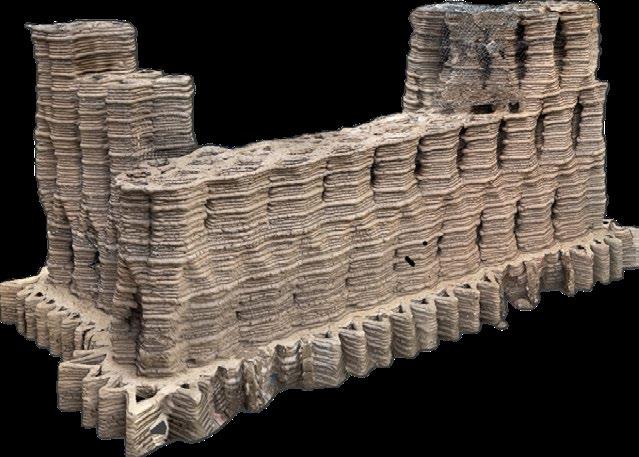

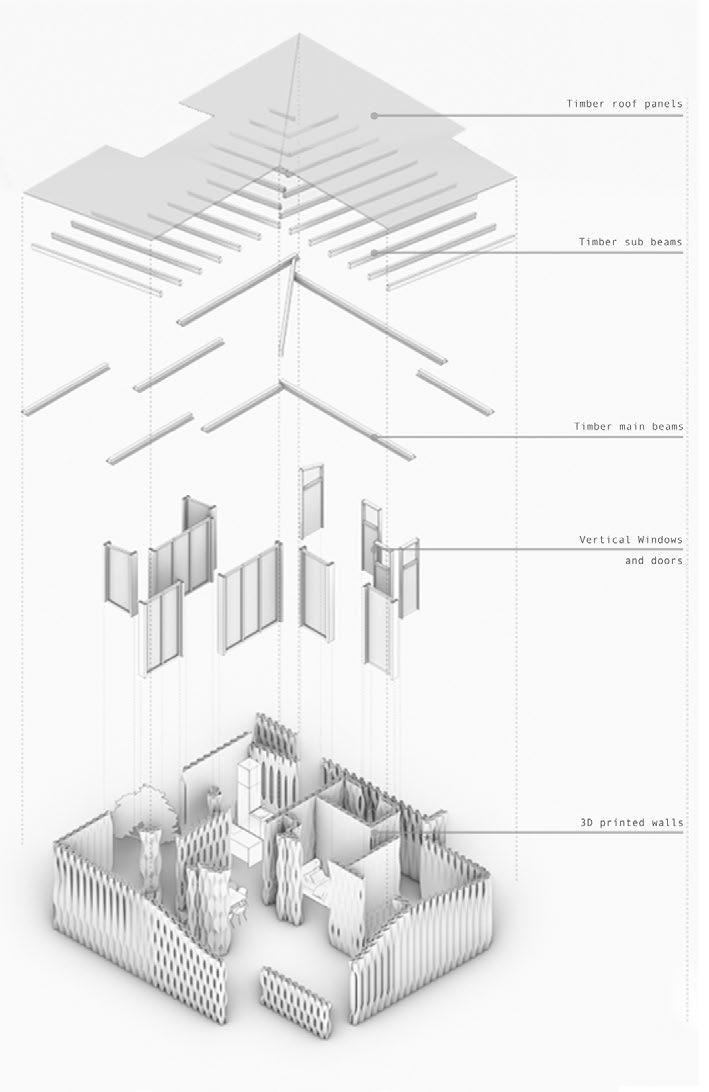

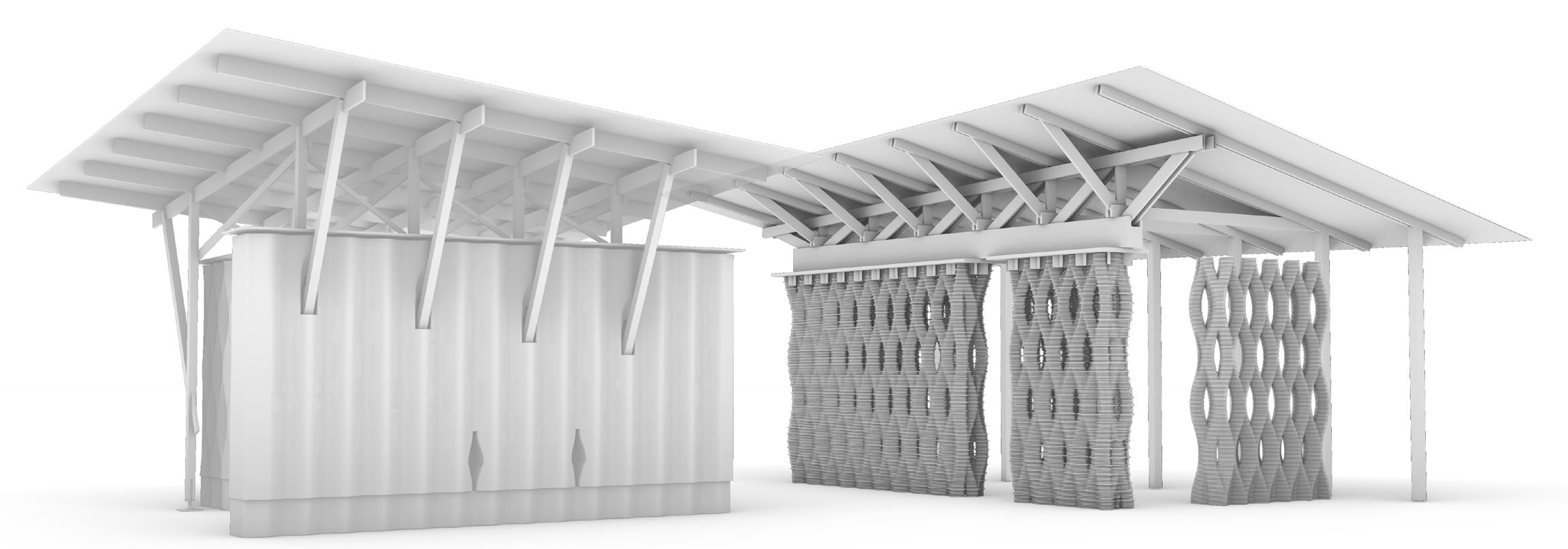

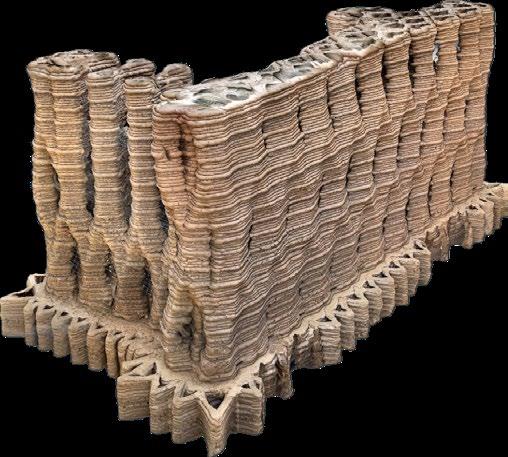

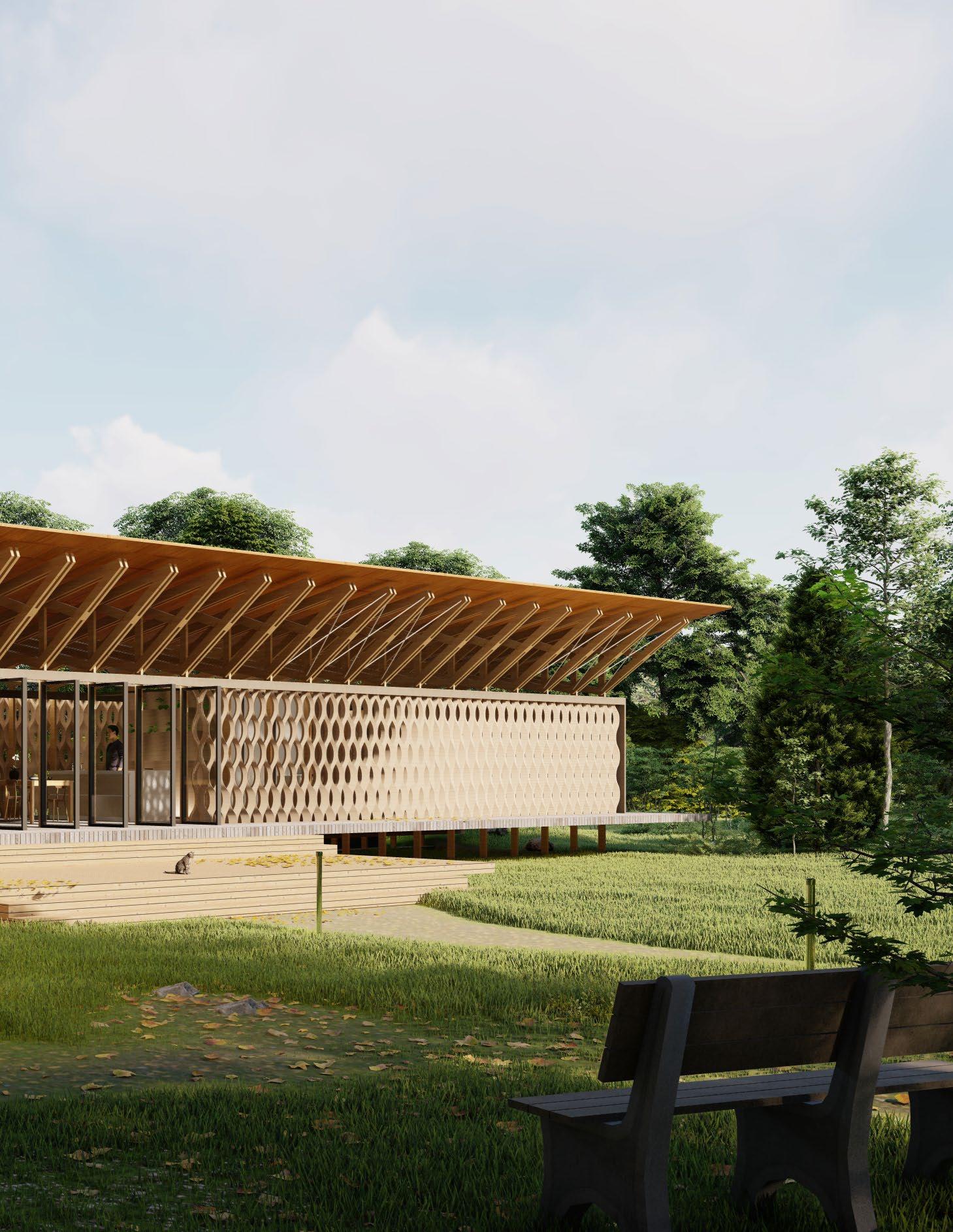

TEIXIT (woven, in Catalan) is the final prototype of the 3D Printing Architecture post-graduate program at IAAC. It is a 1:1 prototype, 3D printed out of an earth mixture sourced from the site. The layout of the structure was designed to respond to existing projects on the site, as well as to accomodate the limitations of the WASP Crane printer. Conceptually, it was designed as a segment of a larger home that will incorporate an existing earth building (TOVA). Practically, it will serve as a covered workshop area for future work on the site.

9

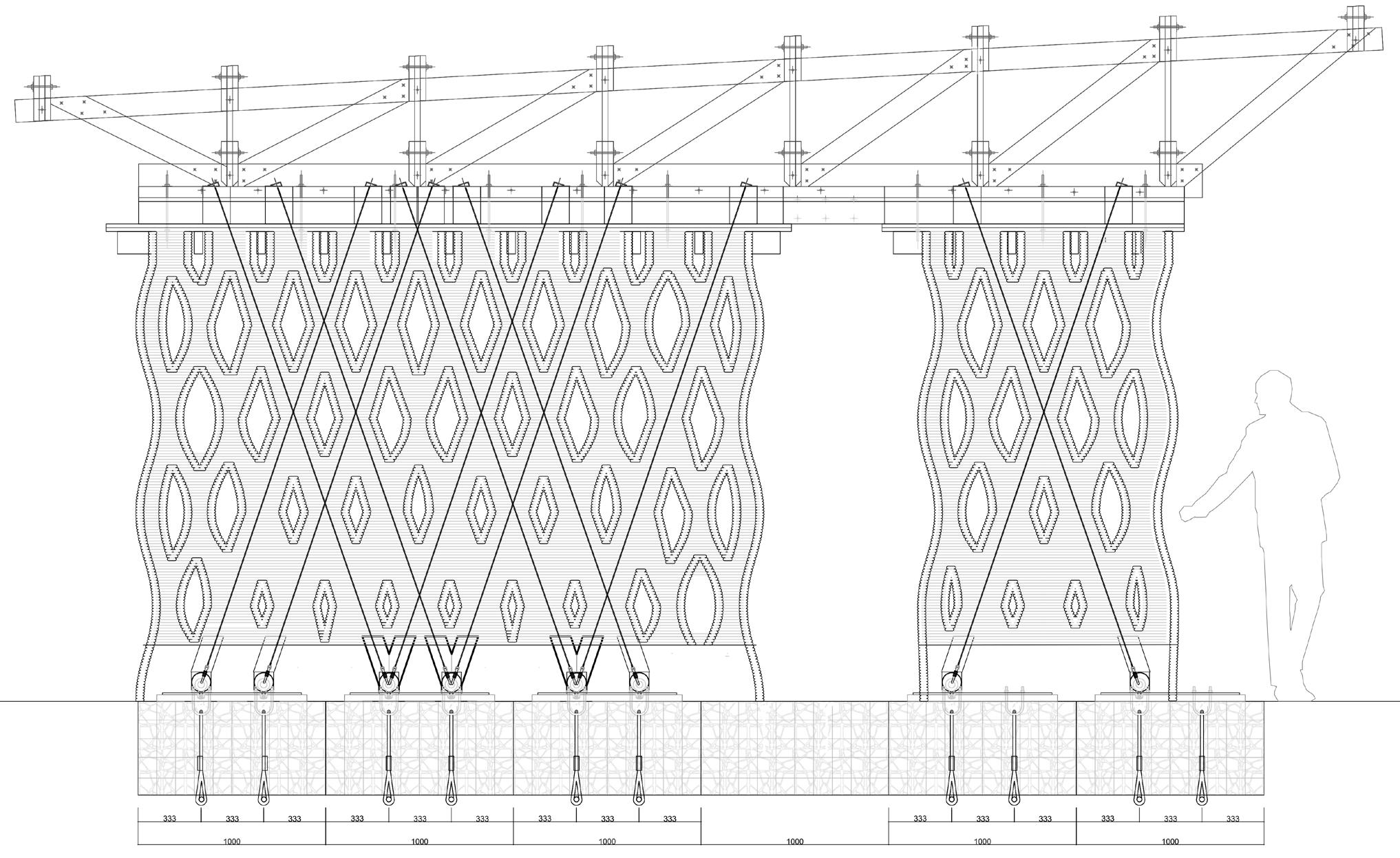

TEIXIT is a self-supporting earthen structure. The walls are load-bearing, supporting their own weight as well as the compressive load of the roof. Steel cables connected between the roof and the foundation resist the tension produced from wind uplift on the roof.

The timber roof was fabricated in a shop and partially preassembled before installation on site. It is designed in segments so as to accomadate deformation in the wall as it shrinks and dries over a number of weeks to its final dimensions.

The base of the walls rest on removeable stone gabions. A base for the walls was cast out of earth augmented with cement. The cast was completed using 3D printed earthen fomwork, which was later removed and recycled.

Foundation

10

Detail: Roof Connection

Detail:

Connection

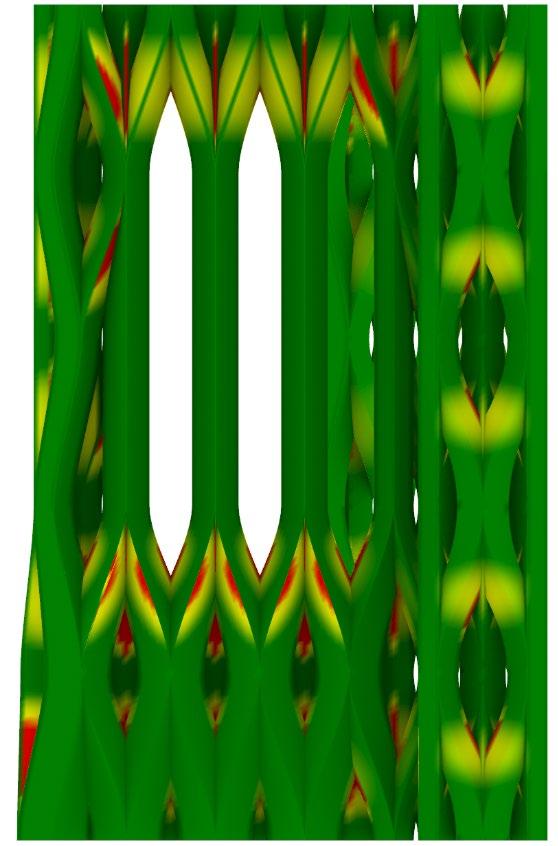

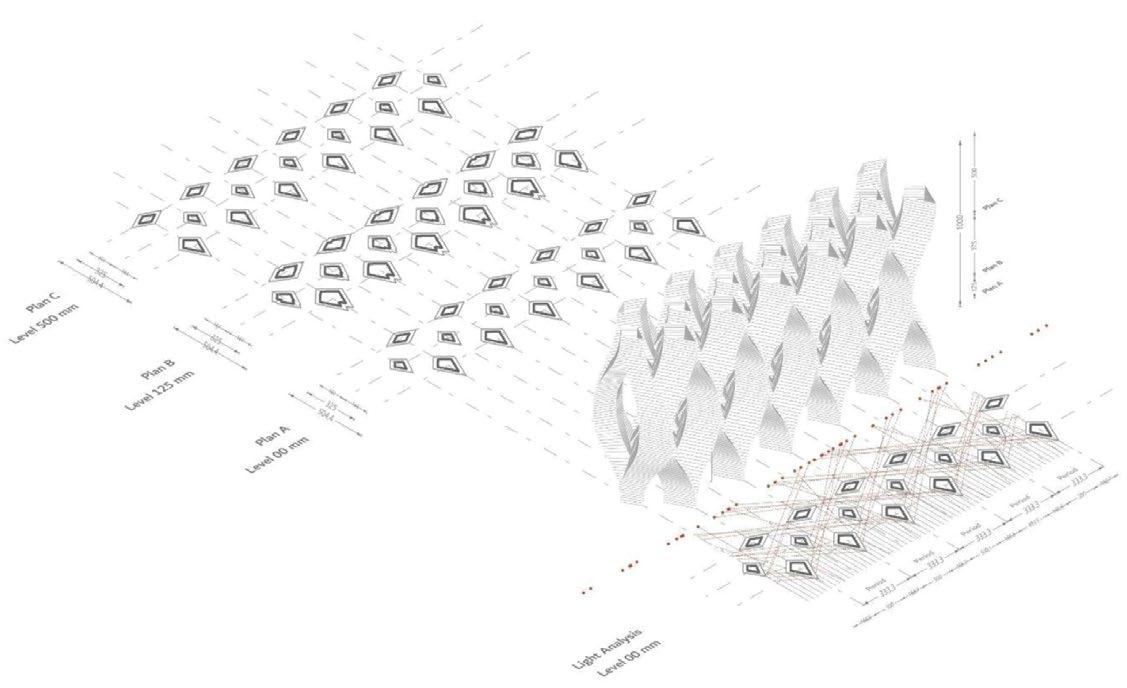

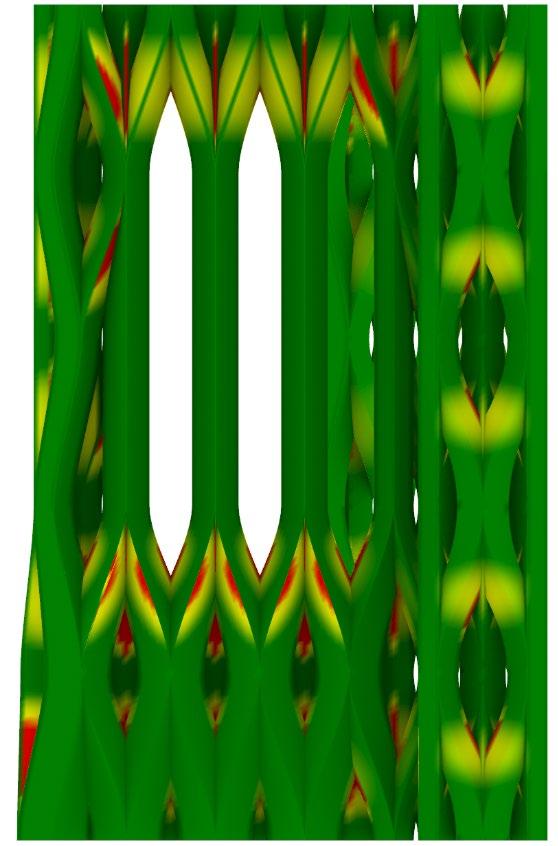

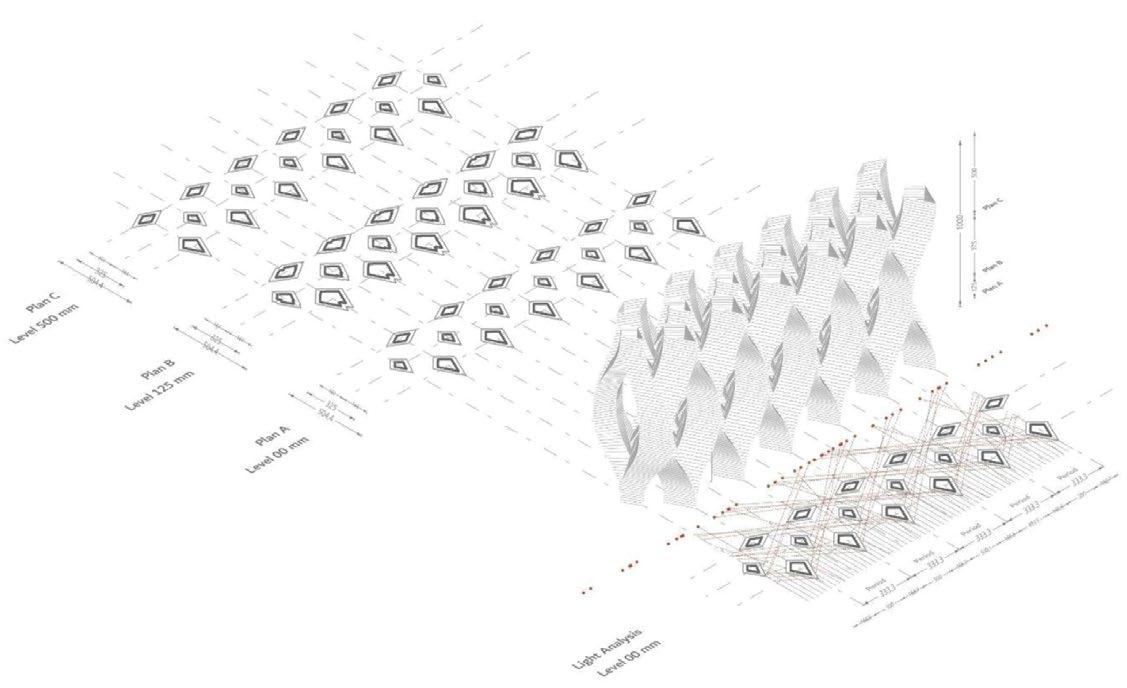

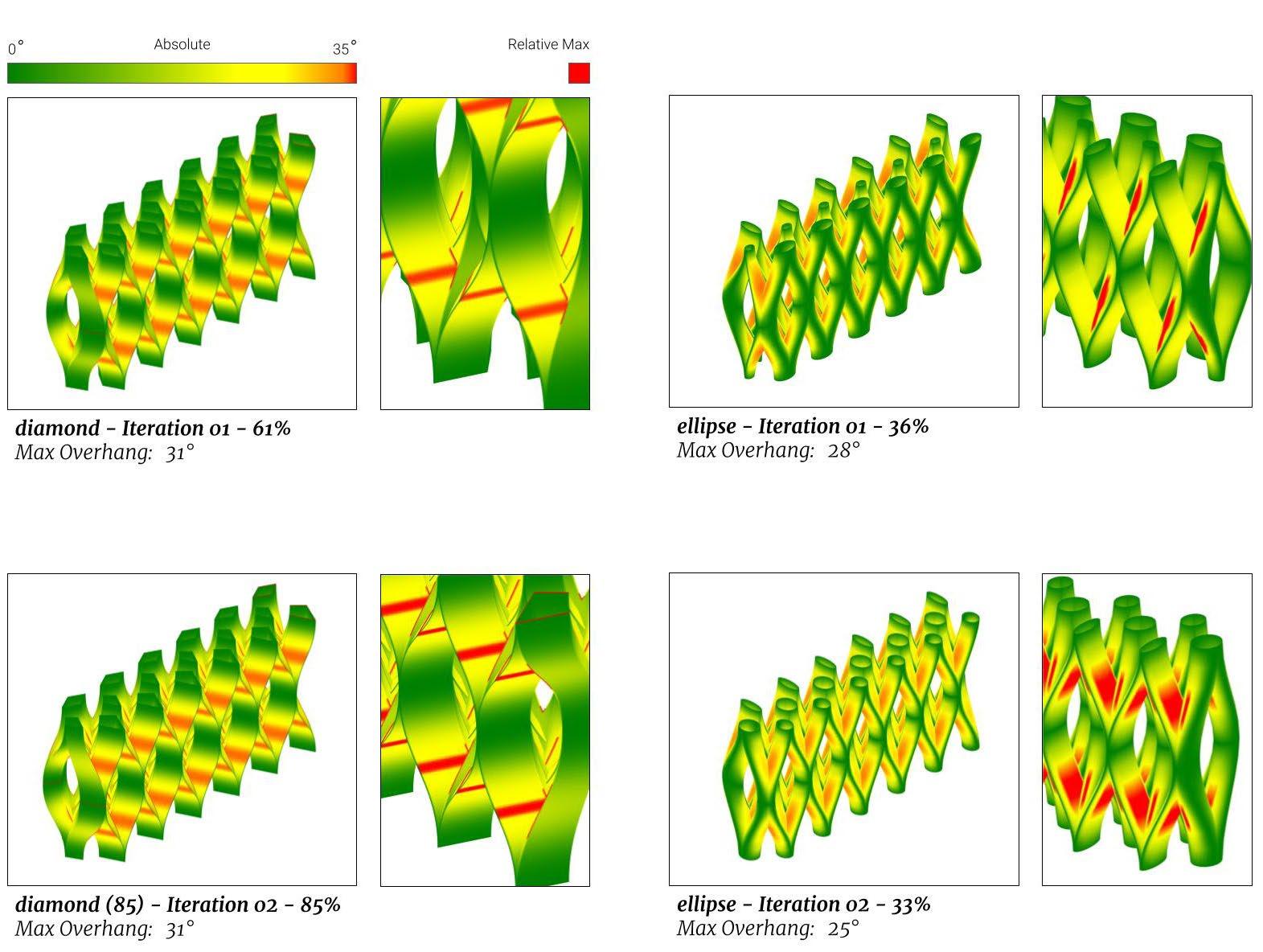

Innovations in 3D-printed earth evolved from the digital and the small scale, through to physial prototypes at 1:10 scale and then on to being integrated at 1:1 in the final project prototype. Our research investigated the feasability of tall windows within earth 3D printing for the purpose of increasing visibility and light from within the structure. This is relevant given that large windows have proven to be challenging in 3D printing due to the difficulty of printing large horizontal spans. We analyzed the printaability of the tall slender columns from a structural and geometric perspective, ultimately arriving at a successful result.

Digital - Design and Analysis

Phsysical - 1:10 Prototyping

Physical - 1:1 Building

11

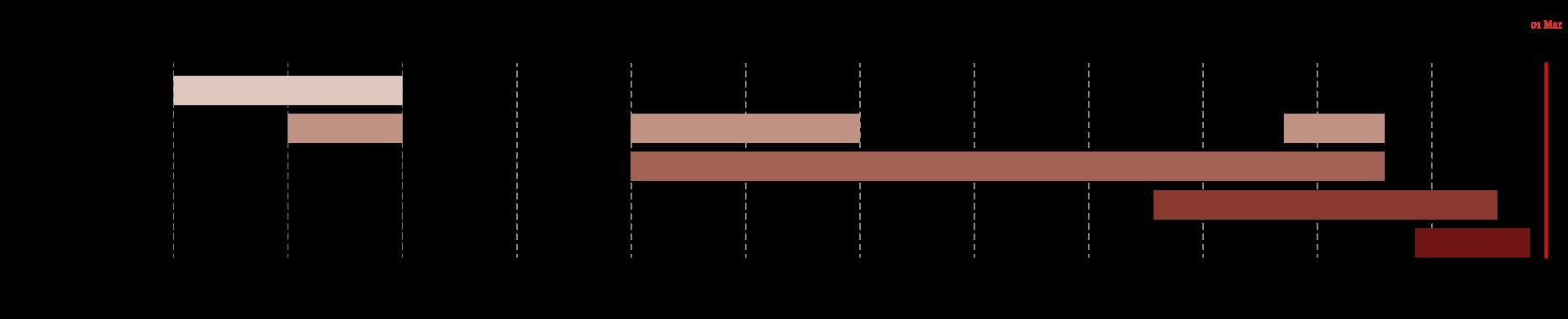

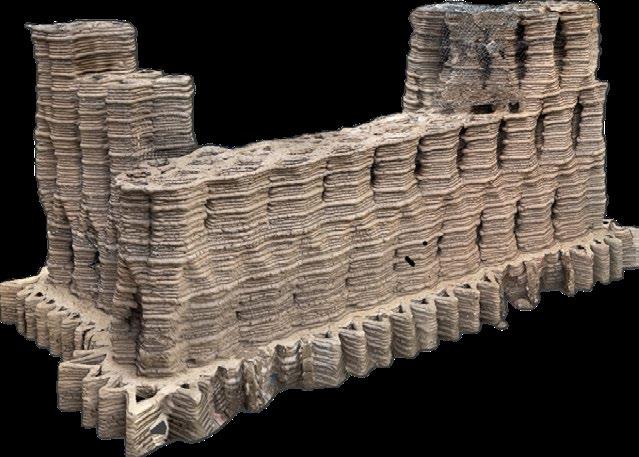

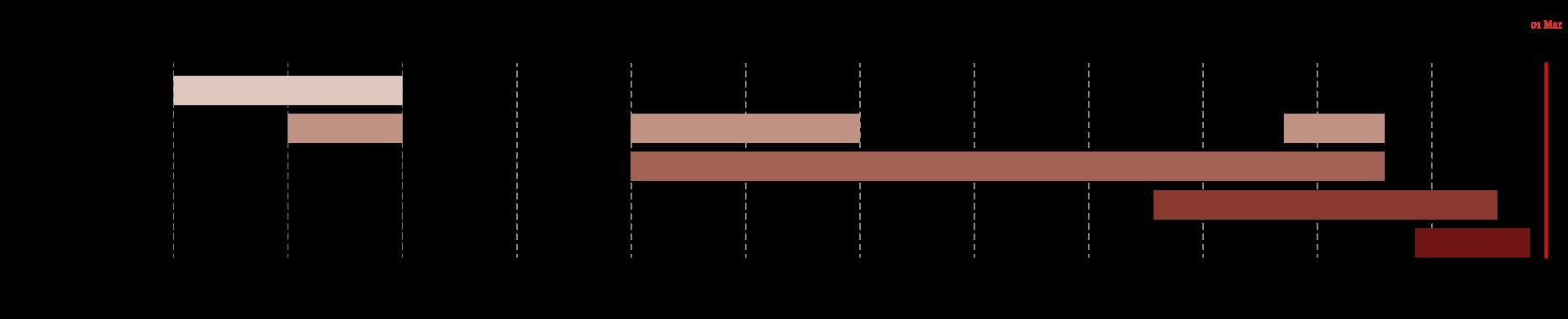

A significant part of the project involved responding to and overcoming challenges in real time, given the unprecedented nature of the reasearch. One such challenge occured when a portion of the wall that was sheltered from sunlight and airflow became saturated with moisture and began to collapse. The wall was digitally scanned, the affected parts were removed, and the internal geometry was adapted to improve stabiltiy and drying. Secondary walls were redesigned to accomodate project timelines and printing continued without further issue.

Local failure

3D Scan of wall

Affected areas removed

Seamless continuation of printing

Original Plan

Local failure

3D Scan of wall

Affected areas removed

Seamless continuation of printing

Original Plan

Project Schedule 12

Revised Design

KIBAHA

Intelligence in 3D printed earth

Project type:

Advisors:

Team:

Contribution:

Tools and Skills:

IAAC, 3DPA Phase I, 2023

Oriol Carrasco, Edouard Cabay, Alex Dubor, Secil Afsar, Nestor Beguin

Joseph Naguib, Sakshi Pawar, Vesela Tabakova, Yang Xiao

Large-scale 3D printing, paremetric modeling, performance analysis, prototyping

3D Printing

Parametric Design

Large-scale Prototyping

16

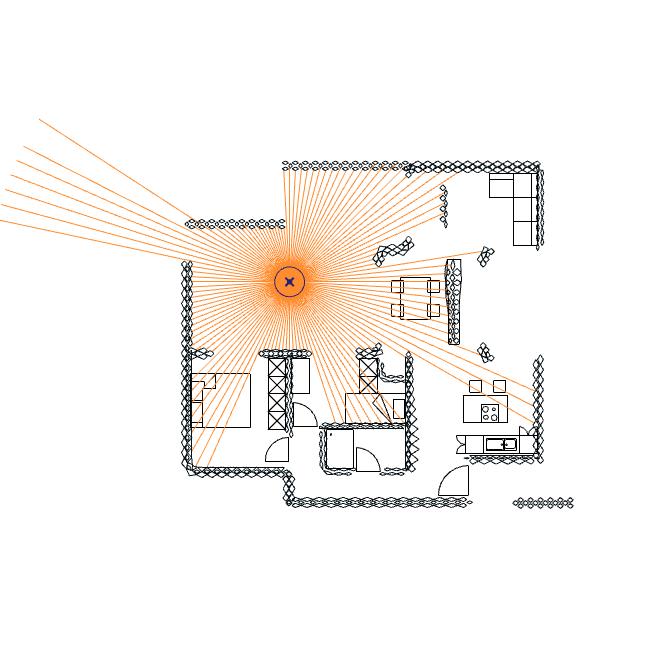

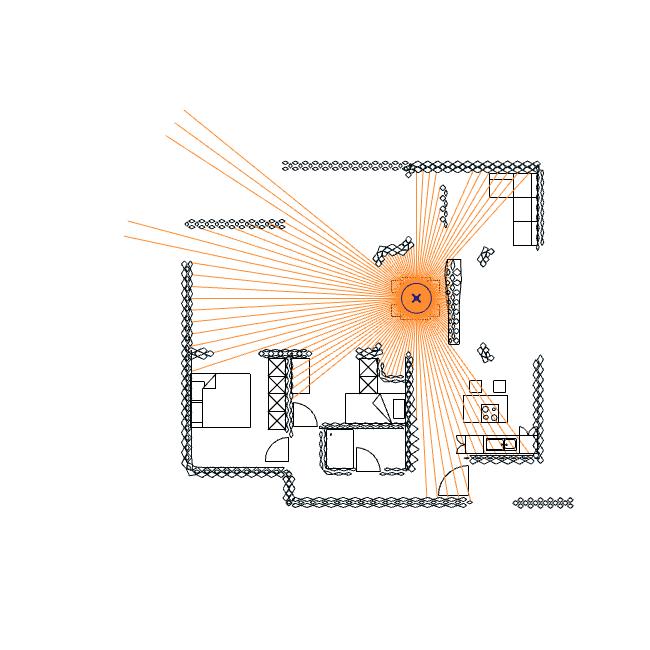

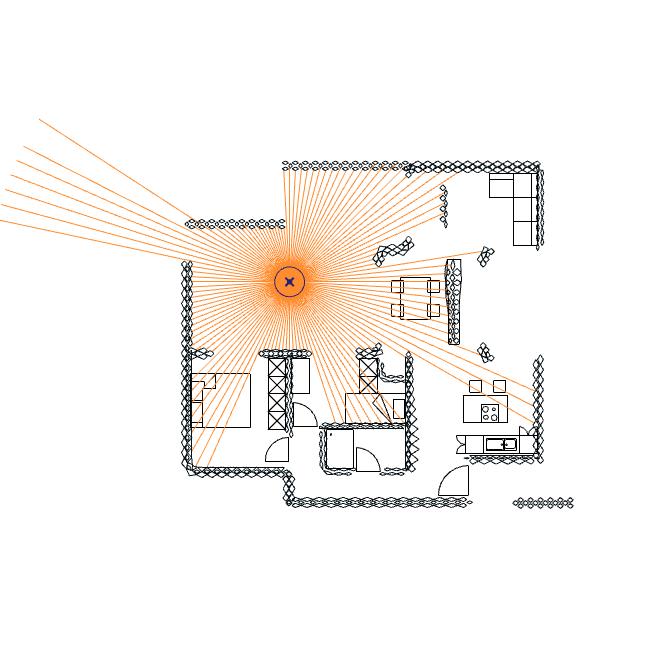

The benefit of 3D printing is the design freedom that is offered and the level of customization that can be achieved at minimal marginal cost. Kibaha is an example of how intelligent design can be printed into buildings. The openings in the walls of this home are precicely tuned to control the light and sightlines into the building. The living room is flooded with natural light and allows occupants to see out, while the bedroom is secluded from view through selective openings.

A gradient of openings ranging from fully closed to fully open permit specific types of light. The angle of the openings allow for direct or diffuse light as desired. A privacy map dictates where an observer outside the house would be permitted to see in, and where the view would be obscured by opaque walls.

17

The openings in the walls are adjusted parametrically prior to printing to obtain specific performance criteria. In this instance, a gradient of openings ranging from open to closed not only allows natural light into the home, but also controls the specific angle at which light can enter, preventing or permitting direct sunlight as desired. A walkaround analysis on the right indicates which areas of the home are visible from the exterior, and which remain secluded.

The feasability of this wall type was tested at one to one scale using natural earth. Analyses for printability and light permeability were carried out prior to printing.

18

PRINT - SCAN - CUT

Preliminary steps towards a hybrid workflow for smooth 3D printed surfaces

Project Type

Advisors:

Team:

Contribution: Tools and Skills:

IAAC, MRAC Masters Studio III, 2023

Marielena Papandreou, Alexandre Dubor

Francisco Martinez, Lucy Mendoza, Hritik Thumar

Research plan, scanning workflow design, parametric design, part discretization, fabrication

Robotic programming

Scanning

Rhino/Grasshopper (Anemone, Robots, Kuka PRC)

Clay 3D printing

Digital Fabrication

22

Front View

Discretization Assembly

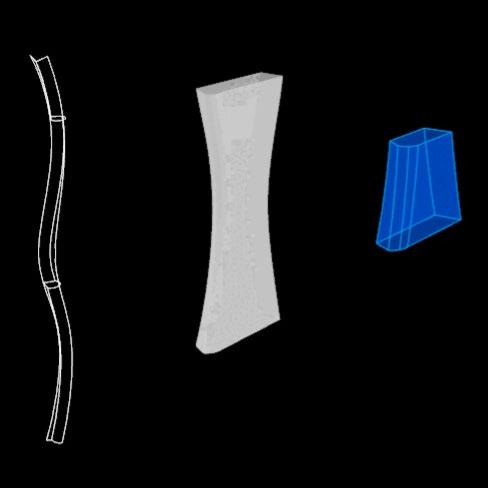

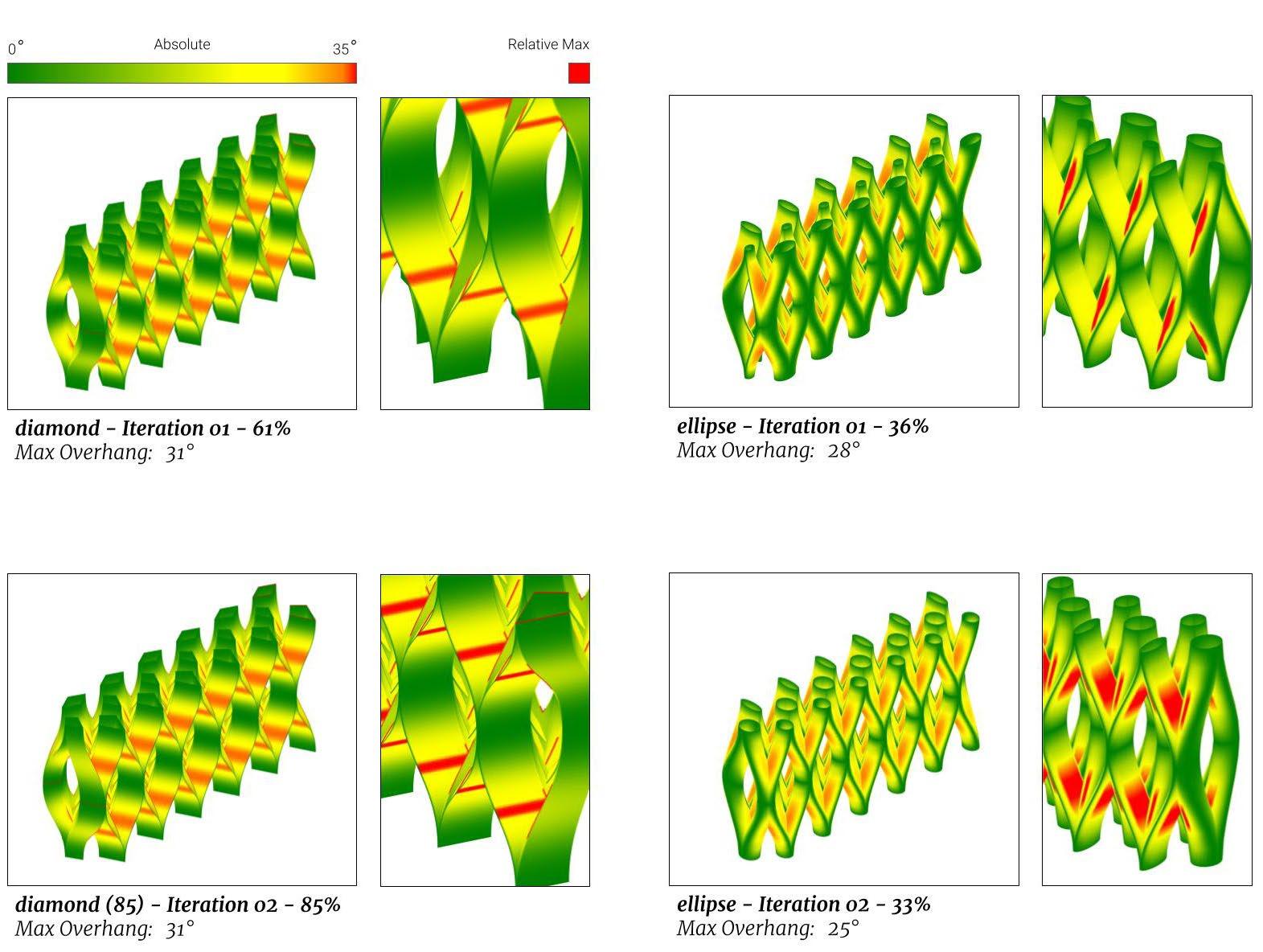

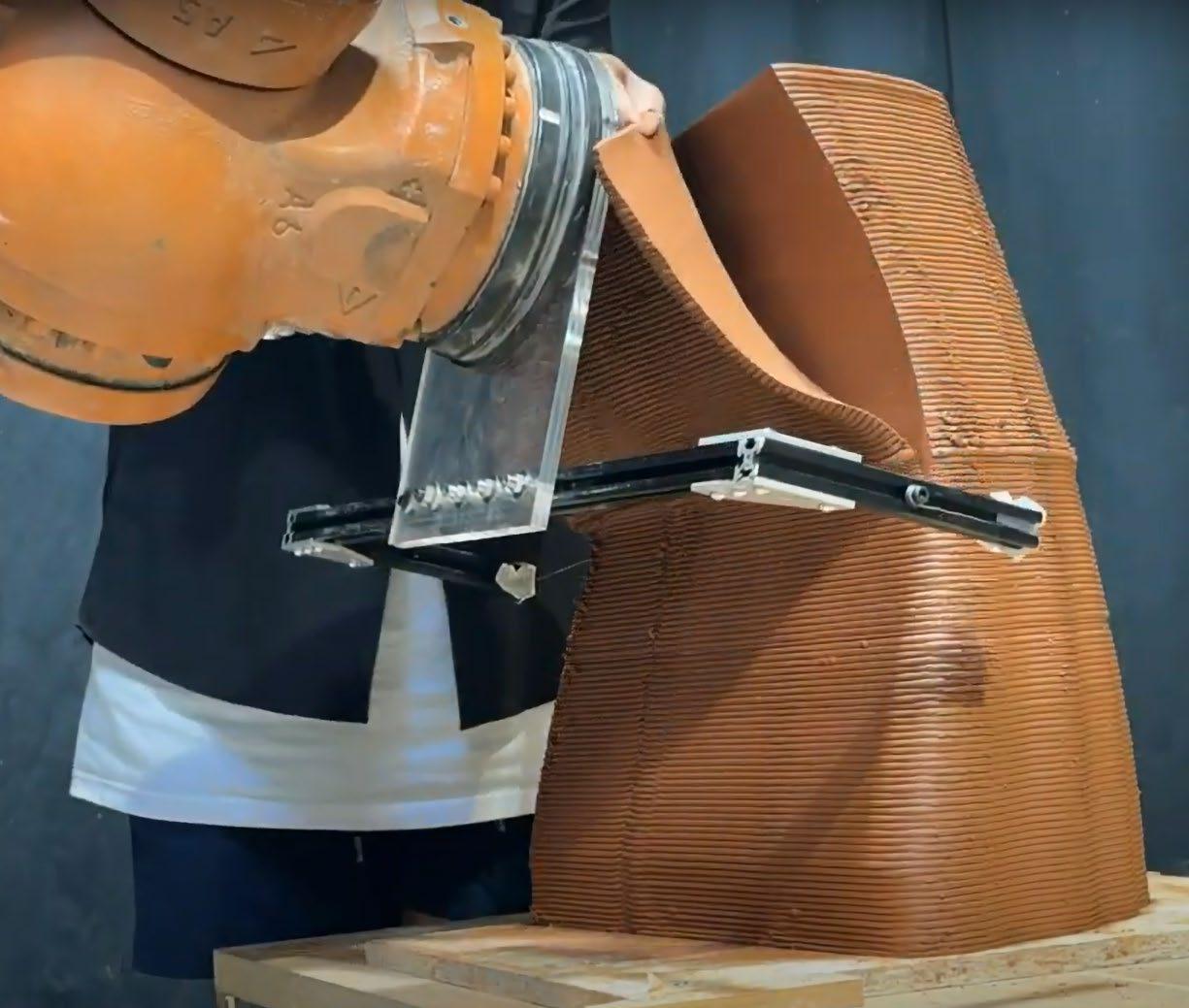

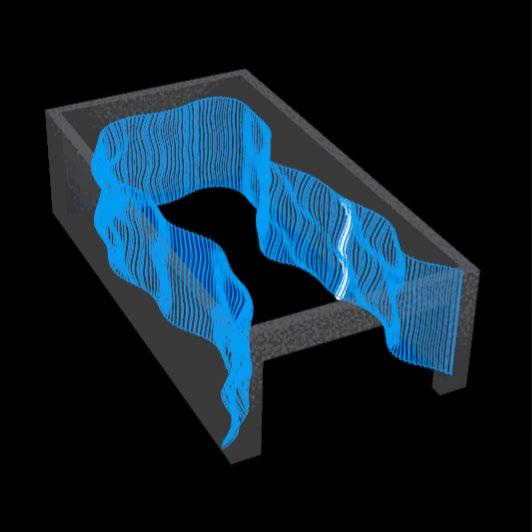

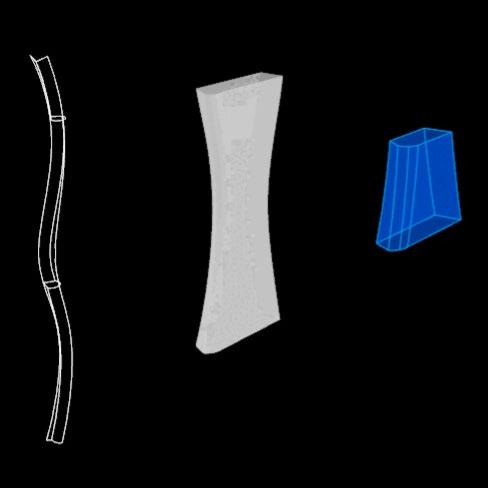

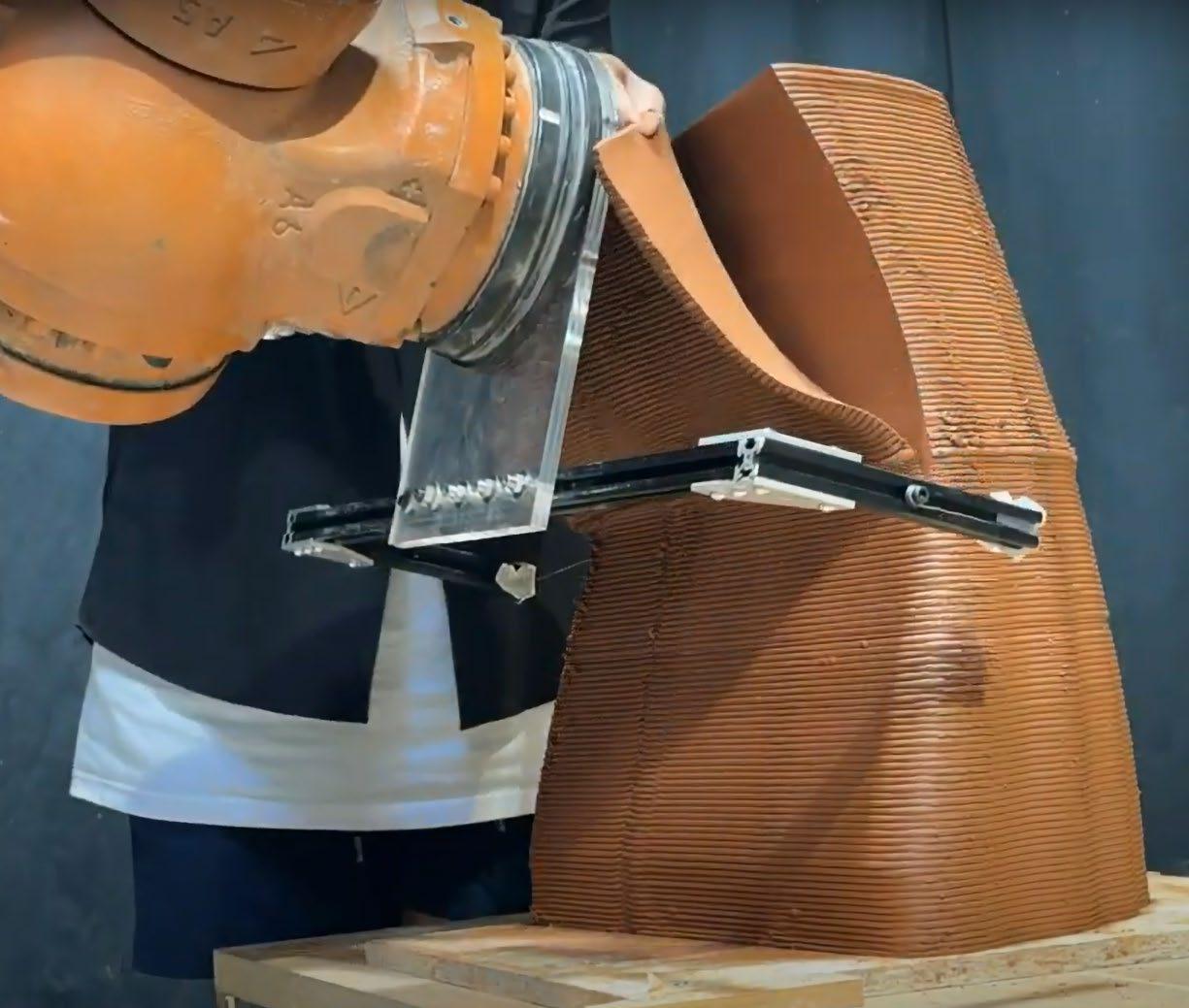

This studio project explores a solution to the problem of rough, extruded surfaces produced as a result of 3D printing. hich are often considered a drawback for its use in architecture and construction. Though these textures can in some cases be used to interesting effect, they are often considered a drawback for use in architecture and construction. The solution was a hybrid workflow (additive and subtractive manufacturing) that allowed for improved alignment and surface finish.

Print

The outcome showed both the aesthetic and alignment benefits of this teqnique as applied to a 3D printed sculpture. Research involved printing at various scales ranging from a desktop cartesian printer up to a Kuka KR150-2; scanning for the purpose of accurate path planning; and finally, wirecutting to remove the ridges left from printing leaving a smooth surface behind.

Before scanning After scanning 23 3D printed object with rough extruded srurface

Complete workflow

Scan

3D scanning proved to be critical in this process in order to bridge the gap between the digital design and the physical object. Due to shrinkage and deformation during printing, the physical part deviates from the shape of the digital part.

The solution was to scan parts after printing and rebuild them digitally. The scan was then compared to the initial model and to existing parts. Accurate accurate cutting paths were then developed from the rebuilt digital parts.

Part alignment and cutting accuracy improved significantly with this process.

Cut

A wirecutting toolpath based off of the scanned object provides an accurate cut depth and geometry. A single pass of the wire provides a drastically improved surface finish.

Printing limitations such as overhang, wirecutter tool edge conditions, and robotic mobility impose limitations on the set of geometries that, once printed, can be wirecut. Within those boundaries, however, rich textural possibilities are available.

Scanned print

Extract new cutting face

Plan new cutting faces

Align scans for global continuity

Plan cutting paths

Scanned print

Extract new cutting face

Plan new cutting faces

Align scans for global continuity

Plan cutting paths

24

Textural explorations

The robot follows a precise wirecutting toolpath from scanned part

This technique can be used to add rich textures to interior spaces. The variance of smooth and rough adds significant depth and visual complexity. Meanwhile, fired clay has a particularly warm and timeless appeal.

This interior is an example of the wirecutting technique applied accross an entire wall. Such a surface is composed of tall, slender elements discretized into blocks that meet size and inclination requirements for printing and firing. Finished components can be stacked atop one another or fixed to the wall mechanically, allowing for straightforward assembly and disassembly.

26

PREDICTIVE DEFORMATION

Initial investigations of AI-Driven prediction of shrinkage and deformation in 3D printed clay

Project type:

Advisors:

Team:

Contribution:

Tools and

Skills:

IAAC, MRAC Software III, 2023

Mateusz Zwierzycki

Francisco Martinez, Lucy Mendoza, Hritik Thumar

Research plan, workflow design, Kangaroo simulation, ANN training

Rhino/Grasshopper (Owl, Kangaroo)

Clay 3D printing

Machine learning, Artificial Neural Network (ANN)

28

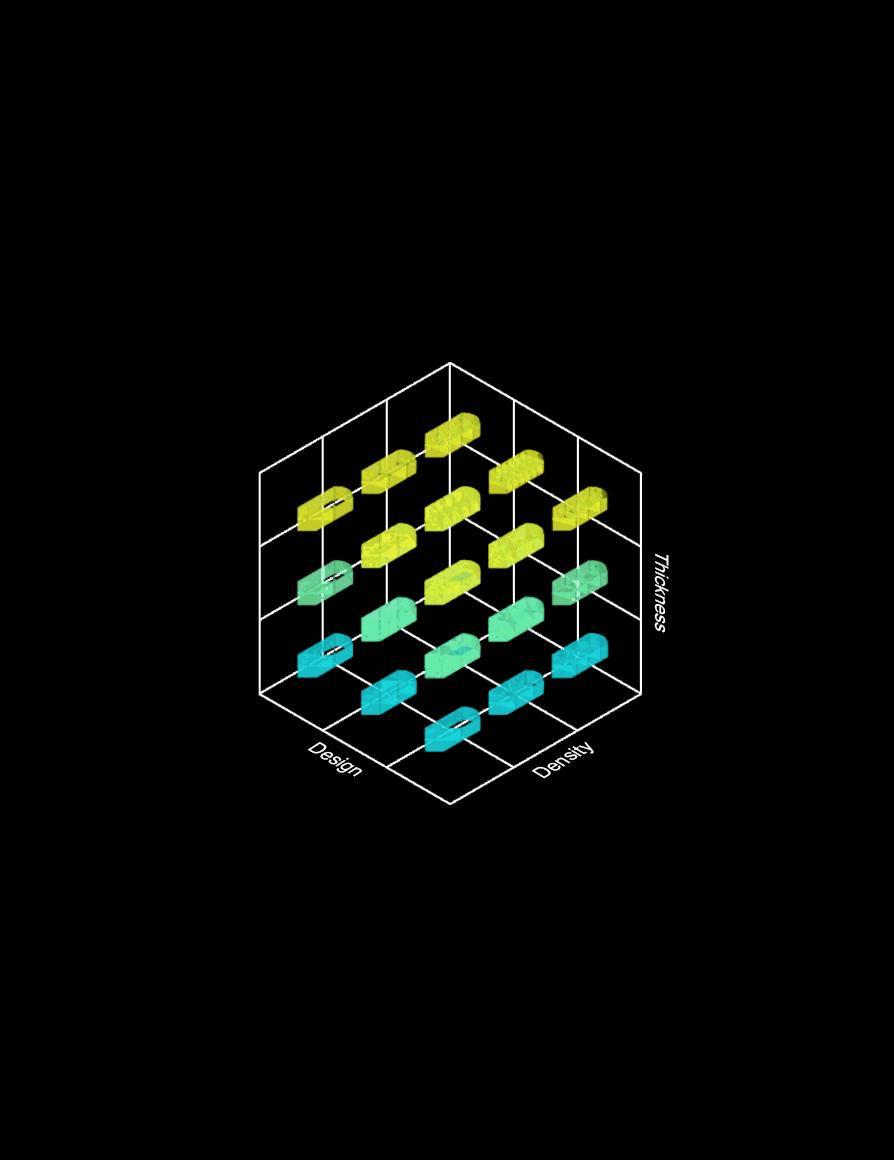

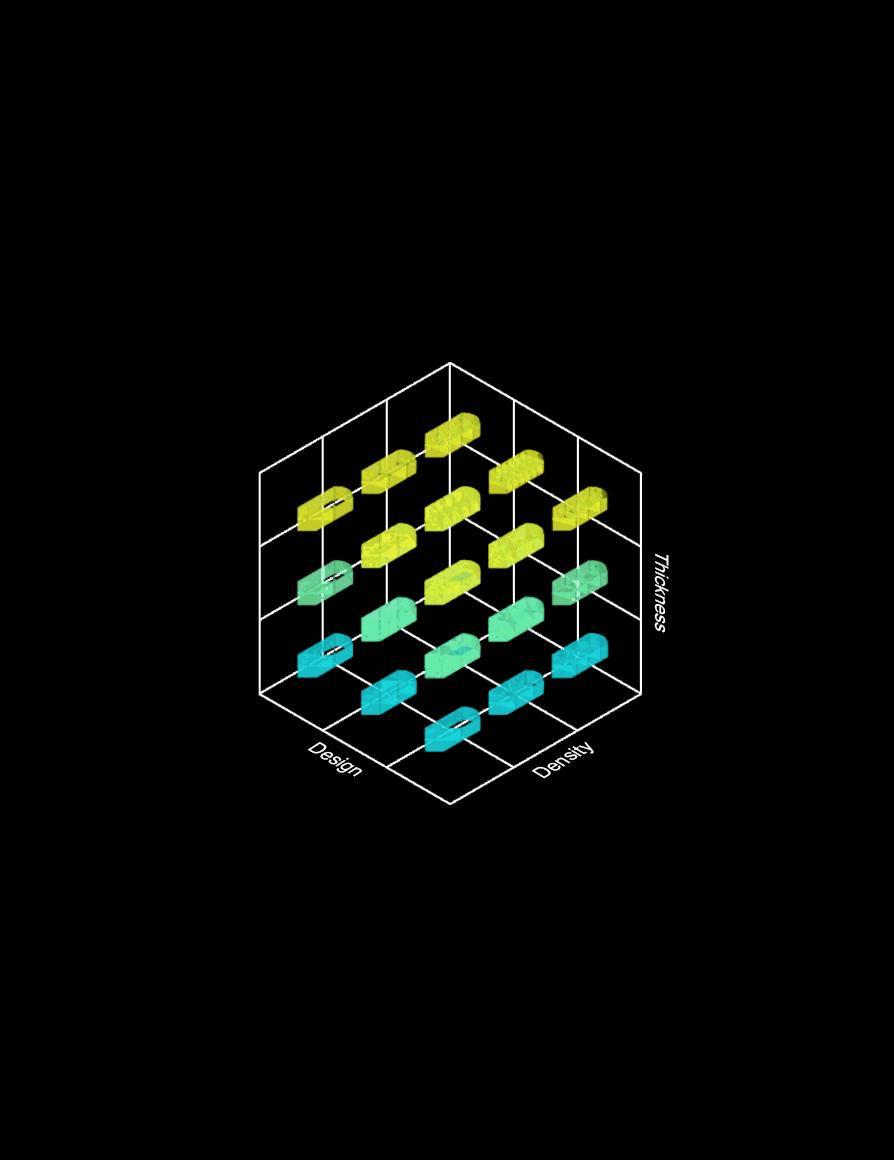

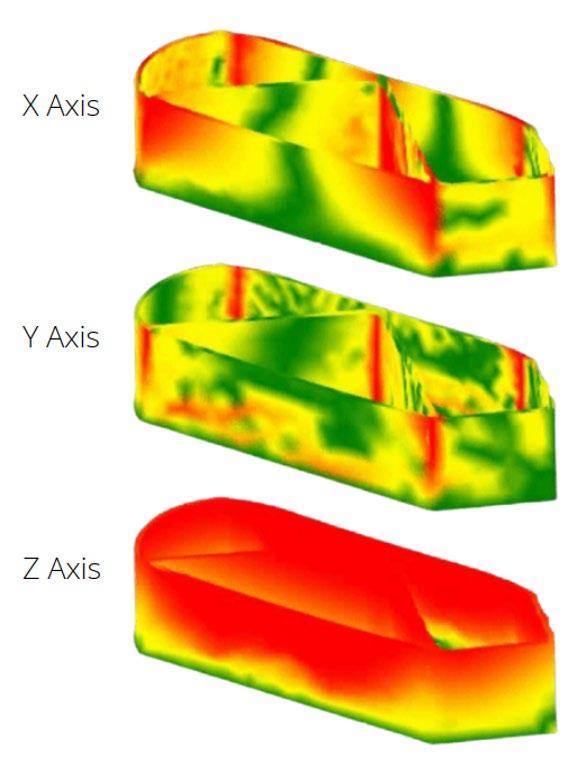

A major obstacle to high quality printed ceramic objects is the unpredictable nature of shrinkage and cracking that occurs during drying and firing. This project is a preliminary step in employing machine learning to solve this problem. The research involved the following:

1. A catalogue of simplified geometries was developed with easily identifiable reference points.

29

Infill Design

Density

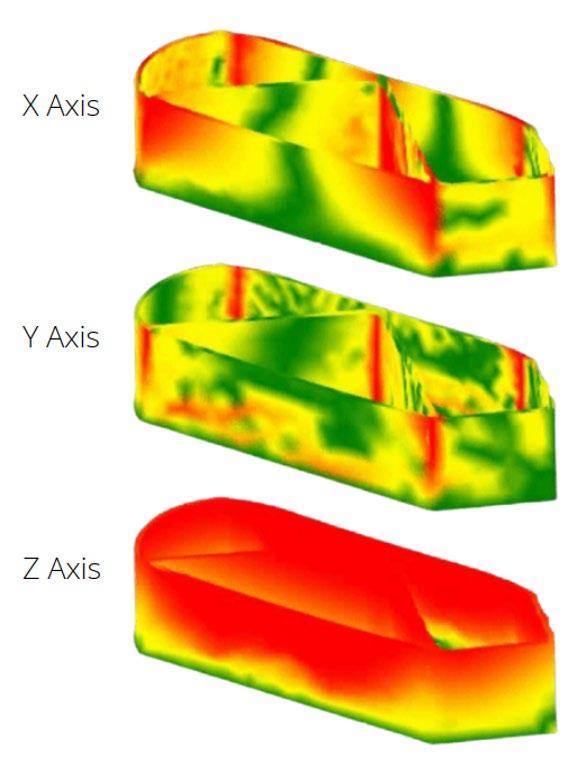

2. Kangaroo was used to create a set of synthetic data to train the Artificial Neural Network (ANN). This, to avoid the time required to print, dry, and fire actual parts.

Synthesized deformation in X, Y, and Z

3. A regression-type ANN was trained and verified on the synthetic data using backpropagation, with a sigmoid activation function. Data inputs included inputs for extrusion thickness, and infill density and type.

A finalized workflow would involve three steps: collection of data; training and verification of the model; and application of the trained model to predictively scale the print to account for shrinkage.

30

OBJECT OF MY AFFECTION

Once I find you, I’ll follow you anywhere. At a respectable distance, of course

Project type:

Advisors:

Team:

Contribution:

Tools and

Skills:

IAAC, MRAC Workshop 2.1, 2023

Carlos Rizzo, Mateus Sanchez, Daniil Koshelyuk

Lucy Mendoza, Joseph Naguib

Concept, target recognition and isolation

Robotic control (ROS Noetic)

Computer vision (OpenCV)

Python

32

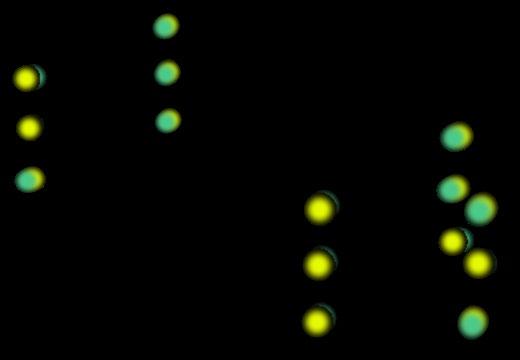

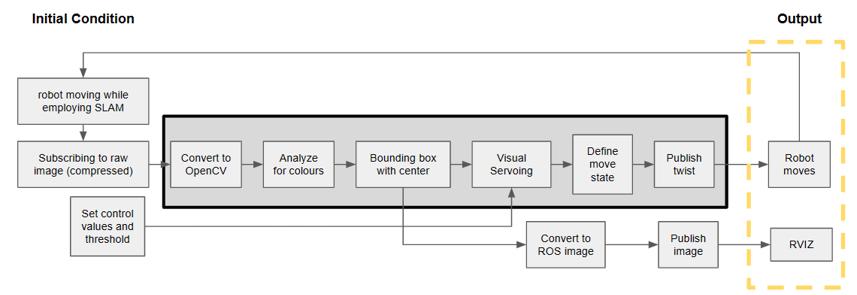

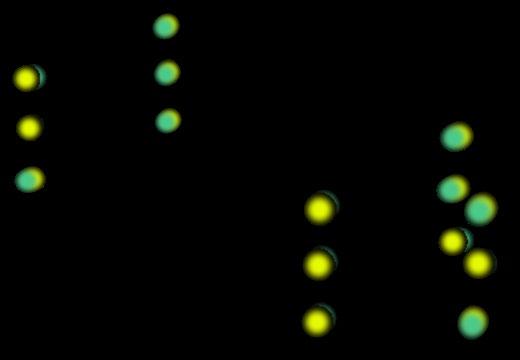

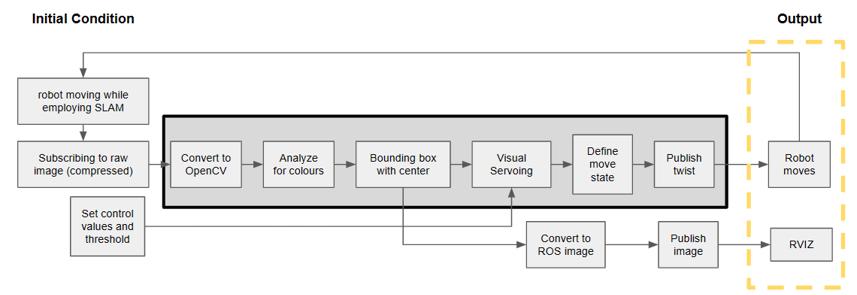

The robot acts based on analysis of a colour video feed. Colour identification and object isolation distinguish the target from the surrounding environment. Target distance and orientation are obtained from the object’s disposition the image stream.

Object detection/colour

Frame

Mask

33

The robot will turn, advance, and retreat based on its anaylsis of the target position.

Advanced iterations of this project would suit ergonomic environments where humans and robots work collaboratively. Consider a scenario where an automated assistant follows a human user at a comfortable distance. This project lays the foundation for such future applications.

34

Pseudocode for robotic control logic

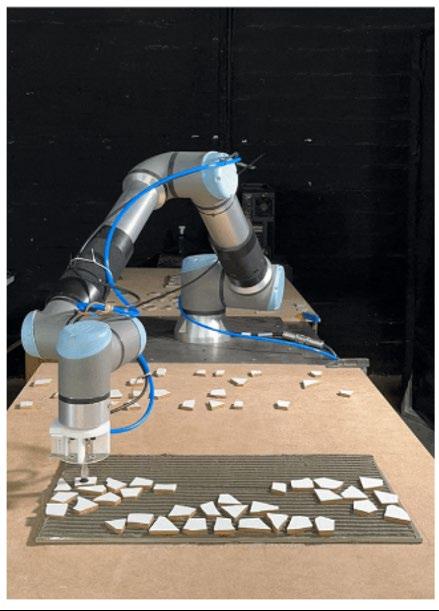

ROBOMOSAIC

Trencadis

reimagined for the age of digital fabrication

Project type:

Advisors:

Team:

Contribution:

Tools and Skills:

IAAC, MRAC Workshop 2.2, 2023

Alexandre Dubor, Vincent Huyghe, Daniil Koshelyuk

Bipradip Biswas, Bora Çobanoğlu

Research plan, scanning workflow design, parametric design, part discretization, fabrication

Scanning

Robotic pick and place

Rhino/Grasshopper (Kangaroo, OpenNest)

Digital workflows

Python

36

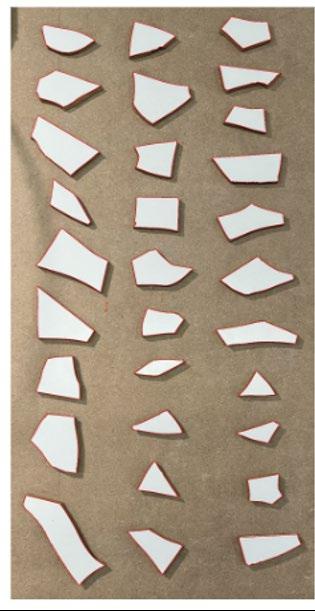

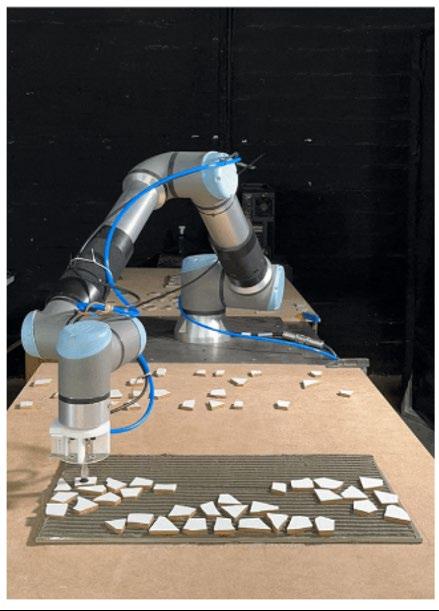

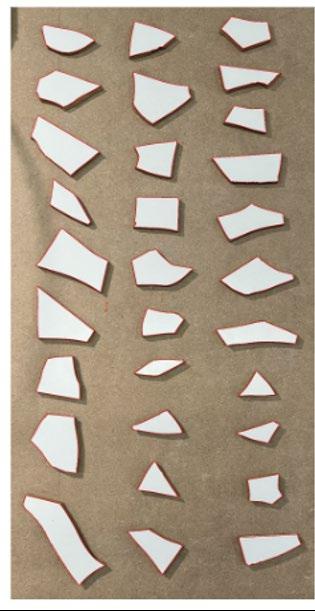

The aim of this project is twofold: to bridge the gap between robotics and artisan craftsmanship, and to explore the idea of the circular economy, where useful materials are diverted from landfill. It is inspired by Gaudi's trencadis technique, which creatively repurposed broken tiles.

Convert to mesh and extract edges

In this modern take, a UR robot is employed to pick-and-place ceramic shards. Shattered tiles are scanned and digitally catalogued. Using parametric tools, the tiles are arranged into intricate shapes and patterns. Finally, the robot meticulously places each tile.

Lay out tiles

Shape and pack to desired design

Scan

Grout and place

37

While beautiful, mosaics are labor-intensive. Extensive use of the teqnique is therefore impractical currently. However, tiles are durable, and mosaics carry profound cultural significance. Perhaps the art of mosaic can be rejuvenated by integrating robotic technology to increase productivity and thereby reduce production costs.

We envisioned a future application of this technology where mosaics embellish otherwise mundane areas like parking lots, pathways, and roadways. While these spaces are often seen as mere utilities, they have the potential to become cultural landmarks.

38

Info

Education and Training Work Experience

Justin Hanlon, BEng, MBA, rmc.

Born: 15 September 1992

Citizenship: Canadian

Post-graduate in 3D Printing Architecture

Institute for Advanced Architecture of Catalonia (IAAC), Barcelona, Spain 2023/2024

Master of Robotics and Advanced Construction

IaaC, Barcelona, Spain 2022/2023

Master of Business Administration

Royal Roads University, Victoria, British Columbia, Canada 2017/2018

Bachelor of Engineering, Mechanical Engineering

Royal Military College of Canada, Kingston, Ontario 2010 – 2015

Military training: Flight training, Basic Military Officer Qualification, first aid, leadership Across Canada 2010 – 2022

Officer, Royal Canadian Air Force 2010 – 2022

Air Operations Officer, HMCS Calgary, Operations ARTEMIS and PROJECTION 2020 – 2021

Tactical Coordinator, 443 Maritime Helicopter Squadron 2019 – 2022

Technical Skills

Written and verbal communication

Rhino, Grasshopper

3D Printing

Sketching

Machine Learning

Digital fabrication

AI Design tools

Python ROS

Languages

English (native)

French (working ability)

39

AB-

Thank you.

in 40

Justin Hanlon Barcelona, Spain just.hanlon@live.com +34 631 430 663

Local failure

3D Scan of wall

Affected areas removed

Seamless continuation of printing

Original Plan

Local failure

3D Scan of wall

Affected areas removed

Seamless continuation of printing

Original Plan

Scanned print

Extract new cutting face

Plan new cutting faces

Align scans for global continuity

Plan cutting paths

Scanned print

Extract new cutting face

Plan new cutting faces

Align scans for global continuity

Plan cutting paths