PACIFIC DENTAL CONFERENCE

42nd DTABC Annual Conference March 7-9, 2024

O ur Approach to a National Collective Voice Full Denture Prosthetics –The Ultimate Discipline: Craftsmanship and Individual Specifications DENTISTRY DEPENDS ON TECHNOLOGY INSIDE PM#40065075 –Return Undeliverable Items To: Craig Kelman & Associates, 3C-2020 Portage Avenue, Winnipeg, MB R3J 0K4

•

THE OFFICIAL PUBLICATION OF THE DENTAL TECHNICIANS ASSOCIATION OF BRITISH COLUMBIA AND THE ASSOCIATION OF DENTAL TECHNOLOGISTS OF ONTARIO SPRING 2024

Vancouver Convention Centre

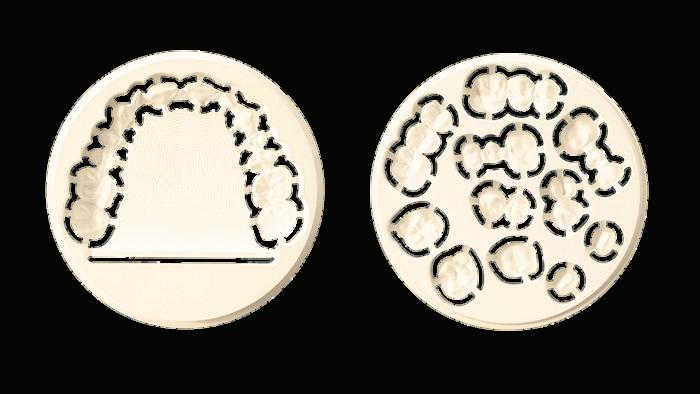

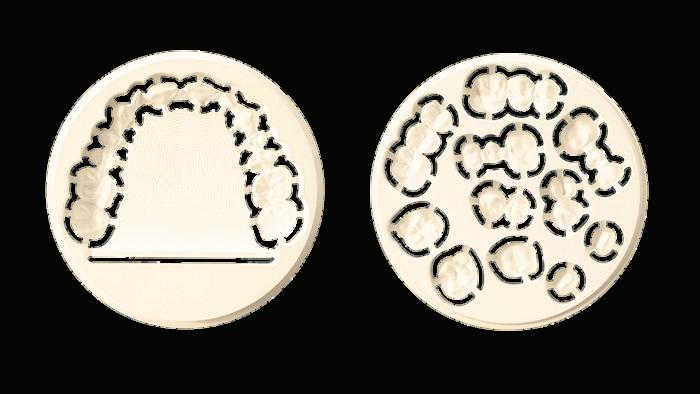

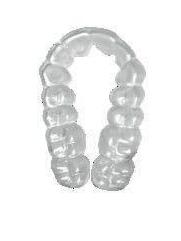

V-Print® splint comfort

FDA 510k-cleared biocompatible 3D print resin to produce clear thermo-flexible therapeutic splints, retainer and night-guards

High flexural strength and excellent wear resistance allow for device as thin as 1 mm

Thermo-flexibility, biocompatibility, odorless and neutral flavor increases patient acceptance

Extremely fracture resistant and durable

Clear-transparent, easy to polish and color stable for excellent esthetics

No sedimentation – no shaking or “rolling” prior to use

V-Print® splint

Material for 3D printing of splints, night-guards and other diagnostic parts

FDA 510k cleared

Biocompatibility and neutral flavor ensure high level of patient acceptance

Clear-transparent – for high patient satisfaction

Rigid with high flexural strength for durable orthodontic objects

Easy to polish and stain resistant

No sedimentation – no shaking or “rolling” prior to use

SOME THINGS NEED

SHAKEN … … V-PRINT DOES

VOCO Canada · toll-free 1-888-658-2584 · Fax 905-824-2788 · infousa@voco.com · www.voco.com Call 1-888-658-2584

TO BE

NOT

Validated for 3D printers from trusted partners like Asiga, Dental Wings, Rapid Shape, Microlay, MiiCraft, Ackuretta, Shera, Straumann and Solflex. For a complete list go to www.voco.dental/3dprintingpartners Introducing V-Print –

new line

3D Print resins: V-Print splint comfort V-Print dentbase V-Print splintV-Print modelV-Print model fastV-Print SG V-Print trayV-Print Try-In V-Print cast

a

of sedimentation-free

Mediloy® RPD • • •

The Largest Distributor of

Removable Prosthetic Teeth

Dentures and removables remain a big focus for Zahn Canada® as baby boomers’ needs and esthetic removable appliances grow we have your solution. We have made enhancements to our inventory and capabilities to meet your needs. Our distribution centres are strategically located across the country which enable us to service you more efficiently.

1-800-496-9500 www.zahncanada.ca

The Association of

Technologists of Ontario emphasized the importance of a national

for regulated dental professions, and with the help of the Dental Technology Association of British Columbia,

a

to ask RDTs across Canada their opinion

This document is printed on paper certified to the standards of the Forest Stewardship Council® (FSC®). THE OFFICIAL PUBLICATION OF THE DENTAL TECHNICIANS ASSOCIATION OF BRITISH COLUMBIA AND THE ASSOCIATION OF DENTAL TECHNOLOGISTS OF ONTARIO ©2024 Craig Kelman & Associates Ltd. All rights reserved. The contents of this publication may not be reproduced by any means, in whole or in part, without prior written consent from the publisher. Published by: 7181 Woodbine Avenue, Suite 235 Markham, ON L3R 1A3 Toll Free: 877-788-ADTO (2386) (within Ontario) Telephone: 416-742-ADTO (2386) Fax: 416-798-2613 www.adto.ca CONTENTS

#273 - 12100 Riverside Way Richmond, BC V6W 1K5 Ashley Opitz, Office Administrator Telephone: 604-278-6279 www.dtabc.ca 3rd Floor, 2020 Portage Avenue Winnipeg, MB R3J 0K4 Tel: 204-985-9780 Fax: 204-985-9795 Email: jenna@kelman.ca www.kelman.ca Managing Editor: Jenna Conrad Design/Layout: Kiersten Drysdale Marketing Manager: Chad Morrison Advertising Coordinator: Stefanie Hagidiakow Return undeliverable Canadian addresses to: Craig Kelman & Associates 3C-2020 Portage Avenue Winnipeg, MB R3J 0K4 Publication Mail Agreement: PM#40065075 DTABC President’s Message 6 ADTO President’s Message 8 HR Insider .................................................................................................................................. 10 Management Tips ................................................................................................................... 12 Classifieds 37 Advertiser Product & Service Centre 38 SPRW 2024 This magazine is printed on paper certified to the standards of the Forest Stewardship Council® (FSC®). 2024 Pacific Dental Conference ............................................... 14 A sneak peek at the Pacific Dental Conference, which will take place from March 7-9, 2024. To see the full program please visit www.pdconf.com Our Approach to a National Collective Voice ........................ 18

MB

on creating

national association. Full Denture Prosthetics – The Ultimate Discipline: Craftsmanship and Individual Specifications ......................... 21 CANDULOR’s 13th KunstZahnWerk competition once again showcased the sound skills and know-how of dental technicians in 2023. The winner was Sebastian Guttenberger and his winning case is overviewed in this article.

Nitrogen Is Essential for Your Dental 3D Printing Curing Oven ..................................... 32 Ackuretta discusses the benefits of incorporating nitrogen into the post-curing process

dental 3D printing, including enhanced mechanical properties, better aesthetics, consistent

curing, and maximized efficiency for dental workflows. 14 21 SPRING 2024 5

Dental

association

created

survey

a

Why

of

UV

MB #273 - 12100 Riverside Way Richmond, BC V6W 1K5

Ashley Opitz, Office Administrator Telephone: 604-278-6279 office@dtabc.ca www.dtabc.ca

DTABC PRESIDENT’S MESSAGE

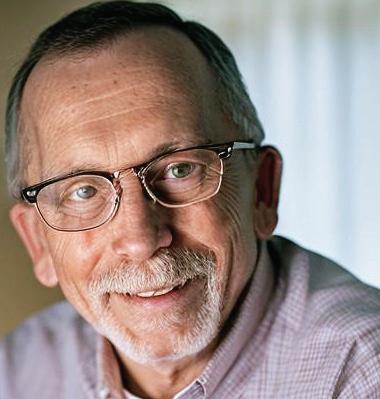

James Neuber, RDT, Past President, Dental Technicians Association of BC

Invest in Your Staff

IDTABC BOARD OF DIRECTORS

PRESIDENT

Will N. Varda, RDT, Anvarda Dental Services Ltd.

VICE-PRESIDENT

Calvin Moon, RDT, Moon Dental Technology Solutions

PAST PRESIDENT

James Neuber, RDT, Ocean Ceramics Ltd.

Ayumi Hirose, RDT, Nacre Dental Ceramics Ltd.

Mohammad Lashgary, RDT, Kinetic Dental Laboratory

Olaf Lutz, RDT, Okanagan Dental Lab Inc.

Chris Opitz, RDT, Shanto Dental Ceramics Ltd.

Donald Park, Smile Innovations Group

MANAGEMENT STAFF

Lih Fen Young, RDT Executive Director lih@dtabc.ca

Ashley Opitz Office Administrator office@dtabc.ca

’m wishing our professional community a happy and prosperous new year! The field offers abundant opportunities, particularly as digital markets expand. Zirconia remains a dominant material, whether for a single molar or a hybrid denture. Lithium disilicate materials are evolving, and 3D printing is finding broader applications in both labs and clinics. In times of significant market changes, there are substantial opportunities to seize.

Having spent over 30 years in this profession, I’ve identified three key factors that can navigate anyone through market shifts:

1. Education: Investing in continuous learning is essential to progress toward your goals.

2. Investment: Whether you’re a lab owner or an employee, financial investment in your education is crucial. The value of paid knowledge surpasses free information.

3. Network: Building relationships with peers, suppliers, and colleagues is vital. These connections offer support when faced with challenges in the field. This year’s Pacific Dental Conference (PDC) promises valuable insights to elevate technicians’ production capabilities. Sevan Purlurian will address common CAD and CAM challenges, Jimmy Stegall will teach

digital dentures in three appointments, Mark Chan will cover the basics of 3D printing, and Dr. Andrew Currie and Brian Lindke will share their clinical and lab processes for hybrid dentures. It’s a power-packed Saturday for technicians.

The PDC provides an exceptional opportunity for high-quality education and networking at an affordable cost. It is also a platform where potential clients seeking similar knowledge gather. If you missed the free early bird registration for PDC this year, available to all members of the Dental Technician Association of BC (DTABC), please join DTABC in time for PDC 2025. You can visit our website at www.dtabc.ca or contact DTABC at office@dtabc.ca for membership details. We are more than happy to address any questions or assist you in any way possible.

In closing, I wish you all a blessed year ahead, and we look forward to seeing you at the PDC!

James R. Neuber, RDT, Digital Full-Mouth Ceramist Past President Dental Technicians Association of BC

James R. Neuber, RDT, Digital Full-Mouth Ceramist Past President Dental Technicians Association of BC

In recognition of James’s unwavering dedication to the profession, we extend our heartfelt gratitude for his invaluable time and significant contributions to DTABC. His commitment has greatly enriched our community, and we sincerely appreciate his ongoing efforts. Additionally, we extend our warmest congratulations to Will Varda on assuming the role of President of DTABC. Will’s leadership and vision are sure to propel our organization to new heights, and we look forward to the positive impact he will bring. A warm welcome is also extended to Ayumi Hirose, our newest member, whose presence adds vibrant energy to our Board. Ayumi represents the promising generation of up-and-coming RDTs, and we are thrilled to have her. Lastly, a heartfelt thank you to Sachiyo Tsunemi for her outstanding contributions and commitment to DTABC during her three-year term on the Board. We wish her the very best in all her future endeavours.

DENTISTRY DEPENDS ON TECHNOLOGY

CLICK HERE TO RETURN TO TABLE OF CONTENTS

SPRING 2024 6

Box 397, 101-1001 West Broadway

7181 Woodbine Avenue, Suite 235

Vancouver, BC V6H 4E4

Markham, ON L3R 1A3

Ashley Opitz, Administrative Assistant

Toll Free: 1-877-788-ADTO (2386)

Toll Free: 1-888-495-4566

(within Ontario)

Telephone: 604-278-6279

Telephone: 416-742-ADTO (2386)

www.dentaltechniciansofbc.com

Fax: 416-798-2613

www.adto.ca

DTABC BOARD OF DIRECTORS

ADTO EXECUTIVE BOARD OF DIRECTORS

PRESIDENT

PRESIDENT

Hal Hamilton, RDT

Karim Sahil, MDT, RDT

VICE PRESIDENT

VICE-PRESIDENT

Chris Opitz, RDT

Shabana Mirza, RDT

John Eggeling, RDT

TREASURER

Nadja Jakobi, RDT

Aura Szigiato, RDT

Greg Tamkin, RDT

Stuart Thomson

SECRETARY

Debra Orozco Blanco, RDT

MANAGEMENT STAFF

ADTO PRESIDENT’S MESSAGE

Karim Sahil, MDT, RDT, President, Association of Dental Technologists of Ontario

Our Collective Voice

As we come out of the winter blues, spring seems to clear our path and vision, allowing us to move confidently and steadily.

This year will mark another advancement in the profession of dental technology. With the help of dental technologists and other professionals from different provinces, we were able to gather enough information to make a firm decision on our direction as a provincial association which focuses on the collective voice of RDTs. An in-depth summary can be read on pages 18-19 on our journey to meet RDTs across Canada on the solidification of our profession.

and four Dental Technology Academy courses, of which one will be in person; all courses are FREE for our members to attend and they will receive their yearly continuing education credits. We will also include many discounts on hands-on courses and CAD/CAM technology, with many accordances that exemplify a win-win situation. Our members can now benefit from the results, so let’s reap our harvest without apology.

Malcolm Ashford Executive Director

MEMBER BENEFITS

Chris Ji, RDT

DIRECTOR OF COMMUNICATIONS AND MEMBER SERVICES

EDUCATION

Aaliyah McPherson, RDT

Renata Cecconi

604-940-2995

PAST PRESIDENTS

2016-2020 - Franklin Parada

2010-2016 - Jason Robson

2007-2010 - Gabriel Ghazal

2004-2007 - Stephen DeLuca

2003 - Michael Hrabowsky

2001-2002 - Al McOrmond

2000 - David Kochberg

1999 - Thomas Kitsos

1998 - Feliks Dawidowicz

1997 - Wilhard Barth

1996 - Bob Huybrechts

1994-1995 - Andre Theberge

1992-1993 - Michael Hrabowsky

1990-1991 - Jamie Matera

1989 - Joe Nagy

With the industry back to its regular schedule this year, the ADTO will be having a summer event followed by a gala in the winter to welcome new graduates and RDTs to the dental technology profession. More details will be released closer to the dates; if you have attended previous ADTO events, then you know they are not events to miss. With the help of our partners and sponsors, we were able to create many different social events which created harmony with other dental associations and dental groups, and we can see the benefits today. We will continue to promote regulated healthcare professionals as a source that provides patient-centred care services.

It will also be another great year when it comes to continued education; we have included ten Toronto Implant Academy courses, of which two will be in person,

We highly encourage our members to attend and provide feedback for better development of future benefits. Technorama2024 and ASM2024 are two of the many upcoming in-person trade shows that should be kept on our calendars. The ADTO is a proponent of these in-person tradeshows, and we welcome all members to join and visit our booth. Many ideas and topics are always discussed, which helps us elevate our programs to benefit our members better. Please keep your eyes peeled for our e-blasts for important information coming this year. The Board of Directors would like to thank everyone for their continuous support and for giving us the possibility to serve.

Karim Sahil, MDT, RDT President Association of Dental Technologists of Ontario

“With the help of dental technologists and other professionals from different provinces, we were able to gather enough information to make a firm decision on our direction as a provincial association which focuses on the collective voice of RDTs.”

CLICK HERE TO RETURN TO TABLE OF CONTENTS

DEPENDS ON TECHNOLOGY

DENTISTRY

MDT, RDT

SPRING 2024 8

NEW THIS YEAR:

• The DAO is partnering with DIAC to offer education for new Denturism professionals.

•Original Show times with no exhibit floor shutdowns

•Elevated education

•New Entertainment

• New Sponsorships and More…

JOIN US AS WE REVIVE THE MAGIC THAT MADE TECHNORAMA LEGENDARY. COME BACK AND EXPERIENCE THE FUTURE BY EMBRACING OUR RICH PAST!

TNR 2024

5-6, 2024

Toronto Airport Hotel & Conference Centre

www.diac.ca/technorama

APRIL

Delta

Register today at

WE ARE TAKING TECHNORAMA BACK TO ITS ROOTS!

Spring Cleaning for Your Dental Lab: A Guide to Employee Management

Kiljon Shukullari, HR Advisory Manager, Peninsula Canada

It’s finally spring, making it the ideal time for your practice to consider refreshing your workplace, starting with employee management. Spring cleaning isn’t just for physical spaces; it’s an opportunity to streamline processes, enhance efficiency, and create a more positive work environment.

Below are some strategies to optimize employee management and ensure your dental lab runs at its best this season.

Streamlining Workflows

The arrival of spring brings a sense of freshness, making it a great time to reassess and refine your workflows. Identify areas where tasks can be streamlined, delegate responsibilities effectively, and establish a clear hierarchy of tasks. Encourage open communication among team members to address any inefficiencies that may have emerged over the winter months.

Task Prioritization

Spring cleaning involves sorting through the clutter and prioritizing what matters most. Ensure that critical tasks are given the attention they deserve, and consider implementing a system that efficiently manages appointments, patient records, and administrative duties. This will contribute to a smoother operation and reduce the risk of oversights.

Organizing the Workplace

A well-organized workplace contributes significantly to employee satisfaction and productivity. Take advantage of the spring season to declutter and reorganize shared spaces. Create an open space by incorporating elements of nature, such as potted plants or seasonal decorations. A tidy and welcoming environment positively influences both staff and patients.

Embracing Digital Solutions

Spring cleaning is synonymous with embracing new technologies and methodologies. Evaluate your current systems and explore digital solutions that can streamline administrative tasks. Whether it’s adopting electronic health records, implementing scheduling software, or utilizing communication platforms, incorporating modern technologies can lead to significant improvements in overall efficiency.

Team Collaboration

Spring is the season of growth and collaboration, making it an ideal time to strengthen the bonds within your team. Foster an environment of open communication and collaboration where team members feel comfortable sharing ideas and providing constructive feedback.

Consider organizing team-building activities that promote unity, reinforcing the idea that each member plays a crucial role in the success of the practice.

Just as the changing seasons prompt us to refresh our surroundings, spring provides an excellent opportunity for dental labs to reevaluate and optimize their employee management strategies. By streamlining workflows, prioritizing tasks, organizing the workplace, embracing digital solutions, and fostering team collaboration, your lab can enter the spring season with renewed energy and efficiency. A commitment to employee management is not only a step toward a more productive workplace but also a key factor in providing excellent service and crafting superior products.

Peninsula has been helping businesses with HR and health and safety compliance for 40 years. We are now trusted by over 120,000 SMB owners across the globe. In Canada, we support over 6,500 businesses in eight provinces, providing a service tailored to your business needs. Clients benefit from access to our 24/7 employer HR and OHS adviceline and coverage on legal through our Peninsula Protect Plus service promise. For more information, please visit www.peninsulagrouplimited.com/ca

CLICK HERE TO RETURN TO TABLE OF CONTENTS

HR INSIDER

SPRING 2024 10

Killarney -Ontario - Balsam lake www.micrylium.com 1-800-489-8868 Less Waste • Less Space PACK

MANAGEMENT TIPS

Ditch Negativity –Embrace Positivity!

Janice Wheeler, President, The Art Of Management Inc.

Check out This Positivity Story: A Tale of Two Frogs

A group of frogs travelled through the woods, and two fell into a deep pit. When the other frogs saw how deep the pit was, they told the two frogs that they were as good as dead. The two frogs ignored the comments and tried to jump out of the pit with all their might. The other frogs kept telling them to stop, that they were just wasting their energy. Finally, one of the frogs took heed of what the other frogs were saying and gave up. He fell back down and died.

The other frog continued to jump as hard as he could. Once again, the crowd of frogs yelled at him to stop and let death come. He leaped even harder and finally made it out. When he got out, the other frogs said, “Did you not hear us?” The frog explained to them that he was deaf. He thought they were encouraging him the entire time!

How Does This Apply to You?

Have you imagined some pretty amazing goals for yourself and your lab, and are you having trouble accomplishing them? If so, is it possible that you have naysayers in your environment who make you feel you can’t achieve those goals? Have a ‘look,’ and if you have such people opposing you, decide to turn a deaf ear to them. Listen to those around you who are encouraging you and helping you.

Don’t Get Stuck in the Past

You may also have experienced past years where your goals were not reached, the targets were not achieved, and basically little changed. You can unwittingly drag this

negativity into the present and become the reason you might be unwilling to set new horizons for the lab – for fear of failure.

In fact, it is common that the focus gets stuck on the failures, which colour the business’s future success with a bit of gloom. Here is a microscopic example of what we mean: On a day-to-day basis, have you ever experienced a brilliant day of creating perfect crowns, bridges, dentures, etc., perfectly smoothly, and then things didn’t go so well with the last one for the day? Did you go home all happy, or did you go home all gloomy? Even though 95% of your day went perfectly?

Somehow, the one setback is the one that gets focused on and bums you out. The successes are ignored, and the setbacks get all the attention. While learning from your mistakes and improving one’s abilities and techniques is appropriate, it is not healthy to focus on them.

An individual can get to a point where they think they are a failure despite 95% of their work being perfect. The more you focus on negativity, the more likely you will see it.

Adjust Your Focus

Therefore, the trick is to focus on the wins, the successes, and the things that are going right. A very healthy exercise is to look at all the things that you have made happen (and all the successes that you have had) before setting new goals or objectives.

You generally will find that you have accomplished quite a bit and can achieve even more IF you focus on the positives (achievements and successes) and ignore the losses.

And Your Team Needs You!

Similarly, don’t forget that your staff also needs YOU to encourage THEM to accomplish their life goals and do well in their jobs. Positivity and enthusiasm for the team should emanate from you.

In Closing

Embrace positivity as your new way of looking at everything. Focus on the good things and look for ways to succeed more often. You can achieve GREAT things and are far more capable than you’ve given yourself credit for!

CLICK HERE TO RETURN TO TABLE OF CONTENTS JANICE WHEELER is the President and co-owner of The Art Of Management Inc., a practice management company dedicated to helping healthcare professionals reach their full potential. For more information, call 416-466 6217, email ami@amican.com, or go to www.amican.com

SPRING 2024 12

PrimeTaper EV ™

installation

OsseoSpeed® surface maintains marginal bone for predictability and clinical

And MicroThread® design mechanically stimulates long-term bone maintenance. Experience an efficient approach to bone maintenance today. 1

Immed ate.

Implant.

Its

Norton MR, Astrom M. The influence of implant surface on maintenance of marginal bone levels for three premium implant brands: A systematic review and meta-analysis. Int J Oral Maxillofac Implants 2020;35(6):1099-111 Dentsply Sirona does not waive any right to its trademarks by not using the symbols ® or ™. 32672842-USX-2312 ©2023 Dentsply Sirona. All rights reserved. Advance with confidence with the PrimeTaper EV ™ Implant and our full EV Implant Family at www.dentsplysirona.com. Part of the Implants Signature Workflows powered by DS Core™. PrimeTaper EV™ Implant Astra Tech Implant® EV OmniTaper EV™ Implant

Implant Shorten your implant

procedure with the innovative PrimeTaper EV ™

Its self-cutting threads cut quickly and engage for linear torque build up.

confidence.1

Pacific Dental Conference

Dental Technicians Association of British Columbia Annual Conference

Saturday, March 9, 2024

Vancouver Convention Centre – West Building

We welcome all Dental Technicians and other dental practitioners to join us for the full three days of programming and social events at the Pacific Dental Conference March 7-9, 2024 including the one day of DTABC programming on Saturday, March 9, 2024

Welcome

Lih Fen Young Director, DTABC

Lih Fen Young Director, DTABC

We are very excited about the program at this year’s conference in partnership with the Pacific Dental Conference [PDC].

This conference provides us the opportunity to come together under one roof and strengthen the profession of dental technology.

The PDC Exhibit Hall (March 7-8) will showcase suppliers with the latest dental technology equipment, materials and methods. We encourage you to spend time visiting the booths to gain insight and network with our industry partners. The breakout sessions on Saturday, feature leading experts who are able to share their knowledge and tips that will help you in your profession.

On behalf of the Board of Directors of the DTABC and our partners at PDC, I would like to thank you for making our annual conference a success and for making it a priority in your continuing education and networking activities. Enjoy and have fun!

2024 DTABC Organizing Committee

Julie Izumi, RDT

Samuel Job, RDT

James Neuber, RDT

Lih Fen Young, RDT, SME

Zoie Jansen, PDC Staff

Bruce Ward Director, PDC

Bruce Ward Director, PDC

Welcome to the 2024 Pacific Dental Conference (PDC), Canada’s largest dental conference taking place between March 7-9, 2024 at the Vancouver Convention Centre.

The PDC welcomes registered attendees to all lectures and exhibits. Make sure you make time on Thursday and Friday to visit the Exhibit Hall as it presents a fantastic opportunity for attendees to explore the latest technologies and equipment offered by a specialized selection of exhibitors.

A big thank you to all the registered attendees for joining PDC, and to the organizers for putting together an exciting event. The promise of an incredible three days, filled with learning, socializing, and enjoyment, sets the stage for a memorable and enriching experience. Wishing everyone a successful and rewarding time at the 2024 Pacific Dental Conference!

Pacific Dental Conference

Concurrent Sessions (morning)

The Power of Digital Workflows

Frankie Acosta, DT

Saturday, 9:00am - 10:30am VCC West - Room 205/206/207

Learning Pattern: Clinical Excellence Digital Dentistry, Removable Prosthodontics, Technology

Frankie Acosta has been a dental technician since 1986. He has owned and operated three full service laboratories. At AA Dental Design, he has built a powerhouse focused on Digital Workflows.

In this lecture, I will take you through all the digital workflows available. Showing you several digital integrations using all types of SW’s and equipment. It is all about the Digital Workflows available today!

Co-sponsored by Dentsply Sirona

So You Want to be a Dental CAD Designer? Do You Have What it Takes?

Sevan Pulurian

Saturday, 9:00am - 10:30am

VCC West - Room 208/209

Learning Pattern: Clinical Excellence Dental Technician

Next Level Dentures –In 3 Appointments!

Jimmy Stegall, MBA, CDT

Saturday, 9:00am - 10:30am VCC West - Room 202/203/204

Learning Pattern: Clinical Excellence Dental Technician

Sevan Pulurian is the Director of CAD/CAM at Pacific Dental, Inc., based in California, where has been for 22 years. Active in the industry since 2001, Sevan has influenced and improved the CAD/CAM technology industry, working with Cerec inlab, Nobel BioCare Mod40 and Forte systems. He’s been a 3Shape Specialist since 2012. He is also a K.O.L. for 3Shape and many other companies.

Everyone wants to be a designer. But is it really that simple? Do you have what it takes? Lets have fun on a 90-min journey into twisted, fun yet crazy world of 3Shape Dental CAD.

Embracing a New Business Model of Open Collaboration

Bob Piercy, BA, BComm

Saturday, 11:00am - 12:30pm VCC West - Room 202/203/204

Learning Pattern: Clinical Excellence Dental Technician

Jimmy Stegall is a dental industry operational guru with over four decades of experience as a technical and clinical educator, author, and research collaborator. He helped build and lead a major dental lab and has now presented 430+ educational events for Dentsply Sirona. As a thought leader, educator, mentor, he has helped to advance digital techniques in dental practices and labs across North America.

Clinical guidelines and record taking methods of digital denture workflows for immediate, reference, and traditional complete dentures, plus the latest materials and technologies will be presented that make chairside steps easier, and results more predictable for the patient, clinician, and technician. Co-sponsored by Dentsply Sirona

With over 15 years of dedicated experience in the dental industry, Bob Piercy has assisted doctors, denturists, and dental labs in delivering exceptional patient care while enhancing the efficiency and profitability of their operations. Piercy envisions a future where state-of-the-art digital solutions will enable practitioners to elevate the quality of care they provide to their valued patients.

This presentation explores the concept of adopting a new business model centered around open communication, knowledge sharing, and strategic partnerships, and how it can be a catalyst for future business success.

Complete Pacific Dental Conference information at... www.pdconf.com Dental Technicians of BC – Sessions Dental Technicians of BC – Sessions Saturday, March 9

Concurrent Sessions (morning)

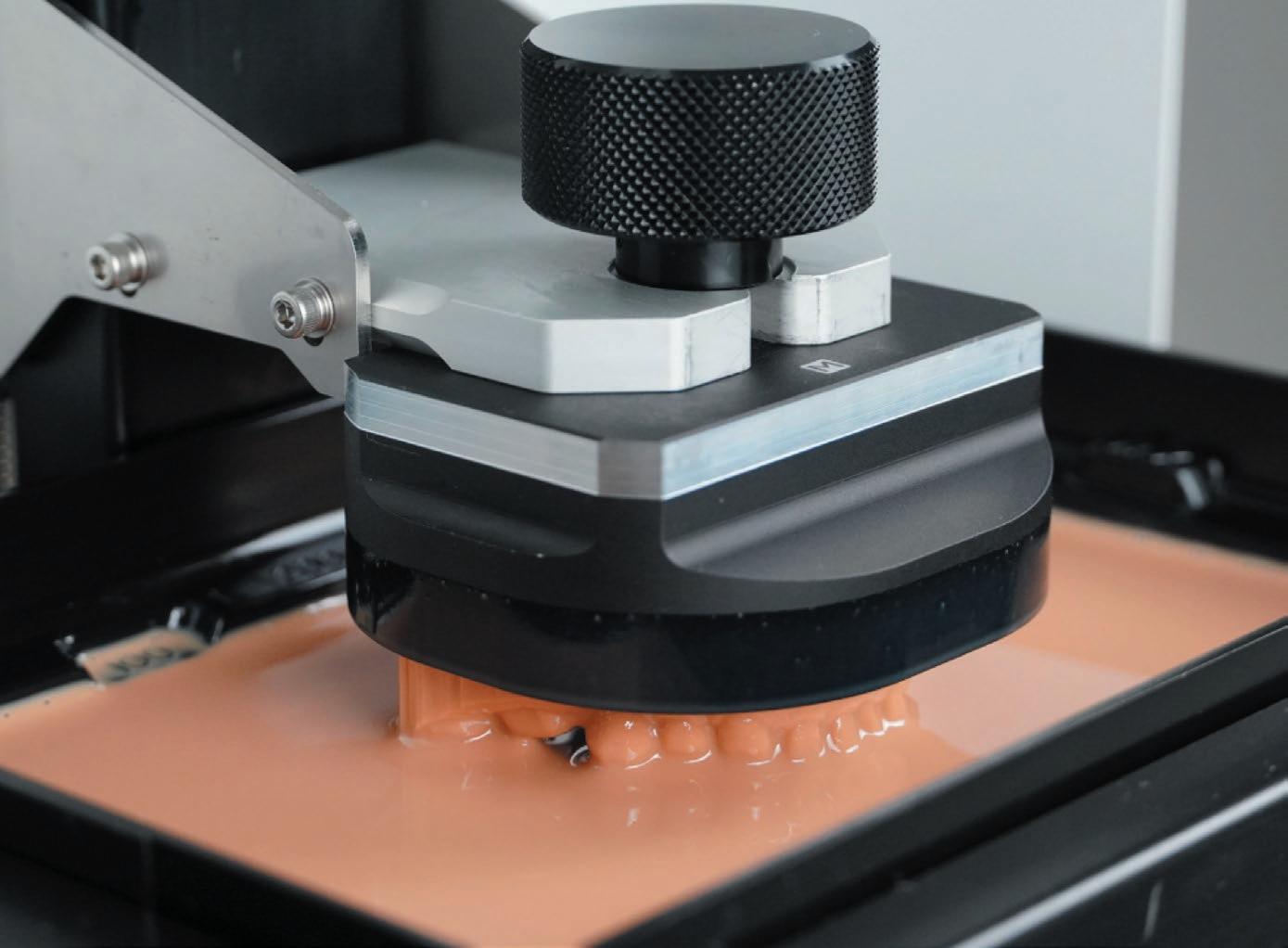

Becoming a Master of CAM Understanding Subtractive Manufacturing

Sevan Pulurian

Saturday, 11:00am - 12:30pm

VCC West - Room 208/209

Learning Pattern: Clinical Excellence Dental Technician

3D Printing Best Practice & Preventive Maintenance for the Modern Day Dental Practice

Mark Chan, DD

Saturday, 11:00am - 12:30pm

VCC West - Room 205/206/207

Learning Pattern: Clinical Excellence Dental Technician

Sevan Pulurian is the Director of CAD/CAM at Pacific Dental, Inc., based in California, where has been for 22 years. Active in the industry since 2001, Sevan has influenced and improved the CAD/CAM technology industry, working with Cerec inlab, Nobel BioCare Mod40 and Forte systems. He’s been a 3Shape Specialist since 2012. He is also a K.O.L. for 3Shape and many other companies.

Let’s take a deep dive into the complex yet simple world of Computer Aided Manufacturing. Get a better understanding of how it all works to get the perfect result.

Concurrent Sessions (afternoon)

A Fly on the Wall: What Every Lab Technician Wants to Tell Their Dentists, but Won’t

Miles Cone, DMD, MS, CDT, FACP

Saturday, 1:30pm - 3:00pm

VCC West - Room 205/206/207

Learning Pattern: Clinical Excellence Digital Dentistry, Fixed Prosthodontics, Photography

Advancements in Full Arch Implant Dentistry – Laboratory

Andrew Currie, DMD, MS, DICOI

Brian Lindke, CDT

Saturday, 1:30pm - 3:00pm

VCC West - Room 202/203/204

Learning Pattern: Clinical Excellence Dental Technician, Implants

Mark Chan joined the Swiss NF team in 2020 as a Techno-Clinical Advisor. In 2009, he received his diploma from Denturism in Toronto at George Brown College with honours. Currently, Mark is practicing in Ontario with a main focus on high-end removable and implant prosthetics. With a passion for both technical and clinical techniques, he is certified in Bio-logic, BPS and SDC denture concepts.

3D Printing Best Practice and Preventive Maintenance for the modern day dental practice. This session will go through basic best practices for modern day dental practice that can be applied to all 3D printers.

Miles Cone graduated from Tufts Dental School and completed a three-year prosthodontic residency in the US Army. In addition to achieving board certification and diplomate status within his specialty, Dr. Cone has earned his designation as a Certified Dental Technician. Dr. Cone’s career centers on his role as a is Key Opinion Leader and co-owner of Nuance Dental Specialists in Portland, Maine.

Dentists are often unaware that their clinical work is not up to the standards required by the dental lab to complete a case with predictability and success. This course will examine the salient pain points dental technicians endure to maintain the business of the dental offices they work with.

Co-sponsored by Curion

After dental school, Andrew Currie completed a two-year, surgery-focused GPR at the Medical College of Georgia. Since 2012 he has dedicated his practice to surgical and implant dentistry, and he handles most of the surgery for his five office locations. Teaching has been a passion of Dr. Currie’s since 2010, and he lectures on implant surgery, grafting, digital dentistry, 3D printing, and implant prosthetics.

Brian Lindke is the owner of SYNrG Lab in Buford, GA specializing in Full digital workflows for immediate load implant dentistry. Specifically, all on 4 and all on 6 protocols. Brian is a key instructor for ITXPros, InstaRisa, Anaxdent and 3DSystems. He maintains an active teaching schedule both nationally and internationally.

Current materials, methods and workflows to keep you on the cutting edge. Topics covered include - implementing today’s newest cutting-edge technologies; Digital 3D Facial analysis; Virtual implant planning and Implant guide design and fabrication.

Dental Technicians of BC – Sessions Dental Technicians of BC – Sessions Saturday, March 9

Other sessions of interest to Dental Technicians of BC Other sessions of interest to Dental Technicians of BC

CSI: Compliance, Safety & Inspections. How to Survive WorkSafeBC Inspections

Blake Clemes, BA, DDS

Thursday, 1:30pm - 4:00pm

VCC West - Room 224

Repeated on Friday, 1:30pm - 4:00pm

VCC West - Room 304/305

Learning Pattern: Clinical Excellence Safety/Infection Control Practice Management

Hot Topics in Infection Control: And Some Cool Tips

Nancy Dewhirst, BSDH, RDH

Friday, 9:00am - 11:30am

VCC East - Ballroom B

Repeated on Friday, 2:00pm - 4:30pm

VCC East - Ballroom B

Learning Pattern: Clinical Excellence Safety/Infection Control Dental Hygiene

Advancements in Full Arch Implant Dentistry – Clinical

Andrew Currie, DMD, MS, DICOI

Brian Lindke, CDT

Friday, 8:30am - 11:00am

VCC West - Room 224

Learning Pattern: Clinical Excellence Dental Technician, Implants

Blake Clemes is an ODA Past President. He has lectured on Health & Safety Legislation as applied to dental offices since 2012. He received his DDS from Western University and completed a Hospital Residency in London, Ontario in 1984. He has received the ODA Service Award and Barnabus Day Award and the Western Dental School Alumni of Distinction Award. He has also received numerous fellowships.

This course covers the legal requirements of the Occupational Health and Safety Regulation under the Workers Compensation Act as per WorkSafeBC as applied in dental offices. You will know the steps required and have the tools necessary to be compliant with this current health and safety legislation.

Nancy Dewhirst practiced dental hygiene for 20 years, is an adjunct dental hygiene faculty at West Coast University, and is a member of Sigma Phi Alpha. She presents over 100 seminars annually in the US and Canada, is Editor-inChief of OSAP’s peer-reviewed Infection Control In Practice, and is published in numerous dental journals, textbooks, and guidance documents.

Update and review the most critical clinical safety concerns and get some cool tips for these hot topics! Optimize the most effective strategies to understand safety challenges, and apply laws, guidelines, and practices to prevent and control infection.

After dental school, Andrew Currie completed a two-year, surgery-focused GPR at the Medical College of Georgia. Since 2012 he has dedicated his practice to surgical and implant dentistry, and he handles most of the surgery for his five office locations. Teaching has been a passion of Dr. Currie’s since 2010, and he lectures on implant surgery, grafting, digital dentistry, 3D printing, and implant prosthetics.

Brian Lindke is the owner of SYNrG Lab in Buford, GA specializing in Full digital workflows for immediate load implant dentistry. Specifically, all on 4 and all on 6 protocols. Brian is a key instructor for ITXPros, InstaRisa, Anaxdent and 3DSystems. He maintains an active teaching schedule both nationally and internationally.

Brian Lindke and Dr. Andrew Currie present creative Clinical and Laboratory processes that raise the bar and increase amazing results. They cover implementing today’s newest cutting-edge technologies; Digital 3D Facial analysis, Virtual implant planning and Implant guide use for efficient, consistent accuracy; which prosthetic materials are best and why; and final prosthetics selection based on prosthetically driven determinants.

Carte Blanche: Aesthetic + Functional Foundations for Removable Full-Arch Prosthetics

Miles Cone, DMD, MS, CDT, FACP

Friday, 1:30pm - 4:00pm

VCC West - Room 302/303

Learning Pattern: Clinical Excellence Digital Dentistry, Fixed Prosthodontics, Photography

Miles Cone graduated from Tufts Dental School and completed a three-year Prosthodontic residency in the US Army. In addition to achieving board certification and diplomate status within his specialty, Dr. Cone has earned his designation as a Certified Dental Technician. Dr. Cone’s career centers on his role as a is Key Opinion Leader and co-owner of Nuance Dental Specialists in Portland, Maine.

Much of what clinicians have learned about removable prosthetics is flawed, and based on outdated, dogmatic principles. This course will discuss cases studies and outline low-cost materials and streamlined techniques for treating edentulous patients with predictable, and profitable outcomes.

Co-sponsored by Cerum Ortho

Our Approach to a National Collective Voice

Dentistry advances with important discussions on topics which relate to all regulated dental professions. Many of these discussions and decisions are made nationally, which eventually branch out from province to province. With the fast-changing world of artificial intelligence, these changes can come much faster than we think. How these changes will affect us should be dictated by a dental technologist.

Dr. James Taylor, the Chief Dental Officer of Canada, had reached out to ask why dental technology does not have a national association like all the other regulated dental professions. If we are not making major decisions on the future of our profession, that means someone else is; this causes us to think, which suggests it’s essential.

“After many discussions, the Association of Dental Technologists of Ontario (ADTO) emphasized the importance of a national association with the College of Dental Technologists of Ontario (CDTO) and the Canadian Alliance of Dental Technology Regulators (CADTR).”

After many discussions, the Association of Dental Technologists of Ontario (ADTO) emphasized the importance of a national association with the College of Dental Technologists of Ontario (CDTO) and the Canadian Alliance of Dental Technology Regulators (CADTR). We were inspired to take on the leadership role with the help of

the Dental Technology Association of British Columbia (DTABC) to open dialogue with other associations across Canada. Surprisingly, we found out that many provinces do not have a professional association. Without the support of an association, we can imagine the lack of support RDTs have across Canada. This also was a big concern. After months

SURVEY RESPONSES FROM AB, BC, ON & QC

CLICK HERE TO RETURN TO TABLE OF CONTENTS

100% 90% 80% 70% 60% 50% 40% 30% 20% 10% 0% Strongly Agree Agree Disagree Strongly Disagree Do you feel a national association will benefit the industry of dental technology and RDTs? A national suggested Fee Guide is beneficial to all RDTs across Canada RDTs need a voice at the table on a national level, to represent the profession of dental technology, like other regulated healthcare professions All provinces should support a national association of dental technology to represent RDTs across Canada in national meetings regarding the profession Changes in the progression of the dental technology profession should remain in the voice of RDTs All dental prostheses created must be supervised by an RDT or a dentist 98% 2% 61% 30% 7% 80% 19% 73% 24% 1% 72% 28% 82% 16% 2% Association of

Dental Technologists of Ontario

SPRING 2024 18

of planning and brainstorming, our board decided it was necessary to come face-to-face with professionals from other provinces.

The ADTO Board created a two-year goal, which was presented at our 2022 AGM.

the advancement of the dental technology profession in Ontario. The results we received were as expected as the sun rises after nightfall; after all, we are dental technologists, and that group identity has

caught their interest. With the creation of a national association, a suggested fee guide can potentially be distributed nationally to all members of that national association. This method has worked very well for other

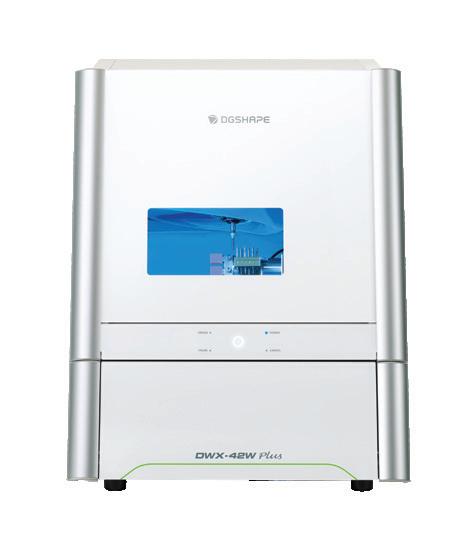

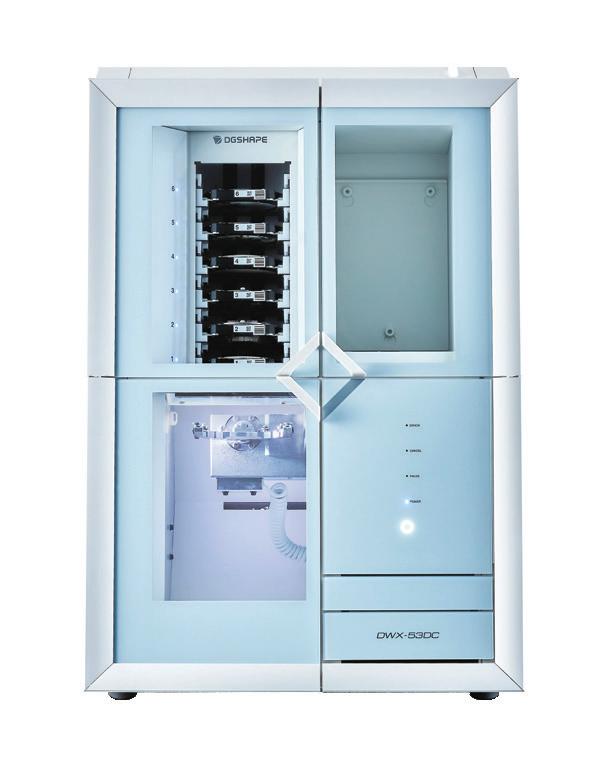

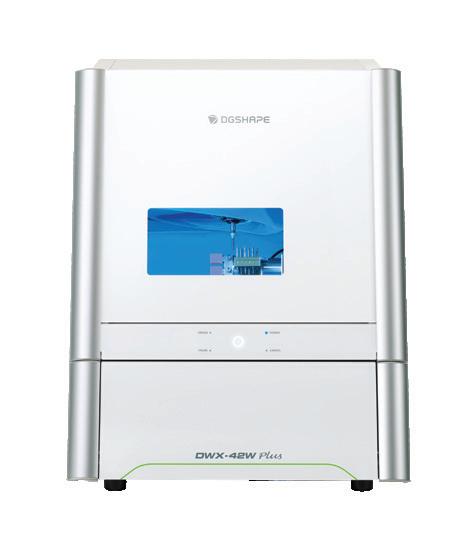

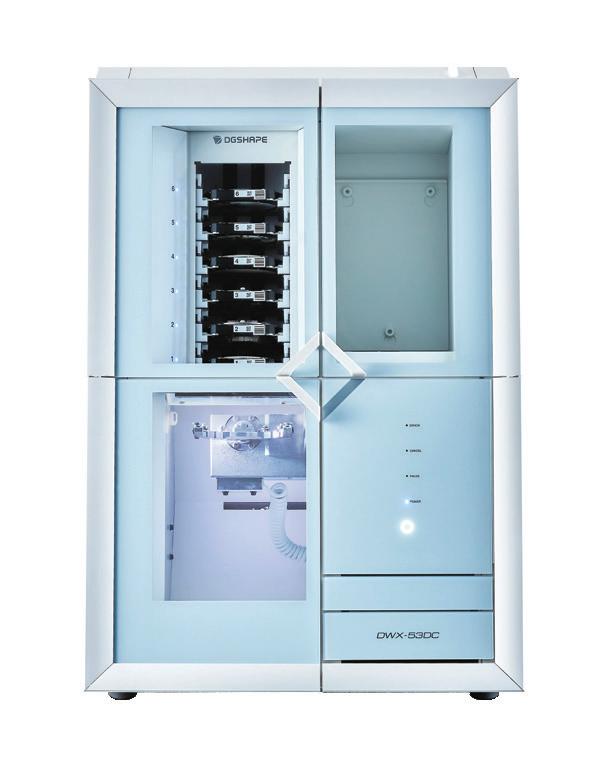

Discover the DGSHAPE Di erence

Roland DGA’s DGSHAPE delivers the competitive advantage for your dental business.

The most trusted name in milling brings product confidence and value to a whole new level. And NOW for a limited time get a FREE 3rd Year Warranty * on the DGSHAPE DWX-53DC, Dry Dental Mill with Automatic Disc Changer.

The DWX-53DC is built to build your dental business as a PMMA and Zirconia workhorse for milling digital dentures, crown and bridge applications, and more. DGSHAPE’s DWX-53DC makes 24-hour production as easy as 1,2,3…Power it on, let it go, and automatically mill jobs unattended.

O ering complete confidence to users of all types, that’s the DGSHAPE Di erence!

CLICK HERE TO RETURN TO TABLE OF CONTENTS

DWX-42W

DWX-52D

*O er valid 01/01/2024 to 03/31/2024 in US, Canada and Latin America only. Terms and conditions apply. Pricing reflects US MSRP. Cannot be combined with any other o er or prior purchase. dgshapeamericas.com/lab SPRING 2024 19

VITA YZ Solutions include zirconia discs in four degrees of transparency, available in White, Color and Multicolor for the fabrication of precise and true-to-shade partially / fully veneered and monolithic restorations. VITA YZ discs are highly accurate due to edge stability, homogeneous microstructure and tested sintering properties.

VITA YZ® Solutions Available in 3D-MASTER Shades 100 YEARS

VITA YZ® ST

© 2024 VITA North America. VITA YZ® Solutions is a registered trademark of VITA Zahnfabrik. 800-828-3839 | vitanorthamerica.com

FULL DENTURE PROSTHETICS –THE ULTIMATE DISCIPLINE:

Craftsmanship and Individual Specifications

Sebastian Guttenberger, MDT – Pirk, Germany

KunstZahnWerk and the Importance of Traditional Manufacturing Methods in a Digital Age

CANDULOR’s 13th KunstZahnWerk competition once again showcased the sound skills and know-how of dental technicians in 2023. This year, we again focused on the fabrication of mucosa-supported full dentures in the maxilla and mandible. The participants completed their competition work based on a detailed model analysis. Among them, Sebastian Guttenberger (Zahntechnik Hierold, Pirk, Germany) accepted the challenge and won first place. In fact, he achieved a double victory, as he also took first place for the documentation of his work. What at first seemed unachievable thus turned into a personal achievement for him and a confirmation of his technical dental skills. In this article, he describes his work philosophy and goes into detail about the competition work.

When dental technology meets passion, the result is a combination of craftsmanship and anatomical-functional understanding. Dental technology competitions such as the KunstZahnWerk are venues for this energy and provide a stage for measuring one’s talents and advancing skills. Participation in the KunstZahnWerk, which is all about full dentures and where dental technicians from all over the world have their work judged by a renowned jury of experts, may, at first sight, seem unattainable. For me, too, the dream of participating had been there for a long time. But my master craftsman’s examination had priority. After successful graduation –and apart from the daily work of fabricating high-quality dental restorations – came the question of which further professional goals to pursue. And that is when KunstZahnWerk sprang to mind again. It was time to face the dream. Backing from my employer and my family provided the necessary incentive. So, full dentures occupied my mind for several weeks.

PATIENT-CUSTOMIZED FULL DENTURES

What is the role of full dentures in the age of artificial intelligence (AI), automation, and CAD/CAM manufacturing? What relevance do manual skills still have? These questions occupy the minds of many of my colleagues. Digitization undoubtedly offers many advantages. However, full

dentures still represent handcrafted work. The realization of aesthetic, functional, and patient-specific aspects that make up a ‘good’ full denture requires skills such as observation, creativity, and an understanding of functional relationships. The basic idea behind the fabrication of dentures is always the same: a denture should be comfortable to wear and inconspicuous for the patient. The focus is on the natural shape of the teeth and – depending on the tooth replacement solution – of the gingiva. Be it digital or analog, a number of preliminary considerations are required prior to realization to prevent problems from occurring in the first place. Digitization is particularly helpful for fixed denture solutions. Digital design not only allows the frameworks to be created but also enables a fully anatomical situation to be defined as the target. This can, for example, be realized by means of 3D printing. Digital technologies can also prove helpful for full dentures. In principle, however, full dentures are based on a sound knowledge of traditional fabrication methods and on taking the patient’s individual circumstances into account.

COMPETITION ENTRY (KUNSTZAHNWERK 2023)

FEMALE PATIENT AND TASK

A mucosa-supported maxillary and mandibular denture is to be created for

a 69-year-old female patient. In the maxilla, the patient has been fitted with a denture for 15 years. Initially anchored via double crowns, abutment teeth 21, 22 and 23* had to be removed. She wears an interim denture in the mandible after teeth 35-44 and 46* had to be extracted due to advanced periodontitis.

• The task: natural-looking dentures according to the dynamic occlusion concepts tooth-totooth or tooth-to-two-tooth setup. This is aggravated by a pronounced atrophy in the mandible, a slight flabby ridge in region 32 to 42* and a change in the mucosa (leukoplakia) in region 35*. The existing dentures exhibit several deficits. The anterior teeth are barely visible in both the upper and lower jaws. Due to the low vertical proportion, the lower third of the face appears squat and the chin pointed. The patient complains about inadequate denture retention. She can only eat by using adhesive cream to fixate the denture in her mouth. She would like a denture with a firm hold, visually more prominent anterior teeth, age-appropriate aesthetics, and adequate chewing performance. Also important to her is an appealing facial appearance, where the chin appears less pointed. Youth photos serve as an orientation.

• The challenge: age-appropriate dentures (full dentures) at pronounced atrophy in the mandible.

CLICK HERE TO RETURN TO TABLE OF CONTENTS

SPRING 2024 21

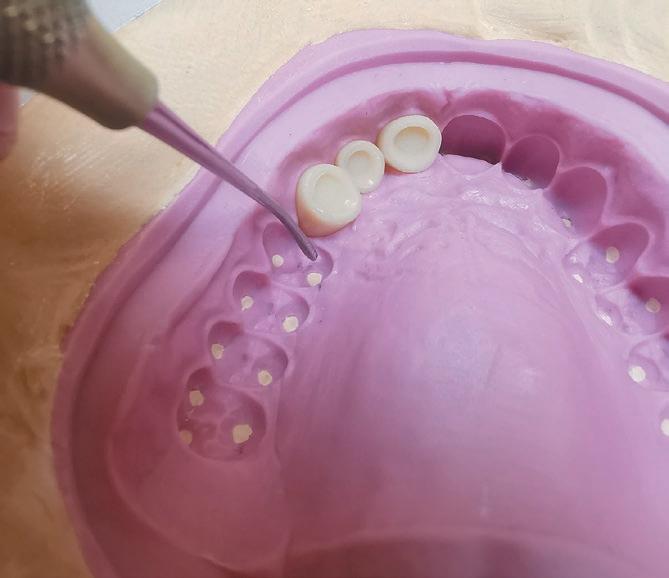

PREPARATORY STEPS BY THE DENTAL TECHNICIAN

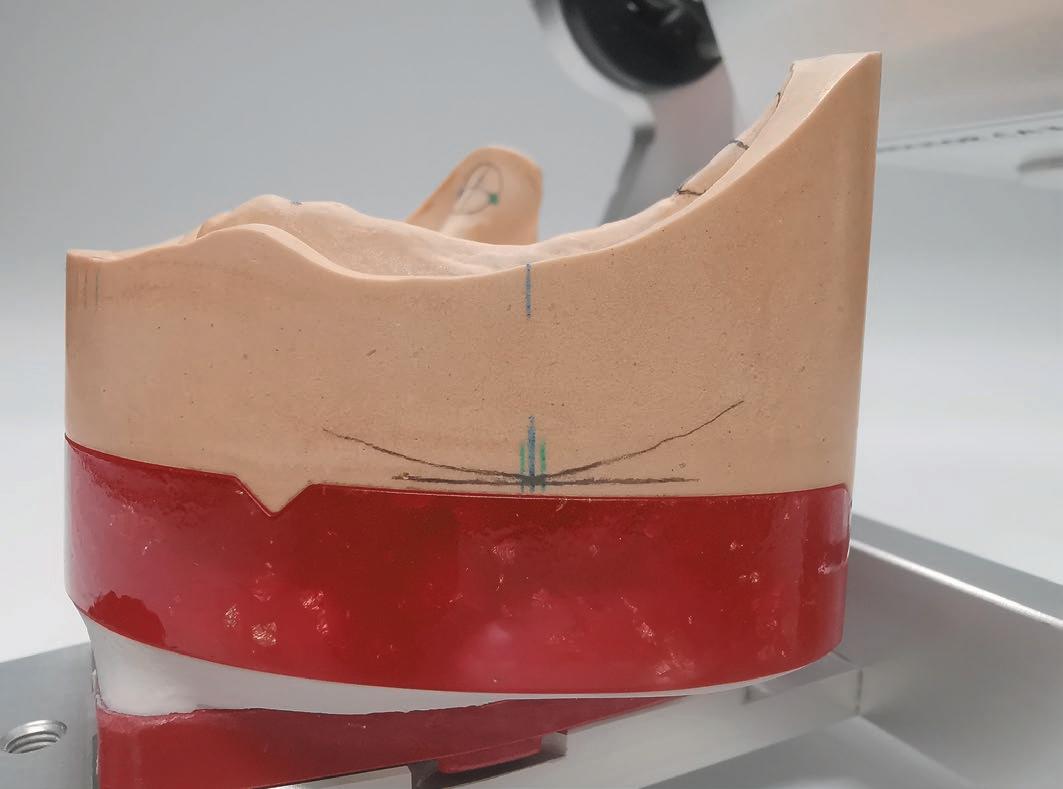

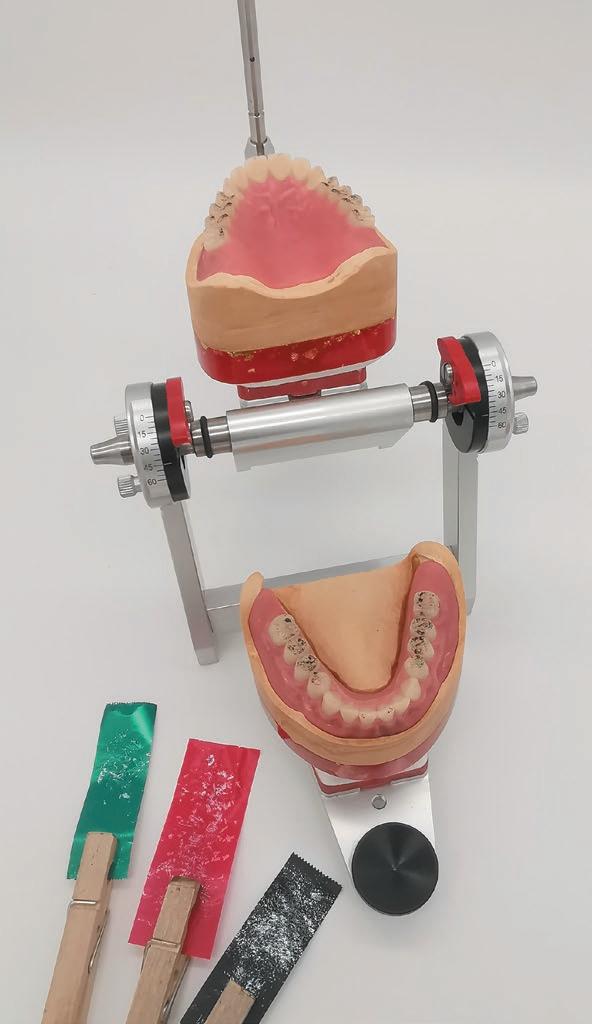

The models of the maxilla and mandible are duplicated, and the master models are fitted with rotation locks (brass cones, milled grooves, magnet) for a Splitcast base (Figures 1 and 2). Preliminary technical dental considerations:

• The increase in vertical relation must be taken into account when articulating.

• As the flabby ridge can lead to a poor suction effect of the denture, adequate finishing of the denture body is required (buccinator support, muscle-gripping denture body, margin design).

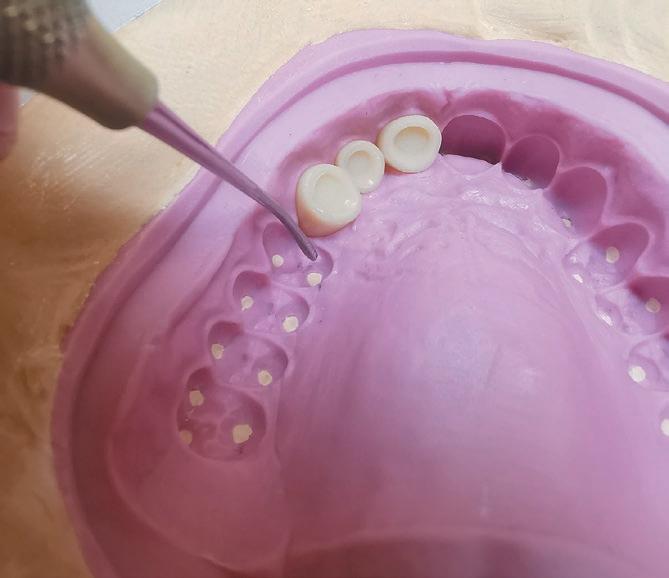

• For an individual set-up of the maxillary teeth according to the physiognomic bite key, a silicone matrix is helpful as a control element (Figure 3).

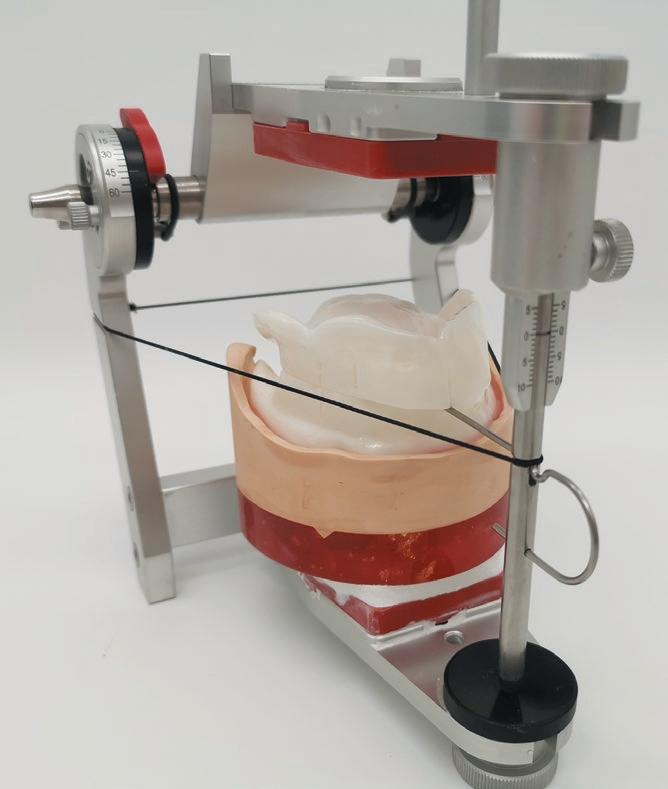

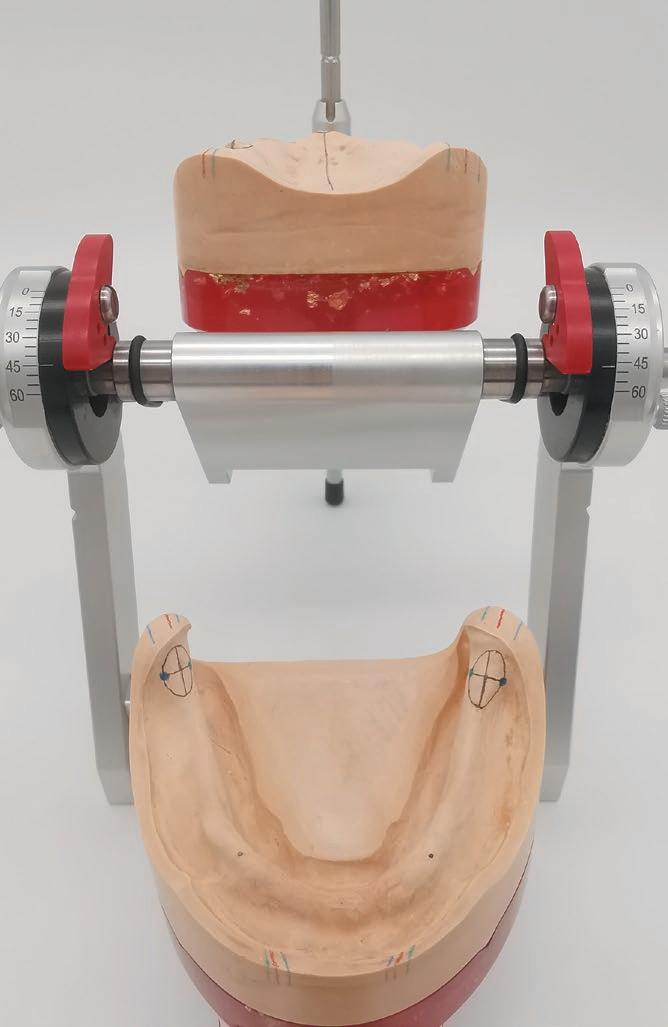

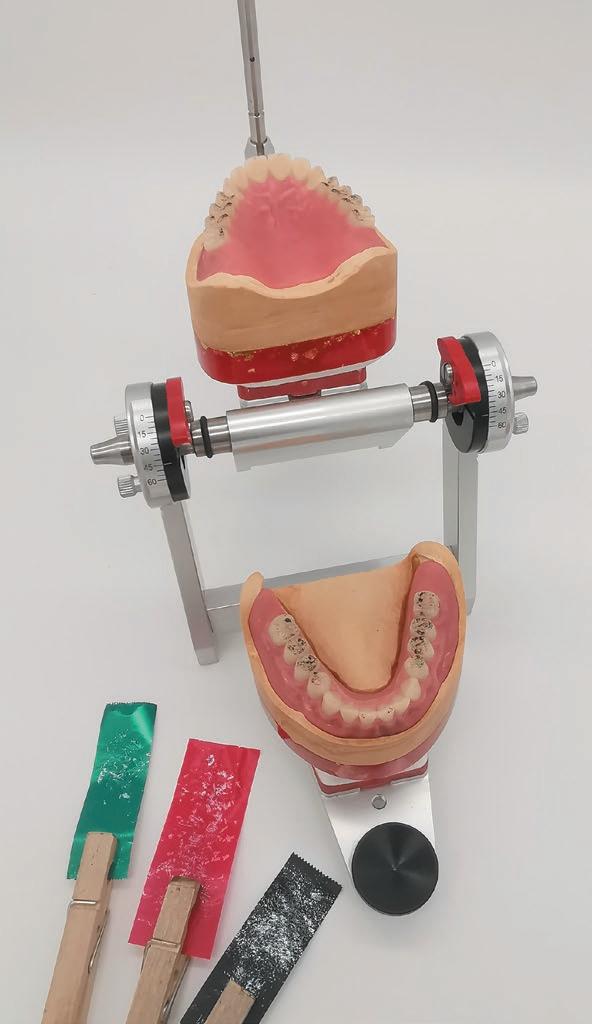

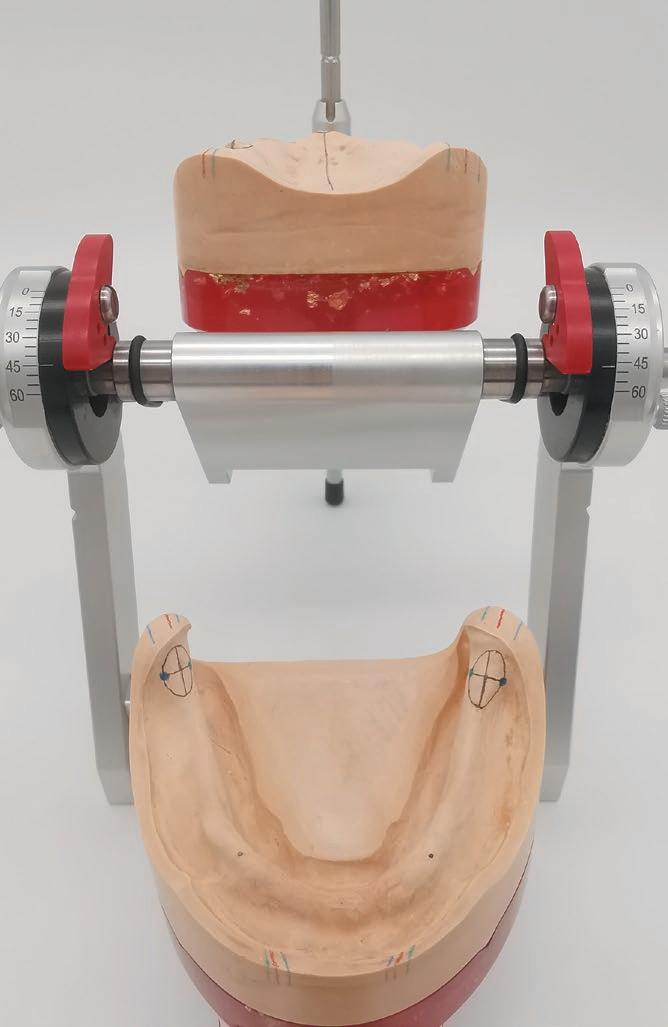

ASSIGNMENT OF THE MODELS IN THE ARTICULATOR

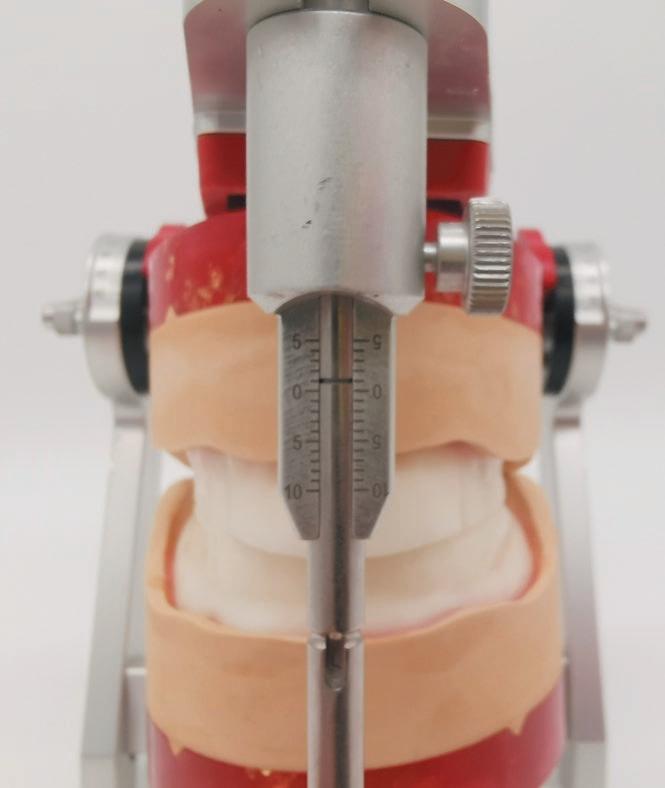

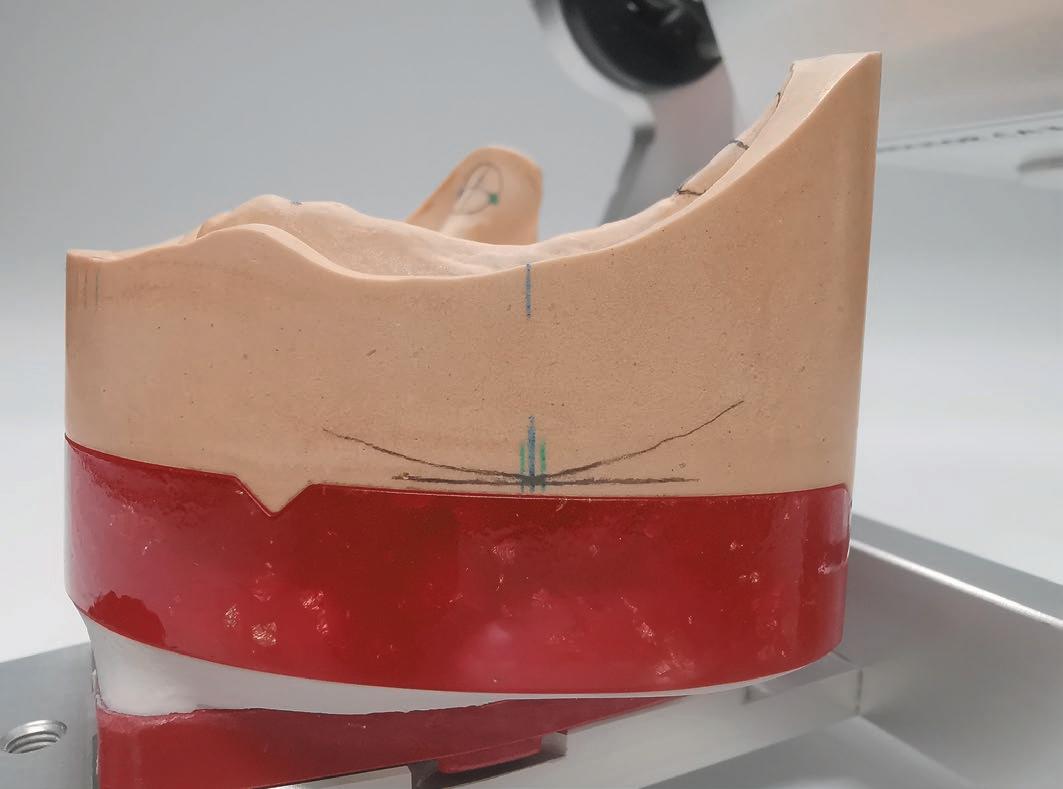

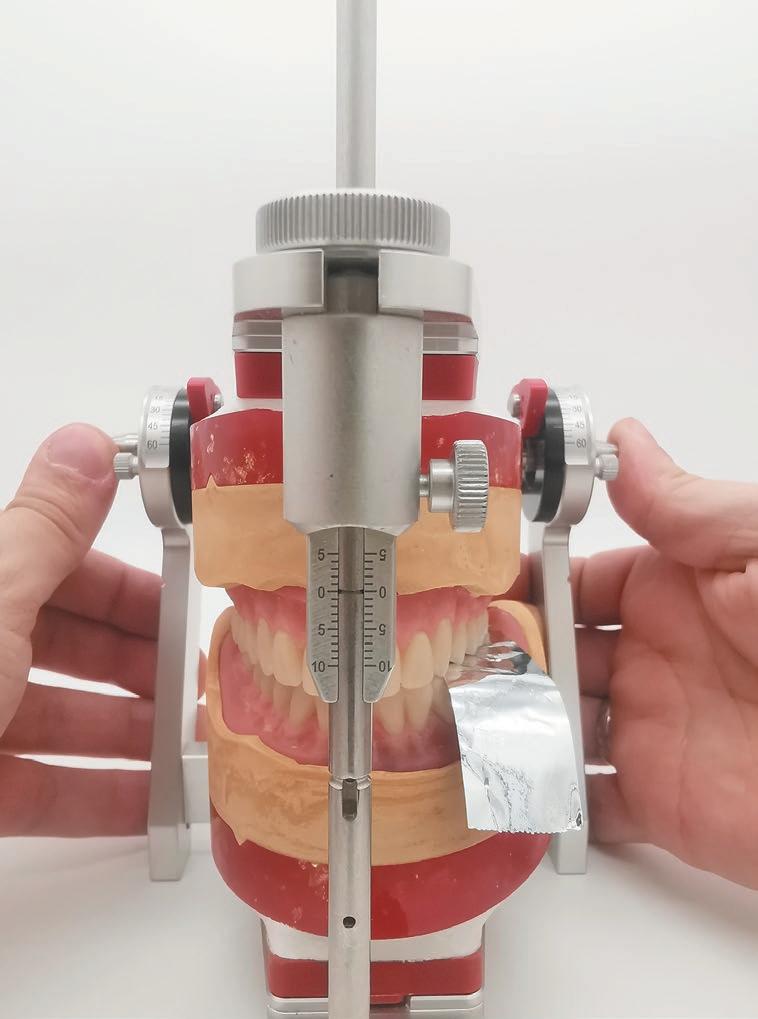

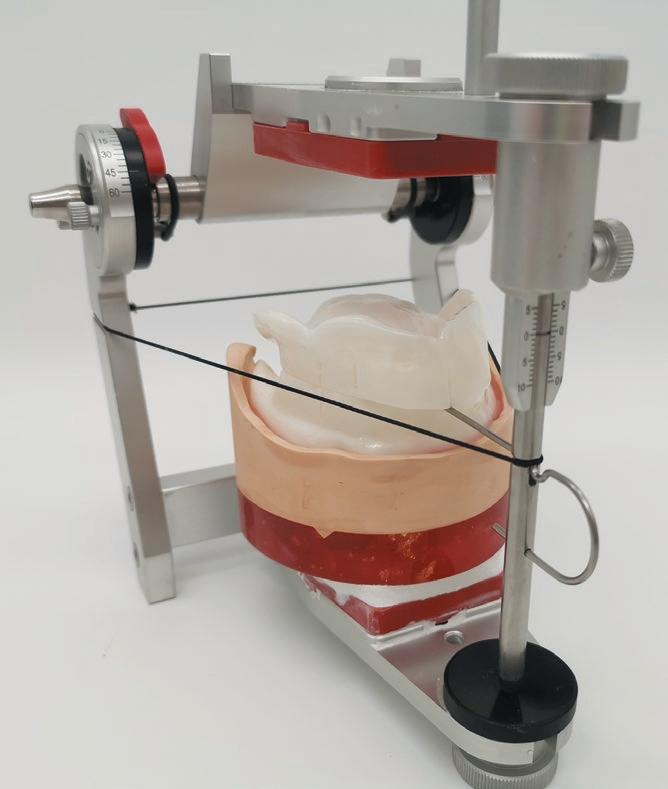

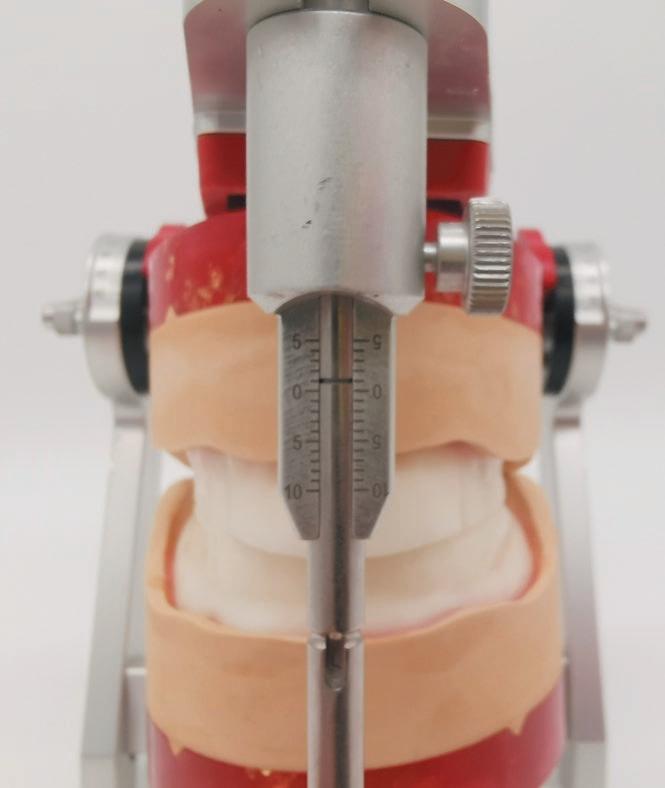

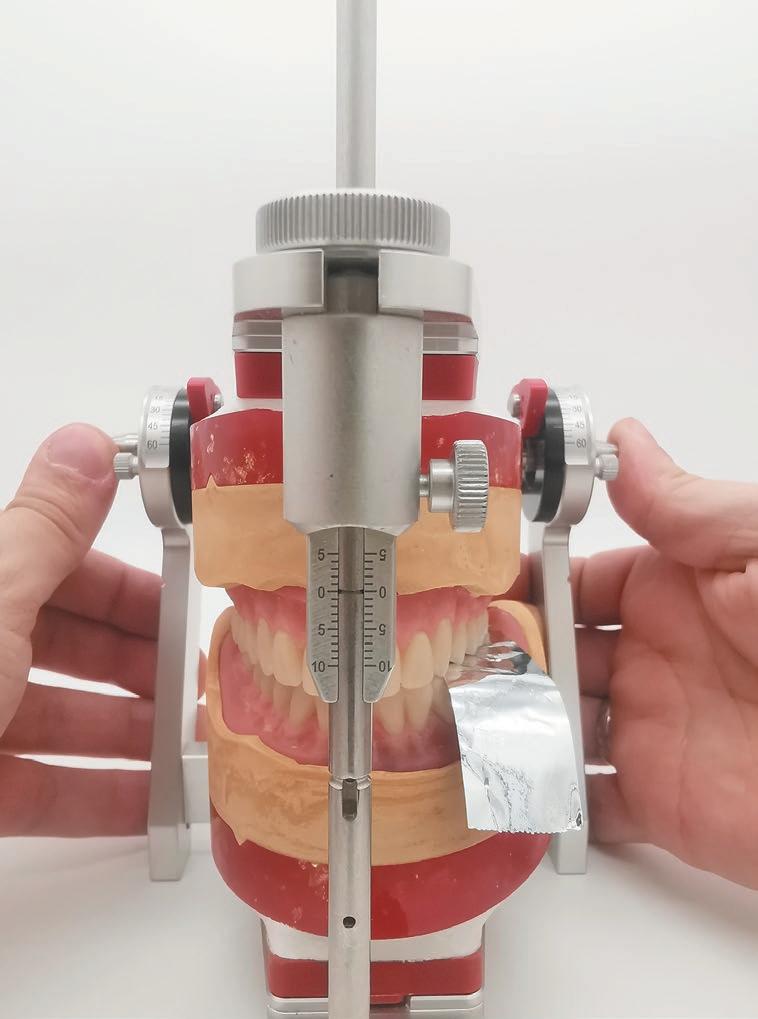

There are various methods for transferring the position of the mandible in relation to the cranium to the articulator. A common approach is the facebow to determine the position of the upper jaw. For the competition work, the mandibular model is transferred to the articulator (CA 3.0, CANDULOR) with a mean value (Figure 4). The condylar path inclination in relation to the Camper’s plane (occlusal plane) is preset at 45° on the right and 47° on the left. To reflect the increase in vertical relation, the support pin is lowered by 1 mm (Figure 5).

Among other things, the objective is to make the maxillary anterior teeth more visible and to make the patient’s physiognomy appear more harmonious.

• Prior to the model analysis, the support pin of the articulator is reset to the zero position.

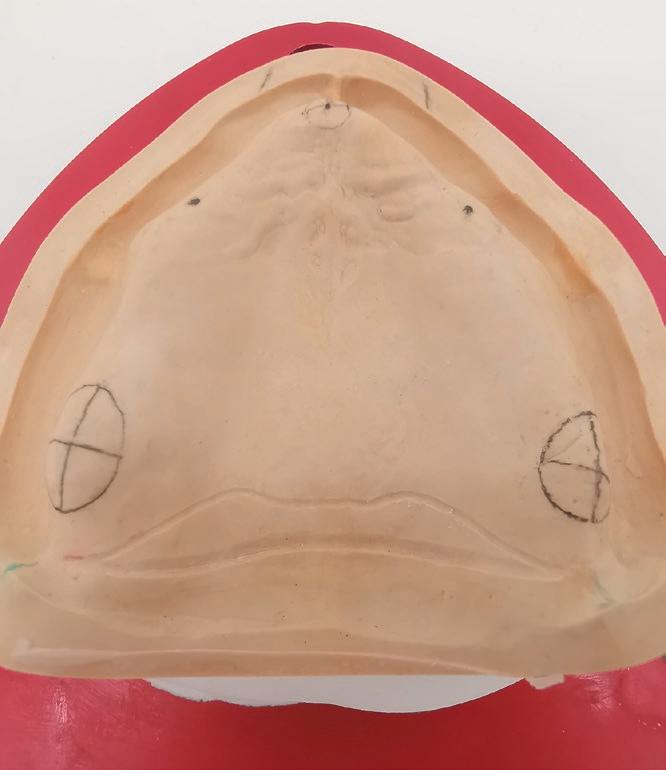

MODEL ANALYSIS

The model analysis initially requires some time but significantly increases the quality of the results. For instance, jaw relationships, the position of the plane of occlusion, and the midline of the maxilla can be determined with the aid of model analysis. The results

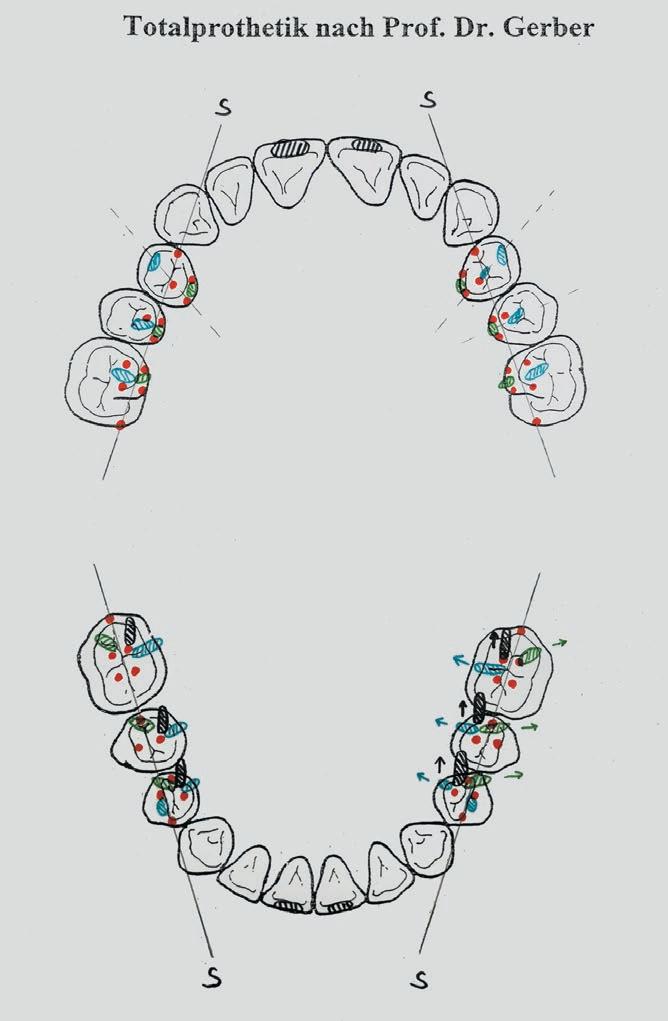

of the model analysis enable a precise tooth set-up according to static aspects, taking muscular balance into account. The procedure, according to P. Lerch, has proven itself and is also applied in this case.

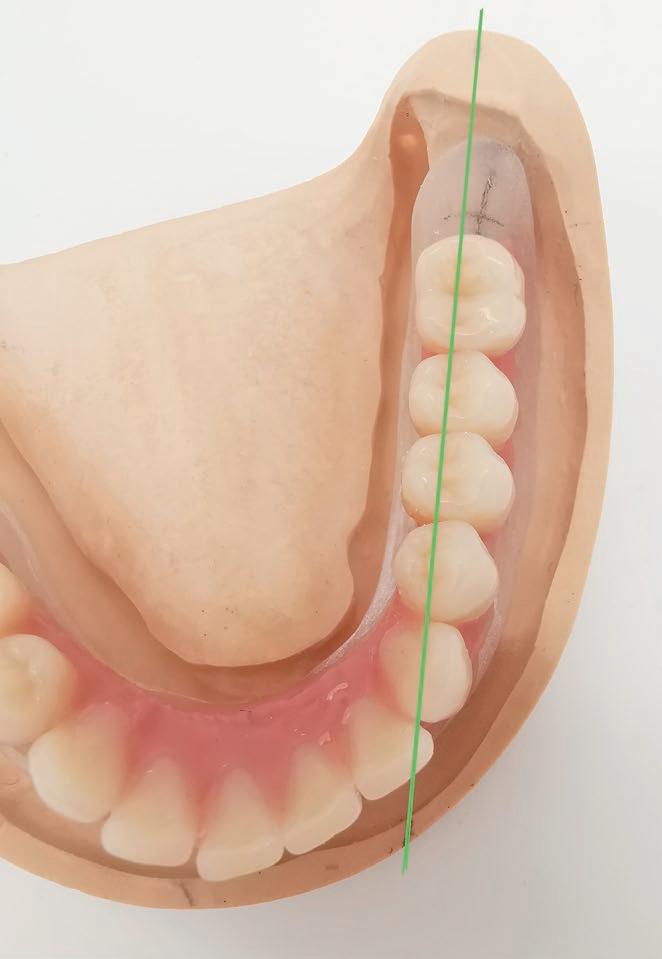

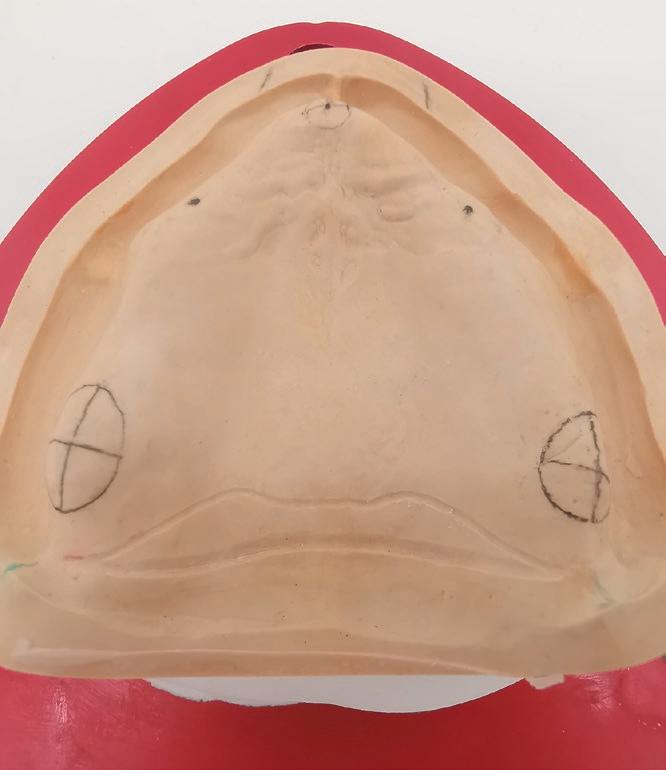

Static lines

After marking the papilla incisiva and the centre of the model as an orientation guide, the positions of the first premolars in the maxilla and mandible are marked.

• In the maxilla, the canine is located at the level of the first large palatal fold, one premolar width to dorsal of the first premolar.

• In the mandible, the positions are marked in extension of the buccal frenulum attachments.

The retromolar triangles in the mandible or the tuber in the maxilla are outlined and bisected sagittally and transversely with

CLICK HERE TO RETURN TO TABLE OF CONTENTS

Figure 3 – Silicone matrix of the physiognomic bite key.

Figure 1 – Duplicating forms of the master models. Figure 2 – Splitcast base for removing the models from the articulator.

Figure 5 – Support pin lowered by 1 mm.

FULL DENTURE PROSTHETICS – THE ULTIMATE DISCIPLINE: CRAFTSMANSHIP AND INDIVIDUAL SPECIFICATIONS SPRING 2024 22

Figure 4 – Transfer of the mandibular model to the articulator with rubber band and incisal needle.

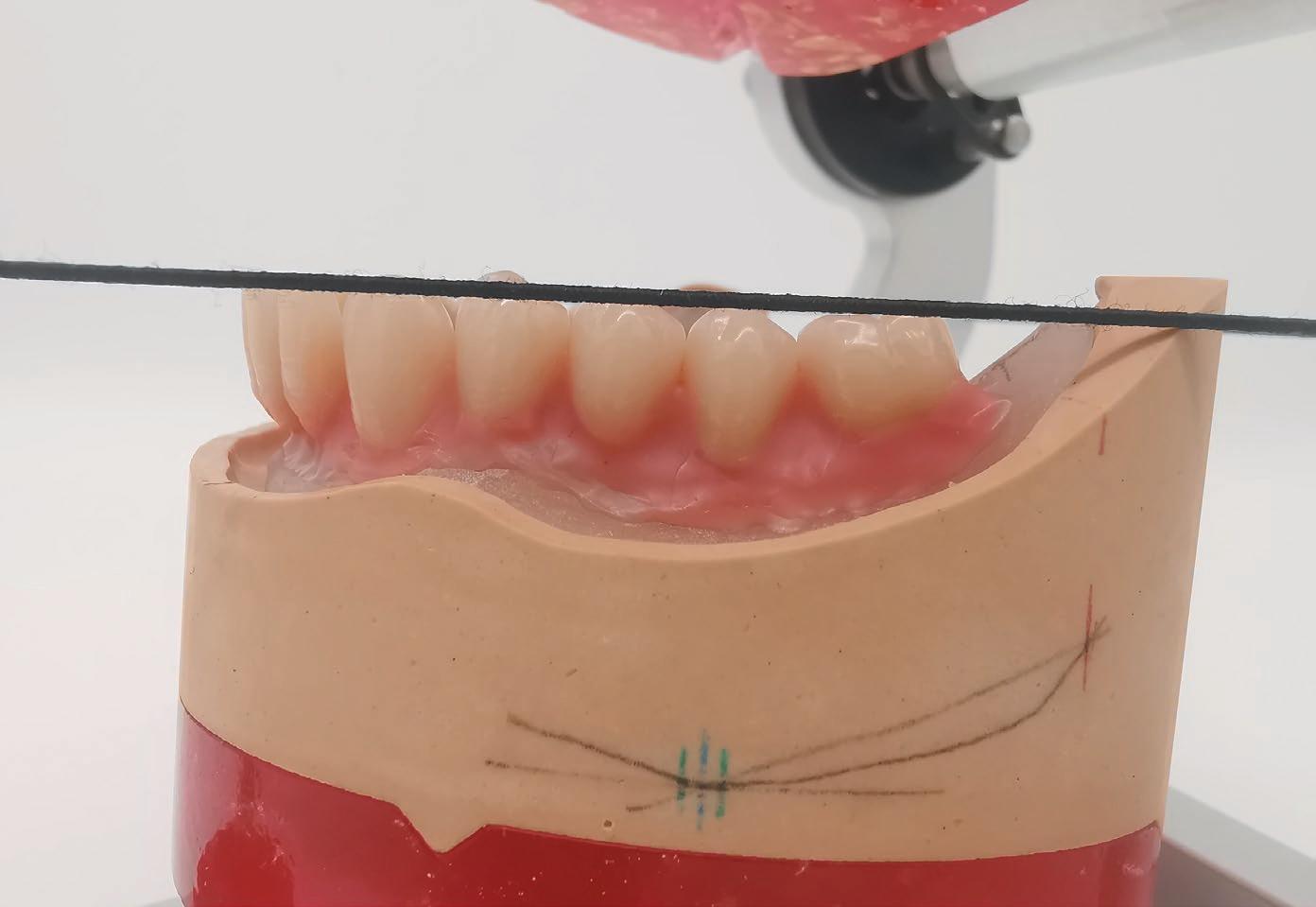

Main Masticatory Centre

The contour of the alveolar ridge is determined with the aid of profile compasses. These are guided at right angles to the model side from mesial to distal to transfer the alveolar ridge contour of the mandible to the side of the model. The main masticatory centre is defined by a tangent parallel to the occlusal plane through the lowest point of the alveolar ridge contour (Figure 8). The point of contact of the tangent marks the main chewing center and can be identified by a vertical line on the model side. In addition, a tolerance range is marked by vertical lines on both sides of the model at a distance of about 1 mm. As a rule, the first molar of the mandible lies within this tolerance range.

Stop Line

a line. The points of intersection are connected to the marked positions of the first premolars (Figure 6). The resulting lines form the basic static lines and are marked in red.

Inner and Outer Contours

The inner and outer contours indicate the tolerance range of the basic statics and create the setup area for the teeth (Figure 7).

• In the mandible, the intersection points of the transversal bisector line are connected with the position of

the first premolars when contouring the retromolar triangles. The line passing through the lingual point represents the inner correction (green), while the line passing through the vestibular point represents the outer correction (blue).

• In the maxilla, the outer correction runs along the vestibular fold and the inner correction as the connecting line of the plica pterygomandibularis and the position of the first premolars.

A line is drawn through the main chewing center point at an angle of 22.5°, which extends to dorsal. The second intersection of this line with the alveolar ridge line can be marked with a vertical line and transferred to the model margin perpendicular to the occlusal plane. This marking forms the stop line and, thus, the most distal point at which a tooth may be in occlusion (Figure 9). Setting a tooth behind this line can cause the mandibular denture to slide ventrally (protraction).

CLICK HERE TO RETURN TO TABLE OF CONTENTS

Figure 6 – Marking of the static lines and the retromolar triangles or tuber.

Figure 7 – Marking the inner and outer contour lines for evaluating the setup area.

Figure 8 – Alveolar ridge contour on the outer side of the model and main chewing center in the mandible (blue).

SPRING 2024 23

Figure 9 – Marking of the stop line (red line).

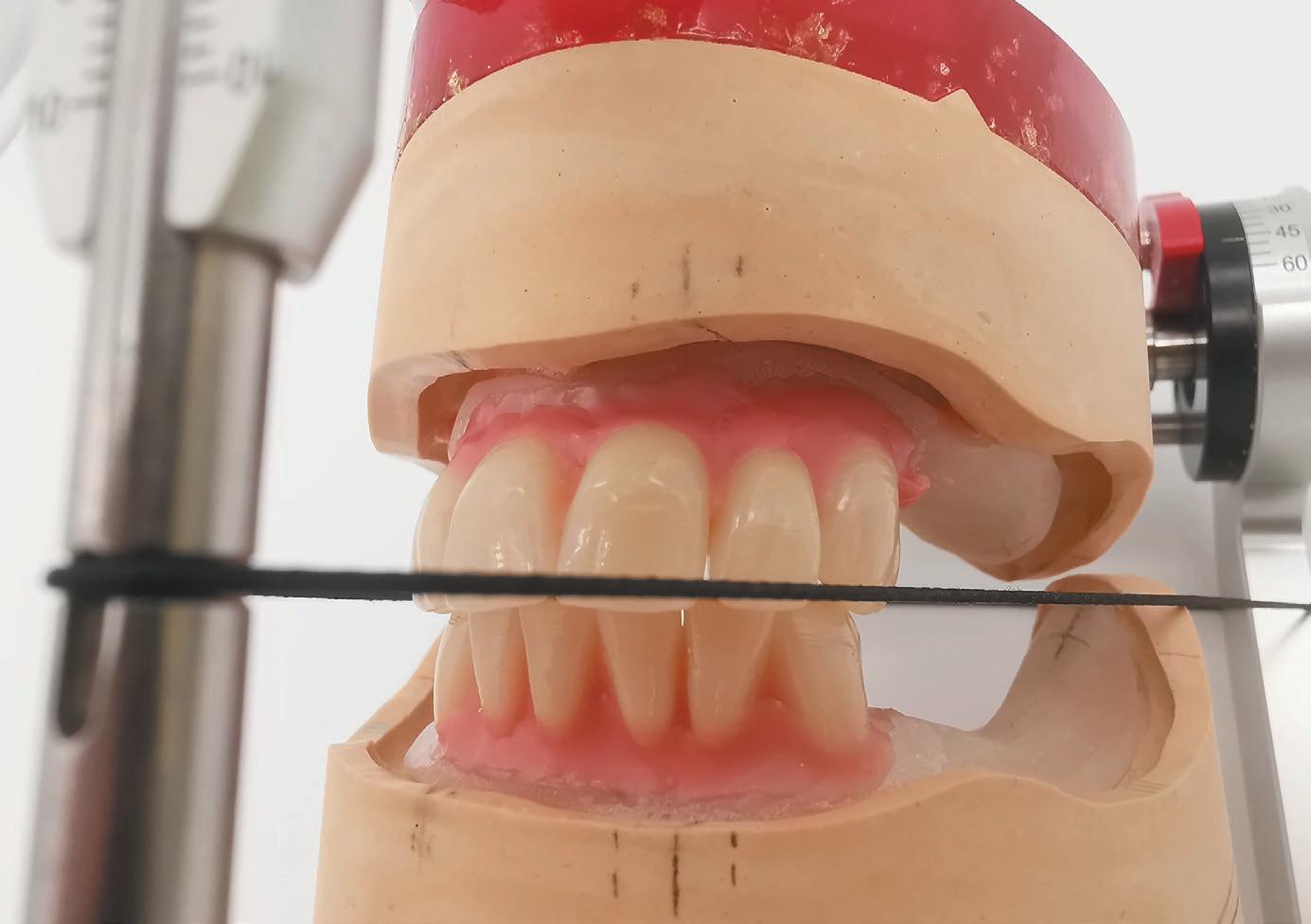

SETUP OF THE TEETH

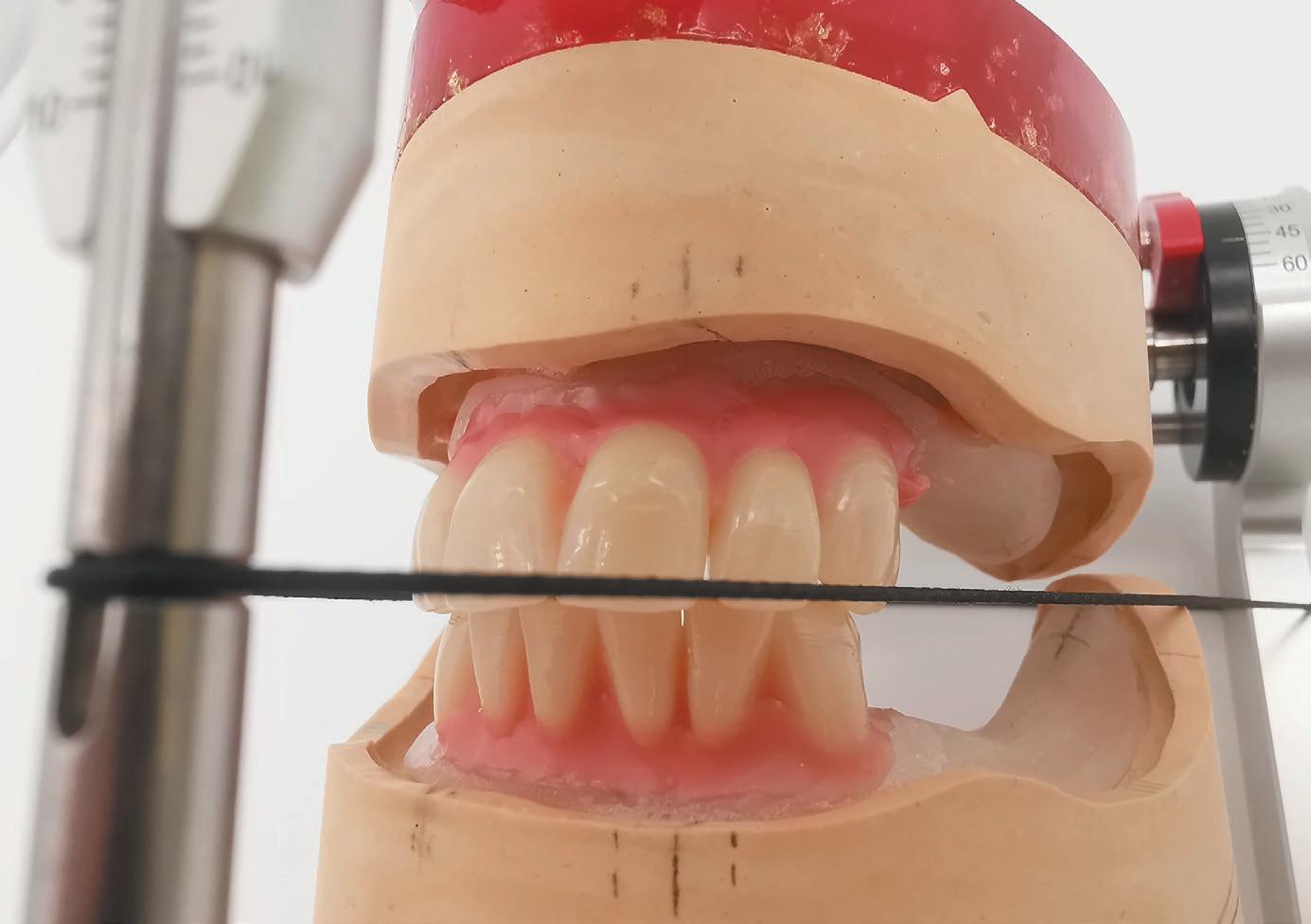

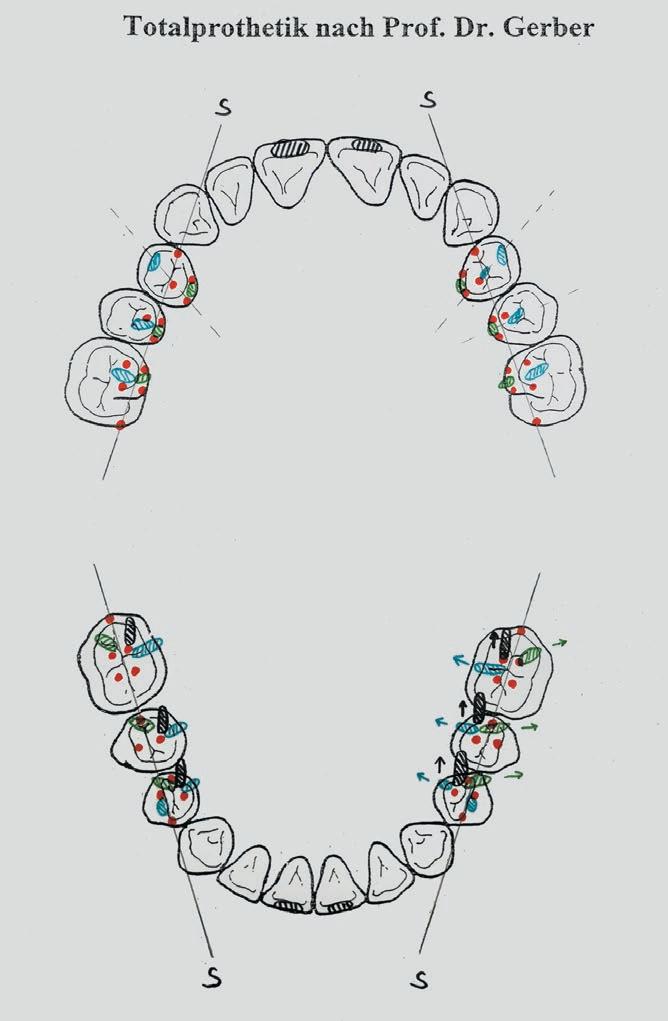

Maxilla Anterior Teeth (PhysioSelect TCR, Candulor)

The information from the analysis is put together like a puzzle when setting up the teeth, and the ideal tooth positioning is evaluated. The bite key provides a rough guide for positioning the teeth. Attention must be paid to ensure that the labial surfaces of the teeth touch the silicone matrix (bite key) (Figure 10). According to the Gerber theory, the central incisors and canines are set up at equal lengths – approximately 0.5-1 mm above the occlusal plane. The lateral incisors are slightly shorter. The tooth axes exhibit slight mesial inclination.

Mandible Anterior Teeth (PhysioSelect TCR, Candulor)

Teeth 32 on 42* are set up oriented to the occlusal plane, whereby a small tolerance is possible due to a slightly nested setup (Figure 11). The canines can be positioned minimally above the occlusal plane (approx. 0.5 mm). When positioning the teeth to labial, the sagittal step must be taken into account (overbites). As the lower anterior teeth do

not play a supporting role in functional loads and should only exhibit slight sliding contacts in protrusion, an individual setup is possible.

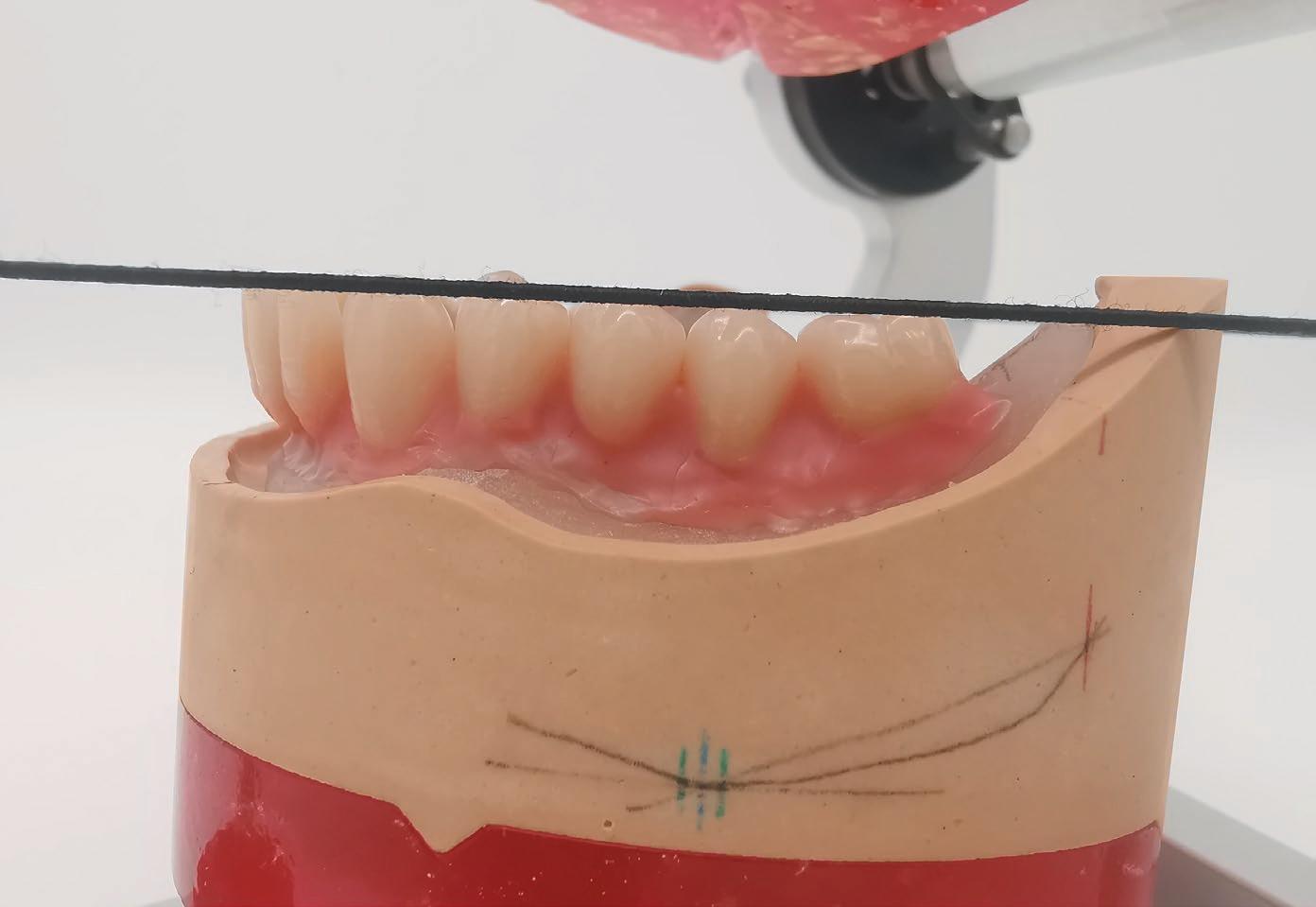

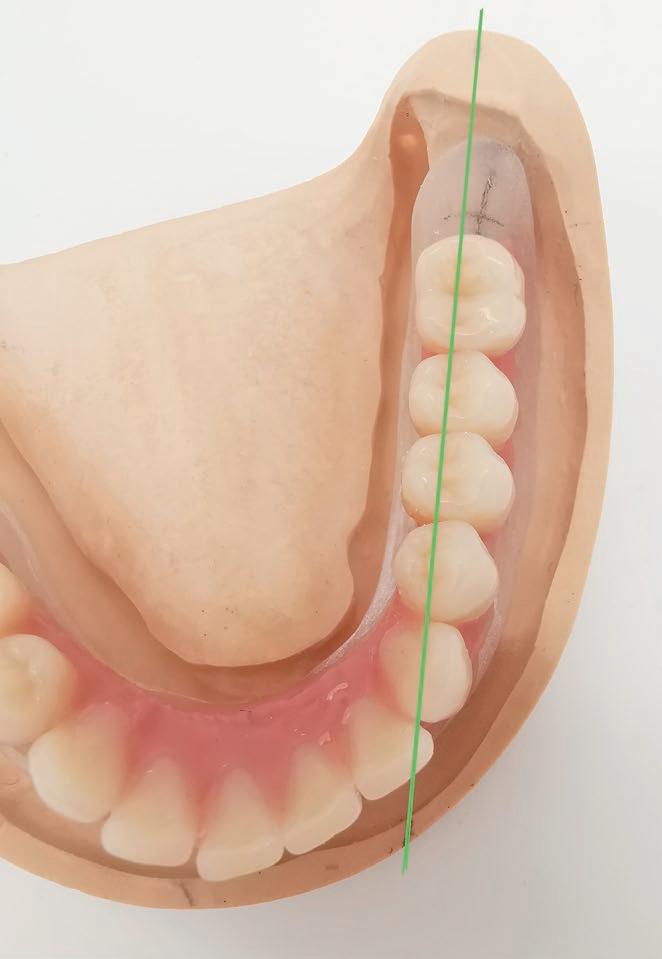

Posterior Teeth in the Mandible (BonSelect TCR)

In the posterior region, the focus is initially on the lower teeth since their position is important for the articulation contacts (Figures 12A and 12B). The first premolars take on the main guidance

CLICK HERE TO RETURN TO TABLE OF CONTENTS

Figure 10 – Setup of the upper anterior teeth with silicone matrix.

Figure 11 – Setup of the lower anterior teeth with slight nesting.

FULL DENTURE PROSTHETICS – THE ULTIMATE DISCIPLINE: CRAFTSMANSHIP AND INDIVIDUAL SPECIFICATIONS SPRING 2024 24

Figures 12A and 12B – Setup of the posterior teeth in the mandible, taking into account the information from the model analysis (e.g., base static line passes through central fissures).

MILLED FLEXIBLE PARTIALS

& STRENGTH FLEXIBILITY

WITH IMPROVED

COMFORT & AESTHETIC FUNCTION

OFFERED IN TWO CLASP OPTIONS:

RE-LINEABLE AND REPAIRABLE STAIN RESISTANT FLEXIBLE BASE COMFORTABLE FIT AND FINISH CAST

BE DESIGNED LIKE A FAST TURNAROUND PROCESSING

PARTIAL CAN

Cast Partials • Implant Supported Overdentures • Laser Welds • BPS/Flexible Processing Soft Liners • Ceramic Milling Services • Setup and Finish Dentures

PRECISION EXPERTISE IN:

function and are set up with an inclination of about 10° distally and 1 mm above the occlusal plane. The second premolars are at the level of the occlusal plane and are inclined to distal by approximately 5°. As there is no space for two molars dorsally, the first molar is replaced by a third premolar. For a harmonious curve of Spee, the molar is tilted slightly to mesial. The mesiobuccal

cusp of the molar is level with the occlusal plane, while the distobuccal cusp stands 0.5 mm above the plane.

Posterior Teeth in the Maxilla (BonSelect TCR)

The upper posterior teeth touch the silicone key with the buccal surfaces (Figures 13A and 13B). Again, the position of the first

premolars is important as these teeth, together with the lower first premolars, provide the main guidance. They are set up at the level of the occlusal plane and inclined about 10° to mesial. The palatal cusps are located in the fossa of the lower first premolars. The second and – in this case – third premolars are treated in the same manner. The molars in the maxilla are slightly inclined to distal and only tangent the occlusal plane with their mesiobuccal cusps, whereby the distobuccal cusps lie slightly above. The main contacts are located on the mesiopalatal cusp of the molars.

• The buccal cusps are out of occlusion and at some distance from the lower buccal cusps so as not to restrict articulation movements.

Grinding in Occlusion and Articulation Movements

Grinding-in of the occlusion begins with checking the contact points and carefully grinding interfering contacts (check on support pin). The main contacts are located on the palatal or mesiopalatal cusps in the maxilla and in the central fossa in the mandible. The aim is to achieve two to three points per tooth, evenly distributed between the left and right tooth rows (Figures 14A, 14B, and 14C).

CLICK HERE TO RETURN TO TABLE OF CONTENTS

Figures 13A and 13B – Setting up the posterior teeth in the maxilla with silicone key and checking the profile of the basal static line to the central fissures.

FULL DENTURE PROSTHETICS – THE ULTIMATE DISCIPLINE: CRAFTSMANSHIP AND INDIVIDUAL SPECIFICATIONS SPRING 2024 26

Figures 14A, 14B, and 14C – Checking and grinding in the articulation movements with coloured occlusal foil. Gerber setup: main guide contacts on posterior teeth, anterior teeth only in sliding contact, canines do not guide.

MODELLING THE DENTURE BODY

Careful design of the denture body in the mandible is important to compensate for the lack of suction effect (flabby ridge) by means of a muscle-gripping design (Figures 15A and 15B). Buccinator supports are modelled to provide a counter abutment for the musculus buccinator, while the lip shield labially provides an abutment for the musculus orbicularis oris. The lower denture is modelled lingually in such a manner that the musculus mylohyoideus and the tongue nestle against the denture body in the rest position.

In addition, palatal folds are designed on the maxillary denture to provide orientation for speech and assist with food comminution.

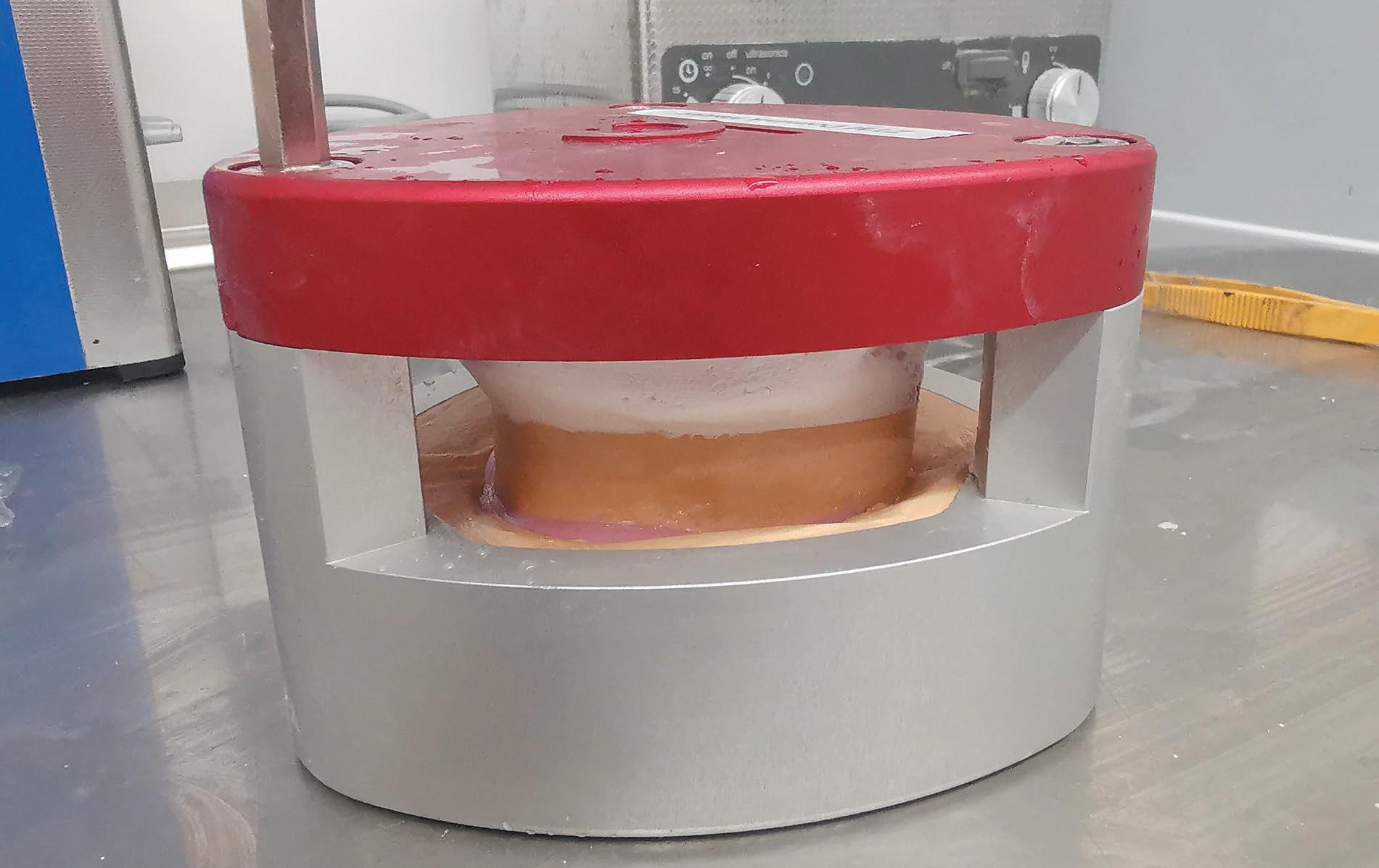

FINISHING OF THE DENTURES

The transfer of wax dentures into resin is performed with the cold press technique (PolyMaster, CANDULOR). The advantage is that the model can be blocked out without the wax melting. By pressing the resin into the PolyMaster, a high accuracy of fit of the dentures is achieved. In addition, the denture

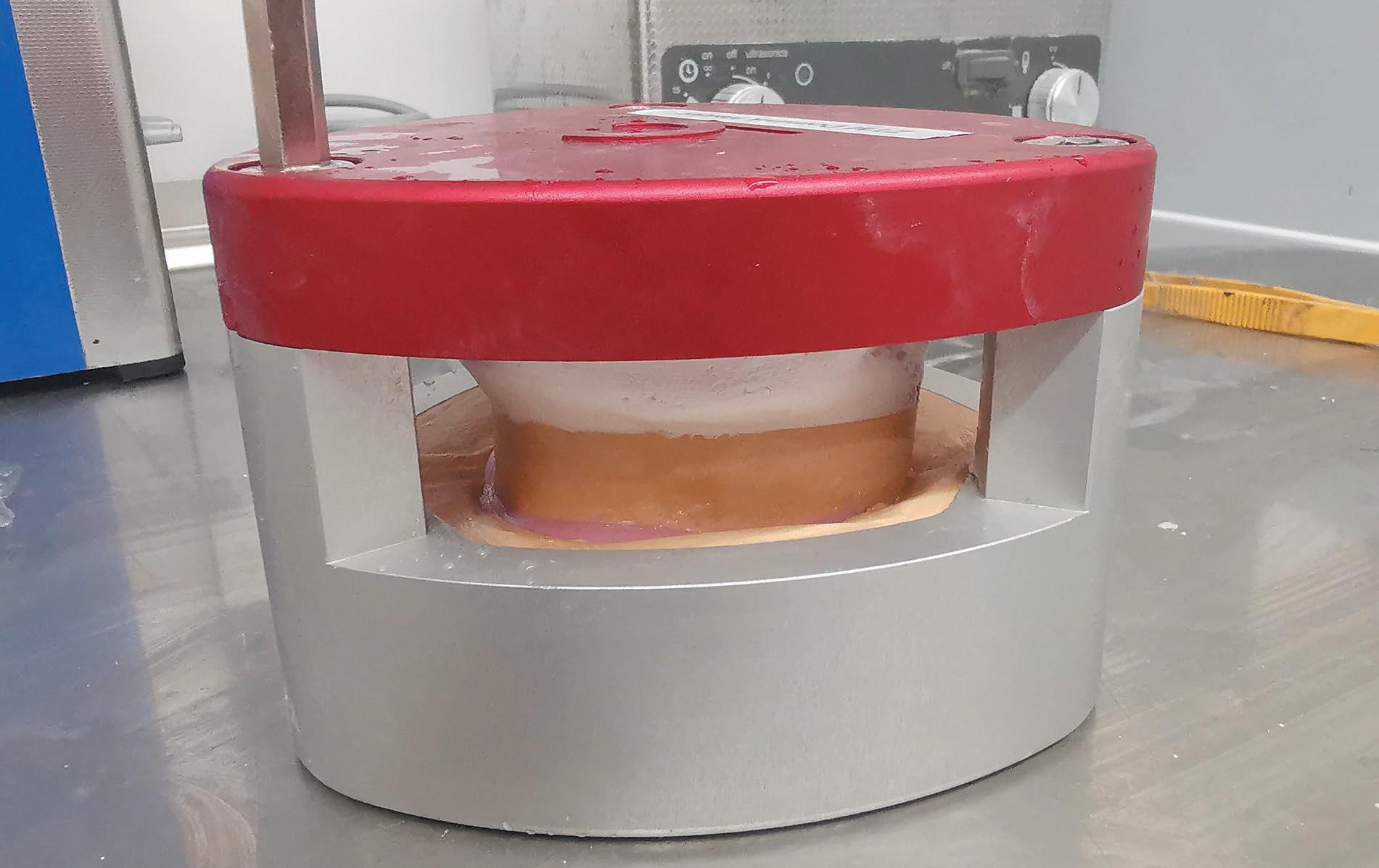

body can be customized with lighter and darker resins as well as intensive shades before inserting the base material (CANDULOR 34). Prior to inserting the models into the PolyMaster, silicone matrices are fabricated and perforated at the cusp tips as well as incisal edges to provide selective support for the teeth (Figure 16). The lower part of the flask is filled with super-hard plaster, and the model is pressed into the plaster. After 20-30 minutes, the lid of the PolyMaster can be removed (Figure 17). The teeth are

CLICK HERE TO RETURN TO TABLE OF CONTENTS

Figures 15A and 15B – Muscle-gripping design of the denture bodies and creation of palatal folds.

Figure 16 – Silicone matrix (Shore hardness 65-75) with perforations at the cusp tips.

SPRING 2024 27

Figure 17 – Models placed in the PolyMaster (cold press).

provided with retention notches basally, sandblasted, and bonded into the matrices with instant adhesive (Figure 18). The vibrating line etching provides a tight seal between the denture base and the palate

and maximizes the suction effect and denture bearing (Figure 19).

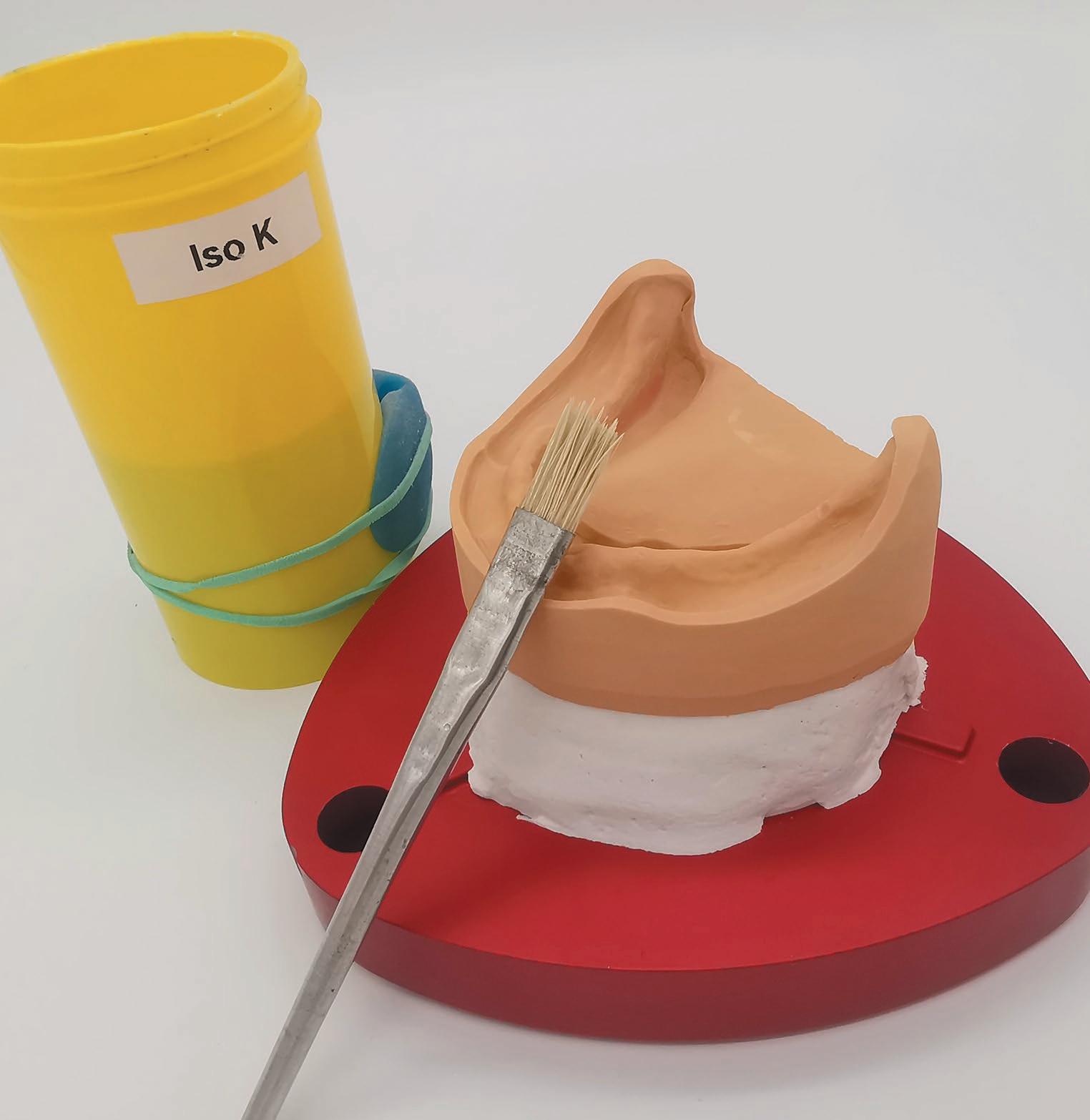

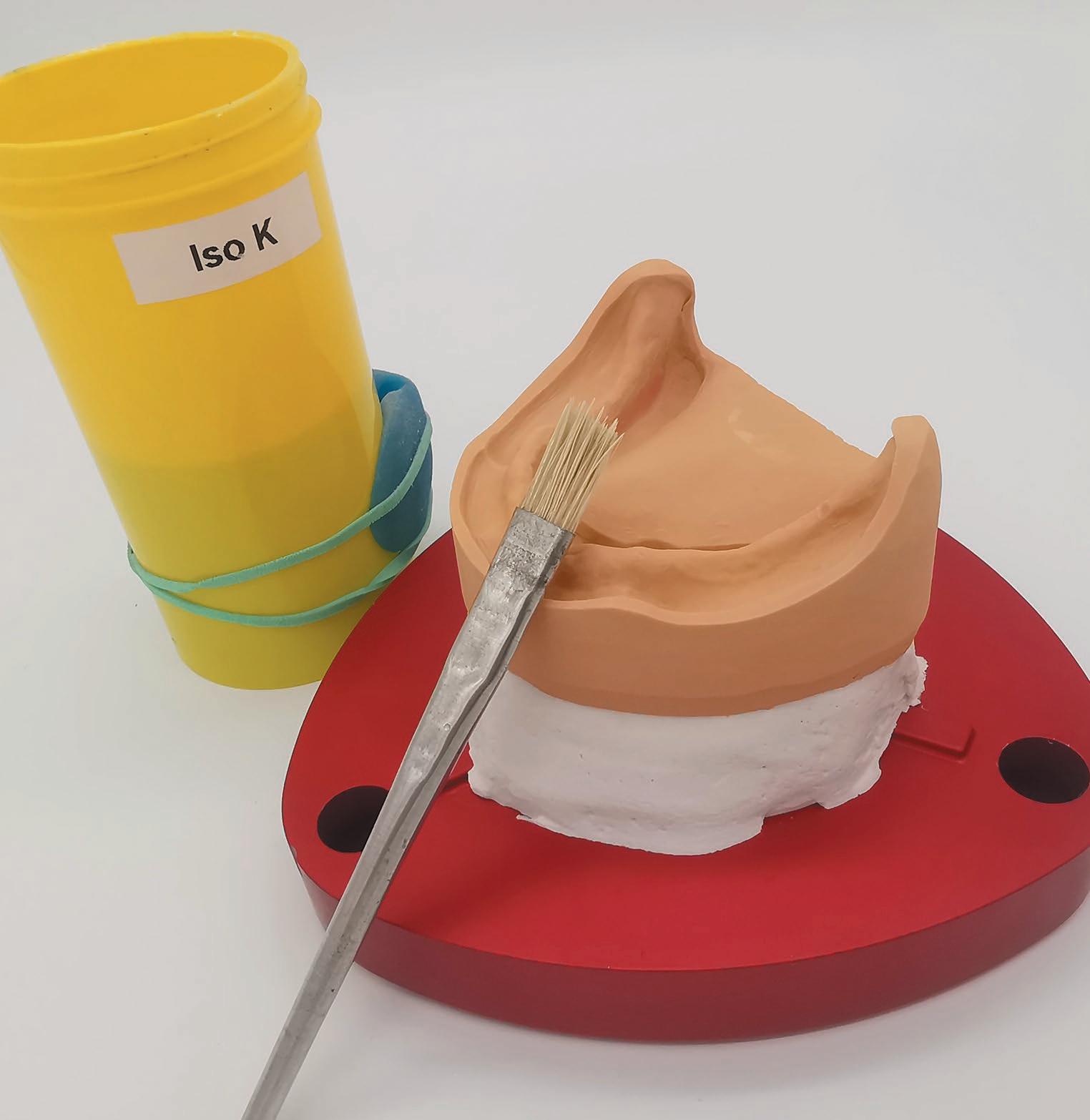

After the models have been wetted and insulated and the teeth have been fixed in the matrix, the resin polymers are

prepared (Figure 20). To provide natural aesthetics, individualization and intensive colour materials should be used in addition to the base material (CANDULOR 34) (Figures 21A and 21B). The teeth are wetted

CLICK HERE TO RETURN TO TABLE OF CONTENTS

Figure 20 – Thin coating of the models with alginate insulation (Iso-K) without forming puddles.

Figures 21A and 21B – Individualization of the red aesthetics using various resins from the CANDULOR range. Mixing the polymers 53, 55, and intensive stain powder (ratio 1:1) with the base material 34.

Figure 19 – Vibrating line etching on the maxillary model for a powerful suction effect.

FULL DENTURE PROSTHETICS – THE ULTIMATE DISCIPLINE: CRAFTSMANSHIP AND INDIVIDUAL SPECIFICATIONS SPRING 2024 28

Figure 18 – Bonding of teeth into the matrix.

with monomer, and the individualization materials are applied, followed by the base material (Figure 22). After screwing the flask closed, polymerization is performed for 20-25 minutes at 40°C water temperature in the pressure pot.

After devesting the dentures, occlusion and articulation are checked, and the support pin is set to zero (Figure 23). This is followed by the removal of the dentures from the models. Tooth necks and proximal spaces are reworked, and the marginal areas as well as the areas for muscle-gripping are optimized. The dorsal prosthetic margin

of the upper denture is shortened to the vibrating line, and both dentures are carefully polished (Figure 24). Here, special attention is paid to the occlusal surfaces so as not to lose the occlusal points and ground facets.

INDIVIDUALIZATION OF THE DENTURES

To provide the dentures with more naturalness and liveliness, the teeth should be individualized. The denture bodies are covered with wax. This serves to protect the already polished gingival portions. The labial and buccal surfaces of the teeth can

then be conditioned and designed with characterization materials (Optiglaze Colour Sets, GC), e.g., ground facets, enamel cracks, and imitation of leukoplakia (Figures 25A and 25B). To add the finishing touch to customization, the lower denture is furnished with a gold inlay at the level of the molar (Figure 26). After final polishing and cleaning of the models as well as dentures, the work is ready for handing over (Figures 27A and 27B, see next page).

CLICK HERE TO RETURN TO TABLE OF CONTENTS

Figure 22 – Application of the individualization materials followed by filling with the ‘dough’ base material.

Figure 24 – Finishing the denture bodies, paying attention to sensitive areas, e.g., the vibrating line.

Figure 23 – Devested denture prior to removal from the model (check of articulation movements).

Figures 25A and 25B – Individualization of teeth with stains and characterization materials.

Figure 26 – Polishing of the gold inlay.

SPRING 2024 29

CONCLUSION

Although dental technology is becoming increasingly digitized, full denture prosthetics currently remain handcrafted work. Aesthetic, functional, and individual aspects require the craftsmanship and creativity of the dental technician. The challenge is to uphold these skills in a digital age. Despite increasing digitization, the knowledge of proven criteria and the skills of analog processes form the basis for solid full denture prosthetics. Cooperation within the dentist-laboratory team, as well as an understanding of the individual needs of the patient, remain indispensable for a successful result and long-term patient satisfaction.

“As I am serious about my craft and the passion for dental technology that comes with it, participating in KunstZahnWerk has been a goal of mine for a long time. I am incredibly proud and grateful that I was now not only able to demonstrate my skills but even won first place. The competition has motivated me to continue improving my skills and to keep challenging myself. In particular, KunstZahnWerk has once again made me aware of the relevance of craftsmanship in dental technology.” – Sebastian Guttenberger, MDT.

*In this article, we refer to the dental scheme: FDA (Fédération Dentaire Internationale/DIN EN ISO 3950:2016-09).

MATERIALS USED

Articulator: CANDULOR Articulator CA 3.0 (CANDULOR)

Tooth lines: PhysioSelect TCR and BonSelect TCR (CANDULOR)

Denture resin: Aesthetic Blue (CANDULOR)

Individualization of the gingiva: Aesthetic Intensive Colours (CANDULOR)

Characterization materials teeth: OPTIGLAZE Colour (GC)

Flask: PolyMaster (CANDULOR)

Insulation plaster-resin: Iso-K (CANDULOR)

Silicone (matrix): Monosil (HLW Dental)

Super-hard plaster: Rocky Mountain (Class 4)

Polymerization light: Bluephase (Ivoclar)

Alloy (gold inlay): Aurumed Norm (Deutsche Aurumed Edelmetalle)

ABOUT THE AUTHOR:

Sebastian Guttenberger

• 2014 – Apprenticeship Examination (Chamber of Crafts Regensburg)

• 2014-2016 – Employed Dental Technician (Zahntechnik Hierold, since 2018: H2 Dental)

• 2019-2020 – Master Class Munich

• 2020 – Awarded the title of Master and the title of Bachelor Professional

• 2020 – Received the Bavarian State Government’s Master Craftsman Award for Outstanding Performance in the Master Craftsman’s Examination

• 2020-2022 – Employed Dental Technician (H2 Dental)

• 2022 – Employed Dental Technician (Zahntechnik Hierold)

CLICK HERE TO RETURN TO TABLE OF CONTENTS

Figures 27A and 27B – The finished dentures in the articulator (competition entry).

FULL DENTURE PROSTHETICS – THE ULTIMATE DISCIPLINE: CRAFTSMANSHIP AND INDIVIDUAL SPECIFICATIONS SPRING 2024 30

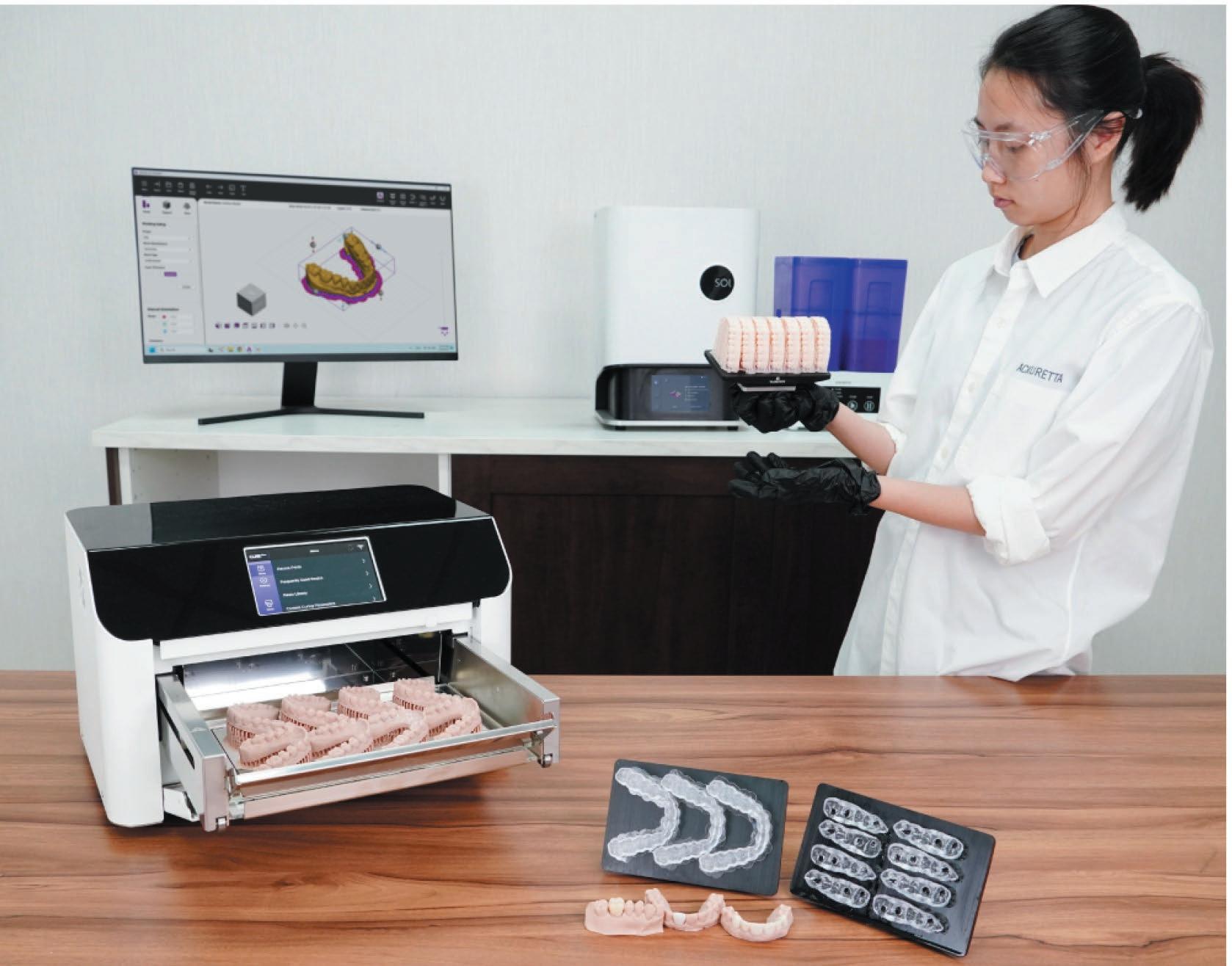

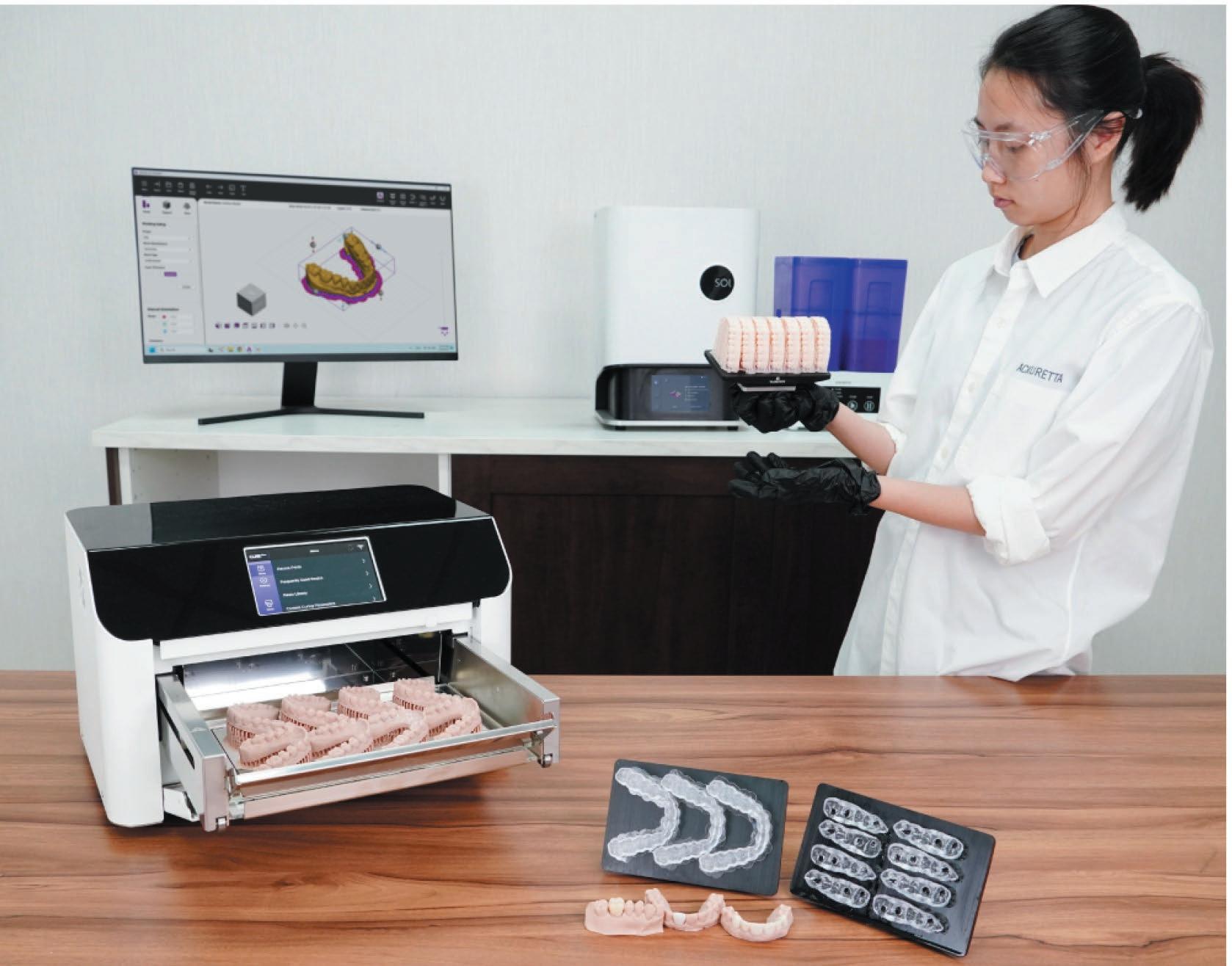

Why Nitrogen Is Essential for Your Dental 3D Printing Curing Oven

The popularity of 3D printing in the dental industry has been expanding, and along with it, the technology itself and the quality of output it is capable of producing. Today, a dentist or lab technician can create a print faster, more easily, and more accurately than ever before. These improvements have led to an increasing number of dental professionals seeking the latest developments to add to their arsenal of tools – including the most advanced UV curing ovens and nitrogen sources.

Having all the right elements working together – from design to delivery – is the key to getting consistent results every time. A fully synchronized UV curing station is the final step to guarantee high-quality, precise, and accurate results.

What is Dental 3D Printing?

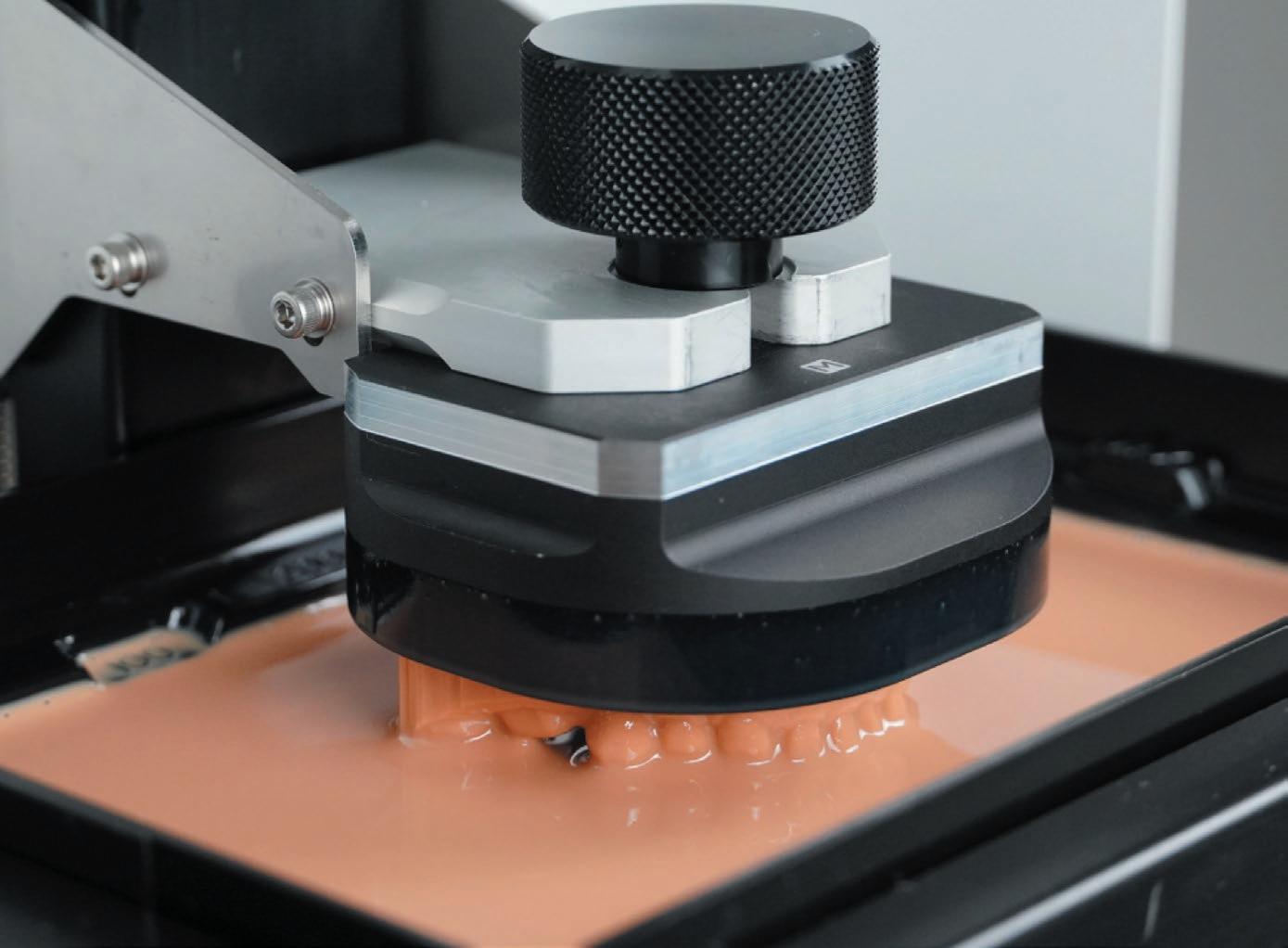

Dental 3D printing is a digital dentistry process that involves producing a final dental application – a crown, model, surgical guide, etc. – via a digital workflow, with

the application created from liquid resin through a polymerization process.

The dental 3D printing workflow includes the initial intraoral scanning and digital design, followed by the printing itself and, perhaps most importantly, post-curing steps. The final application is made from liquid resin, which, through a process of polymerization, creates a solid print. UV light curing – especially the final cure after printing – ensures the quality and biocompatibility of a print; it is where the majority of curing happens. UV lights at specific wavelengths ensure the optimal strength, biocompatibility, and aesthetic of the print. Incorporating nitrogen into post-curing to enhance this final result seamlessly augments the dental 3D printing workflow.

Compared to a traditional analog workflow, 3D printing speeds up the process for the patient and the dental professional. The addition of nitrogen when curing 3D prints brings additional improvements to the accuracy and quality of your final result.

What Are the Benefits of Post-curing with Nitrogen?

Post-curing with nitrogen using UV light solidifies the final print and ensures it has met a set of health standards that reaffirm that it is safe to place in a patient’s mouth. This is especially important for restorative treatments and Class II applications.

CLICK HERE TO RETURN TO TABLE OF CONTENTS

SPRING 2024 32

ACKURETTA

Enhanced Mechanical Properties

Incorporating nitrogen increases the quality of prints by enhancing their mechanical properties, including up to 25% higher flexural strength. The cross-linking that is achieved through post-curing is improved, leading to a stronger and more durable result. Furthermore, incorporating nitrogen into the post-curing process ensures more consistent results. This means that patients are reliably receiving a better and more comfortable solution, and practitioners can deliver the best results possible every time.

Better Aesthetics for Dental Applications

In addition to improved comfort and durability, nitrogen integration yields a higher-quality print with fewer sticky areas and cracks. It also creates enhanced aesthetics for transparent resins and avoids the distorted appearance that often appears after post-curing. Nitrogen integration improves the colour and smoothness of the final result, providing a more natural look and feel for applications that will be placed in a patient’s mouth on a more permanent basis. This, in turn, leads to better patient satisfaction and the potential for more referrals or practice expansion.

Consistent UV Curing for Resin 3D Printing

Nitrogen maximizes the consistency of the 3D printed application and ensures that the print is cured evenly. This increased consistency helps reduce material waste. A curing method that is pre-tested and validated reduces trial-and-error, mistakes and re-prints, leading to the maximized use of all your material investments.

Maximized Efficiency for Dental Workflows

With the oxygen inhibition effect negated, curing happens faster and more evenly, reducing curing time and giving the patient a high-quality result.

Today, patients are better educated on the treatment options available to them and the emerging technologies. They are more

interested and involved in their treatment and want the best quality and price on the market. They also want the least number of visits possible and will seek dentists with established expertise, knowledge, and technology offerings. When it comes to oral health, 3D printing is increasingly being sought by patients and oral healthcare providers due to the benefits it offers that a traditional workflow cannot, with nitrogen increasing the benefits of UV curing further.

The Science of Curing with Nitrogen

Post-printing

UV light curing is a continuation of the polymerization that takes place during the printing process. The print is placed inside a UV curing chamber, which is then hit with UV light of specific wavelengths at all angles. This process ensures that the print is fully cured from all directions and is safe for the patient. While a print may look solid from the outside, some uncured resin may remain inside. Uncured resin can be

toxic and harmful to a patient, which is why UV curing is essential.

When the print is placed in the curing chamber, oxygen is also present inside. This can be problematic due to oxygen’s inhibiting effect on a UV reaction, which reduces curing performance by preventing UV rays from fully penetrating inside the print and curing it completely. In addition, oxygen can create light distortions, causing certain areas to cure unevenly.

When nitrogen is introduced into the chamber, it displaces the oxygen, thereby creating an inert oxygen-free environment, where the UV light can cure the print without any inhibiting effect – there are no layers between the UV light and the print, which means there is more efficient light absorption. It also prevents contamination from dust or other particles which might be present in the chamber, as well as oxidation and discolouration. By substituting air with 95% pure nitrogen, many improvements and enhancements to the final output become possible.

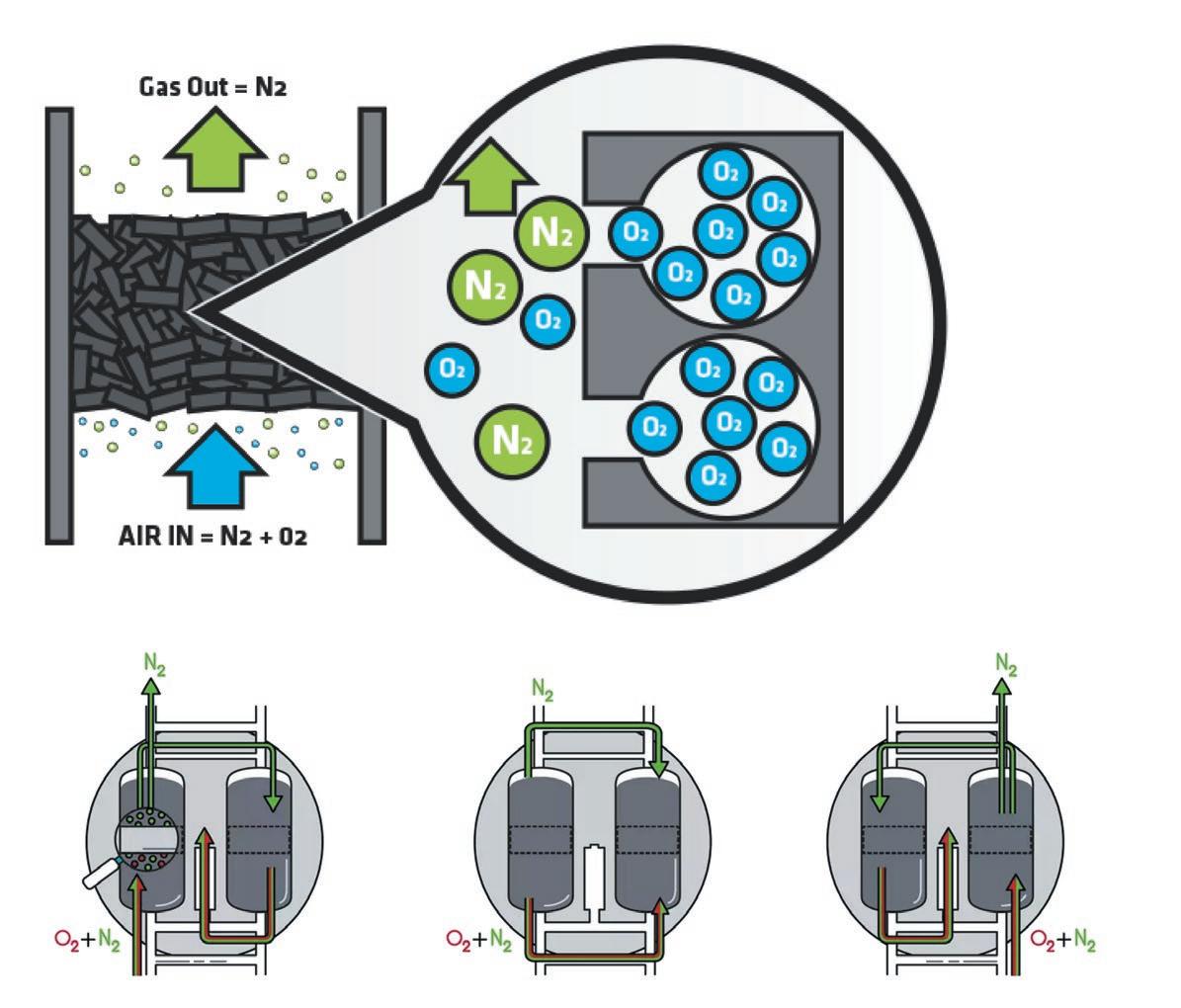

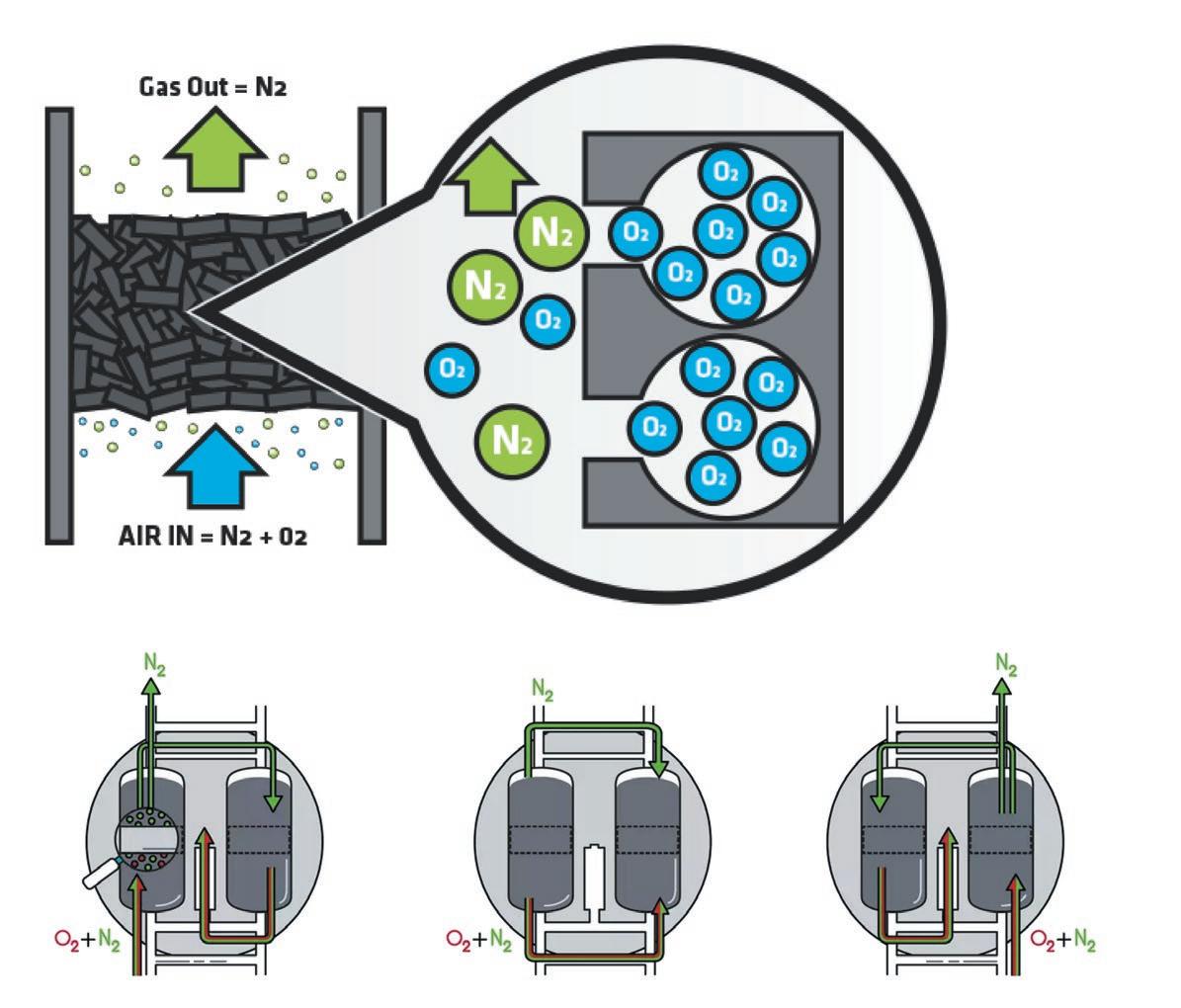

How Does a Nitrogen (N2) Generator Extract Nitrogen from the Air?

There are several different ways to extract nitrogen from the environment. Two of the most common ways to do this are:

• Pressure swing adsorption (PSA)

• Membrane nitrogen generation

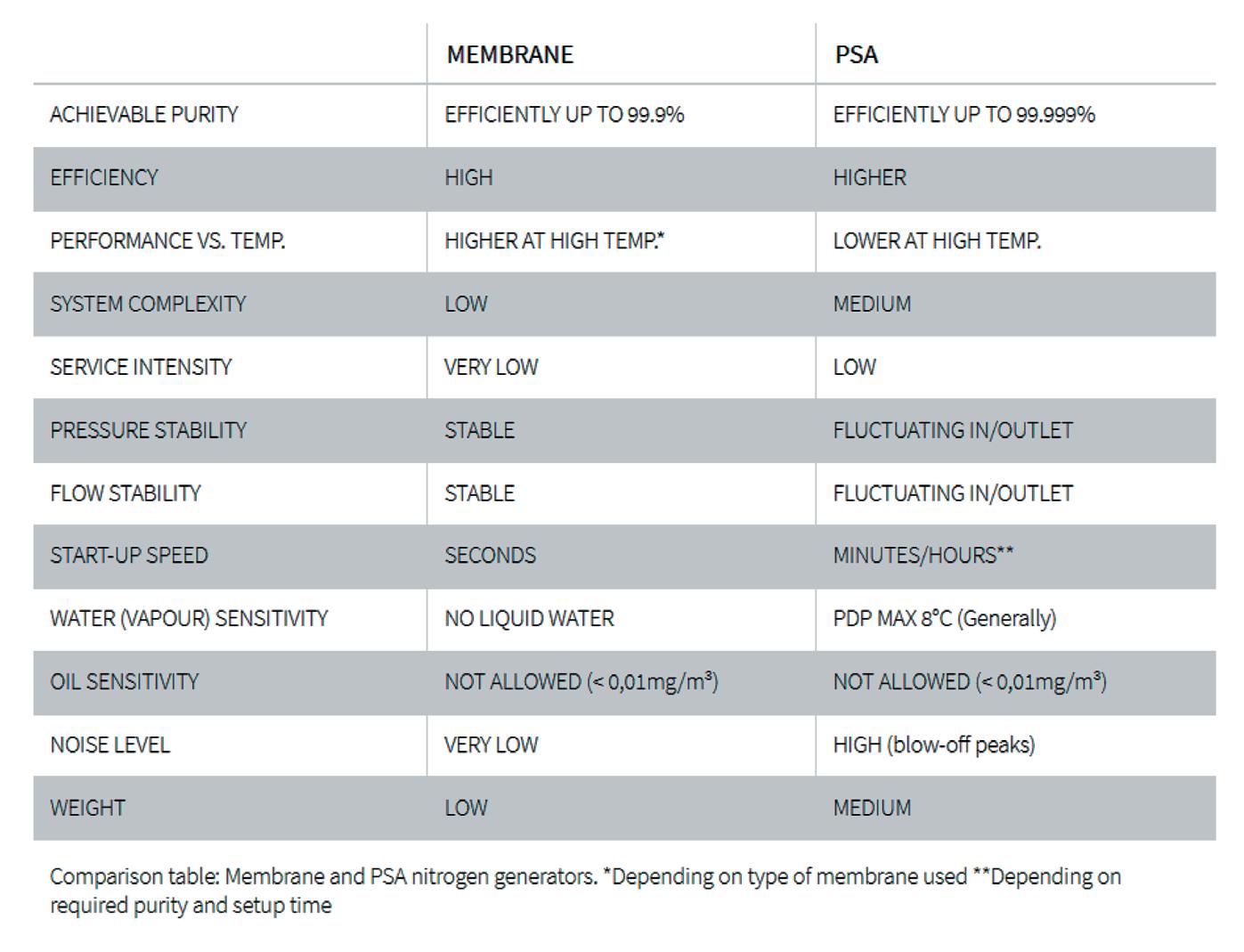

In the digital dental realm, pressure swing adsorption is the most common way to extract nitrogen from the environment.

CLICK HERE TO RETURN TO TABLE OF CONTENTS

SPRING 2024 33

PSA has the potential to deliver top-quality results by creating extremely high nitrogen purity (up to 99.9995%) while being extremely reliable and having a long lifespan, making it a solid investment for a practice.

PSA works by separating the nitrogen molecules from the oxygen molecules that are present in the compressed air being fed into the generator. Each generator has two towers or adsorber vessels, which contain carbon molecular sieves designed to adsorb the oxygen molecules. While one tower goes through a process of adsorption (also known as separation or pressurization), the other goes through desorption (also known as regeneration or depressurization). Both towers work simultaneously, performing opposite functions, and alternate in a cyclical way, thus achieving a constant flow of nitrogen.

Another way for a nitrogen generator to extract nitrogen from the air is through membrane nitrogen generation. This method involves forcing compressed air to flow through hollow fibre membranes. These membranes allow the nitrogen molecules to pass through more easily than other gasses, such as oxygen. They are semi-permeable and allow for easier permeation of oxygen and other gasses while the nitrogen gets pushed through and collected on the other side. Additional processing is done after that to remove any remaining gasses or other impurities. The final result is high-purity nitrogen gas.

Nitrogen Generator and Nitrogen Tanks

Two methods exist to integrate nitrogen into compatible UV curing units and dental 3D printing workflows: using a nitrogen generator or nitrogen tanks.

Nitrogen tanks are the more traditional option. They are an accessible, cost-efficient method with an intuitive installation process. A wide variety of different types and sizes of manufactured tanks can be

used in the UV curing process. One aspect that users should be aware of is that tanks need to be replaced after 35 curing cycles to ensure an inert environment that contains minimal oxygen.

Nitrogen generators offer an unlimited supply of nitrogen, eliminating the need for refills and reducing material waste from the disposal of used tanks. Once a generator is installed, minimal maintenance is required, which can be more convenient for some practices. Generators are, on average, smaller than a nitrogen tank, taking up less space in a practice.

With pre-set settings in nitrogen generators, users don’t have to worry about potentially inconsistent results or malfunctions that could result in a loss of time and material resources.

A significant benefit for some nitrogen generators is that they are built and validated for a specific dental 3D printing workflow, leading to higher quality dental applications, less trial and error, cost savings, and productivity enhancements.

Overall, both tools can be a positive addition to your dental 3D printing workflow.

Nitrogen vs. Vacuum vs. Glycerin: Which Method Is Best for Curing Resin?

While the use of nitrogen as a tool to prevent oxygen inhibition during the curing of a print is the most common, other methods also exist to eliminate oxygen’s negative effects on the final print result.

CLICK HERE TO RETURN TO TABLE OF CONTENTS

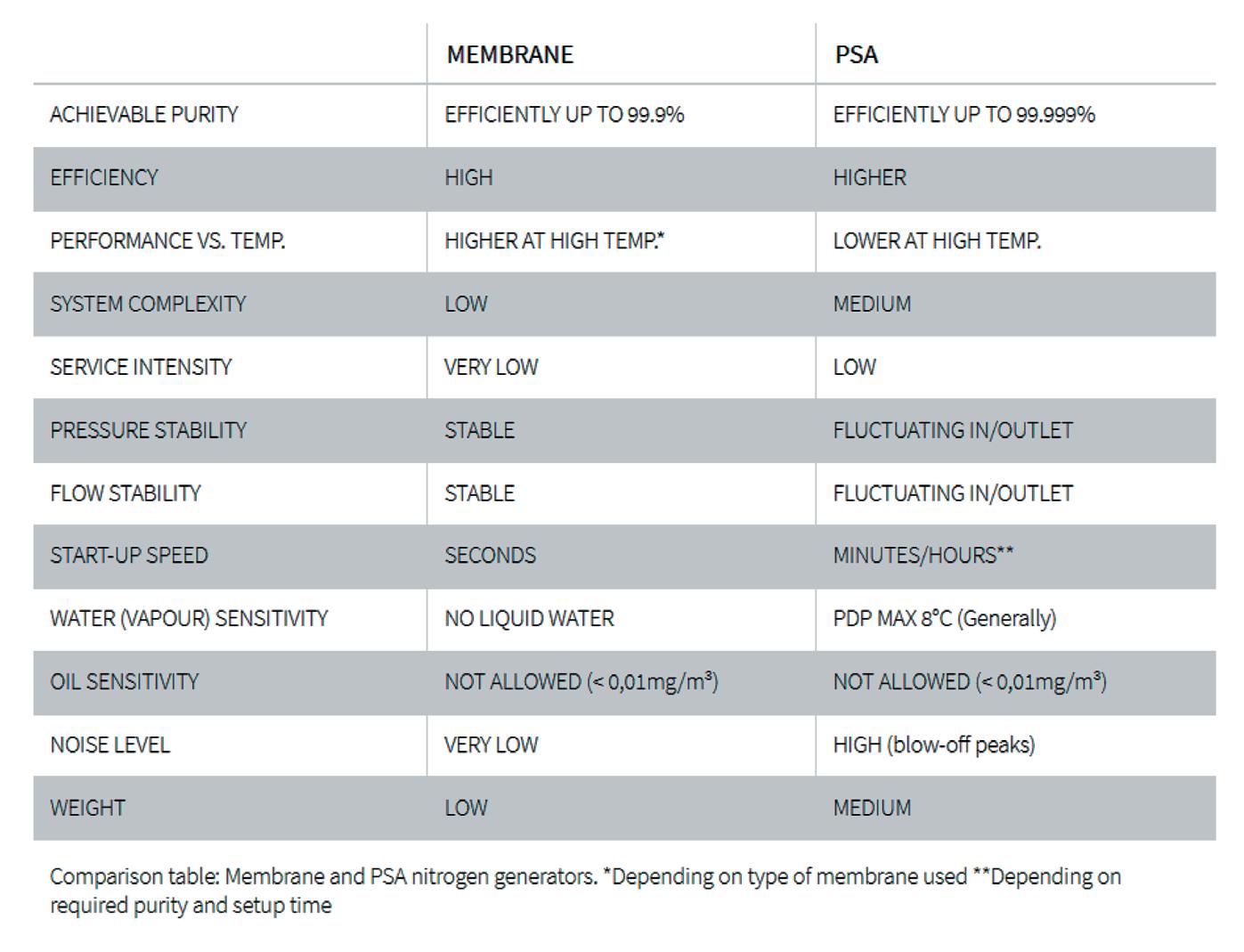

Comparing pressure swing adsorption and membrane nitrogen generation.

SPRING 2024 34

Source: Atlas Copco.

Vacuum Purging

Vacuum purging refers to the removal of oxygen from the resin before it begins printing. This process ensures that once the resin is removed from the vacuum environment, the bubbles will be removed, and the final print will have no inconsistencies or flaws as a result of bubbles being trapped in the resin.

While this can be good for improving the quality of the print and reducing failure rates, it can be very time-consuming, expensive to integrate, and may result in material waste.

Glycerin or Other Liquids

Another way to prevent oxygen from negatively affecting your print is to place the print into a liquid before curing or to coat the print with a thin layer of glycerin before placing it in the UV light curing oven. Once it is in the inert environment, oxygen can no longer affect how the light accesses and penetrates the print, thus eliminating the issues oxygen can cause during UV light curing. By placing the print in a liquid, which then gets placed inside the curing unit, the light will be unhindered, thus allowing the print to cure evenly.

But while this can work for certain applications, not all resins are compatible with this method, and placing them in a liquid for the purpose of improved curing can be problematic.

Despite the many options available to improve a 3D printed application and reduce the negative effects of oxygen, nitrogen is commonly seen as the optimal solution. When evaluating application quality and convenience, it is the leading method that can be employed for improving prints, enhancing mechanical properties, and delivering the best results to your patients.

What You Need in a UV Curing Station in 2024 and Why You Want to Add Nitrogen